Abstract

3D printing, also known as additive manufacturing, is the computer-guided process of fabricating physical objects by depositing successive layers of material. It has transformed manufacturing across virtually every industry, bringing about incredible advances in research and medicine. The rapidly growing consumer market now includes convenient and affordable “desktop” 3D printers. These are being used in the laboratory to create custom 3D-printed equipment, and a growing community of designers are contributing open-source, cost-effective innovations that can be used by both professionals and enthusiasts. User stories from investigators at the National Institutes of Health and the biomedical research community demonstrate the power of 3D printing to save valuable time and funding. While adoption of 3D printing has been slow in the biosciences to date, the potential is vast. The market predicts that within several years, 3D printers could be commonplace within the home; with so many practical uses for 3D printing, we anticipate that the technology will also play an increasingly important role in the laboratory.

Keywords: 3D printing, computer-assisted design, prototyping, equipment

Introduction

3D printing, also known as additive manufacturing, is a broad term describing fabrication processes that generate physical objects in a layer-by-layer fashion. Unlike traditional manufacturing methods—cutting, joining, molding, casting, and milling—3D printing imposes virtually no limits to the complexity of the geometry of an object. It also allows rapid prototyping and the fabrication of low volumes of custom parts. The methods and materials are diverse: 3D printers can extrude liquid, gel, or paste through a nozzle; cure photosensitive liquid polymers with lasers or projected light; selectively sinter or melt an object from a bed of powdered material with a high-powered laser; bind layers of powder through an inkjet-like process; or laminate layers of paper, foil, or film (Table 1).

Table 1.

Comparison of 3D Printing Processes and Materials.

| Type | Extrusion (FDM, FFF, TPE) | Light Polymerization (SLA, DLP, CLIP) | Powder Bed (Binder Jet) | Powder Bed (Heat/ Laser Melting/ Sintering) | Lamination |

|---|---|---|---|---|---|

| Method | Material (often molten plastic filament) is extruded through a nozzle that follows a path in x and y dimensions | Liquid resin is cured with laser light or with a projected image | Liquid binding material is selectively deposited across a layer of powdered substrate | Powdered material is selectively sintered or melted with a laser or electron beam | Layers of paper or film are adhered together and cut to shape with a knife or laser; may incorporate standard inkjet printing methods |

| Layer height | 0.050–0.400 | 0.010–0.200 | ~0.100a | ~0.100a | ~0.100a |

| Materials | Various thermoplastics (ABS, PLA, PVA, HIPS, PC, nylon, etc.); molten glass or sugar, clay, wax, edible materials (chocolate, icing, pancake batter, etc.) | Various acrylic photopolymers; properties can be rigid, flexible, castable, or transparent | Powdered plaster, sugar | Almost any metal alloy, titanium, thermoplastic, or ceramic powder | Paper, metal foil, plastic film |

| Printer cost | Start as low as $350 for small-volume printers and printer kits; can cost upward of $4000 | Desktop models $2500+; commercial printers can range from $20,000 to upward of $200,000 | $15,000–$30,000 | Typically $200,000+ | $30,000+ |

| Support structures required? | Dependent on materials and geometry; dissolvable supports can be used | Dependent on printer type and model geometry | No | No | No |

| Pros | Wide variety of affordable materials; with two or more extruders, can print in multiple colors and materials, print dissolvable support structures | Can achieve very fine detail and complexity, quiet operation | Capable of print at high resolution with full color; does not require support structures | Strong, durable parts; does not require support structures | Capable of printing in full color; does not require support structures |

| Cons | Complex geometries and overhangs require support material; limiting for single-extruder printers | Materials are limited and typically less durable consumables; messy postprocessing | Higher material cost; messy postprocessing; relatively fragile | Printer and material costs are expensive, highly specialized | Limitations in 3D geometry, better for solid structures |

ABS, acrylonitrile butadiene styrene; CLIP, continuous liquid interface production; DLP, digital light processing; FDM, fused deposition modeling; FFF, fused filament fabrication; HIPS, high-impact polystyrene; PC, polycarbonate; PLA, polylactic acid; PVA, polyvinyl alcohol; SLA, stereolithography; TPE, thermoplastic extrusion.

Resolution may be dependent on the thickness of the powder substrate or laminated material.

The most affordable method, and the one dominating the consumer-level market, is fused deposition modeling (FDM), also known as fused filament fabrication or thermoplastic extrusion. FDM printers feed plastic filament through a heated nozzle, which moves in both horizontal and vertical directions along a computer-guided path to deposit layers of molten material. After the initial expenditure for the printer itself, which can range from $350 to upward of $4000, the cost of consumables is relatively nominal. The most commonly used FDM filaments are made of acrylonitrile butadiene styrene (ABS) or polylactic acid (PLA), but a multitude of alternatives with varying strength, temperature, and material properties are available. ABS in particular is inexpensive, lightweight, durable, and resistant to impact. Many, if not most, manufactured plastic goods are made of ABS, including toys, medical devices, automotive trim, kitchen appliances, and general everyday products. With two or more extruders, parts can be printed in multiple colors or materials. More complex shapes can be printed with dissolvable support material.

The global 3D printing market has increased 27% from the late 1980s to 20141 and is expected to exceed $20 billion by the end of the decade.2 What began as a tool for rapid prototyping in manufacturing has expanded to nearly every field of industry, bringing about a “third industrial revolution.”3 3D printing has facilitated incredible advances in science and medicine. 3D prints are being used in surgical implants, and surgeons and patients are benefiting from 3D prints created from patient medical imaging data.4 Bioprinting, the process of layering a cell suspension to generate living tissue, holds the promise of regenerative medicine. Francis Collins, MD, PhD, director of the National Institutes of Health (NIH), calls 3D printing a “potential game changer for medical research.”5

3D-Printing the Lab: Customization and Innovation

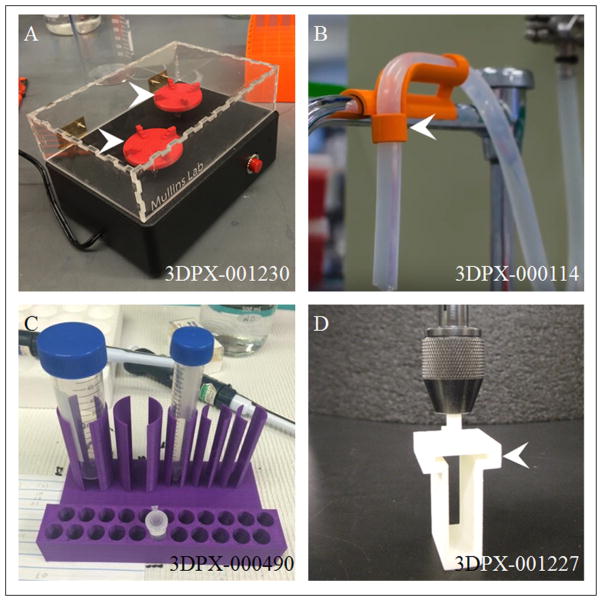

3D printers are not yet widely used in research applications, but they can be a valuable asset in that they provide enhanced experimentation capabilities. The path to scientific discovery is seldom paved with convenient, off-the-shelf solutions; in the laboratory, creative problem solving is essential. Troy Hibbard, PhD, describes himself and fellow scientists as “modern day McGyvers,” able to improvise with everything from binder clips to coffee filters to toilet rolls.6 Now, with a 3D printer in the lab, researchers can trade duct tape and sticky-tack for custom, 3D-printed labware with the same materials, strength, and durability as any commercially manufactured product. Hundreds of files for 3D-printed labware—everything from gel combs and pipette holders to motorized tissue homogenizers and cover slip spinners—can be found online (Fig. 1).

Figure 1.

Examples of 3D-printed lab equipment noted with white arrowheads. (A) Coverslip spinner holder, lab equipment, 3D-printed parts, http://3dprint.nih.gov/discover/3dpx-001230. (B) RO/DI tubing mount for laboratory faucets, http://3dprint.nih.gov/discover/3dpx-000114. (C) Tube rack, http://3dprint.nih.gov/discover/3dpx-000490. (D) Homogenizer tube holder, http://3dprint.nih.gov/discover/3dpx-001227. Model and image credits: (A) Sam Lord (user samjlord); (B) screenshots from “Multiple uses for 3D Printing around NIH Labs,” NIH 3D Print Exchange YouTube Channel, video by Jeremy Swan published on February 6, 2014; (C) Darren Boehning (user boehninglab); and (D) Peter Allen (user pballen).

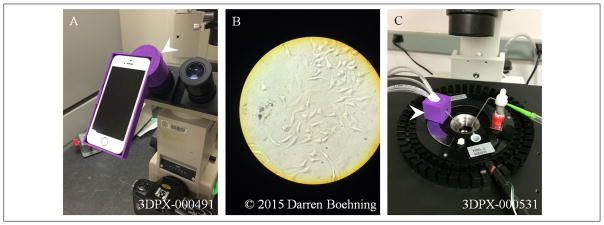

Darren Boehning, PhD, professor in the Department of Biochemistry and Molecular Biology at the University of Texas Health Science Center at Houston, purchased a 3D printer for just these types of simple solutions. Over time, Boehning and his team learned some very simple computer-aided design (CAD) software and were on their way to making custom apparatus, such as the Magnetic Perfusion Manifold Holder7 and the iPhone microscope adapter (Fig. 2).8 “Being able to design and print pieces of equipment that are either not available or are prohibitively expensive is incredibly useful,” says Boehning.9

Figure 2.

Custom 3D models from the laboratory of Dr. Darren Boehning 3D-printed parts noted with white arrowheads. (A) iPhone microscope adapter to accommodate microscopy image capture using an iPhone 5S camera, http://3dprint.nih.gov/discover/3dpx-000491, and (B) raw image of HeLa cells in culture. (C) Magnetic Perfusion Manifold Holder, 3D printed and augmented with neodymium magnets, shown here securing a Warner Instruments perfusion manifold MP-6, http://3dprint.nih.gov/discover/3dpx-000531. Image credits: Darren Boehning.

In the Hoy Lab at Cornell University, Gil Menda, PhD, and graduate student Paul Shamble developed a custom solution for capturing neurophysiological data directly from the brains of jumping spiders. Because the head cavity is highly pressurized, inserting electrodes would cause “catastrophic fluid loss.”10 Their “spider holder” uses dental wax, a soldering iron, and a specifically designed 3D-printed plastic platform.11

Stuart Yuspa, MD, chief of the Laboratory of Cancer Biology and Genetics at the National Cancer Institute, hopes that 3D printing can replace a custom part that has been supplied through traditional manufacturing. In 2008, Yuspa and his colleagues published their protocol, which uses a sterile insert to protect the site on adult mice where primary keratinocytes have been grafted.12 Over the years, the small silicone dome has been manufactured by several vendors, but Yuspa is having difficulties finding a new supplier. The new design method is in its early stages, but he is confident that 3D printing will provide a solution that eliminates dependence on outside manufacturers.

Saving Money with “Pennies’ Worth of Plastic”

3D prints are generally an affordable alternative to traditional retail equipment or machine-shop parts. At Rice University, Jordan Miller, PhD, focuses much of his research on methods for tissue engineering and bioprinting, but as a side project, he designed an open-source orbital shaker.13 Miller estimates it cost him only about $140, while a commercially available shaker could easily cost 10 times that amount. The do-it-yourself (DIY) DNA lab designed by Peter Allen, PhD, and his colleagues at the University of Idaho incorporates 3D-printed components for an estimated cost savings of 50% to 90%.14 Savings can be found in even the most basic plastic tools: a simple gel electrophoresis comb can retail for $6, but the materials of a 3D-printed comb can be less than $0.10.

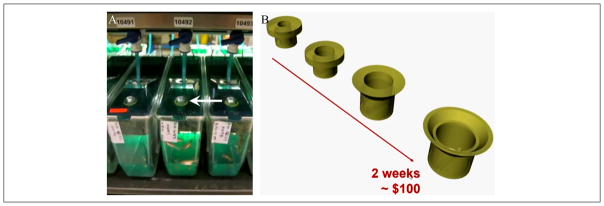

According to Director Collins, “At NIH, we have seen an incredible return on investment; pennies’ worth of plastic have helped investigators address important scientific questions while saving time and money.”5 Perhaps the best example comes from the NIH Zebrafish Facility. Shortly after the opening of the facility, researchers discovered that zebrafish were leaping from their holding tanks through a hole in the tank lid designed to accommodate the automated feeding system. Harold Burgess, PhD, and his team in the Laboratory of Molecular Genetics at the Eunice Kennedy Shriver National Institute of Child Health and Human Development (NICHD) used 3D modeling software to design a plug that would prevent the fish from escaping, without interfering with feeding or ventilation (Fig. 3). With a 3D printer, they were able to quickly test and refine their prototype. In only 2 weeks and at a cost of around $100, they had finalized their design. Burgess points out that had they been reliant on a machine shop, the development cycle would have been “two weeks and $1,000” for each iteration. The facility holds 30,000 tanks, so the final product was mass-manufactured, but the ability to quickly iterate and test new modifications reduced cost, saved time, and spared irreplaceable transgenic lines of zebrafish.

Figure 3.

(A) Holding tanks at the National Institutes of Health (NIH) Zebrafish Facility; the white arrow indicates the hole in the tank lid through which zebrafish were able to escape. (B) Renderings of the 3D design iterations of the 3D-printable feeding plug designed by the Burgess lab at the National Institute of Child Health and Human Development (http://3dprint.nih.gov/discover/3DPX-000110). Image credits: (A) Screenshot from “Examples of 3D Prints at NICHD,” NIH 3D Print Exchange YouTube Channel, video by Jeremy Swan published on January 31, 2014; (B) Harold Burgess, “3D Printing at the Bench: Singular Solutions for New Frontiers in Biology.”

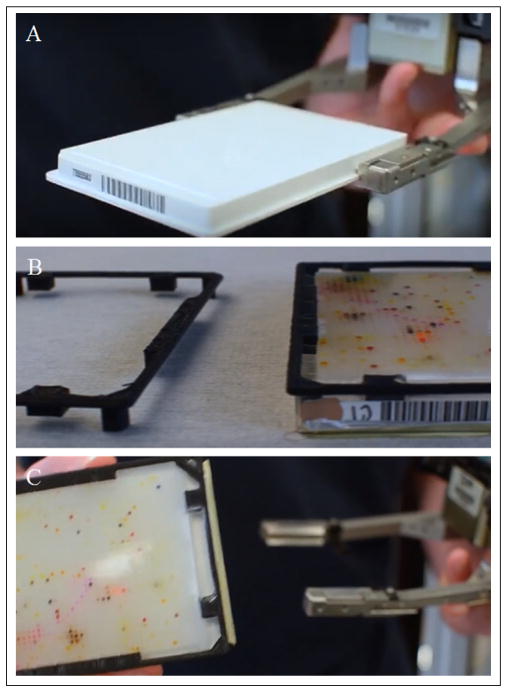

3D printing has also been embraced by engineers at the National Center for Advancing Translational Sciences (NCATS). Sam Michael, director of Automation and Compound Management, and his team maximized efficiency of a large robotic system for drug screening experiments.15 The “gripper” at the end of the robotic arm slides onto the flange of an assay plate to transfer it to and from various incubators and plate readers. If the flange broke, the plate was unusable. As a solution, NCATS engineers designed custom 3D-printed flanges to protect the plates and fix broken ones (Fig. 4).16 Michael says it is a “minor piece,” but without it, expensive libraries of drug compounds and precious reagents would be lost. “As simple as this seems, this was actually a revolutionary step in the process of high-throughput screening,” he says. Similarly, they used 3D printing to create an adapter for low-profile assay plates, to make them compatible with a several hundred-thousand dollar, high-content confocal imaging system.17 The plate reader manufacturer was not willing to accommodate them, so this small solution prevented them from having to modify the machine or their own experimental protocols.

Figure 4.

3D-printed flange for high-throughput drug screening. (A) A Greiner 1536 propylene plate with flange, held in the gripper of a robotic arm. (B) Replacement flange printed in black ABS on an FDM printer alone (left) and attached to a 1536 microplate without a flange (right). (C) Plate, with flange, held in the gripper. The 3D model was created by Eric Jones; files and more information are available at http://3dprint.nih.gov/discover/3DPX-000368. Image credits: (A–C) Screenshots from “How 3D Printing Helps with High Throughput Screening at the NIH,” NIH 3D Print Exchange YouTube Channel, video by Jeremy Swan published on February 6, 2014.

Open-Source Hardware

Joshua Pearce, PhD, is a strong advocate for free and open-source hardware (FOSH). He leads the Michigan Tech Open Sustainability Technology Laboratory (MOST), which has produced, among other things, an open-source calorimeter,18 syringe pump,19 a photometric system for enzymatic nitrate quantification,20 and open-source optics equipment.21 Pearce says that the scientific community has only “scratched the surface of opportunities” to use 3D printing in the laboratory. He has even devised a formula to determine the return on investment (ROI); by substituting a commercial syringe pump with MOST’s open-source version, he calculates potential savings ranging from $168,000 to $2.5 million.22 Pearce says that by funding “open hardware development, rather than purchasing proprietary equipment, the return on investment is astronomical.”

Organizations like Public Lab, the Open Source Hardware Association, and Wevolver are bringing together hobbyists, makers, designers, engineers, and like-minded individuals with an interest in the open-source movement. They are creating communities dedicated to developing and sharing open-source innovations, many of which incorporate 3D printing.

The even more impactful result of this growing movement is the potential to bring science out of the laboratory. Cathal Garvey is a self-proclaimed “biohacker” and founder of Forma Labs (http://formalabs.org), Ireland’s first biomakerspace. The “community lab” provides a variety of donated or DIY laboratory equipment, and members share their expertise. Garvey has made it his mission to “bring biotechnology … into the home, because I feel that’s the ultimate destination for biotechnology, in the same way that it was for computers.”23

Awareness and Recognition

At the National Institute of Allergy and Infectious Diseases (NIAID), we have sought to encourage adoption of 3D printing in the realm of bioscientific and medical research. The NIH 3D Print Exchange (http://3Dprint.nih.gov) is a community-driven, online portal for downloading and sharing 3D-printable models related to biomolecules, chemicals, organisms, anatomy, and custom labware.24 While many of the lab equipment models can be found in other open-source repositories, investigators less familiar with 3D printing were unlikely to find them. We hope that by providing niche content targeted toward a specific and technical demographic, more investigators will become aware of the potential of 3D printing to facilitate scientific discovery.

We also believe that 3D-printable models are a research output in their own right and should be recognized as part of a researcher’s portfolio, similar to open-source scientific software. 3D printed innovations should be shared online and could be included among the nontraditional “altmetrics” that complement conventional means of assessing scholarly output.

Looking toward the Future

Because the technology is still developing, adopting on-site 3D printing resource requires an investment of time for learning and troubleshooting, as the learning curve can be steep. Boehning says, “Our initial problems with printing combined with the fact that no one in the lab had CAD experience, made the 3D printer somewhat of an expensive paperweight.”9 However, there is an extensive online community of 3D printing enthusiasts and resources for support, and several free, user-friendly 3D design and printing applications are available. With a little practice in CAD software, labware can be designed to the user’s exact specifications.

Pearce predicts, “In the not-so-distant future it will be common for scientists to [download] the designs of any equipment they want, customize it at their desks, and print it on a 3D printer.”25 Boehning says they now user the 3D printer so much that soon they could need a sign-up sheet to manage printer time. In the Burgess lab, all new members are required to learn basic CAD skills. “To people in my lab, it’s inconceivable you would be in a molecular biology lab and not have access to a 3D printer,” Burgess says. His testimony is compelling: “[3D printing has] really unleashed people’s creativity. People are no longer satisfied with cobbling something together … they want to come up with exactly the right piece, as they imagined the experiment would be done in an ideal situation.”

Desktop 3D printing is expanding beyond the realm of early adopters and hobbyists, and mainstream demand for 3D printers is growing. 3D printing has the potential to play an important role in the laboratory by reducing costs and helping scientists develop and share innovative solutions to technical problems. The quick and cost-effective nature of 3D printing allows research methods and equipment to evolve at the rapidly advancing pace of bioscience research. The case studies presented here demonstrate the power of 3D printing to solve existing problems and make possible the impossible.

Acknowledgments

The authors gratefully acknowledge Dr. Darren Boehning, Dr. Joshua Pearce, and Dr. Stuart Yuspa for sharing their experiences with 3D printing through email communications and in-person meetings. Dr. Harold Burgess’s remarks were made at a presentation to the NIAID “Science in 3D” meeting on January 20, 2015 (video and transcripts available at http://videocast.nih.gov/launch.asp?18804). We thank Eric Jones and Sam Michael for sharing use cases from NCATS through video interviews, which can be found on the NIH 3D Print Exchange YouTube Channel. We also acknowledge Jeremy Swan, videographer and contributor to the NIH 3D Print Exchange, for video and image capture.

Funding

The authors disclosed receipt of the following financial support for the research, authorship, and/or publication of this article: The authors are founders and project leads for the NIH 3D Print Exchange. The Exchange is owned and managed by the Office of Cyber Infrastructure and Computational Biology, Office of Science Management and Operations, National Institute of Allergy and Infectious Diseases, National Institutes of Health. The site was created in collaboration with the Eunice Kennedy Shriver National Institute for Child Health and Human Development and the National Library of Medicine. Initial funding and support for the Exchange were provided in part by HHS Ignite and HHS Ventures, initiatives from the US Department of Health and Human Services.

Footnotes

Declaration of Conflicting Interests

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

References

- 1.Wohlers Associates. [accessed Sept 29, 2015];Wohlers Report 2014 Uncovers Annual Growth of 34.9% for 3D Printing and Additive Manufacturing Industry. 2014 http://wohlersassociates.com/press63.html.

- 2.Canalys. [accessed Sept 26, 2015];Global 3D Printing Market to Reach $20.2 Billion in 2019. 2015 http://www.canalys.com/newsroom/global-3d-printing-market-reach-202-billion-2019.

- 3.Markillie P. The Third Industrial Revolution. [accessed Sept 27, 2015];Economist. 2012 http://www.economist.com/node/21552901.

- 4.Jones DB, Sung R, Weinberg C, et al. Three-Dimensional Modeling May Improve Surgical Education and Clinical Practice. [accessed Oct 3, 2015];Surg Innov. 2015 doi: 10.1177/1553350615607641. [Online early access]. http://sri.sagepub.com/content/early/2015/09/29/1553350615607641.abstract. [DOI] [PubMed]

- 5.NationalInstitutesofHealth. [accessed Sept 27, 2015];NIHLaunches3DPrintExchangefor Researchers, Students. 2014 http://www.nih.gov/news/health/jun2014/niaid-18.htm.

- 6.Hibbard T. [accessed Oct 3, 2015];You Too Can be a MacGyver in the Lab! 2014 http://bitesizebio.com/19689/you-too-can-be-a-macgyver-in-the-lab/

- 7.boehninglab. Magnetic Perfusion Manifold Holder (3DPX-000531) [accessed Sept 17, 2015];The NIH 3D Print Exchange. 2015 http://3dprint.nih.gov/discover/3dpx-000531.

- 8.boehninglab. iPhone Microscope Adapter (3DPX-000491) [accessed Oct 2, 2015];The NIH 3D Print Exchange. 2014 http://3dprint.nih.gov/discover/3dpx-000491.

- 9.Boehning D. Personal communication. University of Texas Health Science Center; Houston, TX: 2015. [Google Scholar]

- 10.Menda G, Shamble PS, Nitzany EI, et al. Visual Perception in the Brain of a Jumping Spider. Curr Biol. 2014;24:2580–2585. doi: 10.1016/j.cub.2014.09.029. [DOI] [PubMed] [Google Scholar]

- 11.Shamble PS. Spider Holder (3DPX-000740) [accessed Oct 3, 2015];The NIH 3D Print Exchange. 2014 http://3dprint.nih.gov/discover/3dpx-000740.

- 12.Lichti U, Anders J, Yuspa SH. Isolation and Short-Term Culture of Primary Keratinocytes, Hair Follicle Populations and Dermal Cells from Newborn Mice and Keratinocytes from Adult Mice for In Vitro Analysis and for Grafting to Immunodeficient Mice. Nat Protoc. 2008;3:799–810. doi: 10.1038/nprot.2008.50. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.jmil. Orbital Shaker (3DPX-000684) [accessed Oct 3, 2015];The NIH 3D Print Exchange. 2014 http://3dprint.nih.gov/discover/3dpx-000684.

- 14.Damase TR, Stephens D, Spencer A, et al. Open Source and DIY Hardware for DNA Nanotechnology Labs. J Biol Methods. 2015;2:e24. doi: 10.14440/jbm.2015.72. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.How 3D Printing Helps with High Throughput Screening at the NIH. [accessed Sept 25, 2015];NIH 3D Print Exchange You Tube Channel. 2014 https://www.youtube.com/watch?v=M3rObh4kFyM.

- 16.Jones E. Greiner 1536 PP Microplate Flange Replacement (3DPX-000368) [accessed Sept 26, 2015];The NIH 3D Print Exchange. 2015 http://3dprint.nih.gov/discover/3dpx-000368.

- 17.Multiple Uses for 3D Printing around NIH Labs. [accessed Sept 25, 2015];The NIH 3D Print Exchange YouTube Channel. 2014 https://www.you-tube.com/watch?v=3YyjMtZIFew.

- 18.Anzalone GC, Glover AG, Pearce JM. Open-Source Colorimeter. Sensors (Basel) 2013;13:5338–5346. doi: 10.3390/s130405338. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Wijnen B, Hunt EJ, Anzalone GC, et al. Open-Source Syringe Pump Library. PLoS One. 2014;9:e107216. doi: 10.1371/journal.pone.0107216. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Wittbrodt BT, Squires DA, Walbeck J, et al. Open-Source Photometric System for Enzymatic Nitrate Quantification. PLoS One. 2015;10:e0134989. doi: 10.1371/journal.pone.0134989. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Zhang C, Anzalone NC, Faria RP, et al. Open-Source 3D-Printable Optics Equipment. PLoS One. 2013;8:e59840. doi: 10.1371/journal.pone.0059840. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Pearce JM. Return on Investment for Open Source Scientific Hardware Development. [accessed Oct 7, 2015];Sci Public Policy. 2015 doi: 10.1093/scipol/scv034. Online early access. from http://spp.oxfordjournals.org/content/early/2015/06/20/scipol.scv034.abstract) [DOI]

- 23.Garvey C. Bringing Biotechnology into the Home: Cathal Garvey at TEDxDublin. TED Conferences, LLC; 2013. [accessed Oct 3, 2015]. http://tedxtalks.ted.com/video/Bringing-biotechnology-into-the. [Google Scholar]

- 24.Coakley MF, Hurt DE, Weber N, et al. The NIH 3D Print Exchange: A Public Resource for Bioscientific and Biomedical 3D Prints. Additive Manufact. 2014;1:137–140. doi: 10.1089/3dp.2014.1503. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Pearce JM. Personal communication. Michigan Technological University; Houghton, MI: 2015. [Google Scholar]