Abstract

Bi2Sr2CaCu2Ox (Bi-2212) conductor is the only high temperature superconductor manufactured as a round wire and is a very promising conductor for very high field applications. One of the key design parameters of Bi-2212 wire is its filament size, which has been previously reported to affect the critical current density (Jc) and ac losses. Work with 1 bar heat treatment showed that the optimal filament diameter was about 15 μm but it was not well understood at that time that gas bubbles were the main current limiting mechanism. Here we investigated a recent Bi-2212 wire with a 121×18 filament architecture with varying wire diameter (1.0 to 1.5 mm) using 50 bar overpressure processing. This wire is part of a 1.2 km piece length of 1.0 mm diameter made by Oxford Superconducting Technology. We found that Jc is independent of the filament size in the range from 9 to 14 μm, although the n value increased with increasing filament size. A new record Jc (4.2 K, 15 T) of 4200 A/mm2 and JE (4.2 K, 15 T) of 830 A/mm2 were achieved.

Index Terms: superconductor, Bi-2212, critical current density, superconducting magnet

I. Introduction

Bi2Sr2CaCu2Ox (Bi-2212) conductor is the only high temperature superconductor manufactured in the round wire form, which enables twisting and Rutherford cables. It is very promising for very high field applications, such as general purpose research magnets, NMR magnets, and accelerator magnets that can reach fields beyond those achievable using Nb3Sn technology [1]–[8]. Bi-2212 round wire is fabricated as a multifilamentary conductor by the powder-in-tube (PIT) method, but it must be heat treated at final size by partial melting to develop a high Jc [9],[10]. A less than full packing density is a characteristic of all powder-in-tube conductors including MgB2 and Bi-2223 because powders must slide over each other as the metal sheath deforms [11]. We have previously shown that agglomerated filament-diameter-sized bubbles are the principal current limiting mechanism in Bi-2212 wire [9],[12]–[14]. Overpressure heat treatment (OP-HT) eliminates the ~30% – 40% void fraction and improves Jc significantly [1].

Bi-2212 wires are available in multiple architectures and kilometer pieces for high field coil fabrication. One of the key design parameters for manufacturing Bi-2212 wire is the filament size, which is believed to affect Jc and the filament coupling. Based on earlier 1 bar heat treatments with substantial final porosity, it was shown that an optimal filament size is about 15 μm [2], [15]–[17]. In such a 1 bar HT, gas bubbles are the principal current limiting mechanism that could complicate the filament size optimization [9],[12]–[14]. Oxford Superconducting Technology (OST) is routinely producing 2212 wires with varying filament configurations to fit customer wire diameter preferences that are typically based on an optimum filament size of ~15 μm. This leads to 37×18, 19×36 and 55×18 stacks for 0.8 mm diameter wire, 85×7 and 55×18 for 1.0 mm, 85×18 for 1.2 mm, and 121×18 for 1.4 mm [18]. However, as we are making a variety of 2212 coils, we wanted to understand the potential drawbacks to using these architectures at sizes different from their nominal optimized filament diameter. Accordingly we studied a recent Bi-2212 wire with 121×18 filaments that had been designed to be 1.4 mm diameter, which we wanted at 1 mm diameter. After seeing that there was almost no effect on Jc or the filament size distribution of reducing the as-drawn filament diameter to 9 μm for 50 bar OP processing, we asked OST to draw it to 1 mm and have reserved it for a magnet using the single piece length of 1.2 km that they made from it.

II. Experimental detail

The Bi-2212 wire (OST billet pmm151103) was fabricated in 2015 by Oxford Superconducting Technology (OST) using Nexans standard powder lot 87 with a composition of Bi2.17Sr1.94Ca0.90Cu1.98Ox. The Bi-2212 powder was always surrounded by pure silver but the outer sheath of the 121×18 stack was made with a Ag-Mg(0.2wt%) alloy sheath. One piece of the wire was drawn to diameters of 1.5, 1.4, 1.3, 1.2, 1.1 and 1.0 mm to study the effect of filament size on JC. In the remainder of the paper these wires are referred to by their as-drawn diameter, e.g. 1.0 mm wire. Most of the wire was drawn into a single 1200 m long length 1.0 mm in diameter.

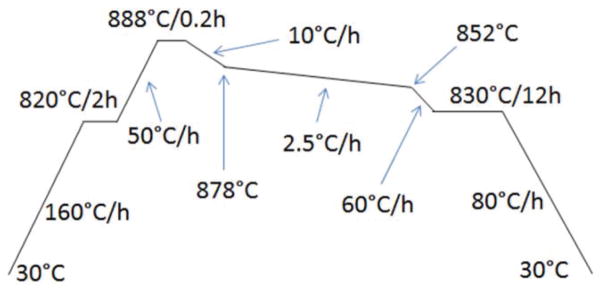

As shown previously [19], Bi-2212 wire is normally densified before the Bi-2212 powder melts in a standard OP-HT. Wire samples were 8 cm in length and hermetically sealed on both ends. To analyze the filament size and wire cross section area, a powder densification heat treatment of 830°C/12h under 50 bar with oxygen partial pressure (pO2) of 1 bar was performed. As shown in Fig. 1, a new shorter full heat treatment schedule was used that, compared to the previous standard HT [9], increases the cooling rate from 2.5°C/h to 60°C/h between 852 and 830°C, and reduces the time at 830°C from 48 to 12 hours. This reduces the total HT time by nearly half. Both 1 bar and 50 bar HT tests showed that the shorter HT achieves the same critical current IC as the standard HT.

Fig. 1.

Schematic heat treatment schedule for 50 bar OP-HT.

Transverse cross-sections of as-drawn, powder densified, and fully-processed wires were dry polished using a series of SiC papers with decreasing grit sizes with final polishing conducted in a suspension of 50 nm alumina in ethanol using an automatic vibratory polisher (Buehler Vibromet). Microstructures were examined with a Zeiss 1540EsB scanning electron microscope (SEM). The cross section area of the wire and 2212 after powder densification was measured with an Olympus BX41M-LED microscope.

Critical currents of fully-processed wires were measured using the four-probe transport method with a 1 μV/cm criterion at 4.2 K in a magnetic field of up to 15 T applied perpendicular to the wire axis. The overall wire critical current density JE was calculated using the densified whole wire cross section. Jc values reported here use the densified cross-section of the filaments after the 830°C/12h densification as the area.

III. Results

Fig. 2 shows SEM image of transverse cross section of the 1.0 mm wire after the powder densification treatment at 830°C/12h. The SEM image was taken after the polished surface was etched for 5 minutes with a mixture of NH3OH·H2O (30% NH3OH) and H2O2·H2O(~29% H2O2)) with a volume ratio of 5:2. The wire diameter was reduced by the 830°C/12h powder densification from 1.00 mm to 0.96 mm, a 4% reduction. Fig. 3 shows the filaments in the 1.0 mm are significantly smaller than in the 1.4 mm wires. Two transverse cross sections of each densified wire were analyzed and their average filament diameters are listed in Table I. The average filament diameters were calculated from the average area of the filaments assuming a round shape. Drawing the wire from 1.5 mm to 1.0 mm reduced the densified filament diameter from 13.8 μm to 9.3 μm, a 1/3 reduction. The fully dense Bi-2212 filling factor is 20.0%, which is lower than in previous OST wires with 37×18 filaments, which had a filling factor of 22.0 % [14]. This difference may arise from a lower tap density in the Nexans powder used in the present study and/or the new wire architecture with 121×18 filaments.

Fig. 2.

SEM image of an etched wire cross section of a 1.0 mm wire after densification at 830°C/12h and 50 bar.

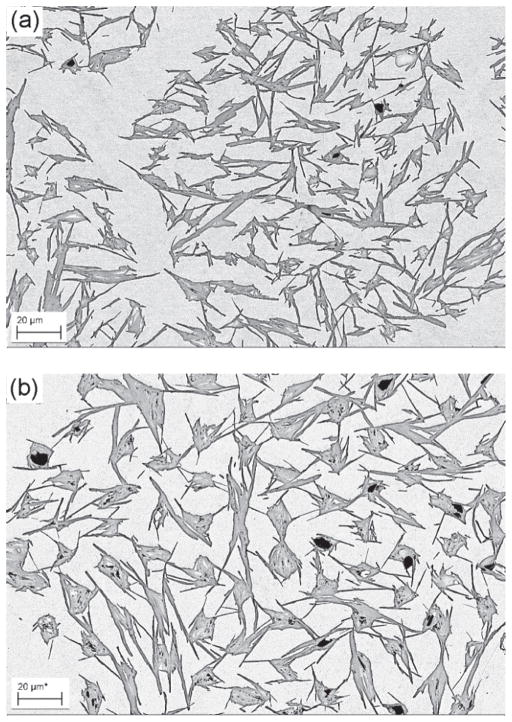

Fig. 3.

SEM images of the transverse cross sections of (a) 1.0 mm and (b) 1.4 mm wires after densification at 830°C/12h and 50 bar.

TABLE I.

Diameter of as-drawn wires, average filament diameter of densified wires, and average IC (4.2 K, 5 T), JE (4.2 K, 5 T), and JC (4.2 K, 5 T) of fully-processed wires

| Wire Diameter mm | Filament diameter* μm | IC (4.2K,5T) A | JE (4.2K,5T ) A/mm2 | Jc (4.2K,5T) A/mm2 |

|---|---|---|---|---|

| 1.0 | 09.3 | 764 | 1014 | 5205 |

| 1.1 | 10.1 | 940 | 1046 | 5370 |

| 1.2 | 11.1 | 1140 | 1056 | 5422 |

| 1.3 | 11.9 | 1361 | 1088 | 5585 |

| 1.4 | 12.9 | 1530 | 1045 | 5364 |

| 1.5 | 13.8 | 1741 | 1042 | 5349 |

Filament diameters were calculated from optical images of cross sections of wires with densified powder (830°C/12h, 50 bar) like those shown in Fig. 3.

Fig. 4 shows the filament size distribution for densified 1.0, 1.2, and 1.4 mm wires. In Fig. 4 the filament diameters were normalized to their corresponding average filament diameters. The range in relative filament size varies from 0.75 to 1.3 in each wire, which indicates that drawing below the 13 μm “optimum” filament diameter from 1.4 mm to 1.0 mm does not change the relative filament size in each wire.

Fig. 4.

Filament size distribution for 1.0, 1.2, and 1.4 mm wires after powder densification at 830°C/12h and 50 bar.

Fig. 5 shows JE (4.2 K, 5 T) and Jc (4.2 K, 5 T) as a function of applied field for 1.0 mm wire. The field dependence of Jc was used to calculate IC (4.2 K, 5 T) values for the 1.4 and 1.5 mm wires because IC (4.2 K, 5 T) values for these wires were beyond the 1400 A maximum of the power supply. The 1.4 and 1.5 mm wires were measured at 7 and 12 T at 4.2 K.

Fig. 5.

Jc (4.2 K) and JE (4.2 K) as a function of applied field for 1.0 mm wire OP-HT under 50 bar. IC (4.2 K, 5 T) = 824.5 A.

Fig. 6 shows Jc (4.2 K, 5 T) and n value as a function of the densified Bi-2212 filament size. It can be seen that Jc is independent of the filament size while the n value is larger at larger wire diameter, suggesting a more uniform Ic distribution in the larger wires. Average IC (4.2 K, 5 T), JE (4.2 K, 5 T), and Jc (4.2 K, 5 T) values are listed in Table I for each wire.

Fig. 6.

Jc (4.2 K, 5 T) and n value as a function of the densified Bi-2212 filament size. The dashed lines are to guide the eye.

Fig. 7 shows SEM images of the fully-heat-treated 1.0 and 1.5 mm wires. There are many connections between the filaments in the 1.0 mm wire, so much so that the filaments have almost lost their original shape, whereas the filaments in the 1.5 mm wire are thicker and still have some of their original shape. Some large size 14:24 AEC particles were observed in the 1.5 mm wire. From the microstructures, it appears the 1.0 mm wire had the better reaction.

Fig. 7.

SEM images of fully-heat-treated wires (a) 1.0 mm and (b) 1.5 mm wire after OP-HT. The large black spots are the alkaline earth cuprate (Sr,Ca)14Cu24Ox (14:24 AEC).

IV. Discussion

Previous studies on optimizing Bi-2212 filament size by Hasegawa et al. [15], Marken et al. [16], [17] and Miao et al. [2] were carried out with 1 bar HT and all found that an optimal filament size is about 15 μm. For these much higher Jc 50 bar OP wires in the present study, Fig. 6 shows that Jc is independent of filament size from 9.3 μm to 13.8 μm. Even though the Jc value of the smaller wire with smaller filaments is comparable to that of the larger wire with larger filaments, the large wires have larger n values, which suggests that current flows more uniformly in the larger wires [20]. Since all the wire samples were from the same billet, the filament configurations are the same in all the wires. The smaller the wire diameter, the smaller the distance between the filaments, resulting in greater 2212 grain coupling between filaments as shown in Fig. 7(a). The increased physical coupling could result in higher ac losses. This will be tested later with ac loss measurement.

Fig. 4 shows that the range of relative filament size varies from 0.75 to 1.3, which is a quite wide size distribution, indicating further optimization of the filament uniformity with more uniform precursor powder is needed for better Jc. Nevertheless, the high filament quality of the conductor is well in evidence in Figs. 2 and 3 and the record high Jc values obtained support the very good wire fabrication process employed at OST.

V. Conclusion

We investigated a Bi-2212 round wire with 121×18 filaments at various diameters from 1.0 to 1.5 mm that were OP-HTed at 50 bar. We found that Jc is independent of the filament size over the range from 9.3 μm to 13.8 μm. A new record Jc (4.2 K, 15 T) of 4200 A/mm2 was achieved in all of the wires.

Acknowledgments

We are very grateful for discussions with Y. Huang and H. Miao at OST and T. Shen at LBNL. The work at the NHMFL was supported by the US Department of Energy Office of High Energy Physics under DE-SC0010421 and by the NHMFL, which is supported by the National Science Foundation under NSF/DMR-1157490, and by the State of Florida. Research reported in this publication was also supported by the National Institute of General Medical Sciences of the National Institutes of Health under Award Number R21GM111302.

Contributor Information

Jianyi Jiang, National High Magnetic Field Laboratory, Florida State University, Tallahassee, FL 32310, USA.

Ashleigh Francis, National High Magnetic Field Laboratory, Florida State University, Tallahassee, FL 32310, USA.

Ryan Alicea, National High Magnetic Field Laboratory, Florida State University, Tallahassee, FL 32310, USA.

Maxime Matras, National High Magnetic Field Laboratory, Florida State University, Tallahassee, FL 32310, USA.

Fumitake Kametani, National High Magnetic Field Laboratory, Florida State University, Tallahassee, FL 32310, USA.

Ulf P. Trociewitz, National High Magnetic Field Laboratory, Florida State University, Tallahassee, FL 32310, USA

Eric E. Hellstrom, National High Magnetic Field Laboratory, Florida State University, Tallahassee, FL 32310, USA

David C. Larbalestier, National High Magnetic Field Laboratory, Florida State University, Tallahassee, FL 32310, USA

References

- 1.Larbalestier DC, Jiang J, Trociewitz UP, Kametani F, Scheuerlein C, Dalban-Canassy M, Matras M, Chen P, Craig NC, Lee PJ, Hellstrom EE. Isotropic round-wire multifilament cuprate superconductor for generation of magnetic fields above 30 T. Nat Mater. 2014;13:375–81. doi: 10.1038/nmat3887. [DOI] [PubMed] [Google Scholar]

- 2.Miao H, Marken KR, Meinesz M, Czabaj B, Hong S. Development of Round Multifilament Bi-2212/Ag Wires for High Field Magnet Applications. IEEE Trans Appl Supercond. 2005;15:2554–2557. [Google Scholar]

- 3.Hasegawa T, Ohtani N, Koizumi T, Aoki Y, Nagaya S, Hirano N, Motowidlo L, Sokolowski RS, Scanlan RM, Dietderich DR, Hanai S. Improvement of superconducting properties of Bi-2212 round wire and primary test results of large capacity Rutherford cable. IEEE Trans Appl Supercond. 2001;11:3034–3037. [Google Scholar]

- 4.Weijers HW, Trociewitz UP, Marken K, Meinesz M, Miao H, Schwartz J. The generation of 25.05 T using a 5.11 T Bi2Sr2CaCu2Ox superconducting insert magnet. Supercond Sci Technol. 2004;17:636–644. [Google Scholar]

- 5.Schwartz J, Effio T, Liu XT, Le QV, Mbaruku AL, Schneider-Muntau HJ, Shen TM, Song HH, Trociewitz UP, Wang XR, Weijers HW. High Field Superconducting Solenoids Via High Temperature Superconductors. IEEE Trans Appl Supercond. 2008;18:70–81. [Google Scholar]

- 6.Godeke A, Acosta P, Cheng D, Dietderich DR, Mentink MGT, Prestemon SO, Sabbi GL, Meinesz M, Hong S, Huang Y, Miao H, Parrell J. Wind-and-react Bi-2212 coil development for accelerator magnets. Supercond Sci Technol. 2010;23:034022. [Google Scholar]

- 7.Kumakura H, Kitaguchi H, Togano K, Sugiyama N. Effect of high oxygen partial pressure heat treatment on the superconducting properties of Bi2Sr2CaCu2Ox/Ag tapes. J Appl Phys. 1996;80:5162–5167. [Google Scholar]

- 8.Dalban-Canassy M, Myers DA, Trociewitz UP, Jiang J, Hellstrom EE, Viouchkov Y, Larbalestier DC. A study of the local variation of the critical current in Ag-alloy clad, round wire Bi2Sr2CaCu2O8+x multi-layer solenoids. Supercond Sci Technol. 2012;25:115015. [Google Scholar]

- 9.Jiang J, Starch WL, Hannion M, Kametani F, Trociewitz UP, Hellstrom EE, Larbalestier DC. Doubled critical current density in Bi-2212 round wires by reduction of the residual bubble density. Supercond Sci Technol. 2011;24:082001. [Google Scholar]

- 10.Shen T, Jiang J, Kametani F, Trociewitz UP, Larbalestier DC, Hellstrom EE. Heat treatment control of Ag-Bi2Sr2CaCu2Ox multifilamentary round wire: investigation of time in the melt. Supercond Sci Technol. 2011;24:115009. [Google Scholar]

- 11.Karuna M, Parrell JA, Larbalestier D. Study of powder density, Ag:superconductor ratio, and microhardness of BSCCO-2212 Ag-sheathed wires and tapes during wire drawing and rolling. IEEE Trans Appl Supercond. 1995;5:1279–1282. [Google Scholar]

- 12.Kametani F, Shen T, Jiang J, Scheuerlein C, Malagoli A, Di Michiel M, Huang Y, Miao H, Parrell JA, Hellstrom EE, Larbalestier DC. Bubble formation within filaments of melt-processed Bi2212 wires and its strongly negative effect on the critical current density. Supercond Sci Technol. 2011;24:075009. [Google Scholar]

- 13.Scheuerlein C, Di Michiel M, Scheel M, Jiang J, Kametani F, Malagoli A, Hellstrom EE, Larbalestier DC. Void and phase evolution during the processing of Bi-2212 superconducting wires monitored by combined fast synchrotron micro-tomography and x-ray diffraction. Supercond Sci Technol. 2011;24:115004. [Google Scholar]

- 14.Jiang J, Miao H, Huang Y, Hong S, Parrell JA, Scheuerlein C, Di Michiel M, Ghosh AK, Trociewitz UP, Hellstrom EE, Larbalestier DC. Reduction of gas bubbles and improved critical current density in Bi-2212 round wire by swaging. IEEE Trans Appl Supercond. 2014;24:6400205. [Google Scholar]

- 15.Hasegawa T, Koizumi T, Hikichi Y, Nakatsu T, Scanlan RM, Hirano N, Nagaya S. BSCCO-2212 conductor development at Oxford Superconducting technology. IEEE Trans Appl Supercond. 2003;13:3335–3338. [Google Scholar]

- 16.Marken KR, Miao H, Meinesz M, Czabaj B, Hong S. HTS conductors for magnets. IEEE Trans Appl Supercond. 2002;12:1136–1140. [Google Scholar]

- 17.Marken KR, Jr, Miao H, Meinesz M, Czabaj B, Hong S. Progress in Bi-2212 wires for high magnetic field applications. IEEE Trans Appl Supercond. 2006;16:992–995. [Google Scholar]

- 18.Huang Y, Miao H, Hong S, Parrell JA. Bi-2212 Round Wire Development for High Field Applications. IEEE Trans Appl Supercond. 2014;24:6400205. [Google Scholar]

- 19.Matras MR, Jiang J, Larbalestier DC, Hellstrom EE. Understanding the densification process of Bi2Sr2CaCu2Ox round wires with overpressure processing and its effect on critical current density. 2016;29:105005. doi: 10.1088/0953-2048/29/10/105005. to appear in Supercond. Sci. Technol. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Warnes WH, Larbalestier DC. Critical current distributions in superconducting composites. Cryogenics. 1986;26:643–653. [Google Scholar]