Abstract

Partial replacement of animal fats with n-3 rich oils is a promising way to improve nutritive value of meat products. In the present work, the effects of porcine fat substitution with soybean oil (SBO) on characteristics of sausages were studied at the oil substitution levels of 25, 35, and 45% by weight of porcine fat. SBO was introduced to the sausages alternatively in native or pre-emulsified forms, the latter with fish protein isolate (FPI) or Na-caseinate (Nc) as emulsifier. Characteristics of the sausages, including cooking loss, water holding capacity, texture attributes, microstructure, and color, were then determined. The sausages added with pre-emulsified SBO stabilized by FPI showed better stability than the control (without added SBO), as indicated by lower cooking loss and higher hardness. Microstructure with better homogeneity was also evident in the sausages added with pre-emulsified SBO stabilized by FPI. However, the sausages added with pre-emulsified SBO stabilized by Nc showed poorer stability than the control, and possessed sponge-like microstructure. Generally, increased oil substitution level led to inferior stability of the product, especially in the sausages formulated with pre-emulsified SBO stabilized by Nc. The results suggested that FPI might be used in comminuted meat products with desirable effects, in the pre-emulsification, on replacement level up to 35% of porcine fat.

Keywords: Fat substitution, Fish protein isolate, Pre-emulsification, Soybean oil

Introduction

Comminuted meat products generally have high content of animal fats, which are important to the flavor and texture attributes of the products (Serdaroğlu 2006). It is recognized that animal fats with abundant saturated fatty acids and cholesterol are associated with some chronic diseases such as obesity, cardiovascular disorders, and colon cancer (Jiménez-Colmenero et al. 2001). Improving the nutritive quality of comminuted meat products by partial replacement of animal fats with vegetable oils has been studied in recent years (Delgado-Pando et al. 2010a, b; Youssef and Barbut 2009, 2010, 2011; Youssef et al. 2011; Domínguez et al. 2017). In this context, vegetable oils with high content of n-3 fatty acids, such as linseed, rapeseed, and soybean oils, are attractive due to their health promoting effects, in particular the reduced risk of cardiovascular diseases (Josquin et al. 2012). Moreover, vegetable oils contain phytochemicals, some of which are antioxidants: the replacement of animal fats with vegetable oils could improve the oxidative stability of meat products (Dzudie et al. 2005).

Fats from various sources differ in their physicochemical properties, affecting the arrangement in myofibrillar protein gel, and thereby altering the product characteristics (Youssef and Barbut 2009, 2010; Youssef et al. 2011). Pre-emulsification technique, the prior preparation of fat/oil mixture in emulsified form before introducing it to a meat product, could impart desirable characteristics to manufactured meat products (Youssef and Barbut 2011). Non-meat proteins as emulsifiers that stabilize the pre-emulsified oil can enhance the protein matrix strength, improving product stability (Jiménez-Colmenero 2007; Delgado-Pando et al. 2010b). The type of non-meat protein plays a crucial role for the properties of the product. Partial replacement of beef fat with pre-emulsified canola oil, stabilized by soy protein and whey protein, reduced the weight loss of sausages (Youssef and Barbut 2011). Nonetheless, incorporation of pre-emulsified canola and flaxseed oils, stabilized by caseinate, to replace porcine fat led to less retained texture profile of the sausages (Pelser et al. 2007).

Fish are typically low-cost resources that can provide proteins with desired functional properties. Emulsifying, fat holding, and gelling capacities of proteins isolated from various fishes such as tilapia (Rawdkuen et al. 2009), arrowtooth flounder, and herring (Sathivel et al. 2004) have been reported. However, only restricted information on utilization of fish protein isolate (FPI) in meat products is currently available. In this work, the yellow stripe trevally (Selaroides leptolepis) was selected as the source of FPI, due to the abundance and low price of this species that is also rich in several essential amino acids. Reported contents include Lys (8.45% of total amino acids, TAC), Leu (6.72% of TAC), His (5.49% of TAC), and Ile (4.31% of TAC) in yellow stripe trevally flesh (Klompong et al. 2009). Therefore, FPI from this fish species might be appropriate in nutritive meat products. The present work aimed to elucidate the characteristics of sausages as influenced by partial replacement of porcine fat with pre-emulsified SBO (preSBO) using FPI as emulsifier. For comparison, also Na-casienate (Nc), a non-meat protein widely employed in meat products, was tested as an alternative to FPI that stabilizes the preSBO.

Materials and methods

Materials

Fresh pork shoulder meat, pork back-fat, SBO, NaCl, sucrose, and monosodium glutamate were purchased from a local market (Songkhla, Thailand). SBO was used without further purification. Lyophilized caseinate from bovine milk was bought from Sigma Aldrich (St Louis, MO, USA). Sodium nitrite was a product of Ajax FineChem (Auckland, New Zealand). Sodium tripolyphosphate was procured from Aditya Birla Chemicals (Samutprakarn, Thailand). Seasoning powder was supplied by Flavor Force Co., Ltd (Bangkok, Thailand).

FPI preparation

To prepare FPI, yellow stripe trevally (Selaroides leptolepis) fish were purchased from a local market (Songkhla, Thailand), their size giving ca. 20 fish/kg, and these samples were taken to Prince of Songkla University within 1 h while kept in ice with 1:2 weight ratio of fish:ice. Preparation of FPI was with the pH-shift method as in Hultin and Kelleher (2000) except with the modifications by Rawdkuen et al. (2009). After washing, the fish meat was separated. The fish flesh was minced and mixed with cold distilled water (4 °C) at a ratio of 1:10 using a homogenizer (Ultra Turrax T25, Ika, Staufen, Germany) at 19,000 rpm for 1 min. The mixture was adjusted to pH 11.2 using 1 M NaOH and allowed to stand in a cold room for 10 min for protein extraction. After removing the insoluble materials by centrifugation at 10,000 rpm for 20 min at 4 °C (CR 22GIII high-speed refrigerated centrifuge; Hitachi, Tokyo, Japan), the supernatant was adjusted to pH 5.5, and coagulated protein was collected with a cheese-cloth. The recovered protein was neutralized, freeze dried (FTS system Flex-Dry™; SP Scientific, New York, USA), and kept at 4 °C for less than 2 months before use. The predominant protein bands of the FPI had molecular weights of ca. 35–50 kDa, suggesting they were for actin myofibrillar proteins (data not shown).

Sausage preparation

All visible fat and connective tissues were removed from porcine meat. Then, the porcine meat and fat were comminuted separately to homogeneous states, before determining their chemical compositions (AOAC 1995). The contents of protein, fat, and moisture in the meat were 24.0, 1.3, and 72.9%, whereas the back-fat had 3.1, 83.3, and 10.9% of protein, fat, and moisture, respectively. The comminuted porcine meat and fat were kept separately in polyethylene bags at −18 °C for less than 2 months. Prior to use, the frozen meat and fat were thawed overnight at 4 °C.

On the day before sausage production, preSBO was prepared by dissolving the proteins (FPI or Nc) in 10 mM phosphate buffer (pH 7) at a concentration of 4% w/v. The protein solution was then mixed with SBO using the homogenizer at 19,000 rpm for 5 min, with SBO having been added in equal amount (oil volume fraction 0.5). The emulsion was stored overnight at 4 °C before use.

The control sausages contained 30% back-fat. In the other cases studied, porcine fat was partially replaced with SBO at 25, 35, or 45% by weight of the back-fat. The SBO introduced to the sausages was alternatively native, FPI stabilized preSBO, or Nc stabilized preSBO. Protein content in the sausages was controlled to 15% for the total protein from porcine meat, back-fat, and FPI or Nc. For the formulation with preSBO adding, the protein amount present in the employed emulsifier (the protein contents of FPI and Nc were 84.7 and 97.0%, respectively) was subtracted from the added amounts of porcine meat to control total protein content of 15%. The water contents of porcine meat, back-fat, and preSBO were accounted for, and water was added to make the final water content 70%. The formulations of sausages are shown in Table 1. The additives were mixed in the added water on the day of use, dissolved and chilled to 4 °C.

Table 1.

The experimental formulations of sausages

| Sample | Oil substitution level (%) | Back-fat (g) | Meat (g) | SBO (mL) | preSBO (mL) | Added water (g) | Total (g) |

|---|---|---|---|---|---|---|---|

| Control | – | 180.1 | 312.5 | – | – | 102.6 | 607.2 |

| NSBO | 25 | 135.1 | 297.9 | 37.5 | – | 118.1 | 600.6 |

| FPI-preSBO | 292.6 | – | 75.0 | 84.5 | 599.2 | ||

| Nc-preSBO | 291.8 | – | 75.0 | 85.1 | 599.0 | ||

| NSBO | 35 | 117.0 | 300.0 | 52.5 | – | 118.6 | 600.1 |

| FPI-preSBO | 292.6 | – | 105.0 | 71.4 | 598.0 | ||

| Nc-preSBO | 291.5 | – | 105.0 | 72.2 | 597.7 | ||

| NSBO | 45 | 99.0 | 299.6 | 67.5 | – | 120.8 | 598.9 |

| FPI-preSBO | 290.0 | – | 135.0 | 60.3 | 596.3 | ||

| Nc-preSBO | 288.8 | – | 135.0 | 61.2 | 596.0 |

Control, the sausages without SBO; NSBO, the sausages with SBO in its native form; FPI-preSBO, the sausages with FPI stabilized preSBO; Nc-preSBO, the sausages with Nc stabilized preSBO

All formulations consisted of NaCl (7.5 g), sucrose (2.5 g), sodium tripolyphosphate (1 g), seasoning powder (0.5 g), and monosodium glutamate (0.4 g)

The sausages were prepared following the method of Jiménez-Colmenero et al. (2010) with slight modifications. The comminuted meat was chopped using a blender (MK-77, National, Tokyo, Japan) at a low speed for 30 s. Half of the back-fat (alternatively SBO) and the additives were added to the mixture and mixed for 1 min. Then, the rest of the back-fat (alternatively SBO) was added along with the additives, and the mixture was further chopped for 1 min. After allowing time for protein extraction (1.5 min), the mixture was finally chopped for 2 min. The temperature was controlled to below 12 °C throughout the process. The batter was stuffed in a cellulose casing (15 mm in diameter), heated at 75 ± 2 °C for 30 min, and then cooled in cold water until the core temperature of the sausages reached 25 °C.

In this work, the sausages without SBO, and the sausages with SBO in its native form, with FPI stabilized preSBO, or with Nc stabilized preSBO are referred to as Control, NSBO, FPI-preSBO, and Nc-preSBO, respectively. The sausages were placed in polyethylene bags, packed without vacuum, and stored at 4 °C for less than 2 weeks, then further analyzed. Twenty sausages (ca. 600 g of meat batter) were produced in each batch, and two replicate batches were prepared separately with each formulation.

Sausage characterization

Cooking loss The sausage sample was weighted carefully (ca. 5 g samples), placed in a polyethylene bag and heated at 80 °C for 20 min. After cooling to room temperature, the cooking loss was determined as the loss of mass from initial to the heated sample, and expressed as percentage of the initial weight (Hur et al. 2008).

Water holding capacity (WHC) The sausage sample was weighted carefully (ca. 5 g samples), placed in a plastic tube, and centrifuged at 1000 × g for 10 min at 4 °C. The WHC is expressed as the percentage of mass loss from initial to the state after centrifugation (Hur et al. 2008).

Color The color of freshly cut cross-section in each sample (about 2 cm thick pieces) was determined using a HunterLab colorimeter (ColorFlex, Hunter Associates Laboratory Inc., VA, USA) and is reported following the CIE system in terms of L* (lightness), a* (redness/greenness), and b* (yellowness/blueness).

Texture profile analysis (TPA) Five cylinder shaped samples (length 250 mm) were prepared from the middle of each sausage and subjected to TPA using a texture analyzer (TA-XT2 Stable Micro System, Surrey, UK). Each sample was compressed to 50% of its original height by a cylindrical plunger (diameter 5 mm) at 5 mm/s speed, for two cycles of compression/decompression. The texture attributes involving hardness (N; the maximum force during the first compression cycle), cohesiveness (the extension to which the sample could be deformed before rupture), chewiness (J; the work required to chew a solid sample to a steady state for swallowing), springiness (10−2 m; the height that the sample recovers after the first compression by the start of the second compression), and gumminess (N; the force needed to disintegrate a semisolid sample to a steady state for swallowing) were then identified (Bourne 1978).

Microstructure Morphology of the sausages in microscale was investigated using a scanning electron microscope (FEI Quanta 400, FEI Europe BV, Eindhoven, the Netherlands) following the method of Jiang and Xiong (2013) with a slight modification. A cubic sample (2.5 × 2.5 × 2.5 mm3) was fixed in glutaraldehyde (2%) for 24 h at 4 °C. Then, it was dehydrated in a series of ethanol solutions with the concentrations 50, 70, 80, and 90%, once in each for 10 min, and finally twice in absolute ethanol for 10 min. The samples were then subjected to a critical point dryer (Balzer model CPD 030, Liechtenstein, Switzerland) using CO2 as the transition fluid. The dried samples were sputter-coated with gold, and observed at an accelerating voltage of 15 kV.

Statistical analysis

The experiments were run in triplicate, and mean values with standard deviations are reported. Two-way analysis of variance (fat/oil incorporated form and oil substitution level) with Duncan’s multiple range test (SPSS for windows: SPSS Inc., Chicago, IL, USA) was performed for mean comparison requiring 95% confidence level for significance.

Results and discussion

Cooking loss and WHC of the sausages

Cooking loss and WHC of control, NSBO, FPI-preSBO, and Nc-preSBO at various oil substitution levels are shown in Table 2. Comparable cooking losses for the control and the NSBO were observed (P > 0.05), irrespective of the SBO levels. In a prior study replacing beef fat with canola oil also had no effect on the cooking loss of sausages with 12% protein content (Youssef et al. 2011). In this current study, introducing the SBO in pre-emulsified form affected the cooking loss, depending on the emulsifier. In comparison to the control, higher cooking losses were found for Nc-preSBO (P < 0.05), whereas significantly lower cooking losses were observed for FPI-preSBO (P < 0.05). These trends suggest that non-meat proteins crucially affect the stability of emulsified meat matrix. Partial replacement of beef fat with pre-emulsified canola oil, using whey protein isolate as emulsifier, could lower cooking loss of sausages (Youssef and Barbut 2011). Nevertheless, replacing porcine fat with pre-emulsified olive oil, stabilized by soy protein isolate, increased weight loss of the sausages (Bloukas et al. 1997).

Table 2.

Cooking loss and water holding capacity (WHC) of the sausages as affected by partial replacement of porcine fat with SBO in alternative forms at various oil substitution levels

| Sample | SBO substitution level (%) | Cooking loss (%) | WHC (%) |

|---|---|---|---|

| Control | – | 12.85 ± 0.85B | 92.10 ± 0.33A |

| NSBO | 25 | 12.47 ± 0.21Bc | 92.07 ± 0.15Ba |

| 35 | 13.87 ± 0.24Bb | 91.21 ± 0.7SBab | |

| 45 | 14.34 ± 0.51Ba | 90.2S ± 0.53Bb | |

| FPI-preSBO | 25 | 9.00 ± 0.28Cb | 91.45 ± 0.29Ba |

| 35 | 9.00 ± 0.52Cb | 90.85 ± 0.34Ba | |

| 45 | 9.99 ± 0.14Ca | 90.46 ± 1.06Bab | |

| Nc-preSBO | 25 | 16.55 ± 0.55Ac | 91.32 ± 0.30Ba |

| 35 | 19.41 ± 1.18Ab | 90.71 ± 0.53Ba | |

| 45 | 22.75 ± 0.43Aa | 90.12 ± 0.84Bab |

Control, the sausages without SBO; NSBO, the sausages with SBO in its native form; FPI-preSBO, the sausages with FPI stabilized preSBO; Ne-preSBO, the sausages with Nc stabilized preSBO

Within one column, different capital letters indicate that tire form of SBO caused a significant difference in means (P < 0.05), and different small letters indicate a significant effect of substitution level within one form of SBO (P < 0.05)

Considering effects of the substitution level, cooking loss consistently increased with oil level for the NSBO and for the Nc-preSBO (P < 0.05). Due to their physicochemical properties, the animal fats tend to provide higher viscoelasticity than the vegetable oils, so better protein gel stability is found in the products with animal fats (Wu et al. 2009). Regarding the FPI-preSBO, cooking loss increased significantly with oil substitution levels up to 45% (P < 0.05), suggesting better retention of fluid than for NSBO and Nc-preSBO. On introducing the oil in pre-emulsified form, the observed reduction in cook loss of the emulsified protein gel might stem from the ability of emulsified lipids to occupy voids in the protein gel matrix (Wu et al. 2009). Lower cooking loss of the fat-reduced meat emulsion was observed when pre-emulsified sunflower oil was added (Kim et al. 2016). However, non-meat proteins employed as emulsifiers in pre-emulsified oils can strongly affect the protein gel strength (Wu et al. 2009; Delgado-Pando et al. 2010a). The FPI on the surfaces of oil droplets might interact with proteins in the continuous phase more effectively than the Nc, giving higher stability to the FPI-preSBO. Reduced stability of sausages was reported when animal fat was replaced with pre-emulsified flaxseed oil, using Nc as emulsifier (Pelser et al. 2007).

Substitution of porcine fat by SBO led to lower WHC of the sausages (see Table 2), regardless of the incorporated SBO forms (P < 0.05). Partial replacement of animal fat with ground-nut and maize oils also lowers the WHC of beef patties (Dzudie et al. 2005). This might be related to how the protein gel immobilizes water in the matrix (Wu et al. 2009). To elucidate this effect, microstructures of the samples formulated with SBO in various forms and at various levels are discussed later.

Textural attributes of the sausages

Texture profiles of the sausages were observed and the results are shown in Table 3. Partial substitution of porcine fat with SBO affected texture of the sausages, depending on SBO form and level. The NSBO and FPI-preSBO showed higher hardness than the control (P < 0.05), which was in accordance with their lower cooking loss as shown in Table 2 (Ulu 2006). Vegetable oil droplets tended to be smaller than animal fat globules (Youssef and Barbut 2010). These small oil droplets have large specific surface area and thereby strong interactions with the protein residues in the matrix, enhancing the resistance to compression of the protein gel (Youssef et al. 2011). Increase in hardness and springiness of fat reduced meat emulsion was found, when pre-emulsified sunflower oil was incorporated to the product (Kim et al. 2016). Hardness of sausages was reported to increase when beef fat was partially replaced with Nc stabilized pre-emulsified olive oil (Youssef et al. 2011). However, reduced hardness of Nc-preSBO relative to the control (P < 0.05) was observed in the present study. Bishop et al. (1993) reported a reduction in the hardness of bologna, when Nc based pre-emulsified corn oil was incorporated to the samples. This tendency is corroborated by the study of Pelser et al. (2007) reporting a less retained texture of the sausages, when porcine fat was partially replaced by Nc stabilized pre-emulsified flaxseed oil. Possibly this was due to the low gelling ability of Nc in the emulsified meat matrix. Heat induced muscle protein gel incorporated with Nc stabilized pre-emulsified oil was found to be a weak gel by behaving like a viscous material but lacked gel-like behavior (Delgado-Pando et al. 2010a). The microbial transglutaminase enzyme could facilitate the interactions of Nc with meat proteins, enhancing the gel strength (Delgado-Pando et al. 2010a).

Table 3.

Texture parameters of sausages as affected by partial replacement of porcine fat with SBO in alternative forms at various oil substitution levels

| Sample | SBO substitution level (%) | Texture parameters | ||||

|---|---|---|---|---|---|---|

| Hardness (N) | Cohesiveness | Chewiness (J) | Springiness (10−2 m) | Gumminess (N) | ||

| Control | – | 0.252 ± 0.011 C | 0.652 ± 0.056A | 0.102 ± 0.009C | 0.833 ± 0.015AB | 0.150 ± 0.005B |

| NSBO | 25 | 0.279 ± 0.009Ba | 0.676 ± 0.036Aa | 0.154 ± 0.004ABa | 0.852 ± 0.013Aa | 0.168 ± 0.002Aa |

| 35 | 0.274 ± 0.012Bb | 0.683 ± 0.014Aa | 0.130 ± 0.004ABb | 0.843 ± 0.042 Aa | 0.161 ± 0.005Ab | |

| 45 | 0.262 ± 0.012Bc | 0.675 ± 0.016Aa | 0.102 ± 0.009ABc | 0.842 ± 0.018Aa | 0.146 ± 0.005Ac | |

| FPI-preSBO | 25 | 0.295 ± 0.009Aa | 0.692 ± 0.02SAa | 0.162 ± 0.002 Aa | 0.847 ± 0.010Aa | 0.167 ± 0.003Aa |

| 35 | 0.282 ± 0.009Ab | 0.689 ± 0.039Aa | 0.141 ± 0.002Ab | 0.841 ± 0.015Aa | 0.159 ± 0.004Ab | |

| 45 | 0.269 ± 0.007Ac | 0.683 ± 0.027Aa | 0.115 ± 0.00SAc | 0.843 ± 0.007Aa | 0.148 ± 0.005Ac | |

| Nc-preSBO | 25 | 0.2851 ± 0.006 Da | 0.682 ± 0.017Aa | 0.149 ± 0.007BCa | 0.861 ± 0.023Aa | 0.163 ± 0.004Aa |

| 35 | 0.255 ± 0.006Db | 0.686 ± 0.009Aa | 0.125 ± 0.006BCb | 0.857 ± 0.028Aa | 0.154 ± 0.005Ab | |

| 45 | 0.227 ± 0.011 Dc | 0.679 ± 0.008Aa | 0.093 ± 0.003BCc | 0.849 ± 0.009Aa | 0.148 ± 0.006Ac | |

Control, the sausages without SBO; NSBO, the sausages with SBO in its native form; FPI-preSBO, the sausages with FPI stabilized preSBO; Nc-preSBO, the sausages with Nc stabilized preSBO

Within one column, different capital letters indicate that the form of SBO caused a significant difference in means (P < 0.05), and different small letters indicate a significant effect of substitution level within one form of SBO (P < 0.05)

Increased hardness of the NSBO and the FPI-preSBO was found with their increased chewiness and gumminess (P < 0.05). This was in agreement with the study of Ulu (2006) suggesting a positive correlation of chewiness, gumminess, and hardness in a meatball model. Increasing gumminess and chewiness of frankfurters has been reported with the partial replacement of beef fat with high-oleic sunflower (Park et al. 1989).

Considering the effects of oil substitution level, increased SBO content consistently lowered hardness, chewiness, and gumminess of the samples. The texture attributes of meat products can be affected by selection of the fat source, with these effects attributable to saturation degree of the fatty acids, and size and distribution of the fat globules (Youssef and Barbut 2011).

Microstructure of the sausages

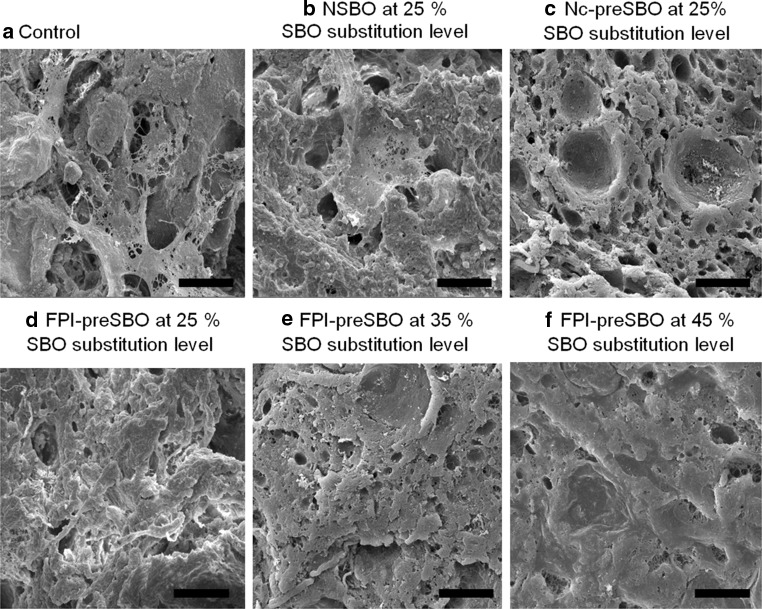

In the present results, the 25% SBO substitution generally provided the sausages with the most improved stability, as indicated by the least cooking loss and the most retained texture attributes. Therefore, the microstructures of sausages with various forms of SBO were elucidated at this particular oil substitution level. The FPI-preSBO had the highest stability among the cases with alternative forms of SBO, so its microstructure was observed at various SBO substitution levels. Microstructures of the selected cases are depicted in Fig. 1.

Fig. 1.

Microstructures of the selected sausage samples (bar 50 μm)

In comparison to the control (Fig. 1a), the FPI-preSBO (Fig. 1d) and NSBO (Fig. 1b) possessed smoother and denser protein gel networks, whereas sponge-like structure with numerous pores and large voids was found in the Nc-preSBO (Fig. 1c). Upon heating and subsequent cooling, the myofibrillar proteins (myosin and actin) play roles in the formation of a three-dimensional gel network, crucially influencing the stability and texture characteristics of a comminuted meat product (Vega-Warner et al. 1999). In the matrix, fat/oil globules can be thoroughly dispersed and embedded into a continuous phase of myofibrillar protein gel (Zhao et al. 2014). Vegetable oils mostly consist of unsaturated fatty acids, which are structurally more flexible than the saturated fatty acids of animal fats. Due to their flexibility, the vegetable oils could interact with proteins at the interfaces more effectively than the animal fats, strengthening the emulsified meat matrix (Wu et al. 2009). Therefore, we could expect more homogeneous microstructure in the NSBO than in the control. Among the present results, the densest and most homogeneous microstructure was observed for the FPI-preSBO, corresponding to the lowest observed cooking loss (Table 2). Myofibrillar gel rigidity increased when the lipids were incorporated in pre-emulsified form, due to enhanced interactions of non-meat proteins localized at interfaces of the emulsified lipid droplets with the continuous phase and its meat proteins (Wu et al. 2009). Moreover, the pre-emulsified vegetable oil droplets tended to be smaller than the animal fat globules, so they could effectively fill cavities in the myofibrillar protein network, resulting in a compact structure of the gel (Wu et al. 2009; Youssef et al. 2011).

However, highly heterogeneous microstructure was found in the Nc-preSBO. A well-organized protein gel was associated with the ability to immobilize water and fat/oil globules by capillary effects and physical entrapment (Gordon et al. 1992; Zhao et al. 2014). Cavities with a broad distribution of sizes were also found in the microstructure of porcine muscle protein gel made with Nc stabilized pre-emulsified oil (Delgado-Pando et al. 2010a). At the presently used temperature (75 °C), Nc may be unable to form a heat induced gel (Youssef and Barbut 2011), so it might not effectively strengthen the emulsified meat matrix and allow coalescence of fat/oil globules, and this causes the large voids that facilitate loss of fluid from the protein gel matrix (Delgado-Pando et al. 2010a). These aspects explained the highest cooking loss observed for the Nc-preSBO (Table 2).

Considering the effects of SBO substitution level, increased SBO content led to tougher structure of the FPI-preSBO protein gel (Fig. 1d–f). Due to the pre-emulsification, the amount of FPI also increased with the SBO substitution level. Self-association might occur for the muscle proteins and the non-meat proteins when the latter are present in excess, and this can reduce the stabilizing effects of the non-meat proteins in the protein gel matrix (Sun et al. 2012). Decreased protein gel strength is observed in chicken breast (or thigh), when the addition of pea protein isolate is increased to 3.5% (or to 4%) (Sun et al. 2012). This might explain the increased cooking loss with the SBO substitution level in sausages, seen in Table 2.

Color of the sausages

Color of the sausages was influenced by partial replacement of porcine fat with SBO as shown in Table 4. The incorporation of SBO increased L* and b*, while it decreased a* of the sausages, regardless of the alternative forms of SBO. The SBO substitution level had a consistent effect only on b* (P < 0.05). Increased lightness and yellowness of sausages is also observed when porcine fat is substituted with olive oil (Bloukas et al. 1997) and fish oil (Domínguez et al. 2017). This tendency was consistent with the study of Yildiz and Serdaroğlu (2008), which reported a decrease in lightness and yellowness of the fermented sausages when pre-emulsified hazelnut oil was used to replace beef fat. On replacing porcine fat with pre-emulsified fish oil (Cáceres et al. 2008) and pre-emulsified sunflower oil (Kim et al. 2016), redness of emulsified meat products can decline. Higher lightness of the sausages formulated with SBO might be expected due to the small size of SBO droplets, with large specific surface that reflects light more effectively than large-sized animal fat globules (Youssef et al. 2011). Increase in b* of the samples formulated with SBO might due to the yellow color of the oil, especially at high SBO substitution levels. The b* was significantly increased by 45% substitution level (P < 0.05). However, in this work, no significant differences in color parameters were observed between the alternative forms of SBO added (P > 0.05).

Table 4.

Color parameters of sausages as affected by partial replacement of porcine fat with SBO in alternative forms at various oil substitution levels

| Sample | SBO substitution level (%) | Color parameters | ||

|---|---|---|---|---|

| L* | a* | b* | ||

| Control | – | 73.89 ± 0.54B | 0.65 ± 0.01A | 14.03 ± 0.83B |

| NSBO | 25 | 76.86 ± 0.33Aab | 0.27 ± 0.02Ba | 15.03 ± 0.20Ab |

| 35 | 77.32 ± 0.57Aa | 0.27 ± 0.03Ba | 15.39 ± 0.67Aab | |

| 45 | 77.29 ± 0.28Aa | 0.29 ± 0.02Ba | 16.01 ± 0.47Aa | |

| FPI-preSBO | 25 | 77.07 ± 0.45Aa | 0.28 ± 0.02Ba | 15.17 ± 0.38Ab |

| 35 | 76.91 ± 0.25Aa | 0.28 ± 0.02Ba | 15.92 ± 0.43Aab | |

| 45 | 76.94 ± 0.23Aa | 0.30 ± 0.02Ba | 16.56 ± 0.23Aa | |

| Nc-preSBO | 25 | 76.36 ± 0.33Aa | 0.28 ± 0.02Ba | 14.98 ± 0.22Ab |

| 35 | 76.89 ± 0.46Aa | 0.29 ± 0.02Ba | 15.35 ± 0.49Ab | |

| 45 | 76.54 ± 0.55Aa | 0.28 ± 0.04Ba | 16.28 ± 0.37Aa | |

Control, the sausages without SBO; NSBO, the sausages with SBO in its native form; FPI-preSBO, the sausages with FPI stabilized preSBO; Ne-preSBO, the sausages with Nc stabilized pre SBO

Within one column, different capital letters indicate that the form of SBO caused a significant difference in means (P < 0.05), and different small letters indicate a significant effect of substitution level within one form of SBO (P < 0.05)

Overall, the technological characteristics and the microstructure of sausages were affected by partial replacement of porcine fat with SBO, depending both on substitution level and form of the SBO. Even when the sausage characteristics including texture attributes, color, and microstructure are significantly affected by added pre-emulsified fish oil, there can be no noticeable differences in the sensorial attributes odor, color, texture, taste, and overall acceptability (Cáceres et al. 2008). This agrees with the report by Delgado-Pando et al. (2010b), showing significant differences in technological characteristics (processing loss, TPA, and color of the sausages) when a combination of plant and marine oils was used to partially replace porcine fat, while the sensorial overall acceptability was unaffected. Therefore, introducing SBO in pre-emulsified form with FPI as the emulsifier might be an advantageous way to produce comminuted meat products with desirable stability.

Conclusion

The partial replacement of porcine fat with SBO affected the characteristics of sausages, in ways dependent on the alternative forms of oil and the substitution level. Introducing pre-emulsified SBO with FPI as the emulsifier successfully improved stability of the meat matrix, as indicated by reduced cooking loss relative to the control. Moreover, improved homogeneity of the microstructure was found in these sausage samples. Generally, increased SBO substitution level degraded stability of the product, especially in the Nc-preSBO cases where Na-caseinate (Nc) was used as the emulsifier. Inferior stability of the sausages added with Nc stabilized preSBO was expected since inability of Nc to form heat induced gel, as evident by a sponge-like microstructure with high heterogeneity and a presence of several large voids. Partial replacement of porcine fat with pre-emulsified SBO appears to be a promising way to produce meat products with desirable stability, and the FPI could be a potent non-meat protein that enhances the stability of comminuted meat products.

Acknowledgement

This research was financial supported by the government budget of Prince of Songkla University (Contract No. AGR580255c), and the author would like to thank Dr. Seppo Karrila (Faculty of Science and Industrial Technology, Prince of Songkla University) for grammar check.

References

- AOAC . Official methods of analysis. 16. Washington: Association of Official Analytical Chemists; 1995. [Google Scholar]

- Bishop DJ, Olson DG, Knipe CL. Pre-emulsified corn oil, pork fat, or added moisture affect quality of reduced fat bologna quality. J Food Sci. 1993;58:484–487. doi: 10.1111/j.1365-2621.1993.tb04306.x. [DOI] [Google Scholar]

- Bloukas JG, Paneras ED, Fournitzis GC. Effect of replacing pork backfat with olive oil on processing and quality characteristics of fermented sausages. Meat Sci. 1997;45:133–144. doi: 10.1016/S0309-1740(96)00113-1. [DOI] [PubMed] [Google Scholar]

- Bourne MC. Texture profile analysis. Food Technol. 1978;33:62–66. [Google Scholar]

- Cáceres E, García ML, Selgas MD. Effect of pre-emulsified fish oil—as source of PUFA n-3—on microstructure and sensory properties of mortadella, a Spanish bologna-type sausage. Meat Sci. 2008;80:183–193. doi: 10.1016/j.meatsci.2007.11.018. [DOI] [PubMed] [Google Scholar]

- Delgado-Pando G, Cofrades S, Ruiz-Capillas C, Solas MT, Jiménez Colmenero F. Characteristics of oil (healthier lipid combination)-in-water emulsions prepared with various protein system. An approach for the development of functional meat products. Eur J Lipid Sci Technol. 2010;112:791–801. doi: 10.1002/ejlt.200900234. [DOI] [Google Scholar]

- Delgado-Pando G, Cofrades S, Ruiz-Capillas C, Solas MT, Jiménez-Colmener F. Healthier lipid combination oil-in-water emulsions prepared with various protein systems: an approach for development of functional meat products. Eur J Lipid Sci Technol. 2010;112:791–801. doi: 10.1002/ejlt.200900234. [DOI] [Google Scholar]

- Domínguez R, Pateiro M, Agregán R, Lorenzo JM. Effect of partial replacement of pork backfat by microencapsulated fish oil or mixed fish and olive oil on the quality of frankfurter type sausage. J Food Sci Technol. 2017;54:26–37. doi: 10.1007/s13197-016-2405-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dzudie T, Kouebou CP, Essia-Ngang JJ, Mbofung CMF. Lipid sources and essential oils effects on quality and stability of beef patties. J Food Eng. 2005;65:67–72. doi: 10.1016/j.jfoodeng.2003.12.004. [DOI] [Google Scholar]

- Gordon A, Baubut S, Schmidt G. Mechanisms of meat batter stabilization: a review. Crit Rev Food Sci Nutr. 1992;32:299–332. doi: 10.1080/10408399209527602. [DOI] [PubMed] [Google Scholar]

- Hultin HO, Kelleher SD. Surimi processing from dark muscle fish. In: Park JW, editor. Surimi and surimi seafood. New York: Marcel Dekker; 2000. pp. 59–67. [Google Scholar]

- Hur SJ, Jin SK, Kin S. Effect of extra virgin olive oil substitution for fat on quality of pork patty. J Sci Food Agric. 2008;88:1231–1237. doi: 10.1002/jsfa.3211. [DOI] [Google Scholar]

- Jiang J, Xiong YL. Extreme pH treatments enhance the structure-reinforcement role of soy protein isolate and its emulsions in pork myofibrillar protein gels in the presence of microbial transglutaminase. Meat Sci. 2013;93:469–476. doi: 10.1016/j.meatsci.2012.11.002. [DOI] [PubMed] [Google Scholar]

- Jiménez-Colmenero F. Healthier lipid formation approaches in meat-based functional foods. Technological options for replacement of meat fats by non-meat fats. Trends Food Sci Technol. 2007;18:567–578. doi: 10.1016/j.tifs.2007.05.006. [DOI] [Google Scholar]

- Jiménez-Colmenero F, Carballo JC, Cofrades S. Healthier meat and meat products: their role as functional foods. Meat Sci. 2001;59:5–13. doi: 10.1016/S0309-1740(01)00053-5. [DOI] [PubMed] [Google Scholar]

- Jiménez-Colmenero F, Herrero A, Pintado T, Solas MT, Ruiz-Capillas C. Influence of emulsified olive oil stabilizing system used pork backfat replacement in frankfurters. Food Res Int. 2010;43:2068–2076. doi: 10.1016/j.foodres.2010.06.010. [DOI] [Google Scholar]

- Josquin NM, Linssen JPH, Houben JH. Quality characteristics of Dutch-style fermented sausages manufactured with partial replacement of pork back-fat with pure, pre-emulsified or encapsulated fish oil. Meat Sci. 2012;90:81–86. doi: 10.1016/j.meatsci.2011.06.001. [DOI] [PubMed] [Google Scholar]

- Kim HW, Lee YJ, Kim YHB. Effects of membrane-filtered soy hull pectin and pre-emulsified fiber/oil on chemical and technological properties of low fat and low salt meat emulsions. J Food Sci Technol. 2016;53:2580–2588. doi: 10.1007/s13197-016-2221-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Klompong V, Benjakul S, Yachai M, Visessanguan W, Shahidi F, Hayes KD. Amino acid composition and antioxidative peptides from protein hydrolysates of yellow stripe trevally (Selaroides leptolepis) J Food Sci. 2009;74:126–133. doi: 10.1111/j.1750-3841.2009.01047.x. [DOI] [PubMed] [Google Scholar]

- Park J, Rhee KS, Keeton JT, Rhee KC. Properties of low-fat frankfurters containing monounsaturated and omega-3 polyunsaturated oils. J Food Sci. 1989;54:500–504. doi: 10.1111/j.1365-2621.1989.tb04637.x. [DOI] [Google Scholar]

- Pelser WM, Linssen JPH, Legger A, Houben JH. Lipid oxidation in n-3 fatty acid enriched Dutch style fermented sausages. Meat Sci. 2007;75:1–11. doi: 10.1016/j.meatsci.2006.06.007. [DOI] [PubMed] [Google Scholar]

- Rawdkuen S, Sai-Ut A, Khamrorn S, Chaijan M, Benjakul S. Biochemical and gelling properties of tilapia surimi and protein recovered using an acid-alkaline process. Food Chem. 2009;112:112–119. doi: 10.1016/j.foodchem.2008.05.047. [DOI] [Google Scholar]

- Sathivel S, Bechtel PJ, Babbitt J, Prinyawiwatkul W, Negulescu II, Reppond KD. Properties of protein powders from Arrowtooth flounder (Atheresthes stomias) and Herring (Clupea harengus) byproducts. J Sci Food Agric. 2004;52:5040–5046. doi: 10.1021/jf0351422. [DOI] [PubMed] [Google Scholar]

- Serdaroğlu M. Improving low fat meatball characteristics by adding whey powder. Meat Sci. 2006;72:155–163. doi: 10.1016/j.meatsci.2005.06.012. [DOI] [PubMed] [Google Scholar]

- Sun J, Wu Z, Xu X, Li P. Effect of peanut protein isolate on functional properties of chicken salt-soluble proteins from breast and thigh muscles during heat-induced gelation. Meat Sci. 2012;91:88–92. doi: 10.1016/j.meatsci.2011.12.010. [DOI] [PubMed] [Google Scholar]

- Ulu H. Effects of carrageenam and guar gum on the cooking and textural properties of low fat meatballs. Food Chem. 2006;95:600–605. doi: 10.1016/j.foodchem.2005.01.039. [DOI] [Google Scholar]

- Vega-Warner V, Merkel RA, Smith DM. Composition, solubility and gel properties of salt soluble proteins from two bovine muscle types. Meat Sci. 1999;51:197–203. doi: 10.1016/S0309-1740(98)00101-6. [DOI] [PubMed] [Google Scholar]

- Wu M, Xiong YL, Chen J, Tang X, Zhou G. Rheological and microstructural properties of porcine myifibrillar protein-lipid emulsion composite gels. J Food Sci. 2009;74:207–217. doi: 10.1111/j.1750-3841.2009.01140.x. [DOI] [PubMed] [Google Scholar]

- Yildiz G, Serdaroğlu M. Effect of replacing beef fat with hazelnut oil on quality characteristics of sucuk—a Turkish fermented sausage. Meat Sci. 2008;78:447–454. doi: 10.1016/j.meatsci.2007.07.013. [DOI] [PubMed] [Google Scholar]

- Youssef MK, Barbut S. Effects of protein level and fat/oil type on emulsion stability, texture, microstructure and color of meat batters. Meat Sci. 2009;82:228–233. doi: 10.1016/j.meatsci.2009.01.015. [DOI] [PubMed] [Google Scholar]

- Youssef MK, Barbut S. Physicochemical effects of the lipid phase and protein level on meat emulsion stability, texture, and microstructure. J Food Sci. 2010;75:108–114. doi: 10.1111/j.1750-3841.2009.01475.x. [DOI] [PubMed] [Google Scholar]

- Youssef MK, Barbut S. Fat reduction in comminuted meat products-effetc of beef fat, regular and pre-emulsified canola oil. Meat Sci. 2011;87:356–360. doi: 10.1016/j.meatsci.2010.11.011. [DOI] [PubMed] [Google Scholar]

- Youssef MK, Barbut S, Smith A. Effects of pre-emulsifying fat/oil on meat batter stability, texture, and microstructure. Int J Food Sci Technol. 2011;46:1216–1224. doi: 10.1111/j.1365-2621.2011.02607.x. [DOI] [Google Scholar]

- Zhao YY, Wang P, Zou YF, Li K, Kang ZL, Xu XL, Zhou GH. Effect of pre-emulsification of plant lipid treated by pulsed ultrasound on the functional properties of chicken breast myofibrillar protein composite gel. Food Res Int. 2014;58:98–104. doi: 10.1016/j.foodres.2014.01.024. [DOI] [Google Scholar]