Abstract

The Pittsburgh Mining Research Division of the U.S. National Institute for Occupational Safety and Health (NIOSH) conducted underground evaluations in an attempt to quantify respirable rock dust generation when using untreated rock dust and rock dust treated with an anticaking additive. Using personal dust monitors, these evaluations measured respirable rock dust levels arising from a flinger-type application of rock dust on rib and roof surfaces. Rock dust with a majority of the respirable component removed was also applied in NIOSH’s Bruceton Experimental Mine using a bantam duster. The respirable dust measurements obtained downwind from both of these tests are presented and discussed. This testing did not measure miners’ exposure to respirable coal mine dust under acceptable mining practices, but indicates the need for effective continuous administrative controls to be exercised when rock dusting to minimize the measured amount of rock dust in the sampling device.

Introduction

Two recent regulations have modified operators’ rock dusting schedules in order to meet compliance standards. First, the 80 percent incombustible requirement in intake entries has increased both on-section and outby-the-section rock dusting. Secondly, the recent change to the respirable dust regulation has increased the number of respirable dust samples taken per sampling cycle. Previously, when only five samples were needed bimonthly, rock dusting could be scheduled to not interfere with the respirable dust sampling schedule.

The significant number of samples now required under new regulations, combined with the need to maintain 80 percent total incombustible content in active mining areas, require the schedules for respirable dust sampling and rock dusting to overlap. Although rock dust is considered a nuisance dust in relation to U.S. Mine Safety and Health Administration (MSHA) sampling, these overlapping schedules raise concerns about the amount of rock dust that potentially is included in the sample. Additionally, the respirable dust maximum was lowered from 2.0 mg/m3 to 1.5 mg/m3 effective Aug.1, 2016, increasing concern that rock dust contamination may be an issue (MSHA, 2016). Currently, the acceptable practice is to apply administrative controls such as keeping the miners upwind during rock dust application, or to schedule rock dusting during a maintenance shift when the number of miners present is lower.

The U.S. National Institute for Occupational Safety and Health’s (NIOSH) research examining rock dust quality has led to the development of hydrophobic rock dusts. In September 2011, NIOSH analyzed several rock dust samples being used in underground coal mines and determined that many of the samples did not meet the rock dust size requirements set forth in Title 30 Code of Federal Regulations Part 75.2, or 30 CFR 75.2 (NIOSH, 2011). Almost half of the samples did not contain the minimum of 70 percent passing through a 200-mesh (75-μm) sieve. Further, all of the samples caked after being wetted and then dried, meaning that they would not meet 30 CFR 75.2 requirements. Since then, several rock dust manufacturers have developed anticaking rock dusts. The anticaking additives used are typically fatty acids that make the rock dust hydrophobic and are added in very low quantities (< 1 percent) (Cybulski, 1975). One function of the anticaking additives developed is as a fluidizing agent (NOW Foods, 2016; Acme-Hardesty Co., 2016; Croda International Plc, 2016). While this development adds to the rock dust fluidity, a potential problem may be the increased airborne re-entrainment of rock dust as a result of vehicles running over the noncaked rock dust.

Respirable dust measurements downwind of rock dusting applications had not previously been collected. Therefore, Pittsburgh Mining Research Division (PMRD) researchers collected sample measurements downwind to identify the extent to which rock dusting activities may contribute to respirable dust sample measurements. Limited tests were conducted by dispersing treated and untreated rock dusts at a mine. Additionally, more controlled tests were conducted within NIOSH’s Bruceton Experimental Mine (BEM) to determine if removal of material sized smaller than 10 μm can adequately reduce the respirable dust measurements downwind.

Test method

NIOSH conducted a series of controlled experiments at a participating mine site to assess the levels of respirable rock dust generated by applications of treated and untreated rock dusts to mine surfaces. Due to results obtained from the mine site testing, a supply of rock dust was classified so that a majority of the respirable dust was removed. The result was 6 percent of material smaller than 10 μm remaining in the final rock dust. This rock dust was then applied in the BEM to assess the reduction in respirable dust measurements downwind.

Mine site tests

The mine site testing evaluated the generation of respirable-sized rock dust during dry applications of untreated rock dust (33 percent smaller than 10 μm) and treated rock dust (38 percent smaller than 10 μm). These particular rock dusts, with similar numbers of particles smaller than 10 μm, have been used extensively during NIOSH research and are used here as a means of comparison to past data. Four tons of both the untreated and treated material were shipped to the mine site. The shipment of eight pallets was received two weeks prior to testing. Each one-ton bag of rock dust was stored outside on the pallet on which it was delivered. The eight bags were covered with brattice cloth to protect them from moisture. The rock dust bags were not lined with a plastic water-resistant liner, nor were they plastic-wrapped on the pallet. Otherwise, the rock dust was shipped and stored in the same manner that the manufacturer normally ships and the mine normally stores one-ton bags of rock dust.

The section of the mine where the testing occurred was 10 breaks inby from the mine portal. Figure 1 shows the layout of the tests in two adjacent entries. The evening prior to each day of testing, the mine roof and ribs were washed with water by mine personnel to remove the existing rock dust. Curtains were hung in the crosscuts as close to the rib as possible so that the entry would be a continuous single entry in the dusted zone to the end of the sampling zone. A scoop was used to remove excess rock dust from the floor before rock dust application. Due to the available entry length, the dusted zone was 82.3 m (270 ft) and the sampling zone was 30.5 m (100 ft). The test entries were 6.1 m (20 ft) wide by 2.7 m (9 ft) high.

Figure 1.

Layout of mine site tests.

A mobile dry rock duster was used to apply dry treated and dry untreated rock dusts to the entries as shown in Fig. 1, in a manner consistent with the practice at that operation. The rock dusts were applied at similar rates and at similar coverages to the mine surfaces. Rock dust failing to adhere to the roof and ribs was allowed to fall and settle on the mine floor. Dust levels measured during this activity are considered to be indicative of dust generation due to rock dust application.

For testing, instrumentation was placed approximately 30.5 m (100 ft) downwind or outby the end of the rock dust zone (Fig. 1). The instruments used were PDM 3600 personal dust monitors (Thermo Fisher Scientific Inc., Waltham, MA), providing continuous dust mass concentrations for one-minute sampling periods (Page et al., 2008, 2016). Two PDM 3600s were located approximately 30.5 m (100 ft) downwind from the end of each application. This location was chosen because, based upon past dust dispersion studies, particles that are smaller than 75 μm tend to settle and fall out of the air stream at 15.2 to 18.3 m (50 to 60 ft). At 30.5 m (100 ft), the dust that is still airborne would be respirable in size. Also, the instrumentation was located at least 30.5 m (100 ft) downwind to allow any airborne dust within the entry to be more uniformly distributed across the entire entry. This approach minimizes uneven concentrations of dust that may be present closer to the applicator. This should also provide dust concentrations that are reproducible for similar test conditions.

The PDM 3600s were positioned at midentry height with one set located on the right side of the entry (right return) and the other on the left (left return). Another PDM 3600 was located approximately 30.5 m (100 ft) upwind from the start of each application, positioned at the same height and in the middle of the entry (intake), as a check on upwind dust levels.

About 16.8 m (55 ft) inby the dusted zone, a permissible continuous-recording anemometer was centerline-placed. Handheld anemometer traverses were conducted periodically during testing to verify ventilation consistency. During application of the untreated and treated rock dusts, ventilation airflow averaged from 23.8 to 34.4 m/min (78 to 113 fpm). The atmospheric pressure was 776 mm Hg with a consistent temperature of 13.3 °C (56 °F) during testing.

BEM tests

Two tests were conducted using a classified rock dust containing less than about 6 percent of material sized smaller than 10 μm. The first test’s ventilation rate used a low airflow of about 30.5 m/min (100 fpm) and the second test used a high airflow of about 67.1 m/min (220 fpm). The entry dimensions are 2 m (6.5) high and 3.4 m (11 ft) wide.

A continuous monitoring anemometer was placed approximately 15.2 m (50 ft) inby the rock duster. The latest updated PDM 3700 personal dust monitor (Thermo Fisher Scientific Inc., Waltham, MA) was used to measure the respirable dust in the BEM tests. As with the mine site tests, the PDM 3700s were used for respirable dust measurements. PDM 3700s were placed approximately 15.2 m (50 ft) inby the rock duster (upwind) and 30.5 and 152 m (100 and 500 ft) outby (downwind) of the rock duster (see Fig. 2).

Figure 2.

General layout of Bruceton Experimental Mine tests.

A third test at a high airflow was conducted using a reference rock dust, which has historically been used in Lake Lynn Experimental Mine (LLEM) testing to determine the recommended minimum requirement of 80 percent total incombustible content (NIOSH, 2010).

Results

Mine site tests

Instead of just one application of rock dust to the 82.3-m (270-ft) section, two passes were made to apply the four total tons of rock dust.

Untreated rock dust application

When two tons of the untreated rock dust were opened and emptied into the scoop of the flinger duster, the rock dust was observed as being extremely moist and wet (Fig. 3). Therefore, a sample was collected from a newly opened bag. When analyzed at the PMRD laboratory in Bruceton, the untreated rock dust contained an average of 12 percent moisture, while the treated rock dust contained an average of 0.13 percent. The moisture content was determined by measuring the mass difference before and after drying the sample in an oven at 105 °C (221 °F) for one hour.

Figure 3.

Untreated rock dust in the scoop. The rock dust is moist throughout.

When the rock dust was emptied into the scoop, it was observed that the rock dust was damp throughout the bag. No dry pockets of dust existed even at the center of the bag. Particle size analysis using the PMRD’s Beckman Coulter analyzer (Beckman Coulter Inc., Brea, CA) indicated the untreated rock dust had a mean particle diameter of 17.8 μm and a median diameter of 15.4 μm. The specific surface area was measured at 8,885 cm2/mL, or 3,290 cm2/g. This product was 99.99 percent smaller than 75 μm, 91.4 percent smaller than 38 μm and 36.2 percent smaller than 10 μm (Table 1).

Table 1.

Description of rock dust particle size distributions of the treated and untreated rock dusts shipped to the mine site. The mine site regularly used rock dust, a classified rock dust in which respirable components were removed, and a reference rock dust previously tested extensively at the U.S. Bureau of Mines and NIOSH (BEM = Bruceton Experimental Mine).

| Test location | Mine site | Mine site | Mine site | BEM | BEM |

| Rock dust | Untreated | Mine’s untreated | Treated | Classified | Reference |

| Mean diameter (μm) | 17.8 | 70.1 | 23.4 | 27.3 | 66.8 |

| Median diameter (μm) | 15.4 | 38.8 | 15.1 | 25.7 | 34 |

| Specific surface area (cm2/g) | 3,290 | 1,943 | 4,365 | 1,214 | 2,810 |

| % < 75 μm | 99.99 | 68.0 | 95.0 | 99.7 | 63.9 |

| % < 38 μm | 91.4 | 49.5 | 77.7 | 82.8 | 51.3 |

| % < 10 μm | 36.2 | 20.5 | 43.1 | 5.9 | 32.5 |

Mine surfaces were still damp from being washed down the previous evening. Some water puddles were present on the mine floor. When the rock dust was applied, it was flung in clumps and did not “dust” the ribs (Fig. 4). Visually, not much dust was generated during dusting, resulting in inadequate application afterwards (Fig. 5). There was a layer of dust about 6.4 to 12.7 mm (0.25 to 0.5 in.) thick residing on the floor.

Figure 4.

Flinger rock dusting machine applying the moist untreated rock dust.

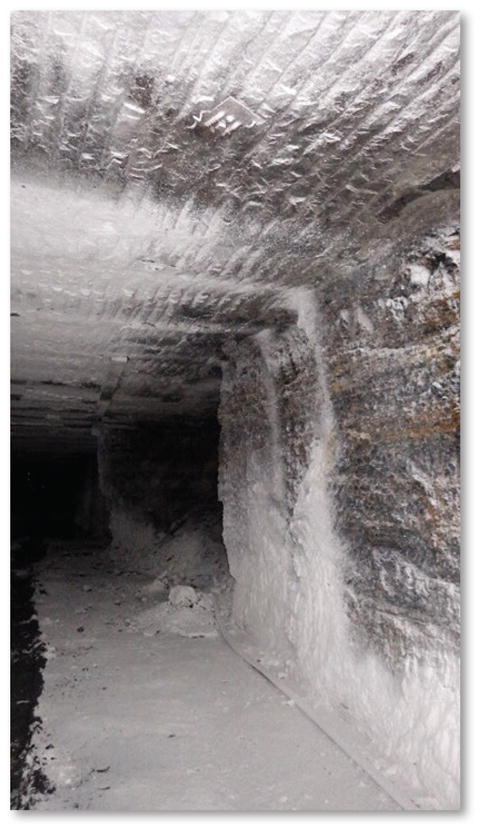

Figure 5.

Moist rock dust applied to the mine entry by the flinger rock dusting machine.

Table 2 provides a summary of the sampling data from the PDM 3600s. In the table, the application of the rock dust is listed as “untreated rock dust,” which is the application of first two tons of material, and “untreated rock dust, 2nd application,” which is the application of the final two tons of material.

Table 2.

Dust sampling data from the mine test site tests.

| Rock dust applied | Average air velocity (ft/min) | Activity time (min) | Average PDM dust concentrations (mg/m3) | ||

|---|---|---|---|---|---|

| Intake | Left return | Right return | |||

| Untreated rock dust | 84 | 12.7 | 0.04 | 0.52 | 0.11 |

| Untreated rock dust, 2nd application | 74 | 12.0 | 0.00 | 1.28 | 1.18 |

| Mine’s untreated rock dust | 78 | 7.0 | 0.04 | 504.23a | 489.38a |

| Treated rock dust | 89 | 4.8 | 0.26 | 1,135.68a, b, c | 635.11a, c |

| Treated rock dust, 2nd application | 80 | 3.5 | 0.03 | 1,111.39a, b, c | 598.67a, c |

PDM Mass Offset Status Code — gains of more than 0.2 mg in two-minute period.

PDM TE Frequency Status Code — tapered element — should be vibrating at frequency range — would invalidate sample due to the frequency outside of the range for less than 1 min.

PDM Flow Out Range Status Code — sampling flow rate varies from 2.2 L/min by more than 0.2 L/min.

PDM 3600 measurements in the intake air were 0.04 mg/ m3. When applying the moisture-laden rock dust with the flinger duster, the dust concentrations measured by the PDM 3600 ranged from 0.11 to 1.28 mg/m3 on the right and left sides downwind of the dusted zone, respectively.

Due to the inadequate distribution of the moisture-lad-en rock dust by the flinger (Fig. 5), mine personnel applied more rock dust to the entry to maintain explosion hazard safety and remain in compliance with 30 CFR 75.403. The mine applied rock dust from its own supply. The mine’s one-ton bags of rock dust are normally shipped on a pallet that is shrinkwrapped with plastic.

The mine’s rock dust was much drier. Particle size analysis indicated that the mine’s rock dust had a mean particle diameter of 70.1 μm and a median diameter of 38.8 μm. The specific surface area was measured at 5,248 cm2/mL, or 1,943 cm2/g. This product was 68.0 percent smaller than 75 μm, 49.5 percent smaller than 38 μm and 20.5 percent smaller than 10 μm (Table 1). The flinger application was more consistent with the dry rock dust as opposed to the moist rock dust (Fig. 6).

Figure 6.

Flinger rock dusting machine applying the mine’s dry rock dust.

During the application of the mine’s dry rock dust overtop of the moisture-laden rock dust, the PDM 3600s downwind of the application measured 504.23 mg/m3 and 489.38 mg/m3 for the left and right returns, respectively. Both PDM 3600 instruments had a PDM Mass Offset Error message afterwards, indicating gains of more than 0.2 mg in a two-minute sampling period.

Treated rock dust application

Four tons of treated material were applied in the adjacent entry. Particle size analysis of the treated rock dust measured a mean particle diameter of 23.4 μm and a median diameter of 15.1 μm. The specific surface area was 11,787 cm2/mL, or 4,365 cm2/g. This product was 95.0 percent smaller than 75 μm, 77.7 percent smaller than 38 μm and 43.1 percent smaller than 10 μm (Table 1).

The testing area had been washed down the previous evening, and instrumentation was placed in a manner similar to the first day. When the four tons of the treated rock dust were opened and emptied into the scoop of the flinger duster, the rock dust was dry and fluffy (Fig. 7). When the treated rock dust was applied with the flinger, the scoop operator had to maintain a constant pace so that he would not be overcome by the dust cloud (Fig. 8). To apply the entire four tons of treated rock dust, the scoop operator re-rock-dusted the same 82.3-m (270-ft) dust zone. Upwind (intake) PDM 3600 concentrations ranged from 0.03 to 0.26 mg/m3. During application of the treated rock dust, downwind PDM 3600 measurements were roughly 1,100 mg/m3 for the left side and roughly 600 mg/m3 for the right side. The differences in the PDM 3600 measurements may be due, again, to variations in entry ventilation and the position of the scoop during the application process, with the operator located on the right side. Nevertheless, the dust concentrations measured were far above what the instrumentation is intended to sample, which is 5 mg/m3 and below.

Figure 7.

Treated rock dust, which was dry and fluffy when loaded into the scoop.

Figure 8.

Scoop operator applying treated rock dust using a flinger rock dusting machine.

BEM tests

Classified rock dust application

For testing within the BEM to determine if the removal of material sized smaller than 10 μm could adequately reduce the respirable dust measurements downwind, a rock dust was classified to remove a large portion of that material.

Particle size analysis indicated that the classified rock dust had a mean particle diameter of 27.3 μm and a median diameter of 25.7 μm. The specific surface area was measured at 3,279 cm2/mL, or 1,214 cm2/g. This product was 99.7 percent smaller than 75 μm, 82.8 percent smaller than 38 μm and 5.9 percent smaller than 10 μm (Table 1).

Reference rock dust

A reference rock dust was also applied at high airflow for comparison. The reference rock dust particle size analysis indicated a mean particle diameter of 66.8 μm and a median diameter of 34.0 μm. The specific surface area was measured at 7,589 cm2/mL, or 2,810 cm2/g. This product was 63.9 percent smaller than 75 μm, 51.3 percent smaller than 38 μm and 32.5 percent smaller than 10 μm (Table 1).

Neither of the rock dusts applied in the BEM were treated. The respirable dust measurements for the classified rock dust applications were much less than those obtained from the mine site testing. However, the measurements, ranging from 17.3 to 43.2 mg/m3, were still above and beyond the limit at which the instrumentation is designed to sample, which is 5 mg/m3. For the lower airflow, 43.2 and 28.8 mg/m3 were measured 30.5 and 152 m (100 and 500 ft) downwind, respectively (Table 3).

Table 3.

Dust sampling data from Bruceton Experimental Mine tests.

| Air velocity (ft/min) | Avg. PDM dust concentrations (mg/m3) | |||

|---|---|---|---|---|

| Intake | 100 ft | 500 ft | ||

| Classified rock dust | 95 | 0.03 | 43.24a, b, c | 28.84a, b, c |

| Classified rock dust | 232 | 0.04 | 20.84a, b, c | 17.33a, b, c |

| Reference rock dust | 221 | NA | 131.61a, b | 94.80a |

PDM Mass Offset Status Code — gains of more than 0.2 mg in two-minute period.

PDM High Filter Load Status Code.

PDM Flow Out Range Status Code — sampling flow rate varies from 2.2 L/min by more than 0.2 L/min.

As expected, at approximately double the flowrate, the measured values were roughly half of those previously measured, resulting in measurement of 20.8 and 17.3 mg/m3 at 30.5 and 152 m (100 and 500 ft) downwind, respectively. When compared with the reference rock dust used previously in LLEM testing, because the respirable content was approximately five times more than that of the classified dust, it is not surprising that the resulting measurements of respirable dust downwind were nearly five times that of the classified. Removing material smaller than 10 μm did lower the measurements obtained on the PDM 3700s, but not lower than the permissible allowable limits.

Summary

This study demonstrates that the PDM 3600 and 3700 personal dust monitors can be overloaded when positioned in the rock dust cloud. Further, surface applications of rock dusts having radically different particle size distributions — the classified untreated rock dust that is 5.9 percent smaller than 10 μm, and the treated rock dust that is 43.1 percent smaller than 10 μm — generated excessive dust levels downwind of application, which led to PDM 3600 and 3700 status codes during testing.

Untreated rock dust readily caked when exposed to moisture, whereas the treated version remained readily dispersible. The only application that generated low measurements of respirable dust utilized an untreated rock dust that was exposed to moisture. This rock dust had clumped before application and did not adequately cover the entry surfaces during application.

This testing did not measure miners’ exposure but rather area dust levels at fixed locations. It is recognized that coordination of the dusting and sampling practices necessary to comply with 30 CFR 75.403 (80 percent total incombustible content) and 30 CFR 75.100 (revised respirable dust rule) is difficult. However, due to elevated levels of respirable dust, acceptable mining practices would dictate that miners not be positioned immediately downwind of rock dust applications.

Another concern raised in this study is the generation of respirable dust due to movement of workers/equipment through accumulations of rock dust on the floor. This concern may be further exacerbated by the addition of anticaking agents. Therefore, additional underground testing should focus on the respirable dust generation due to re-entrainment of the rock dust rather than the application of the rock dust.

Acknowledgments

The authors would like to acknowledge the efforts of Linda Chasko, Jeanne Zimmer, Jim Addis, Connor Brown, Jarod Myers and John Soles for the work and analysis conducted in this research effort.

Footnotes

Disclaimer

Mention of any company or product does not constitute endorsement by NIOSH. The findings and conclusions in this paper are those of the authors and do not necessarily represent the views of NIOSH.

References

- Acme-HardestyCo. [accessed Aug 29, 2016];CalciumStearate, Uses & Applications. 2016 http://www.acme-hardesty.com/product/calcium-stearate/

- Croda International Plc. [accessed Aug 29, 2016];Priolen: Oleine. 2016 http://www.crodaindustrialchemicals.com/home.aspx?s=131&r=185&p=4829.

- Cybulski WG. Coal Dust Explosions and Their Suppression. National Center for Scientific, Technical and Economic Information; Warsaw, Poland: 1975. p. 583. [Google Scholar]

- Mine Safety and Health Administration (MSHA) Respirable Coal Mine Dust RuleEntersFinalPhaseofImplementation. [accessed Aug 29, 2016];2016 https://www.msha.gov/news-media/press-releases/2016/08/01/respirable-coal-mine-dust-rule-enters-final-phase.

- National Institute for Occupational Safety and Health (NIOSH) Report of Investigations 9679: Recommendations for A New Rock Dusting Standard to Prevent Coal Dust Explosions in Intake Airways. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention; 2010. p. 48. DHHS (NIOSH) Publication No. 2010-151. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH) Non-conforming Rock Dust. U.S Department of Health and Human Services, Centers for Disease Control and Prevention; 2011. p. 4. DHHS (NIOSH) Publication No HID 16. [Google Scholar]

- NOW Foods. [accessed Aug. 29, 2016];Magnesium Stearate FAQs. 2016 Mar 31; https://www.nowfoods.com/now/nowledge/magnesium-stearate-faqs.

- Page SJ, Volkwein JC, Vinson RP, Joy GJ, Mischler SE, Tuchman DP, McWilliams LJ. Equivalency of a personal dust monitor to the current United States coal mine respirable dust sampler. Journal of Environmental Monitoring. 2008;10(1):96–101. doi: 10.1039/b714381h. https://doi.org/10.1039/b714381h. [DOI] [PubMed] [Google Scholar]

- Page SJ, Volkwein JC, Vinson RP, Joy GJ, Mischler SE, Tuchman DP, McWilliams LJ. [accessed Aug 30, 2016];Equivalency of A Personal Dust Monitor to the Current United States Coal Mine Respirable Dust Sampler. 2016 doi: 10.1039/b714381h. http://www.cdc.gov/niosh/mining/UserFiles/works/pdfs/eoapd.pdf. [DOI] [PubMed]