Abstract

Ionic liquids (ILs) have been proposed as promising media for the extraction and separation of bioactive compounds from the most diverse origins. This critical review offers a compilation on the main results achieved by the use of ionic-liquid-based processes in the extraction and separation/purification of a large range of bioactive compounds (including small organic extractable compounds from biomass, lipids, and other hydrophobic compounds, proteins, amino acids, nucleic acids, and pharmaceuticals). ILs have been studied as solvents, cosolvents, cosurfactants, electrolytes, and adjuvants, as well as used in the creation of IL-supported materials for separation purposes. The IL-based processes hitherto reported, such as IL-based solid–liquid extractions, IL-based liquid–liquid extractions, IL-modified materials, and IL-based crystallization approaches, are here reviewed and compared in terms of extraction and separation performance. The key accomplishments and future challenges to the field are discussed, with particular emphasis on the major lacunas found within the IL community dedicated to separation processes and by suggesting some steps to overcome the current limitations.

1. Introduction

Much attention is given today to the development of integrated and sustainable technologies to produce, extract, and purify a wide range of bioactive compounds and materials, not only those obtained from biomass conversion and processing but also those produced via fermentation and even by synthetic pathways.1 Over the years, separation techniques have been optimized and scaled up. Extraction methodologies used to carry out the extraction of target compounds from biomass and other raw matrices are usually grouped as mechanical-, high-pressure-, ultrasound-, and microwave-assisted (among others). Separation techniques are more complex in nature due to difficulties in isolating the target compounds at high yields and with high purity levels. In general, extraction and separation methods are connected, and both techniques should be ideally merged and conducted in a single step. However, current extraction-separation processes present several shortcomings, that in addition to low extraction efficiencies and poor selectivity could also add costs to the final product because of the high complexity of separation processes (e.g., by using chromatography) and high time and energy demands. Furthermore, harsh conditions and toxic volatile organic solvents are usually employed. Based on these shortcomings, researchers have been working on the development of alternative extraction and purification processes with “greener” and more sustainable credentials and for which the use of ionic liquids (ILs) has received attention.

ILs are liquid molten salts at temperatures below 100 °C2 and are typically composed of large and unsymmetrical organic cations and organic or inorganic anions. Beyond the excellent chemical, thermal, and electrochemical stability, nonflammability, and negligible volatility displayed by most aprotic ILs, ILs are also recurrently recognized by their excellent solvation ability for a wide range of compounds and materials, from synthetically produced to natural extracted ones, and as good stabilizing media for proteins, enzymes, nucleic acids, among others.3,4 Over the last two decades, ILs have evolved from potential solvents for the processing/complete dissolution of biomass5,6 to selective solvents for the extraction and purification of natural-derived compounds.7,8 In addition to their exceptional solvation ability, since ILs can swell or dissolve a wide range of biomass matrices, thus allowing an easier access to the target compounds, their aqueous solutions also display improved and unique solvation performance, as demonstrated by their outstanding hydrotropic nature9 and as surface-active ingredients,10 allowing enhanced extractions. Moreover, ILs have been recognized as tunable designer solvents, a result of the large number of ion combinations and the possibility of designing task-specific fluids. This feature overcomes the limited selectivity of common volatile organic solvents and thus allows the development of more effective purification platforms. The replacement of volatile organic solvents by nonvolatile ILs also eliminates solvent losses to the atmosphere, decreasing both the environmental footprint and the cost of the process.

The extractive performance and the purity level of the target compounds are crucial parameters to take into account when attempting the development of novel separation processes. Biomass, the matrix most investigated in this review, is a unique, ubiquitous, and sustainable renewable resource for the production of biofuels, heat, power, biomaterials, and biochemicals with commercial application.11 It should be highlighted that a survey of the literature regarding the ability of ILs to dissolve cellulose and other lignocellulosic fractions is outside the scope of this review and for which several valuable review manuscripts are already available.12−14

This critical review summarizes the use of ILs as solvents in the extraction and/or purification of bioactive compounds produced via fermentation or by synthetic routes, or derived from biomass matrices. A wide range of bioactive compounds is considered herein, ranging from small organic compounds, such as phenolic acids, alkaloids, fats, essential oils, carotenoids, vitamins, amino acids, among others, to more complex molecules, such as nucleic acids, proteins, enzymes, and antibodies. Within the range of appraised bioactive compounds and techniques, a large number of ILs have been investigated, their names and acronyms (divided by cation and anion) are provided in Table 1. Different IL-based processes are also addressed, ranging from liquid–liquid extractions (carried out either with hydrophobic ILs, ionic-liquid-based aqueous biphasic systems, or aqueous micellar biphasic systems), solid–liquid extractions (including microwave-assisted, ultrasound-assisted, among others), solid-phase extractions where IL-modified materials have been employed, and induced-precipitation techniques, such as three-phase partitioning and crystallization. Taking into account all of the IL-based techniques, and extraction and separation/purification processes proposed to date, a comprehensive overview on the improvements brought about by the use of ILs is presented. It should be stressed that only separation processes that could be scaled up while allowing the recovery of large amounts of target compounds at relatively low costs are considered. For instance, electrophoretic and chromatographic techniques are not considered in this review, for which several reviews are already available.15−18 Finally, the main challenges that still need to be addressed in the IL-based extraction and separation processes arena are discussed.

Table 1. Name and Acronym of the IL cations and Anions Considered in This Review.

| cation name | acronym | anion name | acronym |

|---|---|---|---|

| 1-(2-cyanoalkyl)-3-methylimidazolium | [(NC)CnC1im]+ | 2-(2-methoxyethoxy)ethylsulfate | [C1(OC2)2SO4]− |

| 1-(4-sulfonylbutyl)-3-methylimidazolium | [(HSO3)C4C1im]+ | 2-(N-morpholino)ethanesulfonate | [MES]− |

| 1,3-dihexyloxymethylimidazolium | [(C6H3OCH2)2im]+ | 2-[bis(2-hydroxyethyl)amino]ethanesulfonate | [BES]− |

| 1-alkyl-1-methylpiperidinium | [CnC1pip]+ | 2-hydroxy-3-morpholinopropanesulfonate | [MOPSO]− |

| 1-alkyl-1-methylpyrrolidinium | [CnC1pyrr]+ | 4-(2-hydroxyethyl)-1-piperazineethanesulfonate | [HEPES]− |

| 1-alkyl-2,3-dimethylimidazolium | [CnC1C1im]+ | 4-chlorophenoxyacetate | [CPA]− |

| 1-alkyl-3-methylimidazolium | [CnC1im]+ | acesulfamate | [Ace]− |

| 1-alkyl-3-methylpyridinium | [CnC1pyr]+ | acrylate | [Acr]− |

| 1-alkylimidazolium | [Cnim]+ | alalinate | [Ala]− |

| 1-alkylpyridinium | [Cnpyr]+ | alkylphosphonate | [CnPO3]− |

| 1-allyl-3-alkylimidazolium | [aCnim]+ | alkylsulfonate | [CnSO3]− |

| 1-benzyl-3-methylimidazolium | [C7H7C1im]+ | alkylsulfate | [CnSO4]− |

| 1-butyl-3-trimethylsilylimidazolium | [C4(C1C1C1Si)im]+ | aminoate | [AA]− |

| 1-carboxyethyl-3-methylimidazolium | [(HOOC)C2C1im]+ | asparatinate | [Asp]− |

| 1-hexyloxymethyl-3-methylimidazolium | [(C6H13OCH2)C1im]+ | benzoate | [Bz]− |

| 1-hydroxyalkyl-3-methylimidazolium | [(OH)CnC1im]+ | bicarbonate | [Bic]– |

| 1-methyl-3-(triethoxy)silypropyl imidazolium | [(C2H5O)3SiC3C1im]+ | bis(2,4,4-trimethylpentyl)phosphinate | [TMPP]− |

| 1-propylamine-3-methylimidazolium | [(NH2)C3C1im]+ | bis(2-ethylhexyl) phosphate | [BEP]− |

| 1-vinyl-3-(2-methoxy-2-oxylethyl)imidazolium | [VC1O(O)C2im]+ | bis(trifluoromethylsulfonyl)imide | [NTf2]− |

| 2-(alkyloxy)-N,N,N-trimethyl-2-oxoethanaminium (betain) | [N111[2O(O)n]]+ ([bet]+) | bitartrate | [Bit]− |

| 2-(hydroxyethyl)-N,N-dimethyl-3-(triethoxy) silypropyl ammonium | [N11[3Si(2O)(2O)(2O)](2OH)]+ | bromide | Br– |

| 3-(2-(butylamino)-2-oxoethyl)-1-ethylimidazolium | [(CH2CONHC4H9)C2im]+ | calkanoate | [Calc] |

| 3-(dimethylamino)-1-propylammonium | [N011(3N)] + | carboxylate | [CnCO2]− |

| 3-alkyl-1-vinyl-limidazolium | [VCnim]+ | chloride | Cl– |

| alkyl-1,8-diazabicyclo[5.4.0]undec-7-enium | [CnDBU]+ | cinnamate | [Cin]− |

| alkyl(tributyl)phosphonium | [Pn444]+ | citrate | [Cit]3− |

| alkyltropine | [Cntro]+ | cysteinate | [Cys]− |

| ammoeng 100 | [N114(2OmOH) (2OnOH)]+ | dialkylphosphate | [(Cn)2PO4]− |

| ammoeng 102 | [N218O(2OmOH) (2OnOH)]+ | dicyanamide | [N(CN)2]− |

| ammoeng 110 | [N221(O)nOH]+ | dihydrogencitrate | [DHCit]− |

| chirally functionalized methylimidazolium | [CwHxNyOz]+ | dihydrogenophosphate | [H2PO4]− |

| decyltris(3-hydroxypropyl)phosphonium | [P10(3OH)(3OH)(3OH)]+ | dimethylcarbamate | [N(C1)2CO2]− |

| ethyl l-phenylalaninium | [C2(l-Phe)]+ | glutarate | [Glut]− |

| hexaalkylguanidinium | [CnCnCnCnCnCnguan]+ | glycinate | [Gly]− |

| N,N,N,N-tetramethyl-3-(triethoxy)silylpropyl-guanidinium | [(C2H5O)3SiC3C1C1C1C1guan]+ | glycolate | [Glyc]− |

| N,N,N-trialkylammonium | [N0nnn]+ | Good’s buffers | [GB]− |

| N,N,N-trimethyl-N-(2-hydroxyethyl)ammonium (cholinium) | [N111(2OH)]+ | hexafluorophosphate | [PF6]− |

| N,N-dialkylammonium | [N00nn]+ | hydrogenosulfate | [HSO4]− |

| N,N-dialkyl-N-(2-hydroxyethyl)ammonium | [N0nn(2OH)]+ | hydroxide | [OH]− |

| N,N-didecyl-N-methyl-d-glucaminium | [C10C10C1gluc]+ | iodide | I– |

| N,N-dimethyl(2-methoxyethyl)ammonium | [N11(2(O)1)0]+ | itaconate | [Ita]− |

| N,N-dimethyl(cyanoethyl)ammonium | [N011(2CN)]+ | lactate | [Lac]− |

| N,N-dimethyl-N-(2- hydroxyethoxyethyl)ammonium | [N11(2(O)2OH)0]+ | levulinate | [Lev]− |

| N-Alkyl-N,N-dimethyl-N-(2-hydroxyethyl)ammonium | [N11n(2OH)]+ | lysinate | [Lys]− |

| N-benzyl-N,N-dimethyl-N-(2-hydroxyethyl)ammonium | [N11(2OH)(C7H7)]+ | malonate | [Mal]2– |

| N-butyl-N-methylmorpholinium | [C4C1mor]+ | methacrylate | [MAcr]− |

| N-ethyl-N-[3-(triethoxy) silypropyl] morpholinium | [(C2H5O)3SiC3C2mor]+ | N- [tris(hydroxymethyl)methyl]-3-amino-2-hydroxypropanesulfonate | [TAPSO]− |

| N-methyl-N,N,N-trioctylammonium | [N1888]+ | nitrate | [NO3]− |

| tetraalkylammonium | [Nnnnn]+ | N-trifluoromethanesulfonyl leucinate | [Tf-Leu]− |

| tetraalkylguanidinium | [CnCnCnCnguan]+ | N-tris(hydroxymethyl) methylglycinate | [Tricine]− |

| tetraalkylphosphonium | [Pnnnn]+ | N-tris(hydroxymethyl)methyl-2-aminoethanesulfonate | [TES]− |

| tetrakis(hydroxymethyl)phosphonium | [P(1OH)(1OH)(1OH)(1OH)]+ | O,O-diethyl dithiophosphate | [DTP]− |

| trihexyltetradecylphosphonium | [P66614]+ | oxalate | [Oxa]2– |

| triisobutyl(methyl)phosphonium | [Pi(444)1]+ | perchlorate | [ClO4]− |

| phenilalaninate | [Phe]− | ||

| phenylacetate | [PhAc]− | ||

| prolinate | [Pro]− | ||

| saccharinate | [Sac]− | ||

| salicylate | [Sal]− | ||

| serinate | [Ser]− | ||

| sorbate | [Sor]− | ||

| succinate | [Suc]− | ||

| sulfate | [SO4]2– | ||

| tetrachloroaluminate | [AlCl4]− | ||

| tetrafluoroborate | [BF4]− | ||

| thiocyanate | [SCN]− | ||

| tricyanomethanide | [C(CN)3]− | ||

| trifluoroacetate | [CF3CO2]− | ||

| trifluoromethanesulfonate | [CF3SO3]− | ||

| tris(pentafluoroethyl)trifluorophosphate | [FAP]− | ||

| valinate | [Val]− |

2. Small and Extractable Bioactive Compounds from Biomass

In the past few years, an increased demand for the use of natural compounds over their synthetic counterparts in nutraceutical, cosmetic, and pharmaceutical products has been experienced (e.g., biopharmaceuticals, natural-extracted antioxidants, among others).19,20 However, conventional extraction processes for the extraction of value-added compounds or fine chemicals from natural sources present several drawbacks, such as a low efficiency, nonselectivity, lengthy procedures, high energetic input, and generally involve the use of volatile and often toxic organic solvents, leading therefore to innate environmental and human concerns. Novel approaches have been proposed addressing the use of more sustainable extraction techniques and the use of safer alternative solvents (solvents produced from renewable resources, water, supercritical fluids, and ionic liquids (ILs)21). Among these, ILs are among the most studied alternative solvents for these purposes.8,22−25 IL-based extraction, separation, and purification technologies for bioactive ingredients from biomass have been extensively studied over the past two decades. ILs and their mixtures with water or organic solvents can be applied directly in the solid–liquid extraction (SLE) of value-added compounds from biomass. Due to their ionic character, ILs can interact with electromagnetic fields; thus, and in addition to more simple SLE approaches, IL-based microwave-assisted extraction (MAE) or ultrasonic-assisted extraction (UAE) may be preferred due to their shorter extraction times and higher extraction efficiencies. If the real matrix is liquid, such as a water-rich extract from biomass, IL-based liquid–liquid extractions (LLE) can be used. To minimize the IL consumption on the overall process, to improve the extraction performance, and to facilitate solvent/material recycling, ILs may also be confined into a solid matrix (IL-modified materials for solid-phase extractions, SPE).

This section addresses the use of ILs in the extraction, separation, and purification of biobased compounds and provides a comprehensive overview of the data hitherto reported on the development of IL-based SLE, including IL-based MAE and IL-based UAE, IL-based LLE (wherein IL-based aqueous biphasic systems are also covered), and IL-based SPE by the use of IL-modified materials. The distribution of the scientific works dealing with each IL-based technique for the extraction of natural compounds is depicted in Figure 1, where the families of natural compounds investigated are also highlighted. In these studies, aqueous solutions of ILs are the preferred choice for extraction/separation purposes, although the use of pure ILs or IL-ethanol/methanol mixtures was also addressed. The extraction of alkaloids, terpenoids, flavonoids, phenolic compounds, saponins, and other polycyclic aromatic compounds from natural sources has been investigated, with their incidence demonstrated in the radial graphs of Figure 1. Figure 2 shows the chemical structures of the compounds studied. The incidence of the use of distinct ILs, achieved by combinations of different ions shown in Figure 3, reveals that, as expected, 1-alkyl-3-methylimidazolium-based ILs are by far the most widely investigated and are mainly combined with the [BF4]−, Cl–, and Br– counterions. In this field, and particularly given the already large number of publications available, the application of more benign and biocompatible options, such as ammonium-based cations (including cholinium), still remains scarcely investigated.

Figure 1.

Distribution of the works dealing with each IL-based technique for the extraction and separation of small organic extractable compounds from biomass. The radial graphs display the number of scientific works addressing distinct families of natural compounds.

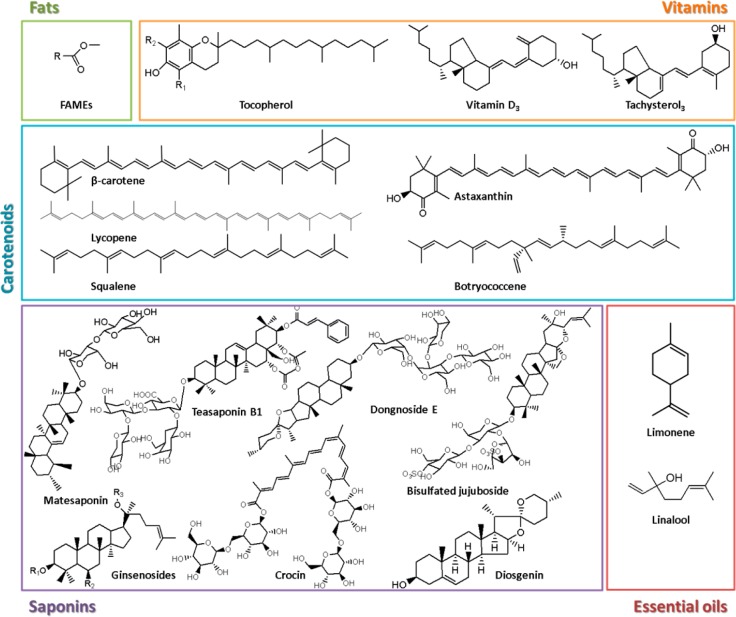

Figure 2.

Chemical structures of small organic compounds extracted and separated from biomass using IL-based techniques.

Figure 3.

ILs used for the extraction and separation of small organic extractable compounds from biomass as a function of cation–anion combinations. The usage incidence (number of articles) is represented by the circles’ size, which proportionally increases as follows: [0–5] < [5–10] < [10–15] < [15–30] < [30–40].

In this section, the issues that promote extraction efficiency are highlighted and a general overview on the advantages and disadvantages of the extraction methods employed is also provided. Moreover, the structure–property relationship between ILs and bioactive ingredients and their respective extraction mechanisms are discussed whenever applicable. Finally, the available methodologies for the back-extraction and recovery of bioactive compounds from IL solutions and simultaneous recovery and reuse of ILs is summarized. However, it can be anticipated that this aspect has been neglected in most of the published scientific studies.

2.1. IL-Based Solid–liquid Extractions

A large number of works exist on the use of IL-based SLE techniques with pure ILs, as well as with their aqueous solutions and IL-methanol/ethanol mixtures, for the extraction and separation of natural compounds, namely alkaloids, terpenoids, flavonoids, phenolics, saponins, lignans, among others.26−76 In addition to more simple SLE, where the biomass is placed in direct contact with the IL-based solvents and only the temperature, extraction time, and solid–liquid ratio are typically optimized, SLE techniques are often integrated with MAE and UAE to enhance the extraction efficiency while attempting to decrease the extraction time and amount of solvent used. This section is thus divided into three parts based on the most frequently employed extraction processes: (i) simple IL-based SLE; (ii) IL-based MAE; and (iii) IL-based UAE. The optimization of the extraction conditions (temperature, extraction time, pH, among others), selection of the IL and its concentration, and solid–liquid ratio are discussed. Table 2 summarizes the ILs employed and the bioactive compounds extracted from different natural sources.

Table 2. Extraction of Small and Extractable Natural Compounds from Biomass Using IL-Based SLE, Including IL-Based MAE and IL-Based UAE.

| bioactive compound | natural source | method | ILs (solvents) used |

|---|---|---|---|

| aesculetin and aesculin | Fraxinus rhynchophylla | IL-UAE | [C7H7C1im]Br, [C7H7C1im]Cl, [C10C1im]Br, [C12C1im]Br, [C2C1im][BF4], [C2C1im]Br, [C4C1im][BF4], [C4C1im][ClO4], [C4C1im][HSO4], [C4C1im][Tos], [C4C1im]Br, [C4C1im]Cl, [C4C1im]I, [C8C1im]Br, [C6C1im]Br, [(HSO3)C4C1im][HSO4], and [(OH)C2C1im]Cl (water)65 |

| artemisinin | Artemisia annua | IL-SLE | [N11(2(O)1)0][C2CO2], [N11(2OH)0][C7CO2] (pure IL)74,75 |

| baicalin, wogonoside, baicalein, and wogonin | Scutellaria baicalensis Georgi | IL-MAE | [C4C1im]Br, [C4C1im]Cl, [C4C1im][BF4], [C4C1im][Oac], [C4C1im][CF3SO3], [C2C1im]Br, [C6C1im]Br, [C8C1C1im]Br, [C10C1im]Br, and [C12C1C1im]Br (water)46 |

| caffeine | Paullinia cupana (guaraná) | IL-SLE | [C2C1im]Cl, [C2C1im][C1CO2], [C4C1im]Cl, [C4C1im][Tos], [C4C1pyrr]Cl, [(OH)C2C1im]Cl (water)29 |

| caffeoylquinic acids | Flos Lonicerae Japonicae | IL-UAE | [C4C1im]Br (water)60 |

| carnosic acid and rosmarinic acid | Rosmarinus officinalis | IL-MAE | [C10C1im]Br, [C2C1im]Br, [C4C1im][BF4], [C4C1im][NO3], [C4C1im]Br, [C4C1im]Br, [C4C1im]Cl, [C6C1im]Br, and [C8C1im]Br (water)47 |

| catharanthine, vinblastine, and vindoline | Catharanthus roseu | IL-UAE | [aC1im]Br, [C2C1im]Br, [C4C1im][BF4], [C4C1im][ClO4], [C4C1im][HSO4], [C4C1im][NO3], [C4C1im][Tos], [C4C1im]Br, [C4C1im]Cl, [C4C1im]I, [C6C1im]Br, and [C8C1im]Br (water)55 |

| cryptotanshinone, tanshinone I, and tanshinone II A | Salvia miltiorrhiza | IL-UAE | [C10C1im]Br, [C12C1im]Br, [C14C1im]Br, [C16C1im]Br, [C8C1im]Br, [C2C1im]Cl, [C4C1im]Cl, [C6C1im]Cl, and [C8C1im]Cl (water)63,76 |

| (+)-catechin, ellagic acid, and pyrocatechol | Acacia catechu and Terminalia chebula | IL-SLE | [N1100][N(C1)2CO2] (pure IL)33 |

| fangchinoline and tetrandrine | Stephaniae tetrandrae | IL-UAE | [C4C1im][BF4] (water)56 |

| forskolin | Coleus forskohlii | IL-UAE | [C4C1im]Cl, [C4C1im]Br, [C4C1im][BF4], [C4pyr][BF4], [N000(2OH)][C0CO2], [C1C1C1C1guan][Lac](water)64 |

| galantamine, narwedine, N-desmethylgalantamine, and ungiminorine | L. aestivum | IL-SLE | [C4C1im]Cl, [C6C1im]Cl, [C8C1im]Cl, [C10C1im]Cl, [C4C1im]Br, [C4C1im][Sac], [C4C1im][Ace], [C4C1C1im]Cl, [C4C1im][C1CO2], [C4C1im][CF3CO2], [C4C1im][SCN], [C4C1im][N(CN)2], [C4C1im][C(CN)3], [C7H7C1im]Cl, [C4C1pyrr]Cl, [N11(2OH)(C7H7)]Cl, and [N221(O)nOH]Cl(water)32 |

| gallic acid | Suaeda glauca Bge. | IL-UAE | [C2C1im]Cl, [C4C1im]Cl, [C6C1im]Cl, and [C8C1im]Cl (water)61 |

| glaucine | Glaucium flavum (papaveraceae) | IL-SLE | [C4C1im][Ace], [C10C1im][Ace], [C6C1im][Ace], [C8C1im][Ace], [C4C1im][Sac], [C4C1im]Br, and [C4C1im]Cl (water)27,28 |

| hydroxycamptothecin and camptothecin | Camptotheca acuminata | IL-UAE | [aC1im]Br, [C7H7C1im]Br, [C2C1im]Br, [C3C1im]Br, [C4C1im][BF4], [C4C1im][ClO4], [C4C1im][HSO4], [C4C1im][NO3], [C4C1im]Br, [C4C1im]Cl, [C6C1im]Br, [C8C1im]Br, and [C6H11C1im]Br (water)54 |

| isoliensinine, liensinine, and neferine | Nelumbo nucifera | IL-MAE | [C2C1im][BF4], [C4C1im][BF4], [C4C1im][PF6], [C4C1im]Br, [C4C1im]Cl, [C6C1im][BF4], and [C8C1im][BF4] (water)44 |

| iristectorin A, iristectorin B, and tectoridin | Iris tectorum | IL-UAE | [C4C1im][BF4], [C6C1im]Br, and [C8C1im]Br (water)58 |

| myricetin, quercetin, kaempferol | Bauhinia championii | IL-MAE | [C2C1im]Br, [C4C1im][BF4], [C4C1im][H2PO4], [C4C1im][HSO4], [C4C1im][PF6], [C4C1im]2[SO4], [C4C1im]Br, [C4C1im]Cl, [C6C1im]Br, and [(HOOC)C1C1im]Cl (water)41 |

| nuciferine, N-nornuciferine, O-nornuciferine | Nelumbo nucifera | IL-MAE | [C2C1im]Br, [C4C1im][BF4], [C4C1im][PF6], [C4C1im]Br, [C4C1im]Cl, [C6C1im]Br, and [C8C1im]Br (water)45 |

| piperine | Piper nigrum (white and black pepper) | IL-SLE | [C10C1im]Cl, [C12C1im]Cl, [C12C1im]Br, [C12C1im][CF3SO3], [C12C1im][C1CO2], [C12C1im][N(CN)2], [C14C1im]Cl, and [N111[2O(O)12]Cl (water)30 |

| piperine | Piper nigrum (white and black pepper) | IL-UAE | [C4C1im][BF4], [C4C1im][H2PO4], [C4C1im][PF6], [C4C1im]Br, [(HSO3)C4C1im]Br, and [C6C1im][BF4] (water)53 |

| polycyclic aromatic hydrocarbons | Petroleum Source Rock | IL-MAE | [C4C1im]Br, [C4C2C1im]Cl, and [C1C1C1im]2[SO4] (water)52 |

| quercetin, ellagic acid, gallic acid, pyrocatechol, trans-resveratrol | Psidium guajava (guava) and Smilax china | IL-MAE | [C2C1im][BF4], [C2C1im]Br, [C4C1im][BF4], [C4C1im][C1SO4], [C4C1im][H2PO4], [C4C1im][N(CN)2], [C4C1im]Br, [C4C1im]Cl, [C4py]Cl, and [C6C1im]Br (water)42 |

| rutin | Saururus chinensis and Flos sophorae | IL-MAE | [C4C1im][BF4], [C4C1im][Tos], [C4C1im]Br, and [C4C1im]Cl (water)43 |

| rutin, hyperoside, and hesperidin | Sorbus tianschanica leaves | IL-MAE | [C4C1im]Cl, [C4C1im]Br, [C4C1im][BF4], [C4C1im][NO3],[C4C1im][HSO4], [C4C1im][ClO4], [C2C1im][BF4], [C6C1im][BF4], and [C8C1im][BF4] (water)44 |

| saponins and polyphenols | Ilex paraguariensis (mate) and Camellia sinensis (tea) | IL-SLE | [aC1im]Cl, [C2C1im][Lac], [C2C1im][CF3SO3], [C2C1im][C2SO4], [C2C1im][C1CO2], [C2C1im][N(CN)2], [C2C1im]Cl, [C4C1im]Cl, [C6C1im]Cl, [C7H7C1im]Cl, [C8C1im]Cl, [N111(2OH)][NTf2], [N111(2OH)]Cl, and [(OH)C2C1im]Cl (water)79 |

| saponins and polyphenols | Ginkgo biloba | IL-SLE | [C4C1im]Cl (pure IL)37 |

| shikimic acid | Illicium verum (star anise) | IL-MAE | [C2C1im][BF4], [C2C1im][CF3SO3], [C2C1im][C1CO2], [C2C1im][NTf2], [C2C1im][PF6], and [C2C1im]Cl (pure IL)51 |

| shikimic acid | Illicium verum (star anise) | IL-SLE | [C2im][HSO4], [C2C1im][HSO4], [(HSO3)C4C1im][H2PO4], [(HSO3)C4C1im][HSO4], [(HSO3)C4C1im][NTf2], [(HSO3)C4C1im]Br, and [(HSO3)C4C1im]Cl (ethanol)36 |

| senkyunolide H, senkyunolide I, Z-ligustilide | Ligusticum chuanxiong | IL-MAE | [N11(2(O)2OH)0][C2CO2] and [N011(2CN)][C2CO2] (pure IL)48 |

| shikimic acid | chinese conifer needles | IL-UAE | [C4C1im]Cl, [C4C1im]BF4, [C4C1im][NO3], [C2C1im]Br, [C3C1im]Br, [C4C1im]Br, [C5C1im]Br, [C6C1im]Br, [C8C1im]Br, [C10C1im]Br, [C7H7C1im]Br, (water)59 |

| shikonin β,β′-dimethylacrylshikonin | Arnebia euchroma | IL-UAE | [C2C1im][BF4], [C4C1im][BF4], [C6C1im][BF4], [C6C1im][PF6], [C8C1im][BF4], and [C8C1im][PF6] (pure IL)67 |

2.1.1. Simple Solid–Liquid Extractions

Recently, various works have been published addressing the use of IL aqueous solutions on the SLE of alkaloids (e.g., glaucine from Glausium flavum),27,28,31 caffeine from Paullinia cupana (guaraná seeds),29 galantamine, narwedine, N-desmethylgalantamine, and ungiminorine from the aerial parts of Leucojum aestivum,32 and piperine from Piper nigrum.30 Bogdanov et al.28 scanned a series of ILs with cations bearing different lengths of their alkyl side chains ([CnC1im]+ series) coupled to different anions (Cl–, Br–, [Ace]−, and [Sac]−) for the extraction of glaucine from Glausium flavum. The effect of the IL concentration in aqueous media, the extraction time, and the biomass-solvent ratio were also optimized. With aqueous solutions of [CnC1im][Ace] (n = 4, 6, and 8), an 85% extraction yield of glaucine was achieved at 80 °C for 1 h, a much higher extraction yield than that obtained with methanol, solutions of potassium acesulfamate, and water under similar conditions.28 The extraction yield of glaucine increased with the IL concentration in aqueous media, reaching a maximum of 99% at an IL concentration of 2 M. The extraction efficiencies obtained show that, besides the effect of the IL anion on the disruption of the matrix structure, there is a major role played by the imidazolium cation on the extraction process due to the aromatic π-cloud which allows strong interactions with polarizable and aromatic solutes.27,28 Similar results were obtained by Cláudio et al.29 and Svinyarov et al.,32 who investigated the extraction of caffeine from guaraná seeds and the extraction of galantamine, narwedine, N-desmethylgalantamine, and ungiminorine from the aerial parts of L. aestivum using aqueous solutions of a series of imidazolium-, pyrrolidinium-, and ammonium-based ILs. At the respective optimal conditions, [C4C1im]Cl was found to be the best IL in both studies.29,32 Extraction yields of caffeine of 9.4 wt % have been obtained, a value significantly higher than that obtained with dichloromethane under a Soxhlet extraction (4.30 wt %).29 An analytical procedure for the SLE of galantamine (widely used in Alzheimer’s disease, poliomyelitis, and other neurological diseases) from L. aestivum biomass, followed by HPLC quantification, was proposed by the other group of researchers.17 The role of the aromatic imidazolium cation of the IL was emphasized by the results obtained by all research groups,28,29,32 who attempted the extraction of aromatic compounds (alkaloids). Although scarcely investigated, Cláudio et al.29 proposed a back-extraction procedure for the target alkaloid followed by the reuse of the IL, a schematic representation of the proposed integrated process is sketched in Figure 4A.

Figure 4.

Schematic diagrams of integrated processes based on ILs comprising the extraction and separation of small organic extractable compounds from biomass and further IL recovery and reuse.29,33,93

Bica and co-workers30 reported the extraction of piperine from black pepper by SLE using aqueous solutions of surface-active ILs ([CnC1im]+, with n = 10, 12, and 14, combined with Cl–, Br–, [CF3SO3]−, [C1CO2]−, and [N(CN)2]− anions, as well as a long chain biodegradable and betain-derived IL, [N111[2O(O)12]]Cl). Below the critical micellar concentration (CMC) of the IL, the extraction yield of piperine was found to be <0.2 wt %, whereas a 4.0 wt % of extraction yield was recorded for IL concentrations higher than the CMC, while revealing a negligible influence of the IL anion.30 In this latter work the ability of the IL to self-aggregate in aqueous media seems to be the main favorable factor for the enhanced extraction yields observed and not the hydrotropic phenomenon9 or the ILs’ capacity to disrupt the cells. Although piperine is an alkaloid and an aromatic compound, it is of a more hydrophobic nature, as shown by its higher octanol–water partition coefficient [log(Kow) of piperine = 2.30 vs log(Kow) of caffeine = −0.13] (Chemspider database accessed on August 2016), thus requiring the creation of hydrophobic cores produced by surface-active ILs to increase its dispersion/solubility in aqueous media. Of particular interest, the biodegradable betain-based IL exhibited a better performance in the extraction of piperine30 and can be used as a prospective IL for greener and large-scale applications. The same group of researchers35 investigated the IL-based SLE of betulin (a pharmaceutically active triterpene from birch bark). In this work, imidazolium-based water-soluble ILs, such as [C2C1im]Cl, [C2C1im]Br, [C2C1im][N(CN)2], and [C2C1im][C1CO2], led to higher betulin yields (28–31 wt %) when compared with hydrophobic ILs based on [BF4]−, [PF6]−, and [NTf2]− anions (∼22 wt %).35 Overall, [C2C1im][C1CO2] was demonstrated to be the optimal solvent for dissolving birch bark and to subsequently extract betulin.35

Tamiflu is an important drug used for the treatment of influenza. Shikimic acid is extensively used as starting material for the synthesis of Tamiflu77 and is predominantly extracted from the Chinese herb Illicium verum (star anise). Ressmann et al.36 explored an alternative and effective method for the extraction of shikimic acid via dissolution of Illicium verum in the presence of Brønsted acidic IL solutions ([(HSO3)C4C1im][HSO4], [(HSO3)C4C1im][NTf2], [(HSO3)C4C1im]Br, and [(HSO3)C4C1im]Cl). Remarkably, the authors36 demonstrated that ILs act both as solvents and catalysts toward the in situ synthesis of shikimic acid ethyl ester and its ketal ester. Most ILs allowed a 81–99% conversion; however, a complete conversion was obtained in the presence of [(HSO3)C4C1im][NTf2], where the sulfonic acid side chain was demonstrated to be the main factor behind the efficient catalytic activity. Along the same lines, Usuki et al.37 further demonstrated the extraction of shikimic acid from Ginkgo biloba leaves using neat [C4C1im]Cl. At optimum conditions, the extraction yield of shikimic acid was 2.5 times higher than that obtained with methanol at 80 °C and 2 times higher than with dimethylformamide at 150 °C. Thus, neat ILs also appear as good alternatives to the commonly used volatile organic solvents in the extraction of shikimic acid.37 However, no attempts at shikimic acid conversion were carried out by Usuki et al.37

(+)-Catechin is an important flavonoid with benefits for human health and a tannin used in leather industries.78 As an alternative protocol, Chowdhury et al.33 proposed the SLE of tannins from Acacia catechu (catechu) and Terminalia chebula (myrobolan) using a protic IL ([N1100][N(C1)2CO2]): the process diagram is sketched in Figure 4B. Various tannins, such as (+)-catechin, gallic acid, ellagic acid, and pyrocatechol, were effectively extracted from the biomass samples using ([N1100][N(C1)2CO2]. High extraction efficiencies for both catechu (85%) and myrobolan (75%) were obtained, while with water as the main solvent, the extraction efficiency decreased to 64% and 52%, respectively.33 Whereas most studies discussed above focused on imidazolium-based ILs, the work reported by Chowdhury et al.33 is a notable example of good extraction yields achieved by other classes of ILs. Finally, and in contrast to aprotic imidazolium-based ILs, [N1100][N(C1)2CO2] can be distilled at around 45 °C under reduced pressure, allowing solvent recovery and reuse. Remaining within the use of protic and distillable ILs, their application in the SLE of artemisinin, a sesquiterpene lactone, from Artemisia annua was proposed by Bioniqs Ltd. in 2006.74 A protic and biodegradable IL, [N110(2OH)][C7CO2], was found to be the best IL investigated and, under the optimum conditions, high extraction yields were obtained when compared to those obtained by hexane at high temperatures. Later, in 2008, Bioniqs Ltd. used molecular simulation to design improved ILs for the SLE of artemisinin, and where [N11(2(O)1)0][C2CO2] leads to a significant improvement in the selectivity and extraction yield of artemisinin.75

Most bioactive compounds discussed above have a moderately high solubility in water; however, aqueous solutions of water-soluble ILs with low alkyl side chain length are not promising solvents when dealing with the extraction of more hydrophobic target biocompounds. To enhance the extraction and separation of such hydrophobic bioactive compounds in aqueous media, Jin et al.38 proposed a family of new water/IL mixtures with amphiphilic anionic functional long-chain carboxylate ILs (LCC-ILs) for the simultaneous dissolution of biomass and extraction of hydrophobic bioactive compounds. The LCC-ILs investigated possess weak polarity and strong hydrogen-bonding basicity simultaneously, thus displaying a high solubility for numerous hydrophobic natural compounds, such as tocopherol, perillyl alcohol, rutin, and ginkgolides. The water/LCC-IL mixtures investigated allowed extraction yields 2 to 12 times higher than that achieved with common organic solvents.38 The authors38 also studied the dissolution mechanism at a microscopic level and demonstrated the formation of nanomicelles when tocopherol is dissolved in water/LCC-IL mixtures, meaning that the formation of IL aggregates achieved by the use of surface-active ILs allows the incorporation of hydrophobic bioactive compounds into the micelle core, thereby enhancing the extraction yield, a similar result to that found by Bica and co-workers30 on the extraction of piperine using surface-active ILs.

2.1.2. Microwave-Assisted Extractions

The simpler SLE processes discussed above may require long extraction times and large volumes of solvent. Higher yields and faster extractions of biocompounds from biomass can be achieved through MAE processes. The pioneering work on the use of IL-MAE processes was reported by Li and co-workers in 2007,26 who demonstrated the effective utilization of aqueous IL solutions in MAE to extract trans-resveratrol from Rhizma polygoni. Through an orthogonal design methodology, the authors26 investigated the effect of the IL chemical structure ([C4C1im][BF4], [C4C1im]Br, and [C4C1im]Cl) and additional experimental conditions. Among the ILs studied, [C4C1im]Br was found to be the best solvent, with a 93% trans-resveratrol extraction yield obtained at the optimum conditions.26 In addition to this pioneering work, many more have followed; however, all have dealt with imidazolium-based ILs, and no studies were found on the use of other IL families in IL-based MAE processes. For instance, Pan and co-workers39,40 studied the extraction of alkaloids, such as isoliensinine, liensinine, neferine, nuciferine, n-nornuciferine, and o-nornuciferine from Nelumbo nucifera and claimed to have developed a rapid, effective, and more environmentally friendly method. In fact, the authors demonstrated that IL-based MAE enhances the extraction efficiencies by up to 50.0% while reducing the extraction time from 2 h to 90 s.39,40 After several optimization studies, including alteration of the chemical structure of the IL, the authors showed that [C4C1im][BF4] was the most effective IL for the extraction of isoliensinine, liensinine, and neferine, whereas [C4C1im]Br exhibited the best results on the extraction of nuciferine, n-nornuciferine, and o-nornuciferine.39,40 It was also concluded that increasing the IL alkyl side chain length (using [CnC1im]Br ILs) up to hexyl enhances the alkaloid extraction efficiency, while a further increase from hexyl to octyl drastically reduces the alkaloids extraction efficiency. These results suggest that surface-active ILs are not favorable for the extraction of these more water-soluble alkaloids and that the mechanism of extraction seems to be ruled by an hydrotropic effect9 and not by a micelle-mediated phenomenon, as discussed in the previous section when dealing with the extraction of more hydrophobic compounds, such as piperine using simpler SLE processes.30

The extraction of flavonoids from natural resources by IL-based MAE strategies was also demonstrated by several research groups,41−43 namely in the extraction of rutin from Saururus chinensis and Flos sophorae,43 of a series of polyphenolic compounds from Smilax china,42 and of kaempferol, myricetin, and quercetin from Bauhinia championii.41 The results obtained by all authors suggest that the extraction of flavonoids is mainly governed by the IL anion and where ILs with higher hydrogen bond acceptor ability, such as [C4C1im][H2PO4], [(HOOC)C1C1im]Cl, and [C4C1im]Br, provide the highest extraction yields.41−43 Du et al.42 additionally compared the quercetin extraction efficiency using pyridinium-based ILs and found that they afford higher extraction yields than their imidazolium counterparts. Thus, the effect of the IL cation, probably dominated by π–π interactions, cannot be ruled out in extractions of flavonoids. At this stage, it is still difficult to identify the most important characteristics of ILs, since only a limited matrix of ILs has been studied. Although some authors41−43 have claimed the pivotal role of the IL anion, the number of IL cations investigated is currently too small to draw general conclusions.

Aqueous solutions of ILs were also applied in the MAE of rutin, hyperoside, and hesperidin from S. tianschanica leaves,44 of ten flavonoid glycosides from Chrysanthemum morifolium Ramat,45 and of baicalin, wogonoside, baicalein, and wogonin from Scutellaria baicalensis Georgi.46 All authors demonstrated the superior performance of IL-based MAE when compared to more traditional methods and solvents. For instance, IL-based MAE resulted in the highest extraction yield (22.28%) of baicalin within 90 s, as compared to water-based MAE (9.77%, 90 s) and IL-SLE (16.94%, 30 min).46 In addition to the work discussed above on the SLE of shikimic acid from star anise, it was later demonstrated that the time of extraction (∼24 h) was drastically reduced to 10 min by using IL-based MAE.51 In this study, [C2C1im][C1CO2] led to the best results (10.7 wt %), whereas the poorer results were achieved with [C2C1im][PF6], with the observed degradation of shikimic acid.51 In this case, the hydrolysis of the hexafluorophosphate anion at high temperatures (100 °C), followed by the production of hydrofluoric acid80 cannot be ignored, highlighting the demand for more stable ILs in addition to the well-studied [BF4]- and [PF6]-based variants.

Lignans are compounds with a characteristic dibenzocyclooctadiene-type skeleton, present in various biomass matrices. IL-based MAE of four lignans from the fruits of Schisandra chinensis – schizandrin, schisantherin A, deoxyschizandrin and γ-schizandrin–was studied by Ma et al.50 Several combinations of imidazolium-based ILs with different anions and different alkyl side chain lengths (n = 2 to 12) were tested, with [C12C1im]Br providing the best extraction efficiencies (yield ≈9.9%).50 The application of IL-based MAE toward the extraction of carsonic acid (a terpenoid) and rosmarinic acid (a phenolic acid) from Rosmarinus officinalis (rosemary) was reported by Liu et al.47 The authors47 demonstrated an increase in the extraction yield of carnosic acid with the increase of the [C8C1im]Br concentration (above the CMC). These results reinforce the relevance of aqueous solutions of surface-active ILs in the extraction of more hydrophobic bioactive compounds, as discussed above.

Unlike the aforementioned studies that focused on imidazolium-based ILs, Yansheng et al.48 explored novel protic ILs composed of an ammonium-based cation and the propionate anion ([N11(2(O)2OH)0][C2CO2] and [N011(2CN)][C2CO2]) for the MAE of some benzofuranoids (senkyunolide H, senkyunolide I and Z-ligustilide) from Ligusticum chuanxiong Hort. The IL [N011(2CN)][C2CO2] led to high extraction yields of benzofuranoids within 1–5 min and at temperatures between 60 and 180 °C. Although not attempted by the authors, the use of protic ILs is advantageous since they can be recovered by distillation at reduced pressure and as attempted by Chowdhury et al.33

Summing up, almost all IL-based MAE processes reported to date are based on imidazolium-based ILs (with two exceptions: one evaluating the effect of the pyridinium cation and the second by employing protic ILs). The majority of ILs investigated comprise cations with short alkyl side chains length. Despite the lack of discussion on the mechanisms behind the improved extraction yields, a number of authors related the success of their extractions to the establishment of strong interactions, mainly hydrogen-bonding and π–π interactions, between the ILs and the target biocompounds. Various processing conditions were also addressed, such as irradiation power, solid–liquid ratio, time of extraction, chemical structure, and concentration of the ILs. In general, higher concentrations of the IL (up to a given limit, since at higher concentrations the viscosity of the solvent increases and leads to a decrease of the mass transfer of the solute as well as to a lower solubility of the target biocompounds) and lower solid–liquid ratios promoted higher extraction yields, while other parameters, such as the irradiation power, resulted in the lack of clear tendencies. Meanwhile, the use of tensioactive ILs promote either the increase or decrease of the extraction yield, depending mostly on the hydrophilic−lipophilic ratio of the target biocompound. However, we think that more studies need to be addressed in this field, since much more conditions need to be explored, namely the size and type of IL aggregates.

2.1.3. Ultrasound-Assisted Extractions

Although the MAE technology is rapid and effective toward the extraction of bioactive compounds from biomass, it is also energy intensive and difficult to scale up.8 To overcome these drawbacks, UAE can be used as a viable alternative to MAE. MAE allows rapid heating by irradiation, with further improvements on the solutes mass transfer, while UAE enhances the mass transfer mechanically.8 Moreover, when extracting thermosensitive biomolecules, UAE is a better choice since the extraction can be achieved without heating. The first demonstration of IL-based UAE for the extraction of natural compounds from biomass was carried out by Cao et al.53 (extraction of piperine from Piper nigru). Thereafter, several works were published demonstrating the use of IL-based UAE for the extraction of different alkaloids from biomass.54−57 For instance, Ma et al.49,54 studied the extraction of four biphenyl cyclooctene lignans from the fruit of Schisandra chinensis Baill, 30- and 10-hydroxycamptothecin, and camptothecin from Camptotheca acuminate, while Yang et al.55 studied the extraction of vindoline, catharanthine, and vinblastine from Catharanthus roseu. Other researchers extracted fangchinoline and tetrandrine from Stephaniae tetrandrae(56) and berberine, jatrorrhizine, and palmatine from Phellodendron amurense Rupr.57 All authors53−57 investigated a large number of ILs with different anions and cation alkyl side chain lengths and found that the extraction of alkaloids is mainly governed by the IL anion, as previously observed by Pan and co-workers with IL-based MAE.39,40 In all these studies,53−57 more hydrophilic ILs, such as [C4C1im]Br and [C4C1im]Cl, display a better performance in the extraction of alkaloids. Nevertheless, considering the observations made by Ma et al.49,54 and Yang et al.,55 wherein the extraction efficiency of alkaloids increases with the cation alkyl side chain length, it is clear that the contribution of the IL cation cannot be neglected. The performance of UAE assisted by ILs was compared against that obtained by other solvents and techniques, including UAE with pure water,49,54,55,57 aqueous solutions of sodium chloride or sodium bromide,49,54,55 heat reflux extraction with pure water57 or methanol,53 regular ultrasound extraction without the presence of IL,53,56 and refluent extraction with ethanol.56 Taking into account the general results reported, it seems that the use of IL-based UAE is advantageous because not only the extraction efficiencies obtained are higher, but they are also achieved within shorter extraction times53−57 and at lower temperatures.55 Some authors reported that the use of ILs contributes to the development of more benign/pollution-free methodologies, justified by the elimination of environmentally harmful organic solvents,55,57 while avoiding the degradation of alkaloids57 that occurs at higher temperatures. Although a relevant aspect for guaranteeing the sustainability of the developed processes, the recyclability of the solvent was only addressed by Ma et al. and Yang et al.49,54,55 They reported no losses in the extraction yields over four cycles of extraction-reuse of the solvent.49,54,55

In addition to alkaloids, IL-based UAE was successfully applied in the extraction of flavonoids (tectoridin, iristectorin A, and iristectorin B) from Iris tectorum.58 The authors58 screened the effect of different aqueous IL solutions and compared their results with those obtained by methanol and aqueous solutions of sodium chloride, finding that the best results were obtained with 0.5 M of [C8C1im]Br.58 Recently, IL-based UAE was also applied in the extraction of shikimic acid from conifer needles,59 caffeoylquinic acid from Flos Lonicerae Japonicae,60 and gallic acid from Suaeda glauca leaves.61 All authors evaluated the extraction yields achieved by several ILs with different cations and anions, and optimized various extraction conditions, including the IL concentration, ultrasonic power, extraction time, solid–liquid ratio, and temperature.59−61 The extraction efficiency generally increases by the application of lower solid–liquid ratios and higher temperatures.58−66,76 In general, all authors reported a dominant impact of the IL cation regarding the extraction yield of flavonoids. Although scarcely investigated and as carried out by Ma et al. and Yang et al.49,54,55 when dealing with the extraction of alkaloids, Chen and co-workers59 have additionally shown that the extraction yield of shikimic acid is reproducible over five cycles of solvent reuse, representing therefore a step toward the development of more sustainable IL-based processes.

The use of IL-based UAE was also explored for the extraction of terpenoids, such as ginsenosides, cryptotanshinone, tanshinone I, and tanshinone II A, from various natural sources.62,63,76 Lin et al.62 used this method for the extraction of ginsenoside derivatives from Ginseng roots, finding [C3C1im]Br to be the best IL with an extraction yield of ∼17 mg g–1, a higher yield than that obtained with water (∼13 mg.g–1) or ethanol (∼6 mg g–1).62 Wu et al.63 and Bi et al.76 reported a comprehensive study on the extraction of tanshinones from Salvia miltiorrhiza using long alkyl chain ILs, [CnC1im]Br (n = 8, 10, 12, 14, 16). The best extractions were obtained with the longest alkyl chain IL investigated ([C16C1im]Br), with yields of 0.6, 1.2, and 1.4 mg g–1 for cryptotanshinone, tanshinone I, and tanshinone IIA, respectively.63 As discussed in the two previous sections, these terpenoids are highly lipophilic and are thus better extracted by micelle-mediated processes.63,76 Harde et al.64 extracted forskolin from Coleus forskohlii roots using six ILs with different cations and anions, from which tetramethyl guanidinium lactate led to the best extraction efficiency (87.4%). The shorter extraction times (4 h) offered by IL-based UAE, as compared to Soxhlet extraction (12 h), show that IL-based UAE is a faster and more efficient approach for the extraction of terpenoids.64 This work64 is also a relevant contribution toward the field of IL-based extraction processes by using ILs other than the well-studied imidazolium-based examples.

Yang et al.65 demonstrated the application of IL-based UAE for the extraction of two benzopyranoids (aesculetin and aesculin) from Fraxinus rhynchophylla. They studied the effects of the IL anion and cation, achieving extraction efficiencies in the range of 60–100%, with [C4C1im]Br appearing to be the best solvent. The authors65 also conducted a comparison study with conventional UAE using several molecular solvents, ethanol-based heating reflux and a simple stirring extraction, and were able to demonstrate65 that IL-based UAE leads to higher extraction yields. On the other hand, Xiao et al.67 employed [CnC1im][BF4] ILs and demonstrated that the extraction yield of β,β′-dimethylacrylshikonin (more hydrophobic than shikonin) significantly increases with the IL cation alkyl chain length.67

Overall, IL-based UAE has been effectively applied to the extraction of a wide variety of natural products from a large number of plant species, although the scalability of the processes and commercial exploitation of the extracted products lagged behind. Compared to IL-based MAE, IL-based UAE offers the advantage of conducting the extractions at lower temperatures, and thus it is more appropriate for the extraction of thermolabile biocompounds. However, the number of ILs tested is still very limited, and the definition of heuristic rules regarding the use of different cations and anions is still lacking. For instance, it has been shown that the IL anion plays a major role in the extraction of alkaloids, while the IL cation alkyl side chain length plays a major role on the extraction of flavonoids. In our opinion, the absence of these rules is related to the absence of more complete studies evaluating both the IL cation and anion in the extraction of similar classes of bioactive compounds. A more complete evaluation is thus required, while attempting the correlation of the extraction yields with the IL properties, namely, their hydrophilic/lipophilic nature and hydrogen bond acidity or basicity. Moreover, the use of ILs that form aggregates, either by a micelle-mediated phenomenon or by a hydrotropic effect,9 needs to be comprehensively addressed to better understand the mechanisms that control the extraction of target biocompounds. Additional extraction conditions, such as the pH, still need to be ascertained, since some extractions may be improved by variation of the speciation of the target molecules, a factor not considered by most of the authors.

2.1.4. More Complex Solid–Liquid Extractions

In view of the advantages of IL-based UAE and MAE discussed above in the extraction of natural bioactive compounds, an integrated approach combining UAE and MAE (UMAE) was developed by Lu et al. for the extraction of gallotannins from Galla chinensis(68) and anthraquinones from Rheum spp. (rhubarb).69 The authors68 studied the replacement of organic solvents in UMAE by [C4C1im][BF4], [C4C1im]Br, and [C4C1im]Cl, whereby [C4C1im]Br was found to be the best solvent in terms of extraction efficiency. Moreover, IL-based UMAE considerably shortened the extraction time from 6 h (attained with IL-based UAE) to 1 min. A comparative analysis of IL-UAME with other methods, such as SLE under heat and reflux conditions, UAE and MAE, was also carried out.69 IL-UMAE led to higher extraction yields (24% improvement) within a shorter extraction time (2 min).69 In addition to IL-UMAE, Liu et al.70 applied IL-based ultrahigh pressure extraction (UPE) for the extraction of tanshinones from Salvia miltiorrhiza. The IL-based UPE approach, using 0.5 M of [C8C1im][PF6] in an ethanol solution, provided higher extraction yields with lower processing times and energy and solvent consumptions.70 This high efficiency of the IL-UPE method was ascribed to an improved disruption of the plants’ tissue cells.70

All the IL-based extraction methodologies discussed above (IL-based SLE, IL-based MAE, IL-based UAE, IL-based UMAE, and IL-based UPE) have limitations in terms of the extraction of some bioactive compounds, since some of them are unstable, labile, thermosensitive, and susceptible to oxidation when in contact with air. To overcome such limitations, recently, a new extraction approach called negative-pressure cavitation extraction (NPCE) has been proposed.72 Compared to the other extraction techniques, NPCE is carried out at low temperatures under an inert atmosphere. Duan et al.72 studied the IL-based NPCE method for the extraction of flavonoids, such as genistin, genistein, and apigenin from the roots of Cajanus cajan (pigeon pea), using [C8C1im]Br. The authors72 initially performed the lab-scale extraction and after optimizing the extraction conditions, the process was scaled-up. Similar extraction yields in lab and pilot scales were obtained, suggesting that IL-based NPCE is an appropriate option for the extraction of natural compounds on an industrial scale. In fact, and to the best of our knowledge, this is the only report on IL-based extraction approaches attempting the scale-up viability of the process.

Recently, Wang et al.73 demonstrated a simultaneous extraction and detection of anthraquinones from the root of Rheum palmatum L., using IL-based microwave homogeneous liquid–liquid microextraction (IL-based MA-HLLME). Enhanced extractions of four anthraquinones, namely aloe-emodin, emodin, chrysophanol, and physcion, were obtained within a short time period.73 Moreover, the proposed IL-based MA-HLLME protocol does not require the use of volatile organic solvents, and it only requires low amounts of solvent compared to IL-based UAE and IL-based heat reflux extractions.

In summary, a wide variety of SLE approaches (simple IL-based SLE, IL-based MAE, IL-based UAE, IL-based UMAE, IL-based UPE, and IL-based NPCE) have been investigated over the past few years for the extraction of bioactive compounds from natural sources. All these techniques have their particular requirements and offer certain benefits compared to others. Although the MAE is a faster technique, it still presents some drawbacks regarding the possible degradation of thermosensitive molecules; for these situations, the UAE seems a better approach to be applied. Nevertheless, whatever the methodology applied, ILs have a definitive role toward an enhanced extraction performance when compared to conventional molecular solvents. Owing to the distinct properties of ILs and their ability to interact with bioactive compounds, via hydrogen-bonding, dispersive, π···π and n···π interactions, they could be realized as tailored solvents, thus surpassing the performance of traditional molecular solvents. Moreover, the role of ILs in SLE processes from biomass is not limited to the improved solute–solvent interactions but also due to the effect of ILs in disrupting the biomass organized structure. The combination of ILs with different SLE methods favors the disruption of plant cells and acts synergistically by improving the mass transfer and solubility of bioactive compounds in IL-based solvents. On the other hand, the use of aqueous solutions of ILs stands out, since it is avoiding the dissolution of the lignocellulosic fraction of most biomass samples considered.

It is clear, however, that more studies need to be carried out regarding the different solid–liquid extraction approaches discussed herein. Other cation families (phosphonium, quaternary ammonium, and cholinium derivatives) need to be evaluated, in particular those with higher hydrogen bond abilities, which seem promising for the extraction of natural compounds. The aromaticity of ILs also plays an important role in the extraction of different compounds, since imidazolium-based ILs are often referred to as the most promising solvents. Nevertheless, there is still a need for further investigation of nonaromatic cations and aromatic anions in order to fully understand their role. When using ILs in aqueous solution, the authors also need to be careful in the selection of the anion structures, and to avoid the use of [PF6]− and [BF4]−, due to their poor stability in water and consequent formation of fluoridric acid.80 Even though we can assume that for some natural compounds the presence of acids is not harmful, up to a certain extent, it, however, represents a loss of IL if its reuse is envisaged.

The use of surface-active ILs, in turn, led either to an increase or to a decrease of the extraction yield, a phenomenon that mainly depends on the hydrophilic–lipophilic ratio of the target biocompound. However, more studies need to be performed, since the size and type of IL aggregates should also be evaluated. For more hydrophobic biocompounds, it has been demonstrated that ILs with the ability to self-aggregate are the most promising solvents, while more hydrophilic compounds are better extracted with ILs with a higher ability to establish hydrogen bonds or to create solute-IL aggregates by a hydrotropic phenomenon.9 It seems that a threshold on the hydrophobic nature of biocompounds exists, and this should be used to a priori identify the most promising classes of ILs to be applied.

It is our belief that more efficient processes will be developed in the near future and properly scaled up. One work72 addressing the SLE technology scale-up was found in the open literature, while successfully demonstrating its potential. Despite the near absence of studies resorting to the scale-up of these extraction processes, their implementation still needs to follow some criteria, namely the market price of the biomolecules being extracted and their purity level, the costs associated with the process and ILs used, and the suitability of recovering and reusing the employed solvents. Everything considered, it will be much easier to define and optimize IL-based methodologies to make the process of solid–liquid extractions more selective and cost-effective and if IL-based methodologies are indeed the best option to replace the conventional processes. Although a large number of reports exists on the use of IL-based SLE of small organic bioactive compounds, most of these were focused on optimizing the extraction yield, and while some attempted the recovery of solutes and reuse of solvents, no indications of the purity of the extracts were provided (an important feature which defines the current price of biocompounds when foreseeing their commercialization).

2.2. IL-Based Liquid–Liquid Extractions

After the extraction steps mainly carried out by the SLE techniques described above, IL-based LLE approaches have been studied as a subsequent stage for the separation and purification of target biocompounds, namely by (i) the application of hydrophobic ILs; and (ii) by the use of IL-based aqueous biphasic systems (ABS). Since most biomass extracts are water-rich, hydrophobic water-immiscible ILs are used initially, defined here as IL-LLE, while in the second option a salting-out agent is added to the water-miscible ILs to create a second liquid phase, defined here as IL-ABS. Although not extensively investigated, IL-based LLE may, in some cases, allow the combination of extraction, purification, and concentration in a single step.81 An overview of IL-based LLE processes for the separation and purification of bioactive compounds is provided in Table 3.

Table 3. Extraction and Separation of Small and Extractable Organic Compounds from Biomass Using IL-Based LLE.

| bioactive compound | natural source | method | ILs (solvents) used |

|---|---|---|---|

| aloe anthraquinones | aloe powder | IL-ABS | [C2C1im]Br + salt + water, [C4C1im]Br + salt + water, [C6C1im]Br + salt + water, [C4C1im][BF4] + salt + water, [C2C1im][BF4] + salt + water [C4C1im][N(CN)2] + salt + water; salt = NaH2PO4, (NH4)2SO4, Na2SO4, and MgSO482 |

| caffeic acid, vanillic acid, gallic acid, and vanillin | lignin depolymerization | IL-ABS | PEG 8000 + NaPA 8000 + [C12C1im]Cl, PEG 8000 + NaPA 8000 + [C14C1im]Cl83 |

| caffeine | – | IL-ABS | [C4C1im][CF3SO3] + sugars + water, [C4C1im][BF4] + sugars + water, [C4C1im] [N(CN)2] + amino acids + water; amino acids = l-Pro, l-Lys84,85 |

| caffeine and nicotine | mixture of alkaloids | IL-LLE | [P66614][NTf2] + K3PO4 + water, [P66614]Br + K3PO4 + water, [P66614]Cl + K3PO4 + water, [P66614][C1SO3] + K3PO4 + water, [P66614][N(CN)2] + K3PO4 + water, [P66614][TMPP] + K3PO4 + water86 |

| caffeine and nicotine | synthetic urine | IL-ABS | [C2C1im]Cl + K3PO4 + water, [C4C1im]Cl + K3PO4 + water, [C6C1im]Cl + K3PO4 + water, [C4C1C1im]Cl + K3PO4 + water, [C7C1im]Cl + K3PO4 + water, [C8C1im]Cl + K3PO4 + water [aC1im]Cl + K3PO4 + water, [C10C1im]Cl + K3PO4 + water, [C12C1im]Cl + K3PO4 + water, [OHC2C1im]Cl + K3PO4 + water, [C7H7C1im]Cl + K3PO4 + water, [C2C1im][CF3SO3] + K3PO4 + water, [C2C1im][CF3SO3] + K3PO4 + water87 |

| capsaicin | Capsicum frutescens | IL-ABS | [N111(2OH)]Cl + acetonitrile + water, [N111(2OH)][Bit] + acetonitrile + water, [N111(2OH)][DHCit] + acetonitrile + water88 |

| codeine and papaverine | Pericarpium papaveris | IL-ABS | [C4C1im]Cl + K2HPO4 + water89 |

| ellagic acid | Acacia catechu and Terminalia chebula | IL-LLE | [N1100][N(C1)2CO2] (pure)33 |

| eugenol and propyl gallate | – | IL-ABS | [C2C1im]Cl + C6H5K3O7/C6H8O7 + water, [C4C1im]Cl + C6H5K3O7/C6H8O7 + water, [C6C1im]Cl + C6H5K3O7/C6H8O7 + water, [C8C1im]Cl + C6H5K3O7/C6H8O7 + water, [C4C1pip]Cl + C6H5K3O7/C6H8O7 + water, [C4C1pyrr]Cl + C6H5K3O7/C6H8O7 + water, PEG + K2HPO4/KH2PO4 + [CnC1im]Cl (n = 2–8)90 |

| flavonoids and pectin | Ponkan peels | IL-ABS | [N111(2OH)][Ala] + K3PO4 + water, [N111(2OH)][Ser] + K3PO4 + water, [N111(2OH)][Cys] + K3PO4 + water, [N111(2OH)][Pro] + K3PO4 + water, [N111(2OH)][Asp] + K3PO4 + water, [N111(2OH)][Val] + K3PO4 + water, [N111(2OH)][Leu] + K3PO4 + water, [N111(2OH)][Phe] + K3PO4 + water,91 |

| gallic acid | – | IL-ABS | [C7C1im]Cl + salt + water, [C8C1im]Cl + salt + water, [C2C1im][CF3SO3] + salt + water, [C4C1im][CF3SO3] + salt + water, [C4C1im][N(CN)2] + salt + water, [C4C1im][C1SO4] + salt + water, [C4C1im][C8SO4] + salt + water, [C4C1im][C2SO4] + salt + water, [C4C1im]Br + salt + water; salt = K3PO4, Na2SO4, and K2HPO4/KH2PO492 |

| gallic, vanillic, and syringic acids | – | IL-ABS | [C4C1im][CF3SO3] + Na2CO3 + water, [C4C1im][SCN] + Na2CO3 + water, [C4C1im][C1SO3] + Na2CO3 + water, [C4C1im][C2SO4] + Na2CO3 + water, [C4C1im][C1SO4] + Na2CO3 + water, [C4C1im][Tos] + Na2CO3 + water, [C4C1im]Br + Na2CO3 + water [C4C1im][N(CN)2] + Na2CO3 + water, [C4C1im][(C1)2PO4] + Na2CO3 + water, [C4C1im]Cl+ Na2CO3 + water, [C4C1im][C1CO2] + Na2CO3 + water93 |

| gallic, vanillic, and syringic acids | mixture of phenolic acids | IL-ABS | PEG 300 + Na2SO4 + 5 wt % [C4C1im][Tos] + water, PEG 300 + Na2SO4 + 5 wt % [C4C1im][SCN] + water, PEG 300 + Na2SO4 + 5 wt % [C4C1im][N(CN)2] + water, PEG 300 + Na2SO4 + 5 wt % [C4C1im][C1CO2] + water, PEG 300 + Na2SO4 + 5 wt % [C4C1im]Cl + water, PEG 300 + Na2SO4 + 5 wt % [C4C1pyrr]Cl + water, PEG 300 + Na2SO4 + 5 wt % [C4C1pip]Cl + water94 |

| glaucine | Glaucium flavum Cr. | IL-ABS | [C4C1im][Ace] + Na2CO3 + water, [C4C1im][Ace] + (NH4)2SO4 + water, [C4C1im][Ace] + MgSO4 + water, [C4C1im][Ace] + NaH2PO4 + water95 |

| glycine | pharmaceutical sample | IL-LLE | [C4C1im][PF6] + dicyclohexano-18-crown-6 + water96 |

| indole-3-butyric acid | pea plants | IL-LLE | [C4C1im][PF6], [C6C1im][PF6], [C8C1im][PF6], [C6C1im][BF4], and [C8C1im][BF4] (water)81 |

| L-tryptophan, caffeine, and β-carotene | – | IL-ABS | [C4C1im][CF3SO3] + sugars + water, [C4C1im][BF4] + sugars + water84 |

| nicotine, caffeine, theophylline, and theobromine | mixture of alkaloids | IL-ABS | [C4C1im]Cl + C6H5K3O7/C6H8O7 + water, [C6C1im]Cl + C6H5K3O7/C6H8O7 + water, [C7C1im]Cl + C6H5K3O7/C6H8O7 + water, [C8C1im]Cl + C6H5K3O7/C6H8O7 + water, [C10C1im]Cl + C6H5K3O7/C6H8O7 + water, [C4C1im]Cl + C6H5K3O7 + water, [C6C1im]Cl + C6H5K3O7 + water, [C8C1im]Cl + C6H5K3O7 + water, [C10C1im]Cl + C6H5K3O7 + water85 |

| para red and Sudan dyes | chili powder | IL-LLE | [C4C1im][PF6] and [C8C1im][PF6] (water)97 |

| trans-zeatin, indole-3-acetic acid | Kappaphycus alvarezii sap | IL-LLE | [C4C1im][PF6], [C8C1im][BF4], and [C4C1C1im][NTf2] (water)98 |

| tyrosol | olive mill wastewater | IL-LLE | [P4441][NTf2], [N4441][NTf2], and [N1888][NTf2] (water)99 |

| vanillin | – | IL-ABS | [C2C1im]Cl + K3PO4 + water, [C4C1im]Cl + K3PO4 + water, [C6C1im]Cl + K3PO4 + water, [C4C1C1im]Cl + K3PO4 + water, [C7C1im]Cl + K3PO4 + water, [aC1im]Cl + K3PO4 + water, [C10C1im]Cl + K3PO4 + water, [C12C1im]Cl + K3PO4 + water, [OHC2C1im]Cl + K3PO4 + water, [C7H7C1im]Cl + K3PO4 + water, [C4C1im][CF3SO3] + K3PO4 + water, [C4C1im][N(CN)2] + K3PO4 + water, [C4C1im][C1SO4] + K3PO4 + water, [C4C1im][C1SO3] + K3PO4 + water, [C4C1im][C1CO2] + K3PO4 + water, [C4C1im]Br + K3PO4 + water100 |

2.1.6. Liquid–Liquid Extraction with Hydrophobic ILs

Hydrophobic ILs ([PF6]-based) were effectively applied by Absalan et al.81 in the extraction of a plant growth regulator, 3-indole-butyric acid (IBA), from its aqueous extracts. The higher extraction efficiency was observed with [C4C1im][PF6], with a preconcentration factor of 100. After the back-extraction of IBA from the IL-rich phase, the IL was successfully reused five times.81 Along the same lines, Prasad and co-workers98 studied three imidazolium-based ILs ([C4C1im][PF6], [C8C1im][BF4], and [C4C1mim][NTf2]) to extract plant growth regulators present in the sap from fresh Kappaphycus alvarezii seaweed. The authors98 showed that [C4C1im][PF6] was able to extract 65% of the total trans-zeatin and 18% of the total indole-3-acetic acid present in the sap, whereas [C4C1mim][NTf2] was not able to extract any compound and in agreement with the findings of Absalan et al.81 who also identified [C4C1im][PF6] as the best IL. Fan et al.97 studied IL-based LLE approaches for red and Sudan dyes from chili powder, using [C4C1im][PF6] and [C8C1im][PF6], the latter IL being the most effective. In another study, glycine was successfully extracted from pharmaceutical wastes by LLE using [C4C1im][PF6] and dicyclohexano-18-crown-6.96

As alternatives to imidazolium-based fluids, Larriba et al.99 proposed the use of [P4441][NTf2], [N4441][NTf2], and [N1888][NTf2] for the extraction of tyrosol, a naturally occurring antioxidant, from olive mill wastewaters. The authors99 showed that at optimum conditions, >94% of tyrosol extraction was achieved with [P4441][NTf2] and [N4441][NTf2], corresponding to higher extraction yields than that obtained with ethyl acetate. The addition of 20 wt % of NaCl to the water-rich medium further increased the extraction efficiency to the IL phase and ascribed by the authors99 as a result of a salting-out effect. In this context, stronger salting-out species can be chosen among the large plethora of salts available. Finally, Larriba et al.99 demonstrated the back-extraction of tyrosol from ILs using an aqueous solution of 0.1 M of NaOH followed by their recycling (after their neutralization with phosphoric acid).

Although six studies have been found resorting to the use of hydrophobic ILs for LLE purposes, this is a significantly low amount when compared, for instance, with the use of IL-based ABS discussed in the next section. In fact, the number of available hydrophobic water-immiscible ILs is much more limited when compared to water-miscible ones; this imposes severe limitations in terms of variability and tuning of the IL chemical structures aiming at optimizing the extraction performance of these systems and which seems to be the main justification for the reduced number of works presented in this section. Furthermore, most of these studies deal with IL anions with poor stability in water, such as [PF6]− and [BF4]−.80 With regard to the potential scale-up of these works, and despite the lack of deeper analyses, it needs to be highlighted that fluorinated-based anions tend to be very costly, having thus an additional relevant impact on the economic viability of the developed processes.

2.1.7. IL-Based Aqueous Biphasic Systems

As highlighted above, IL-based LLE approaches using hydrophobic ILs have several drawbacks. Moreover, most of the successful extractions of natural compounds from biomass were carried out with aqueous solutions of water-miscible imidazolium-based ILs, combined with Cl–, Br–, [C1CO2]−, and [BF4]− anions.8,22−24 Unless total selectivity is reached, after the extraction, a second step for the fractionation of the extracts is usually required, and where ABS can be used.101 The pioneering work of Rogers and co-workers102 established that ABS could be prepared by mixing hydrophilic ILs and inorganic salts in aqueous solution. Typically, inorganic salts induce the salting-out of ILs in aqueous media, thus leading to the creation of two liquid aqueous-rich phases. A recent review of IL-based ABS, comprising both the fundamentals behind their formation and possible application, can be found elsewhere.7 Due to the large plethora of available water-miscible ILs and second phase-forming components of ABS (salts, polymers, carbohydrates, and amino acids), it is possible to tailor the polarities of the phases and IL-based ABS have indeed allowed selective and enhanced separations.7 IL-based ABS has been extensively studied to purify crude extracts from biomass,86,97 for the fractionation of alkaloids87,89,103,104 and antioxidants,90,92,94,100 among others.

A number of alkaloids, such as codeine, papaverine, caffeine, nicotine, theophylline, and theobromine were purified by IL-based ABS.87,89,103 In 2005, Li et al.89 first demonstrated the application of the [C4C1im]Cl/K2HPO4-based ABS for the separation of opium alkaloids (codeine and papaverine), extracted from Pericarpium papaveris. After a previous IL-SLE step with aqueous solutions of [C4C1im]Cl, K2HPO4 was then added to create an ABS. The extraction yields obtained were comparable with those obtained with conventional LLE but with reduced extraction times and without using volatile organic solvents. In contrast to this work, where a single IL was studied, Freire et al.87 explored the extraction of caffeine and nicotine using several imidazolium ILs and K3PO4-based ABS. The authors87 showed that both solutes preferentially partition into the more hydrophobic phase (i.e., the IL-rich phase). The complete extraction of caffeine and nicotine into the IL-rich phase was achieved in a single step after a proper optimization of the IL chemical structure and mixture compositions.87 The capability of ABS composed of phosphonium-based ILs and inorganic salts,104 imidazolium-based ILs and carbohydrates,84 and imidazolium-based ILs and amino acids85 to separate caffeine was also demonstrated. In most cases,84,85,104 caffeine preferentially migrates to the IL-rich phase, although higher extraction efficiencies were obtained in IL-salt ABS due to stronger salting-out effects exerted by salts.87 Passos et al.103 investigated the effect of the IL cation alkyl side chain length ([CnC1im]Cl, n = 4–10) on the partition of a series of alkaloids (nicotine, caffeine, theophylline, and theobromine) of variable hydrophobicity. The authors demonstrated that the partition coefficients of alkaloids increase with the cation alkyl chain length up to n = 6, whereas a further increase in the cation side chain was deleterious to the extraction, explained by the self-aggregation of ILs with long alkyl chains,103 which seems not to be favorable for the extraction of more hydrophilic alkaloids, as discussed above in the SLE section.

IL-based ABS were also investigated for the separation of phenolic compounds, such as vanillin, gallic acid, vanillic acid, syringic acid, eugenol, and propyl gallate.83,90,92,94,100 Cláudio et al.92,100 studied IL-based ABS formed by a wide variety of imidazolium ILs and K3PO4 for the extraction of vanillin and formed by imidazolium ILs + phosphate and sulfate salts for the separation of gallic acid. It was shown that vanillin preferentially migrates to the IL-rich phase,100 while at low pH values the neutral form of gallic acid favorably migrates to the IL-rich phase and at high pH values its anionic form preferentially concentrates in the salt-rich phase.92 This pH-driven phenomenon was later demonstrated to be of high relevance to the fractionation of mixtures of phenolic compounds and to proceed with back-extraction studies and solvent reuse.93

ILs can also be successfully used as adjuvants in conventional polymer-salt-based ABS. Almeida et al.94 investigated ABS composed of polyethylene glycol (PEG) of different molecular weights and Na2SO4, using 5–10 wt % of ILs as adjuvants, for the separation of gallic, vanillic, and syringic acids from aqueous media. The partition extent of phenolic acids into the PEG-rich phase was shown to be dependent on the IL employed, which also preferentially partitions to the polymer-rich phase. The addition of only 5 wt % of IL led to 80–99% extraction efficiencies of all phenolic acids, thus confirming the capability of the IL to tune the polarity of the PEG-rich phase, even in low amounts.94 Santos et al.90 studied ABS composed of various ILs and a citrate (C6H5K3O7/C6H8O7) buffer at pH 7 for the extraction of eugenol and propyl gallate and compared their extraction ability to systems formed by PEG and C6H5K3O7/C6H8O7 (at pH 7), using imidazolium-based ILs as adjuvants. The complete extraction (100%) of the two antioxidants was obtained using both IL-based and PEG-based (with the IL as adjuvant) ABS.90 These results support the enhanced potential of ILs as adjuvants to tailor the polarities of coexisting ABS phases, while minimizing the cost and the environmental impact of the extraction/purification processes. More recently, Santos et al.83 developed an integrated approach for the fractionation of five phenolic compounds from lignin depolymerization using polymeric ABS (composed of PEG and sodium polyacrylate (NaPA) containing ionic surfactants as electrolytes). Two ILs ([CnC1im]Cl, n = 12 and 14) were used among the several surfactants investigated. Simple and fast methods to isolate phenolic compounds from the coexisting phases were successfully implemented by the authors.83

Even though a large number of IL-based ABS have been evaluated for the separation of small natural-derived organic compounds, these have been mainly applied to standard mixtures of biocompounds. Reports on integrated processes comprising both the extraction of biocompounds from biomass and their further purification using IL-based ABS are indeed scarce.79,82,88,91,93,95,105−107 Among these, the extraction of anthraquinone derivatives from Aloe vera using aqueous solutions of ILs, followed by the formation of IL-based ABS (with imidazolium ILs and Na2SO4) for the purification of the extracts, was recently demonstrated.82 Under optimized conditions, the extraction efficiencies of anthraquinones, namely aloe-emodin and chrysophanol, were 92.34% and 90.46%, respectively.82 The authors82 thereafter studied the back-extraction of the target compounds, followed by IL recovery by the formation of a new ABS with the addition of an alkaline salt.82 Bogdanov and co-workers95 also developed an approach to recover ILs after extracting glaucine from crude plant extracts of Glaucium flavum Cr. (Papaveraceae) using IL-based ABS formed by [C4C1im][Ace] and distinct salts. Recently, Wang et al.91 reported the use of biobased ILs comprising the cholinium cation and different amino-acid-derived anions ([N111(2OH)][Ala], [N111(2OH)][Ser], [N111(2OH)][Cys], [N111(2OH)][Pro], [N111(2OH)][Asp], [N111(2OH)][Val], [N111(2OH)][Leu], and [N111(2OH)][Phe]) for the simultaneous extraction of flavonoids and pectin from ponkan peels, which were then isolated by ABS formation with K3PO4. Yang et al.106 and Tan et al.107 demonstrated that an effective extraction and purification of chlorogenic acid from ramie leaves and flavonoids from Apocynum venetum L. leaves could be achieved by coupling IL-based UAE with IL-based ABS. Improved results were obtained by Tan et al.107 since flavonoids mainly partition to the IL-rich top phase, while impurities tend to concentrate in the salt-rich layer. Nevertheless, none of these works completely characterized the extracts and provided purification factors.

In general, IL-based ABS for the extraction and purification of bioactive compounds were mainly carried out with imidazolium-based ILs, combined with chloride, bromide, acetate, dicyanimide, and tetrafluoroborate anions. Only two works79,91 highlighted the potential of more biocompatible and biodegradable cholinium-based ILs as potential alternatives to imidazolium counterparts. Nowadays, there is a large number of more benign ILs available, such as those composed of cholinium-, glycine-, and glycine-betaine-based cations, combined with anions derived from carboxylic acids,108,109 biological buffers,110 and amino acids,111 among others, which deserve to be explored for the extraction of bioactive compounds from biomass. Since the concept behind the use of ABS comprises the separation and purification of target molecules from the main contaminants present in biomass extracts, in future works attention should also be given to the latter, because in some cases it is easier to manipulate the partition behavior of contaminants among the coexisting phases.112,113 Moreover, and as shown in this section, integrated strategies combining IL aqueous solutions used in the extraction of natural compounds from biomass combined with their direct use in the formation of ABS for the purification step are still very scarce. However, only by developing integrated strategies and attempting IL reuse and recovery will it be possible to develop cost-effective techniques while contributing to a lower environmental footprint of real and large-scale applications.

2.3. Solid-Phase Extractions Using IL-Modified Materials