Abstract

In recent years, new-found interest in the hydrogen economy from both industry and academia has helped to shed light on its potential. Hydrogen can enable an energy revolution by providing much needed flexibility in renewable energy systems. As a clean energy carrier, hydrogen offers a range of benefits for simultaneously decarbonizing the transport, residential, commercial and industrial sectors. Hydrogen is shown here to have synergies with other low-carbon alternatives, and can enable a more cost-effective transition to de-carbonized and cleaner energy systems. This paper presents the opportunities for the use of hydrogen in key sectors of the economy and identifies the benefits and challenges within the hydrogen supply chain for power-to-gas, power-to-power and gas-to-gas supply pathways. While industry players have already started the market introduction of hydrogen fuel cell systems, including fuel cell electric vehicles and micro-combined heat and power devices, the use of hydrogen at grid scale requires the challenges of clean hydrogen production, bulk storage and distribution to be resolved. Ultimately, greater government support, in partnership with industry and academia, is still needed to realize hydrogen's potential across all economic sectors.

This article is part of the themed issue ‘The challenges of hydrogen and metals’.

Keywords: hydrogen, energy, fuel cell

1. Introduction

For the first time in history, governments worldwide are making a concerted and coordinated effort to decarbonize their economies to curb the effects of climate change. By December 2016, 116 of the 196 parties had ratified the COP21 Paris agreement and pledged to take action to keep global warming below 2°C [1]. To meet this reduction target, global annual greenhouse gas emissions will need to be reduced by 85% by 2050 [2]. This reduction target is ambitious and will require nothing short of a global-energy revolution, particularly given the rapid growth of the global population (projected to be 9.7bn by 2050) [3]. With an anticipated 150% increase just in the electricity demand to 53.6 billion MWh (from 2010 to 2050) [4], governments will be challenged to identify the best way to reduce greenhouse gas emissions while simultaneously ensuring economic competitiveness, growth and a secure energy supply.

The International Energy Agency predicts that renewables will make the second largest contribution to carbon dioxide (CO2) reductions (32%), after efficiency improvements (38%). The European Commission has proposed a target of 20% renewable energy in the European Union's (EU) overall energy mix by 2020 [5]. Solar and wind power are already at cost parity with fossil fuels in some regions and are being increasingly integrated into the national power grids, especially in Asia and Europe [6]. This has generated a new requirement: flexible solutions to manage the intermittency of these energy sources. Hydrogen emerges as a leading contender in providing flexibility, while carrying energy to all sectors across the energy landscape. The need for system-level change has rekindled interest in the hydrogen economy.

The ‘hydrogen economy’, first coined by Prof. John Bockris during a talk he gave in 1970 at the General Motors Technical Center [7], has created much excitement among scientists, economists (e.g. [8]), industrialists (e.g. [9]), and heads of states/regions, including the USA and the EU [10–12] and more recently Japan [13]. However, the development and realization of such a hydrogen-based economy has been challenging due to the large-scale infrastructural investments needed. For example, in the transport sector, the development of hydrogen as a transport fuel has historically been limited by the decision of what comes first, the cars or the refuelling infrastructure—the ‘chicken-and-egg’ problem. While the potential of hydrogen has always been significant, the challenge in establishing a hydrogen economy has stifled progress. This is mostly because challenges had to be addressed simultaneously within all components of the hydrogen economy: production, storage, transportation and distribution, while strategic policy support had to be maintained.

The case for a hydrogen economy is growing. An increasing number of reports show that hydrogen could have a role in almost every part of the energy system—including electricity generation and transport [9,13–16]—and energy system-level assessments reveal hydrogen to be a technically and economically viable option for decarbonizing heat (e.g. [17,18]). Today, building on important technical advances in hydrogen technologies, as well as several public–private partnerships (e.g. H2USA [19], FCH Joint Undertaking in Europe [20], and Japan's partnership with Toyota [13]), the role of hydrogen in enabling a cost-effective transition to a low-carbon energy system is being appraised with greater coordination. The International Partnerships for Hydrogen and Fuel Cells in the Economy [21] has 18 member countries (plus the European Commission) announcing national roadmaps (e.g. Japan [13], the UK [16], India [22]) and initiatives towards commercialization of hydrogen and fuel cell (H2FC) technologies (e.g. a memorandum of understanding signed by 45 cities and regions pledging to include H2FC technologies in their city decarbonization activities [23]), France is declaring ‘hydrogen territories’ [24] and the USA is examining hydrogen at scale [25].

The benefits of hydrogen are already being recognized commercially for niche applications. For example, hydrogen fuel cells are increasingly replacing batteries in forklift trucks used in warehouses (about 10 000 fuel cell forklifts in use, mostly in the USA [26]) and rapid-response fuel cell power units are replacing diesel generators for back-power applications. This paper will show how the opportunities enabled by hydrogen are extending into a much wider range of applications across all economic sectors, and outlines the challenges that need to be addressed before hydrogen can be used at scale within the energy system.

2. Energy consumption by sector

(a). Transport sector

Global transport activity is projected to double by 2050 [27], unless behavioural changes or new measures are introduced. Transport accounts for almost a quarter of global-energy-related CO2 emissions [28]. In 2012, road transport accounted for 75% of all transport emissions [27], thus this segment of transport is increasingly subjected to emissions regulations. Furthermore, fossil-fuel vehicles are responsible for a significant amount of air pollution in many of the world's mega cities, which is estimated to have caused 6.5 million premature deaths in 2012 [28]. Hydrogen produces no air pollution and has zero carbon impact at the point of use. While carbon-free driving can be achieved when hydrogen is produced from renewable sources, with natural gas-derived hydrogen fuel cell electric vehicles (FCEVs) still offer 30% CO2 savings when compared with diesel and petrol vehicles [29,30]. The roll out of hydrogen-fuelled FCEVs has already begun, with Toyota, Honda and Hyundai releasing vehicles into the market with an initial commitment to produce vehicles in the low thousands per year (Toyota's Mira released in 2015, Hyundai's Tuscan FCEV released in 2016 and Honda's Clarity Fuel Cell to be released in December 2016). Other manufacturers (Daimler, BMW and GM) have announced plans to introduce FCEVs to the market by 2018. However, the numbers of FCEVs are still relatively low. The lack of a hydrogen refuelling infrastructure had been a major barrier to the development of FCEVs. With the building of more of these refuelling stations, it is expected that more FCEVs will finally be on the roads. Public–private initiatives such as the EU's €38 m HyFIVE programme [31], which aims to deploy 185 FCEVs with support from five global original equipment manufacturers (OEMs), is an encouraging step towards the commercialization of FCEVs.

However, vehicle costs are still rather high. Toyota's Mirai (312 mile range) was launched in the UK in 2016 at a price of £66 000 (and US$58 500 in the USA in 2015) with the main costs being attributed to the fuel cell powertrain and the hydrogen storage system. These costs are currently higher than both standard internal combustion engine vehicles (ICEVs) and the most advanced plug-in electric vehicles (PEVs) of a similar size. In the case of PEVs, Tesla announced the Tesla model-3 vehicle, which has a driving range of 215 miles, to be in series production in 2017 for a price of US$35 000 for the cheapest option [32]. However, FCEVs are predicted to become affordable at scale, and cost competitive with ICEVs with an annual production of 0.5–1 million FCEVs [33–36]. In fact, after 2025, a McKinsey & Co. analysis [34] predicts that the total cost of ownership converges for all types of vehicles (FCEV, PEVs and ICEVs) as costs of these vehicles benefit from learning and economies of scale. Another study [37] goes even further to show that if the carbon price is high, then the FCEVs become progressively cheaper than the conventional ICEVs.

While there is clearly much uncertainty regarding how the competition between the types of vehicles will evolve with customers, it is likely that multiple low-carbon options will exist in the market with PEVs used as smaller vehicles for urban driving and FCEVs used as larger vehicles for long-distance driving and fast refuelling. See Gröger et al. [38] for a comparative technical and cost analysis, as well as initial reports on customer preferences. The use of fuel cells in larger vehicles is already being demonstrated by the growing number of programmes deploying fuel cell electric buses (FCEBs) for clean public transport [39] in several pioneering cities around the world. An extensive analysis of the potential of fuel cells in Europe can be found in [39]. The CHIC project, the EU's roll-out strategy for buses aims to add to the fleet of 60 FCEBs running in Europe towards the end of 2016 [26,40]. In Asia, plans for much larger fleets of FCEBs are being announced. In Japan, market deployment of FCEBs has begun, with Toyota announcing 100 FCEBs on the road by the 2020 Tokyo Olympics. In South Korea, the government announced its intent to replace 26 000 compressed natural gas public transport vehicles with FCEBs [26]. The Chinese government announced plans to have 300 FCEBs in two cities and it is anticipated many more will follow [26].

Technical improvements will speed up market penetration of FCEVs; in particular, reducing the amount of platinum used in each vehicle (currently ≈20–40 gPt/FCEV) [38] will drive down costs. An extensive analysis of the key technical challenges, recent improvements and targets for hydrogen proton exchange membrane (PEM) fuel cells in vehicle applications can be found in [36,41].

Above all, significant infrastructure investments will be required over the next decades to drive the uptake of fuel cell vehicles and to transition the technology to a sustainable market phase [42]. Several public–private partnership projects have been launched to build up the networks of hydrogen refuelling stations in the USA (H2USA [19]), Europe (Hydrogen Mobility Europe [43]) and Japan [13]. At the start of 2016, there were only 214 refuelling stations, with approximately 100 announced to be built (35 in the USA and 64 in Europe) [44]. The H2ME2, a €100 million pan-European demonstration project co-funded by OEMs and the FCH Joint Undertaking [43], plans to add 20 hydrogen refuelling stations to the European hydrogen network, with 1230 commercial FCEVs put on the road. Japan recently announced the target of building of 320 stations by 2025, with 800 000 FCEVs to be put on the road by 2030 [13]. Within Europe, Germany has 34, the largest number of hydrogen refuelling stations, followed by the UK with 14 refuelling points [44]. In Germany, H2 MOBILITY Deutschland GmbH (a limited partnership between Air Liquide, Daimler, Linde, OMV, Shell, and Total) plans to construct and operate up to 400 hydrogen refuelling stations in Germany by 2023 [45]. In California, USA, 51 hydrogen refuelling stations currently exist (2016); this is projected to go up to around 90 by 2021, with 30 000 FCEVs projected to be on the roads by the same time [46].

According to a study by McKinsey & Co. [34], a hydrogen supply infrastructure for around 1 million FCEVs requires an investment of €3 billion (production, distribution, retail), of which €1 billion relates to retail infrastructure. This study shows that the capital investment needed for FCEVs is comparable to that needed for a PEV charging infrastructure, which ranges from €1500 to €2500 per vehicle [34]. This report points out that, while it is initially easier to build a PEV charging infrastructure, at some point the infrastructure cost for FCEVs drops below those for PEVs as the number of charging stations becomes commensurate with the number of cars, due to the lengthy recharging time and because investment costs for hydrogen stations decrease with increasing size of these stations. This should then drive fuel costs down to US$8/kWh or less to enable competition of FCEVs with ICEVs [36].

Hydrogen similarly holds promise in other transport applications, including marine and rail. Marine applications range in size from small outboard motors (e.g. a hydrogen fuel cell-operated boat in Bristol, UK [47], and a hydrogen combustion engine catamaran on the Isle of Wight [48], UK) to passenger and car ferries, such as the HySeas project in Scotland, UK [49]. In the rail sector, given the high cost of rail electrification, companies are developing the first prototype trains powered by hydrogen fuel cells for urban rail [50]. The German rail company Alstom recently unveiled its ‘iLint’ passenger train, which operates on PEM fuel cells [51]. In China, the first commercial fuel cell tram line is expected to start its service in late 2017 in the city of Foshan [26]. Shunt locomotives have been demonstrated in India and the USA [26]. In both marine and rail industries, most vehicles are still in the proof-of-concept stage. Real-world applications of these vehicles will be required to assess their potential for success.

(b). Residential and commercial sectors: using hydrogen for heat in buildings

Energy use in the residential and commercial sectors is characterized by energy consumed by households and the services sector (such as businesses, institutions and organizations), respectively [52]. Energy use in both of these sectors is predominantly for heating, cooling, lighting and water heating and for other appliances and equipment [52]. The residential sector accounts for about 40% of global energy used in buildings and industry [53]. This section presents the case being made for using hydrogen to decarbonize heat through the use of boilers or micro-combined heat and power (micro-CHP) systems.

Heat generation accounts for more than half of global-energy consumption and a third of global energy-related CO2 emissions [54]. In the UK, heat consumption currently accounts for 78% of total energy consumption and as much as 85% of domestic energy consumption when excluding transport [55]. Although decarbonizing heat has historically elicited far less attention than decarbonizing power, there is now a widespread acknowledgement of the need to replace current hydrocarbon fuels used for heat generation, mainly natural gas, with low-carbon alternatives if we are to meet climate change mitigation targets by 2050 [56]. Decarbonizing heat in buildings and industry is challenging. The approach to decarbonize heat has been the electrification of heat through the use of a range of technologies, including air or ground-source heat pumps, along with district heating (using low-carbon fuels), solar heating and biomass [53,57,58]. However, as the demand for heat is high and varies throughout the year for countries closer to the poles, these technology options, with high capital expenditure and no alternative function in periods of low heat demand, are costly. Furthermore, they tend to require behavioural or technological change. On the other hand, converting the gas network to hydrogen could provide low-carbon heating that could be less disruptive for consumers and potentially cheaper than current alternatives [17,18].

The use of hydrogen for heat was largely excluded or marginalized in heat assessment or policy documents until the publication of a white paper, commissioned by the H2FC SUPERGEN Hub (UK) in 2014 [53,59], on the role of hydrogen and fuel cells in decarbonizing heat. This white paper showed that both hydrogen and fuel cells could have a credible role in heat provision in the future. It concludes that existing gas networks could be converted to deliver hydrogen instead of natural gas, with heat produced using hydrogen boilers or micro-CHP fuel cells. More recently projects have been commissioned in the UK to further investigate the potential of using hydrogen for heating, including an engineering appraisal of converting the natural gas grid to supply hydrogen in Leeds, the third biggest city in UK. This study, known as the H21 Leeds City Gate report [17], concludes that conversion of the gas grid to hydrogen is technically feasible and economically viable. The study shows that the conversion can be done on a regional level over the summer period with low-cost changes to appliances. While there is a precedent for such a transition programme in the UK, with the conversion of town gas (a mixture of 50% hydrogen with methane (CH4) and carbon monoxide) to natural gas in the 1960s and 1970s, today's gas network is far more complex and requires the collaboration of government, different gas providers, local authorities and customers. In fact, customer acceptance of a new heating technology is very important and could be a significant barrier when changes are required. Natural gas is widely used in many developed (Organisation for Economic Co-operation and Development) countries. For example, in the UK and the Netherlands gas boilers are used in 80% of houses [35], and studies in the UK show a strong customer preference for using gas boilers, which are perceived as safer, cheaper, more effective and easy to control than their alternatives [60,61]. Furthermore, the equipment that already exists could be converted from using natural gas to using hydrogen, enabling a user experience similar to that provided by natural gas, and without the need for disruptive refurbishment of home heating infrastructures or expensive reinforcement of the electricity network [17,18].

Subsequent reports support the assertion that replacing CH4 with hydrogen in the grid in areas with an established gas infrastructure could potentially be more practical and economically viable than alternative options for decarbonizing heat [18,62]. Nonetheless, the success of such a transition depends on the availability of low-carbon hydrogen produced at affordable costs and at rates that meet the energy demand. The H21 Leeds City Gate study [24], which reports carbon emission reductions of 59%, provides an analysis of carbon savings and the financial costs on the basis of hydrogen production through steam methane reforming (SMR) with carbon capture and sequestration (CSS) and salt cavern storage of hydrogen. Salt caverns are available in the UK but CCS needs to be fully demonstrated. There are currently 21 large-scale CCS projects in operation or under construction globally, with a combined CO2 capture capacity of 40 million tonnes per annum [63]. A growing number of academic and industry reports are concluding that CCS technologies are needed to limit CO2 emissions and to limit global temperature rises to 2°C. While the cost of the technology is seen as a major barrier for policymakers, recent reports by the Parliamentary Advisory Group on CCS [64] and the Sustainable Gas Institute [65] in the UK show that, over time, the cost of emitting CO2 becomes far higher than the costs associated with CCS. For further information on the current status of CCS globally, see [63]. It should be noted that, in the long run, other options such as solar techniques or electrolysis, as discussed in §3a, may become more viable than SMR with CCS for producing low-carbon hydrogen.

There are other technical and operational challenges that will need to be addressed in converting the gas grid to supply hydrogen, due to the different properties of hydrogen and natural gas. Hydrogen has a lower volumetric energy density than natural gas, which will result in about 20% lower energy-carrying capacity for hydrogen in a pipeline of the same pipe diameter and pressure drop [53]. While the existing high-pressure gas pipelines (used for transmission) are unlikely to be suitable for carrying hydrogen, most of the investment in the gas grid is in the lower pressure pipelines, the intermediate and local distribution networks, and not the transmission systems [53]. These lower pressure pipelines, particularly those constructed of polyethylene, are considered to be suitable for carrying hydrogen [35]. The transport and distribution of hydrogen is discussed further in §4.

While hydrogen can be used in direct flame combustion boilers, catalytic boilers and gas-powered heat pumps for heating, the most efficient way of using it is in fuel cell micro-CHP systems [66]. Micro-CHP systems are energy conversion devices used to provide heat and electricity simultaneously with combined efficiencies of up to 85–90%. Micro-CHP systems, which gained attention after the first global oil crises in 1973, are mostly used in residential, commercial and industrial buildings. Most of these systems run on natural gas or liquid petroleum gas, but these can be redesigned to use hydrogen in a fuel cell [67]. Fuel cell micro-CHP offers the highest electrical efficiency of any CHP technology, more than 50% to AC power for some variants, as efficient as many conventional thermal power stations [53] while also enabling local use of waste heat without the need for heat networks. The uptake of these systems has been highest in the Asia-Pacific region, due to progressive government subsidies and policies, coupled with consumer interest. In Japan, through a public–private partnership programme (Ene-Farm), around 180 000 residential fuel cell micro-CHP units were sold from 2012 to September 2016, with 50 000 sold in 2016 [26]. Studies show significant carbon savings can be achieved using fuel cell micro-CHP systems: about a 30% reduction according to one study [68]. However, costs need to come down further: the same study [68] predicts that a production rate of 100 000 micro-CHP units per annum per manufacturer is needed for this technology to reach cost parity with conventional gas boilers in Europe. The possibility of using different fuels with micro-CHP systems makes the case for adopting these technologies stronger; natural gas can be used more efficiently in the short term, with bio-based gases in the medium term, and then hydrogen from a future pipeline network, as proposed by the UK HFC Roadmap [16].

Further analysis in different regions, coupled with technology demonstrations, is needed to better understand the broader implications of hydrogen conversion in the residential and commercial sectors. If realized, such a transition would create a pathway to establishing a hydrogen economy. The availability of low-carbon hydrogen in the gas grid not only will enable decarbonization of heat but also will create a synergy in decarbonizing transport, commercial buildings and industry.

(c). Use of hydrogen in industry

The energy consumed by industry is at least one-quarter of the global-energy consumption and more than half of the total primary energy produced when including energy industry losses and self-use [69]. Today, most of the demand generated for hydrogen, of the 60 million tonnes produced worldwide annually (enough to fuel more than 600 million FCEVs [70]), is for industrial applications [15]. Most of the hydrogen (53%) is used for ammonia production (mainly used for nitrogen fertilizers), followed by the oil industry and methanol synthesis (40%); the remainder (7%) is used in the production of polymers and resins [70,71]. These industries can use cheap and relatively impure hydrogen, derived mostly from reforming of fossil fuels [29]. In the EU, more than 60% of hydrogen is produced and used on industrial sites, one-third is generated from by-product sources, and less than 10% is supplied by merchants [15].

The oil industry uses hydrogen for refining crude oil via hydrocracking and hydrotreating, and to eliminate sulfur from diesel and petrol transportation fuels to meet fuel quality directives. Hydrogen production for use in today's refineries accounts for about 5–20% of total refinery emissions [72]. With the decline in light and sweet crude oils and the increasing use of super-heavy crude oils and heavy oil from tar sands, combined with the growth in demand for high-quality, low-sulfur fuels, the demand for hydrogen is growing [15]. Most of the hydrogen used today in the oil refining industry is produced using natural gas steam reformation, which releases CO2 into the atmosphere if not captured. While hydrogen is mostly used as a feedstock in these industries, it can also be used for heat and power generation in the most energy-intensive industries (e.g. steel, chemicals). With such levels of use in high-carbon-intensity industries, decarbonizing hydrogen production can significantly reduce the carbon footprint of fuels and manufactured products.

3. Hydrogen pathways in renewable energy integrated systems

Intermittent power generation from renewable energy technologies requires storage technologies that can provide storage capacity to balance supply and demand, with frequency control and other benefits such as curtailment minimization, demand-side management, contingency grid support, etc. [73]. Studies show the economic benefits of implementing storage to manage high levels of renewable electricity generation (e.g. in the UK £10bn yr−1 saving can potentially be realized with storage technologies in a 2050 high renewable energy scenario) [74]. In fact, the cost of wind power curtailment is increasing as their penetration increases; in 2014 Germany spent €82 m on electricity curtailment from wind power, and this cost is reported to be doubling every year [75]. Besides hydrogen, several different technologies are being investigated for grid-scale electricity storage including lithium ion batteries, redox flow batteries, compressed air energy storage, supercapacitors, thermal energy storage and flywheels. See the UK white paper [76] on grid-scale energy storage for more information on these technologies.

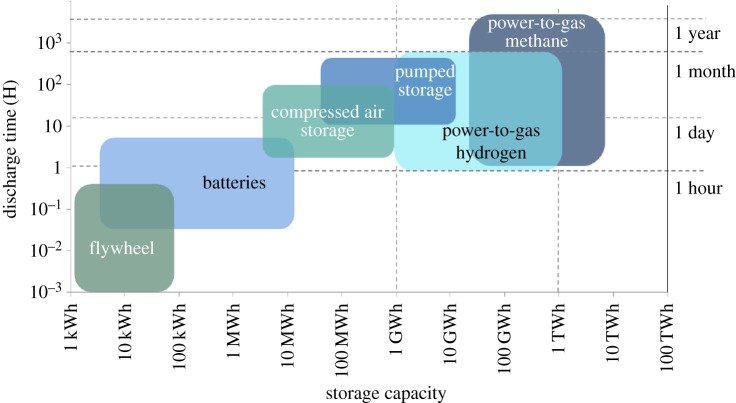

Hydrogen offers several advantages over other grid-scale storage options. Firstly, the use of hydrogen in the power or gas grid offers the opportunity to decarbonize all economic sectors. Secondly, hydrogen can store larger amounts of energy per unit volume than other large-scale energy storage options being considered: it has over 200 times the volumetric energy storage density of pumped hydro storage and 50 times that of compressed air [76]; see figure 1 for a comparison of storage densities against discharge time [77]. Thirdly, hydrogen can be used for both intra-day and inter-seasonal storage, enabling a greater degree of flexibility with day/night and seasonal variations. Different supply pathways exist for the production, storage, and transport and distribution (T&D) of hydrogen to the different end-use applications. The main supply pathways are discussed below as power-to-gas, power-to-power and gas-to-gas and illustrated in figure 2.

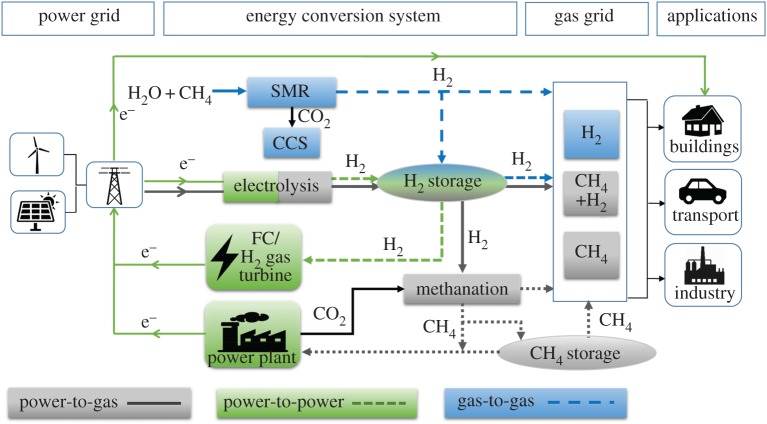

— Power-to-gas (P2G): Electricity is used to generate hydrogen via electrolysis. The hydrogen generated by this process is then either injected into the gas distribution grid (mixed with natural gas or used on its own) or transformed to synthetic CH4 in a subsequent methanation step. The methanation step combines hydrogen with captured CO2 in a methanation reactor (either thermochemical or biological) [5]. The hydrogen gas produced can be stored in both natural gas pipelines and storage sites. This option is gaining growing interest, especially because it can be combined with biogas plants being used for synthetic CH4 production, which enables direct use of the CO2 from the biogas for conversion into CH4 with hydrogen from water electrolysis [78]. This combination, with CCS added, is also interesting for the concept of negative CO2 emissions [79]. A systems analysis of P2G can be found in [5] and [80], with the short-term and long-term business opportunities analysis provided in [81].

— Power-to-power (P2P): Electricity is used to generate hydrogen via electrolysis. The hydrogen generated by this process is then stored in a pressurized tank (for small-scale applications) or an underground cavern (for grid-scale applications) or re-electrified when needed using a fuel cell (kW to MW scale) or a hydrogen gas turbine (multi-MW scale). The hydrogen produced in this case can also be used as a fuel for FCEVs in the transport sector, which is referred to as power-to-fuel in figure 3.

— Gas-to-gas (G2G): SMR is an established process for producing hydrogen from natural gas, and approximately 95% of hydrogen produced worldwide is produced through SMR technology. To lower the carbon footprint, CCS technology is needed to capture the CO2 released as the by-product. This is the pathway considered by the H21 Leeds City Gate study for decarbonizing heat in the UK [17].

Figure 1.

Storage technologies and power/energy characteristics [77]. (Online version in colour.)

Figure 2.

Schematic diagram showing the three main energy conversion pathways (power-to-gas, power-to-power and gas-to-gas) in a renewable energy integrated energy system. FC, fuel cell. (Online version in colour.)

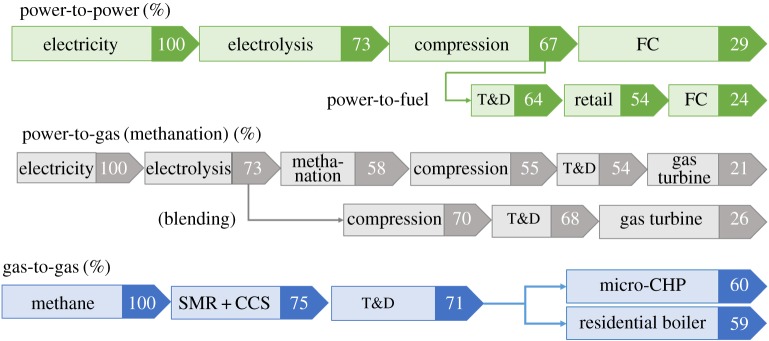

Figure 3.

The step conversion efficiencies for the hydrogen supply pathways being considered. Power-to-power and power-to-gas data from [15] and gas-to-gas data from a UKTM model (SMR+CCS efficiency of 75%, transport and distribution (T&D) loss of 5% (distribution only), residential boiler efficiency 84% and residential micro-CHP fuel cell efficiency 88%). (Online version in colour.)

The optimum hydrogen pathway depends on the trade-off between several factors, including system costs, efficiency, decarbonization impact and the practical feasibility (e.g. public acceptance) of changing the existing energy system in a given area to incorporate these new technologies. Some options may be more desirable on the basis of lower initial capital expenditure, even if it may not be the most optimal in terms of carbon savings. For example, blending hydrogen with CH4 has a limited benefit for decarbonization (80% hydrogen in the gas mixture by volume reduces CO2 emissions by 50%) [62], but requires less change and provides the opportunity to off-load surplus hydrogen produced from excess renewable power, rather than curtail it. However, the amount that can be blended depends on national gas standards, which vary between 0.5% and 25% by volume, with blends in excess of 20% hydrogen requiring end-user appliances to be converted [62] because of the effects of hydrogen on the Wobbe index [82].

An analysis of the total energy efficiency over the whole energy conversion chain is a good starting point for comparing the different pathways. Owing to the number of transformation steps the final efficiencies are rather low for P2P and P2G, in the range 20--30%, but in the case of G2G the final efficiency can be as high as 60% (figure 3).

According to the European Power to Gas Platform, there are approximately 40 P2G demonstration projects in Europe [83]. Germany is currently leading the way in terms of demonstrating the P2G and P2P concept at grid scale: 20 plants were reported to be in operation with 10 facilities being planned or under construction in August 2015 with a power range of 100 kWel to 6 MWel [84]. During the charging phase, the power of the system is determined by the size of the electrolyser and the energy stored is determined by the size and pressure of the hydrogen store. When using the hydrogen, the power and energy produced depends on the system being used to generate the power, with the approximate system efficiencies shown in figure 3. All hydrogen pathways are conditional on having low-carbon hydrogen production (e.g. electrolysis, CCS) facilities and the expansion of intra-day and/or seasonal storage facilities and networks, both topics that are explored in the next two sections.

(a). Hydrogen production at grid scale

One of the major challenges in enabling the hydrogen economy is the scaling up of hydrogen production. A strategic approach requires hydrogen to be produced from a large range of feedstocks using power from many indigenous energy sources—providing the opportunity for countries to become energy independent.

The main hydrogen production options available can be categorized into three main processes: (i) thermochemical, based on the reforming of natural gas, ethanol, biomass or heavy fuel oil, (ii) electrolytic and (iii) photolytic. These processes are at different stages of development, each with benefits and challenges as outlined in [85]. Today, the most advanced and scalable of these options is SMR (producing 95% of hydrogen used worldwide), followed by electrolysis (producing 4% of hydrogen used worldwide). Hence, these are the two main production routes considered in the supply pathways discussed above. While SMR is currently the cheapest route of production, the use of CCS technology is required to deliver low-carbon hydrogen from this route, which will increase the cost. For use in fuel cells (e.g. in FCEVs), the hydrogen produced through the SMR process needs to go through a purification step to obtain the high-purity hydrogen (more than 99.999%) needed to maintain the integrity of the fuel cell catalyst, adding to costs. For heat applications, if boilers are used, as considered by the H21 Leeds City Gate study [17], the hydrogen does not have to be high purity, but it may need to be if fuel cell micro-CHP systems are used, depending on the fuel cell type. SMR is considered to be the most viable in the near term (even without CCS) [85], and as an early market it can help build the hydrogen gas infrastructure needed.

Electrolysis requires high-purity water. Therefore, the water is first treated to remove the minerals and ions prior to the electrolysis process. However, the hydrogen produced is of high purity and can directly be used in fuel cells. When the electricity used is from renewables this process is completely clean (i.e. has no carbon emissions linked to the production step). Otherwise, the carbon footprint depends on the source of electricity. In the short term, this process can be used on site to make hydrogen at refuelling stations, using the existing water and electricity infrastructure. In the long term, renewable electricity will need to be used for the process at central or semi-central facilities. These facilities could potentially receive cost breaks from utilities by using ‘off-peak’ power to make it more economical, and/or also providing grid services such as frequency regulation.

Three main types of electrolyser exist. Alkaline water electrolysers, which have been commercially available for many years; PEM electrolysers, which are becoming commercially established; and solid oxide electrolysers, which are under development [76]. PEM electrolysers, which have instant power cycling capability and a low operational temperature range (80–100°C), are particularly suitable for use with renewables that have varying loads. While over 500 industrial systems exist worldwide (50 kW–4 MW range) [86], grid-scale demonstrations are needed. In 2013, the first grid-scale demonstration systems were connected to electricity networks, with the resulting hydrogen being injected into the local gas grid [87]. Today, producing a unit of hydrogen from water requires four times more energy than from hydrocarbons [88], even by 2025 US Department of Energy [89] estimates a future cost of $4.2 kg−1. Thus, capital cost reduction (e.g. with simplified designs, cheaper and more durable materials) as well as efficiency improvements are required to create a business case for using electrolysis in the grid. Electrolyser affordability, while dependent on system efficiency [90], will improve with increasing use of low-cost electricity, reinforced by income from the provision of balancing services to the electricity system [53]. For Europe, under a long-term decarbonization scenario with emission reduction targets of 80% below the 1990 levels in 2050, a study using the JRC-EU-TIMES model [91] shows electrolysers become the most important form of absorbing excess electricity in 2050. In this scenario, hydrogen obtained through electrolysis alone (using excess electricity from renewables) could constitute about 40% of the electricity stored.

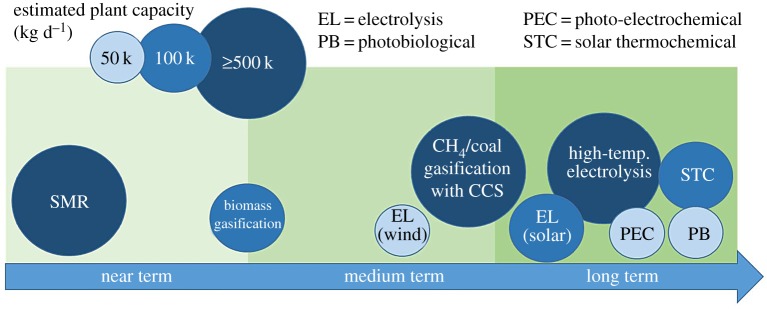

The US Department of Energy anticipates that, while in the short term SMR will continue to be used, in the mid-term hydrogen will be produced from wind-powered electrolysis and biomass gasification, and in the long term high-temperature electrolysis and production routes based on solar energy will be used [92] (as illustrated in figure 4). High-temperature electrolysis of water/steam may provide a cost-effective production of clean hydrogen, using solid oxide electrolysers. While this process will require a third less electricity than low-temperature electrolysis [85] due to higher electrical efficiencies, and is predicted to enable costs comparable to hydrogen production from fossil fuels [93], solid oxide electrolyser performance and lifetime improvements are needed.

Figure 4.

Hydrogen production pathways; expected transition of large-scale hydrogen production routes. (Modified from [92].) (Online version in colour.)

Other hydrogen production options to be developed for use in the long term include photo-electrochemical (PEC) processes (which use light energy to split water into hydrogen and oxygen) and biological processes (e.g. metabolic processes using microorganisms such as microalgae, cyanobacteria, etc.). These technologies are currently at a relatively early stage of development. Hydrogen production from biomass, if scaled and coupled with CCS, can enable a net removal of CO2 from the atmosphere using biomass hydrogen production pathways coupled with CCS, as supported by system-level analysis using the JRC-EU-TIMES model [91].

For a more comprehensive overview of the different hydrogen production technologies, see [85] and [94]; and for updates on system applications, see [95] and [96].

(b). Hydrogen storage at grid scale

Underground geological formations such as salt caverns, aquifers and depleted natural gas or oil reservoirs are considered as the most viable options for bulk hydrogen storage [97]. Hydrogen is already stored in salt caverns in the UK [17,98] and the USA [99–101] and similar hydrogen storage projects are underway across Europe [102]. Salt caverns typically have lower gas capacities but enable higher delivery rates (power throughput) and thus can be used for balancing diurnal variations in energy supply from renewables. Depleted oil reservoirs have high capacity but lower power (and response times) and thus are considered more suitable for seasonal storage.

Currently, salt caverns appear to be the most likely method of storing gaseous hydrogen for energy buffering, with hydrogen loss reported to be as little as 1% and no contamination issues [99,103,104]. A typical large salt cavern field with a volume of 8 × 106 m3 would provide a hydrogen energy storage capacity of 1.3 TWh per field [102] with storage pressures up to 120 bar. In the UK, over 30 large salt caverns (currently used for storing natural gas) are reported to exist [98] as well as many salt bed resources, which could provide tens of GWe storage capacity to the grid. Many depleted oil wells in the North Sea could add to this capacity [17].

For depleted oil and gas wells, initial studies give different results about their viability, highlighting the site-specific nature of geological storage. For example, Lord et al. [99] and Stone et al. [103] suggest that depleted oil and gas reservoirs and aquifers could both leak hydrogen and significantly contaminate hydrogen with impurities (thereby necessitating purification for PEM fuel cell applications). Nonetheless, Amid et al. [97] report that the losses could be reduced to less than 0.1%. Furthermore, Amid et al. [97] suggest that no insurmountable technical barriers appear to exist for hydrogen storage in a depleted gas reservoir for seasonal hydrogen storage. More assessments and pilot studies are needed to determine both the economic and practical viability of different options and each reservoir will need to be assessed on a case-by-case basis. Initial studies assessing the economic and performance characteristics of different hydrogen storage options show notable variations in the cost for a given option by region. A comparative analysis of grid-scale energy storage options in Europe, which looks at availability, performance and economics, etc., can be found in [102], and a more comprehensive economic analysis between large-scale hydrogen storage options, and alternatives, can be found in [101]. In summary, salt cavern stores are considered as a mature option today. Further analysis and pilot studies are needed to demonstrate that the other potential large-scale storage options, such as depleted oil/gas fields, rock caverns and aquifers, could be practically and economically viable.

4. Hydrogen transport and distribution

Hydrogen T&D infrastructure consists of pipelines connecting hydrogen production and storage points to end-use points. Because hydrogen can embrittle steel, and much of the existing high-pressure distribution and transmission pipelines are made of high-strength steel, the pipelines will need to be changed if hydrogen is to be transported through the natural gas pipeline network. That said, the feasibility of gas network conversion should be assessed on the basis of infrastructural changes (e.g. upgrades) that will be needed without the conversion to hydrogen. For example, in the UK, low-pressure pipelines require upgrades to reduce CH4 leakage on both safety and environmental grounds, and these are being converted to polyethylene pipes through what is known as the Iron Mains Replacement Programme. Polyethylene pipes are suitable for transporting hydrogen at low pressures [35]. Further work is needed to assess the suitability and, if need be, the conversion costs of all other system components such as seals between pipes, pressure reduction stations and the end-use components. Such a transition to G2G pathways will take time, and decisions will need to be made in the near term if the governments are to meet the 2050 CO2 reduction target by 2050, and to benefit financially in the long term.

Without infrastructure changes, the P2G model is inclined towards methanation or blending of small amounts of hydrogen. The blending of hydrogen with natural gas could be a transition step towards the conversion of the gas grid to exclusively transport hydrogen. At present, the main uncertainty in this supply pathway is with the amount of hydrogen that can be blended safely. The amount depends on the characteristics of the natural gas used as well as the design of existing appliances [105], and therefore will vary by region. An EU study (NaturalHy) [106] concludes that 30% hydrogen can be added without an adverse increase in risk to the public; another study suggests the safety limit as 20% in the Netherlands, although the standards set the limit as 12% [105]; in Germany, the set limit is 5%, with potential to increase to 20%; in the UK, one study [35] suggests that early levels of hydrogen should be limited to 2–3% within the UK natural gas pipeline. In the US State of Hawaii, the gas grid is already delivering a mix of natural gas with 10% hydrogen. As for the end-use appliances, NaturalHy study reports that with modifications to the appliances and favourable conditions of natural gas quality they can safely operate with up to 20% hydrogen in natural gas [106].

For further information on the conversion of the transmission pipelines for P2G or G2G, see [17,82,105,106] and for alternative hydrogen delivery pathways, see [107].

5. Conclusion

The increased production and use of hydrogen can support climate change and energy security goals within future low-carbon energy systems. The opportunities enabled by hydrogen are more easily captured if all economic sectors are considered and developed together. In transport, OEMs have already introduced hydrogen FCEVs into the market, and a refuelling infrastructure is being built through public–private partnerships with an increasing number of refuelling stations in Europe, Japan and the USA. FCEVs have the advantage of greater range and shorter refuelling time over battery electric vehicles.

With respect to transit solutions, FCEBs have been operating in several European cities and new programmes have been announced to increase their numbers in Europe. Plans for much larger fleets of FCEBs in Japan (over 100) and South Korea (tens of thousands) and China (thousands) have been unveiled. The rail and marine industry is coming forward with demonstration projects with hydrogen fuel cell trams, trains and boats.

Hydrogen offers an important opportunity to decarbonize heat, which is probably the most difficult challenge across the energy landscape. Initial studies show hydrogen to be a leading contender in terms of minimizing costs and disturbances to the customer when decarbonizing heat. However, government targets and policy measures will be required to produce hydrogen at scale with a low-carbon footprint, as higher carbon hydrogen is currently the incumbent technology in terms of cost and scale.

At the energy system level, hydrogen can enable greater penetration of renewables into the grid while carrying energy to all sectors without the need to build costly additional grid capacity. For hydrogen to be used within the gas network, geological (or other large scale) storage options need to be appraised for each region, as well as the suitability of gas pipelines to transmit hydrogen. Such appraisals would yield the most cost-effective pathways for hydrogen and the infrastructure changes needed. A coordinated and sustained effort is needed to drive such a massive transition across the energy landscape. All stakeholders have to ensure that the investment decisions made today do not saddle the energy system with technologies that are sub-optimal in the future. The synergies enabled by hydrogen with other low-carbon alternatives could potentially reduce costs in the long run. It is for these reasons that hydrogen deserves greater attention from governments, industry and academia to jointly assess its place within the future energy system, and to continue to take the steps necessary to demonstrate its benefits to the system as a whole.

Authors' contributions

This paper was conceived and written jointly by N.P.B. and Z.K.

Competing interests

The authors declare that there are no competing interests.

Funding

Funding for this work was provided by EPSRC grant no. EP/J016454/1 for the Hydrogen and Fuel Cell SUPERGEN Hub.

References

- 1.United Nations. 2016. Framework Convention on Climate Change (COP21) Paris Agreement. See http://unfccc.int/paris_agreement/items/9485.php.

- 2.IPCC. 2014. Fifth Assessment Report of the IPCC. Geneva, Switzerland: IPCC.

- 3.United Nations. 2016. World population projected to reach 9.7 billion by 2050. Department of Economic and Social Affairs. See http://www.un.org/en/development/desa/news/population/2015-report.html.

- 4.World Energy Scenarios. 2013. Composing energy futures to 2050. London, UK: World Energy Council. [Google Scholar]

- 5.Götz M, Lefebvre J, Mörs F, McDaniel Koch A, Graf F, Bajohr S, Reimert R, Kolb T. 2016. Renewable power-to-gas: a technological and economic review. Renewable Energy 85, 1371–1390. ( 10.1016/j.renene.2015.07.066) [DOI] [Google Scholar]

- 6.Renewables. 2016 REN21. 2016. Global Status Report. 2016 Renewable Energy Policy Network for the 21st Century. See http://www.ren21.net/wp-content/uploads/2016/10/REN21_GSR2016_FullReport_en_11.pdf.

- 7.Dr. John O'M. Bockris 1923–2013. Infinite Energy Magazine September/October, 30. See http://www.infinite-energy.com/images/pdfs/BockrisObit.pdf.

- 8.Rifkin J. 2004. The hydrogen economy. New York, NY: Tarcher/Penguin. [Google Scholar]

- 9.Ball M, Wietschel M. 2010. The hydrogen economy: opportunities and challenges. Cambridge, UK: Cambridge University Press. [Google Scholar]

- 10.The White House. 2003. Hydrogen economy fact sheet. See https://georgewbush-whitehouse.archives.gov/news/releases/2003/06/20030625-6.html.

- 11.Borthwick W. (ed). 2006. Overview of the hydrogen economy: perspectives from Europe. In Proc. Int. Seminar on the Hydrogen Economy for Sustainable Development, Reykjavik, Iceland, 28 September 2006. United Nations Department of Economic and Social Affairs.

- 12.European Commission. 2003. Hydrogen energy and fuel cells: a vision of our future. See http://www.fch.europa.eu/sites/default/files/documents/hlg_vision_report_en.pdf.

- 13.Ministry of Economy, Trade and Industry. 2016. Compilation of the revised version of the strategic roadmap for hydrogen and fuel cells. Tokyo, Japan: Ministry of Economy, Trade and Industry.

- 14.UK Committee on Climate Change. 2015. Sectoral scenarios for the Fifth Carbon Budget. London, UK: UK Committee on Climate Change.

- 15.International Energy Agency. 2015. Technology roadmap: hydrogen and fuel cells. Paris, France: International Energy Agency.

- 16.E4tech and Element Energy Hydrogen and Fuel Cells. 2016. Opportunities for growth (a roadmap for the UK). London, UK: E4tech and Element Energy. [Google Scholar]

- 17.Northern Gas Networks, Kiwa Gastec and Amec Foster Wheeler. 2016. H21 Leeds City Gate report. Northern Gas Networks, Kiwa Gastec and Amec Foster Wheeler.

- 18.KPMG. 2016. The UK Gas Networks role in a 2050 whole energy system. 2050 Energy Scenarios. See http://www.energynetworks.org/assets/files/gas/futures/KPMG%202050%20Energy%20Scenarios%20-%20The%20UK%20Gas%20Networks%20role%20in%20a%202050%20whole%20en...1.pdf.

- 19. H2USA. 2013. See http://h2usa.org/ .

- 20. Fuel Cell and Hydrogen Joint Undertaking (FCHJU) European Union. See http://www.fch.europa.eu/ .

- 21. International Partnerships for Hydrogen and Fuel Cells in the Economy (IPHE). See http://www.iphe.net/index.html .

- 22.Government of India, Hydrogen Energy and Fuel Cells. 2016. A way forward. ministry of new and renewable Energy. New Delhi, India: Government of India. [Google Scholar]

- 23. Fuel Cells and Hydrogen (FCH) Joint Undertaking. 2016 European regions and cities to enable market entry of fuel cells and hydrogen technologies. See http://www.fch.europa.eu/news/european-regions-and-cities-enable-market-entry-fuel-cells-and-hydrogen-technologies .

- 24.Antoni L, Frois B. 2016. IPHE Country Update May 2016: FRANCE. International Partnership for Hydrogen and Fuel Cell in the Economy. See http://www.iphe.net/docs/Meetings/SC25/25-SC-Statement-France.pdf.

- 25. US Department of Energy. 2016 H2 at scale: deeply decarbonising our energy system. See https://www.hydrogen.energy.gov/pdfs/htac_apr16_10_pivovar.pdf .

- 26.E4tech. 2016 The fuel cell industry review 2016. London, UK: E4tech.

- 27.U.S. Energy Information Administration. 2016 International energy outlook 2016. Report no. DOE/EIA-0484(2016). See https://www.eia.gov/outlooks/ieo/pdf/0484(2016).pdf.

- 28.International Energy Agency. 2009. Transport, energy and CO2: moving toward sustainability. Paris, France: International Energy Agency. [Google Scholar]

- 29.California Fuel Cell Partnership. 2013. Air, climate, energy, water security: a guide to understanding the well-to-wheels impact of fuel cell electric vehicles. See http://cafcp.org/sites/default/files/W2W-2014_Final.pdf.

- 30.International Energy Agency. 2016. Energy technology perspectives 2016: towards sustainable urban energy systems. Paris, France: International Energy Agency. [Google Scholar]

- 31. HyFIVE. 2017 Hydrogen for Innovation Vehicles. See http://www.hyfive.eu/the-hyfive-project/ .

- 32. Tesla Model 3. See https://www.tesla.com/en_GB/model3 .

- 33.Spendelow J, Marcinkoski J.2014. Fuel cell system cost—2013. See https://www.hydrogen.energy.gov/pdfs/14012_fuel_cell_system_cost_2013.pdf .

- 34.McKinsey & Company for Fuel Cells and Hydrogen Joint Undertaking. 2010. A portfolio of power-trains for Europe: a fact-based analysis. See http://www.fch.europa.eu/sites/default/files/documents/ga2010/martin_linder.pdf.

- 35.Dodds PE, McDowall W. 2013. The future of the UK gas network. Energy Policy. 60, 305–316. ( 10.1016/j.enpol.2013.05.030) [DOI] [Google Scholar]

- 36.US Department of Energy. 2015. Quadrennial technology review 2015. Chapter 8: Advancing clean transportation and vehicle systems and technologies. See https://www.energy.gov/sites/prod/files/2015/09/f26/QTR2015-08-Transportation.pdf.

- 37.Offer GJ, Contestabile M, Howey DA, Clague R, Brandon NP. 2011. Techno-economic and behavioural analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system in the UK. Energy Policy 39, 1939–1950. ( 10.1016/j.enpol.2011.01.006) [DOI] [Google Scholar]

- 38.Gröger O, Gasteiger HA, Suchslandc J-P. 2015. Review—Electromobility: batteries or fuel cells? J. Electrochem. Soc. 162, A2605–A2622. ( 10.1149/2.0211514jes) [DOI] [Google Scholar]

- 39.Roland Berger Strategy Consultants. 2015. Fuel cell electric buses—potential for sustainable public transport in Europe. See http://www.fch.europa.eu/sites/default/files/150909_FINAL_Bus_Study_Report_OUT_0.PDF.

- 40. CHIC: Clean Hydrogen In European Cities. See http://chic-project.eu/ .

- 41.Wang C, Wang S, Peng L, Zhang J, Shao Z, Huang J, Sun C, Ouyang M, He X. 2016. Recent progress on the key materials and components for proton exchange membrane fuel cells in vehicle applications. Energies 9, 603 ( 10.3390/en9080603) [DOI] [Google Scholar]

- 42.Ball MW. 2009. The future of hydrogen—opportunities and challenges. Int. J. Hydrogen Energy 32, 615–627. ( 10.1016/j.ijhydene.2008.11.014) [DOI] [Google Scholar]

- 43. Hydrogen Mobility Europe. See http://h2me.eu/ .

- 44. TUV-SUD. 92 new hydrogen refuelling stations worldwide in 2016. See http://www.tuev-sued.de/company/press/press-archive/54-new-hydrogen-refuelling-stations-worldwide-in-2015 .

- 45.Fuel Cells Bulletin, German partners in H2 Mobility Deutschland grow fueling network, Fuel Cells Bulletin, Volume 2015, Issue 11, pp 6–7.

- 46.California Environmental Protection: Air Resources Board. 2015 Annual evaluation of fuel cell electric vehicle deployment and hydrogen fuel station network. West Sacramento, CA: California Environmental Protection: Air Resources Board.

- 47. Bristol Hydrogen Boats. See http://www.bristolhydrogenboats.co.uk/about.html .

- 48. World's first hydrogen powered boat smashes targets. See http://www.cheetahmarine.co.uk/en/deliveries/worlds-first-hydrogen-powered-boat-smashes-targets .

- 49. Scotland's voyage towards a zero emission ferry. See http://www.all-energy.co.uk/__novadocuments/54300?v=635376603478400000 .

- 50. Ballard. 2012 Fuel cells for rail applications. Hydrail Conference, Birmingham, UK, 5 July 2012. See http://hydrail.org/sites/hydrail.org/files/11_laperche-riteau.pdf .

- 51.Alstom. 2016 Alstom unveils its zero-emission train Coradia iLint at InnoTrans. See http://www.alstom.com/press-centre/2016/9/alstom-unveils-its-zero-emission-train-coradia-ilint-at-innotrans/.

- 52.World Energy Outlook Special Report. 2016. 2016 Energy and air pollution. Paris, France: International Energy Agency. [Google Scholar]

- 53.Dodds PE, Staffell I, Hawkes AD, Li F, Grunewald P, McDowall W, Ekins P. 2015. Hydrogen and fuel cell technologies for heating: a review. Int. J. Hydrogen Energy 40, 2065–2083. ( 10.1016/j.ijhydene.2014.11.059) [DOI] [Google Scholar]

- 54.Eisentraut A, Brown A. 2014. Heating without global warming. Paris, France: International Energy Agency. [Google Scholar]

- 55.Department for Business and Industrial Strategy, National Statistics. 2016 Energy consumption in the UK. See https://www.gov.uk/government/statistics/energy-consumption-in-the-uk.

- 56.Skea J. 2012. Research and evidence needs for decarbonisation in the built environment: a UK case study. Building Res. Info. 40, 432–445. ( 10.1080/09613218.2012.670395) [DOI] [Google Scholar]

- 57.Department of Energy and Climate Change. 2012 The future of heating: a strategic framework for low carbon heat in the UK. London, UK: Department of Energy and Climate Change.

- 58.Hoggett R, Ward J, Mitchell C. 2011. Heat in homes: customer choice on fuel and technologies study for scotia gas networks by energy policy group. Exeter, UK: University of Exeter. [Google Scholar]

- 59.Dodds PE, et al. 2014. The role of hydrogen and fuel cells in providing affordable, secure low-carbon heat. London, UK: H2FC SUPERGEN. [Google Scholar]

- 60.UK DECC (Precursor to BEIS). 2013 Home owners' willingness to take up more efficient heating systems. London, UK: Department of Energy and Climate Change.

- 61.Parkhill K, Demski C, Butler C, Spence A, Pidgeon N. 2016. Transforming the UK energy system—public values, attitudes and acceptability. London, UK: Energy Research Centre. [Google Scholar]

- 62.Energy Research Partnership, UK. 2016 Potential role of hydrogen in the UK energy system. London, UK: Energy Research Partnership, UK.

- 63.Global CCS Institute. 2016 The global status of CCS 2016—summary report. Docklands, Australia: Global CCS Institute.

- 64.Parliamentary Advisory Group on CCS. 2016. Lowest cost decarbonisation for the UK: the critical role of CCS. Report of the Parliamentary Advisory Group on CCS—Report to the Secretary of State for Business, Energy & Industrial Strategy. See www.ccsassociation.org/index.php/download_file/view/1043/508/.

- 65.Budinis S, Krevor S, Mac Dowell N, Brandon N, Hawkes A. 2016. Can technology unlock unburnable carbon (White Paper). London, UK: Sustainable Gas Institute, Imperial College. [Google Scholar]

- 66.Ellamla HR, Staffell I, Bujlo P, Pollet BG, Pasupathi S. 2015. Current status of fuel cell based combined heat and power systems for residential sector. J. Power Sources 293, 312–328. ( 10.1016/j.jpowsour.2015.05.050) [DOI] [Google Scholar]

- 67.Chiesa P, Lozza G, Mazzocchi L. 2005. Using hydrogen as gas turbine fuel. J. Eng. Gas Turbines Power 127, 73–80. ( 10.1115/1.1787513) [DOI] [Google Scholar]

- 68.Roland Berger Strategy Consultants, Fuel Cells and Hydrogen Joint Partnerhip. 2015. Advancing Europe's energy systems: stationary fuel cells in distributed generation. Roland Berger Strategy Consultants, Fuel Cells and Hydrogen Joint Partnership.

- 69.International Energy Agency. 2016 Key world energy statistics 2016. See https://www.iea.org/publications/freepublications/publication/KeyWorld2016.pdf.

- 70.Ball M, Weeda M. 2015. The hydrogen economy—vision or reality? Int. J. Hydrogen Energy 40, 7903–7919. ( 10.1016/j.ijhydene.2015.04.032) [DOI] [Google Scholar]

- 71. Essential Chemical Industry. See http://www.essentialchemicalindustry.org/chemicals/hydrogen.html .

- 72.European Technology Platform for Zero Emission Fossil Fuel Power Plants. 2013 CO2 Capture and Storage (CCS) in energy-intensive industries. See http://www.zeroemissionsplatform.eu/library/publication/222-ccsotherind.html.

- 73.Castagneto-Gissey G, Dodds PE. 2016. Regulatory challenges to energy storage deployment: realising energy storage technologies in low-carbon energy systems (Working Paper 1). [Google Scholar]

- 74.Strbac G, et al. 2012. Strategic assessment of the role and value of energy storage systems in the UK low carbon energy future. London, UK: Carbon Trust. [Google Scholar]

- 75.Bundesnetzagentur, Bundeskartellamt. 2016 Monitoring report 2015. See https://www.bundesnetzagentur.de/SharedDocs/Downloads/EN/BNetzA/PressSection/ReportsPublications/2015/Monitoring_Report_2015_Korr.pdf?_blob=publicationFile&v=4.

- 76.Brandon NP, et al. 2016. UK research needs in grid scale energy storage technologies. See http://energysuperstore.org/wp-content/uploads/2016/04/IMPJ4129_White_Paper_UK-Research-Needs-in-Grid-Scale-Energy-Storage-Technologies_WEB.pdf. [Google Scholar]

- 77.California Hydrogen Business Council. 2015. The case for hydrogen (White Paper). Yorba Linda, CA: California Hydrogen Business Council. [Google Scholar]

- 78.Institute of Chemical Engineering. Combination of power-to-gas with biogas plant. Vienna, Austria: Institute of Chemical Engineering; See https://www.tuwien.ac.at/fileadmin/t/tuwien/downloads/Publishing_Texte/Marokko2016_Combination_Power-to-Gas_Biogas_Plant.pdf. [Google Scholar]

- 79.U.S. Department of Agriculture, U.S. Environmental Protection Agency, U.S. Department of Energy. 2014 Biogas opportunities roadmap. See https://www.energy.gov/sites/prod/files/2015/12/f27/biogas_opportunites_roadmap_progress_report_0.pdf.

- 80.Ormandy D, Ezratty V. 2012. Health and thermal comfort: From WHO guidance to housing strategies. Energy Policy 49, 116–121. ( 10.1016/j.enpol.2011.09.003) [DOI] [Google Scholar]

- 81.Vanhoudt W, Barth F, Lanoix J-C, Neave J, Schmidt PR, Weindorf W, Raksha T, Zerhusen J, Michalski J. 2016. Power-to-gas. Short term and long term opportunities to leverage synergies between the electricity and transport sectors through power-to-hydrogen. See http://www.lbst.de/download/2016/Hinicio-LBST_2016_PtH2-study_Fondation-Tuck.pdf.

- 82.Grond L, Schulze P, Holstein J. 2013. Systems analyses power to gas: a technology review. Groningen, The Netherlands: DNV KEMA Energy & Sustainability. [Google Scholar]

- 83. Power to Gas projects in Europe European Power to Gas. See http://www.europeanpowertogas.com/demonstrations .

- 84.DENA. 2015 Power to gas system solution. Berlin, Germany: DENA—German Energy Agency.

- 85.The FreedomCAR and Fuel Partnership, USA. 2009. Hydrogen production. Overview of technology options. See https://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/h2_tech_roadmap.pdf.

- 86.Thomas D.2016. Alkaline vs PEM electrolysers: lessons learnt from Falkenhagen and WindGas Hamburg: Hydrogenics. See http://www.hydrogendays.cz/2016/admin/scripts/source/presentations/PL%2005_%20Denis%20Thomas_HDs2016.pdf .

- 87.ITM Power. 2015. Thüga power-to-gas plant. Sheffield, UK: ITM Power; See http://www.itm-power.com/project/thuga-power-to-gas [Google Scholar]

- 88.Millet P. 2015. Hydrogen production by polymer electrolyte membrane water electrolysis. In Compendium of hydrogen energy (eds Basile A, Veziroğlu TN), pp. 255–286. Oxford, UK: Woodhead Publishing. [Google Scholar]

- 89.US Department of Energy. 2015. Current central hydrogen production from natural gas without CO2 sequestration. In Central natural gas. 3.101 Ed. (ed. US DoE). Washington, DC: US DoE. [Google Scholar]

- 90.Dodds PE. 2015. Economics of hydrogen production. In Compendium of hydrogen energy (eds Subramani V, Basile A, Veziroğlu TN), pp. 63–79. Oxford, UK: Woodhead Publishing. [Google Scholar]

- 91.Sgobbi A, Nijs W, De Miglio R, Chiodi A, Gargiulo M, Thiel C. 2016. How far away is hydrogen? Its role in the medium and long-term decarbonisation of the European energy system. Int. J. Hydrogen Energy 41, 19–35. ( 10.1016/j.ijhydene.2015.09.004) [DOI] [Google Scholar]

- 92. US Department of Energy. 2017 Hydrogen production pathways. See http://energy.gov/eere/fuelcells/hydrogen-production-pathways .

- 93.Hauch A, Ebbesen SD, Højgaard Jensena S, Mogensena M. 2008. Highly efficient high temperature electrolysis. J. Mater. Chem. 18, 2331–2340. ( 10.1039/b718822f) [DOI] [Google Scholar]

- 94.US Office of Energy Efficiency & Renewable Energy: The FreedomCAR and Fuel Partnership. 2009. Hydrogen production and overview of technology options. See https://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/h2_tech_roadmap.pdf.

- 95.Thomas D.2016. Latest developments in large scale stationary hydrogen and fuel cells applications @ Hydrogenics. See http://www.climate-change-solutions.co.uk/wp-content/uploads/2016/03/DenisThomas.pdf .

- 96.ITM Power. 2016 Report and financial statements: year ended 30 April 2016. See http://www.itm-power.com/wp-content/uploads/2016/07/ITM-Annual-Report-2016.pdf.

- 97.Amid A, Mignard D, Wilkinson M.. 2016. Seasonal storage of hydrogen in a depleted natural gas reservoir. Int. J. Hydrogen Energy 41, 5549–5558. ( 10.1016/j.ijhydene.2016.02.036) [DOI] [Google Scholar]

- 98.Gammer D. 2015. The role of hydrogen storage in a clean responsive power system. Loughborough, UK: Energy Technologies Institute. [Google Scholar]

- 99.Lord AS, Kobos PH, Borns DJ. 2014. Geologic storage of hydrogen: scaling up to meet city transportation demands. Int. J. Hydrogen Energy 39, 15 570–15 582. ( 10.1016/j.ijhydene.2014.07.121) [DOI] [Google Scholar]

- 100.Lord AS, Kobos PH, Klise GT, Borns DJ. 2011. A life cycle cost analysis framework for geologic storage of hydrogen: a user's tool. Livermore, CA: Sandia National Laboratories. [Google Scholar]

- 101.Schoenung S. 2011. Economic analysis of large-scale hydrogen storage for renewable utility applications. Livermore, CA: Sandia National Laboratories. [Google Scholar]

- 102.Bünger U, Raksha T, Weindorf W, Simón J, Correas L, Crotogino F. 2014. HyUnder Project: assessment of the potential, the actors and relevant business cases for large scale and long term storage of renewable electricity by hydrogen underground storage in Europe. See http://hyunder.eu/wp-content/uploads/2016/01/D8.1_HyUnder-Executive-Summary.pdf.

- 103.Stone HBJ, Veldhuis I, Richardson RN. 2009. Underground hydrogen storage in the UK. Geol. Soc. Lond. Special Publ. 313, 217–226. ( 10.1144/SP313.13) [DOI] [Google Scholar]

- 104.Usher W, Strachan N. 2012. Critical mid-term uncertainties in long-term decarbonisation pathways. Energy Policy 41, 433–444. ( 10.1016/j.enpol.2011.11.004) [DOI] [Google Scholar]

- 105.Melaina MW, Antonia O, Penev M. 2013. Blending hydrogen into natural gas pipeline networks: a review of key issues. Golden, CO: National Renewable Energy Laboratory. [Google Scholar]

- 106.Florisson O.2010. NATURALHY: Assessing the potential of the existing natural gas network for hydrogen delivery. See http://www.gerg.eu/public/uploads/files/publications/academic_network/2010/1b_Florisson.pdf .

- 107.US Department of Energy. 2013. Hydrogen delivery technical team roadmap. United States driving research and innovation for vehicle efficiency and energy sustainability. See https://energy.gov/sites/prod/files/2014/02/f8/hdtt_roadmap_june2013.pdf. [Google Scholar]