Abstract

AIM:

This study aimed to compare the stresses generated by using two or four root form dental implants supporting mandibular overdentures that were retained with ball and locator attachments.

METHODS:

Under ANSYS environment, four 3D finite element models were prepared. These models simulated complete overdentures supported by two or four implants with either ball or locator attachments as a connection mechanism. The models’ components were created by CAD/CAM package then were imported to ANSYS. Load of 100 N was applied at the right premolar/molar region vertically and at an oblique angle of 110° from lingual direction.

RESULTS:

Within the conditions of this research, in all cases, it was found that cortical and cancellous bone regions were the least to be stressed. Also, the ball attachment produced higher stresses.

CONCLUSION:

Caps deformation and stresses are negligible in cases of using locator attachment in comparison to ball attachments. This may indicate longer lifetime and less repair/maintenance operations in implant overdentures retained by locator attachments. Although the study revealed that bone was insensitive to a number of implants or attachment type, it may be recommended to use two implants in the canine region than using four, where the locator attachments were found to be better.

Keywords: Finite element analysis, Implant, Overdenture, Attachment

Introduction

During the last decades, the classical standard of care for the edentulous patient used to be the provision of maxillary and mandibular complete dentures. However, people who wear conventional dentures often report discomfort or frank pain, lack of retention and stability as well as difficulty in eating.

The retention and stability characteristics are provided mainly by implants through attachments. Thus, various types of attachment systems have been proposed for connecting implant retained mandibular overdentures to underlying implants. The attachments are mainly classified into splinted anchorage systems, such as the bar type, and un-splinted anchorage systems, such as the ball attachment and locator attachment, to apply a retentive force for implant overdentures [1].

Some selection criteria of attaching mechanisms of Implant-retained overdentures were clarified for proper treatment planning. These criteria are mainly related to jaw morphology, amount of available bone, desired level of stability and retention, parallelism of the implants, type of overdenture fabricated, oral hygiene maintenance, maxillo-mandibular relationship, cost considerations, inter-implant distance and finally the patient’s compliance with recall and expectations in regards to psychological needs and esthetic requirements [2, 3]. Owing to the smaller space requirements within prostheses, easy cleaning, more economical incentives and lower sensitivity to techniques; un-splinted ball or locator attachments have been used in many implant overdentures [4-6].

Ball and socket attachments are wide spread stud attachments acting as snap fasteners and are widely available for use with overdentures supported by endosteal implants in various implant systems. Ball and socket attachments serve several advantages; they showed a reasonable success rate as simplest retainers for mandibular overdentures [7]. They were claimed to be less costly, less technique sensitive, minimal chair time requirements and easier to clean than bars. Also, the potential for mucosal hyperplasia was reduced with solitary ball attachments [8]. Ball attachments suffer some disadvantages in comparison with other types of attachments such as higher profile design which is considered disadvantageous. Also, high profile ball attachments may lead to higher concentration of stress patterns at the neck of the ball transferring a greater amount of stresses to the implant and the underlying bone. Resin and metal clips and rubber O-rings can wear reasonably quickly, thus reducing retention of the prosthesis and necessitating replacement. Subsequently, there is a need for regular servicing of overdentures with these types of attachments [9].

The Locator attachment manufactured by Zest Anchors is a resilient, non-splinted, prefabricated attachment of minimal vertical height 3.17mm on external hex implants and only 2.5 mm for a non-hexed internal connection implant which serves as an advantage for cases with limited inter-occlusal height [10]. It was found that short profile distance of locator was advantageous and was related to the reduction of load transfer to the implant [11]. This can be explained by reducing the lever arm length resulting in a better mechanical advantage [12, 13].

The design of locator attachment allows the ability to compensate implant angulations about vertical the plane of up to 20° which equals to 40° divergence between two implants eliminating the need for positioning of angled abutments [2]. Moreover, the locator aids the patient with its characteristic self-aligning feature to easily align and seat the removable overdenture. The rounded edges, “self-aligning feature”, decreases the wear of nylon male leading to better durability of the attachment. This system shows great benefit by doubling the retentive surface area which is called “Dual retention” (internal and external features of the abutment) ensuring long-lasting retention life [14].

The number of implants required to provide an adequate mandibular implant overdenture treatment outcome remains debatable. It was pointed out that the value of fewer implants as a cost saving approach has a merit for many patients. However, the use of more than two implants is recommended in certain cases to produce greater overdenture stability and preserving the supporting peri-implant bone [15].

The protection of the osseointegration bond between the implants and living bone from biomechanical failure can be accomplished through prediction, reduction and prevention of the biological interface over-stressing. In fact, the type, dimensions of the attachment and the number of implants used have its influence on the stresses delivered to the implants then to the bone [8]. It is important that the effect of these parameters be investigated to avoid failure of the implant overdenture. Here raises the question: Do ball and locator attachments induce different stress distribution pattern when used to retain mandibular overdenture supported by either two or four implants?

The finite element method offers an accurate representation of complex geometries, easy model modification and representation of the internal state of stress and other mechanical qualities. It is considered a valuable tool to predict, adjust and prevent future failures in standardised circumstances of research studies [16].

The aim of this study is to compare the stress patterns induced by ball attachments and locator attachments when used to retain mandibular overdentures supported by either two or four root form dental implants.

Materials and Methods

The current finite element study simulates a clinical situation where an edentulous mandible was restored with an implant supported overdenture. That, four finite element models were prepared based on Geng et al., [17] according to the number and location of implant/attachment system as follows:

Two implants in the canine regions with ball & socket attachments.

Four implants; two in the canine regions and two in the first premolar regions with ball & socket attachments.

Two implants in the canine regions with locator attachments.

Four implants; two in the canine regions and two in the first premolar regions with locator attachments.

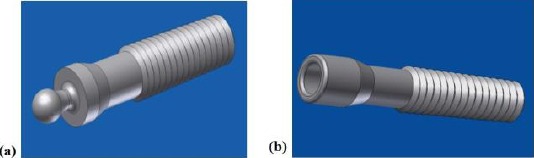

The finite element models components as the overdenture, mucosa, caps, ball & sockets, locator, cortical and cancellous bones were created in “Autodesk Inventor” Version 8 (Autodesk Inc., San Rafael, CA, USA), then exported as SAT files. These components were assembled in ANSYS environment (ANSYS Inc., Canonsburg, PA, USA). Where the designs of the implant and the attachment systems were taken from the manufacturer data. The system analysed in this investigation consisted of the commonly available root form threaded titanium dental implant (Zimmer Dental Inc, USA) with ball attachment or locator (Zest Anchors, Escondido, CA). The root form dental implant had a nominal diameter of 3.7 mm, a length of 13 mm and the shape of the internal hex with a hex width 3.5 mm as presented in Figure 1.

Figure 1.

Implant complex with (A) Ball, and (B) locator models on Autodesk Inventor screen

That implants were located at their planned positions in the inter foramina region. The mesial implant beds were equally spaced from each other and the distal implants. The four implants were perpendicular to the horizontal plane of the superior border of the mandible while maintaining the inter-implant parallelism. Perfect osseointegration was assumed to be presented between implants and bone. The metal cover on nylon caps of both attachments ball and locator was ignored in this study. All materials were assumed to be isotropic, homogenous and linearly elastic and its properties are listed in Table 1.

Table 1.

Material properties of used in the finite element model

The simulated peri-implant bone included an inner layer representing cancellous bone of 22 mm height and 14 mm width covered by an outer thin layer of cortical bone of 2 mm thickness. The simulated covering mucosal layer was of 2 mm thickness. The prosthetic acrylic overdenture was simulated of height 8 mm and width of 8.8 mm [18, 19].

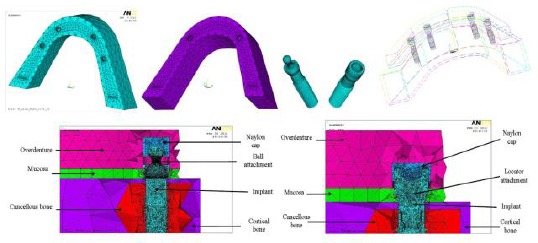

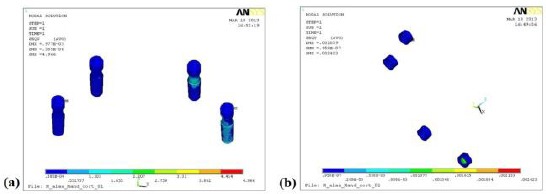

Set of Boolean operations between the modelled components were performed before obtaining the complete model(s) assembled. The meshing of these components was done by 3D brick solid element “Solid-45” which has three degrees of freedom (translation in main axes directions). The resulted numbers of nodes and elements are listed in Table 2, and samples for these meshed components are presented as screen shots from ANSYS screen in Figure 2.

Table 2.

Number of nodes and elements in all meshed components

| 2x Ball Attachment | 4x Ball Attachment | 2x Locator Attachment | 4x Locator Attachment | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Component | Elements | Nodes | Elements | Nodes | Elements | Nodes | Elements | Nodes | |

| Overdenture | 8.219. | 2.272. | 6.228. | 1.724. | 9.658. | 2.796. | 7.287. | 2.056. | |

| Mucosa | 13.234. | 40324. | 7.326. | 2.556. | 13.574. | 4.410. | 7.470. | 2.594. | |

| nylon ring (Cap) | 40.427. | 9.391. | 27.031. | 5.825. | 2.603. | 4.788. | 10.264. | 2.388. | |

| Implant complex | 493.369. | 94.650. | 244.131. | 46.893. | 516.713. | 96.216. | 317.994. | 56.92. | |

| Cortical bone | 5.870. | 2.177. | 4.897. | 1.773. | 5.844. | 2.177. | 4.892. | 1.769. | |

| Spongy bone | 59.199. | 16.428. | 29.451. | 8.313. | 58.867. | 16.356. | 29.486. | 8.307. | |

Figure 2.

Meshed components of the used model(s)

For each model, two loading conditions of 100N were investigated; vertical load, and oblique load at an angle of 110° from the lingual direction on the right premolar/molar region. The lowest plane of each model was considered fixed in the three directions as a boundary condition.

The Linear static analysis was performed on a personal computer (Intel Core to the Due processor, 2.8 GHz, 4.0 GB RAM), using a commercial multipurpose finite element software package (ANSYS version 12.0). The models were verified against similar studies [17, 20].

Results

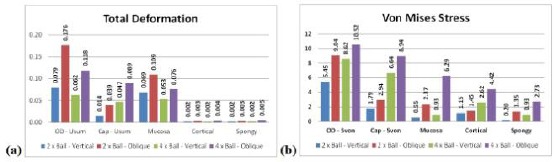

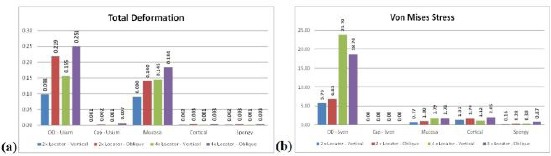

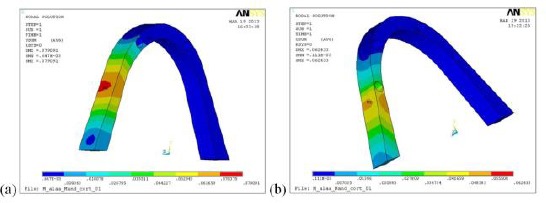

The locations and values of stresses under both vertical and oblique loading conditions were detected in the implant-abutment complex, cortical bone, cancellous bone, mucosa, resilient caps and prosthetic overdenture. The generated total deformations and maximum Von Mises stresses in the four cases were compared in Figures 3 and 4 for ball & socket attachments and locator attachments respectively. The results showed that the nylon caps suffered from high stresses and deformation in the model of ball attachment in comparison to that of the locator attachment. Also, Figures 3 and 4, showed that there was a superiority of using two attachments over using four when both cortical and cancellous bone, were investigated.

Figure 3.

Comparison between using two and four ball & socket attachments

Figure 4.

Comparison between using two and four locator attachments

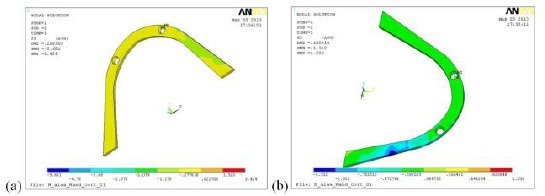

As illustrated in Figure 5, upon application of 100N vertical load on the model with four ball & socket attachments, the overdenture total deformation was reduced by about 18% than when two attachments were used.

Figure 5.

Overdenture total deformation under vertical load in cases of using (a) two and (b) four ball & socket attachment

Using two locator attachments reduced the maximum compressive stresses on mucosa by about 25%, than by using two ball & socket attachments as presented in Figure 6 (a) and (b).

Figure 6.

Mucosa maximum compressive stress under oblique load in cases of using (a) two ball & socket and (b) two locator attachments

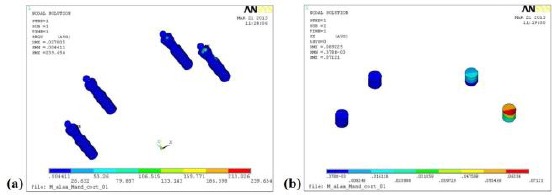

Finally, Figures 7 and 8, showed a very high Von Mises stress values on the ball attachment neck placed close to the applied load in comparison to the locator attachment.

Figure 7.

Ball & Socket attachment Von Mises stress and lateral deformation “Ux” under oblique load in case of using four ball & socket attachments

Figure 8.

Locator attachment Von Mises stresses under vertical load in case of using four implants

Discussion

Ball & socket, as well as locator attachments, are nowadays widely available for use with overdentures supported by endosteal implants in various implant systems. This study aimed to compare the stress patterns induced by these two types of attachments when used to retain mandibular overdentures supported by either two or four root form dental implants.

Regarding all studied models, the overdenture material absorbed the majority of load energy to guard the jaw bone in the four case studies. The generated Von Mises stresses were concentrated at the side of load application and were minimally induced in the contralateral side which was found consistent with the results of other studies [21, 22]. This could be related to the slight movement allowed by the overdenture that might direct the generated stresses to the side of load application unlike fixed restorations or bar retained overdentures that distribute the load to all parts of the prosthesis on both sides of the arch. It is also to be mentioned that a massive increase in values of resultant stresses was obvious under oblique loading conditions, which came in corroboration with other studies [21, 23] that lateral and off-axis loading cause high bending stress.

The locator attachment showed less Von Mises stress values than the ball attachment with vertical as well as oblique loading conditions in implant-abutment complex, supporting alveolar bone and the resilient caps. This is possibly related to the low profile design of the locator attachment and to the rotational pivoting character of its abutment that is advocated to lower the rotational centre and to potentially reduce the lateral forces [24, 25]. The resilience of the locator attachment could be an important factor to allow anteroposterior movement, laterally and intrusive thus reducing the resultant stresses on the implants and supporting peri-implant bone [24, 25].

Regarding the difference in the generated stress distribution pattern of the attachment systems, the maximal stresses induced in the implant-abutment complex in the models with locator attachments were found to be concentrated in the cervical portion of the implant fixture and were not related to the number of implants being two or four. On the other hand, maximum Von Mises stresses were detected in the ball abutments and were found to be concentrated in the area of its neck, also irrespective of the number of implants used to support the overdenture. This finding is consistent with previous studies and might be explained in the light of the high elastic modulus of the implant and attachment compared to that of other zones of the simulated models. Furthermore, most of the stresses were located at the junction of the ball with the rest of the abutment as it is the narrowest portion of cross-sectional diameter [16, 23]. The fact that the ball attachment led to more stress generation than was encountered with the locator attachment, might be attributed to its design with the keyway positioned higher above the implant abutment and the alveolar ridge with a longer lever arm that led to transmission of greater stresses to the peri-implant structures. It was reported that ball attachments as a high-profile attachment are considered disadvantageous in this aspect [26, 27].

Regarding the stress distribution pattern in simulated bone, the highest stress concentration was detected at the crest of the cortical bone, in all investigated cases a finding that came in corroboration with previous 3D-Finite element studies [20, 23]. The Young’s elastic modulus of bone depends on the apparent density or porosity of the tissue [23]. Hence, it might be recognised that the cancellous bone acted as a shock absorber dissipating the generated stresses while the cortical bone acted as a load-carrying member.

The induced stresses on the simulated mucosa also differed according to the type of investigated attachment. Von Mises stresses induced in mucosa were of higher values with locator attachment than with ball attachment in both two and four implant overdenture models. This might be due to the resilient hinging character of the locator attachment that enables a degree of movement of the overdenture.

In all the four models, the area of the inner surface of the cap of the ball abutment nearest to the site of load application was the most to suffer higher Von Mises stress values. Caps deformation and stresses were negligible in cases of using locator attachments in comparison to ball & socket attachments. This may suggest longer lifetime and less need for repair and maintenance operations with locators. Although, both attachment caps shared similar crushing effect dissipating the induced stresses, it seemed that the greater thickness of the acrylic overdenture overlying the locator’s cap as a result of the low profile design of the locator attachment acted as a mechanical absorber taking most of the applied load thus decreasing the induced stresses radiating to the locator’s cap.

Regarding the difference in Von Mises stress distribution pattern as related to a number of implants supporting the overdentures, the stresses generated differed according to the number of supporting implants whether were two or four, under both vertical and oblique loading conditions. Although it might be anticipated by clinicians that the increase in implant number would widely distribute stresses induced in implant-abutment complex bodies and peri-implant bone, these study findings were found antagonistic [28, 29]. The highest stress generation was noticed when four implants were used to support the overdenture when connected to both ball and locator abutments. This finding might not be only related to the implant number only but might also be due to the unequal load reaching the implants and the supporting structures as the load was applied unilaterally on the premolar/molar region.

Within the limitations of this in vitro study, it may be concluded that locator attachments may provide an adequate attachment system when two implants are to be used to support an overdenture when compared to the ball & socket attachments. Stresses developed in the prosthesis differed according to the number of implants that overdenture took the majority of the applied load energy. The negligible load was transferred to the bone in all studied cases. On the other hand, the simulated mucosa carried (absorbed) the greater amount of the applied load with ball & socket over locator’s attachment(s).

Footnotes

Funding: This research did not receive any financial support.

Competing Interests: The authors have declared that no competing interests exist.

References

- 1.Wismeijer D, Van Wass MA, Mulder J. Clinical and radiological results of a patient treated with three treatment modalities for overdenture on implants of (ITI) dental implant system. Clin Oral Impl Res. 1999;10:297–306. doi: 10.1034/j.1600-0501.1999.100406.x. https://doi.org/10.1034/j.1600-0501.1999.100406.x . [DOI] [PubMed] [Google Scholar]

- 2.Gulizio M, Agar J, Kelly R, Taylor T. Effect of implant angulation upon retention of over denture attachments. Int J Prosthodont. 2005;14:3–11. doi: 10.1111/j.1532-849X.2005.00005.x. https://doi.org/10.1111/j.1532-849X.2005.00005.x . PMid:15733129. [DOI] [PubMed] [Google Scholar]

- 3.Trakas T, Michalakis K, Kang K, Hirayama H. Attachment systems for implant retained overdentures: a literature review. Impl Dent. 2006;15:24–34. doi: 10.1097/01.id.0000202419.21665.36. https://doi.org/10.1097/01.id.0000202419.21665.36 . PMid:16569958. [DOI] [PubMed] [Google Scholar]

- 4.Alsabeeha NHM, Payne AGT, Swain MV. Attachment systems for mandibular two-implant overdentures: a review of in vitro investigations on retention and wear features. Int J Prosthodont. 2009;22:429–440. PMid:20095190. [PubMed] [Google Scholar]

- 5.Wang F, Monje A, Huang W, Zhang Z, Wang G, Wu Y. Maxillary Four Implant-retained Overdentures via Locator® Attachment: Intermediate-term Results from a Retrospective Study. Clin Implant Dent Relat Res. 2016;18(3):571–9. doi: 10.1111/cid.12335. https://doi.org/10.1111/cid.12335 . PMid:25810348. [DOI] [PubMed] [Google Scholar]

- 6.Youda N, Matsudate Y, Abue M, Hong G, Sasaki K. Effect of attachment type on load distribution to implant abutments and the residual ridge in mandibular implant-supported overdentures. J Dent Biomech. 2015;6:1758736015576009. doi: 10.1177/1758736015576009. https://doi.org/10.1177/1758736015576009 . [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Krennmair G, Weinlander M, Krainhofner M, Peihslinger E. Implant-supported mandibular overdentures retained with ball or telescopic crown attachments: a 3-year prospective study. Int J Prosthodont. 2006;19:164–170. PMid:16602365. [PubMed] [Google Scholar]

- 8.Sadig W. A comparitive in vitro study on the retention and stability of implant-supported over dentures. Quintessence Int. 2009;40(4):313–319. PMid:19417876. [PubMed] [Google Scholar]

- 9.Pasciuta M, Grossmann Y, Israel M. A prosthetic solution to restoring the edentulous mandible with limited inter-arch space using an implant-tissue-supported overdenture: A clinical report. J Prosthetic Dent. 2005;93:116–120. doi: 10.1016/j.prosdent.2004.09.024. https://doi.org/10.1016/j.prosdent.2004.09.024 . PMid:15674219. [DOI] [PubMed] [Google Scholar]

- 10.Kleis WK, Kammer PW, Hartmann S, Al-Nawas B, Wagner W. A comparison of three different attachment systems for mandibular two implant overdentures: One-year report. Clin Imp Dent Res. 2010;12:209–218. doi: 10.1111/j.1708-8208.2009.00154.x. [DOI] [PubMed] [Google Scholar]

- 11.Ibrahim AM, Radi I AW. The effect of two types of attachments on the bone height changes around divergent implants retaining mandibular overdentures. Cairo Dent J. 2009;25(2):181–189. [Google Scholar]

- 12.Cordaro L, Di Torresanto VM, Petricevic N, Jornet PR, Torsello F. Single unit attachments improve peri-implant soft tissue conditions in mandibular overdentures supported by four implants. Clin Oral Impl Res. 2013;24(5):536–42. doi: 10.1111/j.1600-0501.2012.02426.x. https://doi.org/10.1111/j.1600-0501.2012.02426.x . PMid:22320359. [DOI] [PubMed] [Google Scholar]

- 13.Schneider AL. The use of a self-aligning, low-maintenance overdenture attachment. Dent Today. 2000;19(4):24–26. PMid:19750725. [PubMed] [Google Scholar]

- 14.Kurian BP, D’lima J, Karthikeyan CR, Mathew J, Paul T, Hareesh MT. Prosthetic efficiency of implant-supported overdentures with locator attachment: A Clinical case report. Journal of International Oral Health. 2015;7(10):129–132. [Google Scholar]

- 15.Theodoros T, Konstantinos M, Hiroshi H. Attachment systems for implant retained overdentures. J Impl Dent. 2006;1:24–34. doi: 10.1097/01.id.0000202419.21665.36. [DOI] [PubMed] [Google Scholar]

- 16.Doundoulakis JH, Eckert SE, Lindquist CC, Jeffcoat MK. The implant-supported overdenture as an alternative to complete mandibular denture. J Am Dent Assoc. 2003;134(11):1445–8. doi: 10.14219/jada.archive.2003.0073. https://doi.org/10.14219/jada.archive.2003.0073 . [DOI] [PubMed] [Google Scholar]

- 17.Geng J, Yan W, Xu W, editors. Application of the finite element method in implant dentistry. Springer Science & Business Media. 2008 Sep 26; [Google Scholar]

- 18.Huang HL, Chang CH, Hsu JT, Fallgatter AM, Ko CC. Comparison of implant body designs and threaded designs of dental implants: A 3-dimensional finite element analysis. Int J Maxillofac Imp. 2007;22(4):551–562. [PubMed] [Google Scholar]

- 19.Lui J, Pans S, Dong J, Mo Z, Fan Y, Feng H. Influence of implant number on the biomechanical behavior of mandibular implant-retained/supported overdentures: a three dimensional finite element analysis. J Dent. 2013;41(3):241–249. doi: 10.1016/j.jdent.2012.11.008. https://doi.org/10.1016/j.jdent.2012.11.008 . PMid:23160036. [DOI] [PubMed] [Google Scholar]

- 20.El-Anwar MI, Yousief SA, Soliman TA, Saleh MM, Omar WS. A Finite element study on stresses distribution of two different attachment designs under implant supported overdenture. The Saudi Dental Journal. 2015;27(4):201–207. doi: 10.1016/j.sdentj.2015.03.001. https://doi.org/10.1016/j.sdentj.2015.03.001 . PMid:26644755. PMCid:PMC4642187. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Muntianu LAS. Analyze of the mechanical stress distribution over implants in mandibular overdenture. Metalurgia Int. 2010;15(3):24–26. [Google Scholar]

- 22.Ravindra C, Goyal SC. Study of Biomechanics of Porous Coated Root Form Implant Using Overdenture Attachment: A 3D FEA. J Indian Prosthodont Soc. 2010;10(3):168–175. doi: 10.1007/s13191-010-0035-8. https://doi.org/10.1007/s13191-010-0035-8 . PMid:21886409. PMCid:PMC3081273. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Tada S, Stegaroiu R, Kitamura E, Miyakawa O, Kusakari H. Influence of implant design and bone quality on stress/strain distribution in bone around implants: a three dimensional Finite Element Analysis. Int J Oral Maxillofac Imp. 2003;18:357–368. PMid:12814310. [PubMed] [Google Scholar]

- 24.Kurtzman GM. The locator attachment: Free standing versus bar overdentures. Dent Labor Int plus. 2009;1(1):20–23. [Google Scholar]

- 25.Evtimovska E, Masri R, Driscoll CF, Romberg E. The change in retentive values of locator attachments and hader clips over time. J Prosthodont. 2009;18(6):479–483. doi: 10.1111/j.1532-849X.2009.00474.x. https://doi.org/10.1111/j.1532-849X.2009.00474.x . PMid:19500236. [DOI] [PubMed] [Google Scholar]

- 26.Abdelhamid AM, Assaad NK, Neena AF. Three dimensional finite element analysis to evaluate stress distribution around implant retained mandibular overdenture using two different attachment systems. J Dent Health Oral Disord Ther. 2015;2(5):00065. [Google Scholar]

- 27.Ebadian B, Talebi S, Khodaeian N, Farzin M. Stress analysis of mandibular implant-retained overdenture with independent attachment system: effect of restoration space and attachment height. Fixed Removable Hybrid Prosthesis. 2015;1:61–67. [PubMed] [Google Scholar]

- 28.Bilhan H, Geckili O, Mumcu E, Cilingir A, Bozdag E. The influence of implant number and attachment type on maximum bite force of mandibular overdentures: a retrospective study. Gerodontology. 2012;29(2):e116–20. doi: 10.1111/j.1741-2358.2010.00421.x. https://doi.org/10.1111/j.1741-2358.2010.00421.x . PMid:20735488. [DOI] [PubMed] [Google Scholar]

- 29.Hong HR, Pae A, Kim Y, Paek J, Kim HS, Kwon KR. Effect of implant position, angulation, and attachment height on peri-implant bone stress associated with mandibular two-implant overdentures: a finite element analysis. Int J Oral Maxillofac Imp. 2012;27(5):69–76. [PubMed] [Google Scholar]