Abstract

In the present study, dahi prepared using milk fortified with omega-3 fatty acids (flaxseed oil), phytosterols and soluble fibre (polydextrose) through an oil-in-water emulsion was evaluated for the physico-chemical and sensory quality. The levels of fortificants in fortified dahi were also estimated. Fortification process did not affect the degree of fermentation in terms of pH and acidity. Sensory scores of fortified and control dahi did not differ significantly. Fortified dahi had lower viscosity, firmness and consistency, and higher water holding capacity (WHC) compared to control; however, significant differences were not observed in firmness and consistency values. Storage study indicated that pH, acidity, %WHC, firmness and consistency values and lactic acid bacterial counts did not differ significantly throughout storage period in both the dahi samples and recorded good sensory acceptability during storage. Fortified dahi provides 282.53 mg, 415.92 mg and 1.019 g of α-linolenic acid, total phytosterols and polydextrose, respectively per 100 g of product. Moreover, no loss in the initial content of ALA, phytosterols and polydextrose had occurred after 8 days of storage period. The present study suggests the feasibility of adding flaxseed oil, phytosterols and polydextrose as functional ingredients in the form of water soluble emulsion to milk, which could be converted to dahi with acceptable properties and enhanced nutritional and therapeutic potency.

Keywords: Dahi, Fortification, Omega-3-fatty acids, Phytosterols, Polydextrose

Introduction

Current trends and changing consumer needs indicate a great opportunity for innovations and developments in fermented milks. The increasing demand from consumers for dairy products with functional properties is a key factor driving value sales growth in developed markets. Dahi or curd is an age-old indigenous fermented milk of India and has managed its popularity in Indian diet despite changing lifestyles and food habits. Dahi contains a similar content of nutrients as that in milk from which it is prepared, but, it can be digested and assimilated more easily than fresh milk. It is obtained from pasteurized or boiled milk by souring with lactic acid bacterial culture (Lactococcus lactis ssp. lactis, L. lactis ssp. cremoris, L. lactis ssp. diacetyl lactis). It is consumed either in main course of meal, as a refreshing beverage or as dessert besides being used as a base for the preparation of culinary products. In India, about 7% of the total annual milk production is utilized for making dahi (Prajapati and Sreeja 2014), and this sector is showing a growth rate of more than 20% per annum. Dahi accounts for 90% of total cultured milk products manufactured in India (Behare et al. 2009).

There has been increasing interest in the use of natural food additives and the incorporation of health-promoting substances into the diet. New functional products are developed by modifying traditional food formulae, eliminating or replacing certain ingredients (fat, sugar) or adding wholesome compounds (e.g. omega-3 fatty acids, soluble fibres, vitamins, minerals, phytosterols), which is, at least theoretically, the simplest and most commonly used method (Fogliano and Vitaglione 2005). Omega-3 fatty acids are essential for normal growth and development and may play an important role in the prevention and treatment of coronary artery disease, hypertension, diabetes, arthritis, other inflammatory and autoimmune disorders and cancer. Flaxseed oil is a rich source of alpha linolenic acid (ALA) (~57%), an omega-3 fatty acid that can be converted in the body to eicosapentaenoic acid (EPA), thus providing EPA’s beneficial effects (Tapiero et al. 2002). The recommended dietary intakes of omega-3 fatty acids specified by Indian Council of Medical Research (ICMR 2010) for ALA is 1.6 g per day for men and 1.1 g per day for women. Phytosterols are currently used as functional ingredients due to their capacity to reduce low-density lipoprotein (LDL) cholesterol levels. The Food and Drug Administration (FDA 2010) concluded that a daily dietary intake of 2 g of phytosterols (expressed as non-esterified phytosterols) is required to demonstrate relationship between phytosterol consumption and cholesterol lowering for reduced cardiovascular disease risk. In addition, phytosterols have been described as anti-inflammatory and anticancer compounds (García-Llatas and Rodríguez-Estrada 2011). Polydextrose is approved as a food additive for technical purposes enhancing texture, appearance and taste and for nutritional purposes, it is used to reduce energy and increase fibre content (Tiihonen et al. 2011). Based on energy intake, a level of about 40 g of fibre per 2000 kcal in a diet is recommended by ICMR (2010). Although there is no dietary reference intake for insoluble or soluble fibre, FDA recommended total dietary fibre intakes are about 25 g/day, of which about 25% (about 6 g) should be soluble fibre (FDA 2015). Adding more than one functional ingredient in product formulation might have synergistic effect on health benefits. Micallef and Garg (2008) demonstrated that combined supplementation with phytosterols and omega-3 polyunsaturated fatty acid has both synergistic and complementary lipid-lowering effects in hyperlipidemic men and women.

Milk contains very low levels of omega-3-fatty acids (0.8 wt% of total lipids) and phytosterols (traces) and lacks fibre. It, however, fulfils the requirements of an ideal vehicle for fortification with these substances, which will greatly enhance its nutritive and therapeutic values. In addition to liquid milk, dairy foods such as dahi and yoghurt are also being chosen as popular vehicles for the incorporation of therapeutic ingredients. In recent years, several attempts have been made to add ingredients such as probiotics, calcium, fruits, honey and omega-3 fatty acids among others with the objective of enhancing the dietetic properties of dahi and yoghurt. But, addition of such ingredients has been reported to affect product quality in terms of body, consistency and whey syneresis. Altering the composition of dahi to make it more nutritious, and at the same time ensuring minimal modification in the sensory and functional properties of the end product, is a major challenge encountered by the dairy industry (Pushkala and Srividya 2011). No work is reported in the literature on preparation of dahi using milk fortified with omega-3-fatty acids, phytosterols and soluble fibre.

In light of the above, this study was aimed to prepare dahi from milk fortified with omega-3 fatty acids, phytosterols and soluble fibre, so as to increase health benefits and to provide recommended daily intake of these nutraceuticals through the consumption of dahi, a major dairy product in the Indian houses. Dahi samples were investigated for physico-chemical, microbiological and sensory properties as well as for the level of fortificants viz. ALA, total phytosterols and polydextrose. Studies on the changes in dahi during storage were also carried out.

Materials and methods

Materials

Raw materials and ingredients

Raw cow milk, obtained from the Livestock Research Centre of the National Dairy Research Institute, Bengaluru, India, was warmed at 40 °C and separated into cream and skim milk using cream separator. The skim milk (<0.5% milk fat) and cream (≈40%) were used to standardize the milk with 3% fat and 8.5% solids not fat. Cold-pressed flaxseed oil (HEALTH 1st) manufactured by Prano Flax Pvt. Ltd. (Jaipur, India) was procured from the local market. A commercial food grade phytosterol preparation used in this study was obtained from Bio-gen Extracts Pvt. Ltd. Bengaluru, India. According to the information provided by the suppler, it contained 42.38% of β-sitosterol, 24.81% of stigmasterol, 26.73% of campesterol and 1.84% of brassicasterol. Polydextrose (Litesse® II) and diacetyl tartaric acid ester of mono-diglycerides (DATEM, Panodan® 165 Kosher) were obtained from Danisco (India) Pvt. Ltd., Gurgaon, India. Potato dextrose agar and M17 agar required for microbiological analysis were obtained from HiMedia Laboratories Pvt. Ltd. (Mumbai, India).

Dahi culture

Mixed culture (L. lactis ssp. lactis, L. lactis ssp. cremoris and L. lactis ssp lactis var. diacetyllactis) was obtained from Dairy Microbiology of institute.

Chemicals and standards

Methanol, water, chloroform and hexane of HPLC grade, boron trifluoride methanol complex (14% in methanol) and potassium hydroxide were obtained from HiMedia laboratories Pvt. Ltd. (Mumbai, India). Methyl linolenate, cholesterol, beta-sitosterol, stigmasterol and campesterol were obtained from Sigma Chemical Co. (St. Louis, MO, USA).

Preparation of oil-in-water emulsion

Since, phytosterols are insoluble in water and sparingly soluble in oil and they are converted into water dispersible form to facilitate their dispersion in milk. The process for preparation of stable emulsion containing flaxseed oil, phytosterol and polydextrose for fortification of milk was optimized (Veena 2014). Flaxseed oil and milk fat were used as source of oil and polydextrose solution was used as aqueous medium. A mixture of milk fat (4 g), emulsifier (DATEM) (6.5 g) and phytosterol (10 g) was heated at 120 °C in a paraffin oil bath for 5 min. Flaxseed oil (10 g) was added to the above mixture and the contents were heated for 2 more min followed by blending using a laboratory blender (Remi Motor L56-11, Bombay, India) at 700 rpm for 2 min. Then, polydextrose solution (20 g dissolved in 49.5 g of distilled water) heated at 90 °C was added to the oil phase and blending was continued at 1500 rpm for 5 min to achieve a stable emulsion. The prepared emulsion was cooled to room temperature and kept in the refrigerator at 4 °C till use.

Preparation of dahi from fortified milk

For preparation of fortified milk, the emulsion prepared as above, was added to milk at a rate of 5% (w/w), mixed well, subjected to heat treatment at 60 °C and immediately homogenized (H-102, Goma, Mumbai, India) at 2500 and 500 psi in the first and second stages, respectively. After homogenization, milk samples were heated at 85 °C for 15 min, cooled to 30 °C and inoculated with 2% mixed culture. They were then packed in polypropylene containers of 100 ml capacity and incubated at 30 °C for 8 h. Control dahi sample was prepared in a similar way from milk but without adding emulsion.

To study the degree of fermentation, pH and acidity of control and fortified milk were measured after 0, 2, 4, 6 and 8 h of inoculation with mixed culture (2%).

Sensory evaluation

An acceptance sensory panel assessed the coded dahi samples at random, according to the methodology described by Watts et al. (1989). Sensory evaluation of samples was carried out with a 25-member panel (ages 22–45 year, 19 men and 6 women) who were scientists, students and technical staff from Institute. Dahi samples, in the polypropylene containers were conditioned at room temperature for 15 min before testing. Each panellist was asked to taste the samples and rate the sensory parameters on a 9-point hedonic scale. According to the 9-point structured hedonic scale, the acceptance test was carried out for the attributes of colour and appearance, body and texture, flavour and overall acceptability.

Physico-chemical analysis

pH and acidity

The pH of the dahi (control and fortified) was determined using a pH meter (Cyberscan 2500, Eutech Instruments). Titratable acidity, expressed as percentage of lactic acid, was determined by mixing 10 g of dahi with 10 ml of distilled water and titrating with 0.1 N NaOH using phenolphthalein as an indicator to an end-point of faint pink color.

Viscosity

A Brookfield viscometer (LVDV-II + Pro, Middleboro, MA, USA) was used to determine the viscosity of the dahi. Viscosity measurements were performed using a No. S34 spindle at 1 rpm. Measurements were determined at a temperature of 30 °C after 15 s; the results are expressed as centipoise (cP).

Water-holding capacity (WHC)

Whey separation (expressed in terms of water-holding capacity) was determined by taking 10 g dahi sample in a graduated 15 ml centrifuge tube, and centrifuging it at 3000 rpm (402×g) for 10 min at ambient temperature ranging from 28 to 32 °C. After centrifugation, weight of the clear whey separated was measured (Remeuf et al. 2003) and the water-holding capacity was reported.

Textural analysis

Firmness and consistency, the important textural attributes, were measured using TA.XT. Plus texture analyser (Stable Micro Systems, Godalming, Surrey, UK). For texture analysis, dahi samples were prepared from 80 ml of milk in 100 ml polypropylene cups, the set samples were maintained at 5 ± 1 °C before analysis. The samples were subjected to mono-axial compression of 10 mm distance using cross head speed of 2 mm/s and probe of 25mm diameter. The test conditions were: distance, 10 mm; load cell, 25 kg; pre-test speed, 1 mm/s; test Speed, 1 mm/s; post-test speed, using single compression. The height of the force peak on the compression cycle was recorded as firmness value (N) and the area under the curve as consistency (Ns).

Microbiological analysis

Enumeration of lactic acid bacteria and yeast and mold counts was made after 1, 4 and 8 days of fermentation in 3 triplicate. Each sample (1.0 ml) was added to 9.0 ml of 0.85% sterile saline (sodium chloride) and further dilutions were done according to requirements. The standard pour plate method was employed to determine the counts of microorganisms. Lactic acid bacteria and yeast and molds were enumerated in M17 agar and potato dextrose agar, respectively and plates were incubated at 30 °C for 24–48 h. The enumeration of the microbial counts was performed on plates containing 30–300 colonies, and the results were recorded as log number of colony-forming units per gram (Log cfu/g).

Levels of fortificants

Omega-3 fatty acids (alpha linolenic acid)

Fat was extracted from the accurately weighed ground and homogenized samples using Mojonnier flask and then transesterified to methyl esters as per AOAC official method 996.06 (AOAC 2005). All samples were analysed on Agilent Technologies 7890A GC system (Agilent Technologies, Santa Clara, CA) equipped with a split less injector and hydrogen flame ionization detector. SP2560 fused silica capillary column 100 m × 0.25 mm (i.d.) with 0.20 μm film thickness (Agilent Technologies, USA) was used to separate fatty acid methyl esters. The temperature programme for separation began at 140 °C, which was maintained for 2 min. The oven temperature was then increased to 240 °C at 3 °C/min (ramp) and held there for 10 min. Injector and detector temperatures were maintained at 250 and 280 °C, respectively. Carrier gas, nitrogen, with flow rate 1 ml/min was used. The injection volume was 1 μl. Methyl ester of ALA was identified by comparison of elution time with the standard methyl linolenate and was estimated as weight percent.

Phytosterols

The phytosterols were extracted by direct saponification of the samples with slight modification of the method given by Fletouris et al. (1998). Unsaponifiable matter in the hexane was transferred to a 50 ml conical flask and evaporated to dryness under stream of nitrogen. The residue was dissolved in 10 ml of methanol and filtered through 0.22 μm membrane filter and the filtrate was used for HPLC analysis. Samples were analysed for phytosterol levels by reverse phase HPLC with Waters 515 solvent delivery system, a 20 μl injection loop (Rheodine, PIN7725) and a waters 2489 spectrophotometric UV/Visible detector at 205 nm. Chromatographic separation was carried out using a Sun Fire™ C18 column (4.6 × 250 μm, 5 μm) (Waters, Milford, MA, USA). Isocratic elution was performed with mobile phase of methanol and water (99:1) at a flow rate of 1.0 ml/min. Column temperature was set at 30 °C and injection volume was 20 μl.

Polydextrose

Liquid chromatographic determination of polydextrose in food matrices was adopted as per Noffsinger et al. (1990) with slight modification. One gram of sample was added with 0.2 ml of 1% acetic acid. The solution was diluted with distilled water (10 ml) in such a way that the final concentration of polydextrose in the sample would yield about 1 mg/ml. The diluted sample was heated at 85 °C for 10 min in water bath and cooled to room temperature. The sample was filtered through Whatman No. 40 filter paper. To the filtrate, 2 ml of chloroform was added to defat the sample, and mixed thoroughly. Tubes were centrifuged at 5000 rpm (1118×g) for 10 min. Top aqueous layer was collected and filtered through 0.22 μm filter (PVDF) and the filtrate was used for analysis using HPLC. Samples were analysed for polydextrose levels by using solvent delivery pump (Model 515, waters Associates, Inc., Milford, MA), 20 μl injection loop (Rheodine, PIN7725), Waters Model 2414 refractive index detector and Hi-Plex Ca column, 300 × 7.7 mm (id), 8 μm film (Agilent Technologies, USA). Column temperature was set at 85 °C and injection volume was 20 μl. Isocratic elution with mobile phase of water (HPLC grade) at a flow rate 0.5 ml/min was used. Detector temperature was set at 35 °C.

Storage studies

The fortified and control dahi samples were stored in triplicates at refrigerated temperature (4 °C). Samples were drawn after 1, 4 and 8 days for the analysis of sensory, physico-chemical, textural and microbiological analysis. Fortified dahi was also analyzed for content of ALA, total phytosterols and polydextrose in a fresh sample as well as after eighth day of storage.

Statistical analysis

Mean values and standard deviations of triplicate determinations were reported and statistical significance were set at P < 0.05. Analysis of variance was carried out to determine the difference among treatments means (SYSTAT 6.0.1 software) using the post hoc Bonferroni adjustment test.

Results and discussion

Degree of fermentation

The pH and acidity of control and fortified milk were measured after 0, 2, 4, 6 and 8 h of inoculation with mixed culture. During incubation, the lactic acid bacteria multiply and grow logarithmically and utilize a fraction of lactose converting it into lactic acid. This results in increase in acidity and decrease in pH of milk. It can be seen from the results (Table 1) that at 0 h of incubation, the pH of fortified milk was lower and acidity was higher compared to control milk. However, significant difference (P > 0.05) was not observed for these characteristics between control and fortified milk. With the increase in incubation from 0 to 8 h, pH and acidity of the fortified sample was comparable to those of the control sample. This indicated that type of fortificants did not alter the rate of acid production by the starter culture. Thus, it can be concluded that fortification process did not affect the degree of fermentation measured as pH and acidity. The pH and acidity of control and fortified samples were within the range reported for dahi (Hossain et al. 2012).

Table 1.

Effect of fortification of milk on degree of fermentation

| Hours of incubation | pH | Acidity (% lactic acid) | ||

|---|---|---|---|---|

| Control | Fortified | Control | Fortified | |

| 0 | 6.64 ± 0.055a | 6.51 ± 0.031a | 0.17 ± 0.005a | 0.18 ± 0.01a |

| 2 | 6.36 ± 0.038a | 6.24 ± 0.012a | 0.21 ± 0.021a | 0.24 ± 0.021a |

| 4 | 5.24 ± 0.237a | 5.17 ± 0.20a | 0.47 ± 0.083a | 0.51 ± 0.086a |

| 6 | 4.56 ± 0.081a | 4.54 ± 0.055a | 0.65 ± 0.027a | 0.71 ± 0.014a |

| 8 | 4.48 ± 0.172a | 4.41 ± 0.174a | 0.73 ± 0.036a | 0.74 ± 0.052a |

Results are expressed as Mean ± SD. Mean in each row with different superscripts (a, b) is significantly different (P < 0.05) from each other

Sensory and physico-chemical analysis

The sensory and physico-chemical properties of the dahi samples are given in Table 2. It can be seen from the results that sensory score for colour and appearance of fortified dahi was comparable to control dahi and significant difference was not observed. The body and texture score of dahi prepared using fortified milk was slightly lower than that of control sample; however significant difference was not observed. The fortified dahi had slightly weak texture and less firm compared to control dahi which might be due to the addition of emulsion during preparation of the fortified milk. This may be indicative of dissimilarity in the nature of the bonds involved in the gel structure formation of both dahi samples. Dahi prepared using fortified milk had slightly lower sensory scores for flavour compared to control sample, however, significant difference was not observed. The lower scores obtained for fortified dahi could be attributed to a flaxseed oil flavour. Liutkevicius et al. (2010) studied the effect of addition of cold pressed flaxseed oil on the quality of curd. They observed that enrichment of curd with 2% flaxseed oil resulted in changes in its taste and flavour; which had negative influence on its acceptability. However, in the present study, the level of flaxseed oil and the optimized method of its addition did not affect the flavour of dahi significantly. The scores for overall acceptability of control and fortified dahi did not differ significantly. Though fortified dahi had scored lower than control sample, the product was found acceptable and liked by the panellists, scoring more than 7.0 for all the sensory attributes.

Table 2.

Sensory and physico-chemical properties of control and fortified dahi

| Properties | Control | Fortified dahi |

|---|---|---|

| Sensory properties | ||

| Color and appearance | 7.99 ± 0.01a | 7.95 ± 0.04a |

| Body and texture | 7.83 ± 0.02a | 7.38 ± 0.23a |

| Flavor | 7.97 ± 0.02a | 7.58 ± 0.14a |

| Overall acceptability | 8.01 ± 0.01a | 7.67 ± 0.14a |

| Physico-chemical properties | ||

| pH | 4.44 ± 0.036a | 4.41 ± 0.020a |

| Acidity, %LA | 0.73 ± 0.023a | 0.74 ± 0.018a |

| Viscosity, cP | 4978.3 ± 559.6a | 3548.6 ± 132.2b |

| Water holding capacity, % | 59.80 ± 5.60a | 73.65 ± 2.90b |

| Firmness/hardness (N) | 1.52 ± 0.12a | 1.21 ± 0.05a |

| Consistency (N.sec) | 11.95 ± 0.65a | 10.89 ± 0.69a |

Results are expressed as Mean ± SD. Mean in each row with different superscripts (a, b) is significantly different (P < 0.05) from each other

pH and acidity of dahi prepared using fortified milk was comparable to those of the control sample and significant differences were not observed in pH and acidity between control and fortified samples. This is in accordance with the results reported by Estrada et al. (2011) in which fortification of strawberry yoghurt with microencapsulated fish oil (salmon oil) had no significant effect on yoghurt pH. Fortified dahi had significantly lower viscosity values compared to control. This is because dahi is gel/matrix of casein micelles with entrapped water. Addition of emulsion in fortified milk may interrupt the gel structure of the enriched sample. Viscosity is affected by the strength and number of bonds between casein micelles in yoghurt, as well as their structure and spatial distribution (Lucey and Singh 1998). Similar result was also reported by Izadi et al. (2015) that addition of phytosterol emulsion to non-fat yoghurt decreases the apparent viscosity compared to control sample.

A significant difference in WHC% was observed between control and fortified samples. Fortified dahi had higher water holding capacity than control sample. These results could be due to water retention by swollen polydextrose; besides the bond between the network of milk gel became greater and stronger. It is suggested that polydextrose is a potential cryoprotectant. The cryoprotective effects of polydextrose may be attributed to the numerous hydroxyl groups available for hydrogen bonding with proteins, leading to increased protein hydration, reduced surface tension of water, and decreased aggregation (denaturation) (Park et al. 1993). Though the viscosity and WHC% (objective analysis) differed significantly for fortified dahi when compared to control, the sensory scores (subjective analysis) for body and texture did not show this difference between them. Since commercial dahi or homemade dahi has reasonable variation in the body and texture, the panellists have accorded acceptable scores for the body and texture for both the control and fortified dahi samples. The difference in the body and texture could be more explicitly measured by the objective analysis.

Texture of dahi is an important attribute that determines its acceptability and identity. Both firmness and consistency values were slightly lower for the fortified dahi compared to control sample, however, significant difference was not observed (Table 2). Addition of emulsifier (DATEM), polydextrose, and phytosterols in the form of emulsion during preparation of fortified milk might have influenced the texture of fortified dahi. Lee et al. (1996) investigated the influence of low molecular weight emulsifiers on rheological properties and the microstructure of model processed cheese, made using rennet casein. The sodium dodecyl sulphate (SDS) (anionic) samples showed the lowest hardness, G′ (elastic) and viscosity, the N-cetyl-N,N,N-trimethylammonium bromide (CTAB) (cationic) samples showed the highest while the Emuldan (non-ionic) and lecithin (amphoteric) samples were of intermediate hardness, G′ and viscosity when compared with control. They concluded that electrostatic interactions between the emulsifier and the protein played the major role in determining the rheological properties of the cheese. In the present study, DATEM is used for preparation of an emulsion and is anionic emulsifier. Like SDS, DATEM might have decreased firmness/hardness value of fortified dahi compared to control. Goyal et al. (2016) developed omega-3 fortified dahi with microencapsulated flaxseed oil (MFOP) and reported a significant difference between the firmness values of control and samples with lower firmness in dahi fortified with MFOPs.

Storage stability of dahi

Dahi samples were evaluated for sensory and physico-chemical properties during 8 days of storage. Table 3 shows the sensory and physico-chemical analysis results of control and fortified dahi samples during the storage period. It may be seen from the sensory results that significant differences were not observed in the mean scores for color and appearance as well as overall acceptability of dahi samples during storage up to 8 days. Similar result was also reported by Goyal et al. (2016) in the microencapsulated flaxseed oil fortified dahi during 15 days of storage. Upon storage, considerable reduction in the sensory scores for body, texture and flavor were observed in both control and fortified dahi after 8 days of storage period. It is evident from the data that though the scores for body and texture, flavor and overall acceptability decreased during storage for control as well as fortified dahi samples, but on the same day of evaluation, the sensory scores for the said attributes were similar and comparable in dahi samples. It can be inferred from the data that addition of emulsion in milk did not significantly affect the sensory scores of fortified dahi samples during storage. Our results were consistent with earlier studies (Hanif et al. 2012; Goyal et al. 2016), who reported a decrease in scores for flavor, body and texture during dahi or yoghurt storage.

Table 3.

Effect of storage on sensory and physico-chemical properties of dahi

| Properties | Sample type | Day 1 | Day 4 | Day 8 |

|---|---|---|---|---|

| Sensory properties | ||||

| Color and appearance | Control | 7.99 ± 0.05aA | 7.98 ± 0.02aA | 7.98 ± 0.01aA |

| Fortified | 7.96 ± 0.04aA | 7.95 ± 0.02aA | 7.96 ± 0.02aA | |

| Body and texture | Control | 7.83 ± 0.02aA | 7.75 ± 0.058aA | 7.31 ± 0.02aB |

| Fortified | 7.38 ± 0.23aA | 7.21 ± 0.02aA | 6.98 ± 0.098aB | |

| Flavor | Control | 7.97 ± 0.01aA | 7.81 ± 0.02aA | 7.58 ± 0.14aB |

| Fortified | 7.58 ± 0.14aA | 7.43 ± 0.47bA | 6.86 ± 0.22bB | |

| Overall acceptability | Control | 8.01 ± 0.01aA | 7.94 ± 0.098aA | 7.57 ± 0.12aA |

| Fortified | 7.67 ± 0.14aA | 7.53 ± 0.28aA | 7.24 ± 0.02aA | |

| Physico-chemical and microbiological analysis | ||||

| pH | Control | 4.44 ± 0.036aA | 4.40 ± 0.047aA | 4.35 ± 0.038aA |

| Fortified | 4.41 ± 0.020aA | 4.39 ± 0.04aA | 4.31 ± 0.035aA | |

| Acidity (% lactic acid) | Control | 0.73 ± 0.023aA | 0.75 ± 0.020aA | 0.76 ± 0.004aA |

| Fortified | 0.74 ± 0.018aA | 0.76 ± 0.026aA | 0.78 ± 0.001aA | |

| WHC (%) | Control | 59.80 ± 5.60aA | 62.50 ± 6.42aA | 67.33 ± 0.82aA |

| Fortified | 73.65 ± 2.90bA | 77.92 ± 4.72bA | 81.39 ± 1.17bA | |

| Firmness (N) | Control | 1.52 ± 0.12aA | 1.53 ± 0.05aA | 1.50 ± 0.069aA |

| Fortified | 1.21 ± 0.05aA | 1.22 ± 0.052aA | 1.23 ± 0.046aA | |

| Consistency (N.sec) | Control | 11.95 ± 0.65aA | 11.97 ± 1.045aA | 11.59 ± 0.44aA |

| Fortified | 10.89 ± 0.69aA | 10.85 ± 0.90bA | 10.74 ± 0.917bA | |

| LAB (Log cfu/ml) | Control | 9.15 ± 0.05aA | 9.11 ± 0.02aA | 9.14 ± 0.20aA |

| Fortified | 8.54 ± 0.05aA | 8.51 ± 0.07aA | 8.45 ± 0.31aA | |

Data are presented as Mean ± SD. a, b Means within columns with different lowercase superscript for each attributes are significantly different (P < 0.05) from each other. A, B Means within rows with different uppercase superscript for each attributes are significantly different (P < 0.05) from each other

The pH of control and fortified dahi samples decreased and titratable acidity increased during storage period; the changes were, however, not significant. Significant difference in pH and titratable acidity was also not observed between the samples throughout storage period (Table 3). This is in accordance with results reported by Serra et al. (2009) in which titratable acidity increased slightly after 28 days of cold storage of set and stirred yoghurts. This was attributed to persistent metabolic activity of starters, known as post acidification (Beal et al. 1999). Percent WHC for control and fortified dahi increased from 59.8 to 67.33 and 73.65 to 81.39, respectively, after 8 days of storage. However, significant differences were not observed for %WHC among different storage intervals in both control and fortified dahi. Results of present study are in agreement with Foda et al. (2007) who reported that prolonging the cold storage for 12 days decreased the syneresis of yoghurt compared with fresh samples. This may be attributed to the immobilization of the liquid phase in a three dimensional matrix composed of casein micelles which depends on total solids, Ca2+, pH and preheat treatment of milk (Walstra et al. 1999). In both control and fortified dahi, firmness and consistency values did not differ significantly during 8 days of storage period. Gassem and Frank (1991) and Hanif et al. (2012) also reported that firmness of yoghurt was not significantly affected by storage period. Goyal et al. (2016) also showed that dahi made from milk supplemented with different microencapsulated flaxseed oil had no significant change in firmness till 14 days of storage.

Lactic acid bacterial (LAB) counts of fortified dahi were slightly lower than the control sample, however, significant difference in the count was not observed. This decrease in counts in fortified dahi might be due to the addition emulsion to the milk. DATEM is reported to possess antibacterial activity (Anderson et al. 1999) and synergistically to increase the antibacterial effect of various substances. Makelainen et al. (2007) reported that complex structure of polydextrose dictates that it is only slowly utilized by the intestinal microbiota and in pure culture experiments, most of the tested microbes fail to grow on polydextrose. Hence, DATEM and polydextrose might be responsible for lower counts of LAB in fortified dahi. However, storage period of 8 days did not have much influence on LAB counts in both control and fortified dahi. Not a single colony of yeast and mold was observed on the agar plate in both control and fortified dahi. This indicates that good manufacturing and hygienic storage practices were followed in the present study.

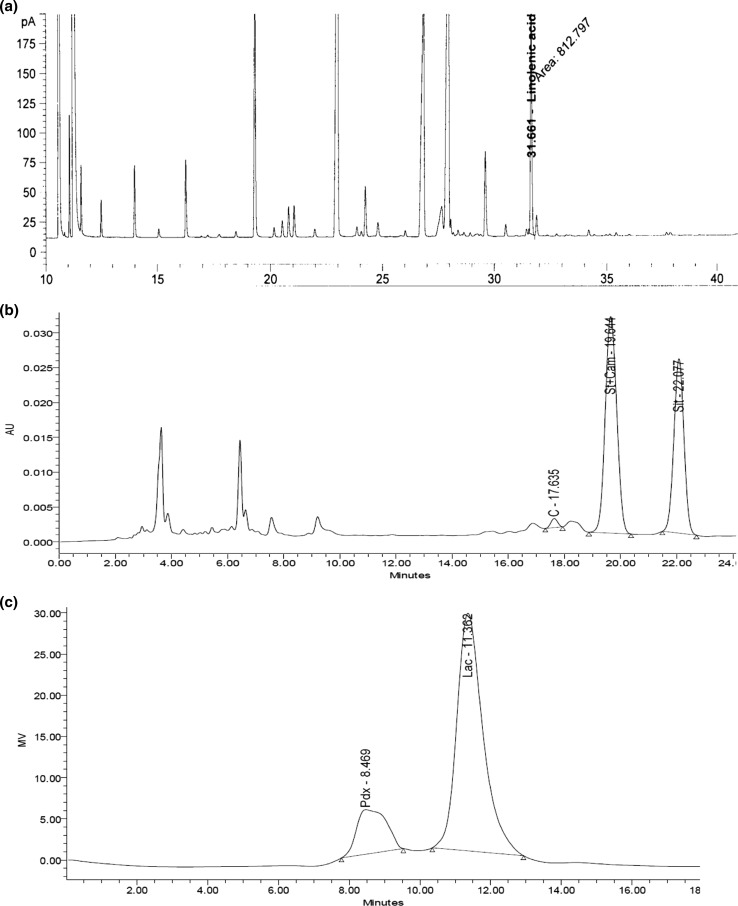

Levels of fortificants

The ALA, phytosterols and polydextrose contents in the fortified dahi analysed during zero and eighth day of storage are reported in Table 4 and the chromatograms are shown in Fig. 1. The mean ALA content of fresh fortified dahi was 282.53 mg/100 g with percent relative standard deviation (RSD) of 2.46. As expected, increased ALA content was observed in fortified dahi due to the addition of flaxseed oil to milk through emulsion at rate of 0.5%. Flaxseed oil is rich in ALA, representing about 57% of its total fatty acids and this has been reflected in our results. Upon 8 days of storage of dahi, no significant decrease or loss in the ALA content was observed due to low temperature storage (4–5 °C) in the milk matrix that could prevent the oxidation of polyunsaturated fatty acids. Similar result was reported in the previous studies in relation to storage stability of flaxseed oil enriched beverages. Liutkevicius et al. (2007) evaluated the fatty acid profile of curd whey beverage enriched with flaxseed oil during storage at 6 °C. Because of the low storage temperature (6 °C) and especially of low pH (3.80–4.18) of the beverage medium, no significant quantitative changes of fatty acids including ALA was detected when beverage was stored for 30 days. Assuming the standard serving size of dahi as 200 ml, approximately 35% of the recommended levels (1.6 g per day) could be met by developed fortified dahi even after 8 days of storage.

Table 4.

Effect of storage on level of fortificants in fortified dahi

| Fortificants | Day zero | Day eight | ||

|---|---|---|---|---|

| Mean ± SD | %RSD | Mean ± SD | %RSD | |

| ALA (mg/100 g) | 282.53 ± 6.95a | 2.46 | 281.96 ± 7.96a | 2.84 |

| Phytosterols (mg/100 g) | 415.92 ± 2.07a | 0.49 | 416.07 ± 5.11a | 1.24 |

| Polydextrose (g/100 g) | 1.019 ± 0.030a | 2.94 | 1.017 ± 0.004a | 0.39 |

Results are expressed as Mean ± SD

RSD, relative standard deviation

Fig. 1.

Chromatograms of fortified dahi sample containing a ALA by GLC, b sterols (C, cholesterol; St + Cam, stigmasterol and campesterol; Sit, β-sitosterol) by HPLC and c polydextrose (Pdx, polydextrose; Lac, lactose) by HPLC

Phytosterol content of fortified dahi sample was expressed as total phytosterols which includes an account of stigmasterol, campesterol and β-sitosterol but not brassicasterol. Brassicasterol was not detected by HPLC due to lower concentration (<2%) in the commercial food grade phytosterol used in this study. It can also be seen from Fig. 1b that on the C18 column, stigmasterol and campesterol were eluted as a single peak. Changes in the HPLC conditions like column temperature, flow rate, different mobile phases and their proportions could not separate stigmasterol and campesterol. Hence, the calculation was made as the total phytosterol content as the elution of campesterol and stigmasterol together is not expected to make any difference. The total phytosterol content of fresh fortified dahi and after 8 days of storage was 415.92 and 416.07 mg/100 g and %RSD of 0.49 and 1.24, respectively. There was no significant loss in initial total phytosterol content after 8 days of storage. The results of the present study were in agreement with previous study by the fact that phytosterols stability was well guaranteed during the shelf life of the product. González-Larena et al. (2012) evaluated the effect of storage at 4, 24 and 37 °C during 6 months at regular time intervals of 2 months on phytosterols (PS) stability in three PS-enriched beverages (skimmed milk with fruit juice and PS; fruit juice and PS; and skimmed milk with PS). No loss in total PS content was observed during storage. Assuming the standard serving size of dahi as 200 ml, approximately 41.5% of the recommended levels (2 g per day) could be met by developed fortified dahi even after 8 days of storage.

The polydextrose content of fresh fortified dahi was 1.019 g/100 g with %RSD of 2.94. Polydextrose is comprised of 90% of soluble fibre. Polydextrose content did not change significantly after 8 days of storage at 4–5 °C. Previous studies indicated that polydextrose remained stable during storage under pH conditions between pH 3 and 7. Polydextrose is a complex branched molecule and contains a wide range of glycosidic bonds which consequently are resistant to hydrolysis. However, extreme processing conditions such as high temperature or low pH may cause slight degradation. Polydextrose appeared to be stable until temperature of 85 °C, then degradation occurs depending on pH (Beer et al. 1991). Fortified dahi provides almost 2.0 g of soluble fibre (polydextrose) in 200 ml serving size of dahi.

Conclusion

The study showed that milk fortified with omega-3-fatty acids, phytosterols and polydextrose could be utilized for preparation of dahi with an acceptable quality. The physico-chemical, textural, microbiological and sensory characteristics of the fortified product i.e., dahi were comparable to those of the control product. The fortified dahi also stored well at 4–5 °C for 8 days. Fortified dahi provides 282.53 mg, 415.92 mg and 1.019 g of ALA, total phytosterols and polydextrose, respectively per 100 g of product. Moreover, no loss in the initial content of ALA, phytosterols and polydextrose had occurred after 8 days of storage. This would not only help in improving the nutritional value but would also bestow functional benefits to the product.

Acknowledgements

First author is thankful to Director, National Dairy Research Institute, Karnal, India for providing financial assistance for carrying out the research work.

Contributor Information

N. Veena, Email: veena.ndri@gmail.com

B. Surendra Nath, Email: bsn_ndri@yahoo.com

Bandla Srinivas, Email: bandla_srinivas@rediffmail.com.

B. V. Balasubramanyam, Email: balundri@yahoo.co.in

References

- Anderson SN, Ewing PJ, Guzman-Harty M, Hilty MD, Liu J, Mazer TB, Meulbroek JA, Schaller J, Lee TSW (1999) Water-miscible esters of mono-and diglycerides having antibacterial activity and their use in inhibiting infection. Int Patent US5908862A

- AOAC . Official methods of analysis. The association of official analytical chemists. 8. Maryland: North Fredrick Avenue Gaithersburg; 2005. p. 481. [Google Scholar]

- Beal C, Skokanova J, Latrille E, Martin N, Corrieu G. Combined effects of culture conditions and storage time on acidification and viscosity of stirred yoghurt. J Dairy Sci. 1999;82:673–681. doi: 10.3168/jds.S0022-0302(99)75283-5. [DOI] [Google Scholar]

- Beer M, Arrigoni E, Uhlmann D, Wechsler D, Amado R. Stability of polydextrose solutions to heat treatment and storage under acid conditions. Lebensmittel-Wissenschaft Technol. 1991;24:245–251. [Google Scholar]

- Behare P, Singh R, Singh RP. Exopolysaccharide-producing mesophilic lactic cultures for preparation of fat-free Dahi—an Indian fermented milk. J Dairy Res. 2009;76:90–97. doi: 10.1017/S0022029908003865. [DOI] [PubMed] [Google Scholar]

- Estrada JD, Boeneke C, Bechtel P, Sathivel S. Developing a strawberry yoghurt fortified with marine fish oil. J Dairy Sci. 2011;94:5760–5769. doi: 10.3168/jds.2011-4226. [DOI] [PubMed] [Google Scholar]

- FDA (2010) 21 CFR Part 101, Food labeling; health claim; phytosterols and risk of coronary heart disease; proposed rule. http://www.gpo.gov/fdsys/pkg/FR-2010-12-08/pdf/2010-30386.pdf. Accessed 8 Dec 2010

- FDA (2015) Specific requirements for health claims, 21CFR101.77. CFR—Code of Federal Regulations Title 21, vol 2. http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=101.77. Accessed 1 April 2015

- Fletouris DJ, Botsoglou NA, Psomas IE, Mantis AI. Rapid determination of cholesterol in milk and milk products by direct saponification and capillary gas chromatography. J Dairy Sci. 1998;81:2833–2840. doi: 10.3168/jds.S0022-0302(98)75842-4. [DOI] [PubMed] [Google Scholar]

- Foda MI, Abd El-Aziz M, Awad AA. Chemical, rheological and sensory evaluation of yoghurt supplemented with turmeric. Int J Dairy Sci. 2007;2:252–259. doi: 10.3923/ijds.2007.252.259. [DOI] [Google Scholar]

- Fogliano V, Vitaglione P. Functional foods: planning and development. Mol Nutr Food Res. 2005;49:256–262. doi: 10.1002/mnfr.200400067. [DOI] [PubMed] [Google Scholar]

- García-Llatas G, Rodríguez-Estrada MT. Current and new insights on phytosterol oxides in plant sterol-enriched food. Chem Phys Lipids. 2011;164:607–624. doi: 10.1016/j.chemphyslip.2011.06.005. [DOI] [PubMed] [Google Scholar]

- Gassem MA, Frank JF. Physical properties of yogurt made from milk treated with proteolytic enzymes. J Dairy Sci. 1991;74:1503–1511. doi: 10.3168/jds.S0022-0302(91)78310-0. [DOI] [Google Scholar]

- González-Larena M, Cilla A, García-Llatas G, Barberá R, Lagarda MJ. Plant sterols and antioxidant parameters in enriched beverages: storage stability. J Agric Food Chem. 2012;60:4725–4734. doi: 10.1021/jf3002679. [DOI] [PubMed] [Google Scholar]

- Goyal A, Sharma V, Sihag MK, Singh AK, Arora S, Sabikhi L. Fortification of dahi (Indian Yoghurt) with omega-3 fatty acids using microencapsulated flaxseed oil microcapsules. J Food Sci Technol. 2016;53:2422–2433. doi: 10.1007/s13197-016-2220-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hanif MS, Zahoor T, Iqbal Z, Ihsan-ul-Haq Arif AM. Effect of storage on rheological and sensory characteristics of cow and buffalo milk yogurt. Pak J Food Sci. 2012;22(2):61–70. [Google Scholar]

- Hossain MN, Fakruddin M, Islam MN. Development of fruit dahi (yoghurt) fortified with strawberry, orange and grape juice. Am J Food Technol. 2012;7:562–570. doi: 10.3923/ajft.2012.562.570. [DOI] [Google Scholar]

- ICMR (2010) Nutrient requirements and recommended dietary allowances for Indians. A report of the expert group of the Indian Council of Medical Research 2009. http://icmr.nic.in/final/RDA-2010.pdf. Accessed 20 Jan 2014

- Izadi Z, Nasirpour A, Garoosi GA, Tamjidi F. Rheological and physical properties of yogurt enriched with phytosterol during storage. J Food Sci Technol. 2015;52(8):5341–5346. doi: 10.1007/s13197-014-1593-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lee SK, Klostermeyer H, Schrader K, Buchheim W. Rheological properties and microstructure of model processed cheese containing low molecular weight emulsifiers. Nahrung. 1996;40(4):189–194. doi: 10.1002/food.19960400406. [DOI] [Google Scholar]

- Liutkevicius A, Narkevicius R, Speicienė V, Zaborskiene G, Sekmokiene D, Abaravicius A, Kucinskiene Z. Study of milk and whey beverages with flaxseed oil. Food Chem Technol. 2007;41:29–35. [Google Scholar]

- Liutkevicius A, Speicienee V, Alencikienee G, Miezzelienee A, Zaborskienee G, Kazernaviciuutee R. Impact of polyunsaturated omega-3 fatty acids on the quality of curd and curd products. Food Chem Technol. 2010;44(1):31–40. [Google Scholar]

- Lucey JA, Singh H. Formation and physical properties of acid milk gels: a review. Food Rev Int. 1998;7:529–542. [Google Scholar]

- Makelainen HS, Makivuokko HA, Salminen SJ, Rautonen NE, Ouwehand AC. The effects of polydextrose and xylitol on microbial community and activity in a 4-stage colon simulator. J Food Sci. 2007;72:M153–M159. doi: 10.1111/j.1750-3841.2007.00350.x. [DOI] [PubMed] [Google Scholar]

- Micallef MA, Garg ML. The lipid-lowering effects of phytosterols and (n − 3) polyunsaturated fatty acids are synergistic and complementary in hyperlipidemic men and women. J Nutr. 2008;138:1086–1090. doi: 10.1093/jn/138.6.1086. [DOI] [PubMed] [Google Scholar]

- Noffsinger JB, Emery M, Hoch DJ, Dokladalova J. Liquid chromatographic determination of polydextrose in food matrixes. J Assoc Off Anal Chem. 1990;73:51–53. [PubMed] [Google Scholar]

- Park JW, Lanier TC, Pilkington DH. Cryostabilization of functional properties of pre-rigor and post-rigor beef by dextrose polymer and/or phosphates. J Food Sci. 1993;58:467–472. doi: 10.1111/j.1365-2621.1993.tb04301.x. [DOI] [Google Scholar]

- Prajapati JB, Sreeja V (2014) Dahi, related products—industry point of view update. http://www.fnbnews.com/FB-Specials/Dahi-related-products–Industry-point-of-view-update. Accessed 16 Jan 2014

- Pushkala R, Srividya N. Influence of aloe gel enrichment on the physicochemical, textural and sensory characteristics of dahi. J Food Sci Eng. 2011;1:141–153. [Google Scholar]

- Remeuf F, Mohammed S, Sodini I, Tissier JP. Preliminary observations on the effects of milk fortification and heating on microstructure and physical properties of stirred yogurt. Int Dairy J. 2003;13:773–782. doi: 10.1016/S0958-6946(03)00092-X. [DOI] [Google Scholar]

- Serra M, Trujillo AJ, Guamis B, Ferragut V. Evaluation of physical properties during storage of set and stirred yoghurts made from ultra-high pressure homogenization-treated milk. Food Hydrocoll. 2009;23:82–91. doi: 10.1016/j.foodhyd.2007.11.015. [DOI] [Google Scholar]

- Tapiero H, Nguyen G, Couvreur P, Tev KD. Polyunsaturated fatty acids and eicosanoids in human health and pathologies. Biomed Pharmacother. 2002;56:215–222. doi: 10.1016/S0753-3322(02)00193-2. [DOI] [PubMed] [Google Scholar]

- Tiihonen KK, Roytio H, Putaala H, Ouwehand AC. Polydextrose functional fibre—improving digestive health, satiety and beyond. Nutrafoods. 2011;10:23–28. doi: 10.1007/BF03223385. [DOI] [Google Scholar]

- Veena N (2014) Development and evaluation of milk fortified with omega-3 fatty acids, phytosterols and soluble dietary fibre. Ph.D. thesis submitted to National dairy Research Institute, Karnal, India

- Walstra P, Geurts TJ, Noomen A, Jellema A, Bockel MAJS. Dairy technology: principle of milk properties and processes. New York: Marcel Dekker Inc; 1999. [Google Scholar]

- Watts BM, Ylimaki GL, Jeffery LE, Elias LG. Basic sensory methods for food evaluation. Ontario: International Development Research Centre; 1989. [Google Scholar]