Abstract

The present research work was undertaken to investigate the effect of xylanase, produced by Penicillium citrinum, on rheological behavior of whole wheat bread dough at large and small deformation respectively. Dough attributes including textural properties (penetration) and structure related characteristics (oscillatory tests) were evaluated. Change in visco-elastic properties of xylanase containing dough was evaluated by oscillatory and creep measurements. The flow experiments were conducted under steady-state condition with shear rate ranging from 0.01 to 100 s−1. Frequency sweep experiments were performed between 0.01 and 10 Hz. It revealed that in both control and xylanase containing dough formulation, the elastic modulus was higher than viscous modulus in the entire range of frequency. Our results represent the adequacy of fitting of dynamic moduli in Power law model and week gel model. Peleg model as well as six element Kelvin model described well the creep behaviour of control and xylanase-containing dough. Uniaxial extensibility was assessed by Kieffer dough and gluten extensibility rig. Lyophilized powder of untreated and xylanase treated doughs were tested under scanning electron microscope. FTIR spectra of lyophilized powder of untreated and xylanase treated dough were recorded in the range of 600–4000 cm−1.

Keywords: Xylanase, Whole wheat bread dough, Dynamic rheology, Extensibility, Scanning electron microscopy

Introduction

Bread is one of the staple foods all over the world. Normally bread is manufactured using refined flour. The refined flour is deficient in dietary fibers. Nowadays consumers are very health conscious. Worldwide demand of healthier, nutritious fiber enriched bread encourages baker to manufacture fiber enriched whole wheat bread (Mann et al. 2004). Epidemiological observations revealed that diseases related to the reduction of blood serum cholesterol, cardiovascular, coronary heart, diabetes, colon cancer can be prevented by incorporation of dietary fibers in the diet (Qiang et al. 2009). Whole wheat flour composed of plant cell walls is rich in dietary fibers. Wheat grain has different characteristics and composition due to presence of cell walls in different tissues of wheat grain. The cell walls of the outermost tissues of wheat grain are hydrophobic and essentially formed of cellulose, lignin and complex arabinoxylans (AX). The cells of inner tissues are mostly hydrophilic and contain arabinoxylan and β-D-glucans. The major fiber present in wheat is arabinoxylan (AX). Water extractable and water unextractable arabinoxylans mainly contribute dietary fiber in the wheat grain. Wheat flour dough is a complex and continuous network of gluten protein where starch molecules are embedded in the mixture. Presence of dietary fibre in bread influences the final bread quality (Cavella et al. 2008). Water extractable arabinoxylan has positive effect on bread quality like dough volume (Courtin et al. 2001), on the contrary water unextractable arabinoxylan has reverse effect on water solubility, viscosity, and hydration properties eventually on dough consistency, bread volume and bread texture (Courtin et al. 2001; Wang et al. 2003).

Adverse effect of flour replacement by whole wheat flour in bread cause dilution of gluten proteins and adverse quality attributes of bread. Fiber enriched flour disturbs the starch–gluten matrix, reduces starch availability for gelatinization, reduces swelling of starch granules, compels gas cells to expand in a particular dimension and adversely affects dough viscoelastic behavior, constraining dough machinability and gassing power. Consequently poorly hydrated gluten results in lower bread volume, produces hard bread of inferior quality with objectionable gritty texture, taste. These undesirable effects can be minimized with the addition of external gluten, surfactants, shortening/surfactant blends and hemicellulase (Kerch et al. 2010). In bread manufacturing, most important attributes is to make softer, smoother, better flavor, better color, more nutritious, and longer shelf life bread (Fernandez et al. 2006).

Xylanase, one of the most important hemicellulase enzymes, due to its ability to degrade arabinoxylan, has an important application in bread quality by increasing water absorption as well as interaction and cross linking with gluten protein. Xylanase significantly improves manufacturing conditions making the dough slacker, softer, viscous, machine friendly, easily sheetable, and less stickier. Additionally, xylanases act as an anti-staling agent in bread manufacturing (Leon et al. 2002).

At the time of mixing, fermentation, sheeting, moulding and oven rise, dough is submitted to stress and to deformation, so that the rheological properties of dough are directly involved in its functional behavior during these steps of the baking process. Although the relationship is not much clear and is possibly indirect (Bloksma 1990), the rheological characteristics of dough also the most important criteria to the quality of the final product. In other way, the rheological behavior of dough, as that of any material, is the mechanical expression of its structure (i.e. the spatial arrangement of the structural elements and their interactions). The purpose of this study was to investigate the effect of xylanase extracted from Penicillium citrinum MTCC 9620 on the rheological properties of whole wheat dough, in order to understand how they affect flow behavior of dough under small and large deformations. Effect of xylanase on microstructure and molecular structure were also investigated.

Materials and methods

Materials

All chemicals used were of analytical grade obtained from Hi-media (India). Whole wheat flour, salt, sugar, yeast, shortening were purchased from the local market.

Proximate analysis of whole wheat flour

Moisture content was determined according to the American Association of Cereal Chemists method (AACC 2000). Fat, ash, crude fibre, dry gluten and protein content were determined according to the methods described in American Organization of Analytical Chemists (AOAC 2000).

Manufacturing of bread dough

Dough was made by mixing wheat flour (100 g); instant dry yeast (3 g); sugar (6 g); salt (1.5 g); shortening (3 g); xylanase (20 µL of 299.5 U/mL), manufactured in laboratory scale fermenter from Penicillium citrinum MTCC 9620 and purified (Ghoshal 2012); and, water according to requirement. Wheat flour, instant dry yeast, shortening, xylanase and water were mixed together in an automatic mixing bowl (Continental, Ambala, India) for 15 min Average of duplicate data was used in analysis.

Rheological properties of dough

Rheological properties of bread dough were measured using a controlled stress rheometer (Bohlin, Gemini, UK) using a 25 mm parallel plate geometry with 2 mm gap between plates. The flow experiments were conducted under steady-state condition with shear rate ranging from 0.01 to 100 s−1. Prior testing the dough samples were allowed to rest for 20 min at room temperature for residual stress release. Frequency sweep experiments were then performed between 0.01 and 10 Hz. Average of duplicate data of rheological experiments was used in analysis.

Modeling of the dynamic rheology data

Oscillation measurements

Data obtained from frequency sweep for dough with and without xylanase were plotted as G′(ω) or G″(ω) versus frequency (ω) in a log–log plot.

Power law model

The power law describes the rheological behavior of dough within the linear visco elastic region because the frequency dispersions of the dynamic mechanical spectra (G′, G″) are more or less straight lines with different slopes. Therefore, each set of data can be fitted in power law equations.

| 1 |

| 2 |

The coefficients G′ ω1 (Pa) and G″ ω2 (Pa) are the storage and loss moduli, respectively, extrapolated to the values of the initial measuring frequency ω1 or ω2; and, x and y are the power law index (dimensionless) for storage modulus and loss modulus respectively.

Week gel model

Week gel model provides a direct link between the microstructure of the material and its rheological properties. Gabriele et al. (2001) proposed power law relaxation modulus to describe the rheological behavior of dough, jam and yoghurt. Week gel model can be used because of its functional simplicity. Week gel model has been used to explore other types of deformation including creep relaxation, uniaxial and biaxial-extension.

| 3 |

where, A is a constant which can be interpreted as the interaction strength between the flow rheological units; and, z is number of flow units interacting with each other to give the observed flow response, also called coordination number.

Creep measurements

Creep test was carried out by applying a constant shear stress (τ = 50 Pa) in the linear visco-elastic region (determined from strain sweep tests) for 60 s and resultant strain was measured as a function of time. After 60 s creep (under constant stress), the stress was removed and the recovery of strain was measured for 180 s. The results were expressed in terms of instantaneous shear creep compliance (J).

Following models were used for modeling of creep data.

Peleg model

Creep data can be modeled by a linear relationship (Steffe 1996):

| 4 |

where, k1 (Pa s) and k2 (Pa) are constants; 1/k1 represents initial decay rate (1/(Pa s)); and, 1/k2 is asymptotic strain (1/Pa).

Burgers model

The Burgers model (Steffe 1996) in terms of compliance function is described by four parameter equation:

| 5 |

where, J0 is instantaneous compliance resulting from instantaneous stress applied; J1 is time-dependent retarded elastic compliance (Kelvin component); λret is retardation time of the Kelvin component; and, μ0 is asymptotic viscosity of the material (viscous flow of bond-free constituents). The instantaneous compliance (J0) is the compliance at zero time and was determined by extrapolation of the compliance to zero time.

Kelvin model

Kelvin model (Steffe 1996) is a six parameter mechanistic model and is an extension of Burger model:

| 6 |

where, (λret)1 = μ1/G1; and (λret)2 = μ2/G2; J1 and J2 are the retarded compliance of first and second Voigt–Kelvin element; and, (λret)1 and (λret)2 are the retardation times of first and second Voigt–Kelvin element respectively.

Determination of dough stickiness and uniaxial extensibility

Dough stickiness was determined in a Texture Analyser (TA-XT plus, Stable Micro System, Surrey, UK) using Chen and Hoseney cell (Hoseney and Chen 1994). Uniaxial extensibility was assessed by Kieffer dough and gluten extensibility rig. The resistance to extension (gf) and extensibility (mm) were determined in tension mode by recording the peak force and the distance at the maximum and the extension limit (Smewing 1995).

Scanning Electron Microscopy (SEM) and Fourier Transform Infrared Spectroscopy (FTIR) study of treated and untreated dough

Lyophilized powder of untreated and xylanase treated dough were tested under scanning electron microscope. SEM was performed on lyophilized powdered samples which were mounted on double side sticky tape on aluminium stubs and sputter coated with gold and palladium alloy. The samples were then visualized and the representative areas were photographed under SEM (JSM-6100, JEOL, Tokyo, Japan) at an accelerated voltage of 10 kV and magnification in the range of 100–2000×.

FTIR spectra were recorded at room temperature (28 ± 2 °C) with a Tensor-27 spectrophotometer (Bruker, Germany) in the range of 600–4000 cm−1 by accumulating 16 scans at 4 cm−1 resolution. For measuring the spectra of lyophilized powder of untreated and xylanase treated dough samples, platinum ATR (attenuated total reflectance) from Bruker, Germany was used. About 2 mg each of dried untreated and xylanase treated powdered dough samples were placed on ATR for measurement. After that the peak intensity of each sample was measured. This entire spectra acquisition procedure took one min per sample.

Statistical analysis

All the experiments were carried out in triplicate. Modeling and statistical parameters (coefficient of determination, standard error, analysis of variance, ANOVA) calculation was carried out using STATISTICA version 6.0 (Statsoft Inc., 2002, Tulsa, USA).

Results and discussion

Proximate analysis of whole wheat flour

Whole wheat flour contained 13.4 ± 0.73% moisture, 12.1 ± 0.64% protein, 10.4 ± 0.43% dry gluten, 2.13 ± 0.32% fat, 1.98 ± 0.69% crude fiber, 1.2 ± 0.51% total ash, and 0.05 ± 0.07% acid insoluble ash. Constituents were calculated on wet basis.

Dough characteristics

Addition of xylanase resulted in reduction of water absorption of wheat flour. Water absorption of xylanase containing dough was 63%, whereas water absorption of control dough was 70% with similar dough consistency. Similar observation has been reported by Courtin et al. (2001). According to Singh et al. 2011 during mixing the dough undergoes an alteration by producing a three dimensional protein–protein, protein–carbohydrate matrices through interaction of starch granules and gluten protein and consequent outcome is alteration of rheological properties. Protein content is positively correlated with water absorption. In xylanase supplemented dough the available protein is higher than control dough as starch and non starch hydrolyzing enzymes result in the liberation of free water and changes the rheological properties of dough (Martinez-Anaya and Jimenez 1998) with lower amount of added water absorption than control. Xylanase addition resulted in the adequate hydration of gluten leading to the higher rise of dough during fermentation producing higher specific volume.

Rheological properties of xylanase supplemented dough

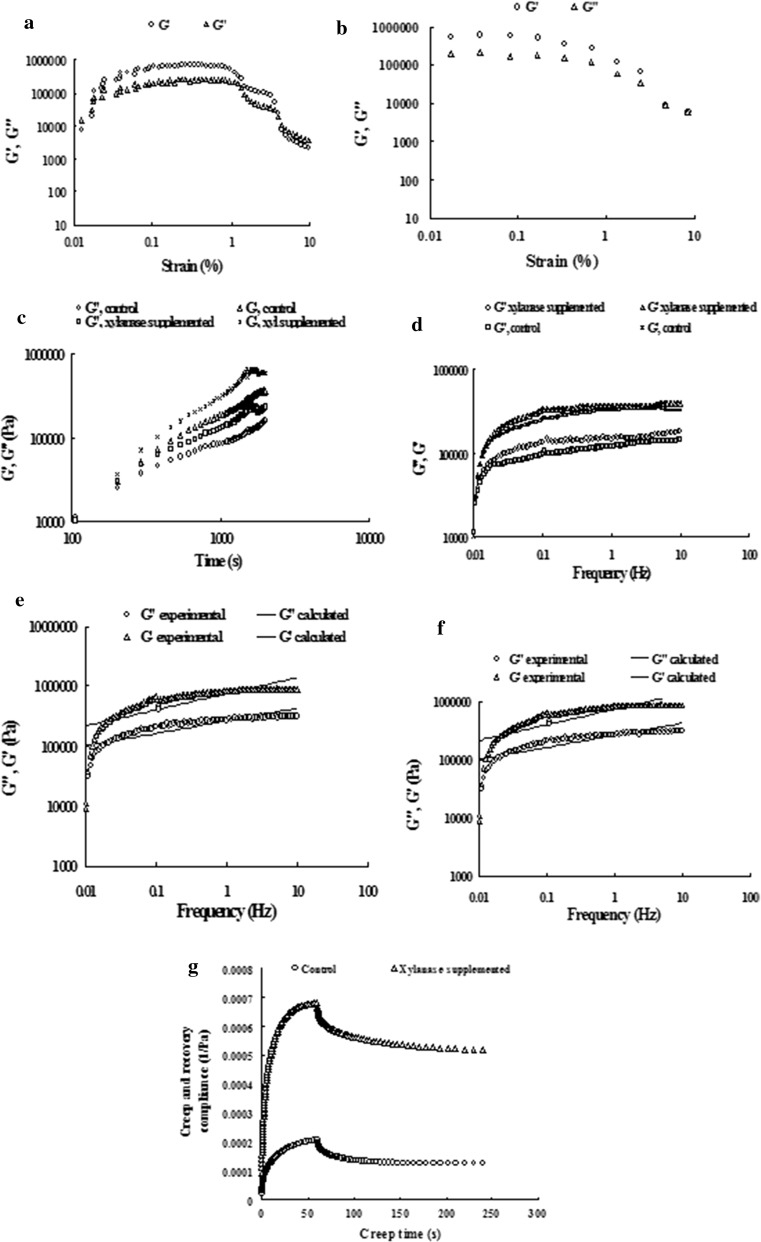

Small deformation oscillatory measurements offer adequate facts about the dough characteristics in terms of structural characteristics of the material as compared to large deformations in the empirical methods like farinograph, mixograph and extensograph (Singh and Singh 2013). The % strain is selected at the middle value in the linear region to get the best experimental results (Karim et al. 2000). In our study, the spectra showed a typical structured system and the spectra exhibited high dependence on the visco-elastic moduli on oscillation frequency. Drop of elastic and viscous modulus, G′, G″ happened above 1% strain after linear range from 0.1 to 1%, indicating the structural breakdown of both control and xylanase added wheat dough (Fig. 1a, b). While crude enzyme extract was used in bread during fermentation, Ridgwell et al. (2001) found gradual decrease in viscosity of dough due to the selective action of xylanase. Oscillatory measurements performed at small strain amplitude, within the linear visco-elastic region, did not destroy the structure at rest. In practice, dough behavior can be considered as linear in harmonic regime up to 1% strain amplitude (Lefebvre 2006; Phan-Thien and Safari- Ardi 1998). Therefore, 0.5% strain level was selected for further frequency sweep experiments.

Fig. 1.

a Strain sweep curve for control bread dough at 0.1 Hz frequency. b Strain sweep curve for xylanase-supplemented bread dough at 1.0 Hz frequency. c Time Vs, dynamic modulus curve for control and xylanase supplemented dough in the linear visco-elastic region. d Frequency sweep curve for control and xylanase-supplemented dough in the linear visco-elastic region. e Power Law model fitting curve for control dough at linear visco-elastic region. f Power law model fitting curve for xylanase-supplemented bread dough at linear visco-elastic region. g Effect of xylanase supplementation on creep test of whole wheat flour dough

The G′ values of both control and xylanase-containing dough were found higher in the linear visco-elastic region (0.5% strain) and 0.1 Hz frequency. The frequency sweep experiments performed under dynamic conditions (in linear visco-elastic region) revealed that for both control and xylanase containing dough formulation, G′ in the entire range of frequency was higher than G″ and both the modulus slightly increased with time (Fig. 1c) and with frequency (Fig. 1d) which suggests a soft solid nature visco-elastic type behavior of both control and xylanase added dough samples. The visco-elastic moduli were higher in xylanase-containing dough as compared to control dough which indicates xylanase addition made the dough stronger and more solid like structure. It is well known that gluten is responsible for the cohesiveness and visco-elastic properties of wheat flour. Xylanase addition might unfold the glutenin protein that support the disulphide/sulphhydryl exchange reaction. Protein–protein interactions tends to offer an increasingly crosslinked structure resulting in higher G′ and eventually stronger dough. Unlike white wheat flour dough, whole wheat flour dough prevents the formation of a strong visco-elastic structure due to presence of bran. It is well known that gluten is responsible for the cohesiveness and visco-elastic properties of wheat flour. tan δ (G″/G′) values were lower than 1 for both the samples which confirm more predominance of elastic behavior and strong dough properties (Singh and Singh 2013). Addition of xylanase cause better visco-elastic behavior and therefore it provides stronger dough structure. Gluten protein is responsible to provide visco-elastic properties of wheat flour dough. Gliadin and glutenin fraction of gluten protein provide viscous and elastic properties respectively therefore gliadin to glutenin ratio is the crucial property for wheat characterization. tan δ was slightly higher in xylanase containing bread dough. These results are similar to those obtained in previous investigations (Caballero et al. 2005). Whereas Collar and Bollain, (2004) reported the protein polymerization promoted by trans-glutaminase counteracted the softening effect of xylanase after a large resting period.

Power law model (Eqs. 1, 2) was used to analyze the oscillation rheology data. Coefficients of Power law model are reported in Table 1. The modulus G′ω1 was greater than G″ω2 for control as well as xylanase-supplemented dough which exhibited the more elastic structure of both the dough. Further G′ω1 and G″ω2 values for xylanase containing dough were significantly (p < 0.05) higher than those for control dough which represented the more visco-elastic nature of xylanase containing dough. x and y values were less than 1 in both the dough. The values of x and y were higher in xylanase containing dough which showed higher dependency on strain value. According to Sivaramakrishnan et al. (2004), higher the values of exponent of Power law model, higher are the dependence of structure on strain. Figure 1e, f represent the adequacy of fitting of Power law model. Deleterious effect of fibrous whole wheat dough demonstrates lower loaf volume, might be due to lower gas retention, objectionable gritty texture, unsuitable taste and mouth feel (Pomeranz et al. 1977). This adverse effect can be counteracted by supplementation of hemicellulase enzymes (Laurikainen et al. 1998). Results of the present study demonstrated that xylanase treatment affected the dough structure as well as dough strength.

Table 1.

| Sample | Power law model | Week gel model | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| G′ω1 | x | R2 | SE | G″ω2 | y | R2 | SE | A | Z | R2 | |

| Control | 3.1 × 105 | 0.194 | 0.928 | 0.37 | 1.21 × 105 | 0.154 | 0.966 | 0.220 | 326,759.9 | 8.1 | 0.754 |

| Xylanase supplemented | 7.3 × 105 | 0.266 | 0.968 | 0.47 | 2.61 × 105 | 0.208 | 0.913 | 0.335 | 774,372.6 | 7.4 | 0.769 |

The results of oscillatory measurement were analyzed using week gel model (Eq. 3). Week gel parameters (A and z) for control and xylanase containing dough are reported in Table 1. The higher the value of A the stronger the starch gluten network in xylanase added dough. Lower value of z represents the higher dependency of both the modulus (G′ and G″) on strain. This also supports the trends found in Power law model coefficients.

Creep measurement of dough

The creep and recovery curves for control and xylanase containing wheat dough exhibited a typical visco-elastic behavior (Steffe 1996). The behavior is similar to the corresponding curves obtained previously for wheat dough (Sivaramakrishnan et al. 2004). Creep-recovery curves are presented in Fig. 1g. After the applied stress was released, the deformation recovered to some extent. Figure 1g reveals that creep compliances or deformation was lower and recovery was higher in xylanase containing dough compared to control. It may therefore, be inferred that xylanase containing dough was stronger than control dough.

Creep compliance data can provide valuable information on the visco-elastic behavior of bread dough (Barbosa-Canovas et al. 1996). In the present study, addition of xylanase resulted dough to become softer might be due to continuous transition from viscous to elastic properties in xylanase containing dough. This indicated that close association of the gliadin fraction of gluten protein, gliadin molecule probably cross linked into complex poly-meric protein structure. Previous studies (Leon et al. 2002) revealed that xylanase supplementation enhanced the degradation of arabinoxylan in dough, eventually increasing water absorption as well as interaction and cross linking with gluten. Various mechanistic models (Peleg, Burgers, and Kelvin) were tested to describe the creep behavior of control and xylanase containing whole wheat dough. Coefficients of Peleg, Burger and Kelvin models are reported in Table 2a–c respectively. Considering the values of coefficients and R2 values, Burger model (Eq. 5) is not suitable to describe the creep behavior of both the dough samples. Coefficients of Peleg model (Eq. 4) as well as six element Kelvin model (Eq. 6) described well the creep behavior of control and xylanase containing dough samples. Similar observation has been reported for hydrocolloid supplemented wheat flour dough and rice flour supplemented dough (Sivaramakrishnan et al. 2004).

Table 2.

Coefficients for (a) Peleg model for control and xylanase-supplemented whole wheat dough samples, (b) Burger model for control and xylanase-supplemented whole wheat dough samples, (c) Kelvin model for control and xylanase-supplemented whole wheat dough samples

| Samples | k1 | k2 | R2 | ||||

|---|---|---|---|---|---|---|---|

| (a) | |||||||

| Control | 14,776.59 | 2408.63 | 0.947 | ||||

| Xylanase-supplemented | 9824.140 | 2607.205 | 0.969 |

| J0 | J1 | λref | µ0 | R2 | |||

|---|---|---|---|---|---|---|---|

| (b) | |||||||

| Control | 0.0003 | −214.5 | 503,794.1 | 2332.7 | 0.809 | ||

| Xylanase-supplemented | 0.00085 | −529 | 604134.3 | 1129 | 0.701 |

| J0 | J1 | (λref) 1 | J2 | (λref) 2 | µ0 | R2 | |

|---|---|---|---|---|---|---|---|

| (c) | |||||||

| Control | 0.0002 | −199 | 80,422 | −7097 | −194,900 | 26 | 0.947 |

| Xylanase-supplemented | 0.0008 | 18,472 | 175,616 | 173,067 | −1,397,649 | 54 | 0.915 |

Creep compliances (Jt), the reciprocal of elastic modulus, provides more quantitative information concerning molecular structures of the material. Jt was studied by applying different mechanistic models (Eqs. 4–6). Samples with the higher Jt values (xylanase containing dough) correspond to those with the narrowest linear intervals and lowest G′ and G″. Higher Jt values indicated that xylanase containing dough samples are softer (lower rigidity and more elasticity) and their ability for structure recovery is higher since they show the stronger long time deformation. Whereas lower Jt values for control dough indicated the sample to the least structure recovery and the firmer and greater deformable owing to their less elasticity.

Instantaneous compliance (J0) represents creep compliance (Jt) at time t = 0 and may be related to the undisturbed gluten-starch network structure. Lower J0 values exhibit higher dough rigidity. J0 values for control dough were substantially lower than xylanase containing dough. Therefore, control dough was more rigid less elastic than xylanase containing dough samples, which is softer, elastic and slacker. This behavior is further reflected in µ0 values (Table 2c). Lower µ0 values may be attributed to the breakdown of gluten-starch network structure for control dough samples, while greater µ0 of xylanase containing dough indicated greater resistance to flow (Table 2c). Xylanase containing dough showed higher µ0 value and higher Jt values, therefore indicates more softer and elastic dough. Corresponding G′ and G″ were also found higher for the xylanase containing dough.

Large deformation of dough was studied in terms of uniaxial extensibility and unfermented dough stickiness. Resistance to extension (Rm, maximum resistance), extensibility (E), and area under the curve (A) were calculated using the Texture Expert 1.22 software (Stable Micro Systems, Surrey, UK). The results are reported in Table 3.

Table 3.

Extensibility and stickiness properties of control and xylanase-supplemented dough

| Sample | KDE | C&H cell | |||

|---|---|---|---|---|---|

| Maximum resistance to extension (Rm) (gf) | Extensibility (E) (mm) | Force (gf) | Area (g.s) | Distance (mm) | |

| Control | 54–61 | 12.9–13.7 | 19.84–37.10 | 0.86–2.85 | 0.82–1.44 |

| Xylanase-supplemented | 34–47 | 13.5–19.5 | 52.04–57.37 | 6.32–9.49 | 3.36–4.36 |

Xylanase containing dough exhibited greater extensibility (13.5–19.5 mm) and less resistance to extension (34–47gf) as compared to control samples. It was found that Rm (maximum resistance) was more in control (54–61 g) than enzyme treated (34–47 g) dough but extensibility (E) increased with xylanase addition from (12.9–13.7) to (13.5–19.46). Therefore, it may be concluded that xylanase addition makes the dough softer. Similar result has been observed by Jiang et al. (2005). These results confirmed that xylanase modified the aggregation properties of gluten protein. In another study, Steffolani et al. (2010) reported that higher extensibility in xylanase containing dough due to modification of interaction among proteins eventually higher gliadin extraction in alcohol. On the contrary, changes in the interaction of glutenin and water soluble pentosans, led to an increase of sulfhydryl (Shf) content and, as a consequence, softening of dough results. Van Oort et al. (1995) reported that changes in dough visco-elastic properties might be due to smaller size of pentosans persuade and redistribution of water occurs which results the modification in the gluten network.

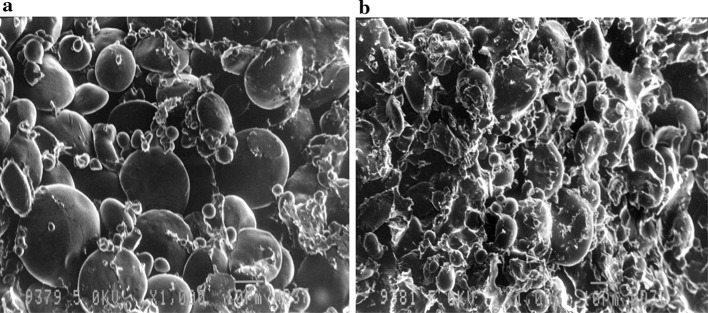

Scanning Electron Microscopy (SEM) of dough

Scanning electron micrograph was taken to investigate the effect of xylanase on microstructure of whole wheat dough. Figure 2a, b represent the SEM of control dough and xylanase containing dough, respectively at 1000× and 2500× magnifications. Two major types of starch granules (large and small) and two different shaped (spherical and oval shaped) starch granules are visible where gluten matrix covers the starch granules in both the cases. Supplementation with xylanase resulted in closed and uninterrupted gluten network in which starch granules are embedded. Higher magnification explores that large starch granules are more swollen and more evenly dispersed within the protein matrix (Fig. 2b). The stronger and more resistant network formation resulted due to presence of coarser gluten fibrils. Greater numbers of pores in the xylanase containing dough than the control dough are visible, whereas in control dough, discontinuous gluten network and less number of pores are visible. Steffolani et al. (2010) described the SEM of pentosanase-supplemented dough which illustrated an open protein matrix and a larger number of pores than the control dough, where starch grains were clearly detectable. In the present study, SEM microphotograph of dough demonstrated that xylanase addition made the dough more uniform with larger number of pores due to more release of gas.

Fig. 2.

SEM of a control dough b xylanase treated dough at ×1000 magnification

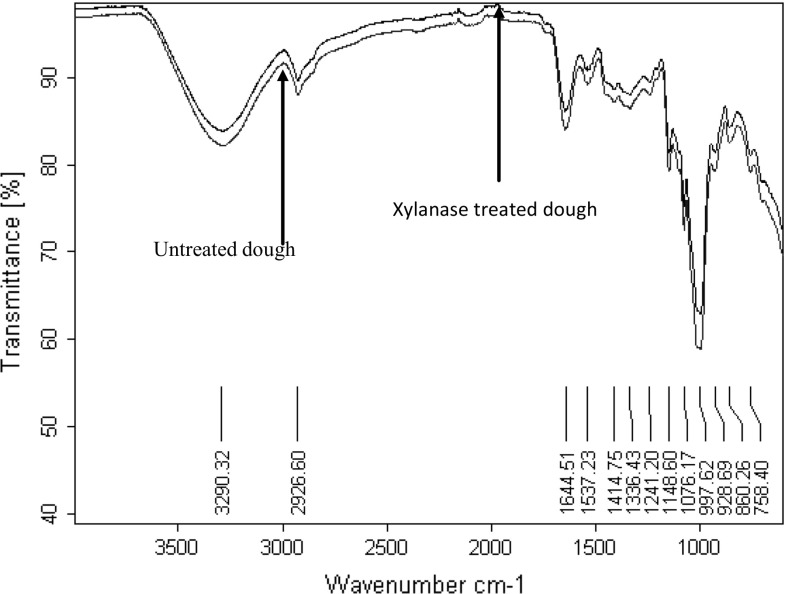

FTIR study of dough

FTIR spectroscopy of control and xylanase containing dough was done in the range of 600–4000 cm−1. Characters of spectral bands were similar for control and xylanase containing dough. Major peaks were obtained in the range 850, 900, 950, 997, 1076, 1148, 1241.2, 1336, 1414, 1537, 1644, 2926.6, and 3290.3 cm−1. Kacurakova et al. (1999) stated that arabinoxylan showed a dominant peak at around 1046 cm−1 whereas maltose showed a more complex spectrum with major peaks at 1150, 1113, 1078 and 998 cm−1. In the present study, control and xylanase containing wheat dough showed peaks at 1148, 1076, 997 cm−1 region which represents presence of maltose and arabinoxylan. Mathlouthi and Koenig (1986) reported the presence of oligosaccharide and polysaccharides in the xylanase containing wheat dough as the absorbance peak was found at 1200–800 cm−1 region. In the present study, several peaks were observed at 1200–800 cm−1 region which indicates the presence of significant amount of starch oligosaccharides and polysaccharides in both the samples. Wilson and Belton (1988) described the detailed spectrum of wheat starch. The spectrum of cell wall polysaccharides which are similar to our findings are described by Kacurakova and Wilson (2001).

Large peak at 1743 cm−1 region representing the carbonyl functional group of triglycerides and fatty acids has also been indicated by several researchers (Sivakesava and Irudayaraj 2000). In the present study, small peaks were observed in that region as very small amount of fatty acid was present. Kavanagh et al. (2000) observed two peaks at 1646 and 1551 cm−1 regions which represent amide I and amide II bonds. In present study, similar peaks were observed in the region of 1644 and 1537.23 cm−1. Salt et al. (2006) described spectra for wheat-water liquors from dough containing salt which also appeared to contain a smaller proportion of malto-oligisaccharides and arabinoxylan as indicated by smaller peak intensity in the saccharide region (1200–850 cm−1). Similar results have been obtained in our present study. Figure 3 confirms the positive correlation with xylanase addition it exhibits that intensity of the band increased in xylanase containing dough. This feature showed a positive interrelation by the release of free sugars like pentoses and hexoses due to hydrolytic action of xylanase thus increasing the intensity of peak. Entrapment of water in starch molecules results swelling of starch granules eventually restraining the presence of extended structure of protein molecules resulting in increased intensity of peak in xylanase containing dough sample.

Fig. 3.

FTIR of control and xylanase-supplemented dough in the wavelength region of 400–4000 cm−1

Conclusion

In our study, linear viscoelastic range was observed from 0.1 to 1%. The frequency sweep test confirmed that xylanase addition made the dough softer and solid like structure as G′ and G″ were higher in xylanase containing dough as compared to control dough. The values of Power law model co-efficient, x and y were higher in xylanase containing dough which showed higher dependency on strain. Week gel model parameters showed higher A value which revealed the stronger starch gluten network in xylanase containing dough, while lower z value represented the higher dependency of both the modulus (G′ and G″) on strain. Creep compliance data revealed that xylanase containing dough was stronger than control dough. Creep test data of control and xylanase containing dough were fitted in Peleg, Kelvin, and Burger Models. Peleg model as well as six element Kelvin model described well the creep behavior of control and xylanase containing dough samples. Large deformation of dough in terms of uniaxial extensibility and unfermented dough stickiness study revealed that xylanase containing bread exhibited greater extensibility and less resistance to extension as compared to control samples. It was found that Rm (maximum resistance) was higher in control than enzyme treated dough but extensibility (E) increased with enzyme supplementation. Therefore, it was concluded that xylanase addition makes the dough softer. SEM study revealed that addition of xylanase resulted in continuous and closed gluten network in which starch granules are embedded. Higher magnification revealed that large starch granules were more swollen and more evenly dispersed within the protein matrix.

Acknowledgement

GG and USS are thankful to AICTE, New Delhi, India for providing financial support to carryout this work.

References

- AACC (2000) American Association of Cereal Chemists. 2000. Approved Methods of the AACC, 10th ed. The Association: St. Paul, MN

- AOAC . Official methods of analysis. 17. Arlington, VA: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Barbosa-Canovas GV, Kokini JL, Ma L, Ibarz A. The rheology of semiliquid foods. Adv Food Nutr Res. 1996;39:1–69. doi: 10.1016/S1043-4526(08)60073-X. [DOI] [PubMed] [Google Scholar]

- Bloksma AH. Dough structure, dough rheology, and baking quality. Cereal Food World. 1990;35:237–244. [Google Scholar]

- Caballero PA, Bonet A, Rosell CM, Gomez M. Effect of microbial transglutaminase on the rheological and thermal properties of insect damaged wheat flour. J Cereal Sci. 2005;42:93–100. doi: 10.1016/j.jcs.2004.12.006. [DOI] [Google Scholar]

- Cavella S, Romano A, Giancone T, Masi P. The influence of dietary fibres on bubble development during bread making. In: Campbell GM, Scanlon MG, Pyle DL, editors. Bubbles in food 2-novelty, health and luxury. St Paul: Eagan Press; 2008. pp. 311–322. [Google Scholar]

- Collar C, Bollain C. Impact of microbial transglutaminase on the viscoelastic profile of formulated bread doughs. Eur Food Res Technol. 2004;218:139–146. doi: 10.1007/s00217-003-0813-1. [DOI] [Google Scholar]

- Courtin CW, Gelders GG, Delcour JA. Use of two endoxylanases with different substrate selectivity for understanding arabinoxylan functionality in wheat flour breadmaking. J Cereal Chem. 2001;78:564–571. doi: 10.1094/CCHEM.2001.78.5.564. [DOI] [Google Scholar]

- Fernandez U, Vodovotz Y, Courtney P, Pascall M. Extended shelf life of soy bread using modified atmosphere packaging. J Food Prot. 2006;69:693–698. doi: 10.4315/0362-028X-69.3.693. [DOI] [PubMed] [Google Scholar]

- Gabriele D, de Bruno C, D’Antona P. A week gel model for foods. Rheol Acta. 2001;40:120–127. doi: 10.1007/s003970000139. [DOI] [Google Scholar]

- Ghoshal G (2012) Studies on the isolation, screening and characterization of a novel xylanase producing organism and its application in food processing. PhD Thesis, Panjab University, Chandigarh, India

- Hoseney RC, Chen WZ (1994) US Patent. 5, 280–616

- Jiang Z, Li X, Yang S, Li L, Tan S. Improvement of the bread making quality of wheat Xour by the hyperthermophilic xylanase from Thermotoga maritima. Food Res Int. 2005;38:37–43. doi: 10.1016/j.foodres.2004.07.007. [DOI] [Google Scholar]

- Kacurakova M, Wilson RH. Developments in mid-infrared FT-IR spectroscopy of selected carbohydrates. Carbohydr Polym. 2001;44:291–303. doi: 10.1016/S0144-8617(00)00245-9. [DOI] [Google Scholar]

- Kacurakova M, Wellner N, Ebringerova A, Hromadkova Z, Wilson RH, Belton PS. Characterisation of xylan-type polysaccharides and associated cell wall components by FT-IR and FT-Raman spectroscopies. Food Hydrocol. 1999;13:35–41. doi: 10.1016/S0268-005X(98)00067-8. [DOI] [Google Scholar]

- Karim AA, Norzian MH, Seow CC. Methods of study of starch retrogradation. Food Chem. 2000;71:9–36. doi: 10.1016/S0308-8146(00)00130-8. [DOI] [Google Scholar]

- Kavanagh GM, Clark AH, Ross-Murphy SB. Heat-induced gelation of globular proteins: part 3. molecular studies on low pH b-lactoglobulin gels. Int J Biol Macromol. 2000;28:41–50. doi: 10.1016/S0141-8130(00)00144-6. [DOI] [PubMed] [Google Scholar]

- Kerch G, Zicans J, Meri RM. The effect of chitosan oligosaccharides on bread staling. J Food Eng. 2010;52:491–495. [Google Scholar]

- Laurikainen H, Poutanen A. Effects of enzymes in fibre-enriched baking. J Sci Food Agric. 1998;76(2):239–2496. doi: 10.1002/(SICI)1097-0010(199802)76:2<239::AID-JSFA942>3.0.CO;2-L. [DOI] [Google Scholar]

- Lefebvre J. An outline of the non-linear viscoelastic behaviour of wheat flour dough in shear. Rheol Acta. 2006;45:525–538. doi: 10.1007/s00397-006-0093-3. [DOI] [Google Scholar]

- Leon AE, Duran E, Barber CBD. Utilization of enzyme mixtures to retard bread crumb firming. J Agric Food Chem. 2002;50:1416–1419. doi: 10.1021/jf0106446. [DOI] [PubMed] [Google Scholar]

- Mann JI, De Leeuw I, Hermansen K, Karamanos B, Karlström B, Katsilambros N, et al. Evidence-based nutritional approaches to the treatment and prevention of diabetes mellitus. Nutr Metab Cardiovasc Dis. 2004;14(6):373–394. doi: 10.1016/S0939-4753(04)80028-0. [DOI] [PubMed] [Google Scholar]

- Martinez-Anaya MA, Jimenez T. Physical properties of enzyme supplemented doughs and relationship with bread quality parameters. Zeitschrift fur Lebensmittel Untersuchung und Forschung A. 1998;206:134–142. doi: 10.1007/s002170050229. [DOI] [Google Scholar]

- Mathlouthi M, Koenig J. Vibrational spectra of carbohydrates. Adv Carbohydr Chem Biochem. 1986;44:7–89. doi: 10.1016/S0065-2318(08)60077-3. [DOI] [PubMed] [Google Scholar]

- Phan-Thien N, Safari-Ardi M. Linear viscoelastic properties of flour–water doughs at different water concentrations. J Non-Newton Fluid Mech. 1998;74:137–150. doi: 10.1016/S0377-0257(97)00071-2. [DOI] [Google Scholar]

- Pomeranz Y, Shogren MD, Finney KF, Bechtel DB. Fiber in bread making. Effects on functional properties. Cereal Chem. 1977;54:25–41. [Google Scholar]

- Qiang X, YomgLie C, QianBing W. Health benefit application of functional oligosaccharides. Carbohydr Polym. 2009;77:435–441. doi: 10.1016/j.carbpol.2009.03.016. [DOI] [Google Scholar]

- Ridgwell RJ, de Michieli JH, Fischer M, Reymond S, Nicholas P, Sievert D. Xylanase induced changes to water and alkali extractable arabinoxylans in wheat flour: their role in lowering batter viscosity. J Cereal Sci. 2001;33:83–96. doi: 10.1006/jcrs.2000.0345. [DOI] [Google Scholar]

- Salt LJ, Wilde PJ, Georget D, Wellner N, Skeggs PK, Mills ENC. Composition and surface properties of dough liquor. J Cereal Sci. 2006;43:284–292. doi: 10.1016/j.jcs.2005.12.013. [DOI] [Google Scholar]

- Singh S, Singh N. Relationship of polymeric proteins and empirical dough rheology with dynamic rheology of dough and gluten from different wheat varieties. Food Hydrocol. 2013;33:342–348. doi: 10.1016/j.foodhyd.2013.04.007. [DOI] [Google Scholar]

- Singh S, Singh N, MacRitchie F. Relationship of polymeric protein with pasting, gel dynamic- and dough empirical rheology in different Indian wheat varieties. Food Hydrocol. 2011;25:19–24. doi: 10.1016/j.foodhyd.2010.05.001. [DOI] [Google Scholar]

- Sivakesava A, Irudayaraj J. Analysis of potato chips using FTIR photoacoustic spectroscopy. J Sci Food Agric. 2000;80:1805–1810. doi: 10.1002/1097-0010(20000915)80:12<1805::AID-JSFA710>3.0.CO;2-L. [DOI] [Google Scholar]

- Sivaramakrishnan HP, Senge B, Chattopadhyay PK. Rheological properties of rice dough for making rice bread. J Food Eng. 2004;62:37–45. doi: 10.1016/S0260-8774(03)00169-9. [DOI] [Google Scholar]

- Smewing J (1995) The measurement of dough and gluten extensibility using the SMS/Kieffer rig and the TA.XT2 texture analyser. Surrey, UK: Stable Micro Systems Ltd

- Steffe JF. Rheological methods in food process engineering. 2. East Lansing: Freeman Press; 1996. [Google Scholar]

- Steffolani ME, Ribotta PD, Pérez GT, León AE. Effect of glucose oxidase, transglutaminase, and pentosanase on wheat proteins: relationship with dough properties and bread-making quality. J Cereal Sci. 2010;51:366–373. doi: 10.1016/j.jcs.2010.01.010. [DOI] [Google Scholar]

- van Oort M, van Straaten F, Laane C. Pentosans and pentosanases in breadmaking. Int Food Ingred. 1995;2:23–27. [Google Scholar]

- Wang M, Hamer RJ, van Vliet T, Gruppen H, Marseill H, Weegels PL. Effect of water unextractable solids on gluten formation and properties: mechanistic considerations. J Cereal Sci. 2003;37:55–64. doi: 10.1006/jcrs.2002.0478. [DOI] [Google Scholar]

- Wilson RH, Belton PS. A fourier-transform infrared study of wheat starch gels. Carbohydr Res. 1988;180:339–344. doi: 10.1016/0008-6215(88)80090-9. [DOI] [Google Scholar]