Abstract

Large strains are applied to liquid crystalline poly-(2,5-bis(3-tetradecylthiophen-2yl)thieno(3,2-b)thiophene) (pBTTT) films when held at elevated temperatures resulting in in-plane polymer alignment. We find that the polymer backbone aligns significantly in the direction of strain, and that the films maintain large quasi-domains similar to that found in spun-cast films on hydrophobic surfaces, highlighted by dark-field transmission electron microscopy imaging. The highly strained films also have nanoscale holes consistent with dewetting. Charge transport in the films is then characterized in a transistor configuration, where the field effect mobility is shown to increase in the direction of polymer backbone alignment, and decrease in the transverse direction. The highest saturated field-effect mobility was found to be 1.67 cm2V−1s−1, representing one of the highest reported mobilities for this material system. The morphology of the oriented films demonstrated here contrast significantly with previous demonstrations of oriented pBTTT films that form a ribbon like morphology, opening up opportunities to explore how differences in molecular packing features of oriented films impact charge transport. Results highlight the role of grain boundaries, differences in charge transport along the polymer backbone and π-stacking direction, and structural features that impact the field dependence of charge transport.

Keywords: polymer semiconductors, charge transport, pBTTT, oriented films, TEM

Graphical Abstract

1. Introduction

Polymer semiconductors have the potential for widespread adoption in large area electronics, and have many unique properties enabling a number of novel device applications.1–3 Critical to most of these applications is charge mobility within deposited films, which is known to have a significant dependence on processing conditions and subsequent film morphology.4,5 In typical solution cast semicrystalline films, the polymer long axis lies primarily in the plane of the film without significant long-range in-plane texture (i.e. fiber texture). In devices, such as organic thin film transistors (OTFTs), charge transport is typically over distances much greater than a single extended chain and intermolecular charge transport is a necessity. Charge transport is then primarily a combination of intramolecular transport along the polymer backbone, and intermolecular π-π transport across cofacially stacked chains.6–8 Charge transport along other intermolecular pathways may also occur, but is expected to be significantly less efficient.9 The inherent anisotropic nature of polymers and levels of disorder in solution cast films results in difficulty in determining key morphological features that dictate charge transport behavior.10 Control of the film morphology through in-plane alignment of the polymer backbone is one approach employed to disentangle the role of various morphological features on charge transport.7,11–18 In these biaxially oriented films, a significant field effect mobility anisotropy is typically observed, with mobility being greatest along the direction of polymer backbone alignment. This is often attributed to charge mobility being greater along the polymer backbone than the π-stacking direction.8,19 Grain boundaries may also impact mobility anisotropy,8, 20 where long-range charge transport anisotropy can differ significantly from local anisotropy in oriented films due to grain boundary effects.8 Yet, challenges associated with resolving structural dependence of charge transport in oriented films remain due to the inability to resolve local polymer morphology. Realizing oriented films with well-defined local polymer stacking characteristics will provide a significant opportunity to inform the structural dependence of charge transport in conjugated polymers.

In this paper, we investigate biaxially oriented liquid crystalline poly(2,5-bis(3-tetradecylthiophen-2yl)thieno(3,2-b)thiophene) (pBTTT) films. This polymer is one of the most intensely studied conjugated polymer systems due to its high field effect mobility and highly ordered morphology.21–26 When spun cast on a hydrophobic substrate, pBTTT is known to form a highly crystalline film with interdigitated alkyl side chains and large highly ordered quasi-domains (not specifically single crystals) with a common in-plane orientation and wide terraced topography.23,24 pBTTT films with long-range uniaxial in-plane alignment of the polymer backbone have also been reported.13,14,20,26 The aligned films have been achieved using flow-coating,14 zone-casting,20 and rubbing.13 In each of these processing methods, highly oriented films are achieved by thermally annealing the initially cast films near the pBTTT melting temperature. These processing approaches result in a well defined oriented film that consists of a unique ribbon-like morphology with fully extended polymer chains that align perpendicular to the ribbon long axis.14,20 OTFT measurements with these films show that this morphology results in significant charge mobility anisotropy, where mobility is favored in the backbone alignment direction.20 The mobility anisotropy was largely attributed differences in grain boundary characteristics along the primary transport directions.20 Here, we demonstrate an alternative alignment approach that yields films with significant polymer in-plane alignment and that maintains the large domains similar to spun cast films, resulting in a vastly different local morphology compared to aligned ribbon phase pBTTT. When applied in an OTFT, the highest saturated field-effect mobility was found to be 1.67 cm2V−1s−1, representing one of the highest reported mobility for this material system. The strain-aligned films provide an opportunity to contrast charge transport behavior in aligned, highly ordered films that have significant, resolvable, differences in local molecular packing character. Below we describe the alignment process, the resulting film morphology, and the relationship between morphology and charge transport in OTFTs.

2. Results and Discussion

2.1. Morphological Characterization

To achieve oriented films, we apply large uniaxial strains to the films while on a host polydimethylsiloxane (PDMS) elastomer substrate, following a similar method previously demonstrated for strain aligned poly(3-hexylthiophene) (P3HT).15 However, unlike P3HT, which is ductile at room temperature, pBTTT is brittle and cracks at strains under 2 %.27 This is believed to be due to the highly crystalline nature of the film. To overcome this brittle behavior, the films are heated to a temperature near its liquid crystalline phase, where it has been previously shown that the side chains become characteristically liquid-like.28 For the pBTTT used in this study, the phase transition is found to occur near 120 °C as measured by differential scanning calorimetry, shown in Figure S1. Heating is accomplished by placing the film, attached to a PDMS substrate, approximately 2 mm above a hot-plate held at 145°C. At this elevated temperature, the film can be strained by over 50 % without crack formation. It is important to note that the PDMS is UV-ozone treated to increase hydrophilicity and minimize film dewetting during straining. The UV-ozone treatment results in a siloxide surface29,30 that limits the strain to approximately 50 %, due to significant PDMS surface cracking at larger applied strains. Once the film is strained to a desired amount it is then transfer printed onto a secondary substrate. This secondary substrate is a silicon oxide surface that allows for effective film transfer off the UV-ozone treated PDMS. The pBTTT films may then be transferred back to a second PDMS stamp and printed onto an octyltrichlorosilane (OTS) treated glass or silicon substrate. The strain and transfer processes are illustrated in Figure 1. The double PDMS transfer process is required for high fidelity printing onto low-energy OTS treated surfaces. We are interested in printing onto an OTS-treated surface as it promotes edge-on stacking (conjugated ring plane perpendicular to the substrate) and surface passivation for high performance OTFTs.20,23 After printed onto the final receiving substrate the films are left “as-cast” or thermally annealed at 180 °C for 2 min. In the following, we characterize the morphology of the films in detail followed by charge transport analysis.

Figure 1.

Schematic of the strain-alignment approach. (a) A spin-cast pBTTT film is transferred onto a PDMS slab, (b) the film is strained while heated into its liquid crystal phase, (c) the strained film is then transferred onto a secondary substrate, (d) the strained film is transferred onto another PDMS slab, (e) and the film is transferred onto a final OTS-treated substrate.

The alignment of the strained films are first characterized by measuring the absorbance of the films under linear polarized light.15 The pBTTT films were printed onto an unmodified glass or OTS-treated glass substrate and absorbance is measured before and after thermal annealing, with absorbance for a film strained by 60 % provided in Figure 2a. In the strained films absorbance is greatest when incident light is polarized parallel to the strain direction and lowest when light is polarized perpendicular to the strain direction. Given that the primary optical transition dipole moment is parallel to the polymer backbone, this indicates that the polymer backbone aligns in the direction of applied strain.14 The change in absorbance anisotropy with strain is quantified by considering the dichroic ratio of the strain-aligned films. Here the dichroic ratio (R) is defined as R = A|| / A⊥, where A|| is the absorbance of light polarized parallel to the strain direction, and A⊥ is the absorbance of light polarized perpendicular to the strain direction (both taken at 550 nm). As shown in Figure 2b, the dichroic ratio increases with applied strain reaching 2.2 for a 60 % strained film. Thermally annealing the strained films is found to significantly increase the dichroic ratio. The increase in dichroic ratio is particularly large when annealing the films on unmodified hydrophilic glass substrates. The origin of this difference is not fully understood. We speculate that the alignment of the pBTTT chains is greatest near the PDMS surface due to direct contact between the pBTTT and the strained elastomer substrate. After the transfer printing process, the highly aligned surface interfaces with air. When the films are then thermally annealed, the chains quickly align vertically through the film increasing the dichroic ratio. This is consistent with the formation of the ribbon morphology where seed crystals at the top surface are believed to template the film (although this occurs near the melting point of the film).20,26 During and after the vertical registration of the polymer chains, the OTS surface does not restrict polymer movement and entropic effects result in lower dichroic ratios. For the oxide surface, stronger adhesion associated with the un-modified glass surface may restrict in-plane chain re-orientation resulting in a higher degree of chain alignment. The dichroic ratio of the 60 % strained and annealed film on an oxide surface reach values similar to that found in highly aligned ribbon phase films.20,26 While the dichroic ratio is lower when annealing the film on an OTS treated substrate, a substantial level of alignment is found and annealed films on OTS-treated substrates are the focus throughout the remainder of the paper.

Figure 2.

(a) UV-vis optical absorbance for 60 % strained pBTTT-C14 as-cast and annealed at 180 °C when on OTS treated glass substrate. (b) Dichroic Ratio taken at 550 nm for pBTTT films printed on oxide glass (annealed at 180 °C), OTS treated glass (annealed at 180 °C) and as-cast plotted as a function of applied strain.

To further investigate the film morphology, the crystalline stacking character of the films were measured using grazing incidence X-ray diffraction (GIXD) with 2D-images shown in Figure 3. For the spun cast films, the diffraction characteristics are similar to previous reports showing strong out of plane (h00) peaks.5,21 These peaks become more focused after thermal annealing indicative of highly edge-on stacking.5 Significant diffraction is also observed near in-plane scattering vector (qxy) of 1.41 Å−1, and 1.71 Å−1, that move vertically on the image plates. This diffraction has previously been attributed to (21–1), (h13), and (h10) indices with additional details given by Cho et al.11 GIXD images are also shown for a 25 % and 50 % strained film with the incident X-ray beam parallel (scattering vector nominally perpendicular) and X-ray beam perpendicular (scattering vector nominally parallel) to the strain direction. The strained films continue to have sharp (h00) out-of-plane peaks indicative of edge-on stacking. As the film is strained, the off-normal scattering is shown to depend on sample orientation with (h10) peaks being significantly larger for the scattering vector perpendicular to the strain direction, and (h-13) peaks being larger for the scattering vector parallel to the strain direction. This anisotropic scattering behavior is similar to biaxially oriented ribbon-phase pBTTT films achieved through flow coating.11 Qualitatively, the diffraction anisotropy appears to be greater in the flow-coated films, consistent with the larger dichroic ratios.

Figure 3.

GIXD, 2-D image plate data for pBTTT films. The images are for (a) an as spun cast (AC) film, (b) a thermally annealed (AN) spun cast film, (c,d) a 25% strained film with X-ray beam parallel (0°) and perpendicular (90°) to the strain direction, (e,f) a 50 % strained film with X-ray beam parallel (0°) and perpendicular (90°) to the strain direction. The strained films are thermally annealed.

As stated above, spun cast pBTTT films on hydrophobic surfaces form a wide-terrace topography, while biaxially oriented pBTTT films typically form a ribbon topography.5 To determine the topography of the strain aligned films, atomic force microscopy (AFM) measurements are performed on the films. As shown in Figure 4(a), the spun cast films have a wide-terrace topography similar to previous reports. As the film is strained, the annealed films continue to have terrace features with similar size and shape as the spun cast films, as shown in Figure 4(b,c). This is in significant contrast to the aligned ribbon topography previously reported for oriented pBTTT films.5 It is important to note that during processing film dewetting often occurs, resulting in holes in the film with diameters up to approximately 300 nm. The dewetting appears to start when straining the film on the PDMS substrate at elevated temperatures. This is minimized by UV-ozone treating the PDMS slab to increase hydrophilicity. However, extensive ozone treatment leads to a brittle PDMS surface that will not stretch sufficiently, and a balance is found between minimizing film dewetting and allowing for large strains without significant PDMS crack formation. Film dewetting that begins with the strain process continues to evolve when annealing the film after transfer printing onto an OTS treated substrate. The amount of dewetting is found to be greater for films that have been strained to larger extents, as shown in Figure 4(d,e). Dewetting is a common feature observed with this material system,20,21 and the impact it has on device behavior is discussed below.

Figure 4.

Tapping-mode AFM images of (a) spin-cast, (b,d) 25 % strained, (c,e) and 50 % strained pBTTT-C14 films on OTS silicon. The images for a–c are 1 μm x 1 μm and d,e are 5 μm x 5 μm. All films are annealed at 180 C for 2 min. The smaller area scans highlight the terraced morphology while the larger area scans show film dewetting features.

The AFM images show distinct terraces, but this does not necessarily reflect well-defined grains with consistent chain orientation or consistent stacking characteristics through the thickness of the film. To better reveal the film texture and local polymer stacking character in the strained films, dark-field transmission electron microscopy (DF-TEM) imaging is employed. This approach has been previously described in detail,24 and here we only give a brief review. DF-TEM images capture the electron diffraction character of the crystalline polymer where image contrast is based on the orientation of in-plane diffraction. Generally in polymer films with no large-scale preferential in-plane orientation, TEM diffraction from the variously oriented crystals result in a ring pattern, shown in Figure 5(a) for a spun cast film. As the film is strained, the diffraction forms arcs associated with the level of in-plane alignment, as shown in Figure 5(b,c) for the strain-aligned films. By tilting the beam such that only a specific arc of the diffraction can pass through a centered objective aperture, contrast based on local crystal orientation can be captured. The image created on the image plane of the objective lens with the tilted beam is thus brightest for the quasi-domains that were oriented so that their diffraction spots could pass through the aperture. By tilting the beam in a number of different orientations, the various crystal contributions that make up the diffraction ring is mapped, shown in Figure S2). Here we use the diffraction corresponding to (h10) peaks [primarily (0–10) and (110)]11 corresponding to π–π stacking to map the crystal orientation as this corresponds to the most intense peaks. The beam tilt was adjusted away from the sample surface normal such that the 30 μm aperture would admit a range of the (h10) ring encompassing an arc of approximately 90°. By acquiring multiple images from the same specimen area but with different beam-tilt configurations, and associating the intensity pattern each pixel displays with its in-plane crystal orientation, a color-coded orientation map can be created with results shown in Figure 5 for a spun cast as well as 25 % and 50 % strained films.

Figure 5.

Diffraction patterns and dark field images for (a) unstrained pBTTT film, (b) 25% strained film, (c) and 50 % strained film. The diffraction patterns show the approximate aperture locations and colors used to generate the color based orientation maps. Inset of the color maps images shows the relative diffraction orientation association with each color.

The TEM orientation map of the spun cast (unstrained) film is similar to a previous demonstration by Zhang et al.24 with quasi-domains of approximately 700 nm (obtained by Fourier transform analysis). These domains are similar to the terraces measured with AFM. The well-defined areal pattern shows that there is a common orientation of polymer chains vertically through the film. In the unstrained film, the colors ascribed to the domains are not distributed equally, i.e., there appear to be major and minor colors, which has been attributed to the fact that they correspond to two sets of intensity patterns that represent different amounts of pixels.24 Thus, we can conclude that no significant long-range in-plane alignment of the polymer backbone is found in the spun cast films. For the strained films, the selected aperture areas for color mapping are only chosen where there is significant (h10) diffraction and other areas are not assigned a color (left as black). For the 25% strained film, the quasi-domains remain similar to the unstrained films, but now preferential alignment of the domains is observed. Domains with polymer backbone alignment significantly away from the strain direction are found to be significantly smaller in area. In the 50 % strained films, the quasi-domains are present but appear to decrease in size for all directions, particularly near locations of film dewetting. The TEM images also show an increasing number of holes in the films with applied strain similar to that observed by AFM. The holes appear as black spots in the DF-TEM images, and are also observed in the corresponding bright field TEM images, shown in Figure S3. Small black areas in the color map may be found that do not directly correspond to holes in the film and are associated with scattering outside the selected aperture positions. However, these regions are a minor contribution to the color map, and the selected aperture positions effectively map the local packing orientation of the polymer in the film. We find that in the strained films, the in-plane texture continues to have a nematic stacking character, as previous identified for spun cast pBTTT films.24 The TEM mapping highlights the local polymer chain orientation evolution with strain and the final orientation distribution. Also of note is that a closer look at the polymer orientation near the holes in the films show that the polymer backbone is oriented tangentially at the edge of the holes, within the resolution of the orientation mapping.

In summary, the morphological characterization shows that the polymer backbone aligns in the direction of strain, with the level of alignment increasing with the magnitude of applied strain. The processing method results in a wide-domain morphology similar to high performance spun cast films but with preferential backbone alignment. This is in significant contrast to aligned ribbon phase films, where the ribbon long axis is perpendicular to the polymer backbone alignment direction and the widths of the nanoscale ribbons are formed by fully-extended polymer chains.20 In addition, the level of uniaxial chain alignment is significantly different, where the aligned ribbon phase can have dichroic ratios over 10,26 and the strain aligned films on OTS-treated substrates have a dichroic ratio up to 4.8. The extended polymer chains of the ribbon phase suggest that there are well-defined grain boundaries with a reduced number of molecular tie-chain coupling between ribbons. In the strain-aligned films demonstrated here, the terrace phase is found to be larger than the extended polymer chain length, and the TEM shows low-angle quasi-domain boundaries suggesting that these boundaries are less sharply defined and similar to the spun cast (0 % strained) film.

2.2. Charge Transport Analysis

To investigate charge transport, the films are printed onto bottom contact, bottom gate OTFT test structures with Pt source-drain electrodes. A focus here is on the saturated field effect mobility. Typical transfer characteristics of devices with a spun cast film and a 50% strained film and a 5 μm channel length are shown in Figure 6. The transfer characteristics in the strained films show good on-off ratios of approximately 107, and threshold voltages consistently near 0 V with various channel lengths. In spun cast films, the short channel length devices have larger threshold voltages, and slightly lower on-off ratios. However, as the channel length increases the threshold voltages move towards 0 V and the on-off ratios increase to values similar to strained films. A comparison of the mobility for spun cast (0 %), 25 %, and 50 % strained films for 5 μm channel length devices is shown in Figure 7. The mobility is plotted vs. the average in-plane chain orientation <cos2(θ)> given by R/(R+1),15 showing a linear relationship over the range of strain considered. We see that the spun-cast films have mobilities similar to previous reports.22,31 When the film is strained, the mobility is found to increase in the direction of backbone alignment and decrease in the transverse direction. We find that the short channel length devices have greater mobility in the parallel to strain direction than the spun cast films despite film dewetting. For 5 μm channel length devices, the highest mobility in the 50 % strained films was found to be 1.67 cm2V−1s−1 (the average was 1.52 cm2V−1s−1), representing one of the highest reported mobilities for this material system.18,22 The linear relationship of the saturated mobility with <cos2(θ)> is consistent with a 2-D mobility tensor along in the b–c axis.11 Extrapolating the mobility for perfect chain alignment (i.e. <cos2(θ)> = 1), the mobility parallel to the backbone direction reaches approximately 2.33 cm2/Vs. In the transverse direction the mobility would drop below zero (−0.29 cm2/Vs). The unphysical negative mobility is likely due to increased film dewetting with strain resulting in a steeper slope than otherwise expected. While a negative mobility is not physical, it highlights the implication of very low mobility in the direction transverse to chain alignment. This may be attributed to significantly lower mobility in the π-stacking direction and the large angle grain boundaries encountered during charge transport.

Figure 6.

Source-drain current (IDS) for OTFTs with variation in gate voltage (VG) under constant source-drain voltage (VDS) of −70 V for a spun cast films (a) and a 50 % strained film (b). The OTFT channel length is 5 μm. The square root of IDS is plotted along with slope used to determine field effect mobility.

Figure 7.

Saturated field-effect mobility of pBTTT films with average polymer in-plane orientation given by <cos2(θ)>. Transistor channel length is 5 μm. The data includes mobility for applied strain applied parallel and perpendicular to the source drain electrodes. The inset illustrates the relative orientation of source-drain electrodes to the strain direction during device testing. The magnitude of applied strain is also given next to the mobility parallel to the strain direction.

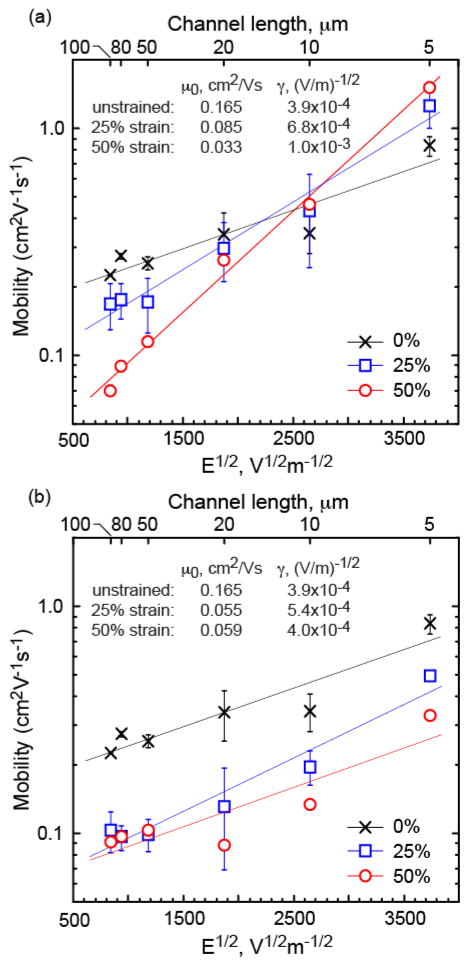

The channel length dependence of the mobility is given in Figure 8 and Figure S4 for spun cast (0 %), 25 %, and 50 % strained films. We find that the mobility drops significantly with channel length in all films. The drop in mobility for the spun cast film is similar to previous reports, attributed to the strong field dependence of the mobility.22 The mobility in the strained films show an even more significant drop with channel length than the spun cast films. The channel length behavior in the strained films is believed to be due to two contributing factors, film dewetting and an anisotropic field dependence of mobility associated with polymer orientation. The impact of holes in the film can be appreciated when considering the drop in mobility anisotropy with channel length for the strained films, shown in Figure 9. In the 25 % strained films there is a slight drop in anisotropy with channel length, while in the 50 % strained film the anisotropy drops significantly, and mobility parallel and perpendicular to the strain direction converge at long channel lengths. The convergence of the mobility anisotropy is believed to be due to the significant increase in film discontinuity in the 50 % strained films, where the benefit of in-plane alignment is diminished. The field dependence also contributes to the channel length behavior of the devices. To gain insight into the field dependence, mobility is plotted with respect to the applied field in Figure 8. Here, the field is taken as the source-drain voltage divided by the channel length.22 This is not strictly accurate as the field will be greater near the source in the saturation regime,22,31 and the discontinuous film will result in a non-uniform dielectric constant and variation in local field intensity. The justification for the use of a constant electric field in the saturation regime is provided elsewhere,31 and the holes are not expected to cause major changes to the local field. We find that the mobility fits well to a Poole-Frenkel transport model where mobility is given by μ = μ0exp[γ*E1/2], where μ0 is the zero-field mobility, γ is scaling prefactor, and E is the applied electric field.31 The fitting parameters for each film are provided in Figure 8. We find that γ increases with applied strain for charge transport parallel to the strain direction. For transport perpendicular to the strain direction, the field dependence remains similar to the spun cast film. Previously, a comparison of as-cast and annealed pBTTT films showed an increase in γ with thermal annealing.31 Here we observe similar behavior for transport parallel and perpendicular to the strain direction, where the favored transport direction (parallel to the strain direction) has a larger field dependence. This is true for the 25 % strained film with very little film dewetting. It is also consistent with an increased field dependence previously observed in aligned P3HT films.15,34 These results suggests that charge transport along the polymer backbone may have a stronger field dependence over intermolecular paths. In as-cast films, the pBTTT film is relatively disordered and conjugation disruption along the polymer backbone may occur frequently. A large component of charge transport may then occur through π-π coupling. Once the films are annealed, the local order improves and charge transport along the polymer backbone is likely to play a more significant role. The contribution of charge transport along the polymer backbone is further increased in strain-aligned films for charge transport parallel to the strain direction. In each case, as charge transport along the polymer backbone is expected to increase, a larger field dependence is observed. For charge transport perpendicular to the strain-alignment direction, π-π transport will remain a major part of the measured mobility, and we find that the field dependence is similar to a spun cast film, consistent with this picture. At this point it is not possible to isolate the anisotropic field dependence and the effect of film dewetting on the channel length dependence, although it is likely both play a role in the reported OTFT characteristics.

Figure 8.

The saturated mobility with applied field (taken as the source-drain voltage divided by the OTFT channel length). The channel length of the devices is also given at the top of the x-axis. (a) The mobility for a spun cast film (0 %) and parallel to the strain direction for 25 % and 50 % strained film. (b) The mobility for the spun cast film (0 %) and perpendicular to the strain direction for 25 % and 50 % strained film.

Figure 9.

The saturated mobility anisotropy (mobility parallel / mobility perpendicular to the strain direction) with OTFT channel length for 25 % and 50 % strained films.

Finally, the field effect mobility is measured as a function of temperature for a spun cast film and a 50 % strain aligned film in an OTFT with Au source-drain electrodes, with results shown in Figure 10. The mobility is found to be a thermally activated process with deviation from Arrhenius type behavior from 220 K to 180 K. This deviation has previously been observed in pBTTT films, and attributed to nanoscopic water.20,35 The activation energy (EA) is extracted from the range of 120 K to 180 K. The activation energy for transport parallel to the strain direction is similar to that found for a spun cast film. The activation energy is found to be 50 % higher for transport perpendicular to the strain direction (EA ~ 35 meV). The results are similar to that found in the aligned ribbon phase pBTTT films.20 The similar activation energy for transport in the spun cast film and parallel to the alignment direction in the aligned films (both strain-aligned and ribbon phase) suggests they all have a similar charge transport bottleneck. The distinctly higher activation energy for transport perpendicular to the alignment suggests the introduction of a unique limiting feature. As charge percolates through the film various morphological features will inhibit transport. While the aligned films increases field effect mobility, it does not remove the limiting feature of transport in the films as compared to spun cast films.

Figure 10.

The field effect mobility of OTFTs for an as-cast annealed (0% strain) and 50 % strained film for transport parallel (para) and perpendicular (perp) to the strain direction. The mobility between 200 K and 120 K are fit to Arrhenius type activation process with activation energy (EA) given in the legend.

3. Conclusions

In this paper we demonstrate biaxially oriented pBTTT films by straining the film while at an elevated temperature near the liquid crystalline phase transition. This process is shown to maintain a wide-domain morphology similar to spun cast films, demonstrating a unique ability to control the level of alignment and local morphology of liquid crystalline polymers. This morphology differs significantly to previous demonstrations of aligned pBTTT that have shown a ribbon phase morphology. During this process the simultaneous formation of some nanoscale dewetting features occurs. Comparing the resultant morphology to the measured field effect mobility provides several insights into charge transport in conjugated polymers.

In the strain-oriented films, the large quasi-domain character with neighboring domains of similar angle suggests that the grain boundaries are not sharply defined similar to the spun cast films. Thus, the improved mobility with increasing strain can be attributed to polymer chain alignment and not grain boundary effects. In contrast, in aligned ribbon phase films, the mobility remains similar to spun cast films even with very large levels of chain alignment (with the caveat that previous ribbon-phase studies have not considered a possible channel length dependence).20 In this case, the extended polymer chains that make up the film likely result in sharper grain boundaries that are greater barriers to charge transport. Extrapolating the field effect mobility with average backbone orientation to a perfectly aligned films, <cos2(θ)> = 1, the mobility in the backbone alignment direction is expected to triple and mobility in the π-stacking direction is expected to be at least an order of magnitude lower, consistent with theoretical predictions.9 Surprisingly, the high mobility in the strain oriented films is achieved although there is clear film dewetting resulting in nanoscale holes in the film. Taking a close look at the TEM imaging, we find that the polymer backbone is found to encircle the holes. This suggests that charge is able to effectively circumvent the holes by moving along the polymer backbone reducing the impact on device performance. However, this does not completely remove adverse effects, as holes in the film impact the channel length dependence of mobility. We also found a strong field dependence of mobility for charge transport parallel to the backbone alignment direction. This suggests that in addition to the effect of holes in the film, a greater field dependence is associated with charge transport along the polymer backbone. Finally, the well-defined, contrasting morphologies of baixially oriented ribbon phase and the wide-domain phase pBTTT provides significant opportunities for further investigations on the morphological limitations of charge transport in conjugated polymer films.

4. Experimental Methods

4.1. Film preparation

The pBTTT was synthesized using a previously reported method21 and had an average molecular mass is 26 kg/mol with polydispersion of 2.0 as measured by GPC in chlorobenzene a 80°C against polystyrene standards. The polymer was dissolved in a solvent pair of chloroform and 1,2-dichlorobenzene with a volume ratio of 1:1 at a concentration of 3 mg/ml. The solution was then spun cast hot (temperature of approximately 65 °C) onto OTS treated Si substrates at 1200(2π) rad/min (1200 rpm) for 40 s. The films were then transfer printed onto a PDMS stamp. Just prior to the transfer printing step, the PDMS was UV-ozone treated for 15 min. The films and PDMS composite was held on a custom built strain stage and placed in close proximity to the surface of a hot plate held at 145 °C. After 30 s, the PDMS with pBTTT film was strained to the desired amount, held at the specified strain and transfer printed onto a silicon substrate with a native oxide surface. The film was left to cool down, it was then transferred to another PDMS stamp removing the film from the oxide silicon surface. The film was then printed onto its final receiving substrate of glass or silicon with or without an OTS-treated surface. The OTS treatment consisted of immersing the substrate in 0.002 mol/L solution of OTS in anhydrous hexadecane for 16 h. The solution casting process was conducted in a nitrogen filled glove-box and the strain and printing process was done in ambient atmosphere.

4.2. Morphology characterization

The UV-visible absorbance was measured using an Ocean Optics Jazz spectrometer.36 The atomic force microscope images were measured with a Bruker Dimension 3000 in tapping mode. The DF-TEM imaging was conducted with a Philips EM400T transmission electron microscope, operated at 120 kV. The images were recorded with an SIS Cantega 2 K CCD camera. X-ray diffraction was performed at the Stanford Synchrotron Radiation Lightsource (SSRL) on beam line 11–3 with an area detector (MAR345 image plate), an energy of 12.735 keV, and an incidence angle of ≈0.12°.

Electrical characterization

The transistor substrates were fabricated by thermally evaporating Ti/Pt (4 nm/35 nm) [or Ti/Au (4 nm/35 nm)] electrodes onto highly doped p-type Si wafer with 200 nm SiO2 gate dielectric. Channel length of the OTFTs varied from 5 μm to 100 μm and the channel widths from 500 μm to 1000 μm. The room-temperature transistor characterization was done using HP 4156B semiconductor parameter analyzer. Transfer characteristics were measured with gate voltage swept from 20V to −50V under source-drain voltage being −70V. Saturated mobility was calculated by using linear fit of IDS1/2 versus VG, from a range of 5 V. The uncertainty was estimated by taking one standard deviation of at least 3 devices and typically 4 to 6 devices. The low temperature mobility was measured with an Agilent 4155C semiconductor parameter analyzer in a Lakeshore low-temperature probe station. The temperature was stepped at 20 K increments at a ramp rate of 1 K/min while keeping the samples under a vacuum of 10−6 torr and using liquid nitrogen as the cryogen. At each temperature step, the IDS was measured while sweeping the gate voltage from 20 V to −60 V and setting the source-drain voltage at −60 V. The activation energy was estimated using Arrhenius equation.

Supplementary Material

Acknowledgments

Funding Sources

National Science Foundation awards: CMMI-1200340, ECCS-1407885, ECCS-1254757, and ECCS-1338012

This research work was supported by the National Science Foundation awards CMMI-1200340 and ECCS-1407885. Low temperature OTFT measurements and contributions to this manuscript by P.J.D and O.D.J. were supported by National Science Foundation awards ECCS-1254757 and ECCS-1338012. Portions of this research were carried out at the Stanford Synchrotron Radiation Lightsource, a Directorate of SLAC National Accelerator Laboratory and an Office of Science User Facility operated for the U.S. Department of Energy Office of Science by Stanford University. We thank Michael F. Toney for assistance with the X-ray diffractions measurements.

Footnotes

Author Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Differential scanning calorimetry data for the pBTTT, additional TEM images, and saturated field effect mobility of the OTFT with variation in channel length are given in the supporting information. This material is available free of charge via the Internet at http://pubs.acs.org.

References

- 1.Schwartz G, Tee BCK, Mei J, Appleton AL, Kim DH, Wang H, Bao Z. Flexible Polymer Transistors with High Pressure Sensitivity for Application in Electronic Skin and Health Monitoring. Nat Commun. 2013;4:1859. doi: 10.1038/ncomms2832. [DOI] [PubMed] [Google Scholar]

- 2.Kang B, Jang M, Chung Y, Kim H, Kwak SK, Oh JH, Cho K. Enhancing 2D Growth of Organic Semiconductor Thin Films with Macroporous Structures via a Small-Molecule Heterointerface. Nat Commun. 2014;5:4752. doi: 10.1038/ncomms5752. [DOI] [PubMed] [Google Scholar]

- 3.Sirringhaus H. 25th Anniversary Article: Organic Field-Effect Transistors: The Path beyond Amorphous Silicon. Adv Mater. 2014;26:1319–1335. doi: 10.1002/adma.201304346. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Salleo A, Kline RJ, DeLongchamp DM, Chabinyc ML. Microstructural Characterization and Charge Transport in Thin Films of Conjugated Polymers. Adv Mater. 2010;22:3812–3838. doi: 10.1002/adma.200903712. [DOI] [PubMed] [Google Scholar]

- 5.Delongchamp DM, Kline RJ, Fischer Da, Richter LJ, Toney MF. Molecular Characterization of Organic Electronic Films. Adv Mater. 2011;23:319–337. doi: 10.1002/adma.201001760. [DOI] [PubMed] [Google Scholar]

- 6.Takacs CJ, Treat ND, Krämer S, Chen Z, Facchetti A, Chabinyc ML, Heeger AJ. Remarkable Order of a High-Performance Polymer. Nano Lett. 2013;13:2522–2527. doi: 10.1021/nl4005805. [DOI] [PubMed] [Google Scholar]

- 7.Luo C, Kyaw AKK, Perez La, Patel S, Wang M, Grimm B, Bazan GC, Kramer EJ, Heeger AJ. General Strategy for Self-Assembly of Highly Oriented Nanocrystalline Semiconducting Polymers with High Mobility. Nano Lett. 2014;14:2764–2771. doi: 10.1021/nl500758w. [DOI] [PubMed] [Google Scholar]

- 8.O’Connor BT, Reid OG, Zhang X, Kline RJ, Richter LJ, Gundlach DJ, Delongchamp DM, Toney MF, Kopidakis N, Rumbles G. Morphological Origin of Charge Transport Anisotropy in Aligned Polythiophene Thin Films. Adv Funct Mater. 2014;24:3422–3431. [Google Scholar]

- 9.Lan Y, Huang CI. Charge Mobility and Transport Behavior in the Regioregular Poly ( 3-Hexylthiophene ) J Phys Chem B. 2009;113:14555–14564. doi: 10.1021/jp904841j. [DOI] [PubMed] [Google Scholar]

- 10.Rivnay J, Mannsfeld SCB, Miller CE, Salleo A, Toney MF. Quantitative Determination of Organic Semiconductor Microstructure from the Molecular to Device Scale. Chem Rev. 2012;112:5488–5519. doi: 10.1021/cr3001109. [DOI] [PubMed] [Google Scholar]

- 11.Cho E, Risko C, Kim D, Gysel R, Miller NC, Breiby DW, McGehee MD, Toney MF, Kline RJ, Bredas JL. Three-Dimensional Packing Structure and Electronic Properties of Biaxially Oriented poly(2,5-bis(3-Alkylthiophene-2-yl)thieno[3,2-B]thiophene) Films. J Am Chem Soc. 2012;134:6177–6190. doi: 10.1021/ja210272z. [DOI] [PubMed] [Google Scholar]

- 12.Yang CY, Soci C, Moses D, Heeger aJ. Aligned rrP3HT Film: Structural Order and Transport Properties. Synth Met. 2005;155:639–642. [Google Scholar]

- 13.Biniek L, Leclerc N, Heiser T, Bechara R, Brinkmann M. Large Scale Alignment and Charge Transport Anisotropy of pBTTT Films Oriented by High Temperature Rubbing. Macromolecules. 2013;46:4014–4023. [Google Scholar]

- 14.Delongchamp DM, Kline RJ, Jung Y, Germack DS, Lin EK, Moad AJ, Richter LJ, Toney MF, Heeney M, Mcculloch I. Controlling the Orientation of Terraced Nanoscale “Ribbons” of a Poly(thiophene) Semiconductor. ACS Nano. 2009;3:780–787. doi: 10.1021/nn800574f. [DOI] [PubMed] [Google Scholar]

- 15.O’Connor B, Kline RJ, Conrad BR, Richter LJ, Gundlach D, Toney MF, DeLongchamp DM. Anisotropic Structure and Charge Transport in Highly Strain-Aligned Regioregular poly(3-Hexylthiophene) Adv Funct Mater. 2011;21:3697–3705. [Google Scholar]

- 16.Tseng HR, Ying L, Hsu BBY, Perez La, Takacs CJ, Bazan GC, Heeger AJ. High Mobility Field Effect Transistors Based on Macroscopically Oriented Regioregular Copolymers. Nano Lett. 2012;12:6353–6357. doi: 10.1021/nl303612z. [DOI] [PubMed] [Google Scholar]

- 17.Tsao HN, Cho D, Andreasen JW, Rouhanipour A, Breiby DW, Pisula W, Müllen K. The Influence of Morphology on High-Performance Polymer Field-Effect Transistors. Adv Mater. 2009;21:209–212. [Google Scholar]

- 18.Wang S, Kiersnowski A, Pisula W, Mullen K, Müllen K. Microstructure Evolution and Device Performance in Solution Processed Polymeric Field-Effect Transistors: The Key Role of the First Monolayer. J Am Chem Soc. 2012;134:4015–4018. doi: 10.1021/ja211630w. [DOI] [PubMed] [Google Scholar]

- 19.Jimison LH, Toney MF, McCulloch I, Heeney M, Salleo A. Charge-Transport Anisotropy Due to Grain Boundaries in Directionally Crystallized Thin Films of Regioregular Poly(3-Hexylthiophene) Adv Mater. 2009;21:1568–1572. [Google Scholar]

- 20.Lee MJ, Gupta D, Zhao N, Heeney M, Mcculloch I, Sirringhaus H. Anisotropy of Charge Transport in a Uniaxially Aligned and Chain-Extended, High-Mobility, Conjugated Polymer Semiconductor. Adv Funct Mater. 2011;21:932–940. [Google Scholar]

- 21.McCulloch I, Heeney M, Bailey C, Genevicius K, Macdonald I, Shkunov M, Sparrowe D, Tierney S, Wagner R, Zhang WM, Chabinyc ML, Kline RJ, Mcgehee MD, Toney MF. Liquid-Crystalline Semiconducting Polymers with High Charge-Carrier Mobility. Nat Mater. 2006;5:328–333. doi: 10.1038/nmat1612. [DOI] [PubMed] [Google Scholar]

- 22.Hamadani BH, Gundlach DJ, McCulloch I, Heeney M. Undoped Polythiophene Field-Effect Transistors with Mobility of 1 cm2 V-1 S-1. Appl Phys Lett. 2007;91:1–4. [Google Scholar]

- 23.Kline RJ, DeLongchamp DM, Fischer Da, Lin EK, Heeney M, McCulloch I, Toney MF. Significant Dependence of Morphology and Charge Carrier Mobility on Substrate Surface Chemistry in High Performance Polythiophene Semiconductor Films. Appl Phys Lett. 2007;90:2005–2008. [Google Scholar]

- 24.Zhang X, Hudson SD, Delongchamp DM, Gundlach DJ, Heeney M, McCulloch I. In-Plane Liquid Crystalline Texture of High-Performance Thienothiophene Copolymer Thin Films. Adv Funct Mater. 2010;20:4098–4106. [Google Scholar]

- 25.Wang C, Jimison LH, Goris L, McCulloch I, Heeney M, Ziegler A, Salleo A. Microstructural Origin of High Mobility in High-Performance Poly(thieno-Thiophene) Thin-Film Transistors. Adv Mater. 2010;22:697–701. doi: 10.1002/adma.200902303. [DOI] [PubMed] [Google Scholar]

- 26.Schuettfort T, Watts B, Thomsen L, Lee M, Sirringhaus H, McNeill CR. Microstructure of Polycrystalline PBTTT Films: Domain Mapping and Structure Formation. ACS Nano. 2012;6:1849–1864. doi: 10.1021/nn2051295. [DOI] [PubMed] [Google Scholar]

- 27.O’Connor B, Chan EP, Chan C, Conrad BR, Richter LJ, Kline RJ, Heeney M, McCulloch I, Soles CL, DeLongchamp DM. Correlations between Mechanical and Electrical Properties of Polythiophenes. ACS Nano. 2010;4:7538–7544. doi: 10.1021/nn1018768. [DOI] [PubMed] [Google Scholar]

- 28.Delongchamp DM, Kline RJ, Jung Y, Lin EK, Fischer DA, Gundlach DJ, Cotts SK, Moad AJ, Richter LJ, Toney MF, Heeney M, McCulloch I. Molecular Basis of Mesophase Ordering in a Thiophene-Based Copolymer. Macromolecules. 2008;41:5709–5715. [Google Scholar]

- 29.Oláh A, Hillborg H, Vancso GJ. Hydrophobic Recovery of UV/ozone Treated Poly(dimethylsiloxane): Adhesion Studies by Contact Mechanics and Mechanism of Surface Modification. Appl Surf Sci. 2005;239:410–423. [Google Scholar]

- 30.Berdichevsky Y, Khandurina J, Guttman A, Lo YH. UV/ozone Modification of Poly(dimethylsiloxane) Microfluidic Channels. Sens Actuators, B. 2004;97:402–408. [Google Scholar]

- 31.Hamadani BH, Richter Ca, Gundlach DJ, Kline RJ, McCulloch I, Heeney M. Influence of Source-Drain Electric Field on Mobility and Charge Transport in Organic Field-Effect Transistors. J Appl Phys. 2007;102:044503. [Google Scholar]

- 32.Noriega R, Rivnay J, Vandewal K, Koch FPV, Stingelin N, Smith P, Toney MF, Salleo A. A General Relationship between Disorder, Aggregation and Charge Transport in Conjugated Polymers. Nat Mater. 2013;12:1038–1044. doi: 10.1038/nmat3722. [DOI] [PubMed] [Google Scholar]

- 33.Liu T, Troisi A. Understanding the Microscopic Origin of the Very High Charge Mobility in PBTTT: Tolerance of Thermal Disorder. Adv Funct Mater. 2014;24:925–933. [Google Scholar]

- 34.Gargi D, Kline RJ, Delongchamp DM, Fischer DA, Toney MF, O’Connor BT. Charge Transport in Highly Face-On Poly ( 3-Hexylthiophene ) Films. J Phys Chem C. 2013;117:17421–17428. [Google Scholar]

- 35.Gomes HL, Stallinga P, Cölle M, De Leeuw DM, Biscarini F. Electrical Instabilities in Organic Semiconductors Caused by Trapped Supercooled Water. Appl Phys Lett. 2006;88:150–153. [Google Scholar]

- 36.Certain commercial equipment, or materials are identified in this paper in order to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement by the National Institute of Standards and Technology, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.