Abstract

With the development of renewable energy and electrified transportation, electrochemical energy storage will be more urgent in the future. Supercapacitors have received extensive attention due to their high power density, fast charge and discharge rates, and long‐term cycling stability. During past five years, supercapacitors have been boomed benefited from the development of nanostructured materials synthesis and the promoted innovation of devices construction. In this review, we have summarized the current state‐of‐the‐art development on the fabrication of high‐performance supercapacitors. From the electrode material perspective, a variety of materials have been explored for advanced electrode materials with smart material‐design strategies such as carbonaceous materials, metal compounds and conducting polymers. Proper nanostructures are engineered to provide sufficient electroactive sites and enhance the kinetics of ion and electron transport. Besides, new‐concept supercapacitors have been developed for practical application. Microsupercapacitors and fiber supercapacitors have been explored for portable and compact electronic devices. Subsequently, we have introduced Li‐/Na‐ion supercapacitors composed of battery‐type electrodes and capacitor‐type electrode. Integrated energy devices are also explored by incorporating supercapacitors with energy conversion systems for sustainable energy storage. In brief, this review provides a comprehensive summary of recent progress on electrode materials design and burgeoning devices constructions for high‐performance supercapacitors.

Keywords: integrated devices, material design, supercapacitors, system constructions

1. Introduction

The past decades have witnessed the rapid depletion of fossil fuels and increasingly worsened environmental pollution, which make energy systems are one of the most important topics in future.1, 2, 3 It has received increasing research interest to seek highly efficient, low cost, and environmentally benign energy sources to substitute fossil fuels.4 Due to ever‐increasing human reliance on energy‐based appliances, electrical energy has become the most important secondary energy source and is indispensable in aspects of daily life.5 Therefore, the search for the next generation energy storage devices with efficient use of energy is extremely important.6 Storage devices with high energy and power densities are in strong demand for most systems such as cellular phones, electric cars, and so on.7 Among various energy storage systems, supercapacitors (SCs) and lithium batteries are at the frontier of this research.8, 9 SCs and battery devices as representative modern energy storage devices have been widely used in our daily life by powering various portable electronic devices and even current plug‐in hybrid electric vehicles.10, 11

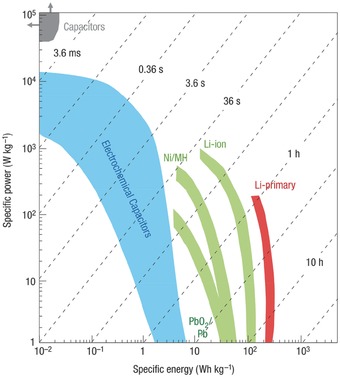

Figure 1 , 12 presents the simplified ‘Ragone plot’ of various energy conversion and storage devices according to their specific power and specific energy output. In comparison, SCs occupy an important position in terms of the specific energy as well as the specific power. Firstly, compared with traditional electrolytic or electrostatic capacitors, SCs can deliver much higher energy density due to the charge storage in an electric double layer in place of a dielectric layer.13 Secondly, SCs can provide faster power delivery than lithium batteries.14, 15 High power density (>10 kW kg–1) means the system can release and deliver high current or uptake pulse when is required.16 SCs are one of the crucial power devices that can be fully charged/discharged in seconds. Hence, SCs are well‐suited for regenerative braking, frequency regulation in smart grids and storing the intermittent energy profiles of renewable energy sources.17, 18 Currently, SCs are being envisaged for several applications in consumer electronics, memory back‐up systems, industrial power and energy management.19, 20 To some extent, SCs fill the gap between conventional capacitors and lithium batteries. However, lithium batteries can deliver higher energy density reaching 200 Wh kg–1 whereas SCs show an energy density in the range of 5–10 Wh kg–1.21 In brief, SCs possess superior power density but limited energy density compared to lithium batteries.

Figure 1.

Ragone plot showing specific power against specific energy output for SCs and batteries devices. Reproduced with permission.12 Copyright 2008, Nature Publishing Group.

The biggest challenge for SCs research is to enhance their specific energy density while retain their intrinsic high specific power density. To date, a great deal of research efforts has been devoted on increasing the energy performance of SCs to be close to or even more than that of batteries. This review begins with the typical in‐depth study on the charge storage mechanism and then illustrates current state‐of‐the‐art improvement in SCs regarding the electrode materials design and booming devices construction. On the following sections, the characteristics will be discussed in details for SCs based on different charge storage mechanisms. Progress towards supercapacitor technologies can make an achievement from the fundamental understanding of charge/discharge behavior of SCs. Besides, SCs is potential for large‐scale deployment such as industrial equipment market and solar electricity storage.

2. Charge Mechanism

SCs also known as ultracapacitors and electrochemical capacitors have attracted intense attentions due to their high specific power, a long cycle life, and fast charge/discharge processes (within seconds).22 Generally, SCs can be divided into electrical double layer capacitors (EDLCs) and pseudocapacitors (PCs) depending on their energy storage mechanism.23 EDLCs store the charge through the ion adsorption/desorption on the electrode/electrolyte interfaces. EDLCs mainly based on high surface area carbon materials which are electrochemically stable. Charge storage in PCs depends on the fast reversible surface redox reactions. Several metal compounds and conducting polymers are the typical materials used for PCs such as RuO2,24 MnO2,25 polypyrrole,26 polyaniline,27 and polythiophene.28 The mechanisms occur mainly on the electrode/electrolyte interface, which ensure SCs fast charge and discharge rates and high power density, and these two mechanisms can occur simultaneously in some cases.

2.1. Mechanism of EDLCs

EDLCs store energy through the ion absorption and desorption during the charge/discharge processes on the electrode/electrolyte interface without the charge transfer reaction.29, 30 The capacitive behaviors are strongly dependent on the surface area of the electrode materials that is accessible to the electrolyte ions.31, 32 It can be expressed as follows:

| (1) |

where C is the capacitance of the EDLCs, εr is the electrolyte dielectric constant, ε0 is vacuum permittivity (8.854 × 10–12 F m–1), d is the effective thickness of the double layer located at the electrolyte/electrode interfaces, and A is the electrode surface area immersed in the electrolyte. Since d in EDLCs is just a few angstroms, which is far less than it in traditional dielectric capacitors.33, 34 hence, higher capacitance can be achieved in EDLCs. The capacitance of EDLCs is dependent on the specific surface area of the electrode, the type of electrolyte and the effective thickness of the double layer.

During the charging process, anions of electrolytes are accumulated on the positive surface of EDLCs, while the surface of negative electrode attracts the cations of electrolytes.35, 36 The energy storage process involves highly reversible non‐faradaic reactions occurring at the electrode/electrolyte interface. This storage mechanism of EDLCs allows for very fast energy uptake and delivery and long cycling life with almost no capacitive fading as compared with other energy storage systems. The underlying cause may be attributed to the physical adsorption and desorption process.

To obtain superior capacitance, it is required to optimize the pore size, pore structure, surface properties and conductivity of the electrode materials.37 Carbon‐based materials are used as EDLCs electrodes due to their high surface area and electronic conductivity. Capacitance values of many tens of farads per gram of the electrode material are achieved in some materials, such as activated carbon, graphene, carbon nanotube, and so on.38, 39, 40 Nevertheless, the electrical double layer capacitance derived from the charge separation is still not able to meet the commercial market expectation in terms of their limited specific energy density.41

2.2. Mechanism of EDLCs

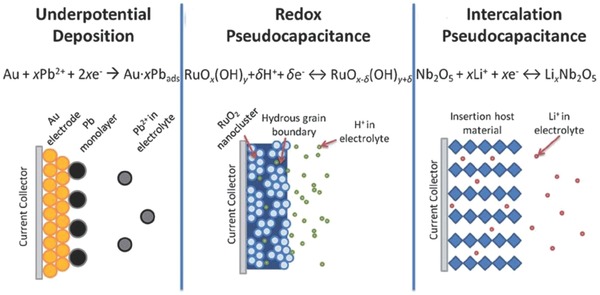

Unlike the EDLCs that physically accumulates charges, pseudocapacitance is a faradaic process that involves surface or near‐surface redox reactions.42 According to Conway's book,43 charge transfer process of PCs that exploits the faradaic reaction to tunnel the electrons across the current collector/electrode44, 45 interfaces can be identified as three faradaic mechanisms as followings, which is illustrated in Figure 2 , 46: (1) underpotential deposition (UPD), (2) redox pseudocapacitance, (3) intercalation pseudocapacitance.

Figure 2.

Different types of reversible redox mechanisms that give rise to pseudocapacitance: underpotential deposition, redox pseudocapacitance, and intercalation pseudocapacitance. Reproduced with permission.46 Copyright 2014, RSC.

UPD involves the faradaic absorption/desorption of metal ions or protons on the surface of metallic active materials (e.g. Au, Pt, Rh, and Ru) to form an adsorbed monolayer above their redox potential, thus UPD is also called two‐dimensional adsorption pseudocapacitance.47, 48

Redox pseudocapacitance occurs at a surface or near surface of electrode material when ions are electrochemically adsorbed, accompanied by the charge transfer process.49 Recently various active materials have been widely investigated as the potential candidates to exhibit redox pseudocapacitance, such as such as transition metal oxides (RuO2,50 MnO2 51) and conducting polymers (polyaniline,52 polypyrrole53). During charging/discharging, transient change in valence states of such active materials occurs with concomitant faradaic charge transfer.

Intercalation pseudocapacitance refers such a process that cations intercalate into the tunnels or layers of host materials accompanied by a faradaic charge‐transfer involving no crystallographic phase change.54 It should be noted that two‐dimensional pathway for ion transportation with minimum structural distortion is needed for this behavior. Materials with the rigid layered lattice framework are require, such as Nb2O5,55 V2O5,56 and MoO3.57 The difference for three mechanisms is their respective different physical processes and the similarity is their electrochemical signatures.

PCs typically exhibit higher specific capacitance and energy density than EDLCs. In general, the specific capacitance associated with faradaic reactions is at least 10 times greater than that of double‐layer processes.58 However, PCs often suffer from low power density and lack of stability due to poor electrical conductivity and framework swelling during cycling.59 The electrode materials should possess redox capability to maintain the charge balance by chemisorption of electrolyte ions upon the continuous charge/discharge processes.

2.3. Electrochemical Characterization

There are many parameters of defining the overall electrochemical performance of SCs in terms of specific capacitance, operating voltage, equivalent series resistance, power density, energy density, and time constant.60, 61 To accurately assessed the capacitive behaviours, a variety of methods have been proposed to measure the three essential parameters: specific capacitance (C s), operating voltage (V) and equivalent series resistance (ESR). And then power density (P) and energy density (E) can be calculated based on the three essential parameters. The common methods for measuring the three fundamental parameters include cyclic voltammetry (CV), galvanic charge/discharge (GCD) and electrochemical impedance spectroscopy (EIS).

Firstly, CV testing can be used for examining the charge storage mechanism and calculating the specific capacitance of the electrode materials in a three‐electrode configuration. CV curves can be obtained based on their response to a voltage sweep which is plotted as current vs. potential. In EDLCs, an almost rectangular is observed in CV curves resulted from the highly reversible adsorption and desorption of ion at electrode‐electrolyte interface.62 The CV curves of PCs can present a rectangular or redox couple peaks resulted from the redox reactions.63, 64, 65

Specific capacitances (F g–1) of the electrode materials can be calculated based on CV curves according to the following equations43:

| (2) |

Where I (mA) is the instantaneous current, ΔV (V) is the applied potential window which presents the range of potential change, m (g) is the weight of the active material, and v (mV s–1) is the scan rate which presents the speed of the potential change during the positive and negative sweeps in the CV measurement.

Secondly, GCD testing is used for the characterization of capacitive behaviours based on their response to the constant current. GCD curves can be obtained according to the functional relation between the potential and time. In a three‐electrode configuration, the specific capacitance can be calculated based on GCD curves according to the following equations43:

| (3) |

Where I (A) is the discharge current, m (g) indicates the mass of the active material, and the value of dV (V)/dt (s) represents slope obtained from the discharge curve in the GCD measurement. In the case of nonlinear response for most of the pseudocapacitive materials, it is suggested to calculate the specific capacitance using the two datum points derived from the discharge curve, dV/dt = (V max–1/2 V max)/(t 2 – t 1), where t 1 and t 2 represent the discharge time of V max and 1/2 V max, respectively.

Thirdly, EIS is always conducted to investigate the transport characteristics of the charge carriers within the capacitive electrode.66, 67 EIS measures the impedance of the devices as a function of frequency by applying a low‐amplitude alternative voltage superimposed on a steady‐state potential, which are usually expressed graphically in a Nyquist plot. In a Nyquist plot, the expression of impedance (Z) can be simplified as: Z = Z′ + jZ′′, in which Z′ and Z′′ could be defined as the real and imaginary part of impedance, respectively. By executing similar analysis, the interpretation of the impedance results can be used to probe aspects of capacitive behaviors of the electrode materials including specific capacitance, charge transfer, mass transport and charge storage mechanisms.68, 69

Furthermore, energy density (E) and power density (P) are two important parameters to evaluate the performance of energy storage devices. Energy density represents the total amount of charges stored in SCs per unit mass or volume, whereas the power density is synonymous to the rate of charge being delivered upon discharging. The equations used to express energy density and power density are as follows43:

| (4) |

| (5) |

Where E (J g−1) is energy density, C (F g–1) is the specific capacitance of the electrode material, V (V) is the potential range, m (g) is the mass of electrodes, and Rs is the equivalent series resistance (ESR) in ohms. Here, the ESR is deduced from the following equation43:

| (6) |

Where △V represents the voltage different. I charge and I discharge represent magnitude of the charge and discharge currents, respectively. According to the energy density formula, the enhanced energy density can be obtained by increasing the specific capacitances and/or widening the potential range.70, 71

Besides, long‐term cycling life is crucial for an electrode material to be used in electrochemical capacitors and their further practical application. Cycling stability can be obtained by observing the degradation before and after a long‐term cycling process through CV or GCD measurements.

2.4. Electrochemical Testing System

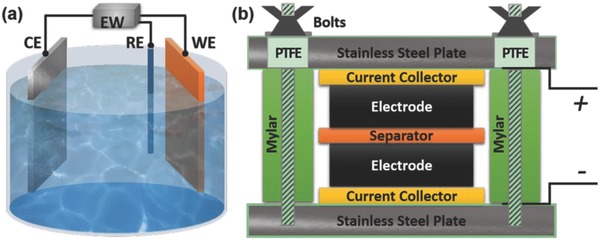

Generally, the electrochemical properties of electrode materials are evaluated in a three‐electrode or two‐electrode systems. The three‐electrode testing system is composited by working electrode (WE), counter electrode (CE) and reference electrode (RE), which is illustrated in Figure 3 a. Three‐electrode testing system is always employed to investigate the electrochemical performances of the active materials. In a three‐electrode setup, the applied voltage across the working electrode is measured with respect to a particular reference electrode.72

Figure 3.

Construction graphs of (a) the three‐electrode testing system (EW: electrochemical workstation, WE: working electrode, CE: counter electrode, RE: reference electrode), and (b) the two‐electrode testing system.

Nonetheless, the two‐electrode testing system is composed by a pair of closely spaced electrodes containing the electro‐active materials attached to the current collector saturated with an electrolyte and a separator sandwiched between the parallel electrodes, as displayed in Figure 3b.73 The separator is a dielectric porous membrane with ion permeable but electrical insulating that allows migration of electrolyte ions while keeping the two electrodes electrically apart. On one hand, the separator acts as a physical barrier between the two electrodes to prevent electrical short circuits. On the other hand, the separator is permeable to the ions allowing rapid ionic charge transfer during the passage of current in an electrochemical cell.

For two‐electrode testing system, the whole electrochemical performance of SCs mainly depends upon both the two electrodes in the given electrolytes. The whole construction is a cell, and the two electrodes are positive and negative electrodes, respectively. In terms of two‐electrode configuration, an SCs cell are grouped into two major categories called symmetric and asymmetric devices depending on the kinds of electrode materials.74

In the case of the symmetric cells, these devices will be composed using the same material with the same mass for both the positive and negative electrodes. In symmetric SCs, the applied voltage is distributed equally on two electrodes. Such a symmetrically configured cell has both electrical double layer capacitance and pseudo‐capacitance. Symmetric capacitors are EDLCs‐based devices, and they store electrostatic charge from the accumulation and separation of ions at the interface between the electrode surface and electrolyte. On this occasion, aqueous, organic or ionic electrolyte solutions are flexible at the request of the existing system.75 Another symmetric capacitors is constructed of pseudocapacitive materials with reasonable potential range. Manganese dioxide‐based electro‐active materials have been investigated in pseudocapacitive symmetric capacitors.76 It should be noted that this type of symmetric SCs is rarely used since the redox reactions only occur either at the positive or the negative voltage, but not on both.

In the case of asymmetric SCs, one pseudocapacitive electrode and one EDLCs electrode have been used for positive and negative electrodes, respectively. In general, the asymmetric devices feature a high energy density and a high power density due to an increased operating potential.77 Asymmetric SCs would combine the advantages of different electrode materials and then achieve a wider operating voltage for the device. By using different types of electrodes that can be operated at different potential windows, an asymmetric capacitor can be manufactured with cell voltages extending up to 2.0 V in an aqueous electrolyte.78 To improve asymmetric SCs performance, effective methods involve the advanced development of electrode materials with optimized architectures. It is worth noting that the matching ratio of positive and negative electrodes should be considered for smart SCs configurations.79 The different mass ratio between positive and negative electrodes will affect the overall capacitance of the device.80, 81 Therefore, it is important to optimize the mass ratio between positive and negative electrodes in two‐electrode system.

In brief, the electrochemical performances of SCs are governed by several parameters including the active electrode material, the nature of electrolyte, and the testing systems. Usually, the effects of these parameters are interlinked and revealed in combination.

3. Electrode Materials

Electrode material is an important factor determining the specific capacitance, which has been receiving intensive attention from research.82 It is evident that controlling the architecture and interface property of electrode materials plays an important role in enhancing high‐performance SCs including high specific capacitance, good rate capability and long cycling stability.83 Fortunately, nanotechnology has opened up new frontiers in materials science and engineering and will play a critical role in advancing the development of charge storage to meet the challenge.84 The morphology and chemical composition of the resultant materials are characterized by scanning electron microscopy (SEM), transmission electron microscopy (TEM), scanning transmission electron microscopy (STEM), powder X‐ray diffraction (XRD), energy dispersive X‐ray spectroscopy (EDX), and X‐ray photoelectron spectroscopy (XPS) measurements and so on. Over the past decades, technological breakthrough in nanoscience paves a new way for the development of materials design, and the electrochemical performance is boosted to several‐fold capacitive enhancement.

Despite of different mechanisms based on EDLCs and PCs, there are some common traits for enhanced electrochemical properties. An electrode material with high surface area and high electric conductivity is expected to develop advancement for SCs.85 At first, high surface area can provide more active sites for EDLCs or pseudocapacitive reactions since the increased surface‐to‐volume ratio supplies maximum contact surface between the active materials and electrolyte ion. High surface area can be obtained by synthesizing nanosized or/and porous electroactive materials.86 In this case, porous structure for electrolyte diffusion is helpful to guarantee easy accessibility for ion penetration, avoiding sacrifices of surface area due to stacking or blockage of active sites. Secondly, high electrical conductivity for fast charge transportation is crucial to realize a high rate capability and power density. The enhanced electric conductivity can be realized by decreasing the size of the electroactive material and/or compositing with other materials with good electrical conductivity.87

The performances for an electrode material are investigated by assembling them into a three‐electrode or two‐electrode systems. In traditional equipment for an electrode, the electrode material, conductive agent, and binders are grinded to form uniform slurry and then it is pasted to current collectors.88 Conductive agents are conductive carbon (e.g. acetylene black) and used to improve the electrical conductivity of the electrode. The presence of binders helps the active materials and conductive agent to be linked and make them good mechanical adhesion to the current collector. However, binders are generally electro‐inert, which bring about potentially greater internal resistance. So far, flexible electrode has emerged as a new electrode configuration with mechanically robust achieving high specific gravimetric and volumetric capacitance. Flexible electrodes have been designed by self‐standing electrode materials with high flexibility or integrated electrode materials with high flexibility on soft‐matter substrates, wherein conductive agent and binder are unnecessary.89, 90 In this part, potential flexible electrode materials electrode will be briefly introduced.

3.1. Carbon Materials

Carbon materials are generally carbon‐based materials, which store charges electrostatically at their surfaces using reversible adsorption/desorption of ions of the electrolyte onto active materials.91 Carbon‐based materials have been widely explored as electrode materials for SCs due to a unique combination of properties such as high surface area, lightweight, good electrical conductivity, controlled pore size distribution and compatibility with other materials. The carbon‐based electrochemical capacitor is first discovered by Becker in 1957. Activated carbon electrodes have been applied into commercial SCs with high power density, yet their energy density is limited which is mainly due to the ill‐defined physical and chemical properties of the activated carbon.92 More research has focused on developing high‐performance SCs based on carbon materials with low‐cost, versatile, highly conductive, chemically stable at wide temperature range. Additionally, carbon‐based free‐standing electrodes are promising for producing wearable electrodes due to their light weight, flexibility, and highly conductive.93, 94

3.1.1. Graphene

Graphene, a two‐dimensional carbon sheet with monoatomic layer thickness, has been widely explored as an ideal electrode material for SCs in the past decade.95, 96 Graphene features unique properties including high theoretical surface area (2630 m2 g–1) and high in‐plane electrical conductivity.97 Graphene sheets (single layer to a few layers)have been synthesized by several effective and facile approaches such as mechanical exfoliation method,98 exfoliation of graphite in organic solvents,99 epitaxial growth and chemical vapor deposition (CVD),100 and the exfoliation and reduction of chemically oxidized graphite.101, 102 Mechanical exfoliation (or the “scotch tape” method) can obtain single graphene but is difficult to massively produce graphene for the practical application.103

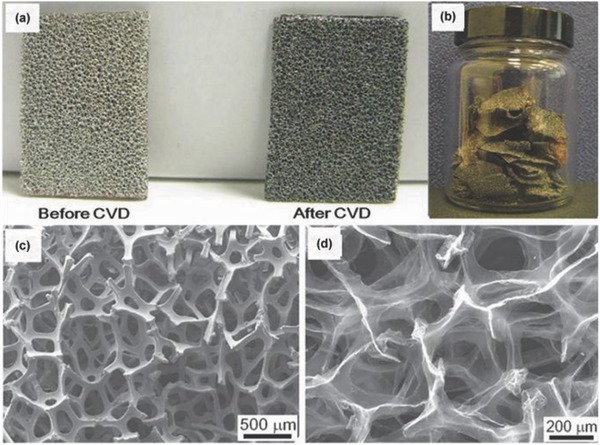

Chemical vapor deposition (CVD) on a metal substrate (Ni, Cu, etc.) has been recognized as an alternative method for fabrication of graphene sheets with high conductivity comparable to the pristine graphene.104 The as‐synthesized graphene possess superior electrical conductivity and high surface area which would facilitate the fast electron transport between the active materials and current collectors.105 Kong et al. first reported the CVD growth of few‐layer graphene films on the polycrystalline Ni substrate.106 However, the employed carbon sources are usually explosive (e.g. CH4).107, 108 Alternative substrates and safe carbon sources for graphene growth have been developed in recent years for mass production. Zhang et al. have reported a good method to scale up the CVD synthesis of graphene by using Ni foam as a sacrificial template and ethanol as the carbon source.109 As illustrated in Figure 4 a, the colour of the Ni foam changed from shiny white to dark gray after the growth of graphene. Figure 4b shows the yield of graphene, the production can be easily scaled up by using a larger CVD chamber. Ethanol used as carbon sources are safe and cheap, which is essential for practical applications. Figure 4c and d investigated the three‐dimensional graphene networks grown on Ni foam after the CVD process and three‐dimensional graphene networks after the removal of Ni foam. Additionally, the as‐synthesized graphene networks can serve as templates for the construction of graphene/NiO composites. Superior electrochemical properties are demonstrated containing a high specific capacitance of 816 F g–1 and a stable cycling performance without any decrease after 2000 cycles.

Figure 4.

a) Photographs of Ni foam before and after the growth of graphene. b) Photograph of the obtained graphene in a single CVD process after removal of Ni foam.c) SEM image of graphene on Ni foam after CVD, and d) SEM image of graphene networks after removal of Ni foam. Reproduced with permission.109

Among these synthesis methods, the exfoliation and reduction of chemically oxidized graphite is used for large‐scale production of graphene.110 A considerable amount of researches have been stimulated on developing cost‐effective graphene‐based energy storage materials with enhanced energy and power density as well as long life‐cycle.111 In this case, graphite is oxidized and exfoliated into graphite oxide (GO) and then graphene is prepared after an reduction process.

GO can be synthesized by either the Brodie,112 Staudenmaier,113 or Hummers114 methods at large‐scale with relatively low cost. The as‐synthesized GO contains oxygen‐containing functional groups including epoxide, carbonyl, hydroxide and carboxylic acid groups. GO has been used as SCs electrode material and exhibits a higher capacitance (189 F g–1) than that of graphene due to an additional pseudocapacitance effect resulted from the oxygen‐containing functional groups on its basal planes.115 Deng et al. found that the specific capacitance increases when the oxygenated species reduces.116 Additionally, GO is easy to be modified for the fabrication of high‐performance SCs.117 Kim et al. have reported progress toward high‐performance SCs based on poly(ionic liquid)‐modified GO electrodes via electrostatic interactions.118 Stable electrochemical performance with a high specific capacitance of 187 F g–1 was observed due to enhanced compatibility with certain ionic liquid electrolytes and improved accessibility of electrolyte ions.

Various routes have been used to reduce GO to graphene to restore the intrinsic specific surface area and electrical conductivity of graphene, and construct graphene‐based nanostructures with desirable channel size, which are all favourable for SCs applications.119, 120 GO can be reduced by reducing aqueous solutions such as hydrazine hydrate, hydrobromic/hydroiodic acid, and so on.121 However, the sheet‐to‐sheet van der Waals interactions between graphene sheets lead to the stacking of the graphene sheets. Consequently, the specific surface area is reduced during the stacking process and inferior specific capacitance is observed.122 Hence, extensive approaches have been explored to reduce the aggregation between graphene sheets.

Firstly, surfactant intercalation has been regarded as a facile method to inhibit aggregation of graphene sheets during reduction. Zhang et al. have conducted schematic studies on a series of surfactant‐stabilized graphene materials with different surfactants.123 The presence of surfactants benefits to stabilize the morphology of single layer or few‐layer structure of graphene sheets during reduction, and enable good dispersibility in aqueous solvents.

Secondly, thermal reduction is used for preparation of graphene to efficiently combine of electrically conductive channels and appropriate pseudocapacitive functional groups in the graphene‐based electrode at the same time.124 Zhi et al. have developed a striking strategy for elaborately constructing rationally functionalized graphene from natural graphite via a modified Hummers method followed by an acid‐assisted ultrarapid thermal‐processing technique.125 On one hand, ultrarapid thermal‐processing allows the efficient recovery of the basal structure electrically conductive channels. On the other hand, the ultrarapid thermal‐processing technique guarantees the preservation of functional groups with pseudocapacitive effects.

Thirdly, graphene sheets are assembled into three‐dimensional porous network and macrostructures.126, 127 To minimize the stacking of graphene sheets, other carbonaceous materials have been added between graphene sheets to design three‐dimensional materials with extraordinary properties. Taking carbon spheres as example, carbon spheres are used as spacer to separate graphene sheets by an assembly approach.128, 129 Electrochemical tests reveal enhanced cycleability and rate performance due to the synergistic effect of the combination of these materials.

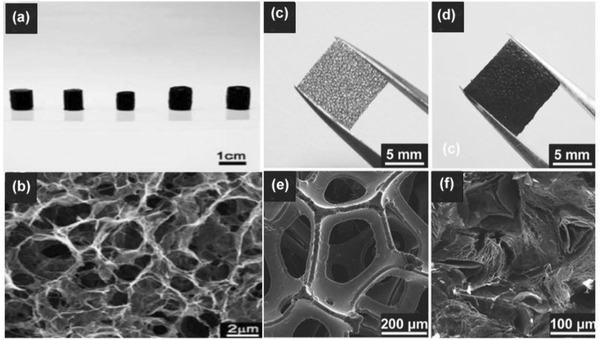

Graphene gels (hydrogels and aerogels) have received particular attention due to their lightweight, large specific surface area and interconnected three‐dimensional porous frameworks. Graphene gels allow multidimensional electron transport and rapid electrolyte ions diffusion.130, 131 For example, Shi groups have reported their works on graphene hydrogels as electrodes with high performance. At first, they prepared graphene hydrogels by a one‐step hydrothermal process as shown in Figure 5 a and b.132 The as‐prepared hydrogels possess a well‐defined three‐dimensional porous network. The unique three‐dimensional morphology provides open channels allowing graphene sheets exposed to electrolytes to optimize the ionic diffusion. The high performances of graphene‐base hydrogels make it promising for SCs applications. However, their capacitance decreases greatly at a high discharge rate and instability for long cycle life because of the relatively low conductivity and large amount of residual oxygenated groups of the hydrogel. To modify the electrochemical properties of graphene‐based hydrogels, Shi and co‐workers have reduced above‐mentioned graphene hydrogels with hydrazine or hydroiodic acid to improve their conductivities and remove their residual oxygenatedgroups.133 The as‐prepared reduced graphene hydrogels perform a high capacitance of 222 F g–1 at a low discharge rate and the capacitance can be retained 74% at an extraordinary fast discharge rate of 100 A g–1.

Figure 5.

a) Photographs of graphene hydrogels with tunable height. b) SEM image of the interior microstructures of freeze‐dried graphene hydrogel. Reproduced with permission.132 Copyright 2010, ACS. c,d) Photographs of a piece of Ni foam before and after coating of graphene gel. e,f) SEM images of Ni foam before and after coating of graphene gel. Reproduced with permission.134

To further improve the capacitive performances of graphene hydrogels, one piece electrode has been constructed by in situ gelation of graphene sheets in the micropore of nickel foams as illustrated in Figure 5c–f.134 The porous structures and good conductivity of nickel foam lead to the shortened distance and fast response for charge transfer. Consequently, excellent performances are achieved including high specific capacitances, long durability, and high rate capability. In addition, Maiti et al. have demonstrated the scalable three‐dimensional shape‐engineering gelation of graphene by a simple immersion of zinc substrates.135 The thickness of graphene gel can be controlled by tuning the immersion time. The gel‐based SCs exhibit excellent rate capability due to the high electrical conductivity and facile ion transport compatible with large areal capacity resulted from constructing thick electrodes.

More approaches have been developed to construct three‐dimensional graphene to hold well‐defined pathways for efficient ionic and electronic transport.136 For example, Huh et al. build three‐dimensional graphene films by using polystyrene colloidal particles as a sacrificial template.137 Zhang et al. obtained porous three‐dimensional graphene‐based bulk materials through efficient and industrially scalable approach.138 The three‐dimensional precursor materials are prepared by in situ hydrothermal polymerization/carbonization of the mixture of cheap biomass or industry carbon sources with GO and then activated to achieve the desired specific surface area and conductivity. Mitlin et al. created three‐dimensional sponge‐like graphene nanoarchitectures via a microwave synthesis process.139

The specific capacitance of graphene‐based EDLCs is strongly affected by the surface area for access to electrolyte ions. Chemical activation with potassium hydroxide (KOH) is considered as an efficient method to enhance the surface area for graphene‐based materials.140 It is suggested that the activation of carbon with KOH proceeds as the following equation: 6KOH + C = 2K + 3H2 + 2K2CO3. Then the reaction is followed by decomposition of K2CO3 and/or reaction of K/K2CO3/CO2 with carbon, which generate nanoscale pores during the activation process.

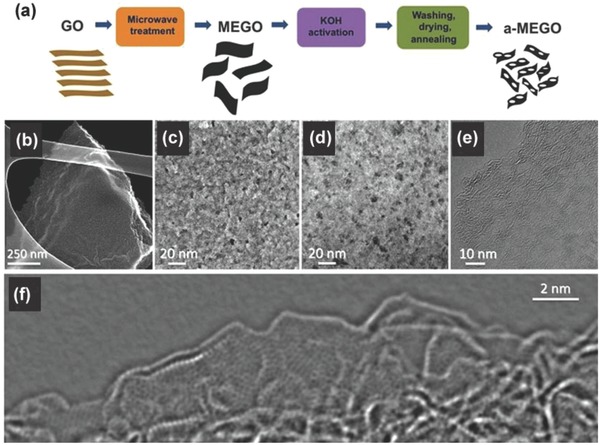

Ruoff and coworks have presented their works on activated graphene‐derived materials and their application in SCs.141, 142 Graphene‐derived carbon with extremely high surface area of up to ≈3,100 m2 g–1 has been prepared by microwave irradiation and activation with KOH. Microwave irradiation treatment on GO produces a large fraction of micro‐ and mesopores to provide a large and accessible specific surface area for charge accommodation. Figure 6 a shows the schematically process of the microwave exfoliation/reduction of graphene followed by chemical activation with KOH. At first, graphene is obtained by reduction of GO by microwave treatment, which is denoted as MEGO. And then, the as‐synthesized MEGO is activated with KOH that generates nanoscale pores while retaining high electrical conductivity. The activated graphene‐based carbon material is denoted as a‐MEGO. The surface area of the activated materials could be controlled by the mass of KOH. During the activation process, graphene is etched and reconstructed into porous networks. Figure 6b–d demonstrate the porous morphology of the activated carbon material with meso‐ and micropores ranging from 1–10 nm. Figure 6e and f illustrate the edge of a‐MEGO with the presence of a dense network of nanoscale pores surrounded by highly curved, predominantly single‐layer carbon and the in‐plane crystallinity. Therefore, a relatively high specific volumetric capacitance and gravimetric energy density are achieved in organic and ionic liquid electrolytes due to improved porosity and enhanced specific surface area. Moreover, this group present a novel method to prepare free‐standing, and flexible porous carbon thin films by chemical activation of reduced GO paper.143 After activation, a high specific surface areas of up to 2400 m2 g–1 and a very high in‐plane electrical conductivity of 5880 S m–1 are achieved, which contributes to excellent specific capacitances and energy densities of 120 F g–1 and 26 Wh kg–1.

Figure 6.

a) Schematic process of the microwave exfoliation/reduction of GO (MEGO) followed by chemical activation with KOH denoted as a‐MEGO. b–d) Low and high magnification SEM images of a‐MEGO. e) High‐resolution phase contrast electron micrograph of the thin edge of a‐MEGO. f) High‐resolution TEM image from the edge of a‐MEGO. Reproduced with permission.141 Copyright 2011, AAAS.

Graphene holds its promise for high‐power, flexible electronics because its characteristic feature of two‐dimensional geometry provides high effective surface area for energy storage.144 Graphene paper or film are ideal materials for flexible energy storage devices benefiting from their strong mechanic and electrical conductivity. Recent advancement has been achieved on the synthesis and fabrication of flexible graphene films by filtration and assembly of individual graphene sheets.145, 146 For example, flexible graphene films incorporated with carbon black nanoparticles147 and cellulose148 are prepared by a simple vacuum filtration method. Carbon black nanoparticles and cellulose are introduced to serve as spacers to mitigate the self‐stacking of individual graphene sheets during the filtration process. Consequently, the resulting flexible electrodes display an improved electrochemical performance compared to the pure graphene paper. However, the further applications of graphene films‐based energy storage devices have been restricted by unsatisfied volumetric performances as a consequence of the compact geometry of the stack and the ion mobility.149

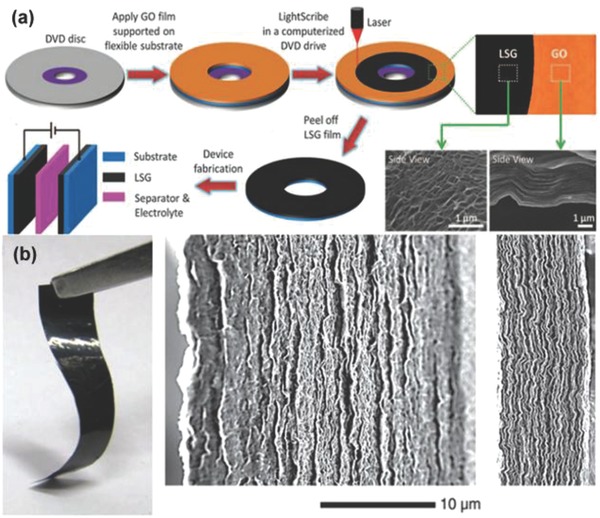

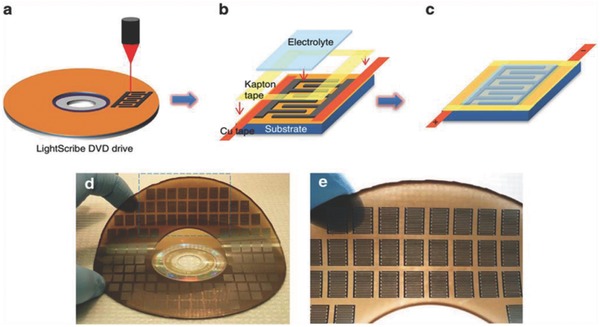

To address this problem, Kaner et al. have developed an all‐solid‐state approach for the production of graphene‐based SCs to avoid the stacking of graphene sheets by a direct laser strategy.150 Figure 7 a illustrates the fabrication process. At first, a GO film was drop‐cast on a flexible substrate and placed on top of a standard LightScribe‐enabled DVD media disc. Then, an infrared laser was applied inside the LightScribe‐enabled DVD optical drive and reduces the GO film to graphene film. The reduction process can be observed that the film colour changes from golden brown to black and the initially stacked GO were converted into well‐exfoliated laser‐scribed graphene by the analysis of SEM images. The as‐prepared laser‐scribed graphene films possess a high specific surface of 1520 m2 g–1 and excellent conductivity of 1738 S m–1. Moreover, the resultant graphene films can serve as flexible electrodes to be directly assembled into symmetric SCs. The as‐fabricated symmetric SCs exhibit an ultrahigh volumetric energy density up to 1.36 mWh cm–3 and a volumetric power density of 20 W cm–3 as well as excellent cycling stability.

Figure 7.

a) The illustration of schematically fabrication process of laser‐scribed graphene‐based SCs. Reproduced with permission.150 Copyright 2012, AAAS. b) A photograph showing the flexibility of the resultant liquid electrolyte‐mediated graphene films and SEM images of cross sections of the resultant liquid electrolyte‐mediated graphene films containing 78.9 volume percent (vol. %) and 27.2 vol. % of H2SO4, respectively. Reproduced with permission.152 Copyright 2013, AAAS.

Additionally, the self‐stacking of graphene sheets could be mitigated by incorporating with carbon or water into internal sheet spaces. Li group have discovered that the resultant wet graphene film after filtration did not occur serious stacking by using water as an effective spacer to prevent the stacking of individual graphene sheets.151 The solvated graphene films possess superior specific surface area and conductivity to its corresponding freeze dried films indicating good connection between individual sheets. Consequently, the resultant solvated graphene films could obtain unprecedented electrochemical performances. Subsequently, they acquired porous yet densely packed carbon electrodes by capillary compression of adaptive graphene gel films in the presence of a nonvolatile liquid electrolyte (H2SO4).152 Figure 7b illustrated the flexibility and cross section images of the films containing 78.9 volume percent (vol. %) and 27.2 vol. % of H2SO4, respectively. The liquid‐mediated dense integration of graphene materials possess high ion‐accessible surface area and low ion transport resistance. In this case, electrochemical capacitors based on the resulting films exhibit a high gravimetric and volumetric capacitances of 200 F g–1 and 18 F cm–3, respectively as well as the energy densities approach 60 Wh L–1.

All these results make it possible to develop new graphene‐based SCs with the combination of high energy density and high power density in terms of gravimetric and volumetric measurements. In addition, transparent flexible thin film based graphene have been synthesized and applied into capacitive touch pad contributed to their high response sensitivity under fast touch rates.153

3.1.2. Carbide‐Derived Carbon

Carbide‐derived carbons (CDCs) have received considerable attraction as electrode materials due to their high specific surface area, controllable porosity and high volumetric capacitance. Gogotsi groups have devoted much effort to synthesize carbons derived from metal carbide and investigated their capacitive behaviors.154 In general, CDCs are prepared by the selective removal of non‐carbon atoms from the corresponding carbides with halogens in an elevated temperature environment or thermal/hydrothermal decomposition. During the high‐temperature chlorination of metal carbides, a large number of micropores can be produced and the pore size distribution of resultant CDCs can be precisely tuned by changing the chlorination temperature and the carbide precursor.

Various types of carbide precursors have been explored for the fabrication of CDCs such as SiC, TiC, VC and so on. The carbide precursors will lead to the change in terms of pore size distribution. Taking the elevated temperature at 1200 °C as example, CDCs are investigated with a pore size range of 0.8 to 2.1 nm while SiC and B4C serve as initial precursors. Elevated temperature is one of key factors for a narrow pore‐size distribution. For example, carbon derived from SiC at 900 and 1200 °C produced an average pore size of 0.65 nm and 1.2 nm. Ti3SiC2 derived CDCs have been produced at temperatures from 200–1200 °C and precise control of size is achieved an average pore size in the range of 0.6–1.6 nm.155 It is an attractive route for the manipulation of the micropore (<2 nm) size distribution. Moreover, the halogenation conditions will affect the resulting pore size and specific surface area and then lead to distinguishing electrochemical performances in either aqueous or non‐aqueous electrolytes. CDCs with mean particle sizes around 20–40 nm have been synthesized by the chlorine treatment of TiC with temperature ranging from 200 to 1200 °C. The CDC produced at 600 °C display the highest capacitance value owing to the high specific surface area and large pore volume.156

Since the CDCs can retain the shape of initial carbides, CDCs with different textures and morphologies are capable to be fabricated depending on the morphology of the carbide precursors such as powders, nanopowders, thin films, fibers and so on. For instance, nanofibrous CDC felts have been derived from electrospun TiC nanofelts with nanofiber diameters of 100–200nm.157 On account of the conformal transformation of TiC into CDC, the resulting CDC felts conserves the unique properties of precursor including interconnectivity and structural integrity and flexibility. Consequently, CDC nanofelts are developed as flexible electrodes and reveal superior gravimetric capacitance in aqueous and organic electrolytes.

Monolithic CDC films are able to be fabricated on various substrates by dry etching procedure and then the as‐prepared CDC films can be directly used as free‐standing electrodes for EDLCs due to their reduced macropore volume, elimination of polymer binders and good adhesion between current collector and active material. Continuous carbon films have been synthesized by dry etching of sputtered TiC films on glassy carbon, Si and other substrates.158 Electrochemical investigation of the resultant CDC film displays a significant increase in the volumetric capacitance up to 180 F cm–3 in 1.5 m tetraethyl ammonium tetrafluoroborate (TEABF4)/acetonitrile (AN) electrolyte. As the chlorination temperature decreases, the volumetric capacitance held back by the decreasing average pore size which is inadaptable for TEA cation adsorption/desorption in pores.

However, the microporous character of CDC significantly suppress the ion motion within individual particles, which is a drawback for their application in EDLCs requiring the presence of an interconnected hierarchical pore structure to ensure both high capacitances (provided by micro‐ and narrow mesopores) and efficient transport throughout the entire material (provided by larger transport pores). Pore size of CDCs has been tailored by various routes such as polymeric precursor routes, templating approaches, and post‐synthetic activation/annealing procedures.

In particular, hard‐templating approach has been explored to design hierarchical porous CDCs materials. Hierarchical micro‐mesopore CDC mesofoams have been obtained by using mesocellular silica foam as a template in combination with a polycarbosilane precursor.159 Ordered mesoporous CDCs have been fabricated using a silica template for the precise regulation of the pore size in the micropore and mesopore ranges.160, 161 The well‐defined hierarchical pore system serve as ion‐highways and allow for enhanced kinetics in adsorption processes, which would lead to increase in capacitance and response rate. Chemical activation is an attractive approach to develop better electrochemical performances by an increase of surface area and volume of small pores <2 nm. As a consequence, the activated CDC exhibit a high capacitance value of 180 F g–1 in organic electrolyte, which is 30% larger than that of untreated samples.162

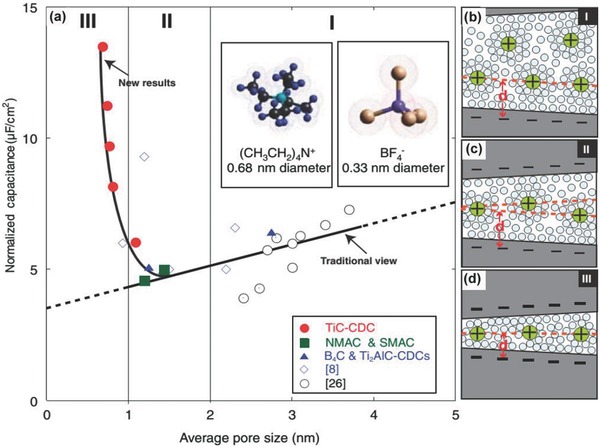

An anomalous increase has been observed for CDCs‐based SCs while the pore size is less than 1 nanometer.163 To explain this behavior, CDCs derived from TiC have been studied in depth on the effect between pore size and normalized capacitance by Brunauer‐Emmett‐Teller (BET) specific surface area. Figure 8 a show the plot of normalized specific capacitance and average pore size. It is noticed that a critical pore size value ca. 1 nm is found in this plot. When the pore size below the critical value, the normalized specific capacitance will increase sharply along with decreasing pore size, which is reverse trend with traditional view. Carbons derived from other precursors are also illustrated this phenomenon, indicating that the size effect is independent of the carbon material. Figure 8a is divided into three regions based on average pore size. The diameters of solvated ions are 0.68 and 0.33 nm for (CH3CH2)4N+ and BF4 –, respectively. Figure 8b–d illustrates the charge mechanism of solvated ions with various pore sizes. When the pore size is larger than twice the solvated ion size in region I, the capacitance is attributed to the compact layers of ions on both adjacent pore walls. The capacitance is already normalized by the surface area. When the pore size decreased to less than 2 nm but larger than 1 nm, the normalized capacitance is reduced due to reduced surface area for double‐layer charge storage.

Figure 8.

a) Plot of specific capacitance normalized by BET specific surface area and average pore size for the carbons. b–d) Drawings of solvated ions with distance between adjacent pore walls to illustrate distinguishing behavior schematically: (b) greater than 2 nm, (c) between 1 and 2 nm, and (d) less than 1 nm. Reproduced with permission.163 Copyright 2006, AAAS.

However, a sharply increase is found for the normalized capacitance when the pore size approaches the size of the electrolyte ions. Such an anomalous trend in subnanometer pores is ascribed to the desolvation of the electrolyte ions entering subnanometer pores. As the CDC samples were exclusively microporous, the capacitance increase for subnanometre pores clearly shows the role of micropores. Partial or complete removal of their solvation shell was allowing the ions to access the micropores. Hence, the resulting smaller charge‐separation distance between the ion centers and the pore walls leads to greatly increased capacitance. A similar result has been observed by another research group.164 More explanation for the anomalous trend have been present by using a heuristic theoretical model and first‐principles density functional theory (DFT) calculations and detailed analyses.165, 166 Besides, the authors have verified the phenomenon by a recent experiment utilizing an ionic liquid electrolyte with no solvation shell around the electrolyte ions.167

3.1.3. Carbon Nanotube

Carbon nanotubes (CNTs) have been widely studied as electrode materials due to the unique open tubular network structure, remarkable mechanical and electrical properties. CNTs can be divided into single‐walled carbon nanotubes (SWNTs) and multi‐walled carbon nanotubes (MWNTs).168 Their open‐ended tunnel is beneficial for electrolyte percolation and facilitate the ion diffusion. However, relatively small specific surface area (generally <500 m2 g–1) limits the energy density of CNTs‐based SCs.169

Resilient and robust framework of CNTs makes them a good choice for free‐standing SCs electrode. Flexible SCs using SWCNTs as stretchable electrodes have been studied to enlighten a broad area of stretchable energy‐storage devices. For example, Roy et al. fabricate flexible and substrate‐free papers made from SWCNTs are modified by plasma treatment.170 Vertically aligned structures are found on its surface, which benefit the enhanced capabilities of 290 F g–1.

CNTs‐based electrodes have been synthesized viachemical vapor deposition method. For instance, Hahm et al. have exploited CNTs and porous carbon nanocups to construct three dimensional hybrid nanostructured electrodes for high‐power and high areal energy EDLCs by using a short channel anodized aluminium oxide as chemical vapor deposition template.171 Li et al. have fabricated flexible and deformable electrodes based on CNT sponges with highly porous conductive networks by the CVD method.172

Moreover, hybrid flexible electrodes can be readily formed by incorporating the CNTs with foreign species (such as graphene).173 Their remarkable mechanical properties make them a good support for active materials. Unique structures for CNTs and graphene are apt to form flexible electrodes without adding extra current collectors, conductive additives or binders.

As a member of carbon family, CNTs inherit intrinsic properties to bridge the defects of graphene sheets and physically separate graphene sheets to prevent aggregation.174 A number of approaches have been employed for the fabrication of hybrid graphene/CNTs films including hydrothermal treatment, electrophoretic deposition, CVD, etc.175, 176 For example, Dai et al. have reported the fabrication of hybrid carbon films by self‐assembly of functionalized two‐dimensional graphene sheets and one‐dimensional CNTs via electrostaticinteractions.177 Hybrid SWCNTs/graphene electrodes have been prepared by a simple casting technique for a high energy density SCs device in ionic liquid.178 Roy et al. have created three‐dimensional pillared vertically aligned CNT/graphene architectures by rational strategy with tunable length of CNT pillars.179

The combination of one‐dimensional CNTs and two‐dimensional graphene sheets display greatly improved electrical, thermal conductivity and mechanical flexibility compared with each of the single components. Significant enhancement has been investigated by combining the advantageous properties of two species, indicating their promising applications for high‐performance SCs.

3.1.4. Porous Material‐Derived Carbon

Porous material‐derived carbon has been regarded as one of the most widely electrode materials owing to their high specific surface area for accumulation of charge.180 A porous network can be divided into micropores (<2 nm in size), mesopores (2–50 nm) and macropores (>50 nm) characterized by a broad distribution of pore size. Better‐performing SCs with optimum pore size result from their facilitated ion penetration and accessibility as well as mobility of the ions within the electrode.181

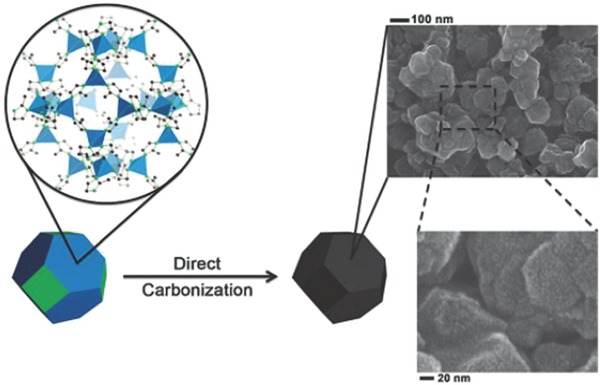

Firstly, metal‐organic frameworks (MOFs) have been investigated extensively as one of porous materials for synthesizing porous carbon with tunable pore structures.182 MOFs are typical inorganic‐organic hybrids assembled by transition‐metal clusters and organic molecules using vapor phase or incipient wetness techniques. It is noting that MOFs are thermally decomposable. Therefore, pure porous carbon networks can be produced by direct carbonization without complicated post‐treatment and the pore texture of the resultant porous carbon is determined by the pore characteristics of MOFs.183, 184 Zeolitic imidazolate framework (such as ZIF‐8) has gained particular attention as sacrificial templates to construct microporous carbons because the zinc metal sublimates or evaporates very easily at high temperature.185 Ariga et al. have synthesized nanoporous carbons with high surface area through direct carbonization of ZIF‐8 as illustrated in Figure 9 .186 Further research has revealed the importance of the pyrolysis temperature for revolution process for porous carbon. The resultant different specific surface area and pore volume is confirmed by nitrogen adsorption measurements. The specific surface areas increased with an increase in the carbonization temperature.

Figure 9.

Schematic illustration of preparation of porous carbon via direct carbonization of ZIF‐8 andthe SEM images of the resultant carbon. Reproduced with permission.186 Copyright 2012, RSC.

Secondly, various precursors emerge as the most viable materials for the fabrication of mesoporous and macroporous carbons by template techniques or directly carbonization such as natural precursors, biomass, polymer and so on.187, 188 Traditional carbon sources such as coal, versatile natural and waste materials have been exploited as fantastic precursors to obtain high quality carbon because of their chemical composition and universal resource acquisition.189, 190, 191 However, the complicated process and relatively high cost have hinder their further application. Béguin et al. directly pyrolyze seaweeds under a nitrogen atmosphere to obtain an oxygen‐enriched carbon.192 The utilization of waste materials including agricultural wastes, foods, and even animal products decrease not only cost competitiveness but also environmental impacts to meet the urgent need for sustainable development strategies.193, 194, 195 Electrochemical applications are generally influenced by high specific surface area and optimum pore size.196, 197 Accordingly, the porous structure of carbon can be created after activation with increased specific surface area and pore volume.198, 199 Activation process make the materials functionally more effective, which is affected by the activation time and temperature.

Thirdly, template carbonization is a particular method for porous carbon with precisely controlled structures and pore size.200 In general, hard and/or soft templates are employed to regulate the pore structures by incorporated into the precursors.201 And then porous carbon are acquired after the removal of templates. Hard/soft templates and activation approach are reported for the synthesis of hierarchically porous carbon monoliths with tunable porosities. Templates with dimensions at different length scales are exploited to generate the multimodal pores.202

Hard template are inorganic oxides such as SiO2,203 MgO204 and so on, and they are usually removed by the use of toxic reagents such as NaOH or HF.205 For instance, mesoporous shell carbon nanospheres with high surface area have been synthesized by co‐assembly of monodisperse silica nanospheres method and display a high specific capacitance of 251 F g–1 and long cyclic life.206 Soft templates are thermally unstable organic polymers thus being removed during the carbonization process. For example, triblock copolymer EO106‐PO70‐EO106 is used as soft template to prepare ordered mesoporous carbonaceous materials.207, 208 They possess substantially larger pores size of the electrolyte ion leading to solvation shell for high capacitance. Mesoporous channels have a lower ion‐transport resistance and a shorter diffusion route but limited high‐rate capacity.209 The application of materials with macro‐porosity is attractive due to fast ions transportation at high rates but limited by relatively low energy density.210

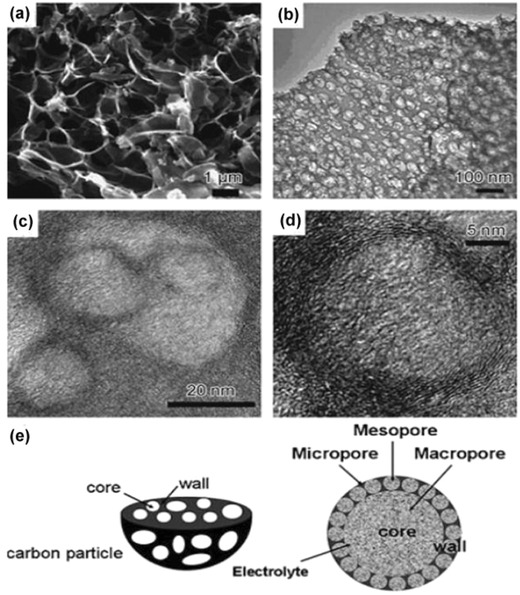

Hierarchical porous electroactive materials are desired for high energy storage attributed to the specially designed pore structures.211 Recently, hierarchical porous carbons provide better accessibility and active sites for energy applications by combining well‐defined macropores and interconnected meso‐ and microspores. Such hierarchically porous carbons feature with improved mass transport facilitated by the macropores and high surface area and pore volume from micro‐/mesopores.212 Cheng group have developed a three‐dimensional hierarchical porous texture combining macroporous cores, mesoporous walls, and micropores.213 Figure 10 a displays the texture of the macroporous cores, which serve as ion‐buffering reservoirs. Mesoporous walls and micropores around the mesopores are characterized by TEM images in Figure 10b and c. Mesoporous walls minimize the diffusion distance for electrolyte ion transport and micropores strengthen the charge accommodation. Figure 10d further reveals the existence of localized graphitic structures providing enhanced electric conductivity. Three‐dimensional porous texture is illustrated schematically with the combination of hierarchical porosity in Figure 10e. The unique structure of the resultant carbon is capable to improve energy and power densities in both aqueous and organic electrolytes.

Figure 10.

a) SEM image of the macroporous cores, b) TEM image of the mesoporous walls, c) TEM image of the micropores, d) high‐resolution TEM image of the localized graphitic mesopore walls, and e) schematic representation of the three‐dimensional porous texture. Reproduced with permission.213

In addition, the recent interest in flexible electronic devices boost textile‐based SCs. Natural cotton composed of cellulose fibers has been used in textiles and clothing. Cotton has been considered as a promising raw material for carbon flexible electrodes due to its low‐cost, light weight and high mechanical flexibility as well as its soft and porous nature.214 Carbon flexible materials are obtained through direct carbonized cotton by simple thermal treatment. The resultant carbons possess high surface area, good electrical conductivity and mechanical flexibility. Moreover, the three‐dimensional network of textiles facilitates the access of electrolytes.215 These features enable carbon‐derived from cotton as candidates for high‐performance SCs.

3.1.5. Heteroatom‐Doped Carbon

Heteroatom‐doped carbon materials have attracted tremendous attention because of their extensive application in energy conversion and storage devices.216, 217 Heteroatom doping with foreign atoms is an alternative strategy to tailor the capacitive behaviors of carbon materials through modulating the electronic properties and the surface chemistry.218, 219, 220 Superior capacitive behaviors result from an extra contribution to capacitive enhancement through Faradic reactions due to the heteroatom doping effects. A large number of efforts have been recently devoted to the synthesis of the incorporation of electron‐withdrawing (such as boron) and electro‐donating heteroatoms (such as nitrogen) into carbon frameworks.

Boron (B) acts as electron acceptor and participates in the carbon lattice by substituting for carbon at the trigonal sites.221 Even low‐level boron doping have a great effect on the capacitive performance through modifying the electronic structure of carbon electrode. B‐doped graphene‐based materials have been developed using high temperature processes with gas‐phase B sources or autoclave treatments under inert gas as promising supercapacitor electrode materials. However, it is difficult to mass production.222 In that case, Han et al. produced more effective B‐reduced GO via a solution process on a large scale.223 The borane‐tetrahydrofuran adduct was used as B source and a high specific surface area of 466 m2 g–1 was achieved with small amounts of Boron components. The supercapacitive performances were tested in two‐ and three‐electrode configurations and demonstrated that energy storage was contributed by ion adsorption on the surface of the materials as well as electrochemical redox reactions. Excellent supercapacitor behavior displayed including high specific capacitance values of 200 F g–1, a good rate response and good stability after 4500 cycles with a low resistivity for ion movement.

Nitrogen (N) doping has been widely used to improve the electrochemical capacitance of carbon materials by modifying surface wettability and electronic conductivity and introducing pseudocapacitive behavior.224, 225, 226 N‐doped carbon could be produced by many process with various nitrogen sources, such as ammonia,227 hydrazine,228 organic amine,229 and C3N4.230 Significantly improved specific capacitances and rate capabilities have been demonstrated due to their enhanced electrical conductivity. Up to now, effective approaches have been proposed to introduce N into carbonaceous matrix involving post‐treatment, in situ doping and direct pyrolysis of N‐containing materials.

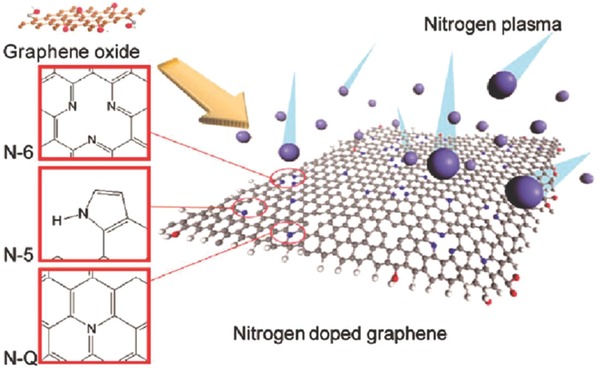

In the post‐treatment procedure, the carbon matrix is generally subjected to ammonia atmosphere at a high temperature. However, it is difficult to control of high‐concentration and uniform nitrogen doping when using ammonia as the nitrogen source. To address these problems, it is of great interest to develop novel nitrogen sources and synthesis methods. Jeong et al. successfully achieved N doping graphene through an effective plasma treatment.231 By the plasma process with physical momentum, N atoms replace the existing carbon atoms. Plasma reduction process produces a large number of defect sites which improve the effectiveness of N doping on the graphene basal plane. Further research on microscopic features of N‐configurations, the presence of pyrrolic N, pyridinic N and graphitic N can be noted which are shown in Figure 11 . The manipulated local electronic structures allow for enhanced binding with ions in the solution. The electrical conductivity of doped graphene is significantly improved as a result of the restoration of the graphene network by the formation of C—N bonded groups and N‐doping. The improved capacitance of 280 F g–1 is obtained due to the N‐configurations at basal planes without sacrificing their excellent cycle life, high power capability, and compatibility with flexible substrates. N‐doped carbon during in situ doping procedure is prepared by incorporating nitrogen‐containing compounds into carbon frameworks followed by carbonization.232 For example, Dopamine serve as nitrogen resources to synthesize N‐doped carbons via an evaporation‐induced self‐assembly process.233

Figure 11.

A schematic illustration of the as‐formed nitrogen‐doped graphene by the plasma doping process and possible nitrogen configurations by the doping treatment. N‐Q, N‐5, N‐6 represent graphitic N, pyrrolic N, and pyridinic N, respectively. Reproduced with permission.231 Copyright 2011, ACS.

Relatively speaking, direct carbonization has emerged as a simple procedure to incorporate N into the sp2 lattice of carbon. The raw material for pyrolysis can divided into polymers, ionic liquid, nature materials, and biomaterials. By this method, N can be preserved at a relatively large content by adjusting the carbonization temperature.234, 235 Firstly, porous nitrogen‐containing organic polymers have emerged as versatile substances due to their highly cross‐linked frameworks.236 Zhi et al. have developed a novel nitrogen‐rich carbon network derived from terephthalonitrile.237 Secondly, ionic liquids have been reported as attractive precursors for the synthesis of heteroatom doped carbonaceous materials via the direct carbonization due to excellent solubility for chemicals and excellent thermal stability features.238 Lu groups have exploited ionic liquid functionalized GO as a shape‐directing agent for synthesis of N‐doped microporous carbon sheets.239 Thirdly, direct carbonization of sustainable renewable resources has been developed as an efficient strategy to fabricate N‐doped energy storage devices due to the low cost and environmental friendliness. Successful examples have been reported in terms of renewable biological resources provided by nature.240 For example, microorganism and protein are available N‐enriched biomass in our daily life. They have been adopted as precursors for large‐scale fabrication of N‐doped materials with high nitrogen concentration.241, 242

Sulfur (S)‐doped carbon nanomaterials have rarely been investigated for SCs. Chen et al. fabricated S‐doped porous graphene frameworks by directly annealing treatment while dibenzyl disulfide was used as S source.243 Parveen et al. have obtained S‐doped graphene via an economical and facile one pot electrochemical methodwhile sodium thiosulphate serve as S source.244 S atom are introduced into the framework via covalent bonds and the synergistic effect resulted from sulfur‐doping enhances the electrochemical activity of graphene‐based materials. In addition to mono‐doping, co‐doped materials are also explored for enhance electrochemical performances such as B, N co‐doped,245, 246 N, S co‐doped,247 N, P‐co‐doped,248 and N, P, S‐co‐doped materials.249 Co‐doped materials have been demonstrated with high specific surface and large pore volume due to synergistic effects from co‐dopants. For graphene, various heteroatoms doping enable that the graphitic carbon atoms in graphene are substituted or covalently bonded by foreign atoms.250, 251 SCs based on doping graphene utilize the robust charging mechanisms of EDLCs yet exhibit comparable capacitances to those of PCs.

In conclusion, heteroatom in doped carbon materials plays a key role in electron transfer and energy conversion processes. The distinct properties are investigated resulting from various dopants, different doping levels and configuration. The fabrication of heteroatom‐doped carbon with enhanced electrochemical performance provides a viable route to promote its applications in electronic devices.

3.1.6. Carbon Grafting with Surface Groups

It has been witnessed that surface modification by functional group is important for carbon‐based materials in terms of capacitive behaviors.252 The surface chemistry of carbon are generally modulated by oxygenic or nitrogenous surface groups to change the hydrophobic/hydrophilic properties such as C=O, —OH, —NH2 and so on. The presence of functional groups made the properties of carbon‐based materials improved on three aspects.

Firstly, more facile and effective composite procedures can be developed based on the participation of surface functional groups. Lai et al. have verified that the surface chemistry of graphene is important for the growth of polyaniline.253 In addition, the surface characteristics are crucial for electrochemical performances improvement of resultant composites. The amine‐modified composites exhibit the largest increase in capacitance.

Secondly, the surface functional groups enable improved hydrophilicity to allow good accessibility of the electrolyte into the carbon‐based electrode and thus affect the electrochemical properties. A hydrophilic carbon nanotube has been designed by modification with sulfonate groups and applied as electrode materials in on‐chip type solid‐state supercapacitor.254 The hydrophilic surface enable good electrolyte affinity and homogeneous dispersibility in water. Consequently, the uniform and dense electrode reveals a high volumetric capacitance and excellent cycling stability due to low ion‐transfer resistance.

Thirdly, specific capacitance and energy density can be enhanced due to the efficient coexistence of EDLCs and PCs derived from surface ion adsorption and the Faradaic reaction of surface functional groups. For example, SWCNTs grafted with carboxylic groups have been developed as electrode materials with a maximum specific capacitance of 146.1 F g–1.255 Three‐dimensional functionalized multilayer graphene have been developed with controllable surface oxygenic surface groups, which displays high specific capacitance of 508 F g–1, highest energy density of 66 Wh kg–1 and good stability with 94% retention after 10000 cycles in aqueous electrolyte.256

In conclusion, a variety of carbons ranging from zero to three dimensional have been researched extensively as EDLCs electrode, such as graphene, CDCs, CNTs and so on. Carbon‐based materials have been widely explored as electrode materials due to their outstanding electrochemical properties containing excellent cycling stability, fast charging and discharging rate and high power density. However, the energy density of existing carbon‐based SCs is limited, generally an order of magnitude lower than that of batteries.257

To address these problems, more efforts have been devoted including carbons with tunable porosity, heteratom‐doping and grafting with surface groups. In the case of porous carbon as electrodes materials, control of structure and morphology play a pivotal role in allowing the effective permeation of the electrolyte to establish electrical double layers for charge storage. Recent development of SCs electrode materials also focus on heteroatoms incorporated carbons. Depending on the type of precursors used in the synthetic step, diverse combination of carbon composition can be prepared. The doped‐species can potentially change the electronic properties of the carbon by altering the electron density on the graphitic surface and affecting the electron affinity of the carbon materials. Recent reports also illustrated that the substitution of carbon with foreign atoms in the graphitic six‐membered ring induces pseudo‐capacitive properties, giving rise to additional enhancement in specific capacitance. Carbon grafting with surface groups have been developed to improve wettability and capacitance performance of carbon materials by chemical surface modification. The charge storage capacity is strongly affected by surface chemistry resulted from the introduction of surface functional groups. The presence of functional species not only increases hydrophilic properties of carbon‐based materials to improve the adsorption and separation properties but also presents pseudo‐capacitive behavior.

3.2. Metal Compounds

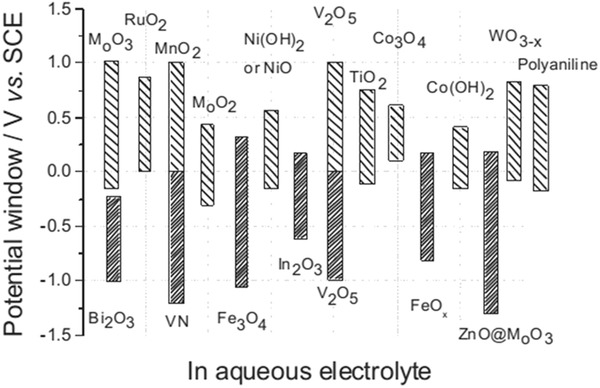

At first, transitional metal oxides and graphene‐like layered metal compounds are exciting fields of research resulted from their pseudocapacitive behaviors.258 Figure 12 summarizes the working potential windows of various pseudocapacitive‐type materials in aqueous electrolyte.259 The cathode and anode materials can be distinguished according to the average working potential above or below 0 V (vs. SCE). The cathode materials have been always studied as electrode materials due to their satisfactory capacitive performance. Increased efforts have also been devoted to improve the capacitive performance of anode materials. However, their electrochemical performances have been restricted in terms of cycling stability and power density due to the low electrical conductivity and volume change during cycling process. Various approaches have been attempted for efficient redox charge transfer and improved power density and long‐term stability.

Figure 12.

Illustration of the working potential windows of various pseudocapacitive‐type materials in aqueous electrolyte. Reproduced with permission.259

3.2.1. Metal Oxides

Metal oxides have been considered as promising electrode materials for PCs since they can provide a variety of oxidation states for fast surface redox reactions. Ruthenium dioxide and manganese dioxide are two representative redox‐active materials and they have demonstrated satisfied specific capacitance and energy density.

Among metal oxides, ruthenium dioxide (RuO2) has attracted much attention as the most promising electrode material for PCs due to their low resistivity, high chemical and thermodynamic stability.260 Rutile phase RuO2 and hydrated RuO2·xH2O are two different phase with electro‐active. RuO2·xH2O has been reported to exhibit a capacitance as high as 1300 Fg–1. RuO2 represents a high theoretical specific capacitance in wide operational potential (1.4 V) based on their high electronic conductivity and multiple valance states for electron transition (Ru2+, Ru3+, Ru4+, Ru6+).261 In addition, their highly reversible faradaic response allows them to present good cycling stability. Amorphous RuO2 has been investigated and shows higher specific capacitance than the crystalline RuO2 due to the flexibility of amorphous state to perform lattice rearrangement upon ion intercalation/deintercalation, allowing more active sites for redox reaction. Typically, amorphous RuO2 can exhibit high specific capacitances as high as 1580 Fg–1.262 Fundamental studies have been done to investigating the electrochemical protonation charge storage mechanism of RuO2, which can be simplified as follows: (1) RuO2 + xH+ + xe– = RuO2–x(OH)x, 0 < x < 2. (2) RuO2 + H+ + e– = RuOOH.

Unfortunately, RuO2 particles often tend to agglomerations, which significantly degrade their electrochemical performance. Hence, the formation and good dispersion of RuO2 particles are of importance to further improve the pseudocapacitive capacitance of the RuO2 electrode.263, 264 In order to utilize both Faradaic and non‐Faradaic processes for large capacity‐charge storage, various RuO2/carbon composites with carbon‐based materials were explored as electrode materials for SCs with enhanced energy‐storage capabilities and lower cost.265 For example, Naoi et al. have prepared nanosized hydrous RuO2/Ketjen Black composites by in situ sol‐gel process induced by ultracentrifugal mechanical force.266 The hydrous RuO2 nanoparticles are highly dispersed on conductive carbon and exhibit the high specific capacitance of 821 Fg–1. Among a variety of carbon materials, CNTs have been employed as supports for composites with RuO2 due to their good electron conductivity and accessible surface textures to increasing the utilization of RuO2. Hydrated amorphousRuO2 nanoparticles are highly dispersed on carboxylated CNTs with the help of bond formation between the RuO2 and the surface carboxyl groups of the CNTs.267

Graphene features flexible conductive network and rich oxygen‐containing functional groups, which are used to anchor RuO2 nanoparticles for enlarged surface area.268 The composites benefit from both advantages of RuO2 and graphene that offer continuous electron pathways and mechanical integrity. Amorphous hydrous RuO2 nanoparticles anchored on the surface of graphene sheets are well dispersed providing a large and accessible surface area as well as effective charge access and propagation. The SCs based on RuO2/graphene composites exhibit the high specific capacitance of 570 Fg–1, enhanced rate capability, high energy/power density and excellent electrochemical stability of 97.9% retention after 1000 cycles. The electrochemical properties of RuO2/graphene composites are superior to pure RuO2, which is indicative that the presence of graphene plays an active role in the improvement of electrochemical performance. Besides, more synthesis methods are explored for RuO2/graphene composites. For instance, Kim et al. have developed in situ chemical synthesis to prepare RuO2/graphene composites.269 Choi et al. have reported the integrative assembly of chemically modified graphene building blocks into hierarchical complex structures with the hybrid composition for high performance flexible pseudocapacitors.270

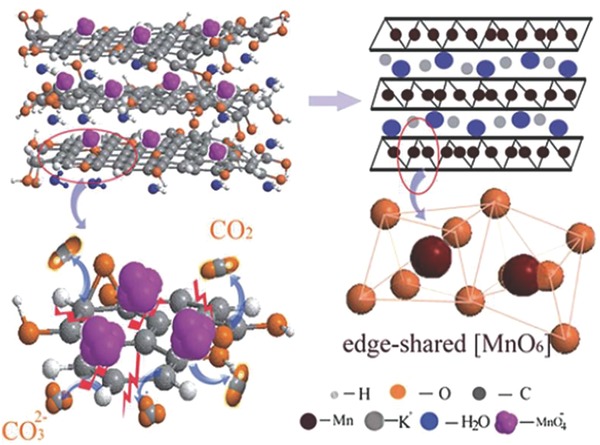

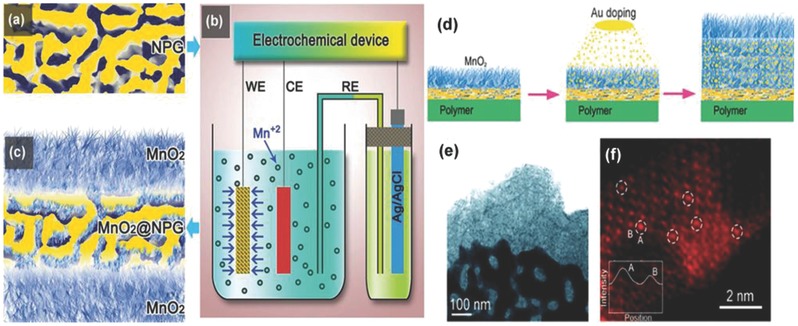

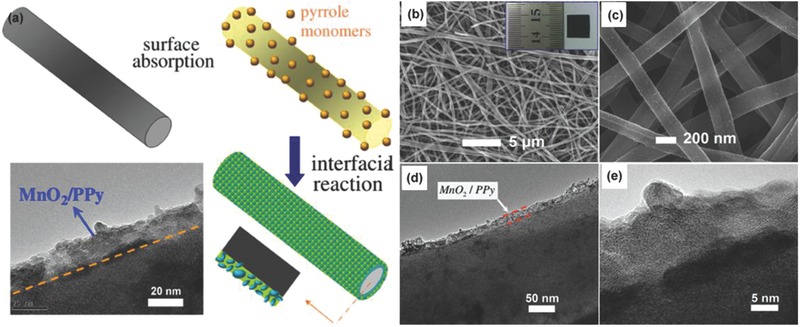

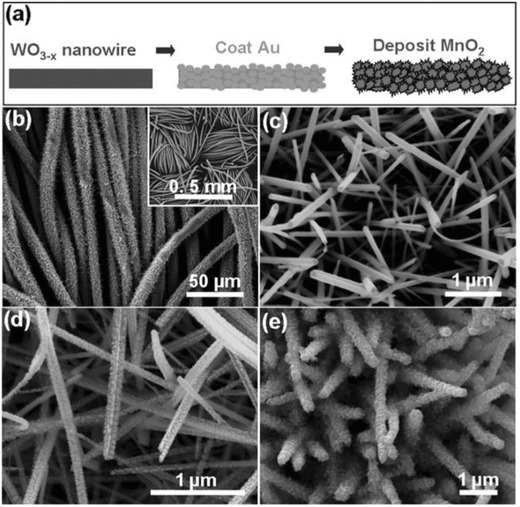

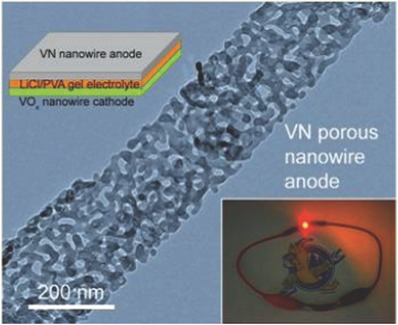

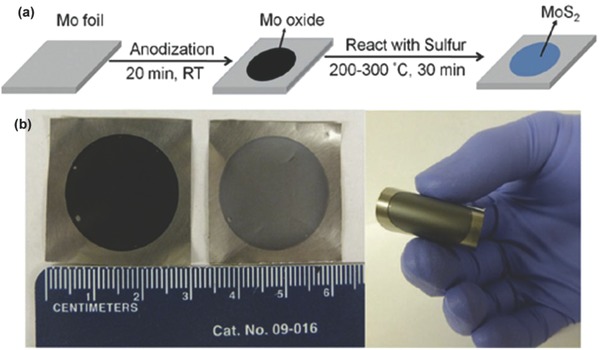

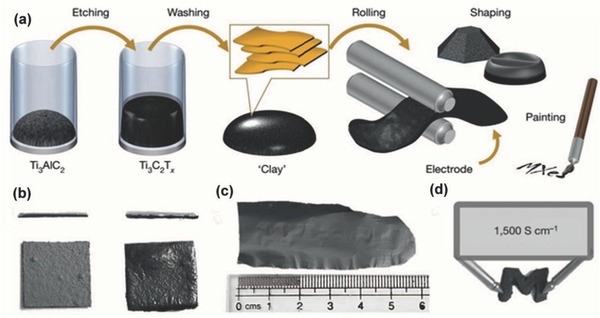

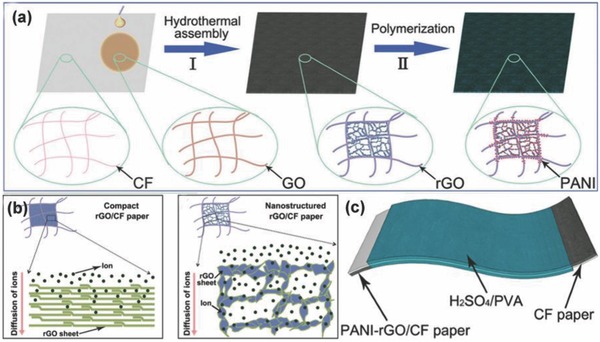

Although RuO2‐based materials are demonstrated as promising candidates for high‐performance SCs, it is impractical for widespread commercial production due to the high cost of precious metals (Ru) and limited abundance in nature. Therefore, alternative pseudocapacitance materials with low cost have been a major subject in supercapacitor research.