Abstract

Smart manufacturing technologies require a cyber-physical infrastructure to collect and analyze data and information across the manufacturing enterprise. This paper describes a concept for a product lifecycle test bed built on a cyber-physical infrastructure that enables smart manufacturing research and development. The test bed consists of a Computer-Aided Technologies (CAx) Lab and a Manufacturing Lab that interface through the product model creating a “digital thread” of information across the product lifecycle. The proposed structure and architecture of the test bed is presented, which highlights the challenges and requirements of implementing a cyber-physical infrastructure for manufacturing. The novel integration of systems across the product lifecycle also helps identify the technologies and standards needed to enable interoperability between design, fabrication, and inspection. Potential research opportunities enabled by the test bed are also discussed, such as providing publicly accessible CAx and manufacturing reference data, virtual factory data, and a representative industrial environment for creating, prototyping, and validating smart manufacturing technologies.

Keywords: Smart manufacturing, product lifecycle, cyber-physical infrastructure, digital thread

1 Introduction

Smart manufacturing is the synthesis of advanced manufacturing capabilities and digital technologies to improve the productivity, agility, and sustainability of manufacturing systems. It applies the cyber-physical system concept through the collaboration of computational elements to control various physical entities in the manufacturing environment (Lee 2008, Wolf 2009). These activities require an appropriately designed cyber-physical infrastructure that supports the collection and analysis of relevant data and information and the ability to act on any decisions driven by this process. Cyber-physical systems require new design methodologies since they differ from existing embedded systems found in manufacturing (Lee 2008). The cyber-physical infrastructure needed for smart manufacturing requires the “co-design” of the computational and physical elements to ensure that they work effectively together within the system’s physical limits (Wolf 2009).

Developing a new design paradigm for smart manufacturing requires access to real industrial systems to understand the means to collect, transmit, analyze, and act on data and information quickly and reliably throughout the manufacturing enterprise and supply chain. But, intellectual-property and cyber-security risks hinder the efforts of researchers to attain such knowledge from industrial collaborations. Instead, researchers often rely on data and information generated by simulations or test beds that emulate manufacturing systems. Abdul Kadir, Xu & Hämmerle (2011) and Altintas, Brecher, Weck & Witt (2005) provide examples of virtual machining simulations that support process design and improvement. A more recent machine monitoring example is the agent provided by the MTConnect Institute to encourage application development (MTConnect Institute 2014). Physical machining test beds have been developed, such as the Automated Manufacturing Research Facility (AMRF) (Simpson, Hocken & Albus 1982) and a more recent MTConnect-enabled machine tool platform for machining data analytics at UC Berkeley (Helu, Robinson, Bhinge, Bänziger & Dornfeld 2014). While all of these examples have helped advance machining technologies, they focus primarily on production and ignore the larger product lifecycle. This perspective limits their ability to enable the development of technologies capable of realizing the full potential of smart manufacturing.

The goal of this study is to extend existing production-focused test bed concepts by designing and architecting a product lifecycle test bed concept that enables smart manufacturing research and development. The design process should highlight the challenges and requirements for introducing cyber-physical infrastructure in manufacturing, such as cyber-security concerns, that have limited the use of smart manufacturing technologies on the shop floor. The subsequent test bed concept should help generate reference architectures that address such concerns and provide a data source other researchers may use to develop and validate smart manufacturing technologies. Even though the technologies that compose the test bed may not be new, the test bed requires the novel integration of systems from each product lifecycle stage (see Figure 1) so that information may flow between design, fabrication, and inspection. This enables the development of technologies and standards that create a “digital thread” to exchange information, including product design and quality and equipment performance and health, across the product lifecycle. Commercial solutions exist that organize data generated across the product lifecycle, but these systems are typically expensive and ideally suited for engineering data management tasks as opposed to the needs of OEMs and other actors in the manufacturing supply chain. Conversely, the product lifecycle test bed concept described in this study enables the integration of heterogeneous solutions from across the product lifecycle, including tools for enterprise resource planning (ERP), manufacturing execution systems (MES), and quality management systems (QMS). These efforts complement existing research and development aimed at reducing cycle time, ensuring first-pass success, and improving the overall performance of the product design and manufacturing process.

Figure 1.

The traditional product lifecycle

2 Test Bed Structure

Smart manufacturing is premised on the generation of intelligence through the efficient and effective use of data and information across the product lifecycle. To provide coverage across the product lifecycle, the test bed concept presented in this paper is composed of two major components: a Computer-Aided Technologies (CAx) Lab and a Manufacturing Lab. Both components focus primarily on machining processes, but the goal of the test bed is to generate a systems-level perspective applicable beyond specific manufacturing process domains.

2.1 Computer-Aided Technologies (CAx) Lab

The purpose of the CAx Lab is to develop and mature systems integration technologies and standards related to data and information exchange across the product lifecycle. This research is vital for smart manufacturing to improve the agility and responsiveness of the product design and manufacturing process. The CAx Lab also provides a platform to design and plan experiments for the Manufacturing Lab, which helps link the virtual and physical world. The structure of the CAx Lab integrates the following components using product lifecycle management (PLM) principles:

Computer-Aided Design (CAD)

This component enables testing of native CAD capabilities, their effect on downstream data uses, and CAD standards implementations. It also supports CAD data interoperability testing using native and derivative data. Detailed testing occurs during the development of test cases that are applied in the Manufacturing Lab, which helps ensure accurate test results since reproducible designs are the goal of the CAD output.

Computer-Aided Manufacture (CAM) & Inspection (CAI)

This component enables testing of the capabilities of CAM and CAI tools. This testing supports experimentation with information in CAD models and/or test cases. Furthermore, the CAM and CAI tools enable interoperability testing of data exchange technologies (e.g., JT, PDF, STEP).

Product Data Management (PDM)

This component includes various PDM systems that manage the test bed’s test cases and data. Having various PDM systems enables the test bed to develop packages for testing data exchange between systems.

2.1.1 Requirements

The CAx Lab should include a heterogeneous mix of top-tier, mid-tier, and open-source software to span all areas of interest. This mix aligns with the situation that industry must support and enables study of software application interoperability. The CAM and CAI software suite should support planning, execution, and gathering of results. PDM and PLM software should provide overall data management needs. Verification and validation (V&V) and data exchange tools are necessary to ensure the quality of product data and allow study of product information exchange. The hardware requirements should align with general industry practice, including application and database servers, workstations, and monitoring dashboard displays. Finally, adequate expertise must be available to ensure the successful operation of the CAx Lab. This should include CAD experts (e.g., designers and drafters), CAM experts (e.g., planners, machinists, and operators), and CAI experts (e.g., inspection planners and operators and statistical process control specialists).

2.2 Manufacturing Lab

The purpose of the Manufacturing Lab is to develop technologies and standards that enable the collection, transmission, and analysis of data and information during fabrication and inspection for monitoring and control. This research is critical for smart manufacturing to ensure that such technologies may be successfully and safely deployed in the manufacturing environment. The intelligence gathered by this research may be used to support performance measurement, diagnostic, and prognostic activities within manufacturing processes, equipment, and systems. It may also feed back to the CAx Lab to complete the link between the virtual and physical worlds and provides designers with the knowledge necessary to make the best decisions early in the product lifecycle. The structure of the Manufacturing Lab includes the following components networked across a real manufacturing facility:

Machine Tools & Inspection Equipment

These components also include any sensors needed to monitor the equipment and production processes that they control as well as different data analysis tools. The data analysis tools may support relatively simple (e.g., energy estimation from power monitoring) or complex (e.g., generated point clouds from coordinate-measurement machines) analyses. The machine tool and inspection equipment systems provide data and infrastructure to create and validate technologies for performance and quality assurance, maintenance, health management, or other purposes at the shop-floor level. They also provide data that may be combined with the CAx test case models described in Section 2.1.

Production Management Systems

This component provides facility-level data, such as production schedules and times. It enables activities similar to the machine tools and inspection equipment, but it focuses at the higher systems level. The systems level has become more significant for manufacturing decision making due to increased competition, globalization, and need for sustainability among other factors (Evans & Annunziata 2012, Helu 2013, Helu et al. 2014).

Data Aggregator

This component collects data from all sources in the Manufacturing Lab and attaches a common timestamp to the data so information from each piece of equipment can be connected with relevant sensor outputs. The data aggregator synthesizes data for each piece of equipment and for each part as it moves through fabrication and inspection. It can also combine the data synthesized for each part with the part’s CAx information from the CAx Lab and improves upon existing manufacturing data management systems by facilitating the interoperability of information across the digital thread. Synthesizing data for each piece of equipment and for each part enables the creation of robust databases that can be used for different types of analysis, such as manufacturing data fusion, pattern identification and matching, and multi-dimensional complex event processing. These databases can also be used to apply machine learning across the digital thread to improve the design of the part or the operation of processes, equipment, and systems (National Institute of Standards and Technology 2015). Cyber-security risks inherent in the manufacturing environment increase the importance of the data aggregator to the larger test bed structure since the data aggregator is the “gate” to networked devices on the shop floor.

2.2.1 Requirements

The Manufacturing Lab should be built within an existing manufacturing facility to ensure the validity of the data collected from the test bed. This facility should be relatively open with data aside from information generated from sensitive jobs (e.g., parts protected by International Traffic in Arms Regulations [ITAR] or export control). One example facility is the NIST Fabrication Technology Shop, which is a contract operation that supports a variety of research activities. While the equipment networked on the shop floor of the selected facility should provide substantial data across the machine, shop-floor, and facility levels, external sensors are needed to capture relevant system characteristics fully. These sensors should be integrated into a multi-sensor system that can fuse the collected data to capture and optimize multiple aspects of process, equipment, and shop-floor operations (Dornfeld, Wright, Vijayaraghavan & Helu 2009). The specific external sensors necessary depend on the metrics and key performance indicators that are relevant for the characteristics of interest. This infrastructure, though, should aim to use efficient and effective sensors so that the sensor system does not interfere with process or shop-floor operations (Helu 2013, Helu et al. 2014, Moriwaki 2002). All collected data must be contextualized with process-related information to determine the physical reasons driving any observed variations or events (Vijayaraghavan & Dornfeld 2010).

The Manufacturing Lab infrastructure should support different data formats and data and communications protocols and standards to reflect current industrial practice. It should be capable of handling a variety of computational powers given the relatively large range of ages of manufacturing equipment. It should also support a potentially large data volume that may result depending on the data sources and machines monitored. The infrastructure should handle analysis and action across the process, machine, shop-floor, and facility levels and over a large range of temporal scales (manufacturing phenomena and decision making may occur over microseconds to weeks or months) (Vijayaraghavan & Dornfeld 2010). Finally, the Manufacturing Lab must be extensible so that it can include any new technologies or standards developed over its use.

3 System Architecture

Figure 2 defines the high-level systems in the test bed. The primary systems are the CAx Lab, Manufacturing Lab, and the public and private web services. While only one CAx Lab is defined in this test bed, it may include many variations of tools. Integrating many types of tools reflects the reality faced by industry. Similarly, while only one Manufacturing Lab is defined in this test bed, multiple manufacturing labs could be interconnected in the future to expand this test bed. A larger test bed with multiple manufacturing labs would help validate the data and technologies generated with the current test bed design and enable further study of assembly-related or enterprise-level considerations.

Figure 2.

Block diagram definition for the test bed

The public and private web services are the interface points for disseminating data and information collected across the test bed. The public web service streams manufacturing data from actual processes and equipment combined with any relevant CAx data for parts made within the test bed. This data can be viewed by users for processes or equipment within the test bed. It can also be viewed for each part made within the test bed. Data should be clear of any intellectual-property (IP) and export-control concerns. Researchers would be able to connect to the public web service and have data available to them for their work. Industry may also connect to the public web service to collect data for development purposes without having to worry about their IP, which should encourage more industry collaboration in standards and technology development. The private web service is available internally to develop new smart manufacturing technologies that may not be ready for public release. Section 4.1 provides an example of such a research activity.

3.1 Implementation

The CAx Lab resources and tools would be implemented on computing hardware, such as workstations and application and database servers. These resources would be linked to the other test bed systems via a research equipment network (REN), which is an isolated, firewall-protected local network within an organization’s primary network. Systems like the REN reflect current industrial practice since they enable machine-to-machine (M2M) communication while protecting equipment, IP, and other sensitive information against cyber-security threats. Cyber-security threats have become a significant concern for industry since M2M communications across the product lifecycle provide opportunities for a variety of attacks that can include altering design files or toolpaths, capturing shop-floor data, or targeting the safety of operators and consumers (Wells, Camelio, Williams & White 2014). Using the REN also provides the infrastructure to develop technologies that facilitate the flow of fabrication and inspection information upstream to the design phase in an automated fashion using PDM tools.

Figure 3 shows the resources that would be implemented in the Manufacturing Lab. The multi-sensor system deployed on each piece of equipment on the shop floor is the primary source of data from the Manufacturing Lab. This data would include process-related information from the equipment controller and data from any sensors external to the equipment. An input-output (IO) bus would create a communications environment that integrates software and hardware tools to organize collected data, some of which may flow through a wireless connection. The IO bus would also include software to translate the collected data into a common definition based on the data format, data and communications protocol, or standard being used by the equipment. One or more machine tools or inspection equipment may use the same IO bus depending on the anticipated amount of data and the physical limitations of the shop floor. The data aggregator wirelessly pulls data from all IO buses in the Manufacturing Lab and stores this data locally in a buffer once it has completed the coordination and synthesis functions described in Section 2.2. After a predetermined time interval, the data aggregator would push all of the data it has stored in its buffer to the public and private web services including any CAx-related data as appropriate. Pushing the stored data from the data aggregator provides two advantages: (1) it ensures the security of the REN by preventing network traffic from entering the test bed, and (2) it creates a time buffer that allows sensitive data to be scrubbed from the data stream. Users may pull data as needed from the public and private web service.

Figure 3.

Network of resources deployed in the Manufacturing Lab

3.2 Product Model

The test bed uses the product model as the interface that connects information between design, fabrication, and inspection. The product model is the three-dimensional CAD representation of a product that contains product and manufacturing information (PMI), which is information related to product specifications and manufacturing requirements (Srinivasan, Barnard Feeney & Frechette 2014). Using the product model allows the test bed to tackle a significant challenge in product design and manufacturing: engineering organizations and designers have primary influence on cost over the product lifecycle, but that cost is paid mostly by original equipment manufacturers (OEMs) and other suppliers that fabricate and support the operation of products (Dencovski, Löwen, Holm, Amberg, Maurmaier & Göhner 2010). The Defense Acquisition University (2011) states that 60% to 80% of the product lifecycle cost occurs during product acquisition, operation, and support. These lifecycle costs need to be understood by engineering organizations and designers, but it can be difficult (if not impossible) for them to grasp their influence on these costs without information from other product lifecycle stages. Similarly, a major issue for OEMs and the larger manufacturing supply chain is a lack of effective information from engineering organizations and designers to clarify design intent. This forces OEMs and suppliers to search for the missing information, which adds unnecessary time and cost to their effort.

The product model may play a significant role in reducing the communication gap between engineering organizations, designers, OEMs, and the manufacturing supply chain. This requires that engineering includes the information needed by suppliers in a product model prior to its release so the product model remains useful to the supply chain. The product model becomes the digital thread of information that moves through the different phases of the product lifecycle. The test bed can use the product model to develop experiments to research these information needs of the lifecycle. A design of experiments may investigate the information needed by different manufacturing environments or process use cases by varying the level of information available in the product model for fabrication and inspection in the Manufacturing Lab. These experiments should reveal trends to assist further research in defining the required lifecycle information for each product lifecycle phase.

3.3 Standards Landscape

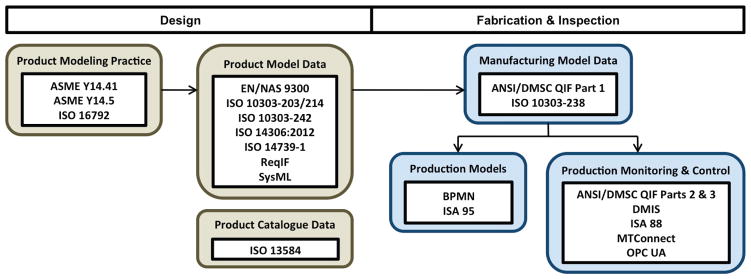

One important feature of the test bed is that its architecture supports the testing of multiple domain standards. Integrating these domain standards provides a means to connect information across different design and manufacturing tools. Figure 4 provides some examples of standards connected to the test bed. The test bed allows study of the interoperability of these domain standards. For example, one may investigate how product model data standards (e.g., ISO 10303), which are used to create model-based definitions, affect the ability to repurpose or reuse product model data in manufacturing model data. Similarly, one may use the infrastructure of the Manufacturing Lab to study how standards focused on interoperability at the process or machine levels (e.g., MTConnect) may integrate with production control standards (e.g., OPC UA, QIF parts 2 and 3) or production model standards (e.g., ISA 95).

Figure 4.

Examples of standards applicable to the product lifecycle test bed

4 Potential Research Opportunities

The test bed has been designed to enable the development of smart manufacturing technologies. These research activities may target the entire product lifecycle or a portion of the product lifecycle for users internal and external to the test bed. Internal users may also study the implementation of technologies within the test bed infrastructure.

4.1 Product and Manufacturing Information (PMI) Test Cases

PMI can be communicated as presentation (human-readable) or representation (machine-readable) data. Since industry has shifted away from two-dimensional (2D) paper-based product definitions to three-dimensional (3D) digital-product definitions (i.e., model-based definitions), it has become important for organizations to have the means to benchmark and validate the conformance of their internal CAx and manufacturing processes to the new PMI paradigm.

NIST developed a system to measure the conformance of CAD to ASME standards for PMI specifically focused on geometric dimensioning and tolerancing (GD&T) information (Lipman, Lubell & Frechette 2014). Figure 5 provides an example of a NIST-generated test case. The test bed can extend the efforts of the NIST system by generating a full-tolerance test case (FTC), or a test case with full product definition and PMI, that can be manufactured in a monitored environment that provides relevant manufacturing data. Publishing these baseline models and their associated manufacturing data to the public allows researchers to overcome IP barriers that prevent the use of real manufacturing and inspection data when developing and validating PMI tools and systems. The published optimized fabrication and inspection plans for each data package may be used by industry to baseline or compare their internal processes and should support research organizations in public demonstrations and transfer of developed PMI technology.

Figure 5.

NIST-generated test case (Lipman et al. 2014)

4.2 Virtual Factory Data

Developing smart manufacturing technologies that target the manufacturing phase requires access to relevant data from real manufacturing systems. Given the challenges in attaining such resources, many researchers must use data from laboratory systems that may not reflect actual industrial conditions or simulations that are difficult to validate outside of the laboratory environment. Those that have access to industrial data must often work within the organization that owns the data, which can limit innovation across different manufacturing domains. There have been some recent tools that address these limitations by generating intelligence without disclosing IP to the public, such as NOVO Optimize, which uses “community data” in its optimization algorithms (Kennametal 2014). Continued innovation in smart manufacturing requires open streams of quality industrially-relevant data that all researchers may use.

Since the data streaming through the public web service may be viewed for each process or equipment networked on the shop floor, the test bed may act as a source of virtual factory. This data would not need to be validated against a real system since it is already from a real manufacturing facility, and it would be “raw” (aside from deleting any ITAR or export-related data), which provides researchers with industrially representative data with any deficiencies that may affect this type of information. This data would enable fabrication-focused research on a variety of topics, including data preprocessing, validation, robustness, and quality; condition monitoring; process monitoring and data analytics; and manufacturing performance measurement.

4.3 Representative Industrial Environment

The test bed is designed to be a representative industrial environment of integrated technology that one can find in many facilities. The process of integrating different pieces of technology often highlights the need for standardization in areas such as physical interfaces, data formats, and data and communications protocols. For example, the design of the test bed can generate reference architectures to address cyber-security concerns when deploying technologies on the shop floor. The test bed also allows internal researchers to test and study the interoperability of various standards, which can identify areas where additional standards may be needed to close the communications gap enabling further innovation in smart manufacturing. It may also be used to test new technologies and their implementation, which can drive the development of new standards.

4.4 Other Potential Long-Term Impacts

There are several opportunities for the test bed to have potential long-term impact. As an introduction of cyber-physical infrastructure to manufacturing, the test bed can help develop technologies and standards applicable to other cyber-physical systems in sectors similar to manufacturing. Similarly, the potential expansion of the test bed to include other Manufacturing Labs can create a cyber-physical systems test bed that may be used to investigate different assembly-related or enterprise-level considerations. Such research can greatly reduce the risks and improve the efficiency of OEMs who must coordinate among a network of suppliers and integrate parts from those suppliers into one or more products.

Another potential long-term impact of the test bed is in delivering a systems perspective applicable to manufacturing domains beyond machining. Growing interest and concern in areas such as sustainability, preventative maintenance, and lifecycle costing drive the need for a systems-level perspective in manufacturing decision making since many of the inefficiencies in manufacturing occur at the systems level (Evans & Annunziata 2012, Helu 2013, Helu et al. 2014). Manufacturers require comprehensive, holistic systems-level tools that address the inherent complexity of manufacturing systems and interconnectedness of manufacturing with other product lifecycle stages (Helu 2013). These tools allow manufacturers to meet new challenges and business drivers in the smart manufacturing environment.

As Section 4.3 describes, the test bed can help prototype new technologies and build a business case for further industrial investment. In this fashion, the test bed can serve as a link to the National Network for Manufacturing Innovation (NNMI), which supports efforts to develop a United States infrastructure for manufacturing research (U.S. Department of Commerce 2014). Public-private partnerships called Institutes for Manufacturing Innovation (IMIs) enable academic research to move towards industrial commercialization. The test bed can mature manufacturing concepts by transitioning them from fundamental research environments to the investment-rich NNMI environment, which accelerates the maturation of concepts into paradigms.

5 Summary

The product lifecycle test bed concept integrates existing technologies for design, fabrication, and inspection in a novel manner to enable a digital thread of information across the product lifecycle. This integration is accomplished by introducing a cyber-physical infrastructure across the product lifecycle through the structure and architecture of the CAx and Manufacturing Labs. By sharing and exchanging data and information between both environments, the test bed supports fundamental and applied research that cultivates the development of smart manufacturing technologies. Section 4 describes several of these research opportunities. Two of the more important research areas are developing standards to support interoperability between design, fabrication, and inspection systems and defining requirements to extend cyber-physical systems into the manufacturing paradigm for smart manufacturing.

One major challenge identified by the test bed design is cyber security. Cyber-security concerns include the loss of data from networked machines and the threat of cyber attacks (e.g., controlling or altering the operation or output of the machine) against these machines. This is one of several reasons why the data aggregator is perhaps the most important component of the test bed since it connects the Manufacturing Lab to the public access point. The data aggregator is also vital for data management, which remains a significant challenge in manufacturing given the different data formats and data and communications protocols and standards within the manufacturing environment. Other challenges highlighted by the design of the test bed include the sharing of data across the product lifecycle because of the large number of applicable software and hardware tools that must be integrated. The physical limitations of the manufacturing environment also further complicate the development of smart manufacturing since these technologies cannot interfere with the process or shop-floor operations, must overcome computational limitations of aging equipment, and must transmit data in an environment that was never designed to do so.

Other identified requirements for introducing a cyber-physical infrastructure in manufacturing include that this infrastructure must be extensible to accommodate continually improving technologies. It must also help determine the actions that drive phenomena occurring during the product lifecycle to enable effective decision making. Future work will focus on addressing these requirements through the physical implementation of the product lifecycle test bed concept within a manufacturing facility. The resulting test bed infrastructure has the potential to enable smart manufacturing technologies that improve the overall performance of the product design and manufacturing system and ensure the efficiency and effectiveness of industry in responding to drivers that have increased the competitiveness of manufacturing. Ultimately, resources like the product lifecycle test bed concept should allow researchers to create tools and technologies that deliver on the promise of smart manufacturing.

Acknowledgments

The authors would like to acknowledge Ed Barkmeyer, Conrad Bock, and Athulan Vijayaraghavan for the helpful feedback that they provided. Certain commercial systems are identified in this paper. Such identification does not imply recommendation or endorsement by NIST. Nor does it imply that the products identified are necessarily the best available for the purpose.

References

- Abdul Kadir A, Xu X, Hämmerle E. Virtual machine tools and virtual machining: A technological review. Robotics and Computer-Integrated Manufacturing. 2011;27(3):494–508. [Google Scholar]

- Altintas Y, Brecher C, Weck M, Witt S. Virtual machine tool. CIRP Annals - Manufacturing Technology. 2005;54(2):115–138. [Google Scholar]

- Defense Acquisition University. [Accessed November 4, 2014];DOD Life Cycle Mmanagement (LCM) & Product Support Manager (PSM) Rapid Deployment Training. 2011 http://www.dau.mil/homepage%20documents/PSM%20RDT%20%28v10%20Tailored%2014%20Jun%2011%29.pdf.

- Dencovski K, Löwen U, Holm T, Amberg M, Maurmaier M, Göhner P. Production System’s Life Cycle-Oriented Innovation of Industrial Information Systems. InTech; 2010. pp. 389–410. book section 19. [Google Scholar]

- Dornfeld D, Wright PK, Vijayaraghavan A, Helu M. Enabling manufacturing research through interoperability. Transactions of NAMRI/SME. 2009;37:443–450. [Google Scholar]

- Evans PC, Annunziata M. Technical report. General Electric; 2012. Industrial Internet: Pushing the boundaries of minds and machines. [Google Scholar]

- Helu M. PhD Dissertation. University of California; Berkeley: 2013. Leveraging Manufacturing Precision to Reduce Product Life Cycle Environmental Impacts. [Google Scholar]

- Helu M, Robinson S, Bhinge R, Bänziger T, Dornfeld D. Development of a machine tool platform to support data mining and statistical modeling of machining processes. Proceedings of the Machine Tool Technology Research Foundation 2014 Annual Meeting; 2014. pp. 171–176. [Google Scholar]

- Kennametal. [Accessed November 4, 2014];NOVO Optimize: NOVO Tool and Process Optimization. 2014 http://www.kennametal.com/content/dam/novosphere/KMT_IMTS_NOVO_Optimize_Brochure.pdf.

- Lee EA. Cyber physical systems: Design challenges. 2008 11th IEEE International Symposium on Object Oriented Real-Time Distributed Computing (ISORC); IEEE; 2008. pp. 363–369. [Google Scholar]

- Lipman R, Lubell J, Frechette SP. [Accessed November 4, 2014];MBE PMI Validation and Conformance Testing. 2014 http://www.nist.gov/el/msid/infotest/mbe-pmi-validation.cfm.

- Moriwaki T. Fundamentals: Sensors in Mechanical Manufacturing: Requirements, Demands, Boundary Conditions, Signal Processing, Communication Techniques, and Man-Machine Interfaces. Wiley-VCH Verlag GmbH; 2002. pp. 24–45. [Google Scholar]

- MTConnect Institute. [Accessed November 4, 2014];MTConnect Agent Simulator. 2014 http://agent.mtconnect.org/

- National Institute of Standards and Technology. [Accessed February 10, 2015];Digital Thead for Smart Manufacturing. 2015 http://www.nist.gov/el/msid/syseng/dtsm.cfm/

- Simpson JA, Hocken RJ, Albus JS. The automated manufacturing research facility of the National Bureau of Standards. Journal of Manufacturing Systems. 1982;1(1):17–32. [Google Scholar]

- Srinivasan V, Barnard Feeney A, Frechette S. A portrait of an ISO STEP tolerancing standard as an enabler of smart manufacturing systems. Journal of Computing and Information Science in Engineering. 2014 Accepted for publication. [Google Scholar]

- U.S. Department of Commerce. [Accessed November 4, 2014];Three Takeaways from National Network for Manufacturing Innovation (NNMI) Day. 2014 http://www.commerce.gov/blog/2014/09/22/three-takeaways-national-network-manufacturing-innovation-nnmi-day.

- Vijayaraghavan A, Dornfeld D. Automated energy monitoring of machine tools. CIRP Annals - Manufacturing Technology. 2010;59(1):21–24. [Google Scholar]

- Wells LJ, Camelio JA, Williams CB, White J. Cyber-physical security challenges in manufacturing systems. Manufacturing Letters. 2014;2(2):74–77. [Google Scholar]

- Wolf W. Cyber-physical systems. Computer. 2009;42(3):88–89. [Google Scholar]