Abstract

This paper presents the results of an experimental investigation carried out to evaluate the effect of fly ash (FA) on fine sand compaction and its suitability as a material for embankments. The literature review demonstrates the lack of research on stabilization of sandy material using FA. The study is concerned with the role of FA content in stabilized soil physical characteristics. The main aim of this paper is to determine the optimum quantity of FA content for stabilization of this type of soil. This is achieved through particle size distribution and compaction (standard proctor) tests. The sand was stabilized with three proportions of FA (5%, 10% and 15%) and constant cement content of 3% was used as an activator. For better comparison, the sand was also stabilized by 3% cement only so that the effect of FA could be observed more clearly. The results were in line with the literature for other types of soil, i.e. as the % of FA increases, reduction in maximum dry density and higher optimum moisture content were observed.

Keywords: Civil engineering, Structural engineering

1. Introduction

A significant share of the world's energy needs is met by coal-fired power stations by burning coal as fuel. There are residues generated in these power plants, which are called Coal Combustion Products (CCPs). All around the world, in general, most of the fly ash (FA) produced is disposed of in a landfill, causing concerns for environmental agencies. This paper is focused on the utilization of FA only as it has proved to be a more viable soil stabilizer in comparison to bottom ash, due to its finer particle size.

The study is concerned with the influence of FA on stabilized sandy soil. Its effect is investigated and analyzed through some laboratory tests, such as particle size distribution (PSD) and compaction (proctor). In this paper, a revision of previous relevant research is outlined. This section covers some general aspects of FA, its sustainability, continued by ground improvement and soil stabilization. The aim of the study presented in this paper is to examine the suitability of class F FA as a suitable material for construction of embankments in geotechnical engineering projects. An increase in utilization of FA would lead to lower disposal rate, less land being used for landfill and replacement of traditional base materials so that CO2 emissions can be lowered.

2. Background

2.1. Fly ash

In 2010, Abmaruzzaman (2010) reported that approximately 80% of the total coal ash produced worldwide was in form of FA. Coal-fired power plants around the world, produce nearly 25% of the world's primary energy needs, in other words, 38% of the worldwide electricity is generated from these coal-fired power plants (Barnes and Sear, 2006). Throughout the past decades, FA has been named as a problematic solid waste due to the conventional disposal methods of FA from thermal power plants and factories, as they have contaminated and degraded arable lands all around the world.

Fly ash ranks as the planet's fifth largest raw material resource (Abmaruzzaman, 2010) and can be used as an alternative to conventional materials in the construction of geotechnical and geoenvironmental infrastructures. By avoiding to mine or quarry for natural-occurring resources, and using coal combustion products as a replacement, sustainable and environmental benefits can be achieved. Energy demand and emissions to the atmosphere can also be reduced by utilizing CCPs (Barnes and Sear, 2006).

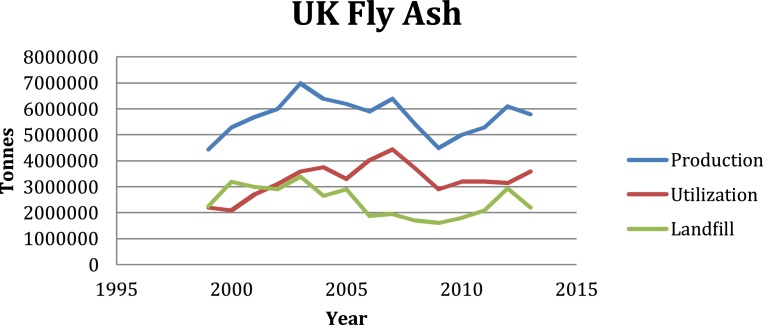

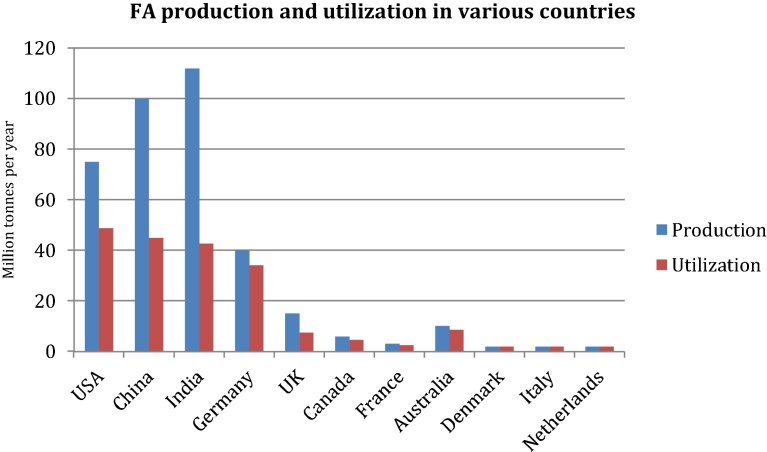

Fig. 1 illustrates the development of FA production, utilization and disposal rates in the UK from 1999 to 2013. It can be seen that, from 1999 to 2003, landfill rates were higher than the utilization rate, however, 2003 onwards it has been lower than the utilization rate. In 2010, 36% of the total FA produced was sent to landfill, this increased to 48% in 2012, while the utilization amount remained at around 32 million tonnes, and then in 2013, the rate of landfill dropped to 38%. The relative utilization and production of fly ashes differ noticeably from one country to another (Fig. 2, Pandey and Singh, 2010). Abmaruzzaman (2010) believes that the disposal of FA will soon be too costly if not banned. This can be seen in Netherlands, where all the FA must be utilized or exported since landfill is prohibited (Eijk et al., 2011).

Fig. 1.

UK FA production, utilization, and landfill values (after Carroll, 2015; UKQAA, 2016).

Fig. 2.

Worldwide FA production, utilization (after Pandey and Singh, 2010).

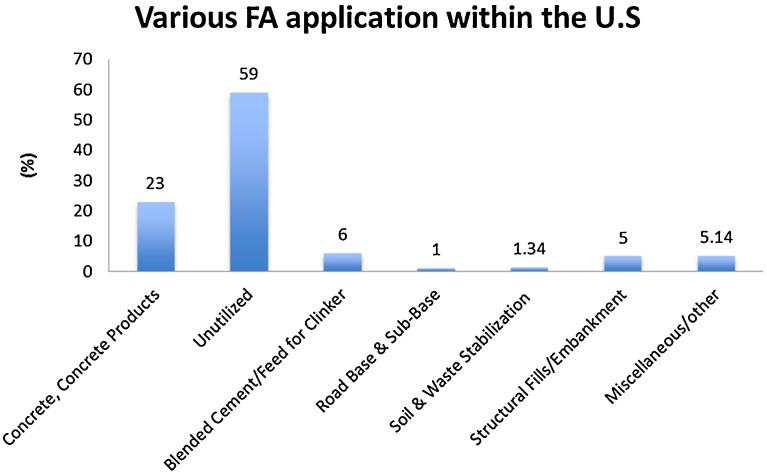

Fly ash has a broad range of applications within the construction industry (Fig. 3). The utilization of FA as a partial replacement for Portland cement in concrete is widespread and considerable volumes are used. Looking at the US FA utilization in that figure, nearly, 60% of the total FA produced was unutilized in 2014 (which, compared with Fig. 2 also demonstrates the unutilization significantly increased in that country since 2010). This is one of the highest unused rates of FA around the world, while the remaining is mostly used for concrete and cement production. FA utilization for soil stabilization, which this study is focused on, is at only 0.34% of total FA produced in US, and 1% for waste stabilization. In road base and sub-base, the utilization was 1%, with structural fills and embankment over 5%.

Fig. 3.

Various FA applications within the U.S 2014 (after ACAA, 2014).

Due to the volumes of material involved in the construction of road, railways and airports, utilizing FA, has a profound impact from the environmental point of view on the surroundings (Celauro et al., 2012). The beneficial reuse of fly ash in embankments construction not only helps ease one of the most pressing environmental problems, disposal of wastes, but may also result in (Cetin and Aydilek, 2013);

-

•

Reducing solid waste disposal costs incurred by industry.

-

•

Reducing landfill requirements.

-

•

Minimizing damage to natural resources caused by excavating earthen materials for construction.

-

•

Obtaining added value from waste materials.

-

•

Conserving production energy.

-

•

Providing sustainable construction.

-

•

Providing economic growth.

The reuse of waste materials, such as fly ash, in highway construction, has a significant potential to minimize the amount of disposed waste materials (Baykal et al., 2004; Cetin and Aydilek, 2013). Bumjoo et al. (2005) studied the suitability of fly and bottom ash mixture in highway embankment construction. In this study, it was found that the optimum water content (OMC) increased, while the maximum dry density (MDD) decreased, as the FA content was increased from 50% to 100% (Bumjoo et al., 2005). In the same study, it was concluded that, with the right design and fly/bottom ash mixture, the results proved suitability for highway embankments and also to be as high as those of conventional sandy soils.

2.2. Ground improvement and stabilization using FA

Ground improvement can be defined ‘as the introduction of materials or energy to soils to affect a change in performance of the ground such that it performs more reliably and can be incorporated into the design process’ (Essler, 2012). Ground improvement techniques are used all around the world to improve the load-bearing capacity and stability of soil, to enable the construction of projects with very long design lives such as embankments, retaining walls and bridges (Cofra, 2005).

Beeghly (2003) explains the main difference between soil modification and soil stabilization. On one hand, soil modification from moderate rates of additives (i.e. 3% quicklime) causes improvements such as drying and swells reduction. On the other hand soil stabilization from higher rates of application is the focus of this paper (Beeghly, 2003). According to O'Flaherty and Hughes (2016) the term ‘modification’ is used to describe the use of a chemical to improve the properties of a soil without causing much increase to its elastic modulus or tensile strength, while the term stabilization is used to describe the utilization of a chemical to achieve a soil stabilized layer with significant strength and stiffness (O'Flaherty and Hughes, 2016).

The stabilization is achieved by the soil particles being glued more chemically than physically. Dealing with weak soil is one of the most major challenges in the construction industry (Cristelo et al., 2013; Senol et al., 2006). This situation probably might occur in road and highway construction (Fauzi et al., 2010; Senol et al., 2006) or in geotechnical engineering. It is vital to find methods of soil improvement techniques so that demands can be met.

Dockter et al. (1999) concluded that coal combustion FA has ‘excellent potential for use in rammed earth construction as a low-cost alternative to Portland cement and other stabilizers because of its pozzolanic properties’. The main purpose of soil stabilization is the rendering of weak soils that are unable to meet a specific project's requirement. Soil stabilization benefits not only from the enhancement of the compressive strength of the soft soil (Bergado et al., 1996; Prabakar et al., 2004) but also to improve the shear strength, filter, drainage system (Prabakar et al., 2004), permeability, soil resistance to the weathering process and traffic usage (ASTM 1992, cited by Zaliha et al., 2013) to meet specific engineering projects requirements (Kolias et al., 2005).

According to Mackiewicz and Ferguson (2005), utilization of FA stabilization of the soil used in subgrade improves the stability of the working platform, which is less susceptible to disturbance by moisture and construction traffic. In embankments made from CCPs, it is necessary to take measures against slope failure caused by rain or embankment collapse caused by an earthquake (Sato and Nishimoto, 2005). Makusa (2012) believes that soil stabilized by FA has some limitations:

-

•

Soil to be stabilized shall have less moisture content; therefore, dewatering may be required.

-

•

Soil-fly ash mixture cured below zero and then soaked in water are highly susceptible to slaking and strength loss.

-

•

Sulfur contents can form expansive minerals in soil-fly ash mixture, which reduces the long-term strength and durability.

In an article, Hossain (2010) states that soils with a ‘liquid limit less than 40% and plasticity index within the range 22–25% are also most suitable for stabilization'. However, the same author concluded that soils do not have to meet the two conditions, and may still be suitable for stabilization (Hossain, 2010). It is, therefore, important to investigate the suitability of soil to be stabilized using different types and combinations of stabilizers and soil types.

It is of interest to note that FA is available free of charge at most power plants, and hence, there are only transportation costs, and laying and rolling costs to be considered. For a given degree of compaction, it is suggested that maximum dry density is lower for stabilized soil than that of soil not stabilized (Makusa, 2012).

2.3. Stabilization activation

There are some common stabilizers, such as lime and cement, and there are some more recent stabilizers such as fly ash (Class C), blast furnace slag, sodium hydroxide and sodium silicate (Palomo et al., 1999). One of the key factors of utlizing cement in stabilizing soils, is that cement reaction is independent of soil minerals, and it relies on the water that may be found in any soil. Makusa (2012) states the following improved properties of cement stabilized soils:

-

•

Decreased cohesiveness.

-

•

Decreased volume expansion or compressibility.

-

•

Increased strength.

Class F fly ash can be used in the stabilization process, if added with another activator, such as lime or cement. It is important to note that the impact of Class F (plus an activator) may differ significantly compare to a Class C stabilized sample. Das and Yudhbir (2005) state that the additional strength gained by utilizing cement or lime is an indication of the FA pozzolanic reactivity, which depends on the carbon content, the fineness and also the quality and quantity of glassy phase present in the FA. It is highly dependable on the pozzolan content of each ash, the degree of self-cementing property of Class C fly ash (Little and Nair, 2009). When lime-based binders were compared to cement-based binders, the mechanical strength achieved by cement-based binders was higher and of a better consistency (Cristelo et al., 2012b). Another advantage of using fly ash and cement together is that it can help in containing the leachate of heavy metals (Kamon et al., 2000).

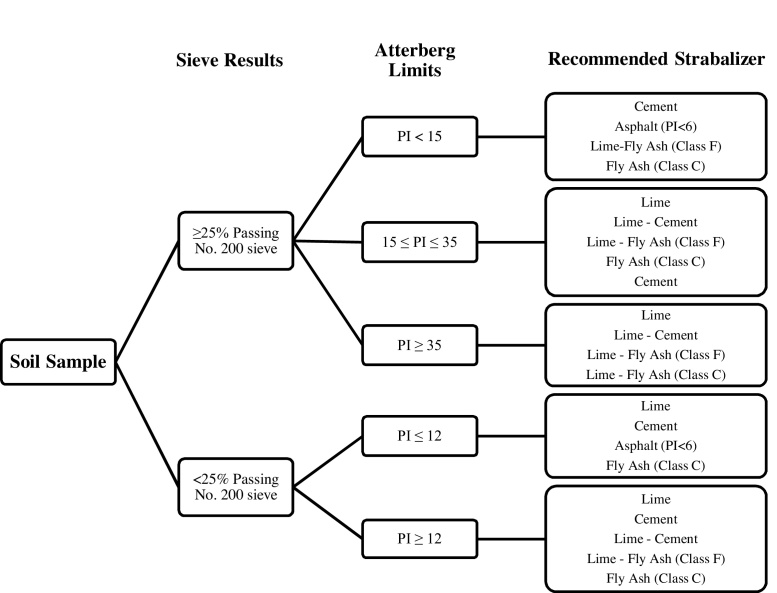

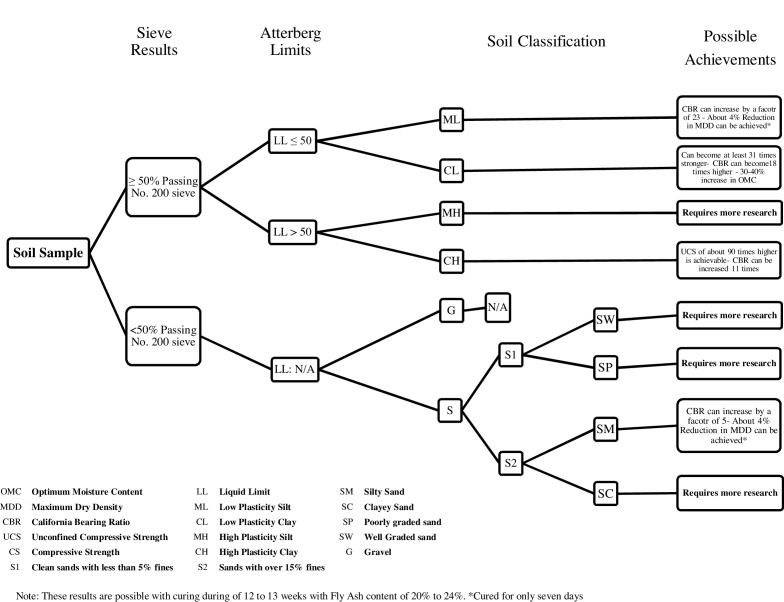

In another article, Kaniraj and Havanagi (1999) explain that there is a significant gain in strength (particularly in the case of class F fly ash) even with a small addition of cement, and the gain depends on the cement content and curing time. A methodology (Fig. 4) has been developed by the U.S air force, by which an appropriate stabilizer can be selected (Little and Nair, 2009).

Fig. 4.

The decision tree of stabilizer selection (after Little and Nair, 2009).

2.4. Laboratory testing

There have been many studies, with different approaches, on the utilization of fly ash. In various researches, where fly ash was utilized for soil stabilization, there were some common laboratory tests performed, in order to obtain a before and after treatment properties, both physical and chemical. Among the most extended tests were:

Particle Size Distribution (Cristelo et al., 2011 and 2012b), Compaction test, rammer method (Cristelo et al., 2011, 2012b; Hossain, 2010; Kamon et al., 2000; Kaniraj and Havanagi, 1999; Kolias et al., 2005; Jackson et al., 2007), California Bearing Capacity (CBR) test (Hossain, 2010; Kolias et al., 2005; Jackson et al., 2007; Sato and Nishimoto, 2005), Compressive Strength (Arioz et al., 2013; Cristelo et al., 2012a; Kamon et al., 2000; Kolias et al., 2005; Sato and Nishimoto, 2005), XRD Analysis (Arioz et al., 2013; Cristelo et al., 2012a; Kolias et al., 2005). For the purpose of this paper, PSD and compaction tests have been performed.

The results of various tests carried out to date are illustrated and are discussed thoroughly further on Table 1. Several researchers (Cristelo et al., 2011; Kolias et al., 2005; Aydilek and Arora, 2005; Santos et al., 2011; Cristelo et al., 2012a, 2012b; Reyes and Pando, 2007; Sahu, 2001; McCarthy et al., 2011) studied the effect of fly ash (both class C and F) on ground improvement through soil stabilization.

Table 1.

Results of soil stabilizing by using fly ash from nine different studies.

| Summary: Experiences of soil stabilization using Fly Ash | |||||||

|---|---|---|---|---|---|---|---|

| Fly Ash | Soil | Activator | Tests | Results |

Source | ||

| Before Treatment | After Treatment | ||||||

| 20% | Fly Ash (FA) | Lean Clay | Cement | 20% FA and 91-day curing |

Kolias et al., 2005 | ||

| OMC | 22% | 30% | |||||

| CS | 0.1 MPa | 3.1 MPa | |||||

| CBR | 10% | 185% | |||||

| MDD | 15.9 KN/m3 | 13.1 KN/m3 | |||||

| 20% | Fly Ash (FA) | Lean Clay | Cement | 20% FA and 28-day curing |

|||

| OMC | 22% | 30% | |||||

| CS | 0.1 MPa | 1.7 MPa | |||||

| MDD | 15.9 KN/m3 | 13.1 KN/m3 | |||||

| 20% | Fly Ash (FA) | Fat Clay | Cement | 20% FA and 91-day curing |

|||

| CS | 0.1 MPa | 1.75 MPa | |||||

| CBR | 10% | 110% | |||||

| 20% | Fly Ash (FA) | Fat Clay | Cement | 20% FA and 28-day curing |

|||

| CS | 0.1 MPa | 1.25 MPa | |||||

| 10% | Fly Ash (FA) | Lean Clay | Cement | 10% FA and 91-day curing |

|||

| OMC | 22% | 26% | |||||

| CS | 0.1 MPa | 1.9 MPa | |||||

| CBR | 10% | 140% | |||||

| MDD | 15.9 KN/m3 | 14.1 KN/m3 | |||||

| 10% | Fly Ash (FA) | Lean Clay | Cement | 10% FA and 28-day curing |

|||

| OMC | 22% | 26% | |||||

| CS | 0.1 MPa | 1.1 MPa | |||||

| MDD | 15.9 KN/m3 | 14.1 KN/m3 | |||||

| 10% | Fly Ash (FA) | Fat Clay | Cement | 10% FA and 91-day curing |

|||

| CS | 0.1 MPa | 0.7 MPa | |||||

| CBR | 10% | 60% | |||||

| 10% | Fly Ash (FA) | Fat Clay | Cement | 10% FA and 28-day curing |

|||

| CS | 0.1 MPa | 0.5 MPa | |||||

| 40% | Fly Ash Class F (FAF) | Silty Sand | Cement | 40% FAF and 28-day curing |

Aydilek and Arora, 2005 | ||

| MDD | 15.46 kN/m3 | ||||||

| UCS | 5.0 MPa | ||||||

| 40% | Fly Ash Class F (FAF) | Silty Sand | Cement | 40% FAF and 7-day curing |

|||

| MDD | 15.46 kN/m3 | ||||||

| UCS | 3.2 MPa | ||||||

| CBR | 140% | ||||||

| 40% | Fly Ash Class F (FAF) | Silty Sand | Lime | 40% FAF and 28-day curing |

|||

| MDD | 15.36 kN/m3 | ||||||

| UCS | 0.4 MPa | ||||||

| 40% | Fly Ash Class F (FAF) | Silty Sand | Lime | 40% FAF and 7-day curing |

|||

| MDD | 15.36 kN/m3 | ||||||

| UCS | 0.3 MPa | ||||||

| CBR | 36% | ||||||

| 60% | Fly Ash (FA) | Low Plasticity Clay | 60% FA and 28-day curing |

Santos et al., 2011 | |||

| OMC | 14% | 28% | |||||

| MDD | 17.9 kN/m3 | 13.9 | |||||

| CS | 2.67 MPa | ||||||

| 40% | Fly Ash (FA) | Low Plasticity Clay | 40% FA and 28-day curing |

||||

| OMC | 14% | 25% | |||||

| MDD | 17.9 kN/m3 | 14.6 kN/m3 | |||||

| CS | 2.65 MPa | ||||||

| 20% | Fly Ash (FA) | Low Plasticity Clay | 20% FA and 28-day curing |

||||

| OMC | 14% | 22.5% | |||||

| MDD | 17.9 kN/m3 | 15.5 kN/m3 | |||||

| CS | 1.35 MPa | ||||||

| 20% | Fly Ash Class F (FAF) | Fat clays | SH & SS | 20% FAF and 84-day curing |

Cristelo et al., 2012a | ||

| UCS | 8.6 MPa | ||||||

| 20% | Fly Ash Class F (FAF) | Fat clays | SH & SS | 20% FAF and 28-day curing |

|||

| UCS | 1.7 MPa | ||||||

| 20% | Fly Ash Class C (FAC) | Fat clays | SH & SS | 20% FAC and 84-day curing |

|||

| UCS | 3.0 MPa | ||||||

| 20% | Fly Ash Class C (FAC) | Fat clays | SH & SS | 20% FAC and 28-day curing |

|||

| UCS | 1.3 MPa | ||||||

| 10% | Fly Ash Class F (FAF) | Fat clays | SH & SS | 10% FAF and 84-day curing |

|||

| UCS | 4.2 MPa | ||||||

| 10% | Fly Ash Class F (FAF) | Fat clays | SH & SS | 10% FAF and 28-day curing |

|||

| UCS | 0.6 MPa | ||||||

| 10% | Fly Ash Class C (FAC) | Fat clays | SH & SS | 10% FAC and 84-day curing |

|||

| UCS | 2.0 MPa | ||||||

| 10% | Fly Ash Class C (FAC) | Fat clays | SH & SS | 10% FAC and 28-day curing |

|||

| UCS | 1.1 MPa | ||||||

| 25% | Fly Ash Class F (FAF) | Granitic Residual Soil | SH & SS | 25% FAF and 7-day curing |

Cristelo et al., 2012b | ||

| UCS | 17 MPa | ||||||

| MDD | 19.2 KN/m3 | ||||||

| 20% | Fly Ash Class C (FAC) | High Plasticity Clay | 20% FAC and 40-day curing |

Reyes and Pando, 2007 | |||

| MDD | 12.1 kN/m3 | ||||||

| UCS | 0.24 MPa | 0.96 MPa | |||||

| 20% | Fly Ash Class C (FAC) | High Plasticity Clay | 20% FAC and 28-day curing |

||||

| MDD | 12.1 kN/m3 | ||||||

| CS | 0.24 MPa | 0.9 MPa | |||||

| 10% | Fly Ash Class C (FAC) | High Plasticity Clay | 10% FAC and 40-day curing |

||||

| MDD | 12.1 kN/m3 | ||||||

| CS | 0.24 MPa | 0.56 MPa | |||||

| 10% | Fly Ash Class C (FAC) | High Plasticity Clay | 10% FAC and 28-day curing |

||||

| MDD | 12.1 kN/m3 | ||||||

| CS | 0.24 MPa | 0.45 MPa | |||||

| 24% | Fly Ash (FA) | Kalahari Sand | 24% FA and 7-day curing |

Sahu, 2001 | |||

| OMC | 5% | 7% | |||||

| MDD | 17.3 KN/m3 | 14.7 KN/m3 | |||||

| CBR | 40% | 10% | |||||

| 24% | Fly Ash (FA) | Calcrete | 24% FA and 7-day curing |

||||

| OMC | 15.60% | 17% | |||||

| MDD | 17.2 KN/m3 | 16.3 KN/m3 | |||||

| CBR | 40% | 90% | |||||

| 24% | Fly Ash (FA) | Silty Sand | 24% FA and 7-day curing |

||||

| OMC | 9% | 9% | |||||

| MDD | 19.0 KN/m3 | 18.2 KN/m3 | |||||

| CBR | 80% | 470% | |||||

| 24% | Fly Ash (FA) | Black Cotton Soil | 24% FA and 7-day curing |

||||

| OMC | 20% | 23.50% | |||||

| MDD | 15.1 KN/m3 | 14.8 KN/m3 | |||||

| CBR | 0% | 25% | |||||

| 24% | Fly Ash (FA) | Low Plasticity Silt | 24% FA and 7-day curing |

||||

| OMC | 12% | 12.30% | |||||

| MDD | 19.8 KN/m3 | 18.9 KN/m3 | |||||

| CBR | 10% | 230% | |||||

| 8% | Fly Ash (FA) | Kalahari Sand | 8% FA and 7-day curing |

||||

| OMC | 5% | 5% | |||||

| MDD | 17.3 KN/m3 | 16.8 KN/m3 | |||||

| CBR | 40% | 30% | |||||

| 8% | Fly Ash (FA) | Calcrete | 8% FA and 7-day curing |

||||

| OMC | 15.60% | 19.90% | |||||

| MDD | 17.2 KN/m3 | 16.4 KN/m3 | |||||

| CBR | 40% | 60% | |||||

| 8% | Fly Ash (FA) | Silty Sand | 8% FA and 7-day curing |

||||

| OMC | 9% | 8.80% | |||||

| MDD | 19.0 KN/m3 | 18.6 KN/m3 | |||||

| CBR | 80% | 315% | |||||

| 8% | Fly Ash (FA) | Black Cotton Soil | 8% FA and 7-day curing |

||||

| OMC | 20% | 22.70% | |||||

| MDD | 15.1 KN/m3 | 15.3 KN/m3 | |||||

| CBR | 0% | 5% | |||||

| 8% | Fly Ash (FA) | Low Plasticity Silt | 8% FA and 7-day curing |

||||

| OMC | 12% | 11.90% | |||||

| MDD | 19.8 KN/m3 | 19.6 KN/m3 | |||||

| CBR | 10% | 40% | |||||

| 40% | Fly Ash Class F (FAF) | Sandy Clay | SH & SS | 40% FAF and 365-day curing |

Cristelo et al., 2011 | ||

| UCS | 43 MPa | ||||||

| 40% | Fly Ash Class F (FAF) | Sandy Clay | SH & SS | 40% FAF and 90-day curing |

|||

| UCS | 17 MPa | ||||||

| 40% | Fly Ash Class F (FAF) | Sandy Clay | SH & SS | 40% FAF and 28-day curing |

|||

| UCS | 8 MPa | ||||||

| 20% | Fly Ash Class F (FAF) | Sandy Clay | SH & SS | 20% FAF and 365-day curing |

|||

| UCS | 24 MPa | ||||||

| 20% | Fly Ash Class F (FAF) | Sandy Clay | SH & SS | 20% FAF and 90-day curing |

|||

| UCS | 5 MPa | ||||||

| 20% | Fly Ash Class F (FAF) | Sandy Clay | SH & SS | 20% FAF and 28-day curing |

|||

| UCS | 3.5 MPa | ||||||

| 24% | Fly Ash -a | Oxford Clay | Lime | 24% FA and 90-day curing |

McCarthy et al., 2011 | ||

| OMC | 25% | 26.90% | |||||

| MDD | 14.9 KN/m3 | 14.3 KN/m3 | |||||

| UCS | 1.9 MPa | ||||||

| 24% | Fly Ash -b | Oxford Clay | Lime | 24% FA and 90-day curing |

|||

| OMC | 25% | 28.10% | |||||

| MDD | 14.9 KN/m3 | 13.7 KN/m3 | |||||

| UCS | 1.5 MPa | ||||||

| 24% | Fly Ash -a | Oxford Clay | Lime | 24% FA and 28-day curing |

|||

| OMC | 25% | 26.90% | |||||

| MDD | 14.9 KN/m3 | 14.3 KN/m3 | |||||

| UCS | 1.4 MPa | ||||||

| 24% | Fly Ash -b | Oxford Clay | Lime | 24% FA and 28-day curing |

|||

| OMC | 25% | 28.10% | |||||

| MDD | 14.9 KN/m3 | 13.7 KN/m3 | |||||

| UCS | 1.2 MPa | ||||||

| 12% | Fly Ash -a | Oxford Clay | Lime | 12% FA and 90-day curing |

|||

| OMC | 25% | 26.70% | |||||

| MDD | 14.9 KN/m3 | 14.4 KN/m3 | |||||

| UCS | 1.7 MPa | ||||||

| 12% | Fly Ash -b | Oxford Clay | Lime | 12% FA and 90-day curing |

|||

| OMC | 25% | 27.40% | |||||

| MDD | 14.9 KN/m3 | 14.0 KN/m3 | |||||

| UCS | 1.4 MPa | ||||||

| 12% | Fly Ash -a | Oxford Clay | Lime | 12% FA and 28-day curing |

|||

| OMC | 25% | 26.70% | |||||

| MDD | 14.9 KN/m3 | 14.4 KN/m3 | |||||

| UCS | 1.3 MPa | ||||||

| 12% | Fly Ash -b | Oxford Clay | Lime | 12% FA and 28-day curing |

|||

| OMC | 25% | 27.40% | |||||

| MDD | 14.9 KN/m3 | 14.0 KN/m3 | |||||

| UCS | 1.2 MPa | ||||||

OMC - Optimum Moisture Content.

MDD - Maximum Dry Density.

CBR - California Bearing Ratio.

UCS - Unconfined Compressive Strength.

CS - Compressive Strength.

SH - Sodium Hydroxide.

SS - Sodium Silicate.

LL - Liquid Limit.

ML - Low Plasticity Silt.

CL - Low Plasticity Clay.

MH - High Plasticity Silt.

CH - High Plasticity Clay.

SM - Silty Sand.

SC - Clayey Sand.

G - Gravel.

After reviewing the results in Table 1, it was found that majority of the soil samples were in the form of clay and very few sandy samples. It can be seen that there is an increase in the CBR value except one case in the study by Sahu (2001), where there was a reduction in CBR, only for the Kalahari Sand, from 40% to 10% when used 24% fly ash, and down to 30% when only 8% fly ash was used. This must be due to the particular properties of Kalahari Sand. Aydilek and Arora (2005) had silty sand stabilized with 40% of Class F fly ash with two different activators, lime and cement. After four weeks of curing, the sample that was stabilized with cement had an unconfined compressive strength of 5.0 MPa, over twelve times more than what was achieved with lime. This was an expected result as Cristelo et al. (2012b) mentioned that regarding mechanical strength, cement-based binders usually deliver significantly better and more consistent results when compared to lime-bases binders.

Furthermore, Santos et al. (2011) show that there is not a significant improvement when the FA contend increased from 40% to 60%, whereas there was a clear improvement from 20% to 40% FA content. It is clear that cement is a more viable option as an activator than lime. Meanwhile in 2011, Cristelo et al. published the results of an extensive research on soil improvement by using Class F FA. The curing periods were as long as a year, which has produced astonishing results, with one sample (40% FA – 365-day curing) reaching 43 MPa in unconfined compressive strength. In the same study, samples were cured at 90 and 28 days as well, with UCS of 17 MPa and 8 MPa (40% FA) respectively. Clearly, the longer the curing period, the higher the strength of the soil. Furthermore, Cristelo et al. (2012a) compared soil stabilization with both class C and class F FA. Using the same percentage (20%) of FA and same curing periods (84-day), the samples, which were stabilized with class F had about three times the strength compared to the samples stabilized with class C. In overall, there were improvements on the physical strength of fly ash stabilized samples in every study. It can be concluded that the most effective stabilization is, using Class F fly ash with cement as the activator and finally, curing period to be maximized. The choice of activator varies for each study. These include; cement, lime, sodium hydroxide (SH) and sodium silicate (SS). In the studies, Cristelo et al. (2011), (2012a) and (2012b), the authors used a mixture of SH and SS.

A new chart (Fig. 5) for various possible results of soil stabilization using FA has been developed from summarizing Table 1. As the main conclusion, it is addressed that further research needs to be carried out on sand, clayey sand in particular, and also on high plasticity silts. The present research is focused on sand only.

Fig. 5.

Various Possible Results of Soil Stabilization Using Fly Ash.

3. Methods

Comprehensive series of laboratory tests consisting of particle size distribution (PSD) and standard compaction test were conducted on untreated soil samples and stabilized samples. A minimum of three samples from each variation of soil was tested so that reliable results can be attained. There were three variations of fly ash content chosen for this study, 5%, 10% and 15% (similar to Cristelo et al., 2012a; 2012b). In this experimental study, a total of 14 compaction tests were performed. The aim of the laboratory tests was to analyze the influence FA content on stabilized soil density and optimal water content, by comparing stabilized soils against pre-treated samples.

As an activator solution, cement with 3% content will be used in this study. The quantity of the cement content is selected as an average based on previous studies (Kolias et al., 2005; Kaniraj and Havanagi, 1999). The proposed tests are described in more detail in the following section. At least, two representatives specimens for determination of the moisture content were taken and, hence, an average derived (BSI, 1990a).

4. Experimental

4.1. Particle size distribution (PSD)

For a basic understanding of the nature of the soil, the distribution of the grain size present in a given soil mass must be known. The grain size distribution of coarse-grained soils (gravelly and/or sandy) is determined by sieve analysis (Das, 2014). The sieves used for the purpose of this study consist of woven-wire square meshes. The PSD tests were performed in accordance to BS 1377–2 1990, Classification tests, the “Dry Sieving Method” (BSI, 1990b). From the classification graph produced as a result of PSD, the grading and unifomitry of the soil sample can be calculated, along with the soil classification using the British soil classification system, which classifies soils with particles size range of 0.06 mm to 2 mm, as sand (BSI, 1990b). According to O'Flaherty and Hughes (2016), the typical values for the Coefficient of Gradation (Cc) and the Uniformity Coefficient (CU) in soil classification, for even graded soils is <1 and <6, respectively.

4.2. Compaction test (2.5 kg Rammer)

In order to find the optimum values, a compaction test is carried out in accordance with BS 1377–4 1990, Compaction-related tests, the “2.5 kg Rammer Method” (BSI, 1990c). The compaction is carried out in a modified CBR mould with soil compacted in three layers and each layer subject to 72 blows from the 2.5 kg rammer (BSI, 1990c). Generally, the optimum moisture content (OMC) of sandy soils is about 11%, and the maximum dry density (MDD) of sandy soils is just over 19 kN/m3 (O'Flaherty and Hughes, 2016). Construction specifications commonly require that mixing, compaction, and final shaping be completed in one or two hours of initial mixing. For the purpose of this study, the samples were compacted within 30 min from the beginning of mixing. Strength and compaction characteristics at no delay define optimum properties of the fly ash treated materials. The unit weight of fly ash-soil mixture is an important parameter since it controls the strength, compressibility, and permeability.

Compaction is often delayed in normal construction operations, which causes the fly ash to bond to the soil particles in a loose state, at which point these bonds must be disrupted to densify the material (Mackiewicz and Ferguson, 2005). Therefore, a portion of the compaction effort is used to reverse the effect caused by the delay with the remaining energy to compact the mixture. When compaction is delayed 1 hour after incorporation of the fly ash, maximum densities can decrease up to 6 to 16 kN/m3 (Mackiewicz and Ferguson, 2005).

5. Materials

5.1. Sand

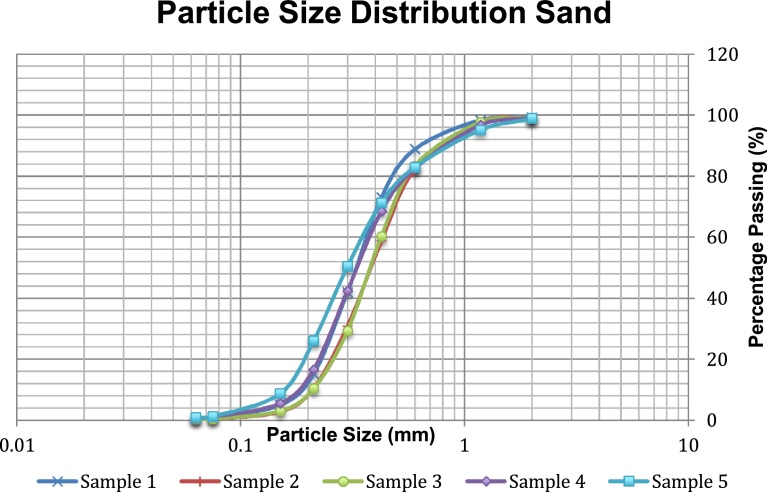

For the purpose of this study, the sand (Building Sand) was obtained from Civils & Lintels, a UK supplier. The sand was delivered in polyethylene bags of 25 kgs. PSD results are provided in Fig. 6. The uniformity coefficient and coefficient of gradation of each sample tested is individually calculated after the derivation of D10, D30 and D60. After calculating the coefficients of the sand, with an average CU value of about 2 and CC value of just under 1 (0.98), and comparing to the typical values presented earlier, it can be concluded that soil does indeed classify as a poorly and/or even graded soil, and also classifying as sand through British Standards. As explained later on, the compaction results of sand, S1, S2 and S3 also do match the typical values presented earlier.

Fig. 6.

PSD of five samples of sand.

5.2. Fly ash

The FA used in this study was obtained from a UK power station, Ratcliffe-on-Soar power station in Nottingham. Ratcliffe-on-Soar is known as one of the most efficient coal-fired power stations in the UK. Ratcliffe-on-Soar power station uses coal as fuel. Upon collection from the power plant, the fly ash was sealed in plastic tubs of 25 kgs and was brought to the University of West London's laboratory. The physical and chemical analyses of the fly ash used arose typical values for class F fly ash, as according to ASTM, they should contain at least 70% by weight of Silicon (SiO2) + Aluminium (Al2O3) + Iron (Fe2O3) (ASTM 2003, cited by Kelly, 2015). The fly ash obtained from Ratcliffe power station contains nearly 75% by weight of SiO2 + Al2O3 + Fe2O3. This classifies the FA in this research as Class F.

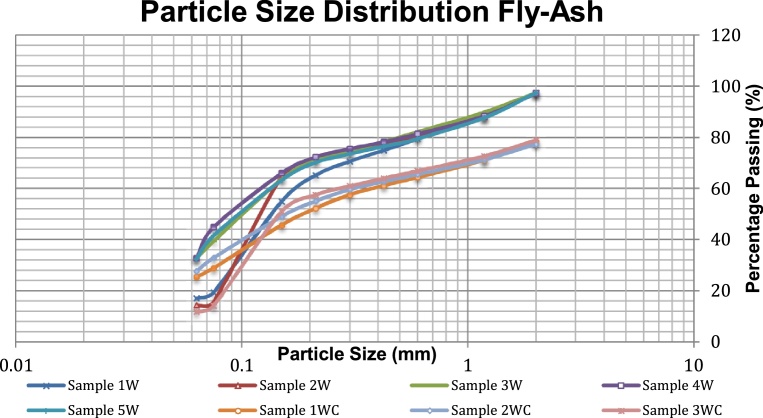

The fly ash, as it was supplied, had rather large particles, in order to produce more homogeneous samples, the FA was oven dried and then sieved through a 2.36 mm sieve. After testing over 30 samples from different tubs, on average about 21% of the FA was greater than 2.36 mm.

For comparison, the PSD for the fly ash was performed without coarse content (W) and with (WC). The five (W) samples shown in Fig. 7, were highly similar, except where two samples, 1 and 2, which had an about half of the accumulative weight passed in comparison to samples 3, 4 and 5. This variation also occurred when testing FA with coarse content. In these cases, the largest portion of the material was retained on 0.075 mm sieve, where in other cases, the highest portion had passed through the smallest sieve (0.063). It seems FA to be having grain size of similar to that of silt.

Fig. 7.

PSD test of five samples of FA without coarse content (W) and PSD test of three samples of FA with coarse content (WC).

5.3. Cement

Ordinary portland cement (OPC) is most commonly used to stabilize soils. On the contrary, rapid-hardening cement is generally avoided, as they do not allow the time required for mixing and compacting in the cement stabilization process (O'Flaherty and Hughes, 2016). The cement chosen for this study is OPC, provided by a UK supplier. The manufacturer provided the following conditions:

-

•

Based on sustainable cement technology.

-

•

Grey in colour.

-

•

Consistent strength meeting all the conformity criteria in BS EN 197-1.

-

•

Manufactured from natural products.

6. Results and discussion

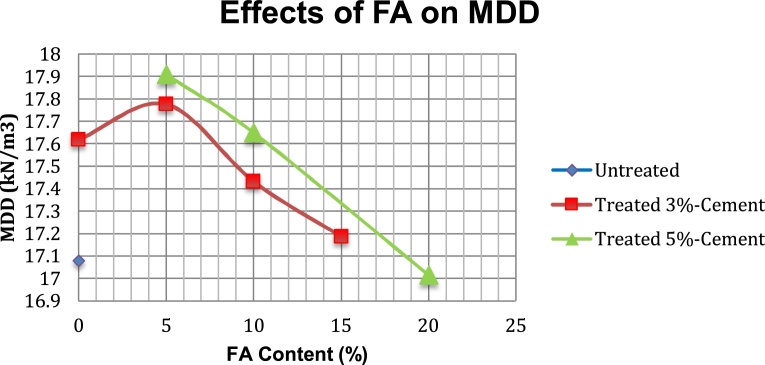

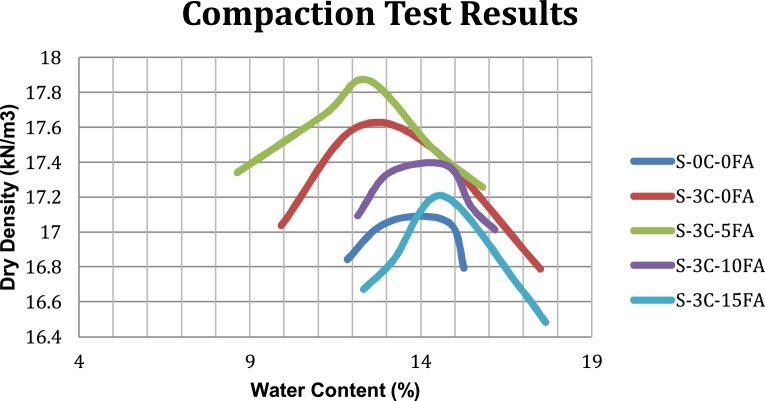

The results of compaction tests (standard proctor) performed with different FA and cement contents are presented in this section and discussed further. Fig. 8 illustrates how the FA content in the stabilized samples affects the maximum dry density. Despite constituting only 3% of the sample (in weigh), the OPC used in this experiment had a profound influence on the dry density.

Fig. 8.

Behaviour of MDD in relevance to FA content (results for 5% of cement: after Wood, 2016).

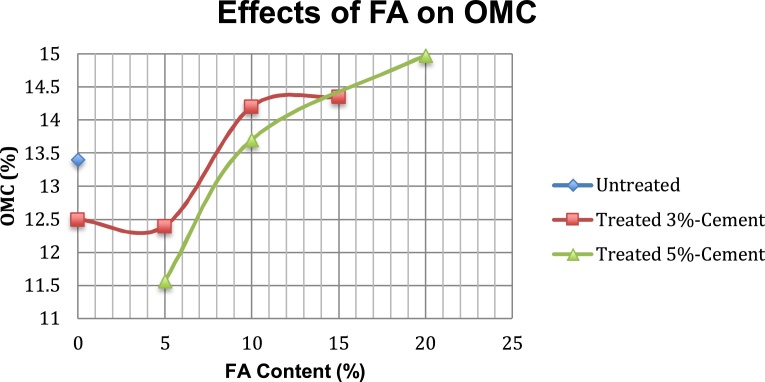

Meanwhile, Fig. 9 presents an increase in the optimum moisture content of the stabilized samples as the FA content raises. It should be noted that the addition of cement only decreased the OMC, and this is believed to be down due to the excess heat generated by the cement during the activation process. As suggested earlier in the literature, by Makusa (2012), and the observation of Table 1, it was anticipated for the OMC to be increased and the MDD to be decreased with as the FA content rises. Figs. 9 and 10 illustrate that this has also occurred to the fine sand used in this research. The decline in MDD is associated with the fact that FA is lightweight compared to sand only, while the increase in OMC is attributed to the extra water required for hydration. Comparing the 3% and 5% cement content samples together, in both Figs. 9 and 10, it clearly can be seen that both lines are producing the same behaviour in regards to an overall MDD reduction and an overall higher OMC. It is evident that samples with FA contents of 10% and over are producing the results, which were anticipated earlier in the literature for other materials. Fig. 8, illustrates that with the addition of 20% FA (S-5C-20FA) a lower MDD in comparison to that of only sand has been achieved with nearly over 1.5% higher OMC (Fig. 9). Both the MDD as well as the OMC show significant dependence upon the FA content.

Fig. 9.

Behaviour of OMC in relevance to FA content (results for 5% of cement: after Wood, 2016).

Fig. 10.

Compaction results of 5%, 10% and 15% FA Stabilized Sand.

In total, there were 120 individual compactions performed, of which the results are tabulated in Table 2 and illustrated on a compaction graph in Fig. 10, which clearly shows a shift to the bottom right of the compaction curves as the FA content increases, in other words, the optimum moisture content and the maximum dry density of a given sample is directly dependent on the FA content. It can be seen that the OMC from 10% to 15% FA did not change as much as it did from 5% to 10% FA. It is unclear at the moment why that is. The addition of cement (S-3C-0FA) into soil had a major effect on the compaction properties of the soil, with MDD increasing by over 0.5 kN/m3 and the OMC dramatically reduced by nearly 1%. It is only with the addition of FA that the OMC begins to be increased and simultaneously the MDD being decreased. The sample S-3C-15FA has an OMC of approximately 14.4%, over 1% increase to just sand samples, while the MDD is still larger than sand alone. Despite this, it can clearly be seen that with the further addition of FA, lower MDD and higher OMC will attainable. Observing the results of Table 2, samples compacted with 5% cement content illustrate the influence cement makes in soil stabilization.

Table 2.

Average OMC and MDD results of various samples.

| Code | OMC (%) | MDD (kN/m3) | |

|---|---|---|---|

| Sand | S-0C-0FA | 13.4 | 17.08 |

| Sand + 3% Cement | S-3C-0FA | 12.5 | 17.62 |

| Sand + 3% Cement + 5% FA | S-3C-5FA | 12.4 | 17.77 |

| Sand + 3% Cement + 10% FA | S-3C-10FA | 14.2 | 17.43 |

| Sand + 3% Cement + 15% FA | S-3C-15FA | 14.35 | 17.18 |

| Sand + 5% Cement + 5% FA | S-5C-5FA | 11.57 | 17.91 |

| Sand + 5% Cement + 10% FA | S-5C-10FA | 13.70 | 17.65 |

| Sand + 5% Cement + 20% FA | S-5C-20FA | 14.98 | 17.01 |

Note: (results for 5% of cement, after Wood, 2016).

In summary: the laboratory tests performed in this research revealed that the use of FA and cement resulted in MDD reduction and an increase in OMC. This effect only occurs when FA content in considerably higher than the cement content. The results of the study show that the influence of cement is rather significant. Comparing samples of same FA percentage (S-3C-5FA with S-5C-5FA & S-3C-10FA with S-5C-10FA), it clearly can be seen that cement has caused a reduction in OMC and a higher MDD. Since cement is only used in this research as an activator and not a stabilizer, its content should be kept at its lowest.

Furthermore, the best results were obtained at 20% FA, with 5% cement, with OMC of about 15%, an increase of 1.6% from sand-only, and MDD of 17.01 kN/m3 from 17.08 kN/m3. Note that if the S-5C-20FA was to be compared to S-5C-5FA, rather than to sand-only, the OMC was increased by 3.4%, while MDD was lowered from 17.91 kN/m3, a reduction of 0.86 kN/m3.

Based on the results of this experimental research, it appears that FA-sandy soil mixtures can be suitable for sustainable embankment construction. Although based on the carried out tests it is not possible to precisely evaluate the effect of the FA and cement contents on the strength and bearing capacity of the treated soil, this could be considered as a preliminary research, from which first estimations on both magnitudes (for example, UCS and CBR) can be derived by means of empirical correlations, as in Patel and Patel (2013). It is necessary to make further tests, like CBR and determination of Resilient Modulus, so that FA utilization in soil stabilization for geotechnical and geoenvironmental infrastructure can be improved.

7. Conclusions

Coal-fired power plants have high importance in the world's energy demands. Being the source of nearly a quarter of the world's primary energy need, it can be assured that the production of any by-product, specifically FA, will continue for the foreseeable future. Innovative technologies will provide increased utilization of wastes, and recycled materials with larger volumes causing a decrease in the demand for natural mineral resources. Even simple technologies may increase the added value of recycled or waste materials producing superior engineering behaviour. At the same time, the need for disposal of large volumes of waste material will be minimized. The key findings based on the literature review are:

-

•

Fine fly ash produces better strength than the respective activated coarse fly ash.

-

•

The strength gain depends on the activator content and curing time.

-

•

The mechanical strength achieved by cement-based binders was higher and of a better consistency.

-

•

Class F had about three times the strength gain, compared to the samples stabilized with class C.

Followed by the outcomes of the results obtained during this study:

-

•

Despite constituting only 3% of the sample (in weigh), the OPC used in this experiment had a profound influence on the dry density.

-

•

The addition of FA resulted in MDD reduction, believed to be caused by FA being lightweight in comparison to sand only.

-

•

The addition of FA also increased the OMC, which is attributed to the extra water required for hydration.

-

•

Samples with FA contents of 10% and over produced resutls in consistance of the literature, higher OMC and lower MDD.

-

•

Further research needs to be carried out on sand, clayey sand in particular, and also on high plasticity silts.

Fly ash can be considered as a valuable resource and needs to be studied, to facilitate the application of fly ash in new and innovative areas of economic interest as the use of fly ash is not only environmental friendly but also cost- effective. It should be pointed out that both the nature of the FA and the type of soil significantly influence the results of stabilization and it is very challenging and unsafe to rely on research carried out with different soils and different FA quantities. Furthermore, currently, there are limited data in the literature reporting the long-term performance of soil stabilization. Also, as still a significant amount of the FA produced around the world is disposed of, and with utilization rates in soil stabilization, ground improvement and sub-base construction being one of the lowest applications, about 7% in the U.S and 1% in the UK, a further detailed study is considered necessary to increase both awareness and the utilization rate of FA within the industry.

More research should also be conducted in the near future to evaluate the effects of FA on the soil strength of treated sands.

Declarations

Author contribution statement

Siavash Mahvash: Conceived and designed the experiments; Performed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Susana Lopez-Querol: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Ali Bahadori-Jahromi: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Competing interest statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- Abmaruzzaman M. A review on the utilisation of fly ash. Prog. Energy Combust. Sci. 2010;36(3):327–363. [Google Scholar]

- ACAA . 2014. Beneficial Use Of Coal Combustion Products: An American Recycling Success Story.https://www.acaa-usa.org/Portals/9/Files/PDFs/2014ReportFinal.pdf (Accessed: 20 September 2016) [Google Scholar]

- Arioz E., Arioz O., Kockar O. Mechanical and Microstructural Properties of Fly Ash Based Geopolymers. Int. J. Chem. Eng. Appl. 2013;4(6):397–400. [Google Scholar]

- Aydilek A.H., Arora S. Class F Fly ash amended soils as highway base materials. ACSE: J. Mater. Civ. Eng. 2005;17(6):640–649. [Google Scholar]

- Barnes D.I., Sear L.K.A. United Kingdom quality ash association; 2006. Ash Utilisation from coal-based power plants. [Google Scholar]

- Baykal G., Edincliler A., Saygili A. Highway embankment construction using fly ash in cold regions. Resour. Conserv. Recycl. 2004;42:209–222. [Google Scholar]

- Beeghly J.H. Recent Experiences with Lime–Fly Ash Stabilization of Pavement Subgrade Soils, Base, and Recycled Asphalt. International Ash Utilization Symposium, Center for Applied Energy Research, University of Kentucky. 2003 [Google Scholar]

- Bergado D., Andersln L., Miura N., Balasubramaniam A. American Society of Civil Engineers; New York: 1996. Soft ground improvement: in lowland and other environment. [Google Scholar]

- BSI . British Standards Institution; London: 1990. BS1377-1: Methods of Test for Soils for civil engineering purposes: General requirements and sample preparation. [Google Scholar]

- BSI . British Standards Institution; London: 1990. BS1377-2: Methods of Test for Soils for civil engineering purposes: Classification tests. [Google Scholar]

- BSI . London; British Standards Institution: 1990. BS1377-4: Methods of Test for Soils for civil engineering purposes: Compaction-related tests. [Google Scholar]

- Bumjoo K., Prezzi M., Salgado R. Geotechnical Properties of Fly and Bottom Ash Mixtures for Use in Highway Embankments. ASCE: J. Geotech. Geoenviron. 2005;137(7):914–924. [Google Scholar]

- Carroll R.A. World of Coal Ash; Tennessee, USA: 2015. Coal Combustion Products in the United Kingdom and the Potential of Stockpile Ash. 5/7 May 2015. [Google Scholar]

- Celauro B., Bevilacqua A., Lo Bosco D., Celauro C. Design Procedures for Soil-Lime Stabilization for Road and Railway Embankments. Part 1-Review of Design Methods. Procedia Soc. Behav. Sci. 2012;53:754–763. [Google Scholar]

- Cetin B., Aydilek A.H. pH and fly ash type effect on trace metal leaching from embankment soils. Resour. Conserv. Recycl. 2013;80:107–117. [Google Scholar]

- Cofra . 2005. Ground Improvement, MebraDrain, BeauDrain and AuGeo [Online]http://www.cofra.co.uk/brochures/PVDUK.pdf [Accessed: 10 Mar 2016] [Google Scholar]

- Cristelo N., Glendinning S., Pinto A.T. Deep soft soil improvement by alkaline activation. ICE: Ground Improvement. 2011;164(G12):73–82. [Google Scholar]

- Cristelo N., Glendinning S., Fernandes L., Pinto A.T. Effect of calcium content on soil stabilisation with alkaline activation. Constr. Build. Mater. 2012;29:167–174. [Google Scholar]

- Cristelo N., Glendinning S., Miranda T., Oliveria D., Silva R. Soil stabilisation using alkaline activation of fly ash for self compacting rammer earth construction. Constr. Build. Mater. 2012;36:727–735. [Google Scholar]

- Cristelo N., Glendinning S., Fernandes L., Pinto A.T. Effects of alkaline-activated fly ash and Portland cement on soft soil stabilisation. Acta Geotech. 2013;8(4):395–405. [Google Scholar]

- Das B.M. fourth ed. Florida; CRC Press: 2014. Advanced Soil Mechanics. [Google Scholar]

- Das S.K., Yudhbir Geotechnical Characterization of Some Indian Fly Ashes. ASCE: J. Mater. Civil Eng. 2005;17(5):544–552. [Google Scholar]

- Dockter B.A., Eylands K.E., Hamre L.L. Use of Bottom Ash and Fly Ash in Rammed-Earth Construction. International Ash Utilization Symposium. Center for Applied Energy Research, University of Kentucky. 1999 [Google Scholar]

- Eijk R.J.V., Winkel H.T., Stam A.F. World of Coal Ash; Colorado, USA: 2011. Transforming Bottom Ash Into Fly Ash. 9/12 May 2011. [Google Scholar]

- Essler R. Design principles for ground improvement. In: Burland J., Chapman T., Skinner H., Brown M., editors. ICE manual of geotechnical engineering: Volume II geotechnical design, construction and verification. ICE Publishing; London: 2012. [Google Scholar]

- Fauzi A., Nazmi W.M., Fauzi U.J. Subgrade stabilization of Kuantan Clay using Fly Ash and bottom ash. The 8th international conference on geotechnical and transportation engineering. 2010 [Google Scholar]

- Hossain K. Development of stabilised soils for construction application. ICE: Ground Improvement. 2010;163(G13):173–185. [Google Scholar]

- Jackson N.M., Mack R., Schultz S., Malek M. World of Coal Ash; Kentucky, USA: 2007. Pavement Subgrade Stabilization and Construction Using Bed and Fly Ash. 7/10 May 2007. [Google Scholar]

- Kamon M., Katsumi T., Sano Y. MSW fly ash stabilized with coal ash for geotechnical application. J. Hazard. Mater. 2000;76(2–3):265–283. doi: 10.1016/s0304-3894(00)00203-x. [DOI] [PubMed] [Google Scholar]

- Kaniraj S., Havanagi V. Compressive strength of cement stabilized fly ash-soil mixtures. Cement Concrete Res. 1999;29:673–677. [Google Scholar]

- Kelly R.P. Parallel and nonconformities in worldwide Fly Ash classification: The need for a robust, universal classification system for fly ash. World of Coal Ash, WOCA conference; 5/7 May 2015, Tennessee, USA; 2015. [Google Scholar]

- Kolias S., Kasselouri-Rigopoulou V., Karahalios A. Stabilisation of clayey soils with high calcium fly ash cement. Cement Concrete Comp. 2005;27(2):301–313. [Google Scholar]

- Little N.D., Nair S. Texas Transportation Institute, A&M University; Texas: 2009. Recommended Practice for stabilization of subgrade soils and base materials. National Cooperative Highway Research Program. [Google Scholar]

- Mackiewicz S.M., Ferguson E.G. World of Coal Ash; Kentucky, USA: April 2005. Stabilizing of Soil with Self-Cementing Coal Ashes. 11/15 April 2005. [Google Scholar]

- Makusa G.P. Lulea University of Technology; 2012. Soil stabilization methods and materials. PhD thesis. [Google Scholar]

- McCarthy M.J., Csetenyi J.L., Jones M.R., Sachdeva A. Clay-Lime stabilization: Characterizing fly ash effects in minimizing the risk of sulphate heave. World of Coal Ash, WOCA Conference; 9-12th May 2011, Denver; 2011. [Google Scholar]

- O'Flaherty C., Hughes D. fifth ed. ICE Publishing; London: 2016. Highways: The location, design, construction and maintenance of road pavements. [Google Scholar]

- Palomo A., Grutzeck M.W., Blanco M.T. Alkali-Activated fly ashes, A cement for the future. Cement Concrete Res. 1999;29:1323–1329. [Google Scholar]

- Pandey V.C., Singh N. Impact of fly ash incorporation in soil systems. Agr. Ecosyst. Environ. 2010:16–27. [Google Scholar]

- Patel M.A., Patel H.S. Laboratory assessment to correlate strength parameter from physical properties of subgrade. Procedia Engineering. 2013;51:200–209. [Google Scholar]

- Prabakar J., Dendorkar N., Morchhale R.K. Influence of fly ash on strength behaviour of typical soils. Constr. Build. Mater. 2004;18:263–276. [Google Scholar]

- Reyes A., Pando M. World of Coal Ash; Kentucky, USA: 2007. Evaluation of CFBC fly ash for improvement of soft clays. 7/10 May 2007. [Google Scholar]

- Sahu B.K. Improvement in California bearing ratio of various soils in Botswana by fly ash. International Ash Utilization Symposium; University of Kentucky, USA; 2001. [Google Scholar]

- Santos F., Li L., Li Y., Amini F. World of Coal Ash; Denver, USA: 2011. Geotechnical Properties of Fly Ash and soil mixtures for use in highway embankments. 9/12 May 2011. [Google Scholar]

- Sato A., Nishimoto S. World of Coal Ash; Kentucky, USA: April 2005. Effective Reuse of Coal Ash as Civil Engineering Material. 11/15 April 2005. [Google Scholar]

- Senol A., Edil T.B., Bin-Shafique M.S., Acosta H., Benson C.H. Soft subgrades stabilization by using various fly ashes. Resour. Conserv. Recy. 2006;46(4):365–376. [Google Scholar]

- UKQAA . United Kingdom quality ash association; 2016. UKQAA Ash Availability Report.http://www.ukqaa.org.uk/wp-content/uploads/2016/01/UKQAA-Ash-Availability-Report-Jan-2016.pdf (Accessed: 05 April 2016) [Google Scholar]

- Wood J. University of West London; 2016. The Utilisation of Class F Fly Ash for Ground Improvement of Sand. Final Year Project-BEng in Civil Engineering. [Google Scholar]

- Zaliha S.Z.S., Kamarudin H., Al Bakri A.M., Binhussain M., Salwa M.S.S. Review on Soil Stabilization Techniques. Australian Journal of Basic and Applied Sciences. 2013;7(5):258–265. [Google Scholar]