Abstract

Large (A) and small (B) granules of wheat starch were separated and their morphological, thermal, structural and pasting properties were investigated. The pasting properties of starches from two wheat varieties showed significant differences. For wheat variety C-306, the unfractionated starch showed higher peak, trough, breakdown, final, and setback viscosities than the starch isolated from wheat variety WH-147. On the contrary, unfractionated starch of variety WH-147 has higher pasting temperature than the starch of the variety C-306. Differential scanning calorimetry results showed that unfractionated starch exhibited the higher gelatinization enthalpy, peak and conclusion temperatures than the isolated A- and B-starch granules from both the varieties. Scanning electron microscopy results revealed that large A-granules appeared to be smooth and displayed disk or lenticular shape having diameter 13–35 μm, while B-granules showed a spherical shape with diameter of 2–6 μm. The variations in structures and content would result in starch granules with different chemical and physical properties.

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-017-2681-x) contains supplementary material, which is available to authorized users.

Keywords: Wheat starch, Granules, Pasting properties, Thermal properties

Introduction

Wheat is the most widely cultivated food grains for human consumption among cereals. Starch is the most abundant carbohydrate component of wheat. Starch is a very important raw material used in the food industry because of its properties, such as a low gelatinization temperature and low tendency to retrograde. It has high viscosity and a high water binding capacity. Thermal and pasting properties of starches largely depend on starch granules. Starch in wheat and some of its kind are deposited in two sizes of granules, whereas in most other plants there is only one size of starch granule. Each amyloplast of the mature wheat endosperm contains a single large A granule, initiated after anthesis, and a variable number of smaller B granules, initiated late in grain filling (Parker et al. 2008). The A and B granules differed according to instant of biosynthesis at some point in grain filling (Shevkani et al. 2017). The granular structure of starch can be changed under certain conditions and degree of change is highly associated with the original structure of starch granules (Blazek et al. 2009). The ordered structure in turn influence starch physical properties such as the viscosity of gels and pastes. Viscosity is largely influenced by the granule shape and swelling power, amylopectin-amylose entanglement and amylose and amylopectin granular interaction. As the starch is heated, the molecular chains open, allowing them to collide with other starch chains to form a network, thickening the liquid (starch gelatinization). Amylose molecules cause gel formation in starch solution during heating. This is because of the linear chains are arranging parallel to each other, moving close enough together to bond due to less space among them. They do not contribute to viscosity probably due to the ease with which they can slip to each other in the cooked paste. The branched amylopectin molecules which are present in high amount compare to amylose molecule contribute viscosity to the cooked paste. Their side chains and bulky shape help them from orienting closely enough to bond together, so they do not usually involve in gel formation. Thus, the present investigation focuses on the comparison of wheat varieties (WH-147 and C-306) starch granules to document the difference in their thermal, pasting and morphological properties. This comparison will aid the appropriate starch granules according to food processing parameters.

Materials and methods

Materials, reagents and standards

Two commercially available wheat (Triticum aestivum) varieties (WH-147 and C-306) were procured from CCS Haryana Agriculture University, Hisar India. The grains of each wheat variety were cleaned manually to remove damaged seeds, dust particles and weeds. Sucrose, potassium hydroxide (KOH), hydrochloric acid (HCl), potassium iodide (KI), iodine, amylose and amylopectin standard were purchased from Hi-media. All the chemicals were of analytical grade.

Starch isolation

Starch was isolated from defatted wheat flour samples of wheat varieties according to the method described by Singh et al. (2004). Stiff dough ball was prepared by mixing wheat flour with water and was kept covered with the moist cloth for 1 h. Starch was then washed manually using distilled water. The starch slurry collected was sieved, settled and centrifuged. Tailing starch was removed using spatula and pure starch fraction was purified by repeatedly suspending the starch in distilled water and centrifugation. The pure starch obtained was dried at 40 °C in hot air oven and was uniformly ground using pestle and mortar.

Separation of A- and B-granule starches

The wheat starch containing both types of starch granules was separated by centrifugation method through sucrose as described by Peng et al. (1999) with slight modifications. Starch 5 ml in distilled water (0.1 g/ml) was added to 10 ml of 80% (w/v) sucrose in a 15 ml glass tube and centrifuged at 430 rpm for 10 min. The supernatant which contained small starch granules was removed and transferred to another tube. Starch pellets were washed with distilled water, suspended in 5 ml of distilled water, and centrifuged four times in fresh 80% sucrose solution. The starch pellet constituents the large starch granule. The supernatants were collected in another tube and centrifuged at 8000 rpm for 5 min, and pellet after centrifuge contains small starch granules.

Swelling power and solubility

Swelling power and solubility of starch was determined using the method of Konik et al. (1993). About 0.5 g of starch was weighed into centrifuge tube and 25 ml of distilled water was added. This was immersed in a water bath at the temperature of 85 °C for 30 min. The slurry was mixed thoroughly with glass rod during the period of heating. The tube was removed and cooled to room temperature and then centrifuged at 6000 rpm for 15 min and sediments were weighed. Thus the swelling power of starch is calculated by using the equation:

The supernatant was carefully sucked into a crucible, weighed and heated over a steam bath and dried in an oven at 120 °C for 4 h. The dry paste was weighed. The difference in weight after drying the supernatant gave the weight of the soluble components.

Amylose and amylopectin content

Amylose content of the isolated starches was determined by iodine binding method as described by Williams et al. (1970). The starch sample (20 mg/on dry matter) was dispersed in 10 ml potassium hydroxide (0.5 N), vortexes for 5 min, and the volume was made up to 100 ml using distilled water. 10 ml of aliquot was taken and added 5 ml hydrochloric acid (0.1 N) and 0.5 ml of iodine reagent (20 g potassium iodide and 2 g resublimed iodine were dissolved in 100 ml distilled water, further 10 ml of this solution diluted to 100 ml was used as iodine reagent) were added and made up to 50 ml. Absorbance was measured at 625 nm. Amylose content (%) was determined from a standard curve developed using amylose and amylopectin blends.

Pasting properties

Pasting properties were analyzed using a Rapid Visco-Analyzer (RVA) (Perten Instruments, Australia). Viscograms of starch was monitored using starch–water suspensions (on dry starch basis, 28 g total matter). Each suspension was tested under the same temperature–time conditions.

Thermal properties

The thermal properties of isolated wheat starches were analyzed using Differential Scanning Calorimetry (PerkinElmer DSC 4000). Starch samples were weighed in an aluminium pan and distilled water was added with the help of a micro syringe to obtain a starch water suspension containing 70% water (w/w). The pan was hermetically sealed and allowed to equilibrate for 1 h. The instrument was calibrated using indium and empty aluminium pan was used as reference. The sample pans were heated from 40 to 110 °C at the rate of 10 °C/min the onset of gelatinization (To), the temperature at peak (Tp), the temperature at the end of gelatinization (Tc) and enthalpy of gelatinization (ΔHgel) were determined.

Scanning electron microscopy

Scanning electron micrographs of starch granules were taken using Scanning Electron Microscope. Starch samples were mounted on the aluminium stubs using double sided adhesive tape and coated with gold. An accelerating potential of 5 kV was used during microscopy.

Fourier transforms infrared spectrometry (FTIR)

Native starch and A- and B-granules of starch samples of two wheat varieties were studied by Fourier transform infrared spectroscopy (FTIR). IR-spectral studies were performed on Shimadzu IR affinity-I 8000 FT-IR spectrometer under dry air at room temperature using potassium bromide (KBr) pellets. 1 mg sample was mixed with 300 mg of KBr supplied with FTIR unit. The samples were pressed directly on to attenuated reflectance KBr crystal into the sampling unit. Spectra were scanned between 4000 and 400 cm−1, acquired at 4 cm−1.

Results and discussion

Composition of wheat starches

Amylose content of starches varied from 16.96 to 24.69%. The amylose to amylopectin ratio of unfractionated wheat starches were 22.17: 77.83 (C-306) and 21.20: 78.79 (WH-147). The B-granules of both varieties showed lower values of amylose content, whereas A-granules were characterized by high amylose to amylopectin ratio [17.58: 82.41 (C-306) 16.87: 83.12 (WH-147)]. Swelling power indicates the ability of starch to hydrate in cooking and heating process (90 °C/30 min). The variation in swelling power of the starch and starch granules is due to change in strength in the bond forces in the granules. Amylose content and granular properties affect the swelling power of the starches (Duffus and Murdoch 1979; Jane et al. 1999). The swelling power of starches and their A- and B-granules ranged from 12.64 to 16.75 g/g. A-granules of both varieties showed lower values of swelling power in comparison to B-granules (Supplementary Table 1).

Pasting properties

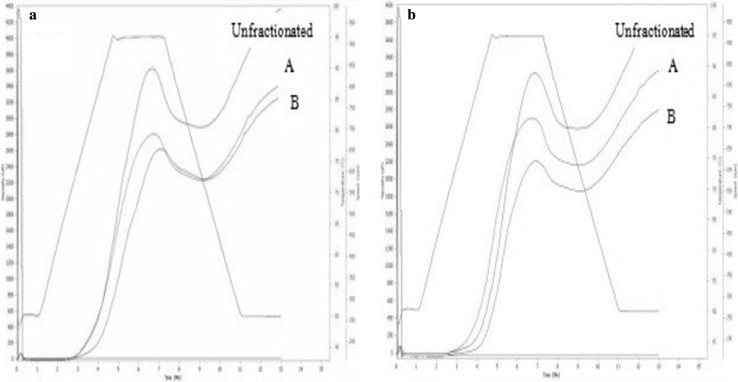

Pasting profiles of unfractionated starches and A- and B-starch granules from two wheat varieties are presented in Fig. 1a, b, and pasting properties are summarized in Table 1. The pasting properties of starches from wheat varieties showed significant differences. For C-306, the unfractionated starch showed a higher peak, through, breakdown, final, and setback viscosities than the unfractionated starch from WH-147. However, the starch from WH-147 had higher pasting temperature than unfractionated starch obtained from the C-306. A-granules showed a higher peak, trough, breakdown, final, and setback viscosities than the B-granules starch, while the B-granule starch had higher pasting temperature than the A-granule starch for both the varieties (Table 1). Though, the B-granules were characterized with the higher peak time in comparison to the A-granules, but the difference was not so significant. Similar results have been reported by Sahlström et al. (2003) and Ao and Jane (2007).

Fig. 1.

Pasting profiles of starches and their subfractions (A- and B-granules) isolated for wheat varieties C 306 (a) and WH 147 (b)

Table 1.

Pasting properties of wheat starches and their subfractions

| Variety | Starch type | PV (cP) | TV (cP) | BD (cP) | FV (cP) | SB (cP) | PT (min) | GT (°C) |

|---|---|---|---|---|---|---|---|---|

| C-306 | Unfractionated | 3611.5 | 2883.0 | 728.5 | 4328.5 | 1445.0 | 6.51 ± 0.21a | 75.0 ± 0.21b |

| A-granules | 2817.0 | 2247.5 | 569.5 | 3449.0 | 1201.5 | 6.71 ± 0.03ab | 74.5 ± 0.19a | |

| B-granules | 2600.0 | 2055.0 | 545.0 | 3252.0 | 1197.0 | 6.99 ± 0.01c | 82.9 ± 0.21 | |

| WH-147 | Unfractionated | 3249.0 | 2521.5 | 669.0 | 3896.5 | 1316.0 | 6.85 ± 0.02bc | 84.0 ± 0.04e |

| A-granules | 2725.0 | 2169.0 | 556.0 | 3264.5 | 1095.5 | 6.69 ± 0.03ab | 78.3 ± 0.1c | |

| B-granules | 2193.5 | 1851.5 | 342.0 | 2751.5 | 900.0 | 6.85 ± 0.10bc | 87.1 ± 0.1f |

Values are expressed as mean ± SD of duplicate samples; values followed by the same letters in the same column are not significantly different at P < 0.05

PV peak viscosity, TV trough viscosity, BD break down viscosity, FV final viscosity, SB set back viscosity, PT pasting time, GT gelatinization temperature

Pasting involves heat mediated granular swelling, the transformation of starch granules in excess water from ordered to disordered state, exudation of the molecular components and eventually the total rapture of the starch granules. During the initial stage of RVA test, the starch granules imbibe water rapidly. However, as the mixture is heated granule begin to swell significantly and the imbibed water aids the melting of the crystalline regions of starch granules which allows for rapid movement of water into and within the granules (Hung and Morita 2005). Starch granules absorb and bind more water while swelling which reduces the available water resulting in physical interactions between them. These interactions referred to as the pasting and results in sudden increase in the viscosity of starch and water mixture. Disruption of granules by shearing action of paddle releases starch molecules in the solution where they can have random interactions among them. The maximum viscosity i.e. peak viscosity is achieved when the rate of granules swelling equals the breakdown of granules. According to Lovedeep et al. (2007) the higher peak viscosity of unfractionated starch from both varieties may be due to presence of granules with a wide range, leading to different swelling patterns. The higher peak viscosity of A-granules compared to B-granules is attributed to their larger granules size, being larger in size A-granule would occupy a relatively larger volume compared to B-granules at a similar quantity (Singh and Kaur 2004). Peak viscosity was observed to be negatively correlated with the amylose content of starches and their fractionated starch granules. Disruption of granules results in a decrease in paste viscosity which is termed as trough viscosity and the difference between peak viscosity and trough viscosity is termed as breakdown viscosity. Therefore breakdown is regarded as the measure of the degree of disintegration of the granules or paste stability. Thus the higher breakdown viscosity of unfractionated and A-granules indicated higher stability compared to B-granules.

Pasting temperature is the temperature at which the viscosity begins to increase during the heating process. The high pasting temperature of starches indicates a higher resistance to swelling and rupture. During the cooling stage, glucan chains of starch molecules entangled to each other forming a gel and increase in the paste viscosity (Fig. 1). The setback viscosity (difference between peak and final viscosity) is exhibited due to recrystallization of amylose molecules in the gel, which is the measure of the gelling ability or retrogradation ability of starches (Hung and Morita 2005). Setback viscosity was higher for A-granules and B-granules for both varieties in comparison to the unfractionated starches (Table 1). This may be attributed due to the differences in amylose contents of the two varieties (Fig. 2).

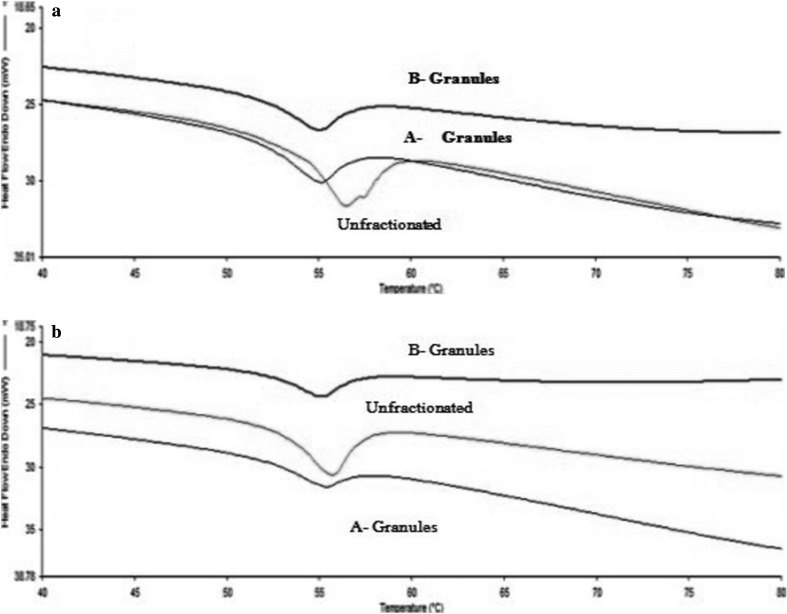

Fig. 2.

Thermographs of starches and their A- and B-granules isolated for wheat varieties C 306 (a) and WH 147 (b)

Thermal properties

Thermal properties of the unfractionated wheat starches and their isolated A- and B-granules were measured by differential scanning calorimetry and results are shown in Table 2. The thermographs of starch samples are shown in Fig. 2. Unfractionated starch granules showed the higher gelatinization, peak and conclusion temperatures than the isolated A- and B-starch granules for the both varieties. The gelatinization temperature indicates the heat stability of the crystalline structure, which depends on the granules size distribution in the starches (Xie et al. 2008; Li and Yeh 2001). In present study, small granules of both the varieties showed higher gelatinization temperature (Table 2). The unfractionated starches exhibited the highest gelatinization enthalpy (ΔH) compared with the isolated A- and B-starch granules (Table 2). The gelatinization enthalpy (ΔH) has been related to the degree of crystallinity value. Starches with higher cristallinity had higher ΔH and lower swelling power (Singh et al. 2009). For both the varieties, A-granules showed a higher relative cristallinity value that requires more energy for gelatinization than the B-starch granules. The ΔH reflected the loss of molecular double helical order rather than crystalline and results from a high degree of cristallinity (Cooke and Michael 1992), which provides structural stability and makes the granules more resistant to gelatinization order. The variation in ΔH in starches from different varieties may be due to differences in quantity of longer chain amylopectin (Singh et al. 2003). Yuan et al. (1993) observed that ΔH decreased with decreasing granule size and the present results agreed with their observation (Table 2). Small granule fractions showed higher gelatinization temperatures than the large granule fractions which is analogous to the results of Peng et al. (1999).

Table 2.

Thermal properties of wheat starches and their subfractions

| Variety | Sample | To (°C) | Tp (°C) | Tc (°C) | Tc–To (°C) | ΔH (J/g) |

|---|---|---|---|---|---|---|

| C-306 | Unfractionated | 53.99 ± 0.04c | 56.69 ± 0.43b | 59.04 ± 0.13b | 5.05 ± 0.08 cd | 13.14 ± 0.09 |

| A-granules | 51.9 ± 0.17a | 55.06 ± 0.13a | 57.17 ± 0.29a | 5.29 ± 0.12d | 7.95 ± 0.13 | |

| B-granules | 52.0 ± 0.19a | 55.20 ± 0.23a | 57.16 ± 0.36a | 5.16 ± 0.17 cd | 6.97 ± 0.04 | |

| WH-147 | Unfractionated | 52.78 ± 0.29 | 55.35 ± 0.14a | 57.16 ± 0.27a | 4.37 ± 0.02a | 12.47 ± 0.13 |

| A-granules | 52.4 ± 0.17ab | 55.12 ± 0.06a | 57.01 ± 0.09a | 4.67 ± 0.09b | 6.41 ± 0.22 | |

| B-granules | 52.5 ± 0.23b | 55.63 ± 0.46a | 57.40 ± 0.41a | 4.91 ± 0.13bc | 5.06 ± 0.29 |

Values are expressed as mean ± SD of duplicate samples; values followed by the same letters in the same column are not significantly different at P < 0.05

T o onset temperature, T p peak temperature, T c conclusion temperature, T c –T o temperature range, ΔH gelatinization enthalpy

Morphological properties by scanning electron microscopy

The SEM of both varieties of unfractionated wheat starch granules showed a clearly bimodal pattern and the large granules were surrounded by small starch granules (Fig. 3). The large A-granules appeared to be smooth and displayed disk or lenticular shape having diameter 13–35 µm. The B-granules showed a spherical or polygonal shape with diameter 2–6 µm. The same results were reported by Singh et al. (2009). Furthermore, it can be noticed from SEM micrographs that A-type starch granules were contaminated to a very minor degree with B-granules. Also, B-granules were contaminated by some disc shaped A-granules. The physicochemical and functional properties of wheat starches may be influenced by differences in granules size and shape (Jane et al.1994 and salman et al. 2009).

Fig. 3.

Scanning electron micrographs of starches of wheat varieties C 306 (a) and WH 147(b) and their isolated A-granules (a1 and b1, respectively) and B-granules (a2 and b2, respectively)

Fourier transforms infrared spectrometry analysis

The infrared spectroscopy is sensitive to structural changes on starch macromolecule, such as helicoidal chain conformation, crystallinity, retrogradation and water content. Figure 4 shows FTIR spectra of the samples in the 4000–400 cm−1 regions. The starches and isolated A- and B-starch granules exhibited similar patterns and showed 16 peaks in the 4000–400 cm−1 region. The IR spectrums of both the starches were described by three main regions, with maximum absorbance peaks near 3500–2400, 1700–1000, 1000–400 cm−1 (Yoo and Jane 2002; Jane et al. 1994).

Fig. 4.

FTIR spectroscopy patterns of starches of wheat varieties C 306 (a) and WH 147 (d) and their isolated A-granules (b and e, respectively) and B-granules (c and f, respectively)

The peaks at 3400 and 2930 cm−1 corresponding to O–H and C–H bond stretching, respectively, while the peaks at 1420 and 1366 cm−1 were attributable to the bending modes of H–C–H, C–H and O–H. The peaks at 1300–1000 cm−1 were attributed to C–O–H stretching with some attribute to C–C stretching. The peaks at 1155, 1097 and 1019 cm−1 were contributed to C–OH and CH2 deformations. The bands at 1047 and 1022 cm−1 were associated with the ordered and amorphous structures of starches, respectively. The ratio of absorbance 1047/1022 cm−1 was used to quantify the degree of order in starch samples. Degree of order of 1.40 for WH-147 was found to be more in comparison to degree of order of 1.23 for C-306. The bands at 930–900 cm−1 were attributed to d-glucopyranosyl ring vibrational modes, 844 ± 10 cm−1 to the C–H absorbance of the d-glucopyranosyl rings and 766 ± 10 cm−1 to d-glucopyranosyl ring stretching. The 1670–1600 cm−1 bands were assigned to H2O bending vibrations. As presented in Fig. 4, the FTIR spectra of starches and isolated A- and B-granules exhibited these patterns. Similar results were presented by the Zeng et al. (2011). Bands at 1053 cm−1 increases with the storage time due to the crystallization of starch chains (Goodfellow and Wilson 1990).

Conclusion

The starches isolated from WH-147 and C-306 wheat grains exhibited a bimodal size distribution of starch granules. The SEM of both varieties unfractionated wheat starch granules showed a clearly bimodal pattern and the large granules were surrounded by small starch granules. The A and B-granules of both starches showed different compositional properties including amylose and amylopectin content, amylopectin/amylose ratio and swelling power. Amylose content was higher in unfractionated starches of both the wheat varieties than the large and small granules. For both wheat varieties A-granules showed a higher peak, trough, breakdown, final, and setback viscosities than the B-granules, while the B-granules had higher pasting temperature than the A-granules. The unfractionated starch exhibited the highest gelatinization enthalpy (ΔH) compared with the isolated A- and B-starch granules. Small granule fractions showed higher gelatinization temperatures than the large granule. FTIR spectra of both starches exhibited similar patterns of absorbance. Degree of order (ratio of absorbance 1047/1022 cm−1) for WH-147 found to be more in comparison to C-306.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Footnotes

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-017-2681-x) contains supplementary material, which is available to authorized users.

References

- Ao Z, Jane JL. Characterization and modelling of the A- and B-granule starches of wheat, triticale, and barley. Carbohydr Polym. 2007;67:46–55. doi: 10.1016/j.carbpol.2006.04.013. [DOI] [Google Scholar]

- Blazek J, Salman H, Rubio AL, Gilbert E, Hanley T, Copeland L. Structural characterization of wheat starch granules differing in amylose content and functional characteristics. Carbohydr Polym. 2009;75:705–711. doi: 10.1016/j.carbpol.2008.09.017. [DOI] [Google Scholar]

- Cooke D, Michael JG. Loss of crystalline and molecular order during starch gelatinisation: origin of the enthalpic transition. Carbohydr Res. 1992;227:103–112. doi: 10.1016/0008-6215(92)85063-6. [DOI] [Google Scholar]

- Duffus CM, Murdoch SM. Variation in starch granule size distribution and amylose content during wheat endosperm development. Cereal Chem. 1979;56:427–429. [Google Scholar]

- Goodfellow BJ, Wilson RH. A Fourier- transforms IR study of the gelation of amylose and amylopectin. Biopolymers. 1990;30:1183–1189. doi: 10.1002/bip.360301304. [DOI] [Google Scholar]

- Hung PV, Morita N. Physicochemical properties of hydroxypropylated and cross-linked starches from A-type and B-type wheat starch granules. Carbohydr Polym. 2005;59:239–246. doi: 10.1016/j.carbpol.2004.09.016. [DOI] [Google Scholar]

- Jane JL, Kasemsuwan T, Leas S, Zobel H, Robyt JF. Anthology of starch granule morphology by scanning electron microscopy. Starch-Stärke. 1994;46:121–129. doi: 10.1002/star.19940460402. [DOI] [Google Scholar]

- Jane JL, Chen YY, Lee LF, McPherson AE, Wong KS, Radosavljevic M, Kasemsuwan T. Effects of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch. Cereal Chem. 1999;76:629–637. doi: 10.1094/CCHEM.1999.76.5.629. [DOI] [Google Scholar]

- Konik CM, Kisklly DM, Gras PW. Starch swelling power, grain hardness and protein relation to sensory properties of Japanese noodles. Starch-Stärke. 1993;45:139–144. doi: 10.1002/star.19930450406. [DOI] [Google Scholar]

- Li JY, Yeh AI. Relationship between thermal, rheological characteristics and swelling power for various starches. J Food Eng. 2001;50:141–148. doi: 10.1016/S0260-8774(00)00236-3. [DOI] [Google Scholar]

- Lovedeep K, Jaspreet S, Owen JM, Harmit S. Physico- chemical, rheological and structural properties of fractionated potato starches. J Food Eng. 2007;82:383–394. doi: 10.1016/j.jfoodeng.2007.02.059. [DOI] [Google Scholar]

- Parker ML, Kirby AR, Morris VJ. In situ imaging of pea starch in seeds. Food Biophys. 2008;3:66–76. doi: 10.1007/s11483-007-9050-7. [DOI] [Google Scholar]

- Peng M, Gao M, Abdel Aal ES, Chibbar RN. Separation and characterization of A- and B-type starch granules in wheat endosperm. Cereal Chem. 1999;76:375–379. doi: 10.1094/CCHEM.1999.76.3.375. [DOI] [Google Scholar]

- Sahlström S, Baevre AB, Brathen E. Impact of starch properties on hearth bread characteristics. II. Purified A- and B-granule fractions. J Cereal Sci. 2003;37:285–293. doi: 10.1006/jcrs.2002.0504. [DOI] [Google Scholar]

- Salman H, Blazek J, Lopez-Rubio A, Gilbert EP, Hanley T, Copeland L. Structure-function relationships in A and B granules from wheat starches of similar amylose content. Carbohydr Polym. 2009;75:420–427. doi: 10.1016/j.carbpol.2008.08.001. [DOI] [Google Scholar]

- Shevkani K, Singh N, Bajaj R, Kaur A. Wheat starch production, structure, functionality and applications: a review. Int J Food Sci Technol. 2017;52:38–58. doi: 10.1111/ijfs.13266. [DOI] [Google Scholar]

- Singh N, Kaur L. Morphological, thermal, rheological and retrogradation properties of potato starch fractions varying in granule size. J Sci Food Agric. 2004;84:1241–1252. doi: 10.1002/jsfa.1746. [DOI] [Google Scholar]

- Singh N, Singh J, Kaur L, Sodhi NS, Gill BS. Morphological, thermal, and rheological properties of starches from different botanical sources. Food Chem. 2003;81:219–231. doi: 10.1016/S0308-8146(02)00416-8. [DOI] [Google Scholar]

- Singh N, Chawla D, Singh J. Influence of acetic anhydride on physicochemical, morphological and thermal properties of corn and potato starch. Food Chem. 2004;86:601–608. doi: 10.1016/j.foodchem.2003.10.008. [DOI] [Google Scholar]

- Singh S, Singh N, Isono N, Noda T. Relationship of granule size distribution and amylopectin structure with pasting, thermal, and retrogradation properties in wheat starch. J Agric Food Chem. 2009;58:1180–1188. doi: 10.1021/jf902753f. [DOI] [PubMed] [Google Scholar]

- Williams PC, Kuzina FD, Hlynka I. A rapid colorimetric procedure for estimating the amylose content of starches and flours. Cereal Chem. 1970;47:411–420. [Google Scholar]

- Xie XS, Cui SW, Li W, Tsao R. Isolation and characterization of wheat bran starch. Food Res Int. 2008;41:882–887. doi: 10.1016/j.foodres.2008.07.016. [DOI] [Google Scholar]

- Yoo SH, Jane JL. Structural and physical characteristics of waxy and other wheat starches. Carbohydr Polym. 2002;49:297–305. doi: 10.1016/S0144-8617(01)00338-1. [DOI] [Google Scholar]

- Yuan RC, Thompson DB, Boyer CD. Fine structure of amylopectin in relation to gelatinization and retrogradation behaviour of maize starches from three wax-containing genotypes in two inbred lines. Cereal Chem. 1993;70:81–89. [Google Scholar]

- Zeng J, Li GL, Gao HY, Ru ZG. Comparison of A and B starch granules from three wheat varieties. Molecules. 2011;16:10570–10591. doi: 10.3390/molecules161210570. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.