Abstract

Water absorption, color, morphology and cooked texture of brown rice were evaluated after selected soaking (30–50 °C, 30 min) and high pressure treatment (HPT) (100–500 MPa; single or two cycle; total holding time 10 min). Water absorption ratio and lightness values of brown rice were increased by soaking and HPT. Hardness and gumminess values of cooked brown rice were reduced while springiness and cohesiveness were elevated by HPT. Scanning electron microscopy indicated that HPT improved the texture of brown rice by disrupting the structure of rice bran layer, which allowed easier water penetration into the rice grain during cooking. Moreover, the two cycle HPT resulted in lighter color and softer texture for cooked brown rice than single cycle HPT primarily caused by the more severe structural disruption of bran layer. Overall, two cycle HPT after soaking could potentially improve the quality of brown rice, taking about the same time as the single cycle HPT. Further, the quality improvements with the two cycle HPT were facilitated at lower pressure levels thereby providing better commercial processing opportunities.

Keywords: Brown rice, High pressure treatment, Color, Texture, Morphology

Introduction

Rice is an important cereal crop, which provides dietary energy and basic nutrition for over half of the world’s population (Deng et al. 2013; Lu et al. 2013). However, rice-rich diets may lack essential vitamins, minerals and other nutrients, owing to monotonous consumption of milled white rice (Shen et al. 2009). Nowadays, due to changes in consumer life style and health awareness, brown rice is receiving increased interest as a source of not only energy but also several other healthy attributes (Mir et al. 2016). Compared with white rice, brown rice is rich in several health beneficial nutrients such as dietary fiber, gamma-oryzanol (an active component of rice bran), antioxidants, essential amino acids, vitamins and minerals (Cui et al. 2010; Han and Lim 2009). Despite its the high nutrient content, brown rice is not well accepted as white rice because of the rough and tough texture making it hard to chew (Chen et al. 2012). Further, the appearance of brown rice is also very not attractive due to its off-white/brownish color (Saunders 1990). Because the endosperm of brown rice is tightly covered with bran that is rich in tough fibers, during cooking, the penetration of water into the kernels is rather restricted and limits the hydration and swelling of the core (Zhang et al. 2015). Although, health conscious consumers tend to buy the brown rice despite these disadvantages and at much higher prices, it would be desirable to improve the color and cooking quality of brown rice to make it attractive for the general population.

In general, textural characteristics of cooked rice are affected by several factors, which include the cultivar, water-absorption capacity, type and amount of starch, amylose/amylopectin content, pre-treatment and cooking method (Lu et al. 2013; Tamura and Ogawa 2012; Tian et al. 2014). In order to obtain uniform water absorption and desired texture, it is a common practice to soak the brown rice in water before it is cooked (Han and Lim 2009). However, the simple soaking treatment takes a long time and hinders production efficiency in commercial practice. Hence, researchers have tried to combine the water soaking treatment with other techniques including microwave treatment (Zhong et al. 2013), plasma treatment (Chen et al. 2012), ultrasonic treatment (Cui et al. 2010) or high pressure treatment (HPT) (Yamakura et al. 2005). HPT is considered a potential non-thermal processing alternative to many conventional processing techniques for food preservation and processing, and has been demonstrated to result in better quality retention, improve functional properties or assist in enhancement of conventional processing (Knorr et al. 2006; Norton and Sun 2008; Ramaswamy 2011; Rastogi et al. 2007). Some studies have shown that HPT improves the texture, flavor and safety of cooked white rice and gelatinization of rice starch (Boluda-Aguilar et al. 2013; Deng et al. 2013; Tian et al. 2014). Prasert and Suwannaporn (2009) found that the HPT generated a homogeneous gelatinization of starch. However, the effect of HPT on the color and textural properties of brown rice is limited. In a previous study from our lab (Yu et al. 2015), it was found that single cycle HPT could shorten the cooking time and reduce the hardness of brown rice. However, this study was somewhat limited for concept testing with a single cycle HPT and lacked details on the influence on appearance, texture, morphology and market potential of HPT that might be possible with a two cycle HPT. Compared with the single cycle HPT, multiple cycle HPT has been shown to cause more significant effects with inactivation of microorganisms (Morales et al. 2008) and higher digestibility of rice starch (Deng et al. 2014). These studies suggest that multiple cycle HPT could be more beneficial for improving the functionality and safety of food. Till this date, high pressure effects on cooking quality of rice have been limited to a single cycle HPT. In the only multiple cycle study (Boluda-Aguilar et al. 2013), which used with white rice, treatment times in the first cycle were 2–4 min at 300–400 MPa while the second cycle used a 20 min holding time at a much higher pressure of 570 MPa.

Therefore, the objective of this study was to investigate the effects of single versus two cycle HPT on the water absorption, color, cooked texture and internal structure of brown rice. The single cycle HPT was a 10 min treatment at a specified pressure as has been used in several applications while the two cycle HPT process comprised of two 5-min yielding the same total holding time of 10 min.

Materials and methods

Materials

A Chinese indica rice cultivar, “Zhongzheyou 1”, was obtained from China National Rice Research Institute (Zhejiang Province, China). Rice grains were cleaned manually to remove foreign matters, filled into polythene bags and stored in a refrigerator at 4 °C until use. Grains were taken out from the refrigerator when needed, warmed up to room temperature and de-husked with a laboratory huller (BLH-3250, Boliheng Machine Inc., Zhejiang, China) to obtain brown rice samples. They were kept sealed in three layers of polyethylene bags (20 cm × 28 cm, China Manufacturing, Shanghai, China) and again stored at 4 °C for further experimentation.

Sample preparation

For each treatment, 10 g samples of prepared brown rice grains were weighed and vacuum packed in a food grade polyethylene bag (6 cm × 8.5 cm, China Manufacturing, Shanghai, China) with 16 mL of distilled water. These sample bags were immersed in water-bath (DKS, Zhongxin Machine Inc., Jiaxing, China) at 30, 40 or 50 °C for 30 min in separate batches, and immediately taken for high pressure treatment.

High pressure treatment (HPT)

HP treatments were given in a laboratory-scale high-pressure processing unit (UHPF-750, Kefa High Pressure Food Processing Inc., Baotou, China) with a 5 L cylindrical pressure chamber capable of operating at pressure selected levels up to a maximum of 600 MPa. Brown rice samples in sealed plastic bags, pre-soaked at different temperatures, were placed in the HP vessel and immediately subjected to pressure treatment, again one batch at a time. Water was used as the pressure-transmitting medium. Different HP treatments were given at pre-selected conditions.

For the first set of samples, a single cycle HPT was given, one pressure treatment at a time, at 100, 200, 300, 400 or 500 MPa for 10 min (holding time). This included all test samples that had been previously soaked at 30, 40 or 50 °C for 30 min. The pressure come-up speed was approximately 100 MPa/min, but depressurization was very rapid (<15 s) which was done by opening the pressure release valve immediately after the treatment holding time. The pressure come-up time and the depressurization time were not included in the HPT time.

The second set of samples, were treated by a two cycle HPT involving the same total holding time of 10 min. The process however was split into two pressure cycles of 5 min, meaning a first pressure treatment cycle of 5 min holding time (half of what was given in the first set), the pressure chamber depressurized and immediately the second identical cycle started. Each two cycle HPT was also given at each of the five pressure levels—100, 200, 300, 400, 500 MPa, separately. Thus, the two cycle HPT samples also had a total pressure holding time of 10 min, but split to two 5 min cycles as opposed to one 10 min HPT in the first set. Treated samples were then analyzed for various quality parameters.

Water absorption

The water absorption ratio (WAR) of brown rice test samples was measured according to the method of Akil et al. (2009) with some modifications. In brief, for this test, the soaked brown rice kernels (with and without HPT) were taken out the bags and immediately wrapped in a filter paper to remove the excess surface water and then weighed. All measurements were made in triplicate. The water absorption ratio (wet basis) was calculated using the following equation.

where WAR is the water absorption ratio of the sample (wet basis), M o is the initial weight of the sample before treatment (g), and M t is the weight of the sample after treatment (g).

Color characteristics

For color determination, the soaked brown rice samples (with and without HPT) were drained and dried in an air oven at 50 °C for 2 h (to a final moisture content of 11–12%). The dried samples were filled into the sample holder of the colorimeter and color parameters were measured using a Chroma Meter (CR-700d/600d, Konica Minolta Sensing Inc., Osaka, Japan) calibrated against a white standard. Color measurements were based on tristimulus parameters, L*, a*, and b*. L* indicates the degree of lightness or darkness (100 = white and 0 = black), a* indicates redness (+a*) to greenness (−a*) and b* indicates yellowness (+b*) to blueness (−b*), respectively (Shen et al. 2009).

Texture profile analysis (TPA) of cooked brown rice

For texture analysis, before cooking, test samples preparation was same as color evaluation. Then each sample was cooked in individual aluminum containers (9 cm × 3.5 cm × 2.5 cm) (10 g rice in 16 mL of distilled water) using a steam cooker (Tiger JBA-S18C, Tokyo communications engineering Inc., Japan) for 40 min and kept warm for 10 min to obtain cooked rice samples for testing (Zhang et al. 2015). After cooking, the cooked rice samples were cooled to room temperature for 10 min. All samples were enclosed in a water bath chamber with water at 35 °C in the bottom to prevent moisture loss before TPA analysis.

The cooked rice samples were then subjected to TPA analysis using a texture analyzer (CT3, Brookfield Engineering Laboratories Inc., USA). The upper layer of grains was removed and the grains from the middle layer were picked for texture determination. Test sample was spread in a single-grain layer covering area represented by the cylindrical plate of the plunger on the base platform of the analyzer. The hardness, springiness, cohesiveness and gumminess of cooked rice were measured as the method suggested by Boluda-Aguilar et al. (2013) with some modifications. A cylindrical probe with a diameter of 16 mm was used to compress the grains to 70% deformation at a test speed of 1.0 mm/s. A two-cycle compression program was used. The resulting data of force–time curve were analyzed and the hardness, cohesiveness, gumminess and springiness were calculated using the TexturePro CT software supplied by the instrument. All measurements were made in triplicate.

Scanning electron microscopy (SEM)

A scanning electron microscope (TM-1000, HITACHI Inc., Japan) was used to measure the morphological properties of brown rice according to the method of Tian et al. (2014) with minor modifications. All test samples of brown rice, both uncooked and cooked, before and after HP treatments, were immediately freeze-dried. After drying, each sample was cracked, mounted on a metallic stub and coated with a thin film of gold (10 nm) in a vacuum evaporator and observed under the microscope and photographed.

Statistical analysis

Statistical analyses were made by using ORIGIN 8.0 (OriginLab Inc., Northampton, MA, USA). Data were reported as means with standard deviations for at least three analyses for each parameter. The significant differences between the means were calculated by one-way analysis of variance (ANOVA) with p value <0.05 set for significant difference.

Results and discussion

Water absorption ratio of brown rice

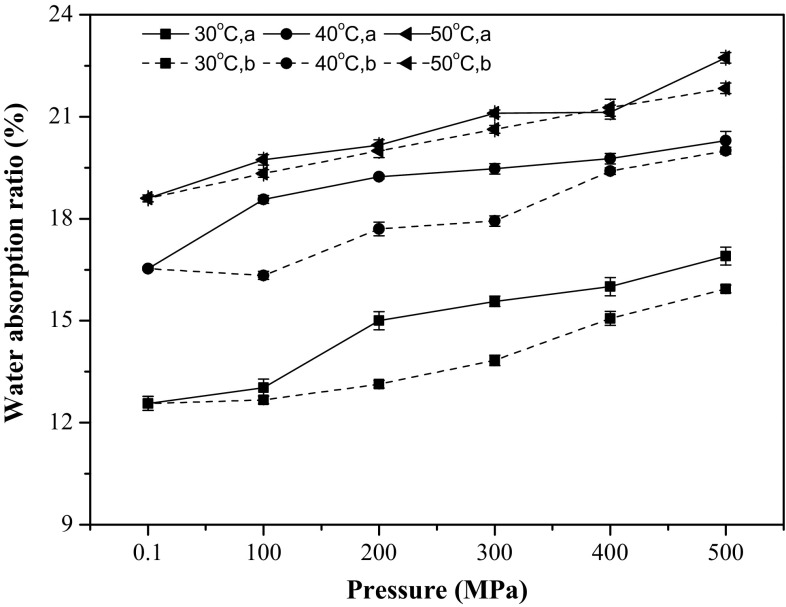

The changes in water absorption ratio of brown rice as affected by different soaking and HPT conditions are shown in Fig. 1. After soaking for 30 min at 30, 40 and 50 °C, the water absorption ratio (WAR) of brown rice were 12.6, 16.5 and 18.6%, respectively, thereby indicating the WAR to increase with an increase in soaking temperature. The results agreed with the findings of Thakur and Gupta (2006), that the soaking temperature increased the rate of moisture migration into the kernel thereby higher soaking temperature yielding higher moisture absorption. Han and Lim (2009) also observed that the rice kernels soaked at 50 °C exhibited faster and higher levels of water absorption than kernels soaked at 25 °C. Moreover, under similar conditions, the increment of moisture uptake was more pronounced between 30 and 40 °C than between 40 and 50 °C.

Fig. 1.

Water absorption ratio of pre-soaked brown rice (at different soaking temperature) subjected to different HP treatments. a single cycle HPT (one 10 min cycle); b two cycle HPT (two 5-min cycles)

The effect of different HP treatments on water absorption ratio of pre-soaked brown rice is also shown in Fig. 1. Compared with no-HPT-control, the water absorption ratio in brown rice after single cycle HPT increased from 12.6 to 16.9%, 16.5 to 20.3%, and 18.6 to 22.7%, when pre-soaked at 30, 40 and 50 °C, respectively. For the two cycle HPT process, the results showed a similar behavior, but with slightly lower WAR values: 15.9% (30 °C), 20.0% (40 °C) and 21.8% (50 °C). These results indicated that during high pressure holding, water molecules could more effectively penetrate through the peripheral bran layer of brown rice which resulted in the grains to absorb more moisture, while the bran layer on surface of brown rice restricted water moisture penetration under the control mode as also observed by other researchers (Hu et al. 2011; Tian et al. 2014).

Further, as shown Fig. 1, the WAR values of pre-soaked brown rice (at same pre-soaking temperature condition), treated by single or two cycle HPT, increased with the treatment pressure. The highest water absorption ratio was achieved at 500 MPa pressure and with the sample pre-soaked at 50 °C for 30 min. The results were similar to some previous studies with white rice, which reported that grains soaked at higher pressures and temperatures absorbed more water than those soaked under ambient conditions (Ahromrit et al. 2006; Huang et al. 2009). Moreover, Douzals et al. (1996) reported that the increase in hydrogen bonding between water and starch at higher pressures could have favorably influenced the water uptake.

However, single cycle HPT process resulted in slightly higher WAR values for brown rice than the two cycle process (p < 0.05) at the same pre-soaking condition. Although both HP treatments had the same total holding times of 10 min, the two cycle process involved two up and down pressure cycles breaking the holding continuity at half time, and therefore had two pressurization and two depressurization steps. This suggests that, apart from the pressure holding time, the pressurization–depressurization process also could influence normal structure of the cell wall and affect water migration. During pressurization, there will be gradual adiabatic compression of water and samples to the target pressure at which it is held for a targeted holding time and followed by a sudden depressurization of the system which reverses the process leading to rapid expansion of the water and sample. The rapid expansion during the pressure releasing could result in cell rupture (Ramaswamy et al. 2003) and such a phenomenon could result in partial reversal of the moisture absorbed during the pressure holding time. The single cycle process has one depressurization step while the two cycle process has two which could lead to an additional loss of absorbed water. This hypothesis might explain the reason for the lower water absorption in the two cycle HPT as compared to the one cycle process. Moreover, the lower water absorption in the two cycle HPT could save the time for the subsequent drying which can improve production efficiency.

Color characteristics

Color parameters of brown rice after different soaking and HP treatments are summarized in Table 1. The initial lightness values of brown rice were 60.4, 60.6 and 59.9 that were pre-soaked at 30, 40 and 50 °C without HPT, respectively. Both one and two cycle HP treatments of soaked brown rice samples demonstrated an increase in the lightness of test samples as compared with no-HP treated brown rice. This was caused by the enhancement of moisture migration into the test samples by the HPT. According to Lamberts et al. (2006), bran pigments (e.g., yellow pigments) which influence yellowness values might better diffuse into the endosperm or soaking water during high pressure soaking process, while inner compounds (e.g., lipids, white endosperm) which affect the lightness might migrate to the rice surface. Since the increased lightness of brown rice will have a positive effect on consumer acceptance, it can be suggested that the presoaking followed by HPT might be a good way to improve the surface appearance of brown rice.

Table 1.

Color parameters of pre-soaked brown rice (at different soaking temperatures) and subjected to different high pressure treatments

| Soaking temperature (°C) | Pressure (MPa) | L* | a* | b* | |||

|---|---|---|---|---|---|---|---|

| A | B | A | B | A | B | ||

| 30 | 100 | 62.0 ± 0.8bcd | 65.0 ± 0.8d | 3.2 ± 0.2b | 2.7 ± 0.1a | 22.1 ± 0.5ef | 20.7 ± 0.2bcd |

| 200 | 63.7 ± 1.4f | 63.5 ± 0.8c | 3.2 ± 0.4b | 3.2 ± 0.1bcd | 21.3 ± 0.5abc | 20.3 ± 0.4abc | |

| 300 | 61.3 ± 0.9bc | 63.1 ± 0.5bc | 3.8 ± 0.4c | 3.0 ± 0.2bc | 21.9 ± 0.4d–f | 20.6 ± 0.8a–d | |

| 400 | 63.6 ± 0.7ef | 63.6 ± 0.7c | 3.3 ± 0.1b | 3.0 ± 0.1abc | 20.9 ± 0.3a | 20.0 ± 0.4a | |

| 500 | 61.1 ± 0.8b | 63.3 ± 0.3bc | 3.7 ± 0.4c | 3.2 ± 0.1bcd | 21.1 ± 0.4ab | 20.8 ± 0.8cd | |

| 40 | 100 | 62.6 ± 0.6de | 62.6 ± 0.8bc | 2.8 ± 0.4a | 3.5 ± 0.4de | 21.0 ± 0.6ab | 20.6 ± 0.5a–d |

| 200 | 62.7 ± 0.7de | 62.4 ± 1.3bc | 3.1 ± 0.2ab | 3.4 ± 0.2de | 21.5 ± 0.2a–d | 20.9 ± 0.3cd | |

| 300 | 61.8 ± 0.6bcd | 62.1 ± 0.7b | 3.3 ± 0.1b | 3.6 ± 0.2e | 22.1 ± 0.2f | 20.7 ± 0.5d | |

| 400 | 60.0 ± 0.7a | 62.4 ± 0.6bc | 3.0 ± 0.3ab | 3.4 ± 0.3de | 21.2 ± 0.4ab | 20.5 ± 0.2abc | |

| 500 | 62.2 ± 0.5cd | 61.1 ± 1.0a | 3.2 ± 0.1b | 3.5 ± 0.2de | 22.0 ± 0.2d–f | 21.2 ± 0.3de | |

| 50 | 100 | 62.4 ± 0.5d | 63.4 ± 0.6bc | 3.0 ± 0.1ab | 2.7 ± 0.3a | 21.5 ± 0.3b–f | 20.9 ± 0.3cd |

| 200 | 59.8 ± 0.4a | 66.5 ± 0.6e | 4.2 ± 0.2d | 3.2 ± 0.4bcd | 22.0 ± 0.1d–f | 21.6 ± 0.2e | |

| 300 | 61.8 ± 0.5bcd | 65.6 ± 1.2de | 3.7 ± 0.1c | 3.0 ± 0.2abc | 21.8 ± 0.8c–f | 20.8 ± 0.4cd | |

| 400 | 62.1 ± 0.8bcd | 65.1 ± 0.9d | 3.3 ± 0.2b | 2.9 ± 0.2ab | 21.5 ± 0.1b–e | 20.5 ± 0.2abc | |

| 500 | 62.1 ± 0.7bcd | 65.5 ± 1.3de | 3.7 ± 0.3c | 3.3 ± 0.4cde | 21.8 ± 0.2c–f | 20.1 ± 0.5ab | |

L*, the color lightness; +a*/− a*, redness/greenness; +b*/− b*, yellowness/blueness

A: single cycle HPT (one 10 min cycle); B: two cycle HPT (two 5-min cycles)

All values are expressed as mean ± SD. Sample means with different lowercase letters in the same column are significantly different (p < 0.05)

When a single cycle HPT was applied, L* values varied only between 59.8 and 63.7 amongst the pressure treated samples indicating no significant difference in L* value at different pressure levels (p > 0.05). Tian et al. (2014) also reported that there was no significant difference in the lightness of normal and waxy rice when treated at 300 and 400 MPa. However, with the two cycle HPT, L* values were slightly higher or equal to those from the single cycle HPT.

Concerning yellowness (b*) of the samples, there was no significant difference for brown rice treated under different pressure levels (p > 0.05), but b* values of brown rice observed with the two cycle HPT were slightly lower than those after single cycle HPT (p < 0.05).

Overall, as compared with single cycle HPT, brown rice under two cycle HPT presented higher lightness and lower yellowness. The changes in surface color of brown rice grain induced by the two cycle HPT might suggest a larger disruptive effect of depressurization process causing development of fissures in the bran layer, facilitating migration of water and components responsible for the lightness and color of brown rice. Further morphological analysis of brown rice was therefore studied using microscopy and discussed in a later section.

Textural properties

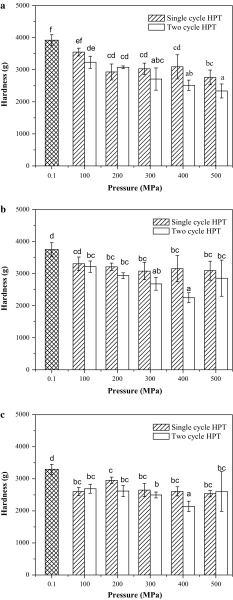

Cooked texture is considered one of the most important quality attributes of brown rice quality that influences its palatability and consumer acceptability. Figure 2 shows the hardness of cooked brown rice after various pre-soaking and HP treatments. The initial hardness values of cooked brown rice were 3920, 3750 and 3300 g in samples that were pre-soaked at 30, 40 and 50 °C, respectively. Hence, before the HPT, there was a slight decrease in the hardness of cooked brown rice associated with higher soaking temperatures (Fig. 2, 0.1 MPa).

Fig. 2.

The hardness of pre-soaked brown rice (at different soaking temperature, a 30 °C; b 40 °C; c 50 °C) subjected to different HP treatments

However, there were major differences in the hardness value of cooked brown rice in the HP treated samples as compared with no-HPT-control. The hardness values of brown rice were decreased by HPT. Yamakura et al. (2005) reported similar results with white rice. The reduction in the hardness of cooked brown rice also indicated that HPT could make cooked brown rice softer, thereby providing a better chance for its acceptance by consumers. Further, as shown in Fig. 2, for the same soaking treatment, hardness values of cooked brown rice treated by single or two cycle HPT decreased with an increase in pressure level (p < 0.05). Moreover, following the two cycle HPT, hardness values were lower than those from the single cycle HPT. Brown rice treated by the two cycle HPT at 300 MPa gave similar softness as obtained by single cycle HPT at 400 MPa, although they involved the same total treatment time. The possibility of using lower pressure levels as with two cycle HPT would be more economical for commercial production. Furthermore, the maximum hardness reduction of brown rice induced by single and two cycle HPT were by 35.3 and 45.4%, respectively. The maximum hardness reduction of brown rice by two cycle HPT could be comparable to that induced by germination which was between 42 and 70% depending on the cultivars (Pal et al. 2016). By contrast, Chen et al. (2012) adopted plasma treatment to modify brown rice, showing that plasma treatment could decrease the hardness of brown rice by 36%. It was found by Zhang et al. (2015) that the hardness value of brown rice treated by combined ultrasonic and enzymatic treatment was lower than untreated samples by 21%. After contrast and analyze, we concluded that two cycle HPT is a potential high efficient method to reduce the hardness of cooked brown rice.

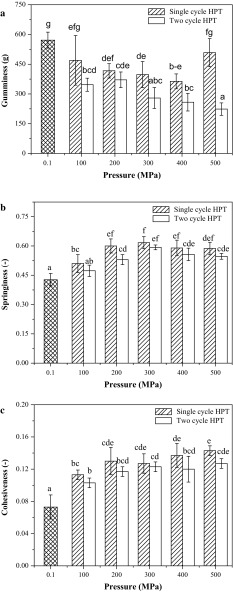

Other textural properties of HP-treated brown rice were also affected by the HPT as shown in Fig. 3. For gumminess (Fig. 3a), there were significant differences between the single and two cycle HPT (p < 0.05). The gumminess represents decrease under single cycle HPT, but without a regular rule. For the two cycle HPT process, the results showed a similar behavior. Moreover, as compared with single cycle HPT, the gumminess of brown rice under two cycle HPT was lower.

Fig. 3.

Cooked texture parameters [a gumminess (g); b springiness (–); c cohesiveness (–)] of pre-soaked brown rice (at 30 °C) subjected to different HP treatments

Springiness is a degree to which cooked grains return to their original shape after partial compression and has been used as a measure of cooked rice quality. In the two cycle TPA, springiness indicates how well a product physically springs back to its original after it has been deformed during the first compression. The springiness of cooked brown rice was increased by the HPT (Fig. 3b). The springiness of cooked brown rice increased with an increase in pressure from 100 to 300 MPa, but decreased thereafter at 400 and 500 MPa (for both single and two cycle HPT). The maximum value was obtained at 300 MPa. The effect on springiness of brown rice by two cycle HPT was different from that induced by germination. Springiness value of germinated brown rice was reduced compared with the untreated brown rice, and the extent of the decline is dependent on the cultivars (Pal et al. 2016). In this study, two cycle HPT not only improved the hardness of brown rice, but also increased its springiness value.

Cohesiveness in TPA indicates how well the product withstands a second deformation following the first. The cohesiveness of cooked brown rice was significantly increased by both HP treatments. However, there were no significant differences with respect to the pressure levels (p > 0.05). Moreover, the cohesiveness values of cooked brown rice were slightly lower with the two cycle HPT (Fig. 3c). The cohesiveness value could be influenced by the depressurization process and hence a more pronounced effect was materialized in the two cycle HPT caused by the two decompressions involved. The increased network disruption associated with the two cycle HPT is supported by the SEM study. Tian et al. (2014) suggested that more compact network might be formed in rice grain under the HP soaking that could cause amylose and amylopectin redistribution leading to increases in cohesiveness.

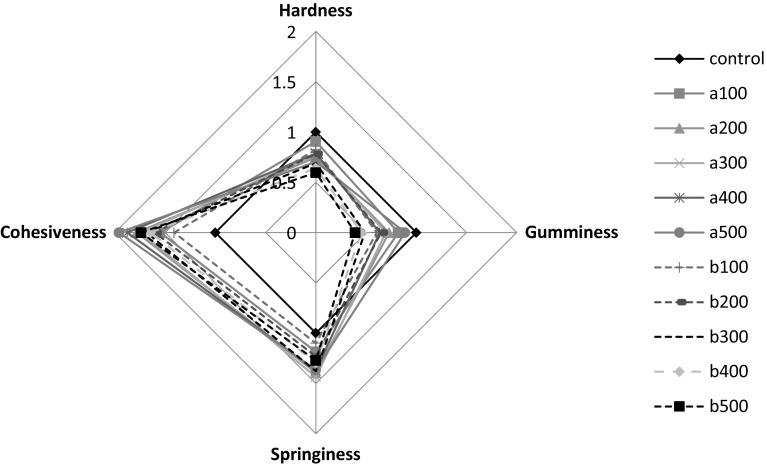

Overall, as represented by the spider graph (Fig. 4), the control sample had the highest hardness and gumminess values as well as the lowest cohesiveness and springiness. Therefore, the springiness and cohesiveness of cooked brown rice were increased by the HP treatments while hardness and gumminess decreased. The magnitudes were dependent on the soaking temperature, pressure level and pressure cycle. The decrease in hardness and gumminess of cooked brown rice were more obvious with the two cycle HPT while an increase in cohesiveness and springiness were more obvious with the single cycle HPT. Taking into account of all these effects on textural quality of brown rice, two cycle HPT is a potential processing to improve the texture of brown rice.

Fig. 4.

The effect of HP treatments on the texture of brown rice. a Single cycle HPT (one 10 min cycle); b two cycle HPT (two 5-min cycles)

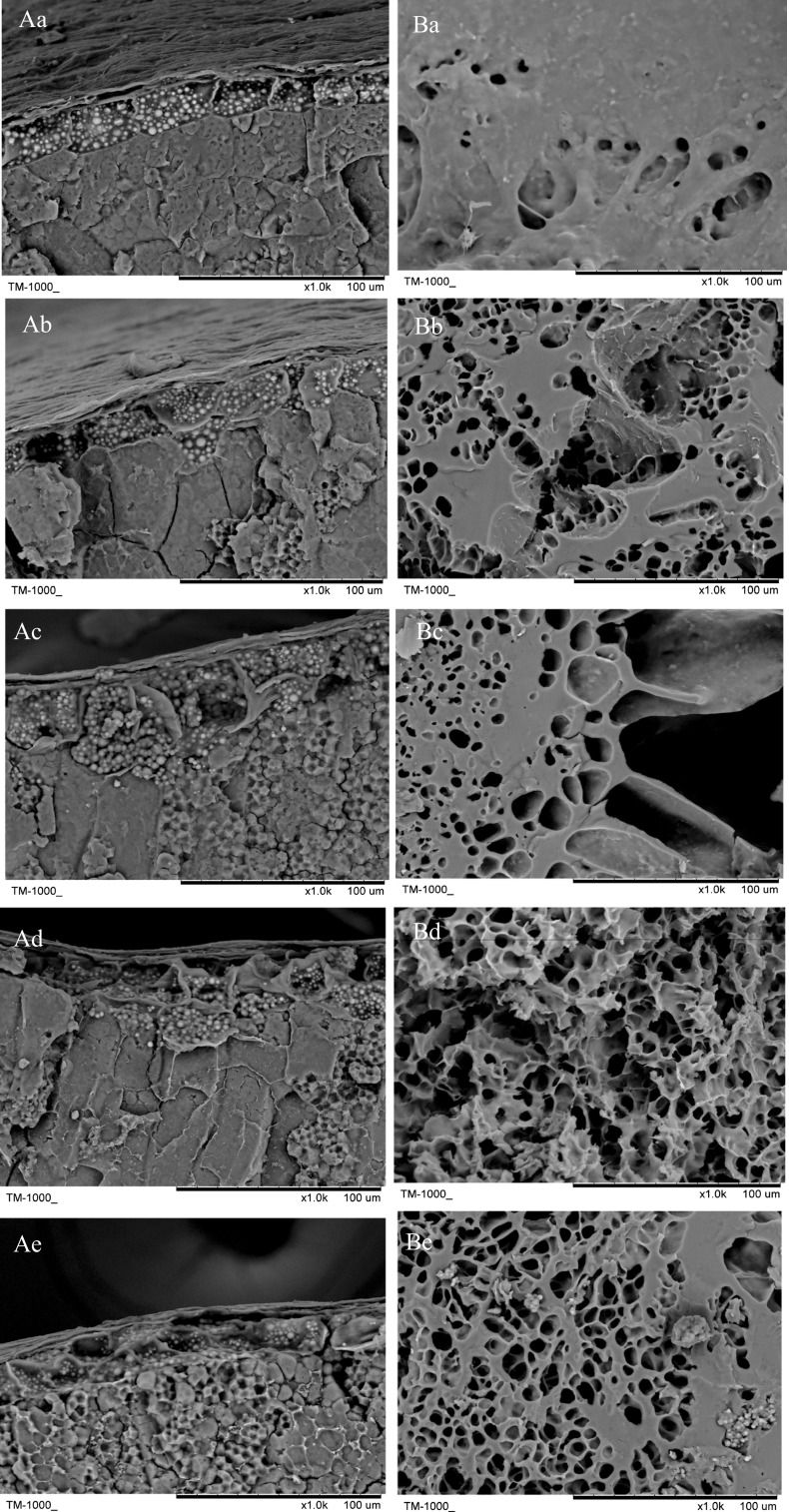

Morphologic properties

As discussed earlier, different soaking and HP treatments showed different effects on the color and texture of brown rice. In order to gain a further insight if this might have contributed by alteration of the surface structure of brown rice due to HPTs, scanning electron microscopy (SEM) was used for morphological analysis. Selected SEM images of uncooked brown rice and those obtained after different soaking and HP treatments are shown in Fig. 5A. The figures show that the bran layer of brown rice mainly consists of pericarp, episperm and aleurone layer as also reported by Bhatnagar et al. (2014). Figure 5Aa shows the natural microstructure of raw brown rice and demonstrates that the structure of pericarp, aleurone layer and endosperm is compact and the cells are intact. Following HPT, the cell structure of aleurone layer clearly lost its integrity (Fig. 5Ab–Ae). The cavities between aleurone layers appeared after HPT even at 100 MPa. When pressure level was increased to 300 MPa, the cavities got larger and boundaries of aleurone layer became obscure. The surface destruction/distortions in bran layer induced by HPT might allow the water to penetrate into rice kernel more easily during the cooking process which helps to promote rapid starch gelatinization leading to lower hardness values in cooked brown rice. This was in accordance with the results discussed earlier in the section of textural properties analysis. Park et al. (2012) also reported that the lower hardness values were likely associated with the enhanced hydration of starch granules in HP treated brown rice during cooking. Moreover, the degree of damage caused to the bran layer under two cycle HPT was more severe than observed for the single cycle HPT (Fig. 5Ab–Ae). This might be due to the stronger impingement produced by the iterative compression and decompression forces (Deng et al. 2014) during two cycle HPT. Although not fully characteristic of static HP treatments as carried out here (except during depressurization), Diels et al. (2003) attributed to the fact that mechanical destruction of cell membranes are caused by the spatial pressure and velocity gradients, turbulence and impingement that occurs in a liquid during dynamic HPT processes. The more severe structural disruption of rice bran layer caused by the two cycle HPT process also leads to better water diffusion into the grains, which could explain the changes in color and textural properties of brown rice treated by the two cycle HPT.

Fig. 5.

SEM images of uncooked (A) and cooked (B) brown rice with different HP treatments. (a no-HP treatment; b HPT at 100 MPa for 10 min; c HPT with two 5-min cycles at 100 MPa; d HPT at 300 MPa for 10 min; e HPT with two 5-min cycles at 300 MPa)

Figure 5B shows the morphology of cooked brown rice after different soaking and HPTs. The SEM images reveal that cooked brown rice with HPT had more network structure and small cavities as compared to those with no-HPT. Generating more network structure likely results in the higher springiness and cohesiveness, which was also reported in a previous study (Tian et al. 2014). In addition, as compared with two cycle HPT, cooked brown rice with a single HPT had more network structure and smaller cavities which explains its association with higher springiness and cohesiveness. Other plausible hypothesis is that the two cycle HPT process has two depressurization steps which could lead to enhanced disruption of structure resulting in slightly lower springiness and cohesiveness.

Conclusion

This study suggested that soaking and HPT could be used for improving the quality of brown rice and presented an opportunity for getting better consumer acceptance. It was observed that the water absorption ratio, color and cooked texture of brown rice were significantly improved by HP treatments. Based on the SEM, it was observed that influence of HPT on the texture property of brown rice could be attributed to changes in rice morphology. Some differences were observed between single and two cycle HPT with respect to the quality of cooked brown rice. The two cycle HPT resulted in lower degree of hydration, slightly lower springiness and cohesiveness; it also resulted in more severe structural disruptions resulting in lower hardness, gumminess and higher lightness, although the two HPTs involved the same total treatment time. Overall, the two cycle HPT was a better choice for improving the cooking quality of brown rice and could likely benefit the rice processing industry.

Acknowledgments

This study was financially supported by the China Postdoctoral Science Foundation (2015M571880).

Compliance with ethical standards

Conflict of interest

None.

References

- Ahromrit A, Ledward DA, Niranjan K. High pressure induced water uptake characteristics of Thai glutinous rice. J Food Eng. 2006;72:225–233. doi: 10.1016/j.jfoodeng.2004.11.013. [DOI] [Google Scholar]

- Akil HM, Cheng LW, Mohd Ishak ZA, Abu Bakar A, Abd Rahman MA. Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos Sci Technol. 2009;69:1942–1948. doi: 10.1016/j.compscitech.2009.04.014. [DOI] [Google Scholar]

- Bhatnagar AS, Prabhakar DS, Prasanth Kumar PK, Raja Rajan RG, Gopala Krishna AG. Processing of commercial rice bran for the production of fat and nutraceutical rich rice brokens, rice germ and pure bran. LWT Food Sci Technol. 2014;58:306–311. doi: 10.1016/j.lwt.2014.03.011. [DOI] [Google Scholar]

- Boluda-Aguilar M, Taboada-Rodríguez A, López-Gómez A, Marín-Iniesta F, Barbosa-Cánovas GV. Quick cooking rice by high hydrostatic pressure processing. LWT Food Sci Technol. 2013;51:196–204. doi: 10.1016/j.lwt.2012.09.021. [DOI] [Google Scholar]

- Chen HH, Chen YK, Chang HC. Evaluation of physicochemical properties of plasma treated brown rice. Food Chem. 2012;135:74–79. doi: 10.1016/j.foodchem.2012.04.092. [DOI] [Google Scholar]

- Cui L, Pan Z, Yue T, Atungulu GG, Berrios J. Effect of ultrasonic treatment of brown rice at different temperatures on cooking properties and quality. Cereal Chem. 2010;87:403–408. doi: 10.1094/CCHEM-02-10-0034. [DOI] [Google Scholar]

- Deng Y, Zhong Y, Yu W, Yue J, Liu Z, Zheng Y, Zhao Y. Effect of hydrostatic high pressure pretreatment on flavor volatile profile of cooked rice. J Cereal Sci. 2013;58:479–487. doi: 10.1016/j.jcs.2013.09.010. [DOI] [Google Scholar]

- Deng Y, Jin Y, Luo Y, Zhong Y, Yue J, Song X, Zhao Y. Impact of continuous or cycle high hydrostatic pressure on the ultrastructure and digestibility of rice starch granules. J Cereal Sci. 2014;60:302–310. doi: 10.1016/j.jcs.2014.06.005. [DOI] [Google Scholar]

- Diels AMJ, Wuytack EY, Michiels CW. Modelling inactivation of Staphylococcus aureus and Yersinia enterocolitica by high-pressure homogenisation at different temperatures. Int J Food Microbiol. 2003;87:55–62. doi: 10.1016/S0168-1605(03)00050-3. [DOI] [PubMed] [Google Scholar]

- Douzals JP, Marechal PA, Coquille JC, Gervais P. Microscopic study of starch gelatinization under high hydrostatic pressure. J Agric Food Chem. 1996;44:1403–1408. doi: 10.1021/jf950239c. [DOI] [Google Scholar]

- Han JA, Lim ST. Effect of presoaking on textural, thermal, and digestive properties of cooked brown rice. Cereal Chem. 2009;86:100–105. doi: 10.1094/CCHEM-86-1-0100. [DOI] [Google Scholar]

- Hu X, Xu X, Jin Z, Tian Y, Bai Y, Xie Z. Retrogradation properties of rice starch gelatinized by heat and high hydrostatic pressure (HHP) J Food Eng. 2011;106:262–266. doi: 10.1016/j.jfoodeng.2011.05.021. [DOI] [Google Scholar]

- Huang SL, Jao CL, Hsu KC. Effects of hydrostatic pressure/heat combinations on water uptake and gelatinization characteristics of japonica rice grains: a kinetic study. J Food Sci. 2009;74:E442–E448. doi: 10.1111/j.1750-3841.2009.01329.x. [DOI] [PubMed] [Google Scholar]

- Knorr D, Heinz V, Buckow R. High pressure application for food biopolymers. Biochim Biophys Acta (BBA) Proteins Proteomics. 2006;1764:619–631. doi: 10.1016/j.bbapap.2006.01.017. [DOI] [PubMed] [Google Scholar]

- Lamberts L, Bie ED, Derycke V, Veraverbeke WS, De Man W, Delcour JA. Effect of processing conditions on color change of brown and milled parboiled rice. Cereal Chem. 2006;83:80–85. doi: 10.1094/CC-83-0080. [DOI] [Google Scholar]

- Lu S, Cik TT, Lii CY, Lai P, Chen HH. Effect of amylose content on structure, texture and α-amylase reactivity of cooked rice. LWT Food Sci Technol. 2013;54:224–228. doi: 10.1016/j.lwt.2013.05.028. [DOI] [Google Scholar]

- Mir SA, Bosco SJ, Shah MA, Mir MM. Effect of puffing on physical and antioxidant properties of brown rice. Food Chem. 2016;191:139–146. doi: 10.1016/j.foodchem.2014.11.025. [DOI] [PubMed] [Google Scholar]

- Morales P, Calzada J, Avila M, Nuñez M. Inactivation of Escherichia coli O157: H7 in ground beef by single-cycle and multiple-cycle high-pressure treatments. J Food Prot. 2008;71:811–815. doi: 10.4315/0362-028X-71.4.811. [DOI] [PubMed] [Google Scholar]

- Norton T, Sun DW. Recent advances in the use of high pressure as an effective processing technique in the food industry. Food Bioprocess Technol. 2008;1:2–34. doi: 10.1007/s11947-007-0007-0. [DOI] [Google Scholar]

- Pal P, Singh N, Kaur P, Kaur A, Virdi AS, Parmar N. Comparison of composition, protein, pasting, and phenolic compounds of brown rice and germinated brown rice from different cultivars. Cereal Chem. 2016;93:584–592. doi: 10.1094/CCHEM-03-16-0066-R. [DOI] [Google Scholar]

- Park CE, Kim YS, Park KJ, Kim BK. Changes in physicochemical characteristics of rice during storage at different temperatures. J Stored Prod Res. 2012;48:25–29. doi: 10.1016/j.jspr.2011.08.005. [DOI] [Google Scholar]

- Prasert W, Suwannaporn P. Optimization of instant jasmine rice process and its physicochemical properties. J Food Eng. 2009;95:54–61. doi: 10.1016/j.jfoodeng.2009.04.008. [DOI] [Google Scholar]

- Ramaswamy HS. High pressure sterilization of foods. In: Aguilera MJ, Simpson R, Welti-Chanes J, Bermudez-Aguirre D, Barbosa-Canovas G, editors. Food engineering interfaces. New York: Springer; 2011. pp. 341–351. [Google Scholar]

- Ramaswamy HS, Riahi E, Idziak E. High-pressure destruction kinetics of E. coli (29055) in apple juice. J Food Sci. 2003;68:1750–1756. doi: 10.1111/j.1365-2621.2003.tb12323.x. [DOI] [Google Scholar]

- Rastogi NK, Raghavarao KS, Balasubramaniam VM, Niranjan K, Knorr D. Opportunities and challenges in high pressure processing of foods. Crit Rev Food Sci Nutr. 2007;47:69–112. doi: 10.1080/10408390600626420. [DOI] [PubMed] [Google Scholar]

- Saunders RM. The properties of rice bran as a food stuff. Cereal Foods World. 1990;35(632):634–636. [Google Scholar]

- Shen Y, Jin L, Xiao P, Lu Y, Bao J. Total phenolics, flavonoids, antioxidant capacity in rice grain and their relations to grain color, size and weight. J Cereal Sci. 2009;49:106–111. doi: 10.1016/j.jcs.2008.07.010. [DOI] [Google Scholar]

- Tamura M, Ogawa Y. Visualization of the coated layer at the surface of rice grain cooked with varying amounts of cooking water. J Cereal Sci. 2012;56:404–409. doi: 10.1016/j.jcs.2012.06.002. [DOI] [Google Scholar]

- Thakur AK, Gupta AK. Water absorption characteristics of paddy, brown rice and husk during soaking. J Food Eng. 2006;75:252–257. doi: 10.1016/j.jfoodeng.2005.04.014. [DOI] [Google Scholar]

- Tian Y, Zhao J, Xie Z, Wang J, Xu X, Jin Z. Effect of different pressure-soaking treatments on color, texture, morphology and retrogradation properties of cooked rice. LWT Food Sci Technol. 2014;55:368–373. doi: 10.1016/j.lwt.2013.09.020. [DOI] [Google Scholar]

- Yamakura M, Haraguchi K, Okadome H, et al. Effects of soaking and high-pressure treatment on the qualities of cooked rice. J Appl Glycosci. 2005;52:85–93. doi: 10.5458/jag.52.85. [DOI] [Google Scholar]

- Yu Y, Ge L, Zhu S, Zhan Y, Zhang Q. Effect of presoaking high hydrostatic pressure on the cooking properties of brown rice. J Food Sci Technol. 2015;52:7904–7913. doi: 10.1007/s13197-015-1901-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang X, Wang L, Cheng M, Wang R, Luo X, Li Y, Chen Z. Influence of ultrasonic enzyme treatment on the cooking and eating quality of brown rice. J Cereal Sci. 2015;63:140–146. doi: 10.1016/j.jcs.2015.03.002. [DOI] [Google Scholar]

- Zhong Y, Tu Z, Liu C, et al. Effect of microwave irradiation on composition, structure and properties of rice (Oryza sativa L.) with different milling degrees. J Cereal Sci. 2013;58:228–233. doi: 10.1016/j.jcs.2013.07.007. [DOI] [Google Scholar]