Abstract

In this study, nano-sized fullerene C60 powder was sufficiently mixed with Cu2SnSe3 powder by ball milling method, and the C60/Cu2SnSe3 composites were prepared by spark plasma sintering technology. The fullerene C60 distributed uniformly in the form of clusters, and the average cluster size was less than 1 μm. With increasing C60 content, the electrical conductivity of C60/Cu2SnSe3 composites decreased, while the Seebeck coefficient was enhanced. The thermal conductivity of composites decreased significantly, which resulted from the phonon scattering by the C60 clusters located on the grain boundaries of the Cu2SnSe3 matrix. The highest figure of merit ZT of 0.38 was achieved at 700 K for 0.8% C60/Cu2SnSe3 composite.

Keywords: thermoelectric alloy, composites, Cu2SnSe3, C60

1. Introduction

Thermoelectric (TE) materials have attracted increasing worldwide attention due to their potential application in electronic cooling, waste heat recovery, and power generation [1,2,3,4]. The conversion efficiency of TE materials is determined by the dimensionless figure of merit, ZT = α2σT/κ, where α is the Seebeck coefficient, σ is the electrical conductivity, T is the absolute temperature, and κ is the total thermal conductivity. The total thermal conductivity is composed of an electron part (κE) and a phonon part (κL). Therefore, to maximize the ZT value of TE materials, a large α and σ, as well as a low κ are required. In recent years, several classes of bulk materials with high ZT have been discovered and developed, such as skutterudites, clathrates, and Cu-based chalcogenide semiconductors.

Cu-based chalcogenide compounds with a diamond-like structure, such as ternary Cu2MSe3 (M = Sn, Ge) and Cu3SbSe4, have attracted a lot of attention recently, due to their quite low thermal conductivity. In several Cu-based chalcogenide compound systems, the Cu2SnSe3 structure has partial “phonon glass electron crystal” (PGEC) characteristic, which makes it possible to achieve high TE performance. The Cu-Se bond network dominates the electron conduction, while the contribution from the element Sn is very weak; thus, the Sn site is suitable for optimization of the TE property. Various attempts, including doping by partial substitution, have been made to improve the thermoelectric properties of Cu2SnSe3 compound [5,6,7]. Shi et al. have reported the In-doped Cu2InxSn1-xSe3 and the maximum ZT value reaches 1.14 at 850 K for Cu2In0.1Sn0.9Se3 sample [8]. Fan et al. fabricated the Cu2GaxSn1-xSe3 samples using hot-press sintering technique and achieved the ZT value of 0.43 for Cu2Ga0.075Sn0.925Se3 sample [9]. In addition, Skoug, et al. also confirmed that doping with isoelectronic Ge on the Sn site is also effective in enhancing the ZT value [10]. Aside from doping, the dispersion of nanostructure phases into the thermoelectric matrix is also an attractive approach to improving the performance of TE materials. However, the Cu2SnSe3-based thermoelectric composites are scarcely investigated, because the enhancement of ZT is unapparent compared with the doping. Although significant reduction in the lattice conductivity can be achieved via enhanced phonon scattering at grain boundaries or matrix/inclusion interfaces, the electrical conductivity of TE composites also decreases, resulting in a marginal improvement of the overall ZT value. In addition, good selection of the dispersed phase and the control of microstructure are also required for TE composite [11,12,13,14]. Therefore, effective enhancement of ZT for TE composites depends on the microstructure of composites—i.e., the distribution or the shape of the component.

Fullerene C60 has very high elastic modulus and is a chemically-stable nonpolar fullerene molecule. C60 and C60-decorated grain boundaries may provide an effective phonon scattering, which could decrease the lattice thermal conductivity. Meanwhile, the scattering of charge carriers (electrons or holes) by the C60 could be ineffective due to the large value of electron (hole) wavelength compared to a fullerene molecule size. Blank and Kulbachinskii, et al. reported that the addition of 0.5 vol % C60 improved the TE properties of Bi0.5Sb1.5Te3 material, and the ZT value obtained was 1.17 at 450 K [15,16]. Shi, et al. found that adding 6.5 mass% C60 into pure CoSb3 can increase the ZT value, while adding amounts between 0.5% and 4.8% into CoSb3 decreased the ZT value [17]. The similar results of Itoh, et al. showed that the maximum ZT value for the 1% C60/Co0.92Ni0.08Sb2.96Te0.04 composite was 0.62 at 800 K, which was evidently higher than that of C60-free sample [18]. Nandihalli, et al. also reported that the ZT value of C60/Ni0.05Mo3Sb5.4Te1.6 composites was enhanced in the whole temperature range due to the large decrease of κL [19]. In this contribution, we attempted to introduce the C60 into a Cu2SnSe3 system and expected to achieve a larger reduction in the thermal conductivity of C60/Cu2SnSe3 composites.

In the present work, the fullerene C60 powder was incorporated into Cu2SnSe3 matrix using ball milling (BM), and C60/Cu2SnSe3 composites were fabricated by spark plasma sintering (SPS) technology. Effects of C60 particles on the thermoelectric properties of C60/Cu2SnSe3 composites were discussed, and the results are beneficial to the development of Cu2SnSe3-based composites with high performance using BM-SPS technology.

2. Experimental Procedures

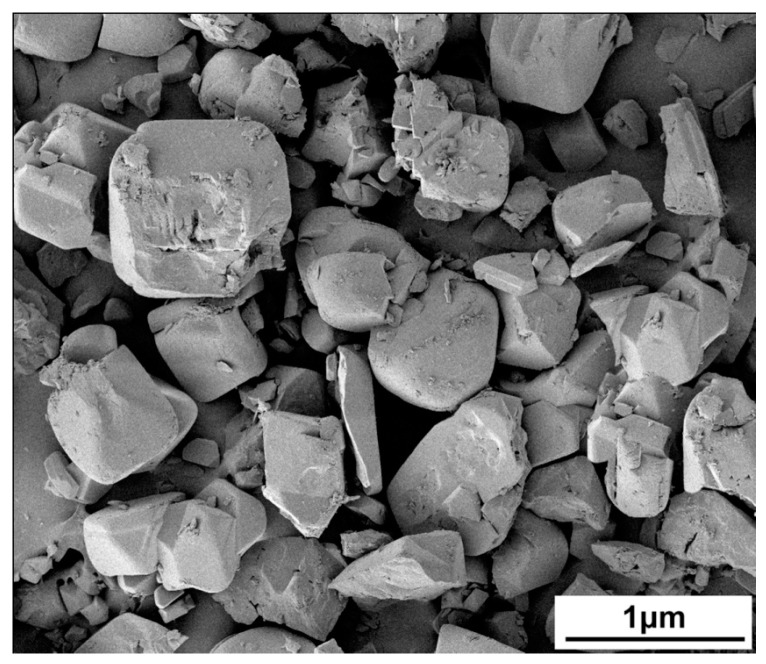

The polycrystalline Cu2SnSe3 samples were synthesized by melting method. The stoichiometric amount of starting materials Cu (powder, 99.95%), Sn (powder, 99.999%), and Se (shot, 99.999%) were first placed in a carbon crucible enclosed in evacuated fused-silica ampoules. The ampoules were slowly heated to 1173 K and held for 12 h in a vertical furnace. Then, the ampoules were slowly cooled to 873 K in 24 h, followed by annealing at this temperature for 2 days. Finally, the obtained ingots were ground into fine powder. Commercially available fullerene powder with average particle size of 500 nm (XFNANO, Nanjing, China) was chosen as the nanoinclusion, as shown in Figure 1. The fullerene C60 purity is 99.98%, and the other 0.02% refers to impurities of C70 and other carbon structures. The fullerene C60 powder was added into the Cu2SnSe3 powder at fractions of 0.4, 0.8, 1.2, and 1.6 vol %, respectively. Then, the C60-added Cu2SnSe3 powders were mechanically ground with planetary ball milling equipment at 150 rpm for 240 min. The as-milled powders were sintered by spark plasma sintering (SPS 2040) at around 860 K for about 8 min under uniaxial pressure of 50 MPa in vacuum.

Figure 1.

SEM image of fullerene powder with average particle size of 500 nm.

The density of the sintered C60/Cu2SnSe3 composites was measured using the Archimedes method. The constituent phases of the samples were determined by X-ray diffractometry (Cu Kα, Rigaku, Rint2000, Tokyo, Japan). The chemical composition of bulk samples was characterized using electron probe micro-analysis (EPMA, JEOL, JXA-8100, Tokyo, Japan) with a wavelength dispersive spectrometer (WDS). The composition was calculated by averaging five spots. The microstructure of all C60/Cu2SnSe3 composites was observed by high-resolution transmission electron microscopy (HRTEM, JEM2100F, JEOL, Tokyo, Japan). The thermal diffusivity (λ) was measured by laser flash method (Netzsch LFA427) in a flowing Ar atmosphere between 300 and 700 K. The thermal conductivity was calculated from the relationship κ = ρλCp, where ρ is the density of the sintered sample and Cp is the specific heat capacity. The electrical conductivity and Seebeck coefficient were measured simultaneously using commercial equipment (ZEM-3, ULVAC-RIKO, Tokyo, Japan) on a bar-type sample with a dimension of 2 × 2 × 10 mm3. The Hall coefficient (RH) was measured using the van der Pauw’s method in vacuum with a magnetic field of 2 T. The carrier concentration (pH) and mobility (μH) were estimated from the relations of pH = 1/(eRH) and μH = σRH, based on the assumption of single band model, where e is the electronic charge. All measurements were performed in a temperature range of 300–700 K.

3. Results and Discussion

3.1. Microstructure and XRD Analysis

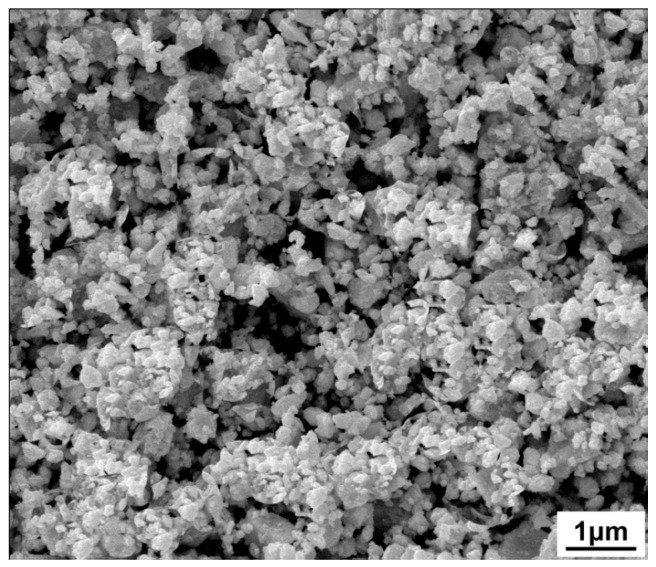

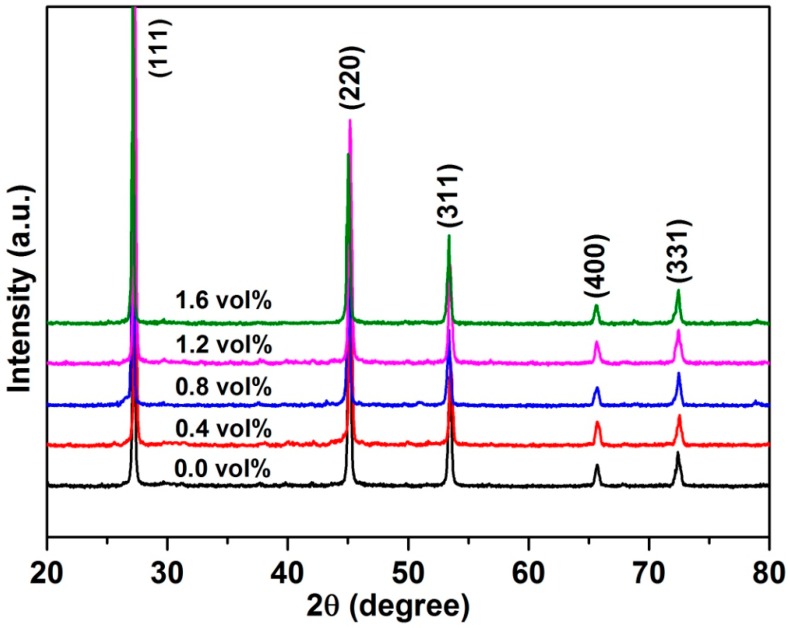

Figure 2 shows the SEM image of the 1.6 vol % C60-added Cu2SnSe3 powder after ball milling. It can be observed that the average particle size of milled C60/Cu2SnSe3 powder was about 100 nm. Figure 3 shows the X-ray diffraction patterns of xC60/Cu2SnSe3 composites (x = 0, 0.4, 0.8, 1.2, and 1.6 vol %) after SPS. The measured relative densities for all C60/Cu2SnSe3 composites after SPS are above 97% of the theoretical value. The diffraction peaks in Figure 3 are well-indexed based on the JCPDS 65-4145 (Joint Committee on Powder Diffraction Standards) of Cu2SnSe3. As the content of C60 in the composites is very low, the diffraction peak of C60 is not found in the XRD pattern of all C60/Cu2SnSe3 samples. Therefore, all C60/Cu2SnSe3 samples show the same XRD patterns with the pure Cu2SnSe3 sample.

Figure 2.

SEM image of the 1.6 vol % C60/Cu2SnSe3 powder after ball milling.

Figure 3.

XRD patterns of sintered C60/Cu2SnSe3 composites.

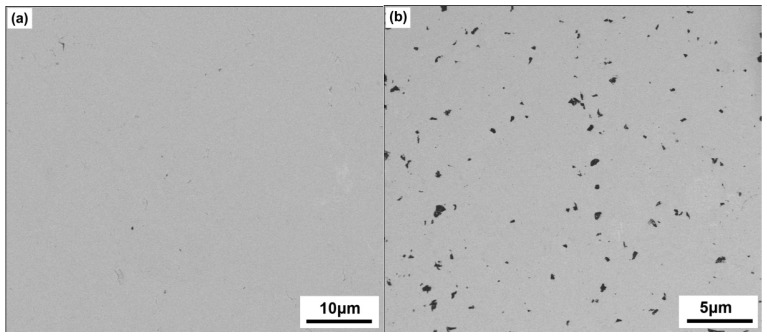

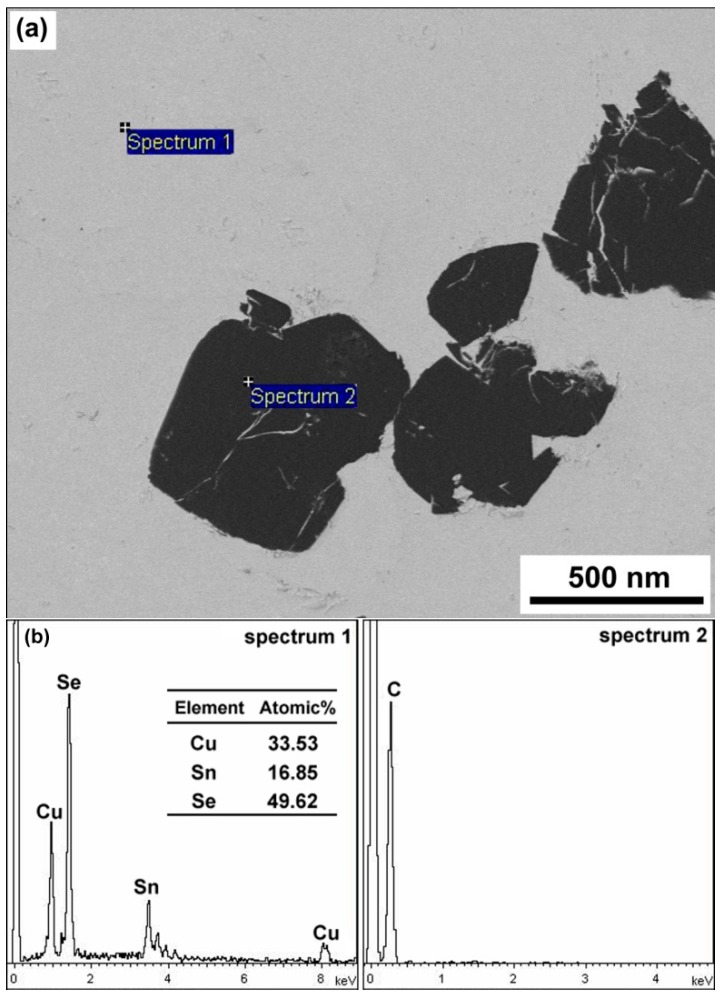

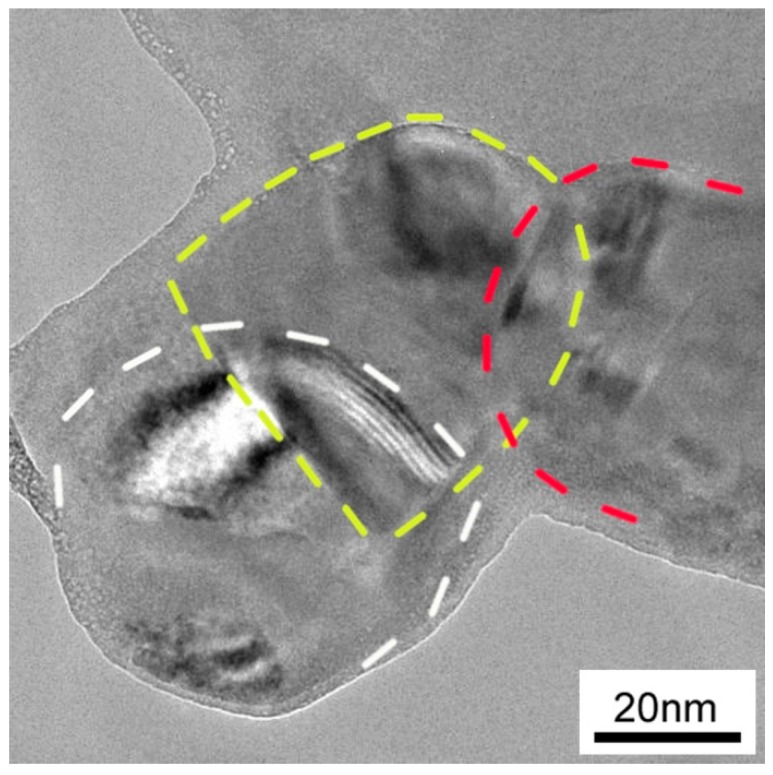

Figure 4a,b show the SEM microstructure of the sintered pure Cu2SnSe3 sample and 1.6 vol % C60/Cu2SnSe3 composite, respectively. The fullerene C60 distributed uniformly in the form of clusters, and the average cluster size was lower than 1 μm. Shi, et al. reported that in the CoSb3 material, most of the C60 molecules agglomerate into irregular micrometer-size clusters located at the grain boundaries [17]. The smaller size of clusters in this study should be due to the ball milling technology. The chemical composition of C60/Cu2SnSe3 composites was characterized by SEM and energy-dispersive X-ray spectroscopy (EDS), as shown in Figure 5. The results of EDS also confirm that the matrix was analyzed to be composed of 33.53 at. %; Cu, 16.85 at. %; Sn, and 49.62 at. %; Se, corresponding to the Cu2SnSe3 phase. The black phase only contains C element, indicating C60 phase. To further analyze the C60 clusters in the C60/Cu2SnSe3 composite, HRTEM of C60/Cu2SnSe3 composite was carried out, as shown in Figure 6. The size of C60 is about 80 nm, which means the ball milling process decreases the average size of C60 particles. According to the theory proposed by Faleev and Zebardaji, et al. [20,21], nano-phases that distribute in the thermoelectric matrix can result in strain fields, which could cause some changes in the band structure of the material and then greatly influence its thermoelectric properties.

Figure 4.

(a) SEM microstructure of the sintered pure Cu2SnSe3; (b) SEM microstructure of sintered 1.6 vol % C60/Cu2SnSe3 composite.

Figure 5.

(a) SEM image of the sintered 1.6% C60/Cu2SnSe3 composite; (b) energy-dispersive X-ray spectroscopy (EDS) results of Cu2SnSe3 matrix and C60 phase.

Figure 6.

High-resolution transmission electron microscopy (HRTEM) image of a C60 particle in the C60/Cu2SnSe3 composite.

3.2. Electrical Transport Properties

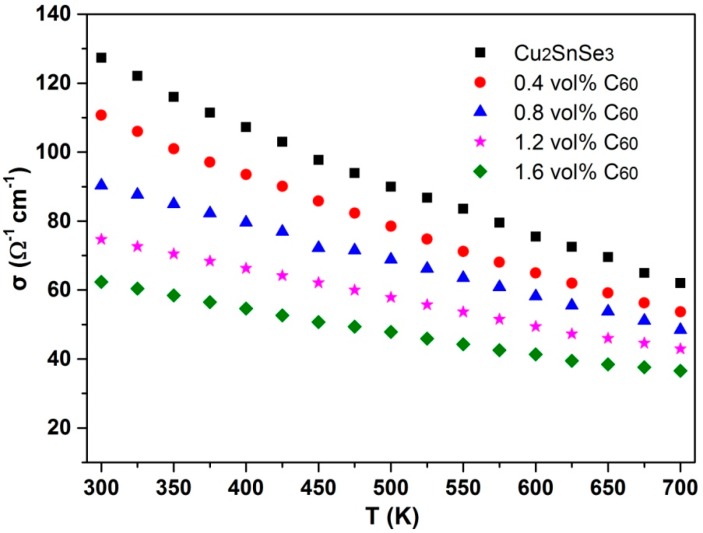

Figure 7 shows the temperature dependence of electrical conductivity (σ) for C60/Cu2SnSe3 composites with different vol % C60. It can be seen that the σ of the Cu2SnSe3 matrix decreases approximately linearly with rising temperature over the measured temperature range, indicating a typical behavior of a heavily-doped semiconductor. The similar tendency of σ was also observed in C60/Cu2SnSe3 composites. In addition, the σ of C60/Cu2SnSe3 composites decreases with increasing C60 content, which should be attributed to the enhanced carrier scattering at the incoherent interfaces between well-dispersed C60 clusters and the Cu2SnSe3 matrix. Generally, in the case of carriers primarily scattered by grain barriers or interfaces between the second phase and matrix in the composites, the carrier mobility can be written as [22]

| (1) |

where b is the average grain size, kB the Boltzmann constant, m* the carrier effective mass, and EB the activation energy characterizing the barrier height between the matrix and the second phase. As the relative density of the xC60/Cu2SnSe3 composite is higher than 97%, the porosity effect can be eliminated. Table 1 lists some physical and structural parameters of xC60/Cu2SnSe3 composites at room temperature. As the C60 could act as an electron acceptor in the p-type C60/Cu2SnSe3 composite, the carrier concentration increases with increasing C60 content, which is consistent with the results of Blank [15]. In addition, it can be noted that the carrier mobility decreases with increasing C60 content. Therefore, the σ of xC60/Cu2SnSe3 composites decreases compared with the σ of the Cu2SnSe3 matrix.

Figure 7.

Temperature dependence of electrical conductivity (σ) of C60/Cu2SnSe3 composites.

Table 1.

Chemical composition, some physical and structural parameters of xC60/Cu2SnSe3 composites at room temperature.

| x (vol %) | Relative Density | σ (Ω−1·cm−1) | p (1019cm−3) | μH (cm2/Vs) | α (μV/K) | κL (Wm−1·K−1) | m* (m0) |

|---|---|---|---|---|---|---|---|

| 0 | 98.7% | 127 | 3.74 | 21.2 | 131 | 2.77 | 2.6 |

| 0.4 | 97.2% | 110 | 4.81 | 14.3 | 165 | 2.22 | 2.8 |

| 0.8 | 98.9% | 90 | 5.01 | 11.2 | 188 | 2.06 | 2.9 |

| 1.2 | 98.2% | 75 | 4.98 | 9.4 | 225 | 1.96 | 3.1 |

| 1.6 | 97.9% | 62 | 5.09 | 7.6 | 252 | 1.81 | 3.2 |

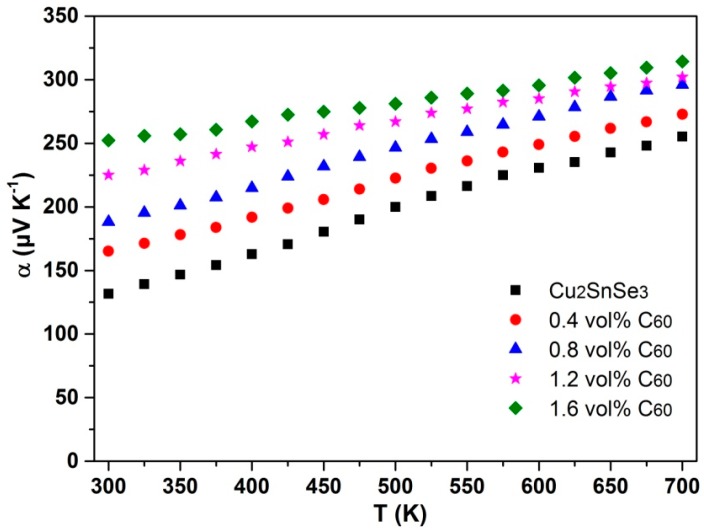

Figure 8 displays the Seebeck coefficient (α) of xC60/Cu2SnSe3 composites as a function of temperature. All composites have a positive α across the whole temperature range, indicating that the holes are major carriers. With rising temperature, the α of all xC60/Cu2SnSe3 composites increases approximately linearly and the α of 1.6% C60/Cu2SnSe3 composite reaches 314 μV/K at 700 K. Moreover, the α of xC60/Cu2SnSe3 composites significantly increases with the increasing content of C60. At room temperature, the α increases from 130 μV/K for the Cu2SnSe3 matrix to 252 μV/K for the 1.6 vol % C60/Cu2SnSe3 composite. The enhancement of α of xC60/Cu2SnSe3 composites should be related to the “energy filter” effect. The Seebeck coefficient can be expressed as [23],

| (2) |

where kB, σ(E), and n(E) are Boltzmann constant, electrical conductivity, and value of density of states (DOS), respectively. Many studies have confirmed that when nano-phases or nano-inclusions are incorporated into a semiconducting matrix material, the band bending at the inclusion/matrix interface will produce a potential energy barrier which could effectively block low energy electrons, while transmitting high energy electrons [24]. This “electron energy filter” could evidently increase the local density of states near the Fermi level (EF) and enhance the Seebeck coefficient.

Figure 8.

Temperature dependence of Seebeck coefficient (α) of C60/Cu2SnSe3 composites.

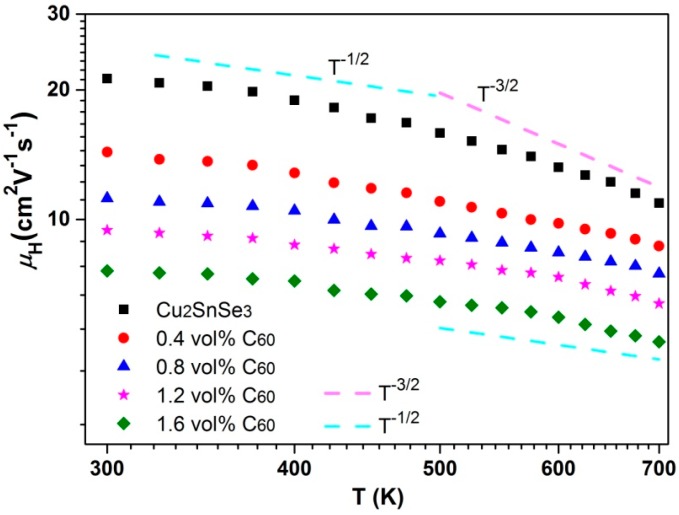

The μH of xC60/Cu2SnSe3 composites is shown in Figure 9. The μH of xC60/Cu2SnSe3 composites decreases with increasing C60 content. In addition, the μH of xC60/Cu2SnSe3 composites was in the order of 10 cm2·V−1·s−1 at room temperature, which was close to that of skutterudites [25,26]. It may be caused by the similar carrier effective mass of Cu2SnSe3 and CoSb3 compounds. The m* can be estimated in the single parabolic band model using the following equations,

| (3) |

| (4) |

where Fr, h, and r are Fermi integral, Planck’s constant, and scattering parameter of relaxation time, respectively. The evaluated equivalent carrier effective mass of xC60/Cu2SnSe3 composites at room temperature is listed in Table 1. It can also be seen from Figure 9 that the μH of pure Cu2SnSe3 shows a temperature dependence of T−1.5 above 500 K, indicating that the acoustic phonon scattering is dominant in the temperature range from 500 to 700 K. Below 500 K, the μH of pure Cu2SnSe3 has a weak temperature dependence relationship and the relationship of μH∝T−0.5 is observed, suggesting that a dominative mechanism is alloy scattering. However, the μH of xC60/Cu2SnSe3 composites deviates from the T−1.5 or T−0.5 dependence over the entire temperature range, indicating that a mixed scattering mechanism dominates these samples.

Figure 9.

Temperature dependence of carrier mobility (μH) of C60/Cu2SnSe3 composites.

3.3. Thermal Transport Properties

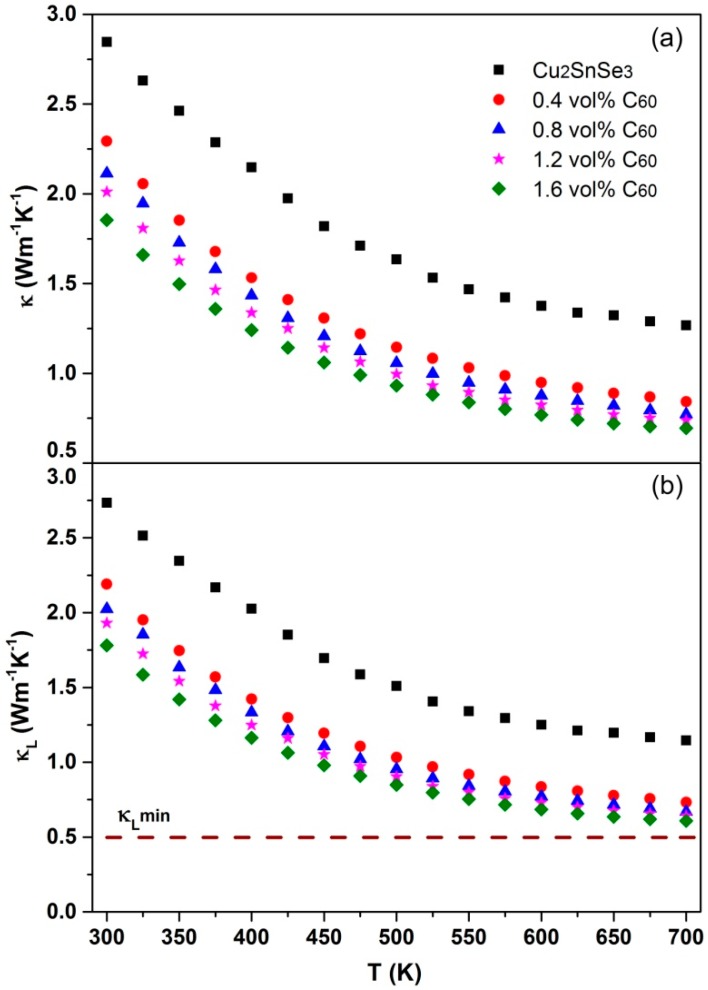

Figure 10 displays the temperature dependence of total thermal conductivity (κ) and lattice thermal conductivity (κL) for C60/Cu2SnSe3 composites. The κL is estimated by subtracting the electronic contribution via the Wiedmann–Franz law (κE = L0σT, where the Lorenz number L0 is taken as a constant of 2.0 × 10−8 V2/K2) from the total thermal conductivity. The κ for all samples declines with increasing temperature. Moreover, the κ of xC60/Cu2SnSe3 composites decreases with increasing C60 content. The achieved κ of 1.6 vol % C60/Cu2SnSe3 composite at room temperature is 1.85 W/mK, which is 34% lower than that of pure Cu2SnSe3. The minimal κ of 1.6 vol % C60/Cu2SnSe3 composite is 0.71 W/mK at 700 K. It is well-known that the grain boundary, wide or point defects, porosity, and impurity could contribute to the decrease of κ. Owing to high relative density of C60/Cu2SnSe3 composites, the reduction of κ originating from the porosity is negligible. Meanwhile, the calculation of κE shows that the reduction of κE has a limited contribution to the decrease of κ. Therefore, the decrease of κ for C60/Cu2SnSe3 composites mainly originates from the depression of κL due to the enhancement of phonon scattering by the C60 inclusions or nano-particles in the composite. Just as shown in Figure 10b, the κL of C60/Cu2SnSe3 composites drastically decreases with the content of C60 increasing. The minimal κL achieved in the present work is 0.68 W/mK at 700 K for the 1.6 vol % C60/Cu2SnSe3 sample, which is 43% lower than that of pure Cu2SnSe3. According to the kinetic theory [27], the minimum lattice thermal conductivity κLmin can be obtained when the phonon mean free path reaches the shortest interatomic distance. The κLmin can be estimated from the formula κL = 1/3Cvνml, where Cv is heat capacity per unit volume of the system using Dulong and Petit value, νm the mean sound velocity, and l the mean free path of phonon. The νm comes from the data in reference [28]. If we assume the minimum l to be the interatomic distance for Cu2SnSe3 (0.238 nm), the κLmin is calculated as 0.52 Wm−1·K−1, just as shown by dashed line in Figure 10b. The κL of 1.6 vol % C60/Cu2SnSe3 composites approaches the κLmin of Cu2SnSe3 at high temperature.

Figure 10.

(a) Temperature dependence of total thermal conductivity (κ) of C60/Cu2SnSe3 composites; (b) temperature dependence of lattice thermal conductivity (κL) of C60/Cu2SnSe3 composites.

3.4. Figure of Merit

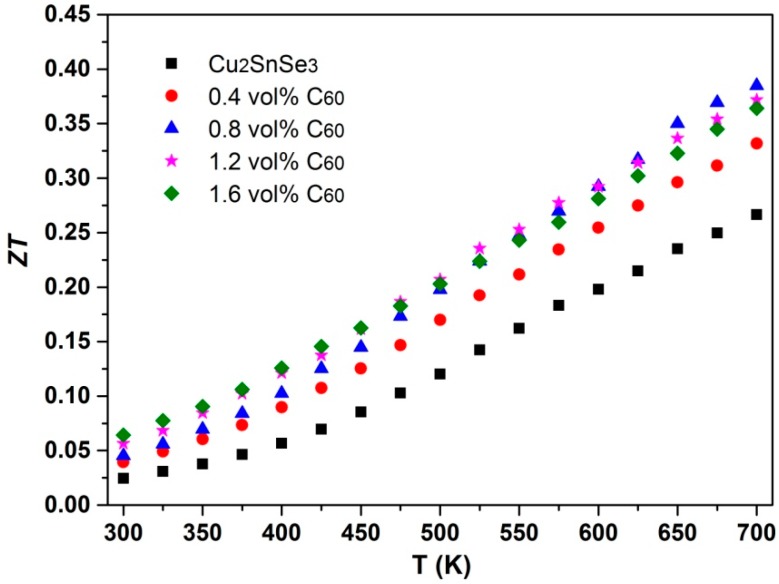

The conversion efficiency of TE materials depends on the maximum dimensionless figure of merit (ZT). Figure 11 shows the dimensionless figure of merit (ZT) of C60/Cu2SnSe3 composites as a function of temperature. Like other doped Cu2SnSe3 investigated before [8,29,30], the ZT value of C60/Cu2SnSe3 composites increases approximately linearly with increasing temperature. Compared with the ZT of the Cu2SnSe3 sample, the ZT value of C60/Cu2SnSe3 composites is enhanced. For the 0.8 vol % C60/Cu2SnSe3sample, the maximum ZT value is 0.38 at 700 K, which is 45% higher than that of the pure Cu2SnSe3 sample. The enhancement of ZT for C60/Cu2SnSe3 composites is mainly attributed to the reduced κL and the enhanced α. The addition of C60 into the Cu2SnSe3 matrix could improve the TE properties, which is a promising process to the design Cu-based chalcogenide compounds with high TE performance. When the material with optimized carrier concentration is selected as the matrix, the higher ZT value of TE composite could be achieved.

Figure 11.

Temperature dependence of the dimensionless figure of merit of (ZT) of C60/Cu2SnSe3 composites.

4. Conclusions

In this study, C60 was incorporated into a Cu2SnSe3 matrix, and C60/Cu2SnSe3 composites were fabricated using BM-SPS method. The C60 phase distributed uniformly in the form of clusters, and the average cluster size was less than 1 μm. With increasing C60 content, the electrical conductivity of C60/Cu2SnSe3 composites decreased, while the Seebeck coefficient of C60/Cu2SnSe3 composites increased due to the “electron energy filter” of the C60 nano-phase. The thermal conductivity of C60/Cu2SnSe3 composites decreased significantly, which originated from the phonon scattering by the C60 clusters located on the grain boundaries of the Cu2SnSe3 matrix. The maximum ZT of 0.38 was obtained at 700 K for 0.8 vol % C60/Cu2SnSe3 composite.

Acknowledgments

This work was supported in part by National Natural Science Foundations of China (51202088 and 51271087) and the Opening Project of State Key Laboratory of High Performance Ceramics and Superfine Microstructure (SKL201405SIC).

Author Contributions

The manuscript was completed through contributions of all authors. Degang Zhao and Jiai Ning performed the experiments. Degang Zhao wrote the paper. Jiai Ning and Min Zuo contributed to the data analysis.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- 1.Disalvo F.J. Thermoelectric cooling and power generation. Science. 1999;285:703–706. doi: 10.1126/science.285.5428.703. [DOI] [PubMed] [Google Scholar]

- 2.Yu Y., Lv L., Wang X.Y., Zhu B., Huang Z., Zu F.Q. Influence of melt overheating treatment on solidification behavior of Bi2Te3-based alloys at different cooling rates. Mater. Des. 2015;88:743–750. [Google Scholar]

- 3.Liu W.S., Yan X., Chen G., Ren Z.F. Recent advances in thermoelectric nanocomposites. Nano Energy. 2012;1:42–56. doi: 10.1016/j.nanoen.2011.10.001. [DOI] [Google Scholar]

- 4.Wan S., Huang X.Y., Qiu P.F., Bai S.Q., Chen L.D. The effect of short carbon fibers on the thermoelectric and mechanical properties of p-type CeFe4Sb12 skutterudite composites. Mater. Des. 2015;67:379–384. doi: 10.1016/j.matdes.2014.11.050. [DOI] [Google Scholar]

- 5.Zerer W.G., Lalonde A., Gibbs Z.M., Heinrich C.P., Panthofer M., Snyder G.J., Tremel W. Influence of a nano phase segregation on the thermoelectric properties of the p-type doped stannite compound Cu2+xZn1-xGeSe4. J. Am. Chem. Soc. 2012;134:7147–7154. doi: 10.1021/ja301452j. [DOI] [PubMed] [Google Scholar]

- 6.Raju C., Falmbigl M., Rogl P., Heinrich P., Royanian E., Bauer E., Mallik R.C. Thermoelectric properties of Zn doped Cu2SnSe3. Mater. Chem. Phys. 2014;147:1022–1028. doi: 10.1016/j.matchemphys.2014.06.054. [DOI] [Google Scholar]

- 7.Liu G.H., Li J.T., Chen K.X., Li Y., Zhou M., Han Y.M., Li L.F. Direct fabrication of highly-dense Cu2ZnSnSe4 bulk materials by combustion synthesis for enhanced thermoelectric properties. Mater. Des. 2016;93:238–246. doi: 10.1016/j.matdes.2015.12.172. [DOI] [Google Scholar]

- 8.Shi X.Y., Xi L.L., Fan J., Zhang W.Q., Chen L.D. Cu-Se bond network and thermoelectric compounds with complex diamondlike structure. Chem. Mater. 2010;22:6029–6031. doi: 10.1021/cm101589c. [DOI] [Google Scholar]

- 9.Fan J., Liu H.L., Shi X.Y., Bai S.Q., Shi X., Chen L.D. Investigation of thermoelectric properties of Cu2GaxSn1-xSe3 diamond-like compounds by hot pressing and spark plasma sintering. Acta Mater. 2013;61:4297–4304. doi: 10.1016/j.actamat.2013.04.003. [DOI] [Google Scholar]

- 10.Skoug E.J., Cain J.D., Morelli D.T. Thermoelectric properties of the Cu2SnSe3-Cu2GeSe3 solid solution. J. Alloy. Compd. 2012;506:18–23. doi: 10.1016/j.jallcom.2010.06.182. [DOI] [Google Scholar]

- 11.Lan Y.C., Minnich A.J., Chen G., Ren Z.F. Enhancement of thermoelectric figure of merit by a bulk nanostructuring approach. Adv. Funct. Mater. 2010;20:357–376. doi: 10.1002/adfm.200901512. [DOI] [Google Scholar]

- 12.Zolriasatein A., Yan X., Bauer E., Rogl P. Influence of PCA on thermoelectric properties and hardness of nanostructured Ba-Cu-Si clatherates. Mater. Des. 2015;87:883–890. [Google Scholar]

- 13.Zebarjadi M., Esfarjani K., Ren Z.F., Chen G. Perspectives on thermoelectric: From fundamentals to device applications. Energy Environ. Sci. 2012;5:5147–5162. doi: 10.1039/C1EE02497C. [DOI] [Google Scholar]

- 14.Kim K.T., Choi S.Y., Shin E.H., Moon K.S., Ha G.H. The influence of CNTs on the thermoelectric properties of a CNT/Bi2Te3 composite. Carbon. 2013;52:541–549. doi: 10.1016/j.carbon.2012.10.008. [DOI] [Google Scholar]

- 15.Blank V.D., Buga S.G., Kulbachinskii V.A., Kytin V.G., Stepanov P.B. Thermoelectric properties of Bi0.5Sb1.5Te3/C60 nanocomposites. Phys. Rev. 2012;86:64–70. doi: 10.1103/PhysRevB.86.075426. [DOI] [Google Scholar]

- 16.Kulbachinskii V.A., Kytin V.G., Popov M.Yu., Buga S.G., Blank V.D. Composites of Bi2-xSbxTe3 nanocrystals and fullerene molecules. J. Solid State Chem. 2012;193:64–70. doi: 10.1016/j.jssc.2012.03.065. [DOI] [Google Scholar]

- 17.Shi X., Chen L., Yang J., Meisner G.P. Enhanced thermoelectric figure of merit of CoSb3 via large-defect scattering. Appl. Phys. Lett. 2004;84:2301–2303. doi: 10.1063/1.1687997. [DOI] [Google Scholar]

- 18.Itoh T., Ishikawa K. Effects of fullerene addition on thermoelectric properties of n-type skutterudite compound. J. Mater. Res. 2007;22:249–255. doi: 10.1557/jmr.2007.0031. [DOI] [Google Scholar]

- 19.Nandihlli N., Lahwal A., Holgate T.C., Tritt T.M. Thermoelectric properties of composites made of Ni0.05Mo3Sb5.4Te1.6 and fullerene. J. Solid State Chem. 2013;203:25–30. doi: 10.1016/j.jssc.2013.03.061. [DOI] [Google Scholar]

- 20.Faleev S.V., Leonard F. Theory of enhancement of thermoelectric properties of materials with nanoinclusions. Phys. Rev. 2008;77:214304. doi: 10.1103/PhysRevB.77.214304. [DOI] [Google Scholar]

- 21.Zebarjadi M., Esfarjani K., Shakouri A., Zeng G., Lu H., Zide J., Gossard A. Effect of nanoparticle scattering on thermoelectric power factor. Appl. Phys. Lett. 2009;94:202105. doi: 10.1063/1.3132057. [DOI] [Google Scholar]

- 22.Orton J.W., Powell M.J. The Hall effect in polycrystalline and powdered semiconductors. Rep. Prog. Phys. 1980;43:1263–1307. doi: 10.1088/0034-4885/43/11/001. [DOI] [Google Scholar]

- 23.Zhao D.G., Zuo M., Geng H.R. Synthesis and thermoelectric properties of CoSb3/WO3 thermoelectric composites. Intermetallics. 2013;40:71–75. doi: 10.1016/j.intermet.2013.04.011. [DOI] [Google Scholar]

- 24.Xiong Z., Chen X.H., Huang X.Y., Bai S.Q., Chen L.D. High thermoelectric performance of Yb0.26Co4Sb12/yGaSb nanocomposites originating from scattering electrons of low energy. Acta Mater. 2010;58:3995–4002. doi: 10.1016/j.actamat.2010.03.025. [DOI] [Google Scholar]

- 25.Xi L.L., Yang J., Lu C.F., Chen L., Zhang W.Q. Systematic study of the multiple-element filling in caged skutterudite CoSb3. Chem. Mater. 2010;22:2384–2394. doi: 10.1021/cm903717w. [DOI] [Google Scholar]

- 26.Shi X., Yang J., Salvador J.R., James R. Multiple-filled skutterudites: High thermoelectric figure of merit through separately optimizing electrical and thermal transports. J. Am. Chem. Soc. 2011;133:7837–7846. doi: 10.1021/ja111199y. [DOI] [PubMed] [Google Scholar]

- 27.Morelli D.T., Jovovic V., Heremans J.P. Intrinsically minimal thermal conductivity in cubic I-V-VI2 semiconductors. Phys. Rev. Lett. 2008;101:035901. doi: 10.1103/PhysRevLett.101.035901. [DOI] [PubMed] [Google Scholar]

- 28.Cho J.Y., Shi X., Salvador J.R., Meisner G.P. Thermoelectric properties and investigations of low thermal conductivity in Ga-doped Cu2GeSe3. Phys. Rev. 2011;84:085207. doi: 10.1103/PhysRevB.84.085207. [DOI] [Google Scholar]

- 29.Liu F.S., Wang B., Ao W.Q., Li Y., Li J.Q. Crystal structure and thermoelectric properties of Cu2Cd1-xZnxSe4 solid solutions. Intermetallics. 2014;55:15–21. doi: 10.1016/j.intermet.2014.06.014. [DOI] [Google Scholar]

- 30.Do D.T., Mahanti S.D. Theoretical study of defects Cu3SbSe4: Search for optimum dopants for enhancing thermoelectric properties. J. Alloy. Compd. 2015;625:346–354. doi: 10.1016/j.jallcom.2014.11.031. [DOI] [Google Scholar]