Abstract

In the last decade microfabrication processes including rapid prototyping techniques have advanced rapidly and achieved a fairly mature stage. These advances have encouraged and enabled the use of microfluidic devices by a wider range of users with applications in biological separations and cell and organoid cultures. Accordingly, a significant current challenge in the field is controlling biomolecular interactions at interfaces and the development of novel biomaterials to satisfy the unique needs of the biomedical applications. Poly(dimethylsiloxane) (PDMS) is one of the most widely used materials in the fabrication of microfluidic devices. The popularity of this material is the result of its low cost, simple fabrication allowing rapid prototyping, high optical transparency, and gas permeability. However, a major drawback of PDMS is its hydrophobicity and fast hydrophobic recovery after surface hydrophilization. This results in significant nonspecific adsorption of proteins as well as small hydrophobic molecules such as therapeutic drugs limiting the utility of PDMS in biomedical microfluidic circuitry. Accordingly, here, we focus on recent advances in surface molecular treatments to prevent fouling of PDMS surfaces towards improving its utility and expanding its use cases in biomedical applications.

Keywords: PDMS, Nonspecific Protein Adsorption, Small Molecule Absorption, Surface Modification, Microfluidics, Microchannels, Tissue-on-Chips

1. INTRODUCTION

Microfluidic platforms, also called lab-on-a-chip devices, have become an important commodity in the life sciences1 in the past two decades. This is due to the many advantages microfluidic platforms offer including easy integration, automation, enhanced performance, reduced sample consumption and analysis time. Silicon and glass based microfluidic devices, which came out of the electronics industry, have now gained enough maturity in the individual component level and reached the time to commence an integration of these components into micro-total analysis systems (micro-TAS)2–9.

Despite their robust application in the electronics industry, silicon and glass based fabrication technologies are not necessarily preferred in lab-on-a-chip applications and life sciences due their high cost, labor intensiveness, and the rigid nature of silicone and glass. Consequently, polymer based fabrication and prototyping have gained attention in the last two decades to alleviate these problems and make microfabrication a cheaper and more accessible technology10–13. Commonly used polymers include poly(dimethylsiloxane) (PDMS)14–21, cyclic olefin copolymer (COC)22, poly(methylmethacrylate) (PMMA)22–25, polycarbonate (PC)23,26,27, polypropylene (PP)27, polystyrene (PS)27, polyvinylchloride (PVC)28, perflouropolyether (PFPE)29, polyurethane30, poly(ethyleneterephthalate) (PET)30 and polyester30. Techniques commonly utilized for manufacturing polymer microfluidic devices which include replica molding31, hot embossing32, injection molding12, and laser ablation10, are reviewed by Becker et al.33. Among all polymer substrates, PDMS is by far the most preferred material for the fabrication of microfluidic devices. This is can be attributed to its favorable properties, including: (1) simple fabrication by replica molding, (2) good mechanical properties, (3) excellent optical transparency from 240 to 1100 nm, (4) biocompatibility and nontoxicity, and (5) high gas permeability34,35.

Although PDMS has many merits, its high hydrophobicity (water contact angle ~108° ± 7°)36–38 often limits its applications where solutions containing biological samples are concerned. A major consequence of this hydrophobicity is undesired nonspecific adsorption of proteins which influences analyte transportation, and thus reduced separation performance and detection sensitivity39. The absorptive nature of PDMS, due to its inherent hydrophobic polymer network structure, may also result in sequestration of small molecules from the solutions that flow through channels, which complicates quantitative analysis of experiments in drug discovery, proteomic analysis, and cell culture applications40,41. Other complications include impedance to flow of polar liquids in the microchannels of a microfluidic device42, and swelling in presence of hydrocarbon solvents43. In an effort to alleviate problems associated with PDMS, many surface modification strategies have been proposed. The recent literature involves excellent reviews on the surface modification of PDMS to resist nonspecific protein adsorption42,44–48. In this review, we first present the limitations of PDMS in microfluidic applications and then review recent surface modification methods to enhance its applicability.

2. PROBLEMS OF PDMS IN MICROFLUIDIC APPLICATIONS

Since its adoption by the Whitesides group for micro-molding techniques31,49 in the 1990s, PDMS has become the staple of microfluidics research as well as other platforms requiring replication of small features from a master mold. PDMS provides both low cost and rapid prototyping capabilities and upon plasma oxidization, can adhere to itself or other materials without adhesives50. Chemical inertness and commercial availability make PDMS the choice of material for microfluidic platforms. Nevertheless, PDMS presents some significant problems that adversely affect its broad usage. Here we discuss these problems and strategies to overcome some of these limitations. We first cite a few of the general physical problems in section 2.1. Then, we focus on problems that relate to use of PDMS in biological applications in section 2.2.

2.1 General problems

The high compliance and flexibility of PDMS, evidenced by a Young’s modulus of ~1.63–2.12 MPa for the commonly used pre-polymer to curing agent ratio of 10:1, make it a good candidate in microfluidics design51,52. It has been reported in previous studies that mixing of a small amount (≤ 5% W/W) of additives in PDMS pre-polymer causes very limited change in its mechanical properties (~2.05 MPa for PDMS with 5% W/W additive)51. High compliance of PDMS provides several important advantages in microfluidic applications such as 1) preservation of micro-scale features imprinted in the PDMS from a master template 2) conforming to other surfaces for reliable bonding 3) making stretchable designs which mimic the biological environment and 4) the ability to create integrated valves and pumping systems53. Although this property has been used advantageously in many microfluidic devices2,54–56, it also creates significant problems. PDMS microchannels can deform and bulge significantly under pressure-driven flow conditions, leading to large variations in pressure drop compared to a rigid-walled channel with an identical initial geometry.

Wang et al. investigated the effect of changing the base-to-curing agent mixing ratio of PDMS on its Young modulus52. They found out that PDMS with 20:1 mixing ratio has a much lower modulus (0.35 MPa) than PDMS with 10:1 mixing ratio (1.63 MPa) while PDMS with 5:1 mixing ratio has a similar modulus (1.56 MPa) to that of PDMS with 10:1 mixing ratio. To characterize PDMS deformation, Hosokawa et al. presented an optical method for monitoring of local pressure in microfluidic devices using a deformable diffraction grating57. Holden et al. built a microfluidic diffusion diluter using PDMS and measured the channel height by fluorescence microscopy to determine the changes in channel cross-sectional area58. Gervais et al. provided theoretical and experimental verification of the extent of PDMS deformation inside rectangular microchannels using confocal microscopy and related the change in height to position along the length of the channel, channel pressure, and the material properties of PDMS59. Recently, Mamadi and his colleagues used a photo-sensitive thiolene resin to create a rigid coating layer over the stiff PDMS micropillar array that reduced deformation by 70% compared with conventionally manufactured samples60.

Swelling with some organic solvents due to the absorptive nature of PDMS and the resulting deformation is another issue that degrades device performance and limits the use of PDMS in solvent manipulation applications13,61–65. Dangla et al. studied the microchannel deformation of PDMS through changes in the channel height using a synthetic Schlieren method when PDMS was in contact with swelling solvents66. Although swelling is desirable in a few applications such as extraction of contaminants from bulk PDMS and changing the surface properties of PDMS40, channel deformation due to swelling often causes inaccurate measurements of flow rates and pressure drops.

The hydrophobicity of PDMS microchannels makes it difficult to introduce aqueous solutions14. Since most of the work in microfluidics relies on using aqueous solutions or mixtures of aqueous and organic solutions, impedance to the flow of polar liquids is a significant obstacle in many applications. In addition, electroosmotic flow, EOF, often expressed as the electroosmotic mobility (μ eof), is unstable and can be poorly controlled in hydrophobic channels. Several modification methods that cover resistance of polar liquids related with hydrophilicity will also be discussed in detail in the further sections.

2.2 Problems in biological applications

Recent years have brought on a heightened interest in using microfluidic platforms towards not only separations and enrichment of biological samples but also in applications where culture of individual cell types and/or recapitulation of full tissue physiology are aimed. Because PDMS is nontoxic, optically transparent, and oxygen permeable, it seems to be the ideal material for culture and imaging of live cells as in the recent drive towards tissue-on-a-chip models67–72. Nevertheless, PDMS presents a number of important limitations that lead to substantial sample loss and poor performance in cell-based microfluidic applications. Given the prominent use of PDMS in such applications, in this section, we highlight these limitations where nonspecific protein adsorption (section 2.2.1), hydrophobic small molecule absorption (section 2.2.2), gas permeability and evaporation (section 2.2.3), and leaching of PDMS oligomers (section 2.2.4) are of particular importance.

2.2.1 Nonspecific protein adsorption

The hydrophobic nature of PDMS has been one of its biggest limitations in biomedical microfluidic applications, because it results in the adsorption of significant quantities of proteins from the surrounding biological environment. It is a major problem to overcome because it mediates subsequent undesirable bioreactions73 that uncontrollably affect the local concentrations of solutes53. Accordingly, modification and/or functionalization of the PDMS surfaces exposed to biological samples to prevent the nonspecific adsorption of proteins has become a critical subject in the recent years. In this regard, oxygen plasma treatment is probably the simplest and most widespread technique to alter surface hydrophobicity of PDMS and thus alleviate the associated drawbacks. Unfortunately, hydrophilized PDMS surfaces tend to recover their native hydrophobic state74 within roughly 15 minutes after treatment, limiting both the shelf life and the long-term use of devices. The efforts towards preventing nonspecific adsorption of proteins and promoting antifouling properties of PDMS substrates used in microfluidic systems will be explained in detail in the following sections.

2.2.2 Hydrophobic small molecular absorption

The inherently hydrophobic polymer network structure of PDMS41–75 allows some hydrophobic pharmaceutical drugs and commonly used fluorescent molecules to diffuse and absorb into the PDMS walls. This presents a major challenge and a strong case against the use of PDMS based microfluidic devices for drug discovery, proteomic analysis, and cell culture applications. This diffusion and absorption of small molecules into PDMS results in reduced molecular concentration of administered molecules and consequently affects the accuracy and reliability of the experiments conducted in PDMS based devices. Toepke et al. demonstrated that the small, hydrophobic fluorescent dye, nile red, was strongly absorbed by PDMS walls of microfluidic channels, validated by the retention of the fluorescence signal after repeated washes41. Regehr et al. indicated that the absorption of estrogen from culture media into the PDMS polymer bulk resulted in the inhibition of activator protein-1 activation. Quantification of estrogen via ELISA provided the evidence that microchannel estrogen partitioned rapidly into the surrounding PDMS76.

The partition coefficient (log P) of a series of routinely used markers (solute molecules) including [3H]-dexamethasone, [3H]-diazepam, [14C]-mannitol, [3H]-phenytoin, and rhodamine 6G and their absorption into PDMS microchannels were quantitatively investigated by Wang et al. They concluded that absorption of a given marker into PDMS depends on the hydrophilic/hydrophobic balance identified by its log P value75. A simple solution to limit small molecule absorption by PDMS is to use a surface layer of paraffin wax or parylene77–78. However, the biocompatibility of such approaches is unknown.

2.2.3 Gas permeability and evaporation

The gas permeability of PDMS is often cited as an advantage. But allowing free diffusion of oxygen and CO2 can also present a major challenge in terms of precisely controlling the oxygen tension in microfluidic devices. Such fine control might be required to induce and study oxygen-tension based behavior such as the zonation of liver. Perhaps a more important challenge associated with this high permeability of PDMS is evaporation of water and other liquids handled in microfluidic devices. This especially becomes a detriment in closed systems at the microscale even where the slightest amount of evaporation causes significant shifts in volume, leading to variations in the concentration and osmolarity of other solutes in the liquid79. Other problems caused by evaporation include the propagation of bubbles and lysis of cells in the microchannels that result in data loss and prematurely ending experiments. In “open” systems where the surface of the liquid is subjected to air, a higher rate of evaporation may still take place through the bulk PDMS layers80,81. This can be overcome by designing closed microfluidic platforms when the open design is not an indispensable feature for device function. Nevertheless, there are several remedies to alleviate effects of evaporation such as changing the curing agent to base ratio82, coating with parylene79, using a large isoosmotic media bath to maintain the desired osmolarity in cell culture83, or changing the geometry of the device84. Although these methods are beneficial for many applications, there can also be limitations and drawbacks to circumvent.

2.2.4 Leaching of PDMS oligomers

To prepare and cure PDMS to be used in microfluidic applications, a pre-polymer base and a crosslinking curing agent are thoroughly mixed, degassed to remove air bubbles, and left to cure at varying temperatures. This is a time and temperature dependent procedure that does not reach 100% crosslinking. The polymer chains that are not crosslinked yet remain in the bulk are often referred to as “low molecular weight (LMW) species” or “oligomers”. They can freely diffuse within the bulk material and can migrate into aqueous solutions within the microfluidic devices. After plasma treatment, hydrophilic surfaces regain their hydrophobicity in roughly 15 minutes by the collection of LMW residues on the surface74. Eddington et al. have concluded that by removing these LMW species from the bulk phase through thermal aging, the hydrophobic recovery of the oxidized surface can be extended to 12 days74.

Soxhlet extraction and multiple extractions in organic solvents are also possible but time consuming routes towards reducing oligomers to negligible levels in bulk material40. Since leaching is difficult to monitor and control, it presents a significant problem in aqueous cell culture environments found in tissue-on-a-chip applications, where the presence of such oligomers can adversely affect the cultured cells and complicate the analyses. Accordingly, leaching of such uncrosslinked oligomers should be carefully taken into consideration and avoided while studying cellular biology in PDMS based microfluidic devices.

3. PDMS SURFACE MODIFICATION STRATEGIES

As evident in our discussion in the preceding section, PDMS has a number of significant limitations that severely reduce its applications in microfluidic applications, especially when conducting experiments with biological samples. While it is possible to replace PDMS completely with other materials such as hard thermoplastics and glass, these prove to be either more costly or harder to work with, thus reducing their usability and accessibility. Therefore, an ideal solution would be to alter the surface properties of PDMS to alleviate problems related to nonspecific adsorption and/or absorption while retaining all the advantages of its bulk properties such as the high fidelity replication and optical clarity. A common approach towards the modification of PDMS surfaces is to use short polymer chains. Poly(ethylene glycol) (PEG), also known as poly(ethylene oxide) (PEO), is a nontoxic and biocompatible polymer that has been commonly utilized to modify PDMS surfaces and reduce nonspecific adsorption of proteins85. Polyacrylamide, poly(vinyl pyrrolidone) (PVP), poly(2-methacryloyloxyethyl phosphorylcholine) (PMPC), hyaluronic acid poly(N-hydroxyethyl acrylamide) (PHEA), hydroxypropyl methylcellulose (HPMC), poly(vinyl alcohol) (PVA), poly(2-hydroxyethyl methacrylate) (pHEMA), poly(acrylic acid) (PAA), dextran, and hydroxylethylcellulose (HEC) have also been utilized for physical and covalent surface modifications of the microchannels47. Table 1 lists the methods and other details (i.e. derivatization procedure, stability, water contact angle (WCA)) for various biomolecular separations performed in microfluidic devices made from surface-modified PDMS. In this section, we review such approaches towards the surface modification of PDMS, ranging from surface activation (section 3.1) and physisorption (section 3.2) strategies to methods that take chemical routes (section 3.3).

Table 1.

PDMS surface modification strategies to alleviate problems related to nonspecific adsorption and/or absorption.

| Modification method | Derivatization of PDMS substrate | Stability | Water contact angle (WCA) (θ/°) | Ref. |

|---|---|---|---|---|

| O2 plasma | n/a | 6 hours | between 50–60 | [36] |

| UV/ozone treatment | n/a | 4.5 months | 46 | [91] |

| Corona discharge | n/a | 1 hours | 50 | [92] |

| Sol-gel method | PDMS modified with TiO2 and derivatized with oligoethyleneoxide | 1 months | 23 | [94] |

| LBL deposition | PDMS coated with PEMs by carbodiimide coupling and covalent attachment of PEG chains | 5 months | 20 | [97] |

| LBL deposition | PDMS covered with PEMs and functionalized with protein G | 4 weeks | between 7.81–21.61 | [100] |

| Non-ionic surfactant | Pluronic added into uncured PDMS | 2 weeks | 62.8 | [104] |

| Non-ionic surfactant | PDMS coated with copoly(DMA-GMA) film | 6 months | 7 | [105] |

| Charged polymers | Immersed into aqueous solution containing PLL-g-PEG copolymers | n/a | 35 | [109] |

| Charged polymers | Coated with PEG | n/a | 58 (advancing) 17 (receding) | [110] |

| Surface segregation and SAMs | ATRP initiator was mixed with PDMS prepolymer and cured in contact with alkylthiolate monolayer | n/a | 58 | [35] |

| Surface segregation and SAMs | PDMS pre-polymer was mixed with a functional molecule, alkenes self-assembled near the functionalized monolayer and reacted with the PDMS backbone | n/a | 83 (static) 33 (advancing) 19 (receding) | [113] |

| Surface segregation and SAMs | Cross-linked PEG silane layers were created on the PDMS surfaces | > 2 months | 33 (advancing) 19 (receding) | [114] |

| Surface segregation and SAMs | Adding PEG molecules into PDMS prepolymer before curing | n/a | 75 | [115] |

| Silanization | PDMS surface silanized with APTES ± GA | n/a | < 60 | [38] |

| Silanization | PDMS microchannels treated with GPTMS and exposed to NH2-PEG solutions | 1 month | 70 | [116] |

| Silanization | PDMS microchannels treated with CPTMS and exposed to alkyne-PEG solutions | 1 month | 64 | [117] |

| Grafting-to | Attachment of PEG onto air plasma treated PDMS surface | 47 days | 22 | [119] |

| Grafting-to | Channel coating of preceramic polymer, AHPCS, and subsequent hydrolysis | n/a | 35 | [120] |

| Grafting-from | MPC was grafted by surface-initiated photo-induced radical polymerization | n/a | 25 | [122] |

| Grafting-from | Grafting PNIPAAm film onto PDMS Surface | n/a | 30 67 (advancing) | [123] |

| Grafting-from | Silanization by MPTMS and PEG was conjugated with peroxide- initiated polymerization | 1 month | 58–65 | [124] |

| Grafting-from | After oxidation of the PDMS surface with UV-ozone plasma generator, ATRP with acrylamide was carried out. | 1 month | between 60–70 (advancing) 5 (receeding) | [127] |

| Grafting-from | PVP chains were grafted from the PDMS surface by SI-ATRP | n/a | 32 (advancing) | [128] |

| Grafting-from | A quaternized polyDMAEMA was grafted onto PDMS surface via copper-mediated ATRP. | n/a | 49.9 (advancing) | [129] |

Abbreviations: TiO2, Titanium dioxide; PEMs, polyelectrolate multilayer; PEG, poly(ethylene glycol); DMA, dimethylmethacrylate; GMA, glycidyl methacrylate; PLL, poly(L-lysine); PEG, poly(ethylene glycol); APTES, (3-aminopropyl) triethoxy silane; GA, glutaraldehyde; GPTMS, 3-glycidoxypropyltrimethoxysilane; CPTMS, 3-chloropropyltrichlorosilane; AHPCS, allylhydridopolycarbosilane; MPC, 2-methacryloyloxyethyl phosphorylcholine; PNIPAAm, poly(N-isopropylacrylamide); MPTMS, 3-methacryloxypropyltrimethoxysilane; MPC, 2-methacryloyloxyethyl phosphorylcholine; PVP, poly(N-vinylpyrrolidone); DMAEMA, dimethylaminoethyl methacrylate.

3.1 Modification by surface activation

3.1.1 O2 plasma

Oxygen plasma treatment relies on the use of an ionized gas to functionalize the outer surface, and is by far the most commonly utilized technique for the surface modification of PDMS based microfluidic devices. The oxygen plasma attacks the siloxane backbone, generates reactive species that forms silanol groups (Si-OH), and renders the PDMS surface hydrophilic. The main drawback of plasma oxidation is the eventual hydrophobic recovery caused by the reorientation of pre-existing low-molecular-weight species (oligomers) from the bulk to the surface86.

Tan et al. reported a novel technique to maintain the hydrophilicity of PDMS devices for several weeks using a scanning radical microjet approach with an oxygen microplasma. The results showed that a plasma power of 70 W and a long plasma treatment over 5 minutes decreased the water contact angle (WCA) from 112° for native PDMS to 60° for treated PDMS. Furthermore, atomic force microscope (AFM) results revealed that surface roughness significantly decreased with a longer plasma treatment time36. Yang et al. showed the effects of O2 plasma treatment on PDMS chemistry, topography, and elasticity as well as their recovery process. After plasma exposure at low density (300 mT, 20 W) for 10–30 seconds, it was found that surface became even smoother. However, with a prolonged exposure time (120 seconds), straight cracks were formed on the surface. Equally important, O2 plasma treatment changed the elasticity of the PDMS surface. As the oxygen exposure time increased, the surface became stiffer (up to a Young’s modulus of ~130 MPa compared to ~3.4 MPa for the untreated PDMS). How these changes influenced the behavior of human mesenchymal stem cells (hMSCs) was also examined. The PDMS elasticity, instead of topography or surface chemistry, was found the major regulator of cell adhesion complexes87. Bartalena et al. highlighted both the depth and mechanical effect of low-energy plasma treatment on PDMS, assessed the dominance of these effects in a quantitative analysis of cell–substrate mechanics88. Recently, Priest et al. demonstrated a rapid, high-precision plasma treatment method of PDMS surface within a microchannel. For this purpose, molten gallium electrode pads were inserted into bulk PDMS to generate localized regions of high electric field-strength along a bonded microchannel. This channel provided a targeted surface treatment by confining the plasma generation and reduced plasma treatment time (Fig. 1)89. The simplicity of the fabrication process and generation of localized plasmas in bonded channels differentiated this approach from previous approaches.

Figure 1.

Microchip with injected electrodes for localized microchannel plasma generation. (a) Chip design, showing the injected electrodes, the main channel, and the localized plasma. (b) Injected electrodes (gallium) adjacent to a 50 mm wide main channel. (c) PDMS microchip with patterned gallium electrodes (100 mm wide) adjacent to a 50 mm wide main channel, with d = 50 μm. High-field regions from L = 300 μm to 800 μm (left to right). Low-field regions are 500 μm long. Cross-section of the microchannel and gallium electrodes is shown in the inset in (c). Reprinted from [88] with permission.

3.1.2 UV/ozone treatments

Another commonly utilized technique to modify PDMS surfaces involves oxidation via ultraviolet (UV) or UV/ozone exposure (UVO). An important advantage of these methods is their ability for much deeper modification of the PDMS surface while avoiding crack failures and mechanical weakening of the material. Nevertheless, UV treatments are about an order of magnitude slower compared to plasma-based techniques90. The impedes their adoption in the laboratory and industry.

Berdichevsky et al. assessed the UV/ozone method to increase the stability and minimize the adsorption of several analytes in a PDMS microfluidic channel. They showed that 14 μm thick film membranes exposed to UV/ozone for 120 minutes remained hydrophilic for more than 3 months, with a contact angle of 46° due to the much higher degree of oxidation of the entire depth of the membrane91.

3.1.3 Corona discharge

Corona discharge treatments exploit the formation of high energy electromagnetic fields closed to charged thin wires or points that creates a region of plasma around the active electrodes by ionizing neutral fluid45. Corona discharge treatment has also been used on PDMS surfaces to obtain hydrophilic surfaces in microfluidic platforms. In addition to achieving wettability in channels, high energy treatment of corona also helps during bonding of molded PDMS to either PDMS or other substrates as a consequence of condensation of the silanol groups on the oxidized surfaces92. Ro et al. developed an inexpensive and an irreversible bonding technique for PDMS microchips using oxidation by corona discharge generated from an easily available source, a Tesla coil92. Hillborg et al. suggested that prolonged exposure to corona discharges leads to the formation of a ~10 nm silica-like surface layer that retards the recovery of hydrophobicity by hindering the transport of LMW species to the surface93. It was also shown that PDMS elastomers immersed in liquid nitrogen or subjected to small mechanical deformations (< 1% strain) after exposure to corona discharge for 1 hour or more regained their hydrophobicity faster than untreated samples kept under identical conditions.

3.1.4 Sol-gel method

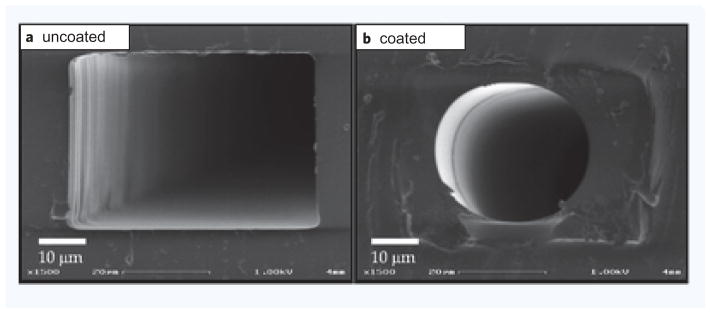

The physical properties of PDMS can be extensively modified using a sol-gel treatment that entails the hydrolysis and condensation of appropriate alkoxy compounds to form nanometer-sized silica on the PDMS channel wall in situ61,94. Roman et al. formed PDMS microchips with 10 nm in diameter SiO2 nanoparticles homogeneously distributed within the PDMS polymer matrix94. In the fabrication process, after curing, PDMS microchips were immersed in the sol–gel precursor tetraethyl orthosilicate (TEOS), then soaked in a solution of ethylamine. Subsequently, the chips were placed in an oven at 95°C to form a more hydrophilic and nonabsorptive surface with nanoparticles. In sol-gel chemistry, the precursor solution can swell and dissolve PDMS as well as giving rise to the contraction and cracking problems during the gelation process. To alleviate this problem, Abate et al. added acid to chemical precursors, TEOS and methyltriethoxysilane, to catalyze the condensation and hydrolysis reactions of the monomeric precursors62. Figure 2 shows uncoated and coated cross-sections of a microchannel that was initially rectangular and turned into a rounded channel as a result of the thick coating deposited on the walls. Gomez-Sjoberg et al. also demonstrated that, by using a sol-gel treatment, it is possible to considerably reduce the absorption of camptothecin and a kinase inhibitor into the microfluidic channel walls of a cell-culture device95. This approach allows experiments at well-controlled drug concentrations compared to untreated PDMS devices.

Figure 2.

Scanning electron micrographs of cross-sections of (a) uncoated and (b) coated PDMS channels. The original channel dimensions are 50 × 35 μm. Reprinted from [62] with permission.

3.2 Physisorption

3.2.1 Layer-by-layer (LBL) deposition

Surface functionalization via layer-by-layer deposition96 is an emerging strategy for preventing nonspecific protein binding. In the LBL assembly technique, thin composite films of polyanions and polycations are fabricated by alternately depositing them onto virtually any substrate surface to create polyelectrolyte multilayers (PEMs)97. Although this method has many advantages including simplicity and efficiency, and provides fine thickness control at the nanoscale, long-term stability is difficult to achieve. PEM stability and surface functionality depends on precise control of many factors such as the ionic strength, type of solvents, temperature, concentration of the solution, and pH of the solution (for weak polyelectrolytes)19.

Makamba et al. produced PDMS surfaces by the crosslinking of PEMs by carbodiimide coupling followed by the covalent attachment of poly(ethylene glycol) (PEG) chains to the PEMs to create long-term stable, permanently hydrophilic and protein-resistant coatings97. Mehta et al. modified the PDMS surface with biofunctional multilayer coatings. The nanocomposite coatings were synthesized by an automated microfluidic perfusion system which was utilized to perform LBL deposition of PDDA (poly(diallyldimethyl ammonium chloride)), clay, type IV collagen, and fibronectin. The resulting multilayer coating promoted marrow cell attachment and spreading as well as providing better flow control19. Qui et al. developed a polyelectrolyte modified PDMS microchip composed of a poly(diallyldimethylammonium chloride) (PDDA) and poly(sodium 4-styrenesulfonate) (PSS) that promises better detection of ascorbic acid and uric acid in clinical analysis in addition to reduced nonspecific adsorption compared to native PDMS98. The reduction of BSA surface adsorption by in situ grafting of PEG on PDMS - through the reaction of the N-hydroxysuccinimidyl ester of methoxy-terminated PEG with Chitosan - was studied by Wang et al.99. The whole modification process proceeded in an aqueous solution without organic solvents that minimizes the environmental pollution and prevents the swelling of the PDMS network. It was also demonstrated that this “brush-like” coating improved EOF. Electrophoresis separations of biomolecules such as amino acids and proteins were achieved on the modified PDMS microchips. PEMs were also utilized in the manufacture of PDMS microfluidic devices that featured functionalized hydrogel plugs designed to selectively capture ERr (Fig. 3)100. The PEM provided high hydrophilicity and low nonspecific adsorption in areas not patterned with the hydrogel plugs, improving device performance.

Figure 3.

Fabrication scheme for the Protein G-Immobilized Hydrogel Microfluidic Protein Chip. (a) The PDMS channel surface was coated with PEMS by layer by layer modification (b) absorption of PI into the PEMS-modified PDMS channel wall; and (c) protein G was covalently bonded to NPA molecules for copolymerization with the acrylamide/bisacrylamide. (d) The UV light emitted from the objective irradiates on the incubated orecursor solution for in situ synthesis of hydrogel beads in the PEMS-modified PDMS channel. (e) Hydrogel plugs were formed within three PDMS channels. Reprinted from [99] with permission.

3.2.2 Nonionic surfactants

Nonionic surfactants are widely used to pretreat microchannels and can easily adsorb to hydrophobic surfaces to render the surface hydrophilic in situ.

Several studies have utilized polyoxyethylene dodecanol, known as Brij-35, to reduce the surface adsorption of proteins in microfluidic systems. Dou et al. coated PDMS microchannels with Brij-35. This treatment improved the hydrophilicity of the interface and reduced the adsorption of large protein molecules101. Tween-20102, n-dodecyl-D-maltoside (DDM)103 and Pluronics (triblock copolymers PEO-b-poly(propylene oxide)-b-PEO, with varying block lengths and ratios)37 are commonly used surfactants for fast and effective surface modification in microchannels. Wu et al. evaluated effects of Pluronic coatings in a PDMS bioreactor and demonstrated an 85% reduction in serum protein adsorption compared to native PDMS. This approach provided steady protein levels in the range of pH 6–12 in the culture system37. Differently, Wu and Hjort et al. modified the PDMS surface by embedding the nonionic surfactant Pluronic into the PDMS prepolymer before curing. Figure 4 shows the migration mechanism of surfactant molecules. When the channel is filled with water, the amphiphilic copolymer Pluronic embedded in PDMS will migrate towards the water/PDMS interface because of the high gradient between the PDMS substrate and water. The migrated molecules and their hydrophobic interaction on the original surface molecules changed the static contact angle of modified PDMS surface from 99° to 63° after immersing the sample in water for 24 hours. In addition, the modified surface reduced the nonspecific adsorption of Immunoglobulin G (IgG) significantly due to the improved hydrophilicity, compared to native PDMS104. Zare’s group coated PDMS surfaces with a nonionic surfactant, n-Dodecyl-b-D-maltoside (DDM), that adsorbs strongly on hydrophobic surfaces with monolayer coverage and causes the surface to become hydrophilic. Dynamic and permanent coating of the PDMS surface with DDM was evaluated. It was shown that the adsorbtion of streptavidin and BSA were suppressed by a factor of 106 with dynamic coating whereas the amount of streptavidin bound to the PDMS surface is reduced by a factor of 102 with permanent coating103. Recently, Sun et al. introduced a new kind of thin-film coating, synthesized from dimethylmethacrylate (DMA) copolymerized poly(glycidyl methacrylate) (GMA). This film demonstrates excellent long-term hydrophilicity and resistance to protein adsorption while enabling arbitrary patterning of cells on planar surfaces with precisely controlled distances of cell populations105.

Figure 4.

Schematics of the process of surface modification of PDMS with Pluronic. Reprinted from [103] with permission.

3.2.3 Charged polymers

Surface modification with charged polymers has been utilized for preparing nonbiofouling surfaces via electrostatic adsorption. A variety of coating materials such as chitosan106, poly(L-lysine) (PLL)60,107 and poly(ethylene imine) (PEI)108 have been grafted with PEG for preventing protein nonspecific binding. Lee and Voros reported the adsorption of poly(L-lysine)-graft-poly(ethylene glycol) (PLL-g-PEG) copolymer onto an oxygen plasma treated PDMS surface from an aqueous solution. The resultant surfaces resisted nonspecific protein adsorption as characterized by optical waveguide light mode spectroscopy (OWLS) and fluorescence microscopy. The PEG-ylation of PDMS surfaces by this approach is shown in Fig. 5109. According to OWLS results, excellent protein resistance was observed. The PLL-g-PEG treated PDMS surfaces were submerged 10 times in a BSA solution and after 12 weeks of preservations, only a trivial amount of serum was detected on the surfaces. 98% of the BSA was repelled. This simple modification method is also superior to conventional PEG-silanization techniques in terms of efficiency in protein resistance110.

Figure 5.

Schematic representation of the PEG-ylation of PDMS surface using PLL-g-PEG. (a) The molecular structure of PLL-g-PEG. (b) Oxygen-plasma treatment of a PDMS surface. (c) Generation of PLL-g-PEG adlayer on top of oxidized PDMS surface driven by the electrostatic interaction between PLL backbone and negatively charged surface. Reprinted from [108] with permission.

3.3 Chemical modifications

Surface modification via physisorption is experimentally simple and quick, but the weak interactions between the surface modifier and the surface result in thermal, mechanical, and solvolytic instabilities. Chemical modifications can maintain long-term stability and overcome these inherent difficulties of physisorption to achieve better surface robustness.

3.3.1 Chemical vapor deposition (CVD)

Chemical vapor deposition (CVD) is a process to create a powder or thin film on the substrate by means of the transformation of gaseous molecules into a solid. Lahann et al. used CVD polymerization between two complementary polymer coatings, poly(4-aminomethyl-p-xylylene-co-p-xylylene) and poly(4-formyl-p-xylylene-co-p-xylylene) to functionalize PDMS. Unreacted functional groups were revealed with the attachment of fluorescently labeled molecules rhodamine-conjugated streptavidin and atto-655 NHS ester on the luminal surfaces, documented by confocal laser scanning microscopy after bonding. These free chemical groups can potentially be used for further surface modification111. More recently, initiated CVD (iCVD) was used to both surface functionalize and bond microfluidic devices112. Bonding was obtained by contacting a pre-patterned surface coated with iCVD-deposited poly(glycidyl methacrylate), PGMA, with an amine functional flat PDMS substrate, prepared either by iCVD coating with poly(4-aminostyrene) (PAS) thin films or by plasma deposition of poly(allylamine) (PAAm), followed by curing. The sealed device was stable against hydrolytic degradation for more than 2 weeks. Remaining epoxy and amine groups could be used for subsequent functionalization.

3.3.2 Surface segregation and self-assembled monolayers (SAMs)

Nonbiofouling surfaces can also be prepared by using self-assembled monolayers (SAMs) obtained by the spontaneous movement of active chemical moieties onto reactive solid surfaces. van Poll et al. demonstrated novel approaches to selectively modify the surface of PDMS by exploiting differences in surface energies and the self-assembly of functional molecules to the surface35,113. In their study, an ATRP initiator, 2-bromo-2-methylpropionate, was mixed into a PDMS prepolymer. This blend was cured in contact with alkylthiolate self-assembled monolayer on the gold template. The initiator molecules were shown to migrate to the water/PDMS interface where they were further exploited to graft poly(oligo(ethylene glycol) methacrylate) chains to the chemical patterned PDMS surface35. A simple in situ approach, to modify intact microfluidic channels embedded in PDMS matrix, was introduced by Sui et al.114. For this purpose, an acidic H2O2 solution was passed through the channels for oxidation. This was followed with a sequential silanization process by injecting neat poly(ethylene glycol) (PEG)-silane solution into the microchannel. Using this solution based approach, functional groups including PEG and amine (NH2), were introduced onto PDMS surfaces for preventing protein adsorption and for the attachment of biomolecules (isothiocyanate, peptide, DNA, and protein) onto microfluidic channels. Also, this method alleviates the need of specialized instruments (i.e., oxygen plasma cleaner, UV light source, and ozone generator) for surface activation and post-assembly process after silanization. Recently, Zhou et al. reported a convenient method without multiple steps and organic solvents to increase wettability of PDMS surface by adding PEG molecules into PDMS prepolymer before curing. The contact angle of modified PDMS surface decreased from 112° on native PDMS to 75°. Moreover, protein adsorption of bovine serum albumin (BSA) was effectively suppressed on this surface115.

3.3.3 Silanization

Surface silanol groups generated on PDMS by surface activation methods can also be reacted with alkoxy- or chlorosilanes that introduce a new surface chemical functionality on the surface. To this end, for reducing nonspecific protein adsorption, Zhang et al. modified O2 plasma-pretreated PDMS microchannels with 3-glycidoxypropyltrimethoxysilane (GPTMS) and 3-chloropropyltrichlorosilane (CPTMS) which were then exposed to a NH2-PEG and alkyne-PEG solutions, respectively116,117. Surface modification by this two-step grafting method was verified by the FTIR-attenuated total reflection (FTIR-ATR) spectra. Contact angles fell dramatically to 70° for NH2-PEG grafting and 64° for PEG “click” grafting, compared with native PDMS, which had a WCA of above 100°. These values remained stable for approximately 30 days. Recently, Chuah et al. silanized PDMS surfaces with (3-aminopropyl)triethoxy silane (APTES) and used glutaraldehyde (GA) crosslinking to modified the surface properties of PDMS, including reduction of hydrophobicity, increased protein immobilization, and variation of nanotopography38. The route followed for the PDMS surface modification is shown in Fig. 6. It was also demonstrated that this covalent surface modification could generate a more biocompatible platform for stabilized cell adhesion.

Figure 6.

Schematic illustration of PDMS surface modification by APTES ± GA + Protein crosslinking and subsequent cell culture. Reprinted from [38] with permission.

3.3.4 Polymer brushes via grafting methods

Grafting is a widely used technique for modifying the surface chemistry with polymer brushes. It involves the generation of surface functional groups on PDMS surface for further modification. Superior mechanical and chemical robustness, coupled with a high degree of synthetic flexibility can be obtained by this method. Polymer grafting can be classified into two categories, grafting-to and grafting-from, which will be discussed in sections 3.3.4.1 and 3.3.4.2.

3.3.4.1 “Grafting-to” methods

In the “grafting-to” approach, preformed functionalized polymer chains are attached to reactive sites on a surface. Makamba et al. created truly stable, hydrophilic, protein resistant, thin film coatings on PDMS surfaces by first crosslinking PEMs deposited onto PDMS by carbodiimide coupling, and then covalently attaching PEG chains to the PEMs97. These samples presented constant contact angles of ~20° over the five-month study and showed strong protein resistance in undiluted rat serum. It was also shown for the first time to provide a constant EOF during the five-months that the measurements were done. This would be useful for many applications that require long-term surface stability97. Wu et al. attached graft copolymers with a glycidyl methacrylate (PGMA) backbone and hydrophilic side-chains of either polyvinylpyrrolidone (PVP) or polyvinyl alcohol (PVA) onto PDMS surfaces. PDMS microchips were first pretreated with O2 plasma and silanized with APTES, and then exposed to the copolymers featuring reactive epoxide groups on GMA repeat units. With this external polymerization, surface adsorption of lysozyme and bovine serum albumin (BSA) was reduced to less than 10% relative to that on the native PDMS surface118. Lillehoj et al. developed a simple and highly stable coating by the attachment of PEG onto air plasma pretreated PDMS surfaces. As a result of PEG coating, channel walls became hydrophilic and exhibited long-term stability maintaining contact angles below 22° for at least 47 days at room temperature under atmospheric conditions119. A hydrophilic silicate glass modified PDMS microchannel designed for glass-like performance was fabricated by channel coating of the preceramic polymer allylhydridopolycarbosilane (AHPCS) and subsequent hydrolysis by Li et al.120. A few hundred nanometer thick, hydrolyzed preceramic polymers in the channels resulted in a lowering of the contact angle from 102° to 35°. Furthermore, this facile approach could be applicable to convert various plastic-material-based microchannels for a variety of microfluidic applications, including separation.

3.3.4.2 “Grafting-from” methods

“Grafting-from” of polymers, also called surface-initiated polymerization (SIP), is a powerful and effective alternative for producing polymer brushes at the surface. In this process, active sites that initiate polymerization are generated on the surface. Then, upon exposure to monomers, polymer chains grow from the surface. Grafting-from can generate much thicker and denser coatings47. Free radical polymerization (FRP) is likely the most widely utilized approach in PDMS surface modification. Hu et al. reported on the feasibility of the grafting process using UV light illumination to generate surface radicals to initiate polymerization121 and obtain covalently attached surface coatings. They used single monomers such as acrylic acid (AA), PEG monomethoxy acrylate, or PEG diacrylate, and mixtures of monomers that include crosslinkers. Goda et al. grafted 2-methacryloyloxyethyl phosphorylcholine (MPC) from PDMS by surface-initiated photo-induced radical polymerization using benzophenone as an initiator. Modified PDMS surfaces possessed an excellent surface hydrophilicity and anti-biofouling property. The WCA of PDMS decreased from 115° to 25° after poly(MPC) grafting. The adsorption of adsorbed single proteins on the poly(MPC)-grafted PDMS membranes were reduced by about 50%–75% compared the native PDMS surface122. Huber et al. developed a novel method that can adsorb proteins from solution and release them on command in less than 1 second by grafting a 4 nm-thick polymer brush from the surface. This active polymer, poly(N-isopropylacrylamide) (PNIPAAm), is thermally switchable between an antifouling hydrophilic state and a protein-adsorbing hydrophobic state123. Recently, Zhang et al. developed a new oriented strategy by choosing peroxide-initiated polymerization instead of photo-initiation and minimizing the usage of organic solvent after modification. They produced grafted 3-methacryloxypropyltrimethoxysilane (G-570) from PDMS surfaces using sodium persulfate as an initiator, which was then reacted with allyl-PEG124. The modified assay revealed remarkable protein-repelling properties for more than 30 days.

Although free radical polymerization is a versatile approach, it has a few drawbacks. These are a) the lack of control of chain length and chain length distribution of the polymer layer, b) forming branched and highly polydisperse polymer chains125, and c) the reduction of initiator efficiency due to the so-called cage effect when the primary free radicals recombine forming macroinitiators with increasing molecular weight126. On the other hand, controlled radical polymerization (CRP) or living radical polymerization (LRP) is highly desirable, provides accurate control over brush density, polydispersity, and composition in addition to permitting the formation of block copolymers on the surface126. Of these, atom transfer radical polymerization (ATRP) is the most widely employed technique due to its high tolerance and compatibility with a wide range of functional monomers for the formation of polymer brushes via surface initiated (SI) polymerization. Xiao et al. modified the PDMS channels with polyacrylamide through ATRP to significantly grow a thin layer of covalently bonded polyacrylamide to resist the irreversible adsorption of lysozyme127. ATRP initiator was first attached to the surface by vapor deposition onto UV/ozone pretreated PDMS. Then, acrylamide was grafted from the surface using Cu(I)Cl, Cu(II)Cl2, and tris[2-(dimethylamino)ethyl]amine solutions. Jin et al. grafted poly(2-methacryloyloxyethyl phosphorylcholine) (poly(MPC)) from various polymeric substrates to investigate the protein adsorption resistance of the surfaces122. The poly(MPC) chain length was altered by varying the molar ratio of monomer to sacrificial initiator in solution. After MPC grafting, the WCA of the surface decreased to 65°. Hydrophilic poly(N-vinylpyrrolidone) (PVP) grafted PDMS elastomer surfaces were fabricated by SI-ATRP for the preparation of anti-biofouling PDMS materials by Wu et al.128. A new chlorosilane ATRP initiator was synthesized and covalently attached to the hydroxylated PDMS without any pretreatment for surface activation to generate hydroxyl groups on the surface. The resulting PVP-modified surfaces significantly inhibited both fibrinogen adsorption (by ~96%) and cell adhesion compared to unmodified controls. A quaternized poly(dimethylaminoethyl methacrylate)-grafted poly(dimethylsiloxane) (PDMS) surface (PDMS-QPDMAEMA) was successfully prepared by Tu et al. via SI-ATRP to evaluate anti-fouling properties with protein adsorption, as well as bacterial and cell adhesion studies129. The stabilized contact angle of the PDMS-QPDMAEMA surface was 49.9° and also exhibited good stability. The adsorption of anionic BSA and fibrinogen were more than RNase-A and lysozyme onto the cationic polymer brush-modified PDMS surface because of the electrostatic interaction between the charged proteins and the charged surfaces. In addition, the introduction of QPDMAEMA onto the PDMS substrate improved its cell-repellent ability where cell coverage on these modified surface reduced to approximately 15% of the native PDMS surface.

4. SUMMARY AND CRITIQUE OF THE CURRENT STATE OF THE ART

This review highlighted surface modification methods published recently in constructing nonbiofouling PDMS surfaces by tailoring surface properties and is intended to serve as a reference for choosing an appropriate and technically feasible method for specific applications. The key advantages and disadvantages of these methods are summarized below.

Surface activation methods including O2 plasma, UV/ozone treatments and corona discharge are commonly utilized for the oxidization of PDMS surfaces to render the surface hydrophilic for promoting aqueous solution filling in microchannel and facilitating PDMS microchip bonding to the flat PDMS or other substrate. In addition, surface activation generates reactive silanol functional groups which can then be reacted with alkoxy- or chlorosilanes for subsequent surface functionalization. The key benefits of these methods are the short treatment times and easy operation. These make it one of the most efficient ways to modify a PDMS surface. An ongoing challenge of these modifications is that the oxidized PDMS surface is known to recover its hydrophobicity just in minutes after exposure to air74. A common hypothesis for this hydrophobic recovery is the migration of uncured PDMS oligomers from the bulk to the surface and the rearrangement of highly mobile polymer chains at room temperature to minimize the surface energy74. Furthermore, the chemical changes involved in these methods are complex and at times poorly controlled. This requires the optimization of the process on a case-by-case basis to prevent chemical, mechanical and morphological changes that negatively impact their performance while still achieving the surface functionality desired. Indeed, most studies reported in the literature seek to prevent the degradation of one or two of these performance parameters while achieving lower nonspecific adsorption instead of finding a universal solution to this major problem. Furthermore, the complex chemical reactions that occur in these processes also brings with it the risk of undesired functional groups forming on the surface. This complexity remains an important inherent limitation of these methods.

Surface silanol groups of PDMS surface can also be created by using sol-gel method where nanometer-sized silica is formed on the PDMS channel wall in situ61. According to contact angle measurements, it was observed that more hydrophilic and stable surfaces can be obtained with the sol-gel method94. But this approach changes the mechanical properties of the materials and penetrates into the PDMS, leading to the commonly observed swelling and cracking of devices62. As the sol-gel formed materials are stiffer and more brittle than PDMS, these limitations are difficult to overcome completely by small modifications of the process.

Physisorption is a simple and efficient approach that relies basically on hydrophobic or electrostatic surface interactions. However, the lack of covalent bonding between the PDMS and the surface modifiers leads to the loss of the surface modifiers relatively quickly through desorption30. Therefore, this method is generally preferred in applications where long term chemical or mechanical stability is not a concern. The same concerns also apply to at least some coating methods such as those deposited by CVD, where the coating layer is not first attached to the PDMS layer through surface activation. To prevent desorption, at least the initial layers of the physisorbed coating may be covalently attached to the PDMS surface through chemical activation (e.g. plasma treatment). This makes the surface modification process more complicated, however, and can suffer from some of the limitations described above. Alternatively, researchers have aimed to prevent desorption and improve layer stability by decreasing the water solubility of the physisorbed materials through crosslinking, again at the cost of added processing steps.

Polymer brushes, as opposed to single hydrophilic surface groups or thin, flat polymer layers, are especially successful in preventing nonspecific protein adsorption, because they provide an additional entropic barrier to protein adsorption through the motion of polymer chains on the surface. Polymer grafting is an especially potent approach to creating such polymer brushes, and can be classified into two categories: grafting-to and grafting-from. “Grafting-to” is a relatively simpler method, where prepolymerized polymers chains are attached to reactive sites on a surface. It can be applied to create a biofouling-resistant layer coupled with various functional groups, but is limited by low surface density of grafted chains due to steric interactions between polymer coils. This confines its use to cases where defects in surface homogeneity and uniformity do not significantly matter in practice. “Grafting-from” involves the creation of radical sites as initiators on the surface for subsequent surface-initiated polymerization. This approach is widely utilized where thickness, homogeneity, and robustness are highly desired. Altering the surface with grafting methods eliminates the thermal and mechanical instabilities over other methods as well as improving inherent difficulties with more surface robustness. Although these methods provide long shelf life and reduce hydrophobicity, it is a laborious and lengthy process which is prohibitve for large scale applications. Bottom-up, single step approaches to creating hydrophilic polymer brushes are of great interest, because they would combine ease of manufacture with the exceptional nonspecific fouling resistance and functionalizability of polymer brushes.

5. FUTURE PERSPECTIVES

PDMS has been an important material in microfluidics research and device industry due to its many advantageous features. Its low cost along with its ease of use are the two most important drivers for its success. Unfortunately, the use of PDMS is not without complications and one must use care in its use. Otherwise, unexpected and artifactual results can plague and unnecessarily halt complete research programs. Alternative materials are rapidly gaining interest in the microfluidics field, yet such alternatives are not yet cost competitive and might require more complicated and specialized machinery.

In this short review we have highlighted some of the more common and important limitations of PDMS especially for biological separation and culture applications. Given our laboratory’s own interest, along with the recent European and American initiatives, in growing and maintaining tissues in microfluidic geometries towards toxicological testing, small molecule absorption is an especially big concern. While we discuss many successful strategies to alleviate the common problems with PDMS, most of them tend to be either confined to specialized labs, lack general practical applicability, or have limited shelf lives in terms of the modifications they achieve. Perhaps more importantly, characterization of the strategies we have discussed is lacking in terms of many physical (Young’s modulus, optical properties) properties as well as their cellular biocompatibility (cellular attachment, viability, etc. after modifications).

We believe that continued research in the field of materials will help in creating new methods for the modification of PDMS and alternative materials with desirable properties for both lab-on-a-chip and tissue-on-a-chip applications. As we point out in the preceding, these materials are getting increasingly used by a very wide audience and more often for biological applications. Accordingly it is important to design these new materials or material modifications to be practical enough for wide adoption while making sure that they meet the criterion for low adsorption/absorption, cellular biocompatibility, and mechanical and optical properties for their intended applications.

Acknowledgments

Dr. Yarmush, and Dr. Usta thank the NIH for funding this work through grants no. 5P41EB002503 (BioMEMS Resource Center), 1R21EB02019201A1 respectively and Dr. Asatekin thanks the NSF for funding this work through grant no. CBET-1553661.

References

- 1.Beebe DJ, Mensing GA, Walker GM. Physics and applications of microfluidics in biology. Annu Rev Biomed Eng. 2002;4:261–286. doi: 10.1146/annurev.bioeng.4.112601.125916. [DOI] [PubMed] [Google Scholar]

- 2.Haeberle S, Zengerle R. Microfluidic platforms for lab-on-a-chip applications. Lab Chip. 2007;7:1094–1110. doi: 10.1039/b706364b. [DOI] [PubMed] [Google Scholar]

- 3.Whitesides GM. The origins and the future of microfluidics. Nature. 2006;442:368–373. doi: 10.1038/nature05058. [DOI] [PubMed] [Google Scholar]

- 4.Mdou M, et al. Lab on a CD. Annu Rev Biomed Eng. 2006;8:601–628. doi: 10.1146/annurev.bioeng.8.061505.095758. [DOI] [PubMed] [Google Scholar]

- 5.Teh SY, Lin R, Hung LH, Lee AP. Droplet microfluidics. Lab Chip. 2008;8:198–220. doi: 10.1039/b715524g. [DOI] [PubMed] [Google Scholar]

- 6.Song H, Chen DL, Ismagilov RF. Reactions in droplets in microfluidic channels. Angew Chem Int Ed Engl. 2006;45:7336–7356. doi: 10.1002/anie.200601554. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Li D. Electrokinetics in Microfluidics. Academic; 2004. [Google Scholar]

- 8.Hunt HC, Wilkinson JS. Optofluidic integration for microanalysis. Microfluid Nanofluid. 2008;4:53–79. doi: 10.1007/s10404-007-0223-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Lee J, Moon H, Fowler J, Schoellhammer T, Kim CJ. Electrowetting and electrowetting-on-dielectric for microscale liquid handling. Sens Actuators A Phys. 2002;95:259–268. [Google Scholar]

- 10.Roberts MA, Rossier JS, Bercier P, Girault H. UV laser machined polymer substrates for the development of microdiagnostic systems. Anal Chem. 1997;69:2035–2042. doi: 10.1021/ac961038q. [DOI] [PubMed] [Google Scholar]

- 11.Effenhauser CS, Bruin GJ, Paulus A, Ehrat M. Integrated capillary electrophoresis on flexible silicone microdevices: Analysis of DNA restriction fragments and detection of single DNA molecules on microchips. Anal Chem. 1997;69:3451–3457. doi: 10.1021/ac9703919. [DOI] [PubMed] [Google Scholar]

- 12.McCormick RM, Nelson RJ, Alonso-Amigo MG, Benvegnu DJ, Hooper HH. Microchannel electrophoretic separations of DNA in injection-molded plastic substrates. Anal Chem. 1997;69:2626–2630. doi: 10.1021/ac9701997. [DOI] [PubMed] [Google Scholar]

- 13.Domenichini M, et al. Fabrication of layered polydimethylsiloxane/perfluoropolyether microfluidic devices with solvent compatibility and valve functionality. Microfluid Nanofluid. 2013;15:753–762. [Google Scholar]

- 14.Hu S, et al. Surface modification of poly(dimethylsiloxane) microfluidic devices by ultraviolet polymer grafting. Anal Chem. 2002;74:4117–4123. doi: 10.1021/ac025700w. [DOI] [PubMed] [Google Scholar]

- 15.Wang B, Abdulali-Kanji Z, Dodwell E, Horton JH. Surface characterization using chemical force microscopy and the flow performance of modified polydimethylsiloxane for microfluidic device applications. Electrophoresis. 2003;24:1442–1450. doi: 10.1002/elps.200390186. [DOI] [PubMed] [Google Scholar]

- 16.Leclerc E, Sakai Y, Fujii T. Microfluidic PDMS (polydimethylsiloxane) bioreactor for large-scale culture of hepatocytes. Biotechnol Prog. 2004;20:750–755. doi: 10.1021/bp0300568. [DOI] [PubMed] [Google Scholar]

- 17.Garcia CD, Dressen BM, Henderson A, Henry CS. Comparison of surfactants for dynamic surface modification of poly(dimethylsiloxane) microchips. Electrophoresis. 2005;26:703–709. doi: 10.1002/elps.200410290. [DOI] [PubMed] [Google Scholar]

- 18.Zhang Q, Xu JJ, Chen HY. Patterning microbeads inside poly(dimethylsiloxane) microfluidic channels and its application for immobilized microfluidic enzyme reactors. Electrophoresis. 2006;27:4943–4951. doi: 10.1002/elps.200600024. [DOI] [PubMed] [Google Scholar]

- 19.Mehta G, Kiel MJ, Lee JW, Kotov N, Linderman JJ. Polyelectrolyte-clay-protein layer films on microfluidic PDMS bioreactor surfaces for primary murine bone marrow culture. Adv Funct Mater. 2007;17:2701–2709. [Google Scholar]

- 20.Liang RP, Gan GH, Qiu JD. Surface modification of poly(dimethylsiloxane) microfluidic devices and its application in simultaneous analysis of uric acid and ascorbic acid in human urine. J Sep Sci. 2008;31:2860–2867. doi: 10.1002/jssc.200800149. [DOI] [PubMed] [Google Scholar]

- 21.Wu MH. Simple poly (dimethylsiloxane) surface modification to control cell adhesion. Surf Interface Anal. 2009;41:11–16. [Google Scholar]

- 22.Tsao CW, Hromada L, Liu J, Kumar P, DeVoe DL. Low temperature bonding of PMMA and COC microfluidic substrates using UV/ozone surface treatment. Lab Chip. 2007;7:499–505. doi: 10.1039/b618901f. [DOI] [PubMed] [Google Scholar]

- 23.Hashimoto M, Barany F, Soper SA. Polymerase chain reaction/ligase detection reaction/hybridization assays using flow-through microfluidic devices for the detection of low-abundant DNA point mutations. Biosens Bioelectron. 2006;21:1915–1923. doi: 10.1016/j.bios.2006.01.014. [DOI] [PubMed] [Google Scholar]

- 24.Lee GB, Chen SH, Huang GR, Sung WC, Lin YH. Microfabricated plastic chips by hot embossing methods and their applications for DNA separation and detection. Sens Actuators B Chem. 2001;75:142–148. [Google Scholar]

- 25.Wang Y, et al. Microarrays assembled in microfluidic chips fabricated from poly(methyl methacrylate) for the detection of low-abundant DNA mutations. Anal Chem. 2003;75:1130–1140. doi: 10.1021/ac020683w. [DOI] [PubMed] [Google Scholar]

- 26.Kempitiya A, Borca-Tasciuc DA, Mohamed HS, Hella MM. Localized microwave heating in microwells for parallel DNA amplification applications. Appl Phys Lett. 2009;94(6) id. 064106. [Google Scholar]

- 27.Liu Y, Rauch CB. DNA probe attachment on plastic surfaces and microfluidic hybridization array channel devices with sample oscillation. Anal Biochem. 2003;317:76–84. doi: 10.1016/s0003-2697(03)00051-4. [DOI] [PubMed] [Google Scholar]

- 28.Swickrath MJ, et al. The design and fabrication of autonomous polymer-based surface tension-confined microfluidic platforms. Microfluid Nanofluid. 2008;4:601–611. [Google Scholar]

- 29.Rolland JP, Van Dam RM, Schorzman DA, Quake SR, DeSimone JM. Solvent-resistant photocurable liquid fluoropolymers for microfluidic device fabrication [corrected] J Am Chem Soc. 2004;126:2322–2323. doi: 10.1021/ja031657y. [DOI] [PubMed] [Google Scholar]

- 30.Shadpour H, Musyimi H, Chen J, Soper SA. Physiochemical properties of various polymer substrates and their effects on microchip electrophoresis performance. J Chromatogr A. 2006;1111:238–251. doi: 10.1016/j.chroma.2005.08.083. [DOI] [PubMed] [Google Scholar]

- 31.Duffy DC, McDonald JC, Schueller OJ, Whitesides GM. Rapid prototyping of microfluidic systems in poly(dimethylsiloxane) Anal Chem. 1998;70:4974–4984. doi: 10.1021/ac980656z. [DOI] [PubMed] [Google Scholar]

- 32.Martynova L, et al. Fabrication of plastic microfluid channels by imprinting methods. Anal Chem. 1997;69:4783–4789. doi: 10.1021/ac970558y. [DOI] [PubMed] [Google Scholar]

- 33.Becker H, Gartner C. Polymer microfabrication methods for microfluidic analytical applications. Electrophoresis. 2000;21:12–26. doi: 10.1002/(SICI)1522-2683(20000101)21:1<12::AID-ELPS12>3.0.CO;2-7. [DOI] [PubMed] [Google Scholar]

- 34.Mata A, Fleischman AJ, Roy S. Characterization of polydimethylsiloxane (PDMS) properties for biomedical micro/nanosystems. Biomed Microdev. 2005;7:281–293. doi: 10.1007/s10544-005-6070-2. [DOI] [PubMed] [Google Scholar]

- 35.van Poll ML, Zhou F, Ramstedt M, Hu L, Huck WT. A self-assembly approach to chemical micropatterning of poly(dimethylsiloxane) Angew Chem Int Ed Engl. 2007;46:6634–6637. doi: 10.1002/anie.200702286. [DOI] [PubMed] [Google Scholar]

- 36.Tan SH, Nguyen NT, Chua YC, Kang TG. Oxygen plasma treatment for reducing hydrophobicity of a sealed polydimethylsiloxane microchannel. Biomicrofluidics. 2010;4:32204. doi: 10.1063/1.3466882. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Wu MH, Urban JP, Cui Z, Cui ZF. Development of PDMS microbioreactor with well-defined and homogenous culture environment for chondrocyte 3-D culture. Biomed Microdev. 2006;8:331–340. doi: 10.1007/s10544-006-9597-y. [DOI] [PubMed] [Google Scholar]

- 38.Chuah YJ, Kuddannaya S, Lee MH, Zhang Y, Kang Y. The effects of poly(dimethylsiloxane) surface silanization on the mesenchymal stem cell fate. Biomater Sci. 2015;3:383–390. doi: 10.1039/c4bm00268g. [DOI] [PubMed] [Google Scholar]

- 39.Belder D, Ludwig M. Surface modification in microchip electrophoresis. Electrophoresis. 2003;24:3595–3606. doi: 10.1002/elps.200305648. [DOI] [PubMed] [Google Scholar]

- 40.Lee JN, Park C, Whitesides GM. Solvent compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal Chem. 2003;75:6544–6554. doi: 10.1021/ac0346712. [DOI] [PubMed] [Google Scholar]

- 41.Toepke MW, Beebe DJ. PDMS absorption of small molecules and consequences in microfluidic applications. Lab Chip. 2006;6:1484–1486. doi: 10.1039/b612140c. [DOI] [PubMed] [Google Scholar]

- 42.Makamba H, Kim JH, Lim K, Park N, Hahn JH. Surface modification of poly(dimethylsiloxane) microchannels. Electrophoresis. 2003;24:3607–3619. doi: 10.1002/elps.200305627. [DOI] [PubMed] [Google Scholar]

- 43.Lee J, Kim MJ, Lee HH. Surface modification of poly(dimethylsiloxane) for retarding swelling in organic solvents. Langmuir. 2006;22:2090–2095. doi: 10.1021/la052621h. [DOI] [PubMed] [Google Scholar]

- 44.Zhou J, Ellis AV, Voelcker NH. Recent developments in PDMS surface modification for microfluidic devices. Electrophoresis. 2010;31:2–16. doi: 10.1002/elps.200900475. [DOI] [PubMed] [Google Scholar]

- 45.Abbasi F, Mirzadeh H, Katbab AA. Modification of polysiloxane polymers for biomedical applications: A review. Polymer Int. 2001;50:1279–1287. [Google Scholar]

- 46.Kartalov EP, Anderson WF, Scherer A. The analytical approach to polydimethylsiloxane microfluidic technology and its biological applications. J Nanosci Nanotechnol. 2006;6:2265–2277. doi: 10.1166/jnn.2006.504. [DOI] [PubMed] [Google Scholar]

- 47.Wong I, Ho CM. Surface molecular property modifications for poly(dimethylsiloxane) (PDMS) based microfluidic devices. Microfluid Nanofluid. 2009;7:291–306. doi: 10.1007/s10404-009-0443-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Zhou J, Khodakov DA, Ellis AV, Voelcker NH. Surface modification for PDMS-based microfluidic devices. Electrophoresis. 2012;33:89–104. doi: 10.1002/elps.201100482. [DOI] [PubMed] [Google Scholar]

- 49.Anderson JR, et al. Fabrication of topologically complex three-dimensional microfluidic systems in PDMS by rapid prototyping. Anal Chem. 2000;72:3158–3164. doi: 10.1021/ac9912294. [DOI] [PubMed] [Google Scholar]

- 50.Mukhopadhyay R. When PDMS isn’t the best. What are its weaknesses, and which other polymers can researchers add to their toolboxes? Anal Chem. 2007;79:3248–3253. doi: 10.1021/ac071903e. [DOI] [PubMed] [Google Scholar]

- 51.Wu Y, Huang Y, Ma H. A facile method for permanent and functional surface modification of poly(dimethylsiloxane) J Am Chem Soc. 2007;129:7226–7227. doi: 10.1021/ja071384x. [DOI] [PubMed] [Google Scholar]

- 52.Wang L, Sun B, Ziemer KS, Barabino GA, Carrier RL. Chemical and physical modifications to poly(dimethylsiloxane) surfaces affect adhesion of Caco-2 cells. J Biomed Mater Res A. 2010;93:1260–1271. doi: 10.1002/jbm.a.32621. [DOI] [PubMed] [Google Scholar]

- 53.Berthier E, Young EW, Beebe D. Engineers are from PDMS-land, Biologists are from Polystyrenia. Lab Chip. 2012;12:1224–1237. doi: 10.1039/c2lc20982a. [DOI] [PubMed] [Google Scholar]

- 54.Unger MA, Chou HP, Thorsen T, Scherer A, Quake SR. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science. 2000;288:113–116. doi: 10.1126/science.288.5463.113. [DOI] [PubMed] [Google Scholar]

- 55.Jeon NL, et al. Design and fabrication of integrated passive valves and pumps for flexible polymer 3-dimensional microfluidic systems. Biomed Microdev. 2002;4:117–121. [Google Scholar]

- 56.Hong JW, Quake SR. Integrated nanoliter systems. Nat Biotechnol. 2003;21:1179–1183. doi: 10.1038/nbt871. [DOI] [PubMed] [Google Scholar]

- 57.Hosokawa K, Hanada K, Maeda R. A polydimethylsiloxane (PDMS) deformable diffraction grating for monitoring of local pressure in microfluidic devices. J Micromech Microeng. 2001;12:1–6. [Google Scholar]

- 58.Holden MA, Kumar S, Beskok A, Cremer PS. Microfluidic diffusion diluter: Bulging of PDMS microchannels under pressure-driven flow. J Micromech Microeng. 2003;13:412–418. [Google Scholar]

- 59.Gervais T, El-Ali J, Gunther A, Jensen KF. Flow-induced deformation of shallow microfluidic channels. Lab Chip. 2006;6:500–507. doi: 10.1039/b513524a. [DOI] [PubMed] [Google Scholar]

- 60.Madadi H, Mohammadi M, Casals-Terre J, Lopez RC. A novel fabrication technique to minimize poly(dimethylsiloxane)-microchannels deformation under high-pressure operation. Electrophoresis. 2013;34:3126–3132. doi: 10.1002/elps.201300340. [DOI] [PubMed] [Google Scholar]

- 61.Roman GT, Culbertson CT. Surface engineering of poly (dimethylsiloxane) microfluidic devices using transition metal sol-gel chemistry. Langmuir. 2006;22:4445–4451. doi: 10.1021/la053085w. [DOI] [PubMed] [Google Scholar]

- 62.Abate AR, Lee D, Do T, Holtze C, Weitz DA. Glass coating for PDMS microfluidic channels by sol-gel methods. Lab Chip. 2008;8:516–518. doi: 10.1039/b800001h. [DOI] [PubMed] [Google Scholar]

- 63.Kim BY, Hong LY, Chung YM, Kim DP, Lee CS. Solvent-resistant PDMS microfluidic devices with hybrid inorganic/organic polymer coatings. Adv Funct Mater. 2009;19:3796–3803. [Google Scholar]

- 64.Yu K, Han YC. A stable PEO-tethered PDMS surface having controllable wetting property by a swelling-deswelling process. Soft Matter. 2006;2:705–709. doi: 10.1039/b602880m. [DOI] [PubMed] [Google Scholar]

- 65.Dangla R, Gallaire F, Baroud CN. Microchannel deformations due to solvent-induced PDMS swelling. Lab Chip. 2010;10:2972–2978. doi: 10.1039/c003504a. [DOI] [PubMed] [Google Scholar]

- 66.Usta OB, et al. Microengineered cell and tissue systems for drug screening and toxicology applications: Evolution of in-vitro liver technologies. Technology. 2015;03:1–26. doi: 10.1142/S2339547815300012. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Prodanov L, et al. Long-term maintenance of a microfluidic 3D human liver sinusoid. Biotechnol Bioeng. 2016;113:241–246. doi: 10.1002/bit.25700. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 68.McCarty WJ, et al. A novelultrathin collagen nanolayer assembly for 3-D microtissue engineering: Layer-by-layer collagen deposition for long-term stable microfluidic hepatocyte culture. Technology. 2014;2:67–74. doi: 10.1142/S2339547814500083. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 69.Hegde M, et al. Dynamic interplay of flow and collagen stabilizes primary hepatocytes culture in a microfluidic platform. Lab Chip. 2014;14:2033–2039. doi: 10.1039/c4lc00071d. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 70.Zhang C, Zhao Z, Rahim NAA, van Noort D, Yu H. Towards a human-on-chip: Culturing multiple cell types on a chip with compartmentalized microenvironments. Lab Chip. 2009;9:3185–3192. doi: 10.1039/b915147h. [DOI] [PubMed] [Google Scholar]

- 71.Sin A, et al. The design and fabrication of three-chamber microscale cell culture analog devices with integrated dissolved oxygen sensors. Biotechnol Progr. 2004;20:338–345. doi: 10.1021/bp034077d. [DOI] [PubMed] [Google Scholar]

- 72.Chen H, Zhang Z, Chen Y, Brook MA, Sheardown H. Protein repellant silicone surfaces by covalent immobilization of poly(ethylene oxide) Biomaterials. 2005;26:2391–2399. doi: 10.1016/j.biomaterials.2004.07.068. [DOI] [PubMed] [Google Scholar]

- 73.Eddington DT, Puccinelli JP, Beebe DJ. Thermal aging and reduced hydrophobic recovery of polydimethylsiloxane. Sens Actuat B Chem. 2006;114:170–172. [Google Scholar]

- 74.Wang JD, Douville NJ, Takayama S, ElSayed M. Quantitative analysis of molecular absorption into PDMS microfluidic channels. Ann Biomed Eng. 2012;40:1862–1873. doi: 10.1007/s10439-012-0562-z. [DOI] [PubMed] [Google Scholar]

- 75.Regehr KJ, et al. Biological implications of polydimethylsiloxane-based microfluidic cell culture. Lab Chip. 2009;9:2132–2139. doi: 10.1039/b903043c. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 76.Ren K, Zhao Y, Su J, Ryan D, Wu H. Convenient method for modifying poly(dimethylsiloxane) to be airtight and resistive against absorption of small molecules. Anal Chem. 2010;82:5965–5971. doi: 10.1021/ac100830t. [DOI] [PubMed] [Google Scholar]

- 77.Sasaki H, Onoe H, Osaki T, Kawano R, Takeuchi S. Parylene-coating in PDMS microfluidic channels prevents the absorption of fluorescent dyes. Sens Actuat B Chem. 2010;150:478–482. [Google Scholar]

- 78.Heo YS, et al. Characterization and resolution of evaporation-mediated osmolality shifts that constrain microfluidic cell culture in poly(dimethylsiloxane) devices. Anal Chem. 2007;79:1126–1134. doi: 10.1021/ac061990v. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 79.Millet LJ, Stewart ME, Sweedler JV, Nuzzo RG, Gillette MU. Microfluidic devices for culturing primary mammalian neurons at low densities. Lab Chip. 2007;7:987–994. doi: 10.1039/b705266a. [DOI] [PubMed] [Google Scholar]

- 80.Barbulovic-Nad I, Yang H, Park PS, Wheeler AR. Digital microfluidics for cell-based assays. Lab Chip. 2008;8:519–526. doi: 10.1039/b717759c. [DOI] [PubMed] [Google Scholar]

- 81.Chang WJ, Akin D, Sedlak M, Ladisch MR, Bashir R. Poly(dimethylsiloxane) (PDMS) and silicon hybrid biochip for bacterial culture. Biomed Microdev. 2003;5:281–290. [Google Scholar]

- 82.Lecault V, et al. High-throughput analysis of single hematopoietic stem cell proliferation in microfluidic cell culture arrays. Nat Methods. 2011;8:581–586. doi: 10.1038/nmeth.1614. [DOI] [PubMed] [Google Scholar]

- 83.Mayer G, Kohler JM. Micromechanical compartments for biotechnological applications: Fabrication and investigation of liquid evaporation. Sens Actuat A Phys. 1997;60:202–207. [Google Scholar]

- 84.Harris JM. Poly(ethylene glycol) Chemistry: Biotechnical and Biomedical Applications. Plenum Press; 1992. [Google Scholar]

- 85.Chen IJ, Lindner E. The stability of radio-frequency plasma-treated polydimethylsiloxane surfaces. Langmuir. 2007;23:3118–3122. doi: 10.1021/la0627720. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 86.Yang Y, Kulangara K, Lam RT, Dharmawan R, Leong KW. Effects of topographical and mechanical property alterations induced by oxygen plasma modification on stem cell behavior. ACS Nano. 2012;6:8591–8598. doi: 10.1021/nn301713d. [DOI] [PubMed] [Google Scholar]

- 87.Bartalena G, Loosli Y, Zambelli T, Snedeker JG. Biomaterial surface modifications can dominate cell-substrate mechanics: The impact of PDMS plasma treatment on a quantitative assay of cell stiffness. Soft Matter. 2012;8:673–681. [Google Scholar]

- 88.Priest C, et al. Microplasma patterning of bonded microchannels using high-precision “injected” electrodes. Lab Chip. 2011;11:541–544. doi: 10.1039/c0lc00339e. [DOI] [PubMed] [Google Scholar]

- 89.Efimenko K, Wallace WE, Genzer J. Surface modification of Sylgard-184 poly(dimethyl siloxane) networks by ultraviolet and ultraviolet/ozone treatment. J Colloid Interf Sci. 2002;254:306–315. doi: 10.1006/jcis.2002.8594. [DOI] [PubMed] [Google Scholar]

- 90.Berdichevsky Y, Khandurina J, Guttman A, Lo YH. UV/ozone modification of poly(dimethylsiloxane) microfluidic channels. Sens Actuat B Chem. 2004;97:402–408. [Google Scholar]

- 91.Ro KW, Lim K, Kim H, Hahn JH. Poly(dimethylsiloxane) microchip for precolumn reaction and micellar electrokinetic chromatography of biogenic amines. Electrophoresis. 2002;23:1129–1137. doi: 10.1002/1522-2683(200204)23:7/8<1129::AID-ELPS1129>3.0.CO;2-4. [DOI] [PubMed] [Google Scholar]

- 92.Hillborg H, Gedde UW. Hydrophobicity recovery of polydimethylsiloxane after exposure to corona discharges. Polymer. 1998;39:1991–1998. [Google Scholar]

- 93.Roman GT, Hlaus T, Bass KJ, Seelhammer TG, Culbertson CT. Sol-gel modified poly(dimethylsiloxane) microfluidic devices with high electroosmotic mobilities and hydrophilic channel wall characteristics. Anal Chem. 2005;77:1414–1422. doi: 10.1021/ac048811z. [DOI] [PubMed] [Google Scholar]