Abstract

Abstract

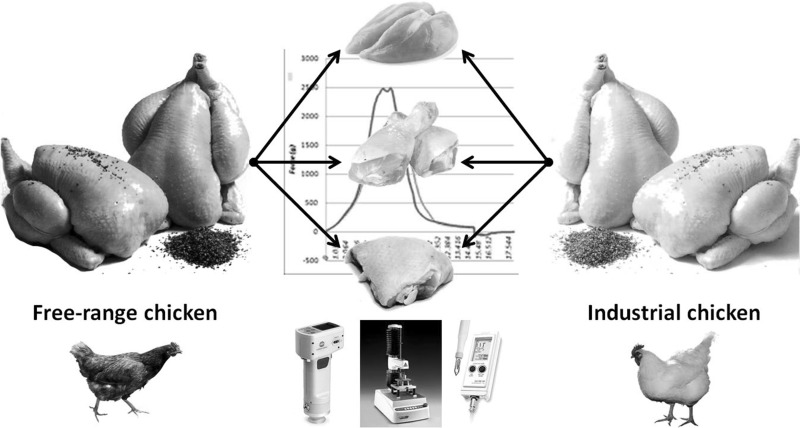

The aim of this study was to determine and compare the quality parameters of broiler chicken meat from free-range and industrial poultry system. Proximate composition, color, pH, shear force, microbial quality and sensory characteristics were evaluated. Both free-range and industrial chicken meat presented PSE (pale, soft and exudative) anomaly (L* > 53). An inverse correlation between lightness, pH and shear force was observed. The free range broiler meat had higher yellow color (b* 11.56) and shear force (2.75 kgf) and lower red color (a* 1.65) and pH (5.75) in comparison to the industrial broiler meat, due intensive physical activity on growing phase and influence of the pre-slaughter stress on the rigor mortis. The thigh cut from free range broiler meat showed higher protein levels (18.00%), while to the thigh and drumstick cuts of industrial broiler meat showed higher total fat levels (3.4 and 5.0%, respectively). In general, each strain and chickens producing methods gave the peculiar characteristics to meat (chemical, physical, microbiological and sensorial).

Graphical Abstract

Keywords: Meat quality, Proximate analysis, Physical parameter, Sensory aspects, Microbiological factors

Introduction

The competition between large companies and the intensive broiler chickens production has contributed to the development of new trends in chicken meat consumption through a strong demand for meat from production systems which ensure food security (Zanusso and Dionello 2003), and animal welfare combined with environmental responsibility, consumer health and sensory quality (Madeira et al. 2010), constituting a market trend that adds value to carcasses and opens new horizons for chicken differentiated (peculiar) meat products (Fanatico et al. 2007). Free-range chicken production is one of the most promising segments of the poultry sector where production takes place with slow-growing strains, and the chicken meat present different sensory characteristics from that raised in confinement, displaying darker, firmer, and sharply flavored meat (Takahashi et al. 2006). Its production aims to attend a market niche constituted of more demanding consumers with greater purchasing appeal (Zanusso and Dionello 2003).

Nutritionally, chicken meat is a source of protein with high biological value, especially compared to vegetable proteins and their micronutrients content, such as vitamin A, thiamine, iron, phosphorus and nicotinic acid (Koblitz 2011). In addition, the low energy value places chicken meat as a healthy food, indicated for use in healthy diets due to its reduced fat content, as well as a higher proportion of polyunsaturated fatty acids (PUFA), when compared to other species meats (Riovanto et al. 2012), factors that make the chicken meat production and consumption popular worldwide. In this sense, the homogeneity of meat quality becomes a major concern for the chicken market and for consumer acceptance (Le Bihan-Duval et al. 2008). Compliment with all quality specifications is, undoubtedly, the main challenge for the meat industry today. On the other hand, monitor intrinsic quality patterns (physical and chemical) is important (Li et al. 2016), as well as the microbiological and sensorial quality of this meat, whether to be able to observe the incidence of anomalies, or to better satisfy the consumers’ preference, therefore creating an instrument of quality assurance (Koblitz 2011). Hence, considering the demand for poultry consumers has grown in recent years and the limited number of scientific studies that emphasize qualitative features of free-range chicken meat, it is relevant and appropriate to conduct a study in order to determine, microbiological and sensory characteristics of free-range chicken meat comparing to the industrial (conventional) system.

Materials and methods

Meat samples

Forty-eight (48) refrigerated (4 ± 1 °C) whole carcasses of male chickens, 24 from free-range and 24 from the industrial (conventional) system were used to perform the comparison of chemical (proximate), physical, microbiological and sensorial analyses. The industrial broilers chicken (Cobb and Ross strain) were purchased at a local market, and aleatory free-range broilers chicken (Gigante Negro, Isa Label, and Paraíso Pedrês or Label Rouge strains) were purchased from a local chicken farm, being acquired at the age of slaughter by the producer. Chicken samples were acquired up to a maximum of 3 days after slaughter and taken to the laboratory properly packed in cool boxes with ice. Breast, thigh, and drumstick samples were taken from the refrigerated chicken carcasses, deboned, skinned and superficial fat removed. Subsequently, were ground and homogenized for the determination of chemical characteristics. The breast samples were used for physical, microbiological and sensory analyses.

Proximate composition analysis

The proximate composition analysis was evaluated using the AOAC Analytical Methods (AOAC 2006a, b, c, d) as follows: Moisture (Method 950.46), Protein (Method 992.15), Total fat (Method 960.39), and Ash Determination (Method 942.05). The carbohydrate percentage was calculated by the difference between the other fractions analyzed. The total caloric value was calculated accordingly to the methodology used by Pedroza and Cozzolino (2001): the corresponding caloric coefficients of 4, 9 and 4 kcal g−1 to proteins, total fat, and carbohydrates, respectively. All analyses were carried out in triplicate.

Physical analysis

The pH analysis was carried out with a penetration electrode at three different points of the chicken muscle using a portable meat pH Meter (HANNA HI99163). Color determinations were performed with a colorimeter (Minolta Chroma Meter CR400) programmed with CIE Lab* system. Readings were made at four different points on the inner surface of the chicken’s left breast muscle. The shear force (SF) was evaluated using cooked samples (cooking in a water bath until reaching an internal temperature of 82 °C). After cooking, the samples were cooled to room temperature and stored at 2 ± 1 °C for 24 h. Afterward, parallelepiped shaped cuts 2.0 × 1.0 × 1.0 cm were made and analyzed in the texture meter (TA.XT Plus Texture Analyzer), coupled with Warner–Bratzler accessory. Samples with fibers perpendicularly oriented to the blade were sheared to measure the shear force at a rate of 20 cm min−1 with a load of 100 kg (Froning and Uijttenboogaart 1988).

Microbiological analysis

Shortly after sampling, the cooled carcasses were taken to the laboratory in order to determine the microbiological quality. The analyses of the total count of mesophilic aerobes, the thermotolerant coliforms, and the presence of Salmonella sp. were performed following the official methodology (Brazil 2003).

Sensory analysis

Sensory analysis was conducted through the difference from the control test described by Dutcosky (2007). Chicken samples were prepared with 0.25% salt (based on the weight of the raw samples) in an industrial oven (180 °C for 30 min) until the internal temperature reached 82 °C. After cooking, samples were cut into relatively uniform portions and kept in a thermal counter until they were served. The test was applied with 30 (thirty) untrained randomly selected panelists. Three samples were presented to the panelist: one called C (control) and two encoded, one of these being equal to the control. The panelists were asked to compare each sample to the control on the following sensory attributes (color, odor, flavor, texture, juiciness, and overall impression) according to the rating scale: 1—Extremely better than control, 2—Much better than control, 3—Regularly better than control, 4—Slightly better than control, 5—No difference from control, 6—Slightly worse than control, 7—Regularly worse than control, 8—Much worse than control, 9—Extremely worse than control. The samples were placed in disposable plastic plates with a glass of water to rinse the mouth.

Statistical analysis

An analysis of variance (ANOVA) was performed for the statistical examination of the data from physical, chemical and microbiological analysis, using the minimum squares method, and the F-test at 5% probability (p < 0.05) was used to compare the means of each area between the treatments. For the sensory analysis data, analysis of variance and Dunnet test was used, comparing the control sample to the others, in order to estimate the degree of difference between them at a significance level of 5%.

Results and discussion

Proximate composition analysis

In general, the proximate composition of the carcass will depend on their genetic makeup, age, diet, and management, as well as environmental conditions (Baracho et al. 2006; Koblitz 2011). In addition, differences in physical and chemical characteristics are related to the chickens’ sexual maturity, growth potential, muscle development, and lineage, besides age at the moment of slaughter and sex (Faria et al. 2009). The proximate composition analysis of the breast, thigh and drumstick proved there was statistical difference (p > 0.05) between the chickens when it came to the protein content of the thighs (15.7 and 18%), and total fat content of the thigh (3, 4 and 2.2%) and the drumstick (5.0 and 3.0%) and caloric value of the drumstick (121.9 and 103.7%) for industrial and free-range broilers, respectively. The results of the proximate composition analysis are displayed in Table 1.

Table 1.

Proximate composition for the breast, thigh, and drumstick of industrial and free-range broilers chicken (mean ± SD, n = 3)

| Analysis | Breast | Thigh | Drumstick | |||

|---|---|---|---|---|---|---|

| Industrial | Free-range | Industrial | Free-range | Industrial | Free-range | |

| Moisture (g.100 g−1) | 76.3 ± 0.79a | 75.7 ± 0.96a | 76.8 ± 1.09a | 76.3 ± 0.94a | 74.4 ± 1.16b | 76.7 ± 0.95a |

| Ash (g.100 g−1) | 1.0 ± 0.09a | 1.0 ± 0.09a | 0.9 ± 0.15a | 0.9 ± 0.11a | 0.9 ± 0.10a | 0.9 ± 0.13a |

| Protein (g.100 g−1) | 19.9 ± 1.95a | 20.1 ± 2.40a | 15.7 ± 2.45b | 18.0 ± 1.29a | 16.9 ± 2.03a | 16.9 ± 1.12a |

| Lipids (g.100 g−1) | 1.3 ± 0.28a | 0.92 ± 0.44a | 3.4 ± 0.75a | 2.2 ± 0.94b | 5.0 ± 1.16a | 3.0 ± 1.14b |

| Carbohydrate (g.100 g−1) | 1.5 ± 0.62a | 3.18 ± 0.78b | 3.20 ± 0.89a | 2.60 ± 0.66a | 2.80 ± 0.89a | 2.50 ± 0.66a |

| Caloric value (kcal/100 g) | 97.4 ± 3.98 | 98.3 ± 3.64 | 102.3 ± 16.08 | 101.5 ± 6.84 | 121.9 ± 12.63a | 103.7 ± 8.50b |

| Pr > F | 0.1040 | 0.3685 | <0.0001 | |||

| Pr > F | 0.3925 | 0.4501 | 0.9913 | |||

| Pr > F | 0.9994 | <0.0001 | 1.0000 | |||

| Pr > F | 0.6993 | <0.0001 | <0.0001 | |||

| Pr > F | 0.9995 | 0.9993 | <0.0001 | |||

Means followed by different letters in the same column differ by the F-test (p ≤ 0.05)

The highest mean for the ash content was observed for the industrial broiler’s breast, whereas thighs and drumsticks had equal means. Free-range broiler chickens had higher protein content (p > 0.05) for breast and thigh, and statistically equal for the drumstick. Altogether the kinds of meat cut had superior amounts of total fat in industrial broiler chicken meat rather than in free-range chickens, as well as the caloric value, except for the chicken breast whose mean was inferior, despite no statistical difference (p > 0.05).

Abeni and Bergoglio (2001) found values lower for moisture (74.81–75.5%) and higher for total fat (1.85–2.58%) in breast meat of three commercial strains. Lichovníková et al. (2009) compared the meat quality of two strains, one fast and another of slow-growing at 49 and 90 days of slaughter, and observed a greater fat percentage (p > 0.05) in the fast-growing chickens and lower moisture content as the chickens aged. Faria et al. (2009) paralleled two free-range chicken strains and verified a greater fat deposition as age advanced (65–95 days) from 0.44 to 0.61% and 0.76 to 0.87% (breast) and from 1.90 to 2.74%, and 2.32 to 2.39% (thigh) for Pescoço Pelado and Paraíso Pedrês, respectively. Breast and thigh’s moisture decreased with the chickens’ age from 74.22 to 73.28% (breast), 75.80 to 75.70%, and 76.38 to 75.93% (thigh) for Pescoço Pelado and Paraíso Pedrês, in that order. The moisture behavior in males Paradise Pedrês breasts increased discreetly with age (73.39% at day 65–73.40% at day 95), similar to what was observed in the drumstick, whose moisture was higher in free-range chickens when compared to industrial chicken. Generally, taking into consideration the advanced age at slaughter, the meat undergoes a reduction in moisture and increase fat content (Fanatico et al. 2005). Results found for moisture of the breast and thigh of the compared strains, corroborate this information.

According to Bogosavljevic-Boskovic et al. (2010), “Label” broilers present 10% more muscular development, in addition to the reduction in intramuscular total fat content, resulting in structural differences in the chickens’ tissues and organs, as well as the biochemical processes involved in metabolism. In their study, these authors evaluated two breeding systems (“extensive indoor” and “free-range”), and observed the breeding system’s effect on the protein and total fat content of the breast (white fibers) and the legs (dark fibers), discovering higher levels of protein and lower levels of total fat in chickens bred with access to paddocks, without significant influence on dry matter content and ash.

Fanatico et al. (2005) noted the limited impact of genotype and production system on the dry matter (moisture), ash, and fat. In this study, fast-growing chickens with access to a paddock presented lower moisture content (p > 0.05) when compared to the genotype that had access to outdoors, without statistical difference between ash and fat content. The data referred to protein between the two strains did not differ except for the thigh where the values were statistically different (15.7 and 18% for industrial and free-range broilers chicken, respectively). Faria et al. (2009) came across similar values for the Pescoço Pelado (19.48%) and Paraíso Pedrês (19.01%) strains, relative to the chickens’ thigh. Greater protein content in free-range broiler chicken meat may be related to a reduction in the fat content of these chickens, which would elevate the protein content of their muscles.

Significant differences (p < 0.05) for moisture and protein were observed in an experiment that related color to chicken breast composition, from three commercial plants, without, however, finding any statistical difference in total fat and ash. The differences were significant in the commercial chicken composition which may indicate genetic predisposition or because by antemortem factors (e.g., management, the chickens’ diet, etc.), which in turn would also influence the meat’s color (Qiao et al. 2002).

Physical analysis

The color analysis of the chickens’ breast revealed significant difference (p < 0.0001) between the colors parameters a* (redness) and b* (yellowness)—scores for industrial and the free-range broilers chickens, respectively—whilst for L* (lightness), no difference was observed, as shown in Table 2.

Table 2.

Color parameters (L*, a*and b*), pH and shear force (SF) of industrial and free-range broilers chicken breasts (mean ± SD, n = 3)

| Chicken breasts | N | Color | pH | SF (kgf) | ||

|---|---|---|---|---|---|---|

| L* | a* | b* | ||||

| Industrial | 12 | 53.59 ± 3.08a | 3.05 ± 1.44a | 4.97 ± 2.33b | 5.90 ± 0.16a | 2.52 ± 0.82b |

| Free-range | 12 | 53.89 ± 3.87a | 1.65 ± 0.49b | 11.56 ± 3.38a | 5.75 ± 0.11b | 2.95 ± 0.99a |

| r > F | 0.6818 | <0.0001 | <0.0001 | <0.0001 | 0.0025 | |

Means followed by different letters in the same column differ by the F-test (p ≤ 0.05)

The L* scores were above 53, i.e., the color was lighter than usual, indicating that the meat may have quality problems, characterized as PSE (pale, soft and exudative) (Koblitz 2011), more specifically due to inadequate antemortem management, such as pre-slaughter factors, stunning methods and cooling regimes (Karunanayaka et al. 2016). This phenomenon may be due to the denaturation of myofibrillar proteins caused by quick post-mortem glycolysis that caused a decrease in the meat pH while it was still warm, a growing problem and concern in the meat industry (Kato et al. 2013). As a result, lower water retention capacity and pH changes compromise the quality of processed meat products, causing damage to their sensory properties, such as reduced succulence and low emulsification capacity (Garcia et al. 2010).

The a* scores for the industrial broiler chicken was higher than that of the free-range, unlike b* which were lower indicating that the free-range chicken meat had the highest intensity of yellow color, this could be clearly observed regardless of the measure of the colorimeter, meanwhile, industrial broiler’s meat had higher red intensity. Faria et al. (2009) stated that the ingestion of larger amount of forage rich in carotenoids by slow-growing chickens provides a greater intensity of yellow color in the meat, resulting in higher b* value.

Pale, soft and exudative (PSE) meats of industrial broilers chicken were observed by Qiao et al. (2002) while analyzing chicken breasts’ meat of three commercial groups. They observed the anomaly in samples with no statistical difference values of L* (61.49, 61.60 and 61.66), and extreme values of a* (3.63, 4.10 and 4.52) and b* (8.78, 9.23 and 9.87), with a significant difference. Although there was a strong evidence of the influence of short-term antemortem stress on meat color, the author explained that the variations could happen due to a possible genetic predisposition or to other factors, in the long term, associated with the breeding of these chickens.

Fanatico et al. (2005) evaluated the influence of different genotypes on the meat quality of slow-growing chickens with or without access to the paddock and noted that the chicken’s breeding system and genotype had a strong impact on the color. In this study, all chickens presented lightness values within the patterns of normality. Faria et al. (2009) also evaluated the color of the meat from two free-range chicken lines, and found normal values of L*(47.13 and 47.51), a*(4.72 and 5.34) and b* (6.29 and 5.23) all without any statistical difference between the free-range Pescoço Pelado and Paraíso Pedrês strains, respectively.

The scientific literature indicates a negative correlation between L* values and pH, and the reduction of lightness as age increases is usually related to a rise in pH values. The results of this study confirm this association, as pH values presented significant difference (p < 0.05) among the chickens with lower means for free-range broiler chicken (5.75) when compared to industrial broiler chicken (5.90) (Table 2).

According to Bogosavljevic-Boskovic et al. (2010), chickens raised with access to the paddock have reduced stress because of the animal’s comfort and welfare; further, their meat has better flavor and aroma when compared to the meat from the conventional breeding system. In the present study free-range chickens, although bred with more freedom, presented lower average pH value lower, indicating a higher post-mortem meat acidification, possibly related to the stress experienced prior to slaughter. The post-mortem pH decline strongly affecting the quality of meat was reported by Debut et al. (2003). The author compared the meat quality of two strains (with fast and slow growth) submitted to different conditions before slaughter and observed the significant effects of these conditions on meat characteristics and some interactions with the genotype, whose effects were greater in the thigh than in the breast. According to this author, the pH decline rate (initial and final) has determined variations in the meat quality, noting that the more acidic it presented, i.e., the lower the pH was, the paler the meat became (higher value of L*), this data agrees with the results of this study.

Qiao et al. (2001) detected an increase in all L*, a* and b* scores (55.95, 3.42 and 5.56, respectively) compared to normal meat, data that resembled to those established in this study (except for the a* and b*scores of the free-range broiler chicken lineage), indicating strong negative correlation with low pH values. Le Bihan-Duval et al. (2008) measured L* (54.9), a* (0.8), and b* (11.8) values, and reported that pH decrease was influenced by the chickens’ behavior during slaughtering, especially the wings movement, highlighting that the literature related to the influence of genetics factors on such behavioral characteristics and the implications of it on meat quality was scarce. This author established the final pH value of 5.64 for chickens of commercial lines affirming that it was a relevant selection criterion on determining the meat’s quality due to being strongly associated with color, water-holding capacity, and texture.

Faria et al. (2009) observed values of 5.90 and 5.82 for the Pescoço Pelado and the Paraíso Pardês strains, respectively. Possibly the selection of chickens with fast growth determines chickens breasts with white fibers of a bigger diameter, which present glycolytic activity and have lower glycogen reserves before slaughter, resulting in differences in pH decline and pH final value between fast- and slow-growing chicken strains. Lichovníková et al. (2009) obtained lower final pH values (p < 0.05) in fast-growing chickens at the 49th and 90th day of slaughter, contrasting with the results attained in this study, attributing the effect of the chickens’ genotype to this, regardless of age.

The meat tenderness was analyzed through the determination of the shear force and displayed a significant difference (p < 0.05) between the chickens (Table 2). Free-range broiler’s meat presented higher value (2.95 kgf cm−2), which indicated it was less tender than the industrial broiler’s meat (2.52 kgf cm−2), these results agree with the data encountered by Fanatico et al. (2005). Contreras-Castillo et al. (2007) affirm shear force has a significant inverse correlation with pH, i.e., low pH meat is less tender; this correlation is confirmed in the present study. The low tenderness presented by the free-range broilers meat, observed in the present experiment, may be attributed to a greater amount of exercise performed by the chickens during pasture (Santos et al. 2005), this would entail an increase in the myofibrils diameter, area and density on the chickens’ breast muscles (Pectoralis muscle), other than that, the elder age at slaughter is strongly correlated to shear force increasing its value significantly (Chen et al. 2007). According to Ramos and Gomide (2009), the meat of younger animals tends to be tenderer, this characteristic decreases with age, because of the accumulation and, especially, the maturation of the connective tissue in the muscle fibers.

Coelho et al. (2007) evaluated the shear force of eight free-range chickens genotypes and observed differences between the genotypes, their study observed higher values than those of present study for Caipirão (3.07 kgf cm−2), Pinto Preto Pesado de Pasto de Pescoço Pelado from Piracicaba—7P (3.30 kgf cm−2), Paraíso Pedrês (3.16 kgf cm−2), Label Rouge (3.19 kgf cm−2), Caipirinha (3.58 kg cm−2), Paraíso Pelado (3.37 kgf cm−2), and Carijó Barbado (3.45 kgf cm−2) strains, all with no statistical difference from control (4.02 kgf cm−2), except for the Caipirão and Embrapa 041 types, which presented means of 3.07 and 2.67 kgf cm−2, as the author interprets, these results could be related to the chickens’ muscular physiology, because the glycolytic metabolism of the pectoral muscle would reduce the effects of the difference between the conventional and the free-range breeding systems.

Microbiological analysis

Microbiological analysis (Table 3) showed that all samples were within the satisfactory standard demanded by the Brazilian legislation, which establishes the maximum limit of 104 (or 4 log) thermotolerant coliforms g−1 of food (Brazil 2001). The presence of coliform bacteria in food is considered a useful indication of post-sanitizing contamination, representing poor hygiene during the processing and storage of food (Franco and Landgraf 2002). Although there is not a standard amount of aerobic mesophilic bacteria in chicken carcasses, the mesophilic count presented a higher level of contamination in free-range broiler chickens, even though without statistical difference (p > 0.05). The high scores of this bacterial group in perishable foods such as chicken are indicative of poor processing during the production chain. Most foods present levels higher than 106 CFU g−1(or log 6) when alterations are detectable, which will vary depending on the types of food and microorganisms present (Franco and Landgraf 2002).

Table 3.

Thermotolerant coliforms and mesophilic bacteria count in free-range and industrial broiler chicken samples (Mean ± SD, n = 3)

| Chicken | N | Thermotolerant coliforms | Mesophilic bacteria |

|---|---|---|---|

| log MPN g−1 | log CFU g−1 | ||

| Industrial | 12 | 2.45 ± 0.86a | 5.12 ± 0.35a |

| Free-range | 12 | 2.75 ± 0.43a | 5.31 ± 0.20a |

| Pr > F | 0.3364 | 0.1408 |

Means followed by different letters in the same column differ by the F-test (p ≤ 0.05). MPN Most probable number, CFU Colony-forming unit

Processed chicken carcasses and raw chicken products often get contaminated with important pathogenic microorganisms related to public health. These are usually associated with muscle hemorrhages and pH which favored the multiplication of microorganisms, as well as the cross contamination that may occurred because of the carcasses exposure to fecal matter and pathogens (Baracho et al. 2006).

A higher incidence of Salmonella was more prevalent in free-range broiler chicken (50%) when compared to the industrial broiler chicken (25%). This data was reached by Bailey and Cosby (2005), who detected this microorganism in 31% of free-range chicken carcasses. These authors consider that chickens bred on the free-range system, are more susceptible to contamination by Salmonella, for they had access to a pasture area being exposed to wild chickens, insects, rodent feces and other potential Salmonella vehicles.

Overall, industrial broilers chicken presented better microbiological quality, less contamination by thermotolerant coliforms and mesophilic bacteria, and a lower percentage of Salmonella occurrences (Table 3).

Sensory analysis

The multiple comparison tests of chicken samples were conducted with 30 tasters, mostly males (66.7%), aged 21–30 years (53.3%), graduate students (83.3%). All claimed to be chicken consumers. The mean values of sensory acceptability for color, odor, flavor, texture, juiciness and overall impression of the industrial and free-range broiler chicken are shown in Table 4. The color was the only sensorial attribute that revealed a significant difference (p < 0.05) among the chickens. The sensory acceptance of color, as well as for odor, texture, juiciness and overall impression, were between the hedonic terms “Slightly better” and “No difference from control” for the industrial, and “No difference of control” and “Slightly worse than control” for the free-range broiler. As for the flavor, the sensory acceptance of the two chicken types was among the terms “Slightly better” and “No difference from the control”.

Table 4.

Mean scores for the sensory acceptability of the chicken samples (Mean ± SD, n = 30)

| Chicken | n | Color | Odor | Flavor | Texture | Juiciness | Overall impression |

|---|---|---|---|---|---|---|---|

| Industrial | 30 | 4.07 ± 0.75b | 4.30 ± 1.01a | 4.40 ± 1.12a | 4.36 ± 0.81a | 4.83 ± 0.90a | 4.40 ± 1.18a |

| Free-range | 30 | 5.47 ± 0.87a | 5.03 ± 0.72a | 4.60 ± 1.23a | 5.13 ± 1.02a | 4.63 ± 1.29a | 4.97 ± 1.24a |

Means followed by different letters in the same column differ by the Dunnet test (p ≤ 0.05)

Coelho et al. (2007) utilized the same instrument as this study to perform a sensorial evaluation on free-range chicken samples and noted that some free-range genotypes analyzed for tenderness and flavor were distinguished by consumers, having average scores ranging from 3.33 to 4.56 (tenderness) and 3.31 to 4.00 (flavor), i.e., from “Slightly worse” to “No difference from control”, meanwhile the control means were 4.75 and 4.32 for tenderness and flavor, respectively, and the samples were classified as “Slightly better” and “No difference from control”. In summary, these attributes presented themselves “Slightly worse” when compared to industrial broilers meat.

Lichovníková et al. (2009) observed significant difference in color of chickens with different genotypes with or without access to paddocks, as for the texture the difference was observed at the 49th day, for flavor and overall acceptance at the 90th day, with better ratings for the slow-growing chickens.

Garcia et al. (2010) did not identify significant differences amongst steaks for taste, preference or general appearance, for chicken breast fillets (with PSE and normal). The results presented in Table 4 corroborates with this study except for color.

Trained panelists are normally used to assess attributes such as flavor and tenderness, seen as they can detect minor differences whereas the untrained might not always identify changes between different samples (Coelho et al. 2007), this situation was observed in this study and supported by Jahan et al. (2005) who evaluated the sensory quality of chicken breast through the descriptive free profile test, and noted that the free-range chickens were not significantly differentiated from the conventional system chickens on the appearance, aroma, flavor and texture attributes. In the present study, despite the occurrence of the PSE phenomenon and its consequences (a type of anomaly), the panelists did not observe differences in terms of odor, taste, texture, juiciness and general impression. Nevertheless, the incidence of PSE meat found in the present study may cause losses to the processing industry due to its low water retention capacity.

Conclusion

The free-range chicken meat showed peculiar meat characteristics (chemical, physical, microbiological and sensorial) in comparison to meat from industrially reared chicken. PSE anomaly in both chickens was observed by the color analysis. Cultural factors may determine the preference by the consumer. The parameters that affect meat quality are complex and may occur throughout the production chain. The understanding of all critical points combined with technologies may reduce risk factors throughout the production chain and can lead to better control and management, reducing losses and improving quality of meat.

Contributor Information

Débora Cristina Fernandes da Silva, Phone: +55 84 33178208, Email: deboracristina@ufersa.edu.br.

Alex Martins Varela de Arruda, Phone: +55 84 33178208, Email: alexmva@ufersa.edu.br.

Alex Augusto Gonçalves, Phone: +55 84 33178208, Email: alaugo@gmail.com.

References

- Abeni F, Bergoglio G. Characterization of different strains of broiler chicken by carcass measurements, chemical and physical parameters and NIRS on breast muscle. Meat Sci. 2001 doi: 10.1016/s0309-1740(00)00084-x. [DOI] [PubMed] [Google Scholar]

- AOAC Authors (2006) Official methods of analysis proximate analysis and calculations total fat meat—item 25. Association of Analytical Communities, Gaithersburg, MD, 17th edn. Reference data: method 960.39 (39.1.05); NFNAP; LIPD; FA

- AOAC Authors (2006) Official methods of analysis proximate analysis and calculations ash determination (Ash)—item 51. Association of Analytical Communities, Gaithersburg, MD, 17th edn. Reference data: method 942.05; MIN; ASH

- AOAC Authors (2006) Official methods of analysis proximate analysis and calculations crude protein meat and meat products including pet foods—item 80. Association of Analytical Communities, Gaithersburg, MD, 17th edn. Reference data: method 992.15 (39.1.16); NFNAP; NITR; NT

- AOAC Authors (2006) Official methods of analysis proximate analysis and calculations moisture (M) meat—item 108. Association of Analytical Communities, Gaithersburg, MD, 17th edn. Reference data: method 950.46 (39.1.02); NFNAP; WATER

- Bailey JS, Cosby DE. Salmonella prevalence in free-range and certified organic chickens. J Food Prot. 2005;68:2451–2453. doi: 10.4315/0362-028X-68.11.2451. [DOI] [PubMed] [Google Scholar]

- Baracho MS, Camargo GA, Lima AMC, Mentem JF, Moura DJ, Moreira J, Naas IA. Variables impacting poultry meat quality from production to pre-slaughter: a review. Braz J Poult Sci. 2006 [Google Scholar]

- Bogosavljevic-Boskovic S, Mitrovic S, Djokovic R, Doskovic V, Djermanovic V. Chemical composition of chicken meat produced in extensive indoor and free-range rearing systems. Afr J Biotechnol. 2010 [Google Scholar]

- Brazil (2001) Ministério da Saúde, Agência Nacional de Vigilância Sanitária (ANVISA). Regulamento técnico sobre padrões microbiológicos para alimentos (Technical regulation on microbiological standards for food). RDC n. 12 de janeiro de 2001. http://www.anvisa.gov.br/legis/resol/12_01rdc.htm

- Brazil (2003) Ministério da Agricultura, do Abastecimento e da Reforma Agrária (MAPA). Métodos analíticos oficiais para análises microbiológicas para o controle de produtos de origem animal e água (Official analytical methods for microbiological analyzes for the animal products and water control). Instrução Normativa 62, de 26 de agosto de 2003. http://extranet.agriculture.gov.br/sislegis

- Chen XD, Ma QG, Tang MY, Li C. Development of breast muscle and meat quality in Arbor Acres broilers, Jingxing 100 crossbred chickens and Beijing fatty chickens. Meat Sci. 2007 doi: 10.1016/j.meatsci.2007.03.008. [DOI] [PubMed] [Google Scholar]

- Coelho AAD, Savino AJM, Rosário MF, Silva MAN, Contreras-Catillo AJ, Spoto AHF. Características da Carcaça e da Carne de Genótipos de Frangos Caipiras—nota prévia (Characteristics of the carcassg and the meat of “Caipiras” Chicken genotype—previous note) Braz J Food Technol. 2007;10:9–15. [Google Scholar]

- Contreras-Castillo C, Pinto AA, Souza GL, Beraquet NJ, Aguiar AP, Cipolli KMVAB, Mendes CMI, Ortega EM. Effect of feed withdrawal periods on carcass yield and breast meat quality of chickens reared using an alternative system. Poult Sci. 2007 [Google Scholar]

- Debut M, Berri C, Baéza E, Sellier N, Arnould C, Guémené D, Jehl N, Boutten B, Jego Y, Beaumont C, Le Bihan-Duval E. Variation of chicken technological meat quality in relation to genotype and pre-slaughter stress conditions. Poult Sci. 2003 doi: 10.1093/ps/82.12.1829. [DOI] [PubMed] [Google Scholar]

- Dutcosky SD. Análise sensorial de alimentos (Food sensory analysis) 2. Curitiba: Champagnat; 2007. p. 239. [Google Scholar]

- Fanatico AC, Cavitt LC, Pillai PB, Emmert JL, Owens CM. Evaluation of slowing growing broiler genotypes grown with and without access: meat quality. Poult Sci. 2005;84:1785–1790. doi: 10.1093/ps/84.11.1785. [DOI] [PubMed] [Google Scholar]

- Fanatico AC, Pillai PB, Emmert JL, Gbur EE, Meullenet JF, Owens CM. Sensory attributes of slow- and fast-growing chicken genotypes raised indoors or with outdoor access. Poult Sci. 2007 doi: 10.3382/ps.2007-00092. [DOI] [PubMed] [Google Scholar]

- Faria PB, Bressan MC, Souza XR, Rodrigues EC, Cardoso GP, Gama LT. Composição proximal e qualidade da carne de frangos das linhagens Paraíso Pedrês e Pescoço Pelado (Proximal composition and meat quality of broilers of “Paraíso Pedrês” and “Pescoço Pelado”) Revis Bras Zootec. 2009 [Google Scholar]

- Franco BDGM, Landgraf M. Microbiologia dos alimentos (Food microbiology) São Paulo: Atheneu; 2002. p. 182. [Google Scholar]

- Froning GH, Uijttenboogaart TG. Effect of postmortem electrical stimulation on color, texture, pH and cooking losses of hot and cold-deboned chicken broiler breast meat. Poult Sci. 1988 [Google Scholar]

- Garcia RG, Freitas LW, Schwingel AW, Farias RM, Caldara FR, Gabriel AMA, Graciano JD, Komiyama CM, Almeida Paz CL. Incidence and physical properties of PSE chicken meat in a commercial processing plant. Revis Bras Ciênc Avíc. 2010;12:233–237. doi: 10.1590/S1516-635X2010000400003. [DOI] [Google Scholar]

- Jahan K, Paterson A, Piggott JR. Sensory quality in retailed organic, free-range and corn-fed chicken breast. Food Res Int. 2005 [Google Scholar]

- Karunanayaka DS, Jayasena DD, Jo C. Prevalence of pale, soft, and exudative (PSE) condition in chicken meat used for commercial meat processing and its effect on roasted chicken breast. J Anim Sci Technol. 2016 doi: 10.1186/s40781-016-0110-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kato T, Barbosa CF, Ida EI, Soares AL, Shimokomaki M, Pedrao MR. Broiler chicken PSE (pale, soft, exudative) meat and water release during chicken carcass thawing and brazilian legislation. Braz Arch Biol Technol. 2013 [Google Scholar]

- Koblitz MGB. Matérias-primas alimentícias: composição e controle de qualidade (Raw materials for food: composition and quality control.) Rio de Janeiro (RJ, Brazil): Guanabara Koogan; 2011. p. 320. [Google Scholar]

- Le Bihan-Duval E, Debut M, Berri CM, Sellier N, Santé-Lhoutellier V, Jégo Y, Beaumont C. Chicken meat quality: genetic variability and relationship with growth and muscle characteristics. BMC Genet. 2008 doi: 10.1186/1471-2156-9-53. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Li X, Wang J, Wang C, Zhang C, Li X, Tang C, Wei X. Effect of dietary phosphorus levels on meat quality and lipid metabolism in broiler chickens. Food Chem. 2016 doi: 10.1016/j.foodchem.2016.02.133. [DOI] [PubMed] [Google Scholar]

- Lichovníková M, Jandásek J, Juzl M, Drackova E. The meat quality of layer males from free-range in comparison with fast-growing chickens. Czech J Anim. 2009;54:490–497. [Google Scholar]

- Madeira LA, Sartori JR, Araújo PC, Pizzolante CC, Saldanha ESPB, Pezzato AC. Avaliação do desempenho e do rendimento de carcaça de quatro linhagens de frangos de corte em dois sistemas de criação. (Evaluation of performance and carcass yield in four broiler chicken lineages in two system of rearing) Revis Bras Zootec. 2010 [Google Scholar]

- Pedroza LFC, Cozzolino SMF. Composição centesimal e de minerais de mariscos crus e cozidos da cidade de Natal/RN (Centesimal composition and minerals of raw and cooked shellfish from the city of Natal/RN) Ciênc Tecnol Aliment. 2001 [Google Scholar]

- Qiao M, Fletcher L, Smith DP, Northcutt JK. The effect of broiler breast meat color on pH, moisture, water-holding capacity and emulsification capacity. Poult Sci. 2001 doi: 10.1093/ps/80.5.676. [DOI] [PubMed] [Google Scholar]

- Qiao M, Fletcher L, Northcutt JK, Smith DP. The relationship between raw broiler breast meat color and composition. Poult Sci. 2002 doi: 10.1093/ps/81.3.422. [DOI] [PubMed] [Google Scholar]

- Ramos EM, Gomide LAM. Avaliação da qualidade de carnes—fundamentos e metodologias (Meat quality assessment—fundamentals and methodologies) Minas Gerais: Editora UFV; 2009. p. 599. [Google Scholar]

- Riovanto R, Marchi M, Cassandro M, Penasa M. Use of near infrared transmittance spectroscopy to predict fatty acid composition of chicken meat. Food Chem. 2012;134(4):2459–2464. doi: 10.1016/j.foodchem.2012.04.038. [DOI] [PubMed] [Google Scholar]

- Santos AL, Sakomura NK, Freitas ER, Fortes CMLS, Carrilho ENVM, Santos JBKF. Estudo do crescimento, desempenho, rendimento de carcaça e qualidade de carne de três linhagens de frango de corte (Study of growth, performance, carcass yield and meat quality of three broiler chicken strains) Revis Bras Zootec. 2005 [Google Scholar]

- Takahashi SE, Mendes AA, Saldanha ESPB, Pizzolante CC, Pelícia K, Garcia RG, Paz ICLA, Quinteiro RR. Efeito do sistema de criação sobre o desempenho e rendimento de carcaça de frangos de corte tipo colonial (Effect of the breeding system on performance and carcass yield of colonial-type broilers) Arq Bras Med Vet Zootec. 2006 [Google Scholar]

- Zanusso JT, Dionello NJL. Produção avícola alternativa—análise dos fatores qualitativos da carne de frangos de corte tipo caipira (Alternative poultry production—analysis of the qualitative factors of the meat of broiler chickens) Revis Bras Agrociênc. 2003;9:191–194. [Google Scholar]