Abstract

Magnetic biochar nanocomposites were obtained by modification of biochar by zero-valent iron. The article provides information on the impact of contact time, initial Cd(II), Co(II), Zn(II), and Pb(II) ion concentrations, dose of the sorbents, solution pH and temperature on the adsorption capacity. On the basis of experiments, it was found that the optimum parameters for the sorption process are phase contact time 360 min (after this time, the equilibrium of all concentrations is reached), the dose of sorbent equal to 5 g/dm3, pH 5 and the temperature 295 K. The values of parameters calculated from the kinetic models and isotherms present the best match to the pseudo second order and Langmuir isotherm models. The calculated thermodynamic parameters ∆H 0, ∆S 0 and ∆G 0 indicate that the sorption of heavy metal ions is an exothermic and spontaneous process as well as favoured at lower temperatures, suggesting the physical character of sorption. The solution of nitric acid(V) at the concentration 0.1 mol/dm3 was the best acidic desorbing agent used for regeneration of metal-loaded magnetic sorbents. The physicochemical properties of synthesized composites were characterized by FTIR, SEM, XRD, XPS and TG analyses. The point characteristics of the double layer for biochar pHPZC and pHIEP were designated.

Keywords: Nanocomposites, Magnetic biochar, Heavy metal ions, Iron modification, Sorption

Background

The growing amount of agricultural wastes which is landfilled or burned causes groundwater contamination or air pollution [1]. These wastes which include hazelnut husks [2]; wood, bark and corn straw [3, 4]; rice husks and empty fruit brunch [5]; potato peel [6] and sugar beet tailing [7] are the raw materials for the production of biochar. In the pyrolysis process, properly selected conditions allow to obtain low-cost sorbents of high porosity and suitable surface area [8, 9]. The addition of biochar to the soil increases its fertility because of its abundant organic matter [10]. Biochar is also used as a sorbent for the removal of heavy metal ions: Cu(II), Cd(II) [11, 12], Cr(VI), Pb(II) [13], Ni(II) [14] and others.

Application of nanocomposites of iron-modified biochar can overcome the difficulties associated with separation of biochar after sorption. These nanocomposites have magnetic properties so that when the external field is applied, they can be removed from the solutions [15]. Fe, Fe2O3 and Fe3O4 are magnetic particles used in two types of modification of biochar by pyrolysis at high temperatures or chemical coprecipitation [16–23]. Zhang et al. [16] obtained magnetic biochar by pretreatment of biomass (cotton wood) in a ferric chloride solution and then subjecting it to a pyrolysis at a temperature 873 K for 1 h. Biochar/γ-Fe2O3 demonstrated the ability of As(V) ion sorption from aqueous solutions. Three novel magnetic biochars were synthesized by Chen et al. [17] by chemical co-precipitation in a solution of ferrous chloride and ferric chloride (molar ratio 1:1) on biomass (orange peels) and then pyrolysis at different temperatures 523, 673, and 973 K. Magnetite biochar (obtained at 523 K) indicates the increase of the sorption percentage of phosphates from 7.5% (for non-magnetic biochar) to 67.3%. In addition, the resulting sorbent is capable of simultaneous removal of phosphates and organic impurities which is important because these compounds coexist in wastewaters. Wang et al. [18] investigated the regeneration of Pb-loaded magnetic biochar. This sorbent was prepared by mixing biochar (obtained from eucalyptus leaf residue) with FeCl3 and FeSO4 solutions and the addition of NaOH up to the pH value 10–11. The use of EDTA-2Na as a desorbing agent gives the yield of 84.1% which confirms that the magnetic biochar can be a sorbent of multi-use. Zero-valent iron-impregnated biochar was obtained by Devi and Saroha [21] and was used for the removal of pentachlorophenol from effluents. It was found that the best sorption parameters were obtained by magnetic biochar at the molar ratio FeSO4:NaBH4 = 1:10 and the sorption percentage was 80.3%.

Zero-valent iron-coated biochar is characterized by high reactivity and high affinity for the impurities in aqueous solutions of the organic compounds: pentachlorophenol [22] and trichloroethylene [23] as well as the heavy metal ions As(V) [24], Cr(VI) [10] and Pb(II) [25].

In this paper, two types of magnetic biochar were used to test the ability of heavy metal ion capture. For modifications, FeSO4 as a source of iron and NaBH4 as a reducing agent at the different molar ratios of FeSO4 to NaBH4 1:1 and 1:2 were used. The obtained sorbents were designated as MBC1 and MBC2, respectively. To understand the mechanism of heavy metal ions Cd(II), Co(II), Zn(II) and Pb(II) adsorption on MBC1 and MBC2, effects of the sorbent dose, phase contact time, initial concentration, solution pH and temperature were investigated. To describe the kinetics and equilibrium adsorption, the pseudo first order, pseudo second order and intraparticle diffusion kinetic models as well as the adsorption isotherms of Langmuir and Freundlich models were applied. Fourier transform infrared spectroscopy, scanning electron microscopy, X-ray photoelectron spectra and TG/DTG curves were used to characterize the physicochemical properties of two modifications. The point of zero charge pHPZC and the isoelectric point pHIEP are also determined. Additionally, the efficiency of sorbent regeneration using HNO3 at different concentrations was determined.

Methods

Preparation of Sorbents

A dry sorbent biochar used in the experiment comes from Coaltec Energy, USA Inc., and is produced in the gasification process. Gasification involves heating the biomass in an oxygen-free atmosphere. The result is a biochar carbon-rich sorbent [26].

Zero-valent iron-coated biochars (magnetic ones) were prepared by dissolving FeSO4·7H2O (0.18 mol/dm3) in 100 cm3 of distilled water while stirring the solution and adding 5 g of biochar. The NaBH4 solution results in a reduction of Fe(II) to Fe(0), and it is added dropwise into the suspension while stirring at 1000 rpm for 30 min under room temperature. Then the nanocomposite was filtered and washed as well as dried in the oven. For the molar ratio of FeSO4 to NaBH4 = 1:1, 4.96 g of FeSO4 and 0.68 g of NaBH4 were used and the sorbent was denoted as MBC1. For the second modification, for MBC2, the same amounts of FeSO4 and 1.36 g of NaBH4 were applied.

Chemicals

The chemicals used in the experiment were of analytical grade and purchased from Avantor Performance Materials (Poland). The stock solutions of Cd(II), Co(II), Zn(II) and Pb(II) ions at a concentration 1000 mg/dm3 were prepared by dissolving the appropriate amounts of salts Cd(NO3)2·4H2O, CoCl2·6H2O, ZnCl2 and Pb(NO3)2 in distilled water; 1 mol/dm3 of HCl and/or 1 mol/dm3 of NaOH were used for pH adjustment.

Sorption and Kinetic Studies

These experiments were carried out in 100 cm3 conical flasks with 0.1 g of sorbents and 20 cm3 of solutions at the concentrations 50–200 mg/dm3, at the phase contact times from 0 to 360 min, at pH 5 and at 295 K. Then after shaking, the solutions were filtered and analysed for residual heavy metal ion concentrations by means of the atomic absorption spectroscopic methods. Finally, the equilibrium sorption capacity q e [mg/g] was calculated according to the equation

| 1 |

where C 0 and C e [mg/dm3] are the initial and equilibrium concentrations, V [dm3] is the volume of the metal ion solution, and m [g] is the mass of magnetic biochars.

To estimate the effect of dose on the Cd(II) ion sorption on two types of sorbents, 0.1 g of MBC1 and MBC2 and the 20 cm3 (5 g/dm3) of 100 mg/dm3 Cd(II) ion solution were used. The investigations were carried out for the doses of sorbents 5, 7.5 and 10 g/dm3, at pH 5, shaken mechanically at 180 rpm on a laboratory shaker at 295 K for 360 min. After shaking, the solutions were filtered and the contents of Cd(II) ions were measured.

The tests of the pH effect on the above-mentioned heavy metal ion sorption were carried out for MBC1 and MBC2. The amounts of the sorbents and the volumes of the solutions are the same as these mentioned above. The samples were shaken at a concentration of 100 mg/dm3 for 360 min and in the pH range 2–6.

The studies of the equilibrium sorption isotherm were conducted applying the same procedure as in kinetic investigations. MBC1 and MBC2 were in contact with the ion solutions at the concentrations 50–600 mg/dm3 for 360 min, at 180 rpm, at pH 5 and at 295 K. The sorption of Cd(II) on MBC1 and MBC2 was also studied as a function of temperature. Tests were carried out at 295, 315 and 335 K for the same solution concentrations as those in the adsorption tests. The thermodynamic parameters were calculated using the following equations:

| 2 |

| 3 |

| 4 |

| 5 |

where C s [mg/g] and C e [mg/g] are the sorption capacities in the adsorbent and adsorbate phases, ∆G 0 [kJ/mol] is the standard free energy changes, R is the gas constant [J/mol K], T is the temperature [K], K d is the distribution coefficient, ∆H 0 is the change of enthalpy [kJ/mol], and ∆S 0 is the change of entropy [kJ/mol].

Efficiency of the sorbent regeneration was tested using distilled water and HNO3 at the concentrations 0.1, 0.5, 1.0, 1.5, 2.0 and 5.0 mol/dm3. After Cd(II) ion sorption at 100 mg/dm3 (pH 5, shaking speed 180 rpm, temperature 295 K), the Cd-loaded MBC2 samples were dried, weighed and shaken with 20 cm3 water or HNO3 at different concentrations for 360 min. The desorption yield was calculated as

| 6 |

where C des [mg/dm3] is the amount of metal ions in solution after regeneration.

Apparatus and Analysis

Experiments were carried out by shaking the samples by means of the laboratory shaker type 358A (Elpin Plus, Poland). The pH values of samples after the sorption were measured using a pHmeter pHM82 (Radiometer, Copenhagen). Subsequently, the amounts of heavy metal ions were determined using an atomic absorption spectrometer AAS (Spectr AA 240 FS, Varian) at 228.8 nm for Cd(II), 240.7 nm for Co(II), 213.9 nm for Zn(II) and 217.0 nm for Pb(II).

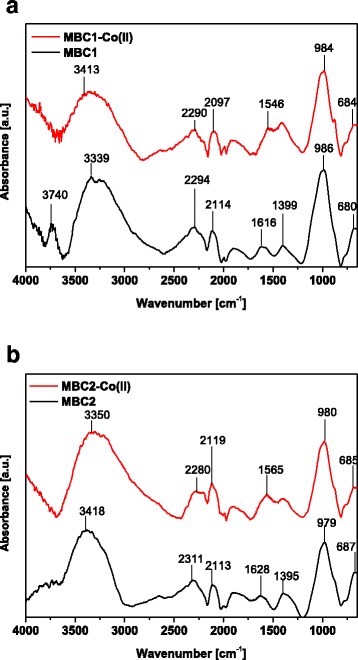

The FTIR spectra of MBC1 and MBC2 were registered by means of a Cary 630 FTIR spectrometer (Agilent Technologies) before and after Co(II) sorption. They were obtained in the range 650–4000 cm−1.

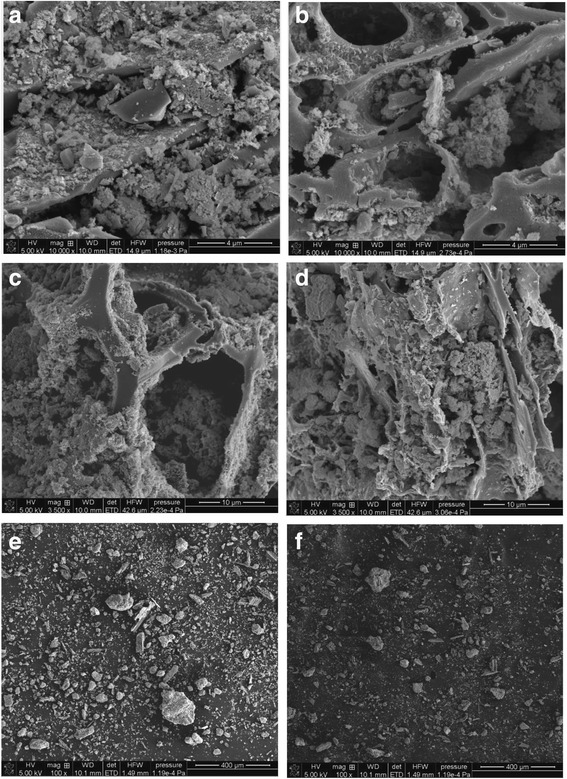

The surface morphology of nanocomposites of iron-modified biochar was observed using the scanning electron microscope SEM (Quanta 3D FEG, FEI).

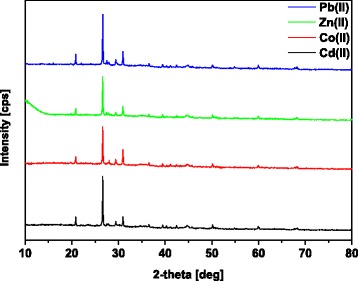

X-ray diffraction (XRD) was obtained using the X-ray diffractometry PANalytical (Empyrean, Netherlands).

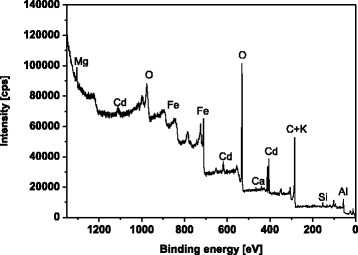

X-ray photoelectron spectra (XPS) of MBC2 after the Cd(II) sorption were obtained using the UHV multi-chamber analytical system (Prevac, Poland).

The thermogravimetric (TG) and derivative thermogravimetric (DTG) analyses for MBC1 and MBC2 were made by means of TA Instruments Q50 TGA in nitrogen atmosphere before and after heavy metal ion sorption.

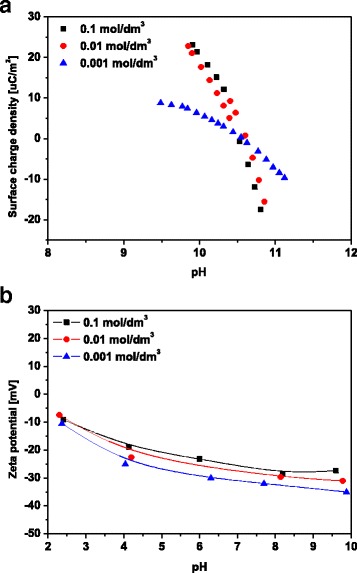

The zeta potential of biochar was determined by electrophoresis using Zetasizer Nano-ZS90 by Malvern. The measurements were performed at 100 ppm concentration ultrasonication of the suspension. As a background electrolyte, NaCl solution was used at the concentrations 0.1, 0.01 and 0.001 mol/dm3. The electrophoretic mobility was converted to the zeta potential in millivolts using the Smoluchowski equation.

Surface charge measurements were performed simultaneously in the suspension of the same solid content to maintain the identical conditions of the experiments in a thermostated Teflon vessel at 298 K. To eliminate the influence of CO2, all potentiometric measurements were performed in nitrogen atmosphere. The pH values were measured using a set of glass REF 451 and calomel pHG201-8 electrodes with the Radiometer assembly. The surface charge density was calculated from the difference of the amounts of added acid or base to obtain the same pH value of suspension as for the background electrolyte. The density of biochar surface charge was determined using the “titr_v3” programme. Comparison of the titration curve of the metal oxide suspension of the same ionic strength is used to determine the surface charge density of metal oxide. The surface charge density is calculated from the ratio of the volume of acid and base added to the suspension in order to obtain the desired pH value:

| 7 |

where ΔV is the ratio of the volume of acid and base added to the suspension in order to obtain the desired pH value, C [mol/dm3] is the concentration of acid/base, F [9.648 × 104 C mol−1] is the Faraday constant, m [g] is the mass of metal oxide, and S w is the specific surface area of metal oxide.

Results and Discussion

Adsorption Kinetics

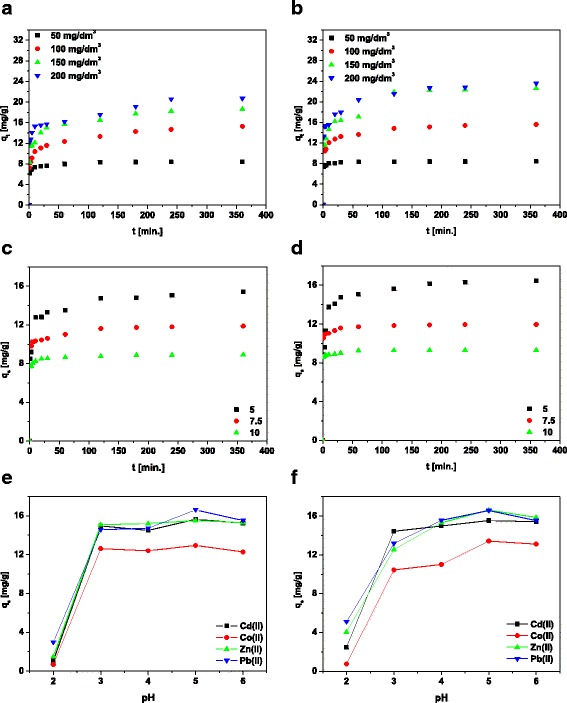

In order to estimate the sorption capacity of MBC1 and MBC2, it is important to determine the equilibrium time for maximum removal of heavy metal ions. Therefore, studies were performed with various initial concentrations from 50 to 200 mg/dm3 and in the contact time range of 1–360 min. Following from Fig. 1a, b, the sorption capacities of metal ions rose sharply at short contact time and slowed gradually as the state of equilibrium was reached. Due to the large number of free active sites on the surface of the magnetic biochar in the initial stage, sorption occurs rapidly [27]. The equilibrium is achieved faster for lower initial concentrations, after approximately 60 min for the Cd(II) ion concentration 50 mg/dm3 and slower for higher initial concentration, for instance after approximately 240 min for the concentration 200 mg/dm3.

Fig. 1.

Effect of the phase contact time on Cd(II) adsorption on a MBC1 and b MBC2, effect of dose of c MBC1 and d MBC2 on Cd(II) sorption and effect of pH on heavy metal ion sorption on e MBC1 and f MBC2

Capacity equilibria increased with the increasing contact time and initial concentration and are equal to 8.40, 15.29, 18.65, and 20.65 mg/g for the Cd(II) at concentrations 50, 100, 150, and 200 mg/dm3, respectively, for MBC1 and 8.41, 15.63, 22.63 and 23.55 mg/g, respectively, for MBC2. In addition, it can be concluded that the modification with a higher content of a reducing agent has a higher value of q e. For Co(II), Zn(II) and Pb(II) ions, the same relationships were found. The values of equilibrium capacities contained in Tables 1 and 2 permit to establish of a series of affinity of heavy metal ions for nanocomposites of iron-modified biochar Pb(II) > Zn(II) > Cd(II) > Co(II).

Table 1.

Parameters for various adsorption kinetic models for Cd(II), Co(II), Zn(II) and Pb(II) sorption on MBC1

| Parameters | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C 0 [mg/dm3] | q exp | PFO | PSO | IPD | |||||||

| q 1 | k 1 | R 2 | q 2 | k 2 | h | R 2 | k i | C | R 2 | ||

| Cd(II) | |||||||||||

| 50 | 8.40 | 1.40 | 0.017 | 0.945 | 8.43 | 0.067 | 4.773 | 1.000 | 0.358 | 6.079 | 0.878 |

| 100 | 15.29 | 6.08 | 0.010 | 0.966 | 15.25 | 0.009 | 2.070 | 0.998 | 1.126 | 6.389 | 0.953 |

| 150 | 18.65 | 7.14 | 0.012 | 0.958 | 18.70 | 0.009 | 2.985 | 0.998 | 1.423 | 7.914 | 0.851 |

| 200 | 20.65 | 8.33 | 0.014 | 0.820 | 20.70 | 0.007 | 2.801 | 0.996 | 1.033 | 11.3146 | 0.889 |

| Zn(II) | |||||||||||

| 50 | 8.82 | 0.81 | 0.024 | 0.913 | 8.84 | 0.165 | 12.892 | 1.000 | 0.339 | 6.946 | 0.820 |

| 100 | 15.87 | 6.32 | 0.015 | 0.977 | 16.02 | 0.010 | 2.595 | 0.999 | 0.732 | 8.571 | 0.886 |

| 150 | 20.41 | 7.19 | 0.010 | 0.981 | 20.44 | 0.007 | 2.814 | 0.997 | 0.610 | 12.409 | 0.799 |

| 200 | 27.59 | 10.09 | 0.006 | 0.866 | 26.76 | 0.005 | 3.326 | 0.993 | 1.523 | 12.854 | 0.964 |

| Co(II) | |||||||||||

| 50 | 7.71 | 2.97 | 0.011 | 0.970 | 7.71 | 0.019 | 1.116 | 0.998 | 0.390 | 3.843 | 0.922 |

| 100 | 12.12 | 6.55 | 0.015 | 0.950 | 12.29 | 0.009 | 1.314 | 0.998 | 0.662 | 4.728 | 0.968 |

| 150 | 14.84 | 7.82 | 0.012 | 0.928 | 14.95 | 0.006 | 1.299 | 0.993 | 0.254 | 7.044 | 0.979 |

| 200 | 17.32 | 10.70 | 0.009 | 0.935 | 17.36 | 0.003 | 0.947 | 0.979 | 0.688 | 6.110 | 0.735 |

| Pb(II) | |||||||||||

| 50 | 8.74 | 0.02 | 0.061 | 0.586 | 8.74 | 3.780 | 288.864 | 1.000 | 0.008 | 8.704 | 0.575 |

| 100 | 16.92 | 0.07 | 0.013 | 0.892 | 16.92 | 0.882 | 252.606 | 1.000 | 0.006 | 16.849 | 0.692 |

| 150 | 23.75 | 0.02 | 0.008 | 0.447 | 23.74 | 4.056 | 286.943 | 1.000 | 0.025 | 23.648 | 0.479 |

| 200 | 33.13 | 0.15 | 0.020 | 0.633 | 33.14 | 0.872 | 957.123 | 1.000 | 0.371 | 31.713 | 0.721 |

Table 2.

Parameters for various adsorption kinetic models for Cd(II), Co(II), Zn(II) and Pb(II) sorption on MBC2

| Parameters | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C 0 [mg/dm3] | q exp | PFO | PSO | IPD | |||||||

| q 1 | k 1 | R 2 | q 2 | k 2 | h | R 2 | k i | C | R 2 | ||

| Cd(II) | |||||||||||

| 50 | 8.41 | 0.54 | 0.019 | 0.914 | 8.42 | 0.227 | 16.087 | 1.000 | 0.224 | 7.188 | 0.897 |

| 100 | 15.63 | 4.42 | 0.013 | 0.978 | 15.67 | 0.016 | 3.846 | 0.999 | 0.756 | 9.385 | 0.933 |

| 150 | 22.63 | 10.41 | 0.018 | 0.968 | 23.02 | 0.006 | 3.189 | 0.998 | 1.472 | 9.698 | 0.960 |

| 200 | 23.55 | 8.20 | 0.011 | 0.964 | 23.59 | 0.006 | 4.072 | 0.999 | 1.076 | 12.664 | 0.893 |

| Zn(II) | |||||||||||

| 50 | 8.82 | 0.24 | 0.025 | 0.913 | 8.83 | 0.658 | 51.259 | 1.000 | 0.187 | 8.007 | 0.789 |

| 100 | 16.85 | 3.53 | 0.012 | 0.965 | 16.87 | 0.020 | 5.820 | 1.000 | 0.449 | 12.168 | 0.914 |

| 150 | 20.57 | 6.40 | 0.008 | 0.963 | 20.40 | 0.008 | 3.124 | 0.997 | 0.613 | 12.870 | 0.888 |

| 200 | 27.93 | 8.20 | 0.012 | 0.971 | 27.99 | 0.007 | 5.546 | 0.999 | 0.891 | 17.933 | 0.967 |

| Co(II) | |||||||||||

| 50 | 8.12 | 1.68 | 0.016 | 0.938 | 8.15 | 0.055 | 3.675 | 1.000 | 0.452 | 5.113 | 0.981 |

| 100 | 12.84 | 6.40 | 0.010 | 0.940 | 12.82 | 0.007 | 1.187 | 0.994 | 0.621 | 5.207 | 0.847 |

| 150 | 15.24 | 7.99 | 0.011 | 0.991 | 15.36 | 0.005 | 1.292 | 0.995 | 0.387 | 6.984 | 0.974 |

| 200 | 18.30 | 8.72 | 0.007 | 0.917 | 17.96 | 0.005 | 1.525 | 0.992 | 0.370 | 8.150 | 0.965 |

| Pb(II) | |||||||||||

| 50 | 8.74 | 0.02 | 0.004 | 0.656 | 8.73 | 2.335 | 178.025 | 1.000 | 0.003 | 8.704 | 0.982 |

| 100 | 16.93 | 0.01 | 0.007 | 0.705 | 16.93 | 5.530 | 158.227 | 1.000 | 0.003 | 16.905 | 0.666 |

| 150 | 23.75 | 0.04 | 0.008 | 0.920 | 23.74 | 1214 | 684.238 | 1.000 | 0.003 | 23.698 | 0.982 |

| 200 | 33.19 | 0.08 | 0.020 | 0.711 | 33.19 | 1.822 | 200.745 | 1.000 | 0.159 | 32.586 | 0.635 |

To describe the kinetics of heavy metal ion adsorption on magnetic sorbents, the pseudo first order (PFO), the pseudo second order (PSO), and the intraparticle diffusion (IPD) models were applied [28–30]. The kinetic parameters and correlation coefficients (R 2) are presented in Tables 1 and 2. According to the results of PFO model, the calculated values of equilibrium capacities were different compared to the experimental ones. The values of R 2 (>0.97) of PSO model indicate that this model seems to be the best to describe sorption process. In addition, the experimental values of q e are similar to the theoretical ones. Moreover, the values of rate constants (k 2) of PSO decrease with the increasing initial concentration of solutions from 0.067 to 0.007 g/(mg min) for MBC1.

Effect of Dose

The relationship between two types of magnetic sorbents loading on the adsorption of Cd(II) ions was investigated by differentiating doses of sorbents (5, 7.5, and 10 g/dm3) while retaining all other parameters such as solution concentration 100 mg/dm3, solution pH 5, phase contact time 360 min and temperature 295 K constant. The effects of sorbent dosage on the removal of Cd(II) ions are presented in Fig. 1c, d. It can be noticed that the increase in dose of magnetic biochars reduces the sorption capacity from 15.42 to 8.93 mg/g for MBC1 and from 16.44 to 9.32 mg/g for MBC2. Therefore, the optimum value is equal to 5 g/dm3 of magnetic sorbents which was applied in the heavy metal ion sorption process.

Effect of Initial pH

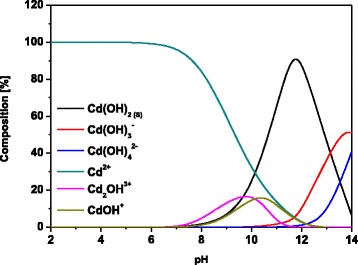

Studies on the effect of pH are very important to optimize the sorption process. The value of pH affects the degree of ionization and the surface charge of the sorbent [31]. The influence of initial pH of the Cd(II), Co(II), Zn(II) and Pb(II) solutions on the sorption capacities of the sorbents was investigated by differentiating the initial pH from 2 to 6 and maintaining the other parameters and is shown in Fig. 1e, f. The presence of negatively charged groups on the surface of magnetic biochars allows sorption of positively charged Cd(II), Co(II), Zn(II) and Pb(II) ions [32]. Sorption of all metal ions at pH 2 is very low due to the presence of hydronium ions that occupy free places on the sorbent surface and excludes the possibility of metal ion binding. While the increase of pH will facilitate ion uptake [33], the equilibrium capacities of all metal ions increase and achieve the highest value at pH 5 (this pH value was selected as optimal for further research). Additionally, based on the speciation diagram (Fig. 2) for the pH values 5.0 and 6.0 Cd2+ was predominant.

Fig. 2.

Speciation diagram for Cd(II)

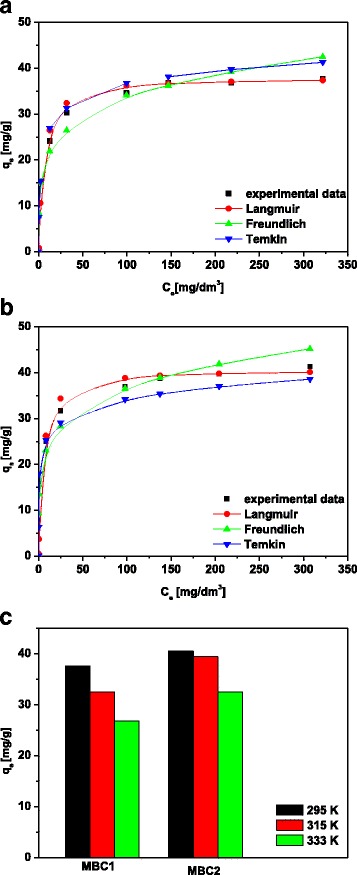

Adsorption Isotherms

To understand interactions between the metal ions and the sorbent is important to calculate the parameters of isotherms and correlation coefficients. The adsorption equilibrium data for Co(II) and Zn(II) ions were calculated using the three equations of the Langmuir, Freundlich and Temkin isotherm models and are listed in Table 3. In Table 4, the isotherm parameters and correlation coefficients as a function of temperature for the adsorption of Cd(II) are presented. Figure 2a, b shows the Cd(II) adsorption isotherms and fitted models. Comparing the parameters of isotherms, it can be stated that the value of R 2 (>0.95) from the Langmuir isotherm is the highest indicating a good fit to the experimental data. The Langmuir isotherm model assumes monolayer adsorption and neglects interactions between the molecules of adsorbate [34, 35]. In addition, the values of R L from 0 to 1 indicate favourable adsorption nature [36].

Table 3.

Adsorption isotherm parameters and correlation coefficients for the adsorption of Co(II) and Zn(II) on MBC1 and MBC2

| Isotherm model | Parameters | MBC1 | MBC2 | ||

|---|---|---|---|---|---|

| Co(II) | Zn(II) | Co(II) | Zn(II) | ||

| Langmuir |

q e,exp | 28.55 | 34.11 | 29.40 | 35.40 |

| q 0 | 27.91 | 34.41 | 29.82 | 35.27 | |

| K L | 0.029 | 0.045 | 0.024 | 0.080 | |

| R L | 0.412 | 0.309 | 0.452 | 0.199 | |

| R 2 | 0.960 | 0.973 | 0.975 | 0.992 | |

| Freundlich |

K F | 8.47 | 12.31 | 8.85 | 15.45 |

| 1/n | 0.182 | 0.157 | 0.177 | 0.133 | |

| R 2 | 0.940 | 0.922 | 0.874 | 0.918 | |

| Temkin |

A | 7.507 | 90.862 | 10.645 | 959.645 |

| B | 3.084 | 2.876 | 3.050 | 2.528 | |

| b T | 803.36 | 861.41 | 812.31 | 980.09 | |

| R 2 | 0.875 | 0.854 | 0.832 | 0.896 | |

Table 4.

Adsorption isotherm parameters and correlation coefficients as a function of temperature for the adsorption of Cd(II) on MBC1and MBC2

| System | Parameters | MBC1 | MBC2 | ||||

|---|---|---|---|---|---|---|---|

| Temperature [K] | |||||||

| 295 | 315 | 335 | 295 | 315 | 335 | ||

| Langmuir | q e,exp | 37.64 | 32.50 | 26.85 | 41.33 | 39.44 | 32.52 |

| q 0 | 38.00 | 35.04 | 28.08 | 41.25 | 41.68 | 32.71 | |

| K L | 0.182 | 0.045 | 0.043 | 0.191 | 0.072 | 0.068 | |

| R L | 0.099 | 0.310 | 0.317 | 0.095 | 0.216 | 0.227 | |

| R 2 | 0.999 | 0.952 | 0.993 | 0.990 | 0.982 | 0.994 | |

| Freundlich | K F | 13.06 | 9.29 | 4.49 | 13.06 | 10.76 | 6.54 |

| 1/n | 0.204 | 0.225 | 0.332 | 0.187 | 0.249 | 0.304 | |

| R 2 | 0.976 | 0.618 | 0.794 | 0.966 | 0.627 | 0.771 | |

| Temkin | A | 37.542 | 7.590 | 0.796 | 102.432 | 5.344 | 1.646 |

| B | 4.103 | 4.255 | 4.974 | 3.990 | 5.660 | 5.347 | |

| b T | 603.84 | 582.35 | 498.15 | 620.99 | 437.77 | 463.38 | |

| R 2 | 0.983 | 0.698 | 0.917 | 0.986 | 0.631 | 0.897 | |

Thermodynamic Tests

The thermodynamic parameters were obtained by the sorption at different temperatures in the range 295–335 K and are calculated (Eqs. 2–5) and listed in Table 5. In contrast to some literature reports [22] with the increasing temperature, the equilibrium capacity decreases from 37.64 mg/g at 295 K to 26.85 mg/g at 335 K for Cd(II) sorption on MBC1 (Table 4). Simultaneously, the value of the equilibrium constant K L decreases with the increasing temperature from 0.182 to 0.043 dm3/mg for MBC1. These results also demonstrate that Cd(II) ion sorption on magnetic sorbents would be more efficient at lower temperatures [35].

Table 5.

Thermodynamic parameters for the sorption of Cd(II) ions on MBC1 and MBC2

| Sorbent | K d | ∆H 0 | ∆S 0 | ∆G 0 | ||||

|---|---|---|---|---|---|---|---|---|

| Temperature [K] | Temperature [K] | |||||||

| 295 | 315 | 335 | 295 | 315 | 335 | |||

| MBC1 | 0.1170 | 0.1120 | 0.0870 | −5.87 | −37.5 | −11.60 | −12.28 | −12.37 |

| MBC2 | 0.1352 | 0.1321 | 0.1167 | −2.36 | −24.2 | −11.95 | −12.71 | −13.18 |

The negative values of enthalpy change reveal that Cd(II) sorption on the magnetic sorbents is an exothermic process. In addition, the value of ∆H 0 in the range up to 40 kJ/mol evidences physical adsorption [37]. The increase in the interactions at the solid-solution interface and reduction of the degree of disorder lead to a negative values of entropy change [38, 39]. The negative values of free energy change in the range −20 to 0 kJ/mol for all temperatures point out that the ion sorption is spontaneous and also testy to the physical character of sorption [38]. The decreasing value of ∆G 0 with the increasing temperature can be associated with more favourable sorption at lower temperatures. In addition, for the exothermic processes, the value of K d decreases with the increasing temperature from 0.1170 to 0.0870 for Cd(II) sorption on MBC1.

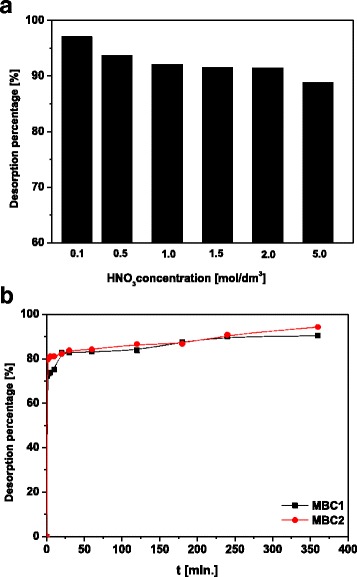

Regeneration of Spent Sorbent

Reducing the cost and toxicity of the wastes after sorption is possible by conducting the regeneration process [40]. In the regeneration, there are used, cheap and easily accessible desorbing agents such as solutions of acids [32], salts, alkalis and complexing agents [18].

In order to investigate the desorption action of Cd-loaded magnetic sorbents, distilled water and solutions of nitric acid(V) at the concentrations 0.1, 0.5, 1.0, 1.5, 2.0 and 5.0 mol/dm3 were applied. The use of distilled water resulted in the yield of 2.41%. The investigations carried out by Reguyal et al. [38] using deionized water proved that the desorption effectiveness is lower than 4% in the case of desorption of sulfamethoxazole-loaded magnetic biochar. Acidic desorbing agents have a higher capacity elution of the positively charged metal ions from the sorbent surface. This is due to the presence of hydronium ions which protonate the sorbent surface [41]. Of the concentrations used in the experiment, the best efficiency of desorption of Cd-loaded MBC2 equal to 97.09% is accounted for 0.1 mol/dm3 HNO3 (Fig. 3a). With an increase in nitric acid(V) concentration, the desorption percentage slightly decreases. For this reason, for further studies, 0.1 mol/dm3 HNO3 was used for desorption kinetics. From Fig. 3b, it can be stated that with an increase of the contact time, efficiency of desorption increases. After the time about 180 min, the percentage of desorption Cd-loaded MBC1 and MBC2 was constant.

Fig. 3.

Isotherm data and fitted models for Cd(II) sorption on a MBC1 and b MBC2 and c effect of temperature on Cd(II) sorption on MBC1 and MBC2

Characterization of the Sorbents

Changes in the vibration of functional groups in the two types of magnetic biochar before and after Co(II) sorption are demonstrated in the FTIR spectra in Fig. 4a, b. The broad bands in the range of 3300 to 3500 cm−1 indicate the presence of hydroxyl groups either free or associated in groups –COOH and –CHO. The sharp peak at 3740 cm−1 in MBC1 before sorption can be assigned to OH group vibrations in mineral matter [42, 43]. The peaks in the range 2000 to 2380 cm−1 correspond to –C≡C– triple bond of alkynes. Also in this wave number range, vibrations of the groups of amines appear [43]. The bands of a wave number from 1395 to 1628 cm−1 testify to the presence of C=O and C=C aromatic vibrations in ring and C=O stretching of ketone and carboxyl groups [37, 44, 45] The presence of C–H aromatic branching results in the bands at about 980 cm−1 [46]. The peak at about 680 cm−1 in magnetic biochar is evidenced by the presence of Fe-biochar bonds. The disappearance of a sharp band at 3740 cm−1 after Co(II) sorption on MBC1 and moving the vibration derived from carboxyl groups causes that the OH and C=O groups are involved in formation of the bonds between the biochar surface and Co(II) ions [44, 47].

Fig. 4.

a Elution of Cd(II) from metal-loaded MBC2 using HNO3 at the concentrations in the range 0–2 mol/dm3 and b effect of the phase contact time on Cd(II) desorption on metal-loaded MBC1 and MBC2 using 0.1 mol/dm3 HNO3

Figure 5a, f presents the SEM images of MBC1 and MBC2 at different magnifications ×10000 (a, b), ×3500 (c, d) and ×100 (e, f). It can be concluded that the sorbent structure is irregular and the nanoparticles Fe(0) are well dispersed on the surface. Based on the images magnified ×100, it can be seen that the smaller are particles in MBC2, the better sorption properties are obtained.

Fig. 5.

FTIR spectra of a MBC1 and b MBC2 before and after the sorption of Co(II)

The XRD analysis is applied to study the ordered structures present in biochars [48]. Figure 6 shows the X-ray diffraction analysis of MBC2 after Cd(II), Co(II), Zn(II) and Pb(II) ion sorption. The main peaks of the highest intensity at 2Ɵ = 26.80 and those at 2Ɵ = 20.58 confirm the silica (quartz) presence. The peaks indicating the presence of carbon appear at 2Ɵ = 29.48 which is due to the presence of calcium carbonate (calcite) and at 2Ɵ = 30.90 due to the calcium magnesium carbonate (dolomite) presence. The peaks at 2Ɵ = 44.80 indicate that Fe(0) occurs in the structure of magnetic biochar. These results are consistent with the previous literature reports [22, 48, 49].

Fig. 6.

SEM images of MBC1 (a, c, e) and MBC2 (b, d, f) at different magnifications

The analysis of MBC2 spectrum after the Cd(II) ion sorption by means of X-ray photoelectron spectroscopy shows that the sorbent surface is composed of the atoms C, O, Fe, Mg, Si, Al, P, Ca, Cd and K (Fig. 7). This confirms the effectiveness of biochar modification by iron.

Fig. 7.

XRD analysis of MBC2 after Cd(II), Co(II), Zn(II) and Pb(II) ion sorption

The XPS analysis also confirmed the presence of hydroxyl, carboxyl and carbonyl groups in the MBC2 samples (Table 6). The presence of C–C bonds in the aromatic ring can act as π donors in the process of ion sorption. In addition, the precipitation process of CdCO3 and Cd(OH)2 on the magnetic biochar surface also occurs. The presence of iron at various degrees of oxidation on the sorbent surface indicates an incomplete reduction to Fe0. Therefore, the modification process still requires further optimization [2].

Table 6.

Fitted C 1s, O 1s, Cd 3d, and Fe 2p peak parameters deduced from the XPS analysis for MBC2 after the Cd(II) ion sorption

| Region | Peak [eV] | Assignment | Atomic content [%] |

|---|---|---|---|

| C 1s | 284.5 | C=C sp2 | 72.7 |

| 286.2 | C–OH, C–O–C | 7.8 | |

| 287.3 | C=O | 4.3 | |

| 288.5 | COO– | 6.1 | |

| 289.6 | Carbonates | 4.9 | |

| 291.2 | π → π* | 4.2 | |

| O 1s | 530.2 | Metal oxides | 32.7 |

| 531.4 | C=O | 35.8 | |

| 532.3 | O=C–OH, C–OH | 22.7 | |

| 533.3 | C–O–C | 8.7 | |

| Cd 3d | 405.6 | CdCO3, Cd(OH)2, –OCdOH | 100 |

| 412.4 | – | – | |

| Fe 2p | 708.6 | Fe(0) | 2.4 |

| 709.6 | Fe(II) | 4.9 | |

| 710.6 | 2.4 | ||

| 714.9 | 2.4 | ||

| 710.6 | Fe(III) | 31.9 | |

| 711.6 | 24.0 | ||

| 712.6 | 16.0 | ||

| 713.6 | 8.0 | ||

| 719.5 | 8.0 |

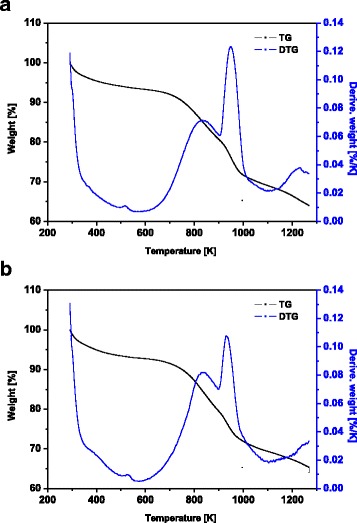

In Fig. 8a, b, the thermogravimetric and derivative thermogravimetric curves for MBC1 and MBC2 are shown. The TG curve presents the percentage weight loss of the sorbent and the DTG curve demonstrates the temperature at which the weight changes are most evident. The heating process is conducted up to 1273 K with the heating rate 283 K/min. From the curves, it can be concluded that the first stage of thermal degradation occurs in the range of 323–473 K which is associated with the loss of moisture. The subsequent degradation stages proceeded up to a temperature of 1073 K which is related with decomposition of hemicellulose, cellulose and lignin. The total weight loss (35%) took place up to a temperature of 1273 K [14, 50]. For both modifications, similar curves of thermal degradation were obtained.

Fig. 8.

XPS full spectra of MBC2 after Cd(II) sorption

The point of zero charge pHPZC is defined as the point at which the surface charge equals zero. The isoelectric point pHIEP is defined as the point at which the electrokinetic potential equals zero. Figure 9a presents a course of potentiometric titration of dispersion of BC at the constant solid to liquid ratio and at three different concentrations of NaCl, with pHPZC = 10.5. The zeta potential value for all studied concentrations in the whole pH range for the BC/electrolyte system is negative and independent of the electrolyte. pHIEP is below 3.

Fig. 9.

TG/DTG curves of a MBC1 and b MBC2

Knowledge of the zeta potential value enables prediction of colloidal system stability. The zeta potential allows to determine electrostatic interactions among the colloidal particles, and thus, it can be referred to the colloidal system stability. The BC zeta potential allows characterization of the double electrical layer at the BC/electrolyte solution interface. The particles BC in the electrolyte possess the electrical charge and the zeta potential allowing determining part of the charge in the double diffusion layer. The results are presented in Fig. 9b. The plot of the zeta potential dependence indicates that the value of the zeta potential changes insignificantly with the pH increase for a given concentration of the electrolyte. The dependence of the zeta potential in the pH function allows to assume that pHIEP has the value <2 and is lower than the pHPZC value, as the zeta potential depends also on the part of the surface charge which is affected by BC ions adsorbing or desorbing on the crystal lattice (Fig. 10). For the electrostatically stabilized systems, the higher the zeta potential is, the more probable the dispersion stability is. For the water systems from −30 to 30 mV, the border for stability of dispersion and its lifespan is assumed. With the rise of absolute value of the zeta potential, colloidal particles possess good dispersion properties, simultaneously with the rise of electrostatic repulsion which is visible for the examined BC/NaCl.

Fig. 10.

a Surface charge of biochar in aqueous solution of NaCl as a function of pH and b diagram of biochar potential zeta dependence on pH value in aqueous NaCl solutions

Conclusions

Magnetic biochar nanocomposites were synthesized. Two types of modifications MBC1 and MBC2 for the removal of Cd(II), Co(II), Zn(II) and Pb(II) ions from aqueous solutions were used. Based on the research, it can be concluded that the operating parameters such as phase contact time, initial concentration of metal ions, dose of the sorbent solution pH and temperature play an important role in the sorption process. Additionally, on the basis of the PSO and Langmuir isotherm models, it can be seen that the higher affinity for the above-mentioned heavy metals is exhibited by MBC2. Therefore, a higher content of a reducing agent has a beneficial effect on the magnetic properties of sorbent. Desorption with 0.1 mol/dm3 HNO3 gives a yield of 97.09% and provides an easy regeneration of the obtained sorbents. The XRD analysis confirmed the presence of Fe(0) in the structure of the magnetic biochars. Following from the presented TG/DTG data, the total weight loss of sorbent up to a temperature 1273 K is about 35%. Both XRD and XPS analyses confirm the presence of iron on the biochar surface which proves successful modification. The point characteristics of the double layer for biochar are pHPZC = 10.5 and pHIEP <3.

Acknowledgements

We are very grateful to Peter Thomas (Coaltec Energy USA, Inc.) for supplying biochar used in our research.

Funding

No additional funds were involved.

Authors’ Contributions

DK conceived of the study and drafted the manuscript. JB participated in the synthesis and analytical part as well as in the manuscript preparation. LVP participated in the chemical experiments and the manuscript preparation. MK carried out the DTA investigations and edited the manuscript. All authors have read and approved the manuscript.

Competing Interests

The authors declare that they have no competing interests.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Footnotes

The original version of this article was revised due to an error in a author name and an error in a sentence.

An erratum to this article is available at https://doi.org/10.1186/s11671-017-2229-z.

References

- 1.Thines KR, Abdullah EC, Mubarak NM, Ruthiraan M. Synthesis of magnetic biochar from agricultural waste biomass to enhancing route for waste water and polymer application: a review. Renew Sustain Energy Rev. 2017;67:257–276. doi: 10.1016/j.rser.2016.09.057. [DOI] [Google Scholar]

- 2.Imamoglu M, Tekir O. Removal of copper(II) and lead(II) ions from aqueous solutions by adsorption on activated carbon from a new precursor hazelnut husks. Desalination. 2008;228:108–113. doi: 10.1016/j.desal.2007.08.011. [DOI] [Google Scholar]

- 3.Mohan D, Pittman CU, Bricka M, Smith F, Yancey B, Mohammad J, Steele PH, Alexandre-Franco MF, Gomez-Serrano V, Gong H. Sorption of arsenic, cadmium, and lead by chars produced from fast pyrolysis of wood and bark during bio-oil production. J Colloid Interface Sci. 2007;310:57–73. doi: 10.1016/j.jcis.2007.01.020. [DOI] [PubMed] [Google Scholar]

- 4.Chen X, Chen G, Chen L, Chen Y, Lehmann J, McBride MB, Hay AG. Adsorption of copper and zinc by biochars produced from pyrolysis of hardwood and corn straw in aqueous solution. Bioresour Technol. 2011;102:8877–8884. doi: 10.1016/j.biortech.2011.06.078. [DOI] [PubMed] [Google Scholar]

- 5.Samsuri AW, Sadegh-Zadeh F, Seh-Bardan BJ. Adsorption of As(III) and As(V) by Fe coated biochars and biochars produced from empty fruit bunch and rice husk. J Environ Chem Eng. 2013;1:981–988. doi: 10.1016/j.jece.2013.08.009. [DOI] [Google Scholar]

- 6.Aman T, Kazi AA, Sabri MU, Bano Q. Potato peels as solid waste for the removal of heavy metal copper(II) from waste water/industrial effluent. Colloids Surf. B Biointerfaces. 2008;63:116–121. doi: 10.1016/j.colsurfb.2007.11.013. [DOI] [PubMed] [Google Scholar]

- 7.Dong X, Ma LQ, Li Y. Characteristics and mechanisms of hexavalent chromium removal by biochar from sugar beet tailing. J Hazard Mater. 2011;190:909–915. doi: 10.1016/j.jhazmat.2011.04.008. [DOI] [PubMed] [Google Scholar]

- 8.McHenry MP. Agricultural bio-char production, renewable energy generation and farm carbon sequestration in Western Australia: certainty, uncertainty and risk. Agric Ecosyst Environ. 2009;129:1–7. doi: 10.1016/j.agee.2008.08.006. [DOI] [Google Scholar]

- 9.Beesley L, Marmiroli M. The immobilisation and retention of soluble arsenic, cadmium and zinc by biochar. Environ Pollut. 2011;159:474–480. doi: 10.1016/j.envpol.2010.10.016. [DOI] [PubMed] [Google Scholar]

- 10.Su H, Fang Z, Tsang PE, Zheng L, Cheng W, Fang J, Zhao D. Remediation of hexavalent chromium contaminated soil by biochar-supported zero-valent iron nanoparticles. J Hazard Mater. 2016;318:533–540. doi: 10.1016/j.jhazmat.2016.07.039. [DOI] [PubMed] [Google Scholar]

- 11.Pellera FM, Giannis A, Kalderis D, Anastasiadou K, Stegmann R, Wang JY, Gidarakos E. Adsorption of Cu(II) ions from aqueous solutions on biochars prepared from agricultural by-products. J Environ Manage. 2012;96:35–42. doi: 10.1016/j.jenvman.2011.10.010. [DOI] [PubMed] [Google Scholar]

- 12.Regmi P, Garcia Moscoso JL, Kumar S, Cao X, Mao J, Schafran G. Removal of copper and cadmium from aqueous solution using switchgrass biochar produced via hydrothermal carbonization process. J Environ Manage. 2012;109:61–69. doi: 10.1016/j.jenvman.2012.04.047. [DOI] [PubMed] [Google Scholar]

- 13.Zhang W, Mao S, Chen H, Huang L, Qiu R. Pb(II) and Cr(VI) sorption by biochars pyrolyzed from the municipal wastewater sludge under different heating conditions. Bioresour Technol. 2013;147:545–552. doi: 10.1016/j.biortech.2013.08.082. [DOI] [PubMed] [Google Scholar]

- 14.Pellera F-M, Gidarakos E. Effect of dried olive pomace-derived biochar on the mobility of cadmium and nickel in soil. J Environ Chem Eng. 2015;3:1163–1176. doi: 10.1016/j.jece.2015.04.005. [DOI] [Google Scholar]

- 15.Shan D, Deng S, Zhao T, Wang B, Wang Y, Huang J, Yu G, Winglee J, Wiesner MR. Preparation of ultrafine magnetic biochar and activated carbon for pharmaceutical adsorption and subsequent degradation by ball milling. J Hazard Mater. 2016;305:156–163. doi: 10.1016/j.jhazmat.2015.11.047. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Zhang M, Gao B, Varnoosfaderani S, Hebard A, Yao Y, Inyang M. Preparation and characterization of a novel magnetic biochar for arsenic removal. Bioresour Technol. 2013;130:457–462. doi: 10.1016/j.biortech.2012.11.132. [DOI] [PubMed] [Google Scholar]

- 17.Chen B, Chen Z, Lv S. A novel magnetic biochar efficiently sorbs organic pollutants and phosphate. Bioresour Technol. 2011;102:716–723. doi: 10.1016/j.biortech.2010.08.067. [DOI] [PubMed] [Google Scholar]

- 18.Ye WS, Kui TY, Chen C, Wu JT, Huang Z, Mo YY, Zhang KX, Chen JB. Regeneration of magnetic biochar derived from eucalyptus leaf residue for lead(II) removal. Bioresour Technol. 2015;186:360–364. doi: 10.1016/j.biortech.2015.03.139. [DOI] [PubMed] [Google Scholar]

- 19.Mohan D, Kumar H, Sarswat A, Alexandre-Franco M, Pitmann CU. Cadmium and lead remediation using magnetic oak wood and oak bark fast pyrolysis bio-chars. Chem Eng J. 2014;236:513–528. doi: 10.1016/j.cej.2013.09.057. [DOI] [Google Scholar]

- 20.Mohan D, Kumar S, Srivastava A. Fluoride removal from ground water using magnetic and nonmagnetic corn stover biochars. Ecol Eng. 2014;73:798–808. doi: 10.1016/j.ecoleng.2014.08.017. [DOI] [Google Scholar]

- 21.Devi P, Saroha AK. Synthesis of the magnetic biochar composites for use as an adsorbent for the removal of pentachlorophenol from the effluent. Bioresour Technol. 2014;169:525–531. doi: 10.1016/j.biortech.2014.07.062. [DOI] [PubMed] [Google Scholar]

- 22.Devi P, Saroha AK. Simultaneous adsorption and dechlorination of pentachlorophenol from effluent by Ni-ZVI magnetic biochar composites synthesized from paper mill sludge. Chem Eng J. 2015;271:195–203. doi: 10.1016/j.cej.2015.02.087. [DOI] [Google Scholar]

- 23.Yan J, Han L, Gao W, Xue S, Chen M. Biochar supported nanoscale zerovalent iron composite used as persulfate activator for removing trichloroethylene. Bioresour Technol. 2015;175:269–274. doi: 10.1016/j.biortech.2014.10.103. [DOI] [PubMed] [Google Scholar]

- 24.Hu X, Ding Z, Zimmerman AR, Wang S, Gao B. Batch and column sorption of arsenic onto iron-impregnated biochar synthesized through hydrolysis. Water Res. 2015;68:206–216. doi: 10.1016/j.watres.2014.10.009. [DOI] [PubMed] [Google Scholar]

- 25.Rama Chandraiah M. Facile synthesis of zero valent iron magnetic biochar composites for Pb(II) removal from the aqueous medium. Alex. Eng. J. 2015;55:619–625. doi: 10.1016/j.aej.2015.12.015. [DOI] [Google Scholar]

- 26.http://www.coaltecenergy.com/biochar/.

- 27.Reddy DHK, Lee SM, Seshaiah K. Biosorption of toxic heavy metal ions from water environment using honeycomb biomass-an industrial waste material. Water Air Soil Pollut. 2012;223:5967–5982. doi: 10.1007/s11270-012-1332-0. [DOI] [Google Scholar]

- 28.Mahmoud ME, Nabil GM, El-Mallah NM, Bassiouny HI, Kumar S, Abdel-Fattah TM. Kinetics, isotherm, and thermodynamic studies of the adsorption of reactive red 195 A dye from water by modified Switchgrass biochar adsorbent. J. Ind. Eng. Chem. 2016;37:156–167. doi: 10.1016/j.jiec.2016.03.020. [DOI] [Google Scholar]

- 29.Ho YS, McKay G. Sorption of dye from aqueous solution by peat. Chem Eng J. 1998;70:115–124. doi: 10.1016/S0923-0467(98)00076-1. [DOI] [Google Scholar]

- 30.Weber WJ, Morris JC. Kinetics of adsorption on carbon from solution. J. Sanit. Eng. Div. 1963;89:31–60. [Google Scholar]

- 31.Reddy DHK, Harinath Y, Seshaiah K, Reddy AVR. Biosorption of Pb(II) from aqueous solutions using chemically modified Moringa oleifera tree leaves. Chem Eng J. 2010;162:626–634. doi: 10.1016/j.cej.2010.06.010. [DOI] [Google Scholar]

- 32.Saeed A, Iqbal M, Akhtar MW. Removal and recovery of lead(II) from single and multimetal (Cd, Cu, Ni, Zn) solutions by crop milling waste (black gram husk) J Hazard Mater. 2005;117:65–73. doi: 10.1016/j.jhazmat.2004.09.008. [DOI] [PubMed] [Google Scholar]

- 33.Edebali S, Pehlivan E. Evaluation of chelate and cation exchange resins to remove copper ions. Powder Technol. 2016;301:520–525. doi: 10.1016/j.powtec.2016.06.011. [DOI] [Google Scholar]

- 34.Oo CW, Kassim MJ, Pizzi A. Characterization and performance of Rhizophora apiculata mangrove polyflavonoid tannins in the adsorption of copper(II) and lead(II) Ind. Crop Prod. 2009;30:152–161. doi: 10.1016/j.indcrop.2009.03.002. [DOI] [Google Scholar]

- 35.Song W, Gao B, Xu X, Xing L, Han S, Duan P, Song W, Jia R. Adsorption-desorption behavior of magnetic amine/Fe3O4 functionalized biopolymer resin towards anionic dyes from wastewater. Bioresour Technol. 2016;210:123–130. doi: 10.1016/j.biortech.2016.01.078. [DOI] [PubMed] [Google Scholar]

- 36.Xing Y, Yang P, Yu J. Biosorption of Pb(II) by the shell of vivipaird snail: implications for heavy metal bioremediation. Sep Sci Technol. 2016;51:2756–2761. doi: 10.1080/01496395.2016.1217242. [DOI] [Google Scholar]

- 37.Fan S, Tang J, Wang Y, Li H, Zhang H, Tang J, Wang Z, Li X. Biochar prepared from co-pyrolysis of municipal sewage sludge and tea waste for the adsorption of methylene blue from aqueous solutions: kinetics, isotherm, thermodynamic and mechanism. J Mol Liq. 2016;220:432–441. doi: 10.1016/j.molliq.2016.04.107. [DOI] [Google Scholar]

- 38.Reguyal F, Sarmah AK, Gao W. Synthesis of magnetic biochar from pine sawdust via oxidative hydrolysis of FeCl2 for the removal sulfamethoxazole from aqueous solution. J Hazard Mater. 2016;321:868–878. doi: 10.1016/j.jhazmat.2016.10.006. [DOI] [PubMed] [Google Scholar]

- 39.Doǧan M, Karaoǧlu MH, Alkan M. Adsorption kinetics of maxilon yellow 4GL and maxilon red GRL dyes on kaolinite. J Hazard Mater. 2009;165:1142–1151. doi: 10.1016/j.jhazmat.2008.10.101. [DOI] [PubMed] [Google Scholar]

- 40.Zeng X, Xu Y, Zhang B, Luo G, Sun P, Zou R, Yao H. Elemental mercury adsorption and regeneration performance of sorbents FeMnOx enhanced via non-thermal plasma. Chem Eng J. 2017;309:503–512. doi: 10.1016/j.cej.2016.10.047. [DOI] [Google Scholar]

- 41.Abdolali A, Ngo HH, Guo W, Zhou JL, Du B, Wei Q, Wang XC, Nguyen PD. Characterization of a multi-metal binding biosorbent: chemical modification and desorption studies. Bioresour Technol. 2015;193:477–487. doi: 10.1016/j.biortech.2015.06.123. [DOI] [PubMed] [Google Scholar]

- 42.Jin J, Li Y, Zhang J, Wu S, Cao Y, Liang P, Zhang J, Wong MH, Wang M, Shan S, Christie P. Influence of pyrolysis temperature on properties and environmental safety of heavy metals in biochars derived from municipal sewage sludge. J Hazard Mater. 2016;320:417–426. doi: 10.1016/j.jhazmat.2016.08.050. [DOI] [PubMed] [Google Scholar]

- 43.Hossain MK, Strezov Vladimir V, Chan KY, Ziolkowski A, Nelson PF. Influence of pyrolysis temperature on production and nutrient properties of wastewater sludge biochar. J Environ Manage. 2011;92:223–228. doi: 10.1016/j.jenvman.2010.09.008. [DOI] [PubMed] [Google Scholar]

- 44.Wang P, Tang L, Wei X, et al. Applied surface science synthesis and application of iron and zinc doped biochar for removal of p-nitrophenol in wastewater and assessment of the influence of co-existed Pb(II) Appl Surf Sci. 2017;392:391–401. doi: 10.1016/j.apsusc.2016.09.052. [DOI] [Google Scholar]

- 45.Mandal A, Singh N, Purakayastha TJ. Characterization of pesticide sorption behaviour of slow pyrolysis biochars as low cost adsorbent for atrazine and imidacloprid removal. Sci Total Environ. 2016;577:376–385. doi: 10.1016/j.scitotenv.2016.10.204. [DOI] [PubMed] [Google Scholar]

- 46.Özçimen D, Ersoy-Meriçboyu A. Characterization of biochar and bio-oil samples obtained from carbonization of various biomass materials. Renew Energy. 2010;35:1319–1324. doi: 10.1016/j.renene.2009.11.042. [DOI] [Google Scholar]

- 47.Kim WK, Shim T, Kim YS, Hyun S, Ryu C, Park YK, Juang J. Characterization of cadmium removal from aqueous solution by biochar produced from a giant Miscanthus at different pyrolytic temperatures. Bioresour Technol. 2013;138:266–270. doi: 10.1016/j.biortech.2013.03.186. [DOI] [PubMed] [Google Scholar]

- 48.Azargohar R, Nanda S, Kozinski JA, Dalai AK, Sutarto R. Effects of temperature on the physicochemical characteristics of fast pyrolysis bio-chars derived from Canadian waste biomass. Fuel. 2014;125:90–100. doi: 10.1016/j.fuel.2014.01.083. [DOI] [Google Scholar]

- 49.Han Z, Sani B, Mrozik W, Obst M, Beckingham B, Karapanagioti HK, Werner D. Magnetite impregnation effects on the sorbent properties of activated carbons and biochars. Water Res. 2015;70:394–403. doi: 10.1016/j.watres.2014.12.016. [DOI] [PubMed] [Google Scholar]

- 50.Li H, Awadh S, Mahyoub A, Liao W, Xia S, Zhao H, Guo M, Ma P. Effect of pyrolysis temperature on characteristics and aromatic contaminants adsorption behavior of magnetic biochar derived from pyrolysis oil distillation residue. Bioresour Technol. 2016;223:20–26. doi: 10.1016/j.biortech.2016.10.033. [DOI] [PubMed] [Google Scholar]