Abstract

The challenge of science and technology is to design and make materials that will dominate the future of our society. In this context, black phosphorus has emerged as a new, intriguing two‐dimensional (2D) material, together with its monolayer, which is referred to as phosphorene. The exploration of this new 2D material demands various fabrication methods to achieve potential applications— this demand motivated this review. This article is aimed at supplementing the concrete understanding of existing phosphorene fabrication techniques, which forms the foundation for a variety of applications. Here, the major issue of the degradation encountered in realizing devices based on few‐layered black phosphorus and phosphorene is reviewed. The prospects of phosphorene in future research are also described by discussing its significance and explaining ways to advance state‐of‐art of phosphorene‐based devices. In addition, a detailed presentation on the demand for future studies to promote well‐systemized fabrication methods towards large‐area, high‐yield and perfectly protected phosphorene for the development of reliable devices in optoelectronic applications and other areas is offered.

Keywords: black phosphorus, exfoliation, fabrication, passivation, phosphorene, two‐dimensional materials

1. Introduction

As a result of the interest brought about by the superior optical and electronic properties of graphene, two‐dimensional (2D) materials have been extensively studied in recent years due to their widespread applications in the field of novel photonic devices, including photodetectors, optical absorbers, optical modulators, and fiber lasers.1, 2 Most of the applications currently being developed with 2D materials are particularly pertinent because they directly address many of the scientific challenges confronting the modern world. These materials, as a result of their self‐limiting nature, have emerged as candidates with a great capability to move present research from the nanometer scale to the 2D regime by supplementing innumerable research opportunities to allow exploration of the photonic applications based on them. The key factor of 2D materials lies on the ability of their band gap (E g) to be tuned based on the thickness of their layers so they exhibit either insulator or metal properties; this advantage can be employed in broadband photonic device applications.3, 4

However, so far the available 2D materials have either a very small band gap, from zero to about 0.3 eV (e.g., graphene and metallic dichalcogenides), or a reasonably large band gap, from 1 to 2 eV (e.g., semiconducting dichalcogenides). In this light, black phosphorous (BP), a new class of 2D layered materials with a layer‐dependent band gap ranging from 0.3 eV (bulk) to 1.5 eV (monolayer), can bridge the gap between the gapless graphene and large band gap transition metal dichalcogenides (TMDCs). Unlike few‐layer TMDCs, which mostly have an indirect band gap, few‐layer BP always has a direct bandgap for all thicknesses, a significant benefit for optoelectronic applications.5, 6, 7 Furthermore, the carrier mobility of phosphorene is significantly higher than other 2D materials including transition TMDCs. Phosphorene conducts electrons quickly, at a similar rate as that of graphene, but it has a considerable band gap, which is absent in graphene.8, 9, 10, 11, 12 The most striking property of layered BP is its in‐plane anisotropy, i.e., angular‐dependent optical conductivity and carrier mobility.13 One intriguing prospect is that heterostructures consisting of BP and another isotropic material may inherit anisotropic electrical and optical properties from BP, leading to new characteristics and possible optoelectronic applications. In addition, the strong resonant absorption of BP at infrared telecommunication wavelengths as well as its ultrafast carrier dynamics makes it an attractive saturable absorber for ultrafast laser photonics.14

It is noteworthy that BP is the only stable form of phosphorus that can be mechanically exfoliated in a similar manner as that of graphene and other 2D materials.15 BP can be produced from red phosphorous under high temperature and high pressure, where the layers (L) in BP are held by weak interlayer van der Waals forces.5 Remarkably, the layered black phosphorous (BP) material can be reduced to one single atomic layer in the vertical direction as a result of its van der Waals structure. The monolayer of BP, known as phosphorene, exhibits physical properties that can be significantly different from those of its bulk counterpart.16 Phosphorene has changed the landscape of many research areas in science and technology, particularly in condensed matter physics, and it has received much attention recently for its use as the base component of novel nanodevices, e.g., transistors, nanomechanical resonators, photovoltaics, photodetectors, batteries and sensors.9, 10, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37

The important challenge in realizing phosphorene devices is caused by its strong reaction with oxygen and water and so it should be well‐protected from degradation by encapsulating or sandwiching between different materials. According to a survey, 80% of the papers published in phosphorene are found to be at the theoretical level and there are many things as yet unexplored.38 The production of cheap, uniform, defect‐free layers and their simplicity are promising in the field of phosphorene device fabrication, and this forms the main scope of the present review.

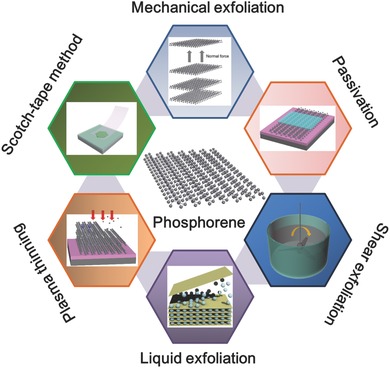

The rapidly increasing number of publications in the area of phosphorene research forms a strong motivation for the comprehensive review presented here. The presented review is organized with an emphasis on the fabrication of phosphorene, as it is the dominant topic in the area of 2D materials research. In this review we describe the recent progress in BP from the viewpoint of fabrication and the underlying mechanisms that are related to it. The review begins with an overview of the structure of phosphorene and continues by highlighting the properties of phosphorene. The production of phosphorene by different methods is discussed under two main topics: growth of bulk and few‐layered BP. Special attention is given to tabulating the experimental details with all growth parameters to benefit readers and researchers who are interested in this field. This review includes a detailed discussion of the key lessons learnt from the different fabrication techniques as well as the major difficulties encountered by researchers in implementing phosphorene in different device structures. Figure 1 gives a schematic representation of the overview of the review presented here.

Figure 1.

Schematic representation for the overview of the present review.

2. Structure and Fundamentals of Phosphorene

In the past year, a new two‐dimensional material, i.e., BP has generated considerable excitement in the research community. Tremendous efforts are still ongoing to uncover the full potential of BP. Remarkably, the recent successful demonstration of phosphorene, the monolayer of BP, has given a renaissance to this material. The crystal structure of BP was first determined in 1935 from X‐ray diffraction studies of BP powder by Hultgren et al.39

2.1. Structure of Black Phosphorus and Phosphorene

Phosphorene has a puckered structure with reduced symmetry, in comparison to graphene, that gives rise to two anisotropic in‐plane directions.40 Figure 2 shows the lattice structure of phosphorene and the electronic band structures of monolayer, bilayer, trilayer and bulk BP. Due to the puckered configuration of phosphorene, anisotropy is observed in its optical properties,41, 42, 43 mechanical properties,13, 44, 45, 46 thermoelectric properties,47 electrical conductance48 and Poisson's ratio.45, 49, 50, 51 The high in‐plane anisotropic conductivity of few‐layer BP has also been reported.41 The quasi‐two‐dimensional puckered structure results in a highly anisotropic and nonlinear Young's modulus and ultimate strain.46 These anisotropic behaviors were found to be modulated with the biaxial or uniaxial strain imposed on BP, and the anisotropy could pave the way for realizing novel optoelectronic, electronic and nano‐mechanical devices using BP.40, 45, 48, 52, 53 The atomic layers of BP are stacked together by means of van der Waals interactions similar to those in graphene. Interestingly, single‐layer BP is covalently bonded with sp3 phosphorus atoms, where each phosphorus atom is covalently bonded to three neighboring phosphorus atoms with one lone pair of electrons, thereby forming a quadrangular pyramid‐shaped structure. Favron et al.54 designated the monolayer of exfoliated BP as stratophosphane or 2D‐phosphane instead of phosphorene, because the monolayer is made up of tervalent phosphorus atoms in agreement with the IUPAC nomenclature of the phosphane group. The top and side views of the three stacking structures AC, AA and AB for bilayer BP, together with their corresponding band structures, are presented in Figure 3 a–f. It is found that three stackings represent the stacking manner in their respective band structures where the decrease in the interlayer nearest P atoms distance cause the increase in interlayer Coulomb interactions. Hence, AC stacking has the maximum energy barrier at the time of sliding processes with comparatively harder exfoliation than the other sliding pathways.55

Figure 2.

a) Three‐dimensional lattice structure of phosphorene. Reproduced with permission.22 Copyright 2014, American Institute of Physics. b) Lattice structure of BP with atomic vibrational patterns of the phonon modes (A1g, B2g and A). Reproduced with permission.148 Copyright 2015, Nature Publishing Group. c) Crystalline orientation of 15L BP flake. Reproduced with permission.63 Copyright 2014, American Chemical Society. d) Calculated electronic band structure of monolayer, bilayer, trilayer and bulk BP in Brillouin zone in which the energy is scaled with respect to Fermi energy E F. Reproduced with permission.156 Copyright 2014, IOP.

Figure 3.

Top (left panel) and side (right panel) views of three stacking structures for bilayer BP: a) AC, b) AA and c) AB stacking. d–f) The corresponding band structures for the three stackings mentioned above. The Fermi level is set to 0 eV. The valence bands VB1 and VB2, as well as the conduction bands CB1 and CB2, are denoted in (f). Reproduced with permission.55 Copyright 2015, IOP. g–i) Schematic diagram of saturable absorption in multi‐layer BP nanoparticles. Reproduced with permission.12 Copyright 2015, The Optical Society of America.

2.2. Properties

BP is a semiconductor with a direct band gap that is layer‐dependent and varies significantly between ≈2.2 eV in a monolayer and ≈0.3 eV in the bulk.34, 41, 42, 56, 57, 58, 59, 60, 61, 62, 63, 64, 65, 66 As a direct and narrow‐bandgap semiconductor, p‐type black phosphorus has significant advantages as a building block for functional optoelectronic devices.56, 67 Phosphorene monolayer (0.53‐nm thick) is a semiconductor with a direct band gap of 0.9 eV.57, 68 It has been reported that its E g varies significantly between 0.9 eV in a monolayer and 0.1 eV in the bulk with the capability of tuning the electronic properties.69 The optical conductivity and optical absorption spectra of multi‐layer black phosphorus are reported to vary with the layer thickness, doping and light polarization at a frequency range of 2500 to 5000 cm−1.43 BP flakes have shown exciting electronic properties, as indicated by their hole mobility of 100 cm2 V−1 s−1 to 1000 cm2 V−1 s−1 with an on/off ratio of 102 to 105 at room temperature.21, 22, 35 As reflected from its structural anisotropy, BP has a larger carrier mobility than MoS2 and its photoresponsivity is larger than that of graphene.21, 26, 34, 70, 71 Combined with its high mobility, this shows potential for use in fast and broadband photodetector and solar cell applications.24, 41

Theoretical studies have shown that the in‐plane Young's modulus and ideal strain values of single‐layer BP are 41.3 GPa and 0.48, respectively, in the direction perpendicular to the pucker, and 106.4 GPa and 0.11, respectively, in the parallel direction.46 BP has the ability to withstand a tensile strain of up to 30% and 32% for monolayer and multi‐layer BP, respectively; the superior flexibility of phosphorene can also be utilized for practical large‐magnitude strain engineering.46, 72 The presence of a negative Poisson's ratio (ν = –0.027) in the out‐of‐plane direction under a uniaxial deformation in the direction parallel to the pucker in single‐layer BP was confirmed from first‐principles calculations.49 Due to the Hall mobility in the BP two‐dimensional electron gas, quantum oscillations at the extreme quantum limit are observed.73 Its Seebeck coefficient (S), measured at a temperature of 300 K to 385 K, is found to be S = +335 ± 10 µV K–1 at room temperature, which is evidence of a naturally occurring p‐type conductivity.74 Apart from its ability to tune the band gap between the valence band and conduction band local extrema, strain also plays a significant role in tuning the effective masses, thereby affecting the exciton anisotropy and binding strength.75 The properties of BP depends on the layer thickness,42 applied strain force,45, 48, 52, 53, 64, 76 stacking order77, 78 and external electric field,79 enabling the realization of devices for different applications such as electronics,35, 37, 80, 81, 82, 83 optoelectronics,84, 85, 86 energy storage,79, 87 saturable absorbers (SA),2, 88, 89, 90, 91, 92 pulsed lasers93, 94, 95 and sensing.96

In particular, the nonlinear optical property in terms of saturable absorption was observed in BP flake as well as its composites.2, 90, 93 Figure 3g–i depicts the schematic diagram of the saturable absorption in multi‐layer BP nanoparticles. A saturable absorber is a passive mode‐locking element for the generation of ultrashort pulses in solid‐state lasers. The mode‐locking and Q‐switching operation of fiber lasers based on BP is generously influenced by the saturable absorption parameters that form a major part of periodically modulating intracavity loss and managing the continuous‐wave laser into pulsed operations. BP‐based SAs with 648 fs, 940 fs, 786 fs and 272 fs mode‐locked pulses around 1.5 µm have been produced with the aid of Er‐doped fiber lasers showed maximum average output powers of 5.6 mW, 1.5 mW, 1 mW and 0.5 mW, respectively.2, 91, 97, 98 Similar to graphene‐based saturable absorbers,99, 100 absorption bleaching originates from Pauli blocking processes, in which a large number of photogenerated carriers cause band filling. A saturation intensity of 1.53 MW cm–2 can be obtained,93 which is comparable to those reported for graphene and semiconductor saturable absorber mirrors (SESAMs).101 The modulation depth of BP is found to be around 10.6%,93 comparable to that of carbon‐nanotube‐based saturable absorbers, which also have resonant absorption in the telecommunication bands.102 The advantages of BP as a saturable absorber lie in its strong resonant absorption at infrared telecom wavelenths as well as its ultrafast carrier dynamics, affording applications for ultrafast laser photonics.

3. Bulk growth of BP

The growing interest in phosphorene due to its great potential has increased the demand for large BP crystals for use in industrial applications.27 Table 1 depicts the different studies based on bulk growth of BP. BP in its bulk form can be synthesized through different methods such as the high‐pressure route,35, 103, 104, 105, 106, 107, 108 recrystallization from bismuth (Bi) flux,59, 60, 109 chemical vapor transport110, 111, 112, 113, 114 and mechanical milling.115, 116

Table 1.

Studies on bulk growth of BP

| Method | Parameters | Starting material | Final Product | Reference |

|---|---|---|---|---|

| High pressure | Pressure (≈11 000 to 13 000 kg cm–2), 200 °C | white phosphorus | black phosphorus | 103 |

| High pressure | 10 kbar, 1000 °C cooled to 600 °C | red P | BP | 35, 105 |

| High pressure | 10 kbar, 1000 °C cooled to 600 °C | red P | BP | 108 |

| HPHT | 2 to 5 GPa | white P, red P | BP | 107 |

| HPHT | 4 GPa, 800 °C, 10 min | red P | BP | 118 |

| Bi‐flux | quartz ampoule, Ar, 400 °C, 48 h | white P, red P (1 g), Bi (20 g) | BP | 109 |

| CVT | 873 K for 10 h | red P (500 mg), AuSn (364 mg), SnI4 (10 mg) | BP | 121 |

| CVT | ampoule (10 cm length, 1.0 cm diameter, wall thickness of 0.25 cm), 7.5 h, 550 °C | red P (500 mg), Sn (20 mg), SnI4 (10 mg) | BP | 122 |

| CVT‐low pressure | silica glass ampoule (10 cm in length, 10 mm in diameter), 10–3 mbar, 873 K, 23 h | red P (500 mg), AuSn (364 mg), SnI4 (10 mg) | BP | 112 |

| CVT‐low pressure | silica glass ampoule (15 cm in length, 1.14 cm diameter), ≈1 × 10–5 Torr, 700 °C, 3 h | red P (1 g), Sn (40 mg) SnI4 (20 mg) | BP | 123 |

| CVT‐low pressure | quartz ampoule (12 cm long), 873 K, 24 h | red P (500 mg), AuSn (364 mg) and SnI4 (10 mg) | BP | 121 |

| CVT‐low pressure | evacuated Pyrex tube, 923 K, 5 h | red P (500 mg), Sn (20 mg), SnI4 (10 mg) | BP | 114 |

| Mechanical milling | 10 stainless steel balls (10 mm or 12.7 mm in diameter), Ar, 1 h | red P | BP, BP‐AB composite | 115 |

| Mechanical milling | 7 g, 9, 20 mm; 20, 10 mm; 30, 6 mm in dia, Ar (1.2 MPa), 400 rpm, 12 h | red P | BP | 116 |

3.1. High‐Pressure Route

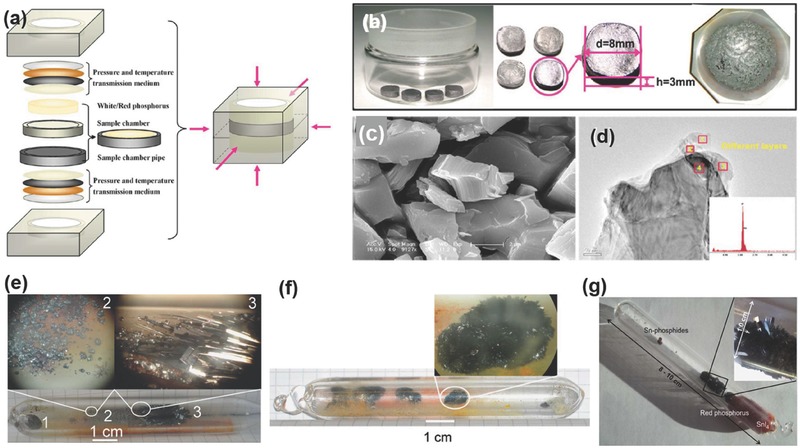

Bridgman103, 104 explained the discovery of black phosphorus as an event that occurred when ordinary white phosphorus (white P) was forced to change into red phosphorus (red P) under high hydrostatic pressure. The transition from white to black phosphorus occurred when pressure (≈11 000 to 13 000 kg cm–2) was applied at room temperature to the white phosphorus through a kerosene medium at 200 °C, in an oil bath controlled by a thermostat. Black phosphorus exhibits two distinct characteristic fractures: it is coarsely granular, like sugar (not in its crystalline form), and it is fibrous with a metallic luster (similar in appearance to graphite). Bulk BP was also produced under a constant pressure of 10 kbar by heating red phosphorus to 1000 °C and slow cooling it to 600 °C at a cooling rate of 100 °C h–1.35, 105, 108 The high‐pressure environment was provided by a cubic‐anvil type of apparatus. Synthesized BP should be kept in an inert atmosphere. A high‐temperature high‐pressure (HTHP) method (see Figure 4 a) was reported for the preparation of BP using a cubic‐anvil high‐pressure apparatus under a pressure of 2 to 5 GPa, where the blocks of white P and red P powder were shaped into cylindrical capsules (3‐mm thick and 10‐mm in diameter) in a chamber made of sintered boron nitride.107, 117, 118 Subsequently, pressure was applied with six tungsten carbide anvils to the cube containing the sample and a heater. The successfully synthesized WBP (black P obtained from white P) under different conditions has a metallic luster and a dark gray color. Figure 4 depicts scanning electron microscopy (SEM) and transmission electron microscopy (TEM) images of WBP. It was revealed that the synthesized WBP could be easily distinguished from their appearance (metallic luster, dark grey in color). High resolution TEM (HRTEM) confirmed the puckered layer structure with polycrystallinity as seen from the concentric diffraction rings and irregular diffraction spots.

Figure 4.

Bulk BP synthesis: a) Schematic of HTHP experimental setup. b) Photograph of the WBP sample. c,d) SEM and TEM images of WBP. Reproduced with permission.107 Copyright 2012, American Chemical Society. Photograph of silica ampoule after the CVT reaction at a temperature of e) 873 K and f) 923 K where 1, 2 and 3 represent the bulk residue, violet phosphorus and the main product black phosphorus, respectively. Reproduced with permission.112 Copyright 2008, Elsevier. g) Silica glass ampoule after CVT synthesis showing large bunches of BP. Reproduced with permission.122 Copyright 2014, Elsevier.

3.2. Recrystallization From Bi Flux

The preparation of needle‐shaped BP single crystals from a solution of white P in liquid bismuth, usually called the bismuth‐flux method, was reported by Brown and Rundqvist59 in 1965. Maruyama et al.60, 119 adopted the same method to obtain BP from a solution of white P or polycrystalline BP in Bi. From the reports of Iwasaki et al.,120 the needle‐shaped BP crystals grown by the Bi‐flux method demonstrate a 2D Anderson localization in electrical properties at low temperatures; this has not been reported in crystals obtained from high‐pressure and high‐temperature routes. It confirms the significant dependence of the BP electrical conductivity at low temperatures on the growth method. Baba et al.109 reported on BP crystals grown in different shapes from a solution of white P in liquid Bi via an improved Bi‐flux method, with reduced chemical impurities. As red P does not dissolve directly in Bi, it cannot be used as the starting material in the Bi‐flux method. It is also very difficult to have highly pure white P due to its chemical activity.109 On the other hand, white P can be readily converted by the action of heat or light on red P. Though the commercial white P can be purified by water‐steam distillation, it is very challenging to remove the sulfur, selenium and arsenic impurities. The entire process of converting the red P to white P and the crystallization of BP was carried out in an evacuated quartz‐glass apparatus inside vacuum because white P should not be exposed to air as it is poisonous, highly reactive and inflammable in air.109 A quartz ampoule containing the white P (with a melting point of 44.1 °C) was melted at 80 °C and then moved towards the Bi (heated to 300 °C). Later, the ampoule was placed in an electric furnace, heated to 400 °C for 48 h and finally cooled down.

3.3. Chemical Vapor Transport

Single crystals of BP can be grown by the chemical vapor transport (CVT) method.110, 111, 121 The process is detailed as follows: red phosphorus (500 mg), Gold Tin metal (AuSn) (364 mg) and Tin (IV) Iodide (SnI4) (10 mg) were sealed in an evacuated 12‐cm‐long quartz ampoule. The charged end of the ampoule was placed horizontally at the center of a single‐zone tube furnace. The ampoule was slow heated to 873 K for 10 h and maintained at the same temperature for 24 h. The ampoule was subsequently cooled to 773 K at a rate of 40 K h–1. BP single crystals larger than 1 cm were crystallized in the form of flakes at the cold end of the ampoule. The low‐pressure route, with the use of a mineralizer as the reaction promoter, was of interest because of its high yield in non‐toxic experimental conditions.112, 113, 114, 121, 122, 123 The red phosphorus, converted to BP by SnI4 mineralization, gives red phosphorus and Au as its byproducts.113, 124

Nilges et al.112 used the mineralizer SnI4 prepared from tin powder (1.2 g) and iodine (4 g) in 25 mL toluene (starting materials) that was refluxed for 30 min; the synthesis process adopted by them for the low‐pressure route is subsequently described. AuSn was synthesized from an equimolar mixture of gold and tin in a sealed evacuated silica ampoule, and AuSn was adopted as a binary precursor to accelerate the reaction of polyphosphide Au3SnP7 at elevated temperatures prior to the transport reaction. The starting materials were melted by a H2/O2 burner before the growth process. The starting materials of red phosphorus, AuSn and SnI4 were placed in the silica ampoule (10 cm in length, 10 mm in diameter), which was evacuated to a 10–3 mbar pressure and placed in a muffle furnace (873 K, 23 h), resulting in the formation of BP crystals (>1 cm). Nilges et al. also reported a total conversion of red P to BP by extending the reaction time to 70 h at 923 K. The formation of violet phosphorus was an intermediate step in the transformation of red to black phosphorus and therefore, a reaction time longer than 32.5 h or a reaction temperature of 923 K promotes the complete conversion of violet to black phosphorus.112 The Sn to SnI4 ratio is the most critical factor for the successful growth of high quality BP bulk crystals.123 Figure 4e,f shows the photograph of the silica ampoule after the reaction at temperatures of 873 K and 923 K, with a clear identification of the bulk residue, the violet phosphorus and the main product (black phosphorus). The final BP product was collected and washed repeatedly with hot toluene and acetone for an enhanced removal of the residual mineralizer.114 A modified mineralizer‐assisted short‐way transport reaction involving red phosphorus, Sn/SnI4 as the mineralization additive to promote short reaction times, and high‐quality large BP crystals was also reported in the literature.122 Moreover, the silica glass ampoule (10 cm length, 1.0 cm diameter and a wall thickness of 0.25 cm) containing Sn (20 mg), SnI4 (10 mg) and red phosphorus (500 mg) was evacuated and placed horizontally in a muffle furnace, set to a temperature of 650 °C and then cooled for 7.5 h to 550 °C. A clear picture of the silica glass ampoule after the synthesis, where SnI4 (orange) and red phosphorus (red) from the gas phase are condensed at the right hand side of the ampoule, is shown in Figure 4g. Additionally, Sn‐Phosphides can also be observed as small round spheres resulting from the excessive Sn reaction.

3.4. Mechanical Milling

BP can be prepared by a mechanical milling process using a mixer mill and a planetary ball‐mill apparatus with red phosphorus powder as the starting material.115 The process was carried out in a stainless steel pot with 10 stainless steel balls (10 mm or 12.7 mm in diameter) in Ar atmosphere for 1 h. Composites with a composition of BP and acetylene black (AB) (80 wt% BP, 20 wt% AB) were prepared by a similar milling technique (a mixer mill) for 1 h. The mixer mill apparatus was found to yield black phosphorus with higher crystallinity depending on the difference in the impact of the mechanochemical reaction for two types of ball‐mill apparatuses.115, 125 Additionally, the mixer mill apparatus provides a more efficient impact interaction than the planetary ball‐mill apparatus in the process of converting red phosphorus to black phosphorus. The composites (BP‐AB) showed less agglomeration with secondary particles (1–5 µm) compared to the synthesized BP, which showed more agglomeration and formed secondary 30 µm‐sized particles. The mechanical milling of BP and AB leads to a decrease in the size of the secondary particles of the composites. Sun et al.116 synthesized BP from red phosphorus by means of a high‐energy mechanical milling method in a ball‐mill instrument. Red phosphorus (7 g) was cleaned with 5% sodium hydroxide solution and distilled water for the removal of oxides. A stainless steel vessel (with a 0.1 L capacity) containing red phosphorus and different sized stainless steel balls (9, 20 mm; 20, 10 mm; 30, 6 mm in diameter) was sealed in an Ar‐filled (1.2 MPa) glove box and rotated for 12 h at 400 rpm.

4. Fabrication of Few‐Layered BP

The higher intralayer strength and weaker interlayer cohesion of phosphorene enables their top‐down synthesis by the cleaving of layers from bulk BP.126 Apart from the dry and wet transfer methods, few‐layered BP can also be fabricated by other methods and we will discuss them in detail in this section.

4.1. Dry Transfer Methods: Mechanical Exfoliation

The mechanical exfoliation (ME) technique is widely adopted in the fabrication of BP.105, 121, 127, 128, 129 Because of its simplicity and ability to produce high‐quality materials, this technique was first utilized in the fabrication of graphene, and it is also growing to be more attractive for the synthesis of other 2D materials (much earlier for MoS2) that are different from their bulk forms.130, 131, 132, 133, 134 According to theoretical studies, 2D materials may be intrinsically unstable after exfoliation, which was later explained by the fact that the exfoliated monolayers are stabilized by the formation of ripples, enabling the extension of 2D materials to the third dimension.135, 136, 137 The process involved in this method is difficult for obtaining uniform samples, as one can obtain flakes that have different types of layers; the ME process is also a time‐consuming one.138

The main challenge of ME is that the performance of BP‐based devices not only depends on the number of layers but also on the quality of the crystal lattice.35, 86, 105 Moreover, the top‐down approach of mechanical exfoliation has been of significance in obtaining the highest‐quality samples. Because thickness is one of the critical parameters that defines the electronic, optical, and thermal properties of two‐dimensional crystals, it is natural to ask if we can achieve monolayer phosphorene. The method seems to be neither high throughput nor high yield.139 The studies of BP using mechanical exfoliation method is tabulated in Table 2 . A single sheet can be exfoliated when the van der Waals attraction present between the first and second layers can be overcome without destroying the consecutive sheets. The first identification of the exfoliated flakes is usually achieved by optical contrast in a microscope, where the regions with different colors represent phosphorene flakes of different thicknesses.63

Table 2.

Mechanical Exfoliation

| Method | BP Thickness (nm) | Substrate | Substrate thickness (nm) | Device structure | Protection | Reference |

|---|---|---|---|---|---|---|

| ME | 0.7 (≈1 L), 1.1 to 1.6 | SiO2/Si | 285/90 (SiO2) | – | – | 57 |

| ME | 1.3 (≈2L) | SiO2/Si | 275 (SiO2) | – | – | 63 |

| ME | ≈200–20 | glass | – | – | PDMS | 105 |

| ME | 20, <5 | SiO2/Si | 300 (SiO2) | – | Resist (ZEP520A) | 127 |

| ME | ≈10–12 | SiO2/Si | 300 (SiO2) | – | PMMA | 128 |

| ME | 25 | SiO2 | 285 (SiO2) | – | – | 121 |

| ME | 2L, 3L, 4L | SiO2/Si | 275 (SiO2) | – | – | 152 |

| ME | 1L, 2L to 5L | SiO2/Si | 275 (SiO2) | – | – | 154 |

| ME | ≈25 | – | – | – | PDMS | 108 |

| ME‐Scotch‐PDMS | 1.6 (≈2L) | SiO2/Si | 285 (SiO2) | – | PDMS | 156 |

| ME‐Scotch‐PDMS | 8–30 | SiO2/Si | 285 (SiO2) | – | PDMS | 155 |

| ME‐Scotch‐PDMS | 2.8 (≈2L) | SiO2/Si | 305/291 (SiO2) | – | PDMS | 150 |

| ME‐Scotch‐PDMS | 6 to 47 (≈11L to 90L) | SiO2/Si | 300 (SiO2) | – | PMMA/MMA | 28 |

| ME‐Scotch | >15 | SiO2/Si | 300 (SiO2) | – | AlOx | 36 |

| ME‐Scotch | 10, 8, 5 | SiO2/Si | 90 (SiO2) | – | – | 35 |

| ME‐Scotch | 9.5–29.6 | SiN (free standing) | 200 | – | PMMA/PVA | 148 |

| ME‐Scotch | 12 | SiO2/Si, glass | 285 (SiO2) | – | PDMS | 37 |

| ME‐Scotch | ≈10 | SiO2/Si | 300 (SiO2) | – | PMMA | 22 |

| ME‐Scotch | 2.8 (≈5L) | SiO2/Si | 300 (SiO2) | – | – | 54 |

| ME‐Scotch | 10L, 15L, 25L | – | – | – | – | 2 |

| ME‐Scotch | 4.8 | SiO2/Si | 300 (SiO2) | FET sensor | – | 29 |

| ME‐Scotch | 1L to 6L | SiO2/Si | 275 (SiO2) | – | – | 129 |

4.1.1. First‐Principles Calculations on Mechanical Exfoliation

An important question arises when we think of how the origin of the research interest in few‐layered BP occurred a very long time (almost a century) after its bulk synthesis.103, 140 Thanks to the mechanical exfoliation techniques, the realization of phosphorene from its bulk counterpart is made possible. There is almost no report available to supplement a solid understanding of the exfoliating mechanism for advanced practical applications. Mu and Si55 described the sliding processes of bilayer phosphorene by calculating the sliding energies (E s) using first‐principles calculations with density functional theory (DFT) SIESTA code, including the van der Waals (vdW) correction to address the above‐mentioned issue. Bilayer phosphorene is favored to AB stacking due to its minimum E s; the energy curve generated is also reasonable when the vdW interaction is taken into account.141 To be more specific, all the possible sliding pathways are explicitly depicted in this energy surface and it will serve as an important guide for experimental research.

Therefore, the exfoliation of the bilayer phosphorene to create a monolayer along the x‐direction requires overcoming the maximum energy barrier of approximately 270 meV. In the case of the sliding process along the y‐direction, the energy barrier is approximately 110 meV, which is two times smaller in magnitude than that of the x‐direction. The important fact is that the minimum energy barrier exists when the sliding is along the diagonal (xy) direction as a result of the low energy barrier of approximately 60 meV that originates from the puckered structure of BP; this energy barrier is slightly larger than that of bilayer boron nitride (h‐BN), graphene and other lubricant materials.142, 143, 144 To reduce the energy barrier in phosphorus allotropes, the blue phosphorene might be a good candidate with its more planar in‐plane configuration.145, 146 The comparable energy barriers of MoS2, from the experimental and theoretical perspectives, can also be found in literature.147 The significance of this is that the interlayer sliding constraints determine the contribution of interlayer Coulomb interactions to the sliding energy profile which in turn results in different sliding pathways. Hence, the optimal pathway is to slide the BP along the diagonal direction.

4.1.2. A Scotch‐Tape‐Based Mechanical Exfoliation Method

Mechanical exfoliation using scotch‐tape has been reported in many studies.28, 29, 35, 36, 37, 148 The isolation of single‐layer phosphorene that can be performed by means of a classical scotch tape (also called as blue Nitto tape)‐based mechanical exfoliation is divided into two steps: (i) Exfoliation of BP layers from bulk BP using scotch tape and (ii) transfer of the exfoliated BP layers onto the substrate (usually SiO2). The transfer is performed by aligning the desired BP flake to the targeted substrate. The exfoliation process must be carried out inside a glove box and kept under vacuum. It is then possible to explore the enormous quantities of information obtained to develop a suitable means for the protection of few‐layer BP from degradation. Other preventive measures should also be emphasized due to the easy degradation of the material when exposed to air and the challenges faced in protecting the surface from oxidation.

Researchers have adopted different approaches to protect BP from oxidation once it is mechanically exfoliated. Saito et al.127 reported that they covered the BP flakes with a resist (ZEP 520 A) immediately after exfoliation. The resist on the substrate was eventually removed by placing the substrate in N‐methyl‐2‐pyrrolidone (NMP) for 40–60 min at 323 K, followed by sprinkling acetone and drowning it in isopropyl alcohol. Luo et al.148 used 1‐µm‐thick poly(vinyl alcohol) (PVA) baked at 70 °C for 5 min, coated the PVA with a 200‐nm‐thick poly(methyl methacrylate) (PMMA) and baked the resulting stack at 70 °C for 5 min. The exfoliated BP flakes were transferred to the PMMA/PVA stack which was then cleaved off and flipped over to be mounted on a glass plate for further investigation. The flake, together with the PMMA/PVA stack, was transferred to the desired substrate (200‐nm‐thick free standing SiN). The sample was drenched (for >12 h) in acetone (>70 mL) to remove the PMMA/PVA and then dried with nitrogen (see Figure 5 d). They also suggested that using a large amount of acetone along with a long soaking time is needed for the effective removal of PMMA. No baking or annealing was performed through the entire processing steps to prevent excessive oxidation and also to retain the BP crystallinity. An optical image of the exfoliated BP flake suspended on slits is shown in Figure 6 b. The degradation of BP was also found to be minimized by coating with only PMMA.36, 105, 128 The approximate time to cover the flake with PMMA after exfoliation (investigation under a microscope) was estimated to be less than 30 min.22 An optical image and AFM of the BP flake on Si/SiO2 and the device fabricated by Koenig et al.22 is shown in Figure 6e,f. Another effective approach is to adopt atomic‐layer‐deposited AlOx overlayers to effectively suppress the ambient degradation of BP.36

Figure 5.

Mechanical Exfoliation of BP: The bilayer BP's a) sliding energy surface, b) sliding energy profiles, and c) band gaps of the three pathways. Symbols x, y and xy label the pathways along the x, y and diagonal directions, respectively. Reproduced with permission.55 Copyright 2015, Institute of Physics. d) Steps involved in the flake preparation and transfer process. Reproduced with permission.148 Copyright 2015, Nature Publishing Group. e) Three‐step exfoliation of BP with PDMS. 1) Exfoliation on PDMS‐1, 2) flakes are rolled on the semi‐spherical PDMS‐2 stamp and 3) the stamp is rolled on the SiO2/Si substrate. Reproduced with permission.150 Copyright 2015, Nature Publishing Group. f–h) Isolation of few‐layer BP. f) Transmission mode optical microscopy image of few‐layer BP on the PDMS substrate. Optical transmittance line profile to highlight the reduction of approximately 5.5% in the thinner part of the flake. g) Bright‐field optical image of the same flake after transferring to the SiO2/Si substrate (flake was broken during the transfer). h) AFM image of the dashed square region in (g) with a topographic line profile taken along the horizontal dashed black line. Reproduced with permission.156 Copyright 2014, IOP.

Figure 6.

a) Optical image of mechanically exfoliated phosphorene flake (scale bar: 6 µm). Inset: AFM line scan showing a height of 0.7 nm and the monolayer region marked by a grey dashed line. Reproduced with permission.240 Copyright 2015, Nature Publishing Group. b) optical image of the PMMA/PVA‐assisted mechanically exfoliated BP flake suspended on slits (scale bar: 15 µm). Reproduced with permission.148 Copyright 2015, Nature Publishign Group. c) Optical micrograph of BP nanosheet on the Al2O3/patterned bottom gate. Inset: optical image of the fabricated dual‐gate BP FET. d) Photograph of dual‐gate device fabricated on glass. Reproduced with permission.37 Copyright 2015, American Chemical Society. e) Optical image of the BP flake on Si/SiO2. Inset: Same flake after fabrication of electrical contacts (scale bar: 50 µm). f) AFM image. Reproduced with permission.22 Copyright 2014, American Institute of Physics.

BP nanosheets were mechanically exfoliated from single crystal bulk BP using Scotch tape and PDMS elastomer on 285‐nm‐thick SiO2/p+‐doped silicon and glass substrates.37 Figure 6c,d presents the optical micrograph of the BP nanosheet on an Al2O3/patterned bottom gate and also the photograph of a fabricated dual‐gate BP FET device on glass. Wang et al.105 exfoliated BP flakes onto a PDMS stamp on a glass slide. The glass slide is kept in a vacuum chamber (p ≈ 5 mTorr) immediately after the careful identification of promising flakes for further usage by optical microscopy. The pre‐patterned substrate that fits well with the geometry of the chosen flake was used. Wang et al. carried out the transfer by aligning the selected BP flake to the target device area on the substrate. The slide was then lowered to make contact between the PDMS and the substrate. The PDMS was later peeled carefully, leaving BP on the substrate because of the van der Waals forces existing between BP and the surface. This efficient dry transfer method was ≈70% successful in the fabrication of good‐quality suspended BP nanoelectromechanical systems (NEMS) with sophisticated structures. They were also able to preserve the crystal quality better than with the conventional lithography process accompanied by wet transfer techniques. These wet transfer techniques involve the exposure of BP flakes to wet chemical processes, causing undesired chemical reactions and prolonged time in the ambient condition that leads to unwanted oxidation.

Favron et al.54 performed the exfoliation of BP in the dark or inside a nitrogen‐filled glove box to protect it from degradation. A SiO2/Si substrate was coated with 20 nm of parylene C to minimize the influence of hydrophilicity on the surface. The presence of parylene is used for a clear identification of the exfoliated flakes and also as a protection against degradation.28, 149, 150 The samples can also be washed with acetone, methanol and isopropanol (approximately 1 minute for each step) so that the residue from the scotch tape can be removed; this is followed by baking at 180 °C for 5 min to remove the remaining solvent.57 An optical image of a mechanically exfoliated monolayer BP flake, as reported by Wang et al.,57 is shown in Figure 6a. Liu et al.151 spin‐coated PMMA onto exfoliated BP flakes (twice, at 2000 rpm, for 1 min each time) and anisole solvent was later baked out at ≈150 °C for 5 min. The PMMA/BP/SiO2/Si stack was soaked in 2 m KOH to etch the SiO2/Si and release the PMMA/BP. The KOH will not significantly affect BP because BP is more stable than red phosphorus. The PMMA/BP films were rinsed in ultrapure deionized water to remove the etching residues, and the remaining water was removed from the interface of the PMMA/BP films by successive ≈70 °C and ≈150 °C heating steps, with each step performed for 10 min. Later, the PMMA was dissolved with hot acetone vapor (at ≈45 to 55 °C) in necked Erlenmeyer flasks. The grids were stored in a N2 glove box, prior to characterization, to prevent BP degradation in ambient conditions. The overall process can be classified in the following steps: (1) exfoliate BP onto the SiO2/Si wafer; (2) spin coat PMMA onto the sample; (3) etch the SiO2/Si with aqueous 2 m KOH solution; (4) rinse the PMMA/BP sample in an H2O bath and (5) transfer the BP flakes onto another SiO2/Si wafer. To slow the reaction of phosphorene with moisture and other possible reactants from the environment, Zhang et al.63, 152 placed the exfoliated samples in a microscope‐compatible chamber with a slow flow of nitrogen as the protecting gas. Figure 7 represents the morphological studies of the bi‐layer BP and the few‐layered BP flake grown by mechanical exfoliation.63, 152

Figure 7.

a) Optical micrograph of the device fabricated by the bi‐layer BP (labeled as “2L”). b) PSI image of the region marked as a square with a dashed line in (a). c,d) Optical image and PSI image of another exfoliated few‐layered BP flake, respectively. Reproduced with permission.152 Copyright 2015, American Chemical Society. e) Optical image of 2L BP. f) AFM image of 2L BP taken from the region indicated by the box with a dashed line in (e). Reproduced with permission.63 Copyright 2014, American Chemical Society. g) Optical micrograph of monolayer phosphorene (labeled as “1L”). Inset: Molecular structure representation of phosphorene. h) PSI image of the dashed‐line square given in (g). Reproduced with permission.154 Copyright 2015, Nature Publishing Group. i) HRTEM image of a 2D‐phosphane layer. Reproduced with permission.54 Copyright 2014, the authors.

Atomic force microscopy (AFM) and Raman spectroscopy have been employed to study the sample thickness of TMDs but they are not reliable for studying one or two layers of phosphorene.153 Because the scanning rate of AFM is slow in comparison to the fast degradation of phosphorene in ambient conditions, AFM may show an error of one or two layers due to the large surface roughness. There is also the possibility of introducing potential contaminants from the AFM system. Interestingly, phosphorene has a non‐monotonic dependence on the layer number ascribed to the complicated Davydov‐related effects, unlike TMDs, which have a monotonic dependence in the Raman mode frequency.54 The phosphorene can also be damaged by the high‐power laser adopted in characterization by Raman spectroscopy. Yang et al.154 reported a different approach for determining the layer number by means of optical interferometry i.e., phase‐shifting interferometry (PSI) to measure the optical path length (OPL) reflected from the exfoliated phosphorene by analyzing the digitized interference pattern. The virtual thickness of a phosphorene flake is amplified by more than 20 times in the optical interferometer due to the multiple interfacial light reflections, and this is helpful for easy identification of the flakes. PSI adopts non‐focused and very low‐density light from a light‐emitting diode source to achieve fast imaging without causing any damage to the phosphorene samples. Figure 7g,h shows an optical micrograph of monolayer phosphorene and its PSI image. HRTEM can be employed for structural analysis of few‐layered BP. The puckered structure of 2D‐phosphane is clearly revealed from the HRTEM image (see Figure 7i) reported by Favron et al.54

4.1.3. Modified Mechanical Exfoliation Technique

Modified mechanical exfoliation was introduced by Castellanos‐Gomez et al.155, 156, 157 to optimize the deposition of atomically thin BP flakes. Conventional mechanical exfoliation with adhesive tape yields a low density of few‐layer BP flakes, leaving traces of adhesive on the surface and thereby reducing the quality. A better solution could be using an intermediate viscoelastic surface in exfoliation, which increases the yield and further reduces the contamination of exfoliated flakes. Commercially available bulk BP was cleaved multiple times by blue Nitto tape. Later, the tape containing thin BP crystallites was slightly pressed against a poly‐dimethylsiloxane (PDMS)‐based substrate and peeled off rapidly. Finally, the thin flakes present on the surface of the PDMS substrate were moved to the desired substrates by simply putting the PDMS substrate in gentle contact with the new acceptor substrate and peeling it off slowly (approximately 5–10 minutes to peel off the stamp completely from the surface). Island et al.155 reported that long‐term exposure to ambient conditions results in a layer‐by‐layer etching process of BP flakes, which they were able to etch down to a single‐layer (phosphorene) thickness (≈0.7 nm). Their results demonstrated that the initial exposure of BP flakes to air results in n‐type doping, whereas a longer exposure to air leads to strong p‐type doping ascribed to the presence of absorbed water.

Another modified Scotch‐tape exfoliation technique was reported in the literature where BP was first exfoliated onto a flat PDMS stamp and then transferred onto a curved PDMS stamp.28, 150, 158 Later, the curved PDMS stamp covered with flakes is rolled onto the desired substrate. BP films were also produced by the micromechanical cleavage of bulk BP crystals directly onto a PDMS stamp.108 As a result of the viscoelastic properties of PDMS, the BP film adheres to the fiber end when the film is gently lifted up from the PDMS stamp.156 Tayari et al.28 deposited 300 nm of copolymer (methyl methacrylate, MMA) and 200 nm of polymer (polymethyl methacrylate) and annealed the deposition at 170 °C for 15 minutes to protect BP field‐effect transistors (FETs) against degradation. Figure 5f–h shows a transmission mode optical microscopy image of few‐layer BP on a PDMS substrate, a bright field optical image of the same flake after transferring to a SiO2/Si substrate and an AFM image. The significant role of the polymer layer is to form a water‐impermeable superstrate that suppresses oxidation and hence, the BP surface is free of the surface roughening caused by oxidation.22, 28, 36, 54, 156

4.2. Wet Transfer Methods: Liquid‐Phase Exfoliation

Liquid exfoliation or liquid phase exfoliation (LPE) can be broadly classified into the following basic categories of (i) oxidation followed by subsequent dispersion into suitable solvents, (ii) ion intercalation, (iii) ion exchange, (iv) ultrasonication‐assisted exfoliation and (v) shear exfoliation.135 Figure 8 describes the detailed schematics of the liquid exfoliation mechanisms. In the LPE method, one can achieve large quantities of dispersed nanosheets of layered materials which are more suitable for industrial‐scale applications. The liquid exfoliation of layered compounds in modern research started and progressed based on the graphite intercalation compounds and graphite oxide.159, 160 An earlier study reported in inorganic layered compounds showed the exfoliation of vermiculite clay in liquids via ion intercalation and shear mixing.161 A few studies were later demonstrated on the use of ultrasonic agitators for ion intercalation‐assisted exfoliation of TaS2, NbS2, MoS2 and layered oxides.162, 163, 164, 165 The LPE method is selective to the dispersion liquid and hence, different solvent have different dispersibility and are found to have diverse nonlinear properties.12, 166 A solution‐based mechanical exfoliation process was also reported by mixing BP crystals with ethanol solution.90

Figure 8.

Schematic illustration of liquid exfoliation mechanism. a) Ion intercalation: Ions (yellow spheres) are intercalated between the layers in the liquid, swelling the crystal and weakening the interlayer attraction. Shear, ultrasonication or thermal agitation can completely separate the layers, thus producing the final exfoliated dispersion. b) Ion exchange: Ions found between the layers in layered materials balance the surface charge on the layers. These ions (red spheres) can be interchanged in the liquid for other larger ions (yellow spheres), and further agitation yields the exfoliated dispersion. c) Sonication assisted exfoliation: The layered material is sonicated in a solvent to form a nanosheet by means of exfoliation. In the case of a good solvent with an appropriate surface energy, stabilized nanosheets are formed; bad solvents cause reaggregation leading to sedimentation. Reproduced with permission.135 Copyright 2013, AAAS.

The primary approach in liquid exfoliation is the oxidization first demonstrated in graphite.159 This is regarded as one of the oldest methods of exfoliating layered crystals with a low reducing potential followed by subsequent dispersion into suitable solvents.135 The amount and the type of oxides attached can be changed by means of oxidation to tune the properties such as electrical conductivity and luminescence.167 There are a few disadvantages with this method as it may be responsible for chemical groups and defects that scatter electrons and lead to high resistivity. Intercalation is a broadly adopted method in liquid exfoliation as the layered materials can adsorb guest molecules in the spacing existing between their layers, thereby forming inclusion complexes.168, 169 The intercalation process increases the layer spacing, weakens the interlayer adhesion and reduces the energy barrier to exfoliation.135 The role of the intercalants, such as n‐butyllithium169 and IBr,168 is to transfer charge to the layers and subsequently decrease the interlayer binding. The exfoliation process is completed with the aid of further thermal shock treatments168 or ultrasonication169 in a liquid. The final step is to stabilize the exfoliated flakes either by incorporating a surface charge or by adding surfactant.168 Although the intercalation techniques are sensitive to ambient conditions, they yield a large quantity of the exfoliated nanosheets.169, 170

Ion‐exchange methods make use of the exchangeable interlayer of cationic counterions present in clays and metal oxides.161, 171, 172 The most recent approach in liquid‐phase exfoliation was performed by ultrasonication in a solvent by exposing the 2D materials to ultrasonic waves that develop cavitation bubbles and collapse into high‐energy jets to cleave the layered crystallites, leading to exfoliation.93, 135, 173 It was demonstrated that the energy difference between the exfoliated and re‐aggregated flakes depends on the surface energy of the solvent and may be small if both the solvent and 2D material have the same surface energy.160 By ultrasonication with organic solvents and ionic liquids, shear exfoliation methods have been widely utilized in the liquid exfoliation of BP. Interestingly, there is a correlation between the cohesive energy of a 2D material and the solvent used that determines the capability of a particular solvent to achieve efficient exfoliation and create a stable dispersion.174 The cohesive energies can be evaluated by using two significant parameters: (a) the Hildebrand solubility parameter and (b) the Hansen solubility parameter. The Hildebrand solubility parameter is the measure of a solvent's total cohesive energy per unit volume and the Hansen solubility parameter is the measure of the dispersive, polar and hydrogen bonding components of a solvent's cohesive energy per unit volume.175, 176 If the Hansen solubility parameters of the desired 2D material and solvent are the same, that solvent would be the best candidate for exfoliation. Table 3 shows the experimental parameters and devices based on liquid exfoliation in previous literature.

Table 3.

Liquid Exfoliation

| Method | Parameters | Solvent | BP Thickness (nm) | Device structure | Centrifugation | Reference |

|---|---|---|---|---|---|---|

| Ultrasonication | 750 W, 5 h, 2 g L–1 | CHP | 2 | – | 1 krpm, 180 min 2 krpm, 3 krpm, 4 krpm, 5 krpm, 10 krpm and 16 krpm for 2 h | 191 |

| Ultrasonication | 400 W, 43 h, RT, ≈6 mg mL–1 | ethanol | 4 to 25 | pulsed laser | 4000 rpm, 60 min | 93 |

| Ultrasonication | 1 mg mL–1, 2 h | IPA, NMP, EA | 5 to 10 | – | 1500 rpm, 20 min | 12 |

| Ultrasonication | 1 mg mL–1, 90 min | NMP | 30 to 60 | – | 3000 rpm, 10 min | 185 |

| Ultrasonication | 3 h | IPA | 5 | saturable absorber | 1500 rpm, 20 min | 239 |

| Ultrasonication | 4 h | NMP | 3 to 9 | saturable absorber mirror | 1500 rpm, 45 min | 95 |

| Ultrasonication | 3 h, 200 W, BP (5 mg), NMP (3 mL) | NMP | 4.9 to 1.9 | flexible memory device | 7000 rpm, 20 min | 118 |

| Ultrasonication | 40 kHz frequency, 80% power, 4 h | NMP | 5.3, 2.8, 1.5 to 2.5 | saturable absorber | 3000 rpm, 10 min 12000 rpm, 20 min (5 to 12 L) 18000 rpm, 20 min (1 to 7 L) | 67 |

| Ultrasonication | 130 W, 15 h, 10 µg mL–1 | DMF, DMSO | 5.8 to 11.8 | – | 2000 rpm, 30 min | 182 |

| Ultrasonication | 15 mg, 20 mL, 12 h | DMF, DMSO | 26 | sensors | 500 rpm, 30 min | 195 |

| Ultrasonication | 40 kHz, 300 W, 10 h | NMP | ≈0.6 to 2 | saturable absorber | 1500 rpm, 10 min | 91 |

| Ultrasonication | – | NMP | 23 | saturable absorber | – | 85 |

| Ultrasonication | 20 mL, 0.1 mg mL–1, 10 h | NMP | 0.84 to 4.22 | sodium‐ion batteries | 5000 rpm, 30 min | 187 |

| Ultrasonication | 5 mg mL–1, 0.164 mol dm–3 of BP in NMP, 820 W, 37 kHz frequency, 30% power, 24 h, 30 °C | NMP | 0.9 to 1.6, 3.5 to 5 | – | 1500 rpm, 45 min | 186 |

| Ultrasonication | 10 mg, 20 mL, 0.5 mg mL–1 | Different solvents | 1 L, 2L | – | 30 min | 196 |

| Ultrasonication | 50 mg, 100 mL, 8 h | water | 2 | photosensitizers | 1500 rpm for 10 min | 114 |

| Ultrasonication | BP, 0.4 g, 12.8 mmol, water (100 mL) 30 min, 20 kHz, 100 W | water | few nm to <20 | biomedical | – | 197 |

| Ultrasonication (tip) | 1 to 10 mg mL–1, 950 W, 30 to 300 min | water | 9.4 | lithium ion battery | 1500 to 5000 rpm for 30 min | 173 |

| Ultrasonication (tip) | ≈30 W power, ≈1 mg mL–1, 1 h | acetone, chloroform, hexane, ethanol, IPA, DMF, and NMP | 16 to 128 | – | 500 to 15 000 rpm for 10 min | 183 |

| Ultrasonication (tip and bath) | BP (25 mg), NMP (25 mL), tip‐sonication (3 h, 1200 W, 19 to 25 kHz), bath‐sonication (300 W, 10 h, below 277 K) | NMP | ≈1.5 | photothermal agents | 7000 rpm, 20 min, 12 000 rpm, 20 min | 205 |

| Ultrasonication, mechanical milling | up to 6 h, 30 min, 400 W, RT | DMF, NMP, DIGLYM, AN | 2 to 5 (3 to 10 L), 20 to 30 | gas sensing | 5000 rpm, 10 000 rpm, 16 000 rpm | 110 |

| Ionic liquids | 100 W, 24 h, ≈0.95 mg mL | I Ls, [HOEMIM] [TfO], [HOEMIM] [BF4] | 3.58, 5.5, 8.9 | – | 4000 rpm, 45 min | 200 |

| Shear mixing | 6 g of BP, 100 mL of NMP sonicated for 2 h, 700 mL of NMP shear mixed at 5000 rpm for 4 h | NMP | 1 L, 2 L | – | – | 196 |

| Shear exfoliation | 0.05 mg mL–1 | NMP | ≈0.9 to 3.5 | rechargeable nanoscale battery | 6000 rpm | 207 |

4.2.1. Theoretical Studies of Liquid Exfoliation of Phosphorene

The surface energies of the solvent and layered materials play a crucial role in tuning the exfoliation efficiency of the liquid‐exfoliation process. The surface energy of bilayer phosphorene was estimated to be ≈58.6 mJ m–2 based on a barrier energy of 60 meV, which fits well in the range of surface energies of solvents such as ethanol (22.0 mJ m–2), methanol (41.4 mJ m–2), water (72.7 mJ m–2) and formamide (57 mJ m–2).55 This theoretical study clearly supports the thinking that BP can be easily exfoliated by LPE.55, 177 Figure 5a–c shows the sliding energy surface, sliding energy profiles and band gaps of the three pathways of bilayer BP.

The quest for new exfoliating media is necessary to find environmental friendly solvents, thereby avoiding toxic and impractical solvents.178, 179, 180, 181 Therefore, Sresht et al.126 studied the LPE of phosphorene in the solvents dimethyl sulfoxide (DMSO), dimethylformamide (DMF), isopropyl alcohol (IPA), NMP and N‐cyclohexyl‐2‐pyrrolidone (CHP) using three molecular‐scale computer experiments to model the solvent–phosphorene interactions via atomistic force fields assisted by ab initio calculations and lattice dynamics. The energy needed to peel a single phosphorene monolayer from a stack of BP was measured, with a detailed explanation of the role of the wedges present in solvent molecules for initiating the exfoliation. The main findings of their simulations are given as follows: (1) the lower value of the primary minimum in CHP than the corresponding minimum for vacuum accounts for the easier aggregation of phosphorene monolayers in CHP than in vacuum; this indicates that CHP is a poor choice for LPE and agrees well with experimental results,182 (2) the cohesive strength of IPA is attributed to the hydrogen bonding networks between confined molecules,182 (3) the large energy barrier in DMF is due to (a) the small size and planarity of the DMF molecule giving rise to an enhanced intercalation ability and (b) the substantial cohesive energy that causes the high density, viscosity and boiling point, (4) DMSO, with its enhanced packing along with its high cohesive energy, high boiling point, density and viscosity, gives the optimal dispersion environment as supported by previous works,182, 183 and (5) the strong cohesive dipolar forces in certain solvents (DMSO, IPA) increase their suitability as stable dispersion media and therefore, solvent planarity improves the dispersion stability and leads to a greater degree of confinement of the solvent molecules between the 2D BP sheets.

The performance of a solvent based on the shape of its molecules in interfacial layers with phosphorene was clearly demonstrated by Sresht et al.126 In general, LPE starts by the penetration of a wedge of solvent molecules in the interlayer gap of 2D materials. Consequently, the solvents with planar molecules near the phosphorene surface (NMP, DMSO) act as molecular wedges for efficient intercalation.126 The intercalation can be successful if and only if the new phosphorene surfaces established by the solvent wedge are sustained by sorption forces that exist between the solvent molecules and the corresponding 2D material. Moreover, the cohesive energy density of the solvent molecules in the final interfacial layer of solvent, confined between the sheets, is high and continues to diminish if strong sorptive interactions exist between the confined molecules and the sheets, which favors the stable dispersion of phosphorene. The simulation studies showed that the phosphorene exfoliation is easier if the adhesion between the phosphorene and solvent is stronger than the cohesion between the solvent molecules.126 Accordingly, the solvent's molecular shape is more important and has to be taken into account in LPE.

4.2.2. Ultrasonication‐Based Exfoliation

Different approaches were adopted in the ultrasonication of 2D materials including organic solvent‐based exfoliation, stabilizer‐based exfoliation, ionic liquid‐based exfoliation, salt‐assisted exfoliation, intercalant‐assisted exfoliation and ion exchange‐based exfoliation.184 Ultrasonication can be performed either by the bath sonication or the tip sonication technique. Bath sonication is used in majority of studies and hence, we do not mention it specifically and the general term of ultrasonication is used to denote “bath sonication” throughout this article.

4.2.2.1. Organic‐Solvent‐Based Sonication

: One of the approaches used involved BP crystals mixed with ethanol solution and ultrasonicated (400 W) at room temperature (RT) for 43 h. The resulting solution was centrifuged (at 4000 rpm for 60 min) to eliminate larger particles and led to a final purified BP‐ethanol mixture (with a concentration of ≈6 mg mL–1).93 It was also reported that BP powder was obtained by grinding bulk BP crystal dispersed in different solvents such as IPA, NMP and ethyl alcohol (EA) to obtain 1 mg mL–1 dispersions, and the dispersions were ultrasonicated for 2 h. The dispersions were then allowed to settle for more than 24 h to enable the removal of large‐size sedimentations by centrifugation (at 1500 rpm for 20 min).12 The interesting fact behind the formation of thin BP nanoflakes in the solution is that the interlayer van der Waals bonding is broken down by the ultrasonic energy.95

The NMP solvent for obtaining stable, highly concentrated (≈0.4 mg mL–1) BP dispersions was used in LPE in most of the reported studies.12, 67, 85, 91, 95, 118, 160, 166, 183, 185, 186, 187 NMP and DMF are well suit for liquid exfoliation owing to their relatively high boiling points and surface tension (≈40 mJ m–2).166, 183, 188 However, phosphorene, extracted by NMP solution, cannot be used directly either in the fabrication of electronic devices or for optical investigations because of its poor volatility. The exfoliated nanosheets are further stabilized electrostatically or sterically by interaction with the solvent or by the presence of an adsorbed surfactant or a polymer.160, 189, 190 This method is more suitable for the large‐scale exfoliation of BP and a uniform dispersion can be achieved in the exfoliation medium. Specifically, the production yield is generally low and the phosphorene is unstable in other conventional solvents (water) limiting its applications.67 Guo et al.67 reported a basic NMP‐based LPE method for the fabrication of phosphorene with an excellent water stability, a controllable size, a number of layers and high yield. The schematic of the synthesis process of basic NMP‐exfoliated phosphorene is given in Figure 9 g. The basic NMP‐exfoliation process can be detailed as follows: bulk BP (15 mg) was added to a saturated NaOH NMP solution (30 mL) and sonicated for 4 hours at 40 kHz frequency and 80% power, and the phosphorene in NMP was separated and transferred to water by centrifugation (at 3000 rpm for 10 min) in order to remove the unexfoliated bulk BP. Figure 9h shows the photographs of phosphorene dispersed in NMP and water, with five bottles containing (1) pure water, (2) NMP‐exfoliated phosphorene in NMP, (3) NMP‐exfoliated phosphorene in water, (4) basic NMP‐exfoliated phosphorene in NMP, and (5) basic NMP‐exfoliated phosphorene in water. Compared to mechanical exfoliation, LPE is unable to yield 2D materials with an exact size and thickness. Guo et al.67 adopted different centrifugation speeds to control the phosphorene thickness. The supernatant solution was centrifuged at 12 000 rpm for 20 min to obtain 5.3 ± 2.0 nm thick (5 to 12 L) phosphorene samples with an average diameter of ≈670 nm (referred to as 12000 phosphorene) and further centrifuged at 18 000 rpm for 20 min to obtain 2.8 ± 1.5 nm thick (1 to 7 L) phosphorene samples with average diameter of ≈210 nm (referred to as 18000 phosphorene). The height‐mode AFM and TEM images of 12000 and 18000 phosphorene are shown in Figure 9i–l. The results are also demonstrated for the two conditions with and without the addition of NaOH to NMP, which confirms that a thorough exfoliation of BP was achieved by the basic NMP process (with NaOH) than by the NMP‐only exfoliation (without NaOH). Additionally, the phosphorene obtained from basic NMP‐exfoliation has excellent stability in both NMP and water. The basic NMP‐exfoliated phosphorene with a zeta potential of −30.9 mV is physically stable (in water) and has a more negative charge than the NMP‐exfoliated phosphorene with a zeta potential of −19.7 mV. The negative charge of phosphorene corresponds to the OH– ions, obtained by adding NaOH, that are absorbed on the surface of phosphorene leading to an excellent stability in water.

Figure 9.

a–f) Synthesis and studies of the BP QDs: a) Steps followed in the fabrication and surface modification of BP QDs. b) TEM image. c) Magnified TEM image. d) HRTEM image. e) AFM image. f) Photo of synthesized BP QDs, i) PEG‐modified BP QDs and ii) BP QDs dispersed in water or phosphate‐buffered saline (PBS) solution. Reproduced with permission.205 g) Schematic of synthesis process of basic NMP‐exfoliated phosphorene. h) Picture of phosphorene dispersed in NMP and water. The five bottles contain the following: 1) pure water, 2) NMP‐exfoliated phosphorene in NMP, 3) NMP‐exfoliated phosphorene in water, 4) basic NMP‐exfoliated phosphorene in NMP, and 5) basic NMP‐exfoliated phosphorene in water. Height‐mode AFM images of i) 12000 and j) 18000 phosphorene, and TEM images of k) 12000 and l) 18000 phosphorene are shown. Reproduced with permission.67

The improved basic NMP‐exfoliation method reported by Guo et al.67 may provide a better solution for this problem. Zhang et al.118 synthesized BP quantum dots (QDs), with an average size of 1.9 to 4.9 nm and excellent stability in NMP, using ice‐bath sonication (3 h, 200 W). The BP (5 mg) and NMP (1 mL) ingredients were grinded in a mortar for 20 min, transferred to a glass vial with 3 mL of NMP and sonicated for 3 h. The resultant dispersion was centrifuged for 20 min at 7000 rpm. All the experiments were conducted in a glove box except the sonication and centrifugation processes. Photographs of the BP QD suspension (left) and the Tyndall effect observed in the BP QD suspension (right) together with their TEM images are shown in Figure 10 c,d. Hanlon et al.191 reported on high‐quality, mono‐ and few‐layer BP (FL BP) created by LPE in the CHP solvent with remarkably stable nanosheets. Bulk BP is ground with a pestle and mortar immersed in CHP (with a concentration of 2 g L–1), which is sonicated for 5 hours to give a brown dispersion. At the time of sonication, 4 mL of the sample was collected for further sonication of ≈80 h, and it was subsequently centrifuged at 1 krpm for 180 min to yield a stable dispersion (designated as std‐BP). The stock dispersions were centrifuged at 1000 rpm for different time periods of 5 to 240 min. The aliquots of the std‐BP dispersion were centrifuged at 5 krpm for 120 min. The resultant stock dispersions can be readily size‐selected to yield a small or large nanosheet, which is the primary advantage of this technique.192, 193, 194 The supernatant was subjected to controlled centrifugation with subsequently increasing rotation speeds of 2 krpm, 3 krpm, 4 krpm, 5 krpm, 10 krpm and 16 krpm, with each step performed for 2 h to yield samples with varying size distributions, including decreased sizes in the respective sediments. The main impact of this study is that the solvation shell of the solvent (CHP) molecules can protect the exfoliated nanosheets from reacting with water. Figure 11 a–e shows a photograph, low‐resolution TEM images and the low‐by‐pass bright‐field scanning transmission electron microscopy (STEM) image of the FL BP dispersion in CHP. A Butterworth‐filtered high‐angle annular dark field (HAADF) STEM image of the BP‐exfoliated dispersion in isopropanol, indicating the intact lattice, can be observed in Figure 11f.

Figure 10.

Liquid‐phase‐exfoliated BP nanoflakes: a) Photograph of few‐layered BP dispersions in DMSO and DMF solvents, (left) after sonication, and (right) after centrifugation and supernatant collection. b) Characterization of BP nanoflakes. 1) Low‐magnification SEM image of BP nanoflakes on the SiO2/Si substrate showing a “coffee‐ring” structure. Scale bar: 200 µm. 2) Magnified SEM image of the central area of the rings. Scale bar: 200 nm. 3) SEM image of individual BP nanoflakes present at the outer region of the coffee rings. Scale bar: 200 nm. 4) AFM image of the same area shown in (3) with height profiles (inset) corresponding to the drawn lines represented by the same colors. Reproduced with permission.182 c) Photographs of the BP QD suspension (left) and the Tyndall effect observed in the BP QD suspension (right). d) TEM image of BP QDs. e) Enlarged TEM image of BP QDs. HRTEM images of BP QDs with different lattice fringes. Scale bar: 5 nm. Reproduced with permission.118

Figure 11.

a–f) Liquid exfoliated FL BP: Dispersion in CHP. a) Photograph. b–d) Low‐resolution TEM images. e) Low‐by‐pass bright‐field STEM image. Dispersion in isopropanol. f) Butterworth‐filtered HAADF STEM image indicating the intact lattice Reproduced with permission.241 Copyright 2015, Nature Publishing Group. g–k) IL‐exfoliated BP nanosheets dispersions: g) Photograph of BP in [BMIM][TfO] and [HOEMIM][TfO] (top) and Tyndall effect of diluted dispersions (bottom). h–k) Electron microscopy studies of BP‐[HOEMIM][TfO]. h) Low‐magnification TEM image. The arrows points to wrinkles and distinguishable edges. i) SAED pattern. j) HRTEM image. k) Magnified HRTEM image of selected area in (j). Reproduced with permission.200 Copyright 2015, American Chemical Society. l–p) LPE exfoliated BP suspension in isopropanol: l) Photograph. m) SEM image. n–p) TEM images. p) TEM image of a monolayer BP. Inset (n): contrast change (ca. 75 counts) from a line profile across the 3L thick BP. Inset (p): Histogram of contrast changes from 100 flakes where the intensity change (25, 50, etc.) corresponds to monolayers, bilayers, etc. Reproduced with permission.196 Copyright 2015, American Chemical Society.

Yasaei et al.182 examined various solvents from different chemical families such as alcohols, chloro‐organic solvents, ketones, cyclic or aliphatic pyrrolidones, N‐alkyl‐substituted amides and organosulfur compounds, which encompass a wide range of surface tensions (21.7 to 42.78 dyne cm–1) and polar interaction parameters (2.98 to 9.3 MPa1/2) to understand their performance in BP exfoliation. The bulk BP crystal (0.02 mg in 10 mL) was immersed in different solvents for a 15 h sonication (130 W, a total input energy of 1 MJ) and they found that aprotic and polar solvents such as DMF and DMSO as more suitable for atomically thin BP flakes, leaving stable and uniform dispersions.195 A 30 min centrifugation was performed at 2000 rpm, after which the supernatants with concentrations of up to 10 µg mL–1 were collected and dispersed in IPA. The dispersed flakes in the solution offer the best protection from degradation. Photographs of few‐layered BP dispersions in DMSO and DMF solvents after sonication, and after centrifugation and supernatant collection, are displayed in Figure 10a. Figure 10b shows AFM and SEM images of the BP nanoflakes on a SiO2/Si substrate where a “coffee‐ring” structure is observed in the low‐magnification SEM.

Woomer et al.196 surveyed the experimental conditions for liquid exfoliation and explored the first large‐scale production (10 g scale) of monolayer, bilayer and few‐layer phosphorus. The experimental process is described as follows: grounded BP was sonicated in anhydrous, deoxygenated organic liquids (isopropanol for 16 h) under inert atmosphere resulting in a change of color from black to reddish‐brown and finally to yellow that signifies a change in the electronic structure of BP. The color remains the same after few weeks with limited reaggregation, indicating the presence of small phosphorus particulates. They experimented with different solvents such as N‐methyl‐2‐pyrrolidone, 2‐propanol, cyclopentanone, 1‐cyclohexyl‐2‐pyrrolidone, 1‐dodecyl‐2‐pyrrolidinone, benzyl benzoate, 1‐octyl‐2‐pyrrolidone, 1‐vinyl‐2‐pyrrolidinone, benzyl ether, 1,3‐dimethyl‐2‐imidazolidinone, cyclohexanone, chlorobenzene, dimethylsulfoxide, benzonitrile, N‐methylformamide, dimethylformamide and benzaldehyde to understand their abilities in BP exfoliation. BP (10 mg) added to each solvent (20 mL) was sonicated (at 22 and 30 °C) for 13 h under anhydrous and air‐free conditions, which were centrifuged (at 3000 rpm for 30 min) further to remove unexfoliated BP. Benzonitrile was found to be a suitable candidate with a mean concentration of 0.11 ± 0.02 mg mL–1. Figure 11l–p shows a photograph, SEM image and TEM images; particularly noteworthy is the TEM image of a monolayer BP of an exfoliated BP suspension in isopropanol synthesized by Woomer et al.196

4.2.2.2. Water‐Based Sonication

: Wang et al.114 used distilled water as the solvent, and it was bubbled with argon to eliminate the dissolved oxygen molecules to overcome the problem of oxidation in the sonication process. A scalable clean exfoliation with water of few‐layer BP was recently demonstrated by means of the tip sonication method.173 Bulk BP crystals were grounded to BP powders, the powders were dispersed in 20 mL of deionized (DI) water to obtain a concentration of 1 to 10 mg mL–1, and the dispersions were tip sonicated for 30 to 300 min. The supernatant was decanted from the settled dispersion after 12 h for centrifugation, yielding a BP nanosheet dispersion with a high concentration. The interesting finding of this study is that the BP nanosheets retain the high quality of the bulk crystals, with the excellent qualities of a very high crystallinity, an impurity‐free structure and stability in water. Lee et al.197 prepared few‐nm to <20 nm BP nanodots with an average diameter of ≈10 nm and a height of ≈8.7 nm, where BP (0.4 g, 12.8 mmol) was dispersed in distilled water (100 mL) for a 30 min sonication (20 kHz, 100 W). The supernatant liquid collected from the dispersion was ultrasonicated for 10 min and these steps were repeated two or more times to create smaller‐sized BP particles.

4.2.2.3. Ionic‐Liquid‐Based Sonication

: Ionic liquids (ILs) are molten salts at RT that have been considered as green solvents for decades,198 with exciting properties such as non‐volatility, high thermal stability, high viscosity, high ionic conductivity, nontoxicity, versatile solubility and solvent recyclability compared to conventional organic solvents.198, 199 ILs are presented by researchers for efficient exfoliation of 2D materials to obtain a stable yield with a high concentration of the suspended nanoflakes.200, 201, 202, 203 ILs exhibit viscosities that are 1−3 orders of magnitude more than those of conventional organic solvents; this influences the rate of mass transport within the solution by preventing the BP nanosheets from restacking.198, 200 An environmentally friendly liquid exfoliation by means of ionic liquids was reported by Zhao et al.200 to exfoliate highly pure, crystalline, atomic‐scale and uniform mono‐ to few‐layer BP nanosheets by mild grinding and weak sonication. The first step in IL‐exfoliation was grinding bulk BP (30 mg) with ILs (0.5 mL) for 20 min using an agate mortar with a pestle that supplements the mechanical shear forces to reduce the exfoliation time due to the increase in the surface area of BP.118, 182, 203 The next step was to disperse the mixtures in ILs (3 mg mL−1 BP) by ice‐bath sonication (100 W) for 24 h to obtain suspensions of BP flakes which were further centrifuged at 4000 rpm for 45 min to remove the unexfoliated BP. The stable dispersions of BP nanosheets were obtained, with higher concentrations (≈0.95 mg mL−1) than the concentration (0.4 mg mL−1) obtained in NMP, and without sedimentation and aggregation.183

Zhao et al.200 employed nine ILs, which included 1‐butyl‐3‐methylimidazolium tetrafluoroborate ([BMIM] [BF4]), [BMIM] trifluoromethansulfonate ([TfO]), [BMIM] bis((trifluoromethyl)sulfonyl)imide ([Tf2N]), 1‐ethyl‐3‐methylimidazolium ([EMIM]) [Tf2N], [EMIM] [BF4], 1‐hexyl‐3‐methylimidazolium ([HMIM]) [BF4], 1‐octyl‐3‐methylimidazolium ([OMIM]) [BF4], 1‐hydroxyethyl‐3‐methylimidazolium ([HOEMIM]) [TfO] and [HOEMIM] [BF4]. Figure 11g shows a photograph of BP in [BMIM][TfO] and [HOEMIM][TfO] and the Tyndall effect of the diluted dispersions. It was found that all ILs employed were efficient in yielding highly concentrated BP nanosheet dispersions in which the coulombic force and π−π interactions between the aromatic ILs cations and the phosphorene layers are more significant in obtaining stabilized exfoliated BP nanoflakes.201 ILs with larger surface tensions yield higher‐concentration dispersions as a result of the easy break down in the interlayer van der Waals forces of bulk BP by the large surface tension, thereby preventing detached BP layers from restacking.183, 200, 204 The cations influence the concentration of the suspension by changing the cationic chain length, as observed from comparing [EMIM] [BF4], [BMIM] [BF4], [HMIM] [BF4], [OMIM] [BF4], and [HOEMIM] [BF4]. It was also demonstrated that the [HMIM][BF4], with a relatively low surface tension, gives rise to a high‐concentration suspension where the viscosity of [HMIM][BF4] (177 cP at 303 K) is higher than the viscosity of the other ILs (28−90 cP at 303 K). Electron microscopy studies of BP‐[HOEMIM][TfO] including the low‐magnification TEM image, the selected area electron diffraction (SAED) pattern, the HRTEM image and the magnified HRTEM image of selected areas are shown in Figure 11h–k. Hence, ILs are found to be more suitable solvents for the fabrication of atomically thin BP nanoflakes due to their strong cohesive dipolar nature and the planarity of the solvents.

4.2.2.4. Tip‐Sonication‐Based Exfoliation