Abstract

Supercapacitors such as electric double‐layer capacitors (EDLCs) and pseudocapacitors are becoming increasingly important in the field of electrical energy storage. Theoretical study of energy storage in EDLCs focuses on solving for the electric double‐layer structure in different electrode geometries and electrolyte components, which can be achieved by molecular simulations such as classical molecular dynamics (MD), classical density functional theory (classical DFT), and Monte‐Carlo (MC) methods. In recent years, combining first‐principles and classical simulations to investigate the carbon‐based EDLCs has shed light on the importance of quantum capacitance in graphene‐like 2D systems. More recently, the development of joint density functional theory (JDFT) enables self‐consistent electronic‐structure calculation for an electrode being solvated by an electrolyte. In contrast with the large amount of theoretical and computational effort on EDLCs, theoretical understanding of pseudocapacitance is very limited. In this review, we first introduce popular modeling methods and then focus on several important aspects of EDLCs including nanoconfinement, quantum capacitance, dielectric screening, and novel 2D electrode design; we also briefly touch upon pseudocapactive mechanism in RuO2. We summarize and conclude with an outlook for the future of materials simulation and design for capacitive energy storage.

Keywords: electric double layers, electrolytes, joint density functional theory, molecular simulations, porous materials, supercapacitors

1. Introduction

1.1. Basics of Capacitive Energy Storage

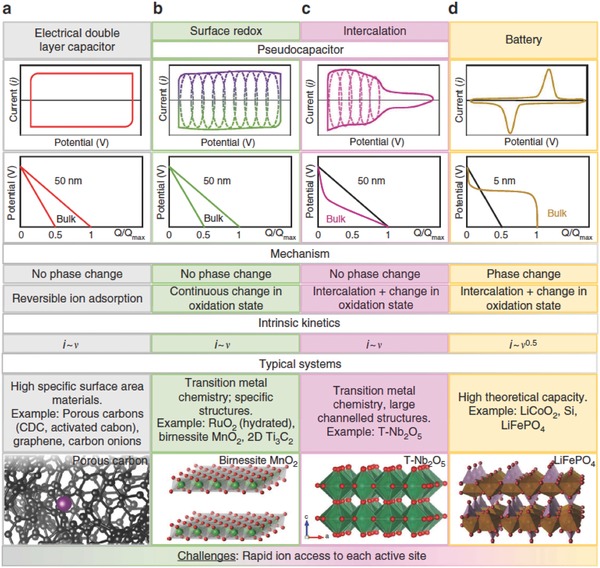

World wide adoption of renewable energy, in the form of solar and wind energy, combined with the electrification of transportation and the proliferation of mobile devices are all driving the need for efficient, cost‐effective electric energy storage devices in sizes ranging from hand‐held to grid‐based. The most commonly used electric energy storage devices are batteries and supercapacitors. A battery stores energy by bulk redox/intercalation reactions, while a supercapacitor stores energy through surface ion‐adsorption or surface redox/intercalation reactions. A battery has high energy density but low power density, while a supercapacitor boasts of high power density due to the fast surface physical and chemical processes.1 The global supercapacitor market was $1.2B in 2014 and by some estimates will grow over 20% per year to more than $7B in 2023.2 There are two main types of supercapacitors: electric double‐layer capacitors (EDLCs) store electrical energy through formation of electric double layer at the electrode/electrolyte interface (Figure 1 a), while pseudocapacitors store electrical energy by reversible surface redox reaction (Figure 1b) or ion intercalation (Figure 1c). EDLCs, pseudocapacitors, and batteries exhibit distinctly different electrochemical behavior in cyclic voltammetry (CV), as shown in Figure 1.3

Figure 1.

Cyclic voltammetry curves, galvanostatic charging profiles, key mechanism descriptions, and typical systems for: a) electric double‐layer capacitor; b) surface redox pseudocapacitor; c) intercalation pseudocapacitor; d) battery. Reproduced with permission.3 Copyright 2016, Nature Publishing Group.

1.2. Operating Mechanism of Electric Double‐Layer Capacitors

1.2.1. The Helmholtz Model of an Electric Double Layer

In EDLCs, electrical energy is stored by the formation of an electric double layer (EDL) through the counterion adsorption at the electrode surface. The concept of the EDL originated from the interfacial double layer model in classical surface physical chemistry, first proposed by Hermann von Helmholtz in 1853,4 and formed by the coion exclusion and counterion adsorption. According to the Helmholtz model, the differential capacitance of an EDL can be computed by:

| (1) |

where A is the area of the electrode, εr is the dielectric constant of the electrolyte solvent, ε0 is vacuum permittivity, and d is the thickness of the Helmholtz layer. Note that this is independent of applied voltage or properties of the electrolyte other than the solvent dielectric constant.

One can use Equation (1) to estimate the areal capacitance (Cd = C/A) for a planar electrode. The value of d in aqueous electrolytes is several angstroms. Here we assume d = 0.3 nm, the size of a typical atom; for an aqueous electrolyte, the value of εr should be about 6 instead of 80 for water in a high electric field.5 Thus, Cd is about 18 µF cm–2, in good agreement with the average reported values for aqueous electrolyte EDLCs (≈15 µF cm–2).6 Ionic liquids (IL) usually have a dielectric constant about 10, but their sizes tend to be larger, so we estimate their Cd to be about 10 µF cm–2, which is close to the experimental value of ≈11 µF cm–2.6

1.2.2. The Gouy‐Chapman Model and Beyond

Gouy7 in 1910 and Chapman8 in 1913 derived, independently, an improved model for differential capacitance, which exhibits dependence on electrode voltage and ionic concentration. The “Gouy‐Chapman” (GC) model introduced the diffuse layer, which describes the ion charge distribution as a function of distance to the electrode surface, and used the Maxwell–Boltzmann statistics to account for the thermal effect. In 1924, Stern proposed combining the Helmholtz model with the Gouy‐Chapman model to describe the electrode/electrolyte interface: a subset of the ions with finite size adsorb on the surface to form the “Stern Layer”, while others form the Gouy‐Chapman diffuse layer. This model is known as the “Gouy‐Chapman‐Stern” (GCS) model.9 The GCS model gives a more general description of the electrode/electrolyte interfacial behavior, but is highly simplified. For example, the diffusive ions in the GCS model are treated as point charges. Thus, important ionic features that influence capacitance, such as radii and valences, are ignored. A more rigorous model is necessary, especially for systems utilizing an ionic liquid electrolyte where the diffuse layer and ion steric effect have large influence on the charge capacitive behavior.

Fast forward to 2007, Kornyshev proposed a model to describe the interfacial capacitance of the metal/ionic liquid system by solving the “Poisson‐Fermi” equation, which treats the electrolyte by a mean‐field lattice‐gas model.10 They derived an analytical expression for the differential capacitance:

| (2) |

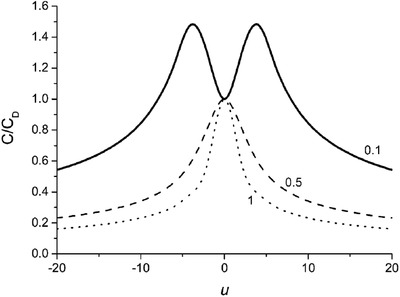

where γ is reduced concentration of ions, C0 is the linear Gouy‐Chapman capacitance defined by C 0 = ε/4πLD, L D is the Debye length, and u0 is surface electric potential in reduced unit. They found that (Figure 2 ) when the concentration changes from low (γ = 0.1) to high (γ = 1), the differential capacitance curve changes from the “Bactrian‐camel” shape to the “bell” shape, due to the competition between the Stern layer and the diffuse layer, which cannot be captured by the traditional GCS model. This analytical method provides a clear physical picture for the interfacial capacitive behavior. It has been improved recently by adding the short‐range correlation for the ionic liquid electrolyte.11 Independently, Bazant et al. derived the same analytical solution (Equation (2)) from solving a modified Poisson‐Nernst‐Planck (MPNP) equation to describe the ion transport during dynamic charging at large bias voltage.12, 13

Figure 2.

Differential capacitance as a function of electrode potential for different values of the lattice‐saturation parameter γ which is proportional to ion concentration: Bactrian‐camel shape versus bell shape. Reproduced with permission.10 Copyright 2007, American Chemical Society.

1.3. An Estimate of How Many Ions Need to be Separated when Charging a Typical EDLC Device

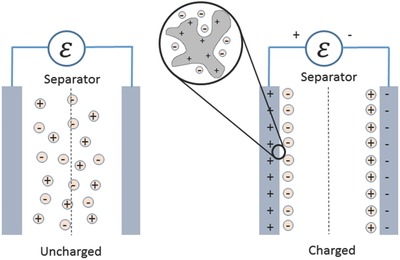

By pairing two electric double layers at the postive and negative electrodes, one obtains an EDLC. Since the energy is stored through formation of the EDL at the interface, the capacitance per unit weight or specific capacitance of a material generally increases with the specific surface area (SSA). This is why activated carbons with SSA of 1000 to 2000 m2 g–1 are used in commercial EDLCs. A typical EDLC consists of two symmetric porous carbon electrodes sandwiching a separator, with the electrolyte stored mainly inside the pore volumes of the electrodes (for a commercial device, volume contribution from the separator is negligible). When charged up, the ions separate and form two separate EDLs at the two opposite electrodes (Figure 3 ). Here we present a simple phenomenological estimate of how many ions are separated when charging an EDLC device to give the readers a general idea of the degree of ion separation when cycling an EDLC device. A typical organic‐electrolyte activated‐carbon‐electrode EDLC has a specific capacitance of about 100 F g–1 based on the weight of carbon. Suppose 1 g of carbon for the positive electrode is charged to 1.5 V, while 1g of carbon for the negative electrode is charged to –1.5 V. This leads to a surface charge of +150 C on the positive electrode and –150 C on the negative electrode. The typical pore volume of activated carbon is 0.90 cm3 g–1 and a typical concentration of an organic electrolyte is 1 m of tetraethylammonium tetrafluoborate (TEABF4) in acetonitrile. Hence the total numbers of available ions in this EDLC are 174 C of cations and 174 C of anions. In other words, ion separation is close to 90% when the EDLC is fully charged: the majority of the anions move to the positive electrode, while the majority of the cations move to the negative electrode. The typical thickness of an EDLC electrode is about 200 µm coated on two sides of a current collector (such as Al foil), so the typical length of ions traveled during cycling of an EDLC should be about 100 µm on a timescale of seconds. Thickness of a typical separator is about 40 µm, so we have neglected it in this simple estimate.

Figure 3.

Schematic of an EDLC device consisting of two electrodes in an electrochemical cell.

1.4. Recent Experimental Advances in EDLCs

The most widely used electrode materials for EDLCs are porous carbon‐based materials,14, 15 such as activated graphene oxide,16 activated carbons (AC),17 carbide‐derived carbons (CDC),18, 19, 20 carbon nanotubes (CNT),21, 22, 23 onion‐like carbons (OLC)24, 25 and graphene.26, 27 The gravimetric capacitance of these carbon materials is sensitive to their structure, especially the porosity and SSA. The pore size can also greatly affect the ion partitioning and packing inside the pores, which may cause a large change in capacitance. The relationship between the pore size and the capacitance of ionic liquids has been investigated experimentally by Simon and Gogotsi.28, 29, 30 This important work reveals the pore size‐dependent capacitance and suggests that the capacitance maximum can be achieved by optimally matching the pore size and ion size. Carbon nanotubes (CNT) have been used as novel electrode materials in EDLCs.31, 32 The reported capacitance of single‐wall CNT (SWCNT) is 180 F g–1 (or ≈14 µF cm–2) with an aqueous electrolyte,22 and the SSA is estimated to be 1315 m2 g–1.33 Onion‐like carbons have also been reported as promising EDLC electrode materials exhibiting very large power density at discharging rate of up to 200 V s–1.24, 34 Moreover, graphene's unique electronic structure has large influence on the charge capacitive behavior.17, 26

1.5. Experimental Techniques for Characterizing Electric Double Layer

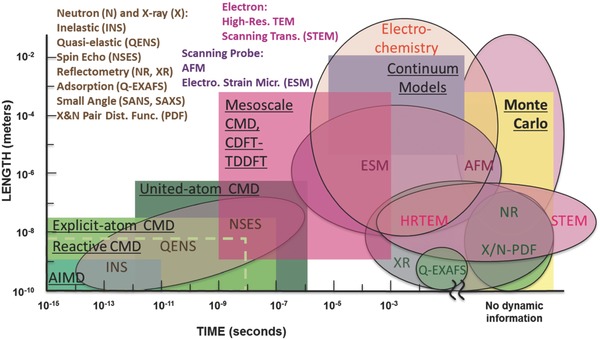

Characterizing EDL with various experimental techniques is important in both revealing the underlying physics and validating the theoretical predictions and simulations. In a multiyear center effort,35 computational/theoretical modeling methods are combined with complementary experimental characterization tools that probe similar spatial and/or temporal scales, as shown in Figure 4 , to shed light on the microscopic mechanism of EDL structure and dynamics. Among the experimental methods, Quasi‐Elastic Neutron Scattering (QENS) is an effective technique to study microscopic dynamics on the time scale of pico‐seconds to nano‐seconds for spatially constrained diffusion and long‐range translational diffusion of ions inside porous carbons.36, 37 Another important tool to probe the solid/liquid interfacial structure on a flat substrate is X‐ray reflectivity, which can provide the structural change of the electrolyte at the interface with sub‐angstrom resolution and under applied potential.38, 39, 40

Figure 4.

The length and time scales of different simulation and experimental techniques. CMD: classical molecular dynamics; AIMD: ab initio molecular dynamics; CDFT: classical density functional theory; TDDFT, time‐dependent density functional theory. In this figure ESM stands for electrochemical strain microscopy, while throughout the text it stands for effective screening medium.

Electrochemical Strain Microscopy has been developed to explore dynamic electrochemical processes, such as voltage‐controlled ion transport, intercalation and local electrochemical reactivity at the nanometer and meso scales. In particular, for the intercalation process, Electrochemical Strain Microscopy can clearly measure ion dynamics and electrode structure changes, such as expansion and distortion.41, 42, 43, 44 Nuclear Magnetic Resonance (NMR)45, 46 can measure the structure of ion sorption and configuration in supercapacitor electrodes and also provide the picture of ion dynamics in supercapacitor.47 Scanning Probe Microscopy (SPM) can directly measure the structure of EDL through the AFM tip that approaches the surface. By measuring the force during the surface scanning, one can obtain the exact structure of EDL, such as the oscillating ion distribution.41, 48, 49, 50 Other experimental probes, not shown in Figure 4 but useful for characterizing EDLs, include Sum Frequency Generation (SFG)51 and Second Harmonic Generation (SHG),52 which can provide the structural information of carbon at interface, such as molecular vibration and bond stretching. Scanning Transmission Electron Microscope (STEM) is also used to visualize the structure at interfaces.

1.6. Important Issues in Capacitive Energy Storage

In general, the energy density of a carbon EDLC is below 10 Wh kg–1, while a Li‐ion battery's energy density is about 100 Wh kg–1. So for capacitors, the most urgent issue is to improve their energy density so that they can better compete with batteries.1 To design materials and interfaces for EDLCs with higher energy density requires a deeper understanding of the factors contributing to the total capacitance of an EDLC.

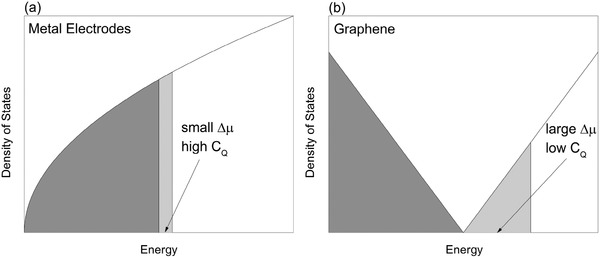

1.6.1. Classical vs. Quantum Capacitance

From conventional EDL theory, the capacitance of EDLCs stems from the adsorption of counterion at the charged electrode surface. This EDL capacitance can be obtained from classical thermodynamics and electrostatics.10, 53 Thus, we refer to it as “classical capacitance”, which is not explicitly dependent on the electronic state of electrodes. The macroscopic electrode potential is related to the electron chemical potential μe. For an ideal metal electrode, which has extremely large electronic density of states (DOS), adding or removing a few electrons does not cause a significant shift in μe (Figure 5 a). Thus, the macroscopic electrode potential change is dominated by the surface potential drop of the EDL. However, for materials with low electronic DOS at the Fermi level, adding or removing the same number of electrons from the electrode can result in a significant potential drop (Figure 5b). This capacitance due to the electrode being a poor metal is called quantum capacitance (C Q), which is especially important for graphene. Different from CQ, the capacitance due to the electrolyte response and EDL formation is defined as EDL capacitance (CEDL).

Figure 5.

Comparison of charging behavior between a typical metal (a) and graphene (b) from the perspective of the electronic density of states. With the same amount of excess charge, graphene exhibits significantly larger shift in the Fermi level (Δµ) than a typical metal.

1.6.2. Pore Size, Surface Area, and Pore Geometry

Experimental studies have shown that optimal pore size is related to ion size and can result in a maximum in the capacitance.28, 29 Theoretical calculations and molecular simulations also verified this phenomenon and predicted that capacitance oscillates with pore size for ionic liquids inside an ideal slit pore.53, 54, 55 However, treating a porous carbon as a single slit pore is problematic because a real porous carbon can exhibit complex features such as a broad distribution and/or a bimodal distribution. These complexities make such systems difficult to model. In particular, ion accessibility and selectivity in a distribution of nanopores can have a significant impact on the macroscopic capacitance.

Specific surface area (SSA) and pore geometry are also important factors in determining EDLC performance. For a flat single layer graphene in contact with electrolyte on both sides, the theoretical SSA is about 2630 m2 g–1. However, in porous carbon, the SSA is strongly related to the pore geometry. In particular, the curvature is important in porous carbons dominated by micropores.56, 57, 58 Numerical simulation of the Poisson‐Boltzmann (PB) equation has shown that the capacitance of a cylindrical or spherical electrode is radius (R 0)‐dependent when R 0 is small; for large R 0, the capacitance approaches that of a planar electrode.59, 60 However, an electrode composed of real porous carbon is not in an ideal geometry such as planar, cylindrical or spherical. Thus, the pore size, SSA and pore geometry are coupled together.

1.6.3. Electrolytes

The capacitance can be effectively varied by changing the ion size, valence, and concentration in the electrolyte, which calls for guidance from simulations. For ionic liquids, the cation and anion are usually different in size. As a result, the charging behavior on the two electrodes become asymmetric, as is observed experimentally.61 Moreover, solvent is also very important to the energy density of supercapacitor since, for example, it dictates the electrochemical window. Organic solvents offer electrochemical windows up to 3V. Aqueous electrolytes usually have higher capacitance than ionic liquid, but suffer from narrow voltage window of about 1.2V. In addition, the capacitance depends on the scan rate and a promising EDLC is also expected to have large capacitance at fast charging/discharging rate. This requires fast ion transport in response to the electrode charge. The time‐dependent charging behavior can in principle be simulated by molecular dynamics (MD) or solving the Poisson‐Nernst‐Planck (PNP) equation, but difference of many orders of magnitude exists between the simulated time scale (on the order of ns to µs) and the experimental scan rate (seconds).12, 13, 62 A multiscale approach is needed to bridge the gap.

1.6.4. Defects and Functional Groups on Carbon

Introducing surface defects can change the surface structure, atomic bonding and SSA, hence the EDL structure and capacitance.63 Simulations need to take into account changes in both the electrode's electronic structure and the EDL structure.64 Functionalization is another effective way to modify the graphene electrode and improve the capacitive performance. The mechanism of how functional group influences capacitance can be more complicated than surface defect due to the possible redox reaction caused by functional groups. When the functional group is introduced on a graphene electrode, the electronic structure change can cause C Q to change, and the interaction between the functional group and the electrolyte also influences the EDL structure and C EDL.

1.6.5. EDLCs vs. Pseudocapacitors

The methods to model EDLCs have been well developed. However, currently there is no appropriate method for modeling pseudocapacitance due to the complexity of interfacial redox processes. The pseudocapacitance can be affected by many factors, such as the diffusing behavior of reactant species, EDL at interface, and surface redox kinetics. These issues are difficult to be self‐consistently captured in the same model. So developing a feasible model to capture the pseudocapacitance is urgently needed.

2. Classical Methods to Simulate EDLCs

In this section, we briefly review the most commonly used classical methods to simulate EDL and EDLCs. These include classical density functional theory (CDFT), classical molecular dynamics (CMD), and grand canonical Monte Carlo (GCMC). In both CDFT and GCMC, coarse‐grained models are commonly used for the electrolyte, while in CMD all‐atom models are usually employed.

2.1. Coarse‐Grained Classical Density Functional Theory

CDFT is a powerful method to simulate the equilibrium properties of complex liquids and soft materials. Both primitive and non‐primitive coarse‐grained models are employed to represent the ionic species, impurities, and solvent molecules in the electrolyte solution.65 The model system consists of charged hard spheres for ionic species and a hard‐sphere dimer for solvent molecules. CDFT was used to simulate the EDL structure and capacitance for the electrolyte solution in various pore geometries.66, 67, 68, 69, 70 The details of the CDFT calculations have been published before.57, 71, 72, 73 The density profiles of cations, anions, impurities, and the solvent segments inside the pore can be obtained by minimization of the grand potential, given the number densities of ions and solvent molecules in the bulk, system temperature, pore size, pore geometry, and the surface electrical potential. To illustrate, we may consider an electrolyte system containing spherical cations and anions and solvent molecules represented by two tangentially connected spheres of opposite charge. The grand potential is given by74

| (3) |

where β−1 = kB T, R≡R(r δ+, r δ−) represents two coordinates specifying the positions of two segments in each solvent molecule, μa is the chemical potential of an ionic species, μM is the chemical potential of the solvent, Ψa(r) stands for the external potential for ions, and ΨM(R) is the summation of the external potential for a solvent molecule. F is the total intrinsic Helmholtz energy

| (4) |

where V b stands for the bonding potential of the solvent molecule and Fex is the excess contribution due to intermolecular interactions. The detailed expression for each contribution and the numerical details can be found from a previous study.65 The mean electrostatic potential can be obtained from the density distributions of the ions by using the Poisson equation. The surface charge density Q is obtained from the condition of overall charge neutrality. The differential capacitance C d of the EDLs can be calculated as a derivative of the surface charge density Q with respect to the surface potential.

Time‐dependent density functional theory (TDDFT) is an extension of the classical DFT to describe dynamic or time‐dependent processes based on the assumption of local thermodynamic equilibrium.75, 76, 77 For ion diffusion in an electrolyte solution near electrodes, TDDFT asserts that the time evolution for the local density profiles of ionic species, ρi(r,t), follows the generalized diffusion equation

| (5) |

where Di stands for the self‐diffusivity of ion i, μi(r,t) is the local chemical potential and can be obtained by a derivative of the intrinsic Helmholtz energy F with respect to the density, and Vi(r) denotes the external potential from the electrodes. With TDDFT, one can examine the ion dynamics inside the nanopores during charging.

2.2. Atomistic Classical Molecular Dynamics

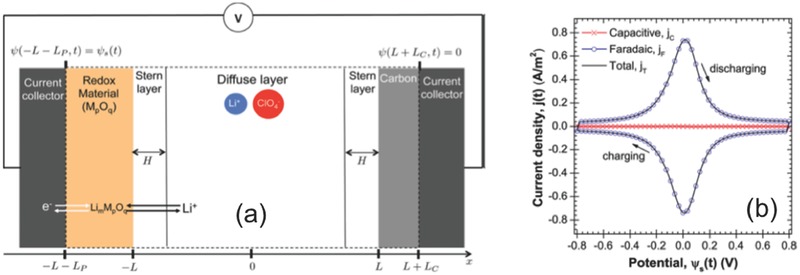

Atomistic molecular dynamics (MD) simulations have been broadly and effectively employed to investigate the structure of EDL and capacitance of EDLCs. The key for MD simulation to accurately capture the fundamental aspects of EDLCs relies on the model used for the electrode/electrolyte interface. To simulate the charged electrodes, two methodologies have been developed: the constant‐charge method and the constant‐potential method. In the constant‐charge method, a partial charge (of equal value) is assigned to each atom on the electrode surface. The potential associated with each value of surface charging is calculated by solving Poisson's equation. Due to the simplicity of implementation, the constant‐charge method has been widely adopted by researchers to simulate electrodes with simplified geometries, such as graphene basal planes,43, 78, 79, 80, 81 carbon onions,82 carbon nanotubes83, 84 and slit pores.54, 85 These studies provide insights into the charging mechanism of EDLCs, and the results match well with the experimental results in both capacitance and interfacial structures.86

The constant‐charge method neglects possible fluctuations and inhomogeneities in surface charges induced by electrolytes. The constant‐potential method overcomes this drawback and constrains a constant‐potential drop between the two electrodes by redistributing the surface charge over the course of simulation. The charges on the electrode atoms fluctuate in order to satisfy the condition of minimizing the electrostatic energy of the system.87, 88, 89 Researchers have compared these two different methods. Merlet and co‐workers modeled a supercapacitor based on 1‐butyl‐3‐methylimidazolium hexafluorophosphate (BMIM‐PF6) and carbon electrodes, and found that both methods showed quite similar ionic density profiles at low potential drop for the planar surface.90 Wang et al. modeled the LiClO4‐acetonitrile/graphite EDLCs and drew a similar conclusion.91 However, in both studies, the structural difference becomes significant when the potential difference is high (over 5 V).92 The constant‐potential method is about one order of magnitude slower than the constant‐charge method,90, 93, 94 but it allows MD simulations to explore more complex and inhomogeneous electrode systems, such as rough surfaces,95, 96, 97 activated carbon98 and amorphous carbide‐derived carbons (CDCs),99, 100, 101 where the constant‐charge method is not applicable.

Accurate force fields for the electrolyte are also necessary for MD simulations of EDLCs. Many force fields have been developed for room‐temperature ionic liquids (RTILs), including coarse grained,102, 103, 104 united‐atom,105, 106, 107 all‐atom108, 109 and polarizable force fields.110, 111, 112, 113 Coarse‐grained force fields simplify the whole molecule into a few or even one bead, and are hence useful in reducing computational cost to capture long‐time dynamics100 and interfacial properties.104, 105 But their lack of atomic details for the electrolyte molecule may limit the degree of agreement that can be achieved with experiments.114 All‐atom force fields provide a richer representation of the electrostatic interactions and molecule configurations in the EDL. However, the non‐polarizable all‐atom force fields for ionic liquids usually overestimate the ion‐ion interactions, resulting in smaller diffusion coefficients and higher viscosities compared with experimental results. Scaling partial charges has been considered as an effective way to compensate the polarization effect and recover diffusion coefficients and electrical conductivity.115, 116, 117, 118, 119 Another solution is to use a polarizable force field. The inclusion of electronic polarizability has been shown to not only improve dynamic properties, but also reproduce local ion structures,111, 120 although at an order of magnitude higher computational cost.121

2.3. Constant‐Voltage Grand Canonical Monte Carlo

Kiyohara et al. developed a constant voltage GCMC to simulate an EDLC system with planar electrodes and coarse‐grained ions.122, 123 The Monte Carlo steps include ion insertion, deletion, migration and exchange in the electrolyte as well as charge balance and exchange among electrodes. Given the electrode setup, the bulk electrolyte activity, and the applied potential, many millions of MC steps are performed to reach the equilibrium. Then EDL structure, surface charge, and capacitance can be derived, similar to the process from the CDFT method. The oscillatory behavior in the capacitance of an ionic liquid electrolyte in a slit nanopore shown by CDFT and CMD simulations was successfully reproduced by constant voltage GCMC.124, 125 Unlike the available CDFT method which is limited to simulate EDLC in one dimension (hence can treat only one pore size in a single simulation), the GCMC method is three‐dimensional and can simulate a multiple‐sized and more realistic porous electrode with both pure and mixture of electrolytes.

3. Ab Initio Simulations of the Electrochemical Interfaces

When the electron or the electronic structure plays an important role at the electrochemical interfaces, ab initio simulations are necessary. The electronic effect can originate from the electron‐solvent repulsion at the charged interface and influence the structure and screening potential of the EDL, as revealed by ab initio MD simulations of the aqueous electrolyte/Pt interface.126 For carbon‐based EDLCs, the main concern is due to the low electronic density of states at the Fermi level; in this review, we mainly focus on this quantum capacitance (C Q) effect, which has been briefly introduced in 1.6.1. One can compute the total capacitance (C tot) by combining C EDL from classical simulation and C Q from the electronic structure calculation. At the same surface charge density, the total electrode potential drop can be divided into contributions from C Q and C EDL.80, 127 Methods have also been developed to capture the polarization effect self‐consistently at the electronic‐structure level. Here, the electronic chemical potential shift Δμe is treated as the electrode potential drop and has contributions from band filling/emptying in the electrode and ionic screening in the electrolyte. Currently, there are two methods that can capture the electronic structure of the electrode in contact with the EDL: the effective screening medium (ESM) method and joint density functional theory (JDFT).

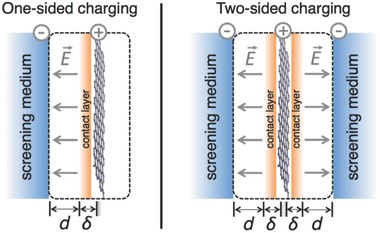

3.1. Effective Screening Medium (ESM)

The original idea of ESM was proposed by Otani et al. to achieve first‐principles calculation of charged surfaces and interfaces taking into account ionic screening.128 In the ESM method an infinite dielectric medium is inserted at the boundary of the periodic cell that can ideally screen all the excessive charge in the periodic cell through setting a mirror charge at the dielectric boundary (Figure 6 ).129 The position and dielectric constant of the ESM are adjustable, which can influence the electrostatic potential of the whole system. The total energy functional includes the electrostatic interaction between the electronic system and the ESM; the electrostatic potential is obtained by solving the Poisson equation. ESM can capture the polarization effect on the electrode from ionic screening of electrolyte. The thickness of the vacuum slab between the screening medium and the electrode is given, so the vacuum part can be regarded as a dielectric capacitor with εr = 1 and Cvac = εA/d. Here, A is the surface area and d is the vacuum slab thickness. By subtracting the contribution of the vacuum slab from Δμe, one can obtain the potential drop due to the electrode and then compute C Q. However, there are still several limitations in ESM: first, the mirror charge in ESM cannot be used to describe the EDL in the electrolyte because the thermal behavior and ion diffusion are not included in the Poisson equation; second, the liquid response to the electrode charge cannot be captured in ESM. Thus, ESM is more applicable to study the electrode capacitive behavior.

Figure 6.

Simulation setup for one‐ and two‐sided charging within the effective‐screening‐medium (ESM) method (shown here for a positive bias). Reproduced with permission.129 Copyright 2015, American Physical Society.

3.2. Joint Density Functional Theory (JDFT)

3.2.1. Theoretical Framework

The concept of Joint Density Functional Theory (JDFT) was originally proposed by Arias, aimed at solving the solid/liquid interface self‐consistently.130 The philosophy of JDFT is treating the solute by electronic DFT and solvent by classical DFT. By minimizing the total free energy, one can obtain the equilibrium state of the solute/solvent system. The free energy functional in JDFT formalism can be written as131

| (6) |

A HK is the electronic energy functional from Hohenberg‐Kohn Theorems and A lq is the classical density functional of the liquid free energy.131 ΔA is the coupling energy related to the interaction between solute (the electrode) and solvent (the liquid).

3.2.2. Implicit solvation and linear polarizable continuum model

Besides classical DFT, the solvation effect and the electrolyte response in JDFT can be more easily described by implicit solvation with linear response approximation. For example, the total free energy functional of an electronic system solvated in the linear polarizable continuum model (Linear PCM) can be written as:132

| (7) |

A TXC is the single particle Kohn‐Sham kinetic energy plus exchange‐correlation energy. The second term on the right‐hand side is the electrostatic energy of electron and nuclei in electrostatic field. The last two terms correspond to the energy of the electric field in the dielectric medium and the energy contributed by electrolyte ions described by the Debye‐Hückel theory. In this equation, n(r) is the electron density of the explicit system, N(r,{Z I,R I}) is the nuclei density and φ(r) is the total electrostatic potential including Hartree potential and solvation contribution. The local dielectric constant ε(r) and inverse Debye length κ(r) are determined from the local solvent density, cavity function, bulk dielectric constant (εb) and the inverse Debye screening length in the bulk fluid (κb).133 The equilibrium state of the solute/solvent system is given by minimizing the total free energy functional with respect to n(r) and φ(r).132 Advanced solvation models have been developed for JDFT, including non‐local effects,134 nonlinear dielectric response,135 spherically averaged liquid susceptibility ansatz (SaLSA), and charge‐asymmetric nonlocally determined local‐electric (CANDLE) solvation model.136, 137 SaLSA and CANDLE can capture the nonlocal dielectric response of polar solvent.138

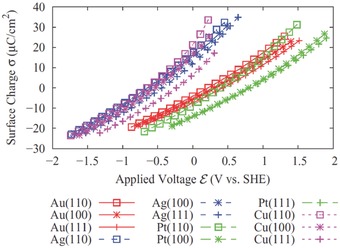

3.2.3. Electrochemical Simulation by JDFT

In a two‐electrode electrochemical cell, the electrode potential μ (the voltage) of the working electrode is defined by the energy required to move one electron from the working electrode (electronic chemical potential at μW) to the reference electrode (electronic chemical potential at μR): so ε = μR − μW per the fundamental charge. If we choose zero potential as a reference, then ε = −μ. When the electrode in the simulation is neutral, the calculated μ is related to the potential of zero charge (PZC). By plotting the calculated PZC and experimental PZC of different metal surfaces, one can extrapolate the potential of standard hydrogen electrode (SHE). Figure 7 shows the JDFT‐simulated curves of surface charge density vs. the electrode potential (vs. SHE) for various metal surfaces with Linear PCM.

Figure 7.

Charge‐potential curve of different metal surfaces from joint DFT (JDFT) calculation with Linear polarizable continuum model (PCM) electrolyte. Reproduced with permission.132 Copyright 2012, American Physical Society.

4. EDL Capacitance Inside Nanopores

Having introduced the simulation methods, now we can review how they have been applied to understand capacitive energy storage. The most interesting feature of an EDLC is the structure and capacitance of the double layer confined inside the nanopores. In this section we focus our narrative on the double layer confined in different pore size/geometry from classical simulations, while leaving the electrode chemistry for the next section.

4.1. Capacitance vs. Pore Size

4.1.1. Classical DFT Perspective

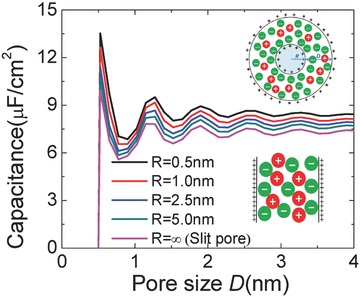

Despite the fact that a great variety of porous carbons have been utilized in EDLCs, the effects of the pore geometry on the EDL structure is not well understood.114 At the heart of the issue is the question: What is the microscopic structure of porous electrodes and how does the capacitance of EDLCs depend on the electrode pore geometry and electrolyte composition? Whereas practical porous electrodes involve micropores with complicated morphology and pore size distributions,101, 139 theoretical modeling of EDLCs is mostly based on simplistic models to represent the pore geometry and the electrolyte‐electrode interactions.140 Specifically, three types of electrode structures are commonly used in theoretical investigations:141, 142, 143 (i) planar surfaces (e.g., a flat surface or slit pores); (ii) cylindrical pores with their concave inner surfaces or cylindrical particles with their convex outer surfaces (e.g., carbon nanotubes); (iii) spherical surfaces (e.g., onion‐like carbons). The slit and cylindrical pore models are conventionally used for porous materials characterization.144 Recent simulations and experiments indicate that both the pore size and geometry play an important role in determining the capacitance of EDLCs.145, 146, 147, 148 An important question is whether this behavior based on the slit pore or solid particles is generally valid for realistic carbon electrodes.

CDFT is an ideal computational tool for examining the pore size and geometry effects, as it is computationally efficient and applicable over a wide range of pore sizes ranging from that below the ionic dimensionality to mesoscopic scales. To take into account both the pore size and the curvature, a spherical‐shell pore model is used (Figure 8 top inset). The EDL capacitance exhibits oscillatory dependence on the pore size for different inner core radii (Figure 8), as observed in previous CDFT and CMD simulations of ionic liquids in slit pores.53, 54 The distance between neighboring peaks (or valleys) is approximately 1.5 times the ion diameter. The oscillatory variation of the integral capacitance is closely related to the layering structures of ion distributions near the charged surfaces.53 As the inner radius R decreases, the capacitance increases significantly, because a smaller inner core radius results in more counterions in the pore thus a larger capacitance. This work suggests the significant role of convex surfaces for the synthesis of new porous electrodes to optimize EDLC performance. In particular, the spherical shell model provides a simple yet generic description of both pore size and curvature. The curvature effect on capacitance was also found in CMD simulations of the idealized carbon onion electrodes with the ionic liquid electrolyte.149

Figure 8.

Integral capacitance vs. pore size (D) for a coarse‐grained ionic liquid electrolyte (0.5 nm in diameter for both cation and anion) confined between two spherical shells of different inner radii (R). Reproduced with permission.57 Copyright 2016, American Chemical Society.

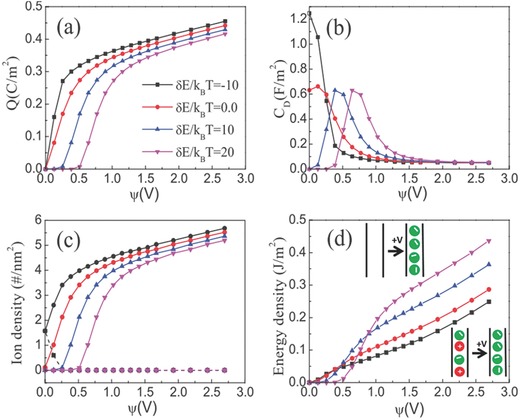

Energy storage via electrosorption depends not only on the electrode pores and ionic species but also on specific interactions between mobile ions and the surface of electrode materials. Recently, Kondrat and Kornyshev found that the capacitive performance is sensitive to the ion affinity with nanopores: their theoretical results show electrodes with ionophobic nanopores may have slightly lower, the same, or even higher energy storage capacity than the ionophilic ones, all depending on the electrode voltage.150, 151, 152 It has also been shown that the charging kinetics of an empty ionophobic nanopore is much faster than that of an ionophilic nanopore at similar conditions.151, 153 Experimentally, the ionophobicity may be controlled by modifying the surface properties of nanoporous materials or by introducing special functional groups to the ionic species. The effects of non‐electrostatic ion‐surface interactions were examined by CDFT.154, 155 The ionophobicity of nanopores was controlled by δE, the resolvation energy or the energy cost to transfer an ion from the bulk to the slit pore (Figure 9 a): negative δE promotes adsorption of ions within the pore (viz., an ionophilic pore), while a positive δE means an ionophobic pore. Figure 9b indicates that the peak capacitance shifts to a higher potential as the ionophobicity increases, because higher potentials are needed to drive ions into the pore with increased ionophobicity (Figure 9c). Figure 9d shows that, at low electrical potential, the energy density for an ionophilic pore is higher than that of an ionophobic pore, while the trend reverses at high potentials. Hence, the energy stored in the EDLC can be promoted by the ionophobicity only when the electrode voltage is larger than a critical value.154

Figure 9.

a) Surface charge density, b) differential capacitance, c) average cation and anion densities inside the nanopore, and d) the energy stored per unit of surface area for an EDLC containing a 1.0 m organic electrolyte from coarse‐grained classical DFT. Pore size is D = 0.6 nm; both cations and anions are at 0.5 nm in diameter. δE represents the ion transfer energy from the bulk reservoir into the nanopore. In (c), the solid lines are average densities inside the pore for the counterions, and the dashed lines are for the coions. Reproduced with permission.154 Copyright 2016, IOP Publishing.

4.1.2. Classical MD Perspective

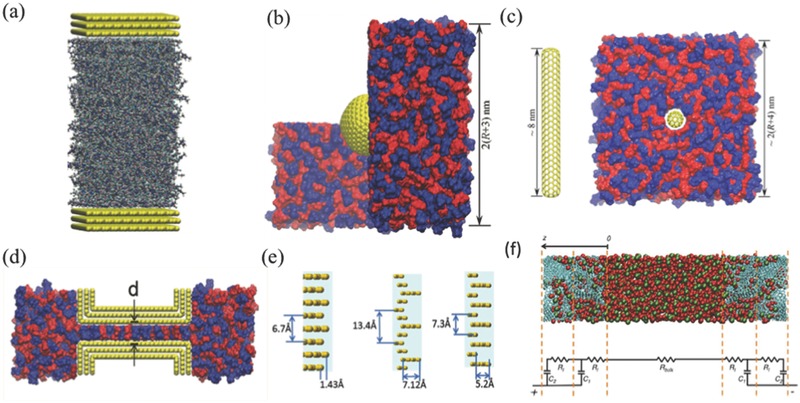

Although coarse‐grained CDFT is good at capturing most important trends, for atomistic details all‐atom CMD simulations are needed. Many CMD simulations have been devoted to studying the planar electrode (Figure 10 a), where differential capacitance is usually found to be bell‐shape or Bactrian‐camel‐shape.78, 107, 156, 157 Feng and coworkers built spherical149 and cylindrical83 electrodes to study influence of curvature effects on capacitance (Figure 10b,c). The differential capacitance was found to be weakly dependent on applied voltage and increase with the electrode curvature.143 The slit pore model has been adopted by Feng et al. (Figure 10d) to explain the abnormal increase of capacitance when the pore size is close to ion size for porous carbon electrodes.54 Qiao and coworkers also used slit pore models to investigate the charging behavior in subnanometer pores.62, 153 The simplified electrode models in the CMD simulations usually lead to lower capacitances.101 Vatamanu and coworkers showed that the surface roughness (Figure 10e) could increase the energy storage.95, 96, 97, 158, 159, 160 Palmer and coworkers conducted quench molecular dynamics (QMD) simulations to generate porous carbon models by mimicking the thermal quenching of systems of carbon atoms.139, 161 Their atomistic models for Ti‐CDCs were then used by Merlet et al. to study the capacitance in microporous carbon electrodes (Figure 10f), where quantitative agreement with experimental results was reached.101 Moreover, these detailed CDC models allowed the exploration of ion structure and charging mechanism in nanoconfinement.100, 162, 163

Figure 10.

Electrode models used in classical molecular dynamics simulations: a) Planar electrode. Adapted with permission.78 Copyright 2014, IOP Publishing. b) Exohedral spherical electrode. Adapted with permission.149 Copyright 2012, American Chemical Society. c) Exohedral cylindrical electrode. Adapted with permission.83 Copyright 2013, American Chemical Society. d) Slit pore. Adapted with permission.54 Copyright 2011, American Chemical Society. e) Rough surface. Adapted with permission.114 Copyright 2015, American Chemical Society. f) Realistic pore. Adapted with permission.100 Copyright 2014, American Chemical Society.

4.2. Capacitance vs. Electrolyte Composition

Due to their higher voltage window, nonaqueous electrolytes including organic and ionic liquid electrolytes are preferred than aqueous electrolytes for higher‐energy‐density EDLCs. This subsection focuses on the interplay of ions and solvent dipoles in the organic electrolyte and the mixture of ionic liquids when confined in nanopores.

4.2.1. Classical DFT Perspective

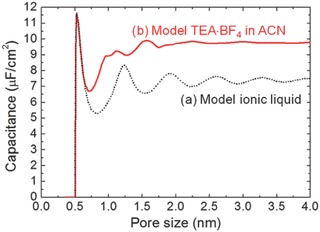

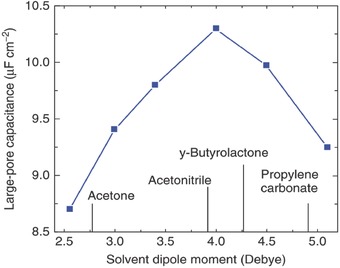

In organic electrolytes, salts such as tetraethylammonium tetrafluoroborate are dissolved in an organic solvent. Acetonitrile (ACN) and propylene carbonate are the most popular solvents. In the coarse‐grained CDFT models, the polar solvent can be represented by a dipole or a connected hard‐sphere dimer, while ions are modeled as charged hard spheres. Figure 11 shows how the capacitance changes with the width of the slit pore for both the coarse‐grained organic and ionic liquid electrolytes.71, 72 In the case of the ionic liquid electrolyte (Figure 11a), the capacitance displays an oscillatory pattern with the slit pore width. The period of the oscillation is about 0.75 nm or 1.5 times the ion diameter. The dampened magnitude converges to about 7.5 µF cm–2. The capacitance maximum at the pore size of 0.5 nm or same as the ion diameter agrees with the experiment.29 The curve for the organic electrolyte (Figure 11b) also displays such a maximum at the pore size close to the ion diameter but shows a roughly constant capacitance beyond 1.0 nm or twice the ion diameter. Moreover, Figure 11 shows that at the large pore size (≈ 4 nm), the model organic electrolyte has a 30% higher capacitance than the ionic liquid electrolyte. To bridge the gap for the large‐pore capacitance, various dipole moments for the solvent were examined by CDFT:74 it was found that the weakly polar solvent has a capacitance closer to that of an ionic liquid, while a capacitance maximum can be achieved at an optimal dipole moment of 4.0 Debye (Figure 12 ).

Figure 11.

Integral capacitance vs. the pore size for an EDLC with (a) ionic liquid and (b) organic electrolyte (at 1.5 V relative to the bulk electrolyte) from coarse‐grained classical DFT. Reproduced with permission.71 Copyright 2012, American Chemical Society.

Figure 12.

Integral capacitance (of an organic‐electrolyte EDLC with a 4.0‐nm pore) vs. the solvent dipole moment (at 1.5 V relative to the bulk electrolyte) from coarse‐grained classical DFT. Reproduced with permission.74 Copyright 2014, Royal Society of Chemistry.

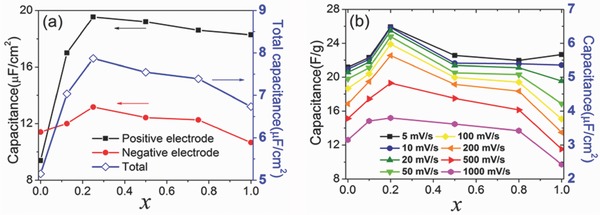

An effective strategy to increase the EDLC performance is to use IL mixtures as the electrolyte.61 However, little is known about how the EDL structure would be affected by the RTIL mixture composition.164, 165, 166, 167 CDFT was used to model a IL mixture based on coarse‐grained models for 1‐ethyl‐3‐methylimidazolium bis(trifluoromethylsulfonyl)imide (EMI‐TFSI) and 1‐ethyl‐3‐methylimidazolium tetrafluoroborate (EMI‐BF4) which differ in the size of the anion. Figure 13 a shows that the capacitance versus composition of the RTIL mixture has a maximum at 25%.73 This is because using a mixture allows more counterions to accumulate on the electrode surface while simultaneously excluding more coions from the electrode surface. The combined result yields a net increase in the counterion density and therefore a larger capacitance. Good agreement has been achieved between the CDFT simulation (Figure 13a) and the experiment (Figure 13b).73 Some small amounts of impurity (e.g., water, alkali salts, and organic solvents) in RTILs may affect the electrochemical performance, which was examined by CDFT.168, 169 It was found that with strong binding of impurity to the ionic species, the RTIL/impurity mixture can lead to an enhanced capacitance oscillation. In certain‐sized pores, a significant increase in the capacitance can be obtained.

Figure 13.

a) Integral capacitance for the positive, negative and total electrodes versus the mole fraction of EMI‐BF4 in the EMI‐BF4/EMI‐TFSI (x) from coarse‐grained classical DFT; operating potential window fixed as 3.0 V between two electrodes. b) Experimental integral capacitance versus x for a symmetric EDLC operating at 3.0 V at different scan rates. Note that only the right y‐axis can be directly compared between (a) and (b) panels. Reproduced with permission.73 Copyright 2016, American Chemical Society.

4.2.2. Classical MD Perspective

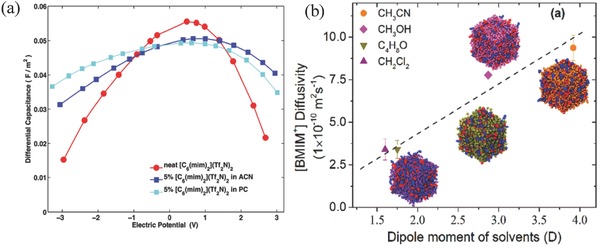

Ionic liquids often suffer from high viscosity, and organic solvents can be added to improve the transport properties. From their all‐atom CMD simulations, Feng et al. found strong layering and ordering of solvent molecules near neutral surface and distinct contact adsorption of counterions near the charged surface that cannot be described by the Helmholtz model.148 They further constructed a model called “counter‐charge layer in generalized solvents” to describe the structure and capacitance of planar electrode immersed by mixture of RTILs and organic solvents.170 Their model predicted that the integral capacitance would increase by less than 10% as the mass fraction of acetonitrile (ACN) in the mixture increases from 0 to 50%. This slight increase of capacitance was confirmed for dicationic ionic liquids in organic solvents.171 For differential capacitance, CMD simulations show that the bell shape becomes more diffused (Figure 14 a) with the addition of polar solvents. In addition, the solvent helps alleviate the size‐asymmetry effect of ions, generating more symmetric differential‐capacitance curve for positive and negative electrodes.172 Vatamanu et al. also reported that the differential capacitance for solvated ILs is weakly dependent on surface roughness.96 Recently, Thompson and coworkers combined MD simulations with neutron scattering and reported that the diffusivity and conductivity of an ionic liquid has a positive correlation with the dipole moment and concentration of the organic solvent added, as shown in Figure 14b.173 Furthermore, Zhang et al. studied the effect of solvent polarity on the EDL structure and capacitance of graphene‐based EDLCs.174

Figure 14.

Solvent effect on the ionic liquid electrolyte from all‐atom classical MD simulations: (a) differential capacitance of a dicationic ionic liquid on the graphite basal plane with added solvents (acetonitrile, ACN; propylene carbonate, PC) in 5% molar ratio: [C6(mim)2](Tf2N)2 = 1‐hexyl‐3‐dimethylimidazolium bis[(trifluoromethyl)sulfonyl]imide; Reproduced with permission.171 Copyright 2014, IOP Publishing. (b) cation diffusivity in 1‐butyl‐3‐methyl‐imidazolium bis[(trifluoromethyl)sulfonyl]imide, [BMIM+][Tf2N−], in solvents of different dipole moments at 50 wt%. Reproduced with permission.173 Copyright 2017, American Chemical Society.

Many RTILs have melting points above 0 °C,175 preventing their uses for low‐temperature applications. Mixing ILs has been proven as a successful strategy to expand the temperature range.176, 177 MD simulations conducted by Li et al. demonstrated that the binary mixture of RTILs outperformed neat RTILs with wider operation temperature, higher conductivity and favorable differential capacitance.178 Experiments have also shown that mixing RTILs extends the voltage window for EDLCs by balancing the charge storage between cathode and anode.61 While a considerable number of MD simulations have been conducted to investigate the structural and transport properties of bulk RTIL mixtures, further knowledge of the interfacial structure and capacitive behavior of RTILs needs more MD investigation of these aspects.179, 180, 181

4.3. Ion Dynamics in Nanopores

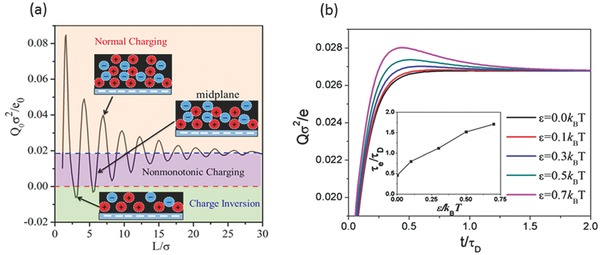

4.3.1. Classical Time‐Dependent DFT Simulation

Understanding charging kinetics and ion dynamics inside the nanoporous electrodes is challenging both experimentally and computationally.100, 151, 153, 182, 183, 184, 185 Using coarse‐grained models for ions, classical time‐dependent density functional theory (classical TDDFT) is able to describe the charging behavior of ions in a slit pore.186 For example, TDDFT predicts that the density profiles of ions can vary with time in a wave‐like fashion for an IL electrolyte,187 due to the alternating ion layers near the electrodes (Figure 15 a). TDDFT results further show that the dispersion interaction between ions makes the surface charge a non‐monotonic function of time (Figure 15b). However, the dispersion interaction between the electrode and ionic liquid does not change the monotonic evolution of surface charge density.188 Both the ion‐ion and the electrode‐ion dispersion interactions increase the duration of the EDL charging process.188 TDDFT was also used to examine ion conductance in nanochannels.189 In narrow pores with a high gating voltage, the ion conductivity shows an oscillatory dependence on the pore size owing to the strong overlap of electric double layers.189

Figure 15.

a) Equilibrium surface charge density versus the cell width (L) predicted by classical DFT; Q0 is the surface charge density at equilibrium; σ = 0.5 nm is the ion diameter. Reproduced with permission.187 Copyright 2014, American Chemical Society. b) Evolution of surface charge density for different strengths of dispersion forces (ε) between ions from TDDFT; inset, time to equilibrium as a function of ε; relaxation time τD = σ2 D–1, where D represents ion diffusivity; for a typical ionic liquid, τD ≈ 5 ns. Reproduced with permission.188 Copyright 2016, American Physical Society.

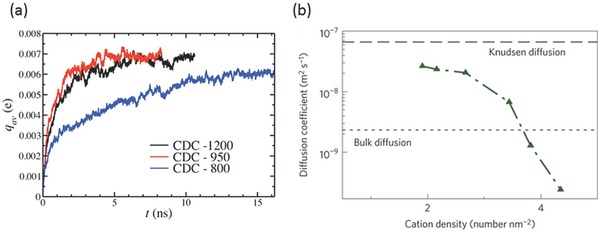

4.3.2. Charging Dynamics from MD Simulation

Although nanoporous materials of high SSA are promising electrode materials to enhance energy density, the nanoconfined environment may slow down ion dynamics and thus decrease power density of EDLCs.190, 191 In their classical MD simulations, Pean et al. used realistic carbon models to study the charging of CDC electrodes.100 Based on the response of average charge densities on each electrode atom to a step electric potential (Figure 16 a), they found that the ion packing in confinement and the ion‐wall interaction are key factors affecting the ion dynamics in electrified nanoporous electrodes. They further showed that the transmission line model, with inputs such as bulk electrolyte conductivity and capacitance from equilibrium MD simulations, matches well with the non‐equilibrium simulations in the charging/discharging curve.192 Diffusion of ions in confinement was found to be slower by one order of magnitude compared to bulk electrolyte and by an additional factor of four for counterions due to their strong electrostatic interaction with the electrode wall.193 On the other hand, Kondrat and coworkers used a slit pore model and reported that ion's self‐diffusion is dependent on ion densities and composition and could be higher than the bulk value, as shown in Figure 16b.153 Of note, these simulations used coarse‐grained models for the electrolytes.

Figure 16.

a) Classical MD simulations of the average charge per carbon atom on the electrode vs. time for a coarse‐grained ionic liquid inside the realistic models of carbide‐derived carbons (CDCs) in response to a step electric potential: a sudden potential jump from 0 to 1 V is applied at t = 0 between the electrodes; reproduiced with permission.100 Copyright 2014, American Chemical Society. b) Classical MD simulations of cation's self‐diffusion coefficient inside a negatively charged ionophobic slit pore at different cation densities; ions are modelled as charged Lennard‐Jones particles of 0.34 nm in diameter; pore size is at 0.53 nm. Reproduced with permission.153 Copyright 2014, Nature Publishing Group.

Using atomistic MD simulations under quasistatic charging conditions, Qiao et al. examined ion dynamics inside charged slit pores.62 They found a complex, pore‐size‐dependent charging dynamics: when the pore size is close to one‐layer‐ion thickness, ion diffusivity can exceed the bulk values at certain charge states, while for wider pores, ion diffusivity is below the bulk values. They further conducted cyclic charging/discharging simulations of EDLC based on RTILs and subnanometer slit pore at rates orders of magnitude higher than experimental values.184 They found distinct transport properties at pore entrance and pore center: rapid ion migration near the entrance but sloshing dynamics inside the pore. Moreover, the charge storage is dominated by the migration of counterions, deviating significantly from quasistatic charging/discharging conditions. The uneven distribution of ions along the electrode surface was further confirmed for RTIL in cylindrical nanopores.194 Electroneutral region, consisted of trapped coion/counterion pairs, was found as a result of rapid overfilling of counterions.

5. Quantum Capacitance of Carbon EDLCs

Besides EDL structure and pore size/geometry, the next important factor in EDLCs is the electrode's electronic structure and chemistry. The electronic structure for an EDLC electrode is typically dictated by the electronic density of states (DOS) near the Fermi level. A limited DOS contributes to the charging of an EDLC unfavorably due to the band filling/emptying, leading to quantum capacitance, which is a focus of discussion in this section.

5.1. Origin of Quantum Capacitance

In early 1970s, Randin and Yeager observed an unexpectedly low capacitance in stress‐annealed pyrolytic graphite electrode in contact with an aqueous electrolyte, even when the electrolyte concentration was high.195, 196 The measured differential capacitance showed a “U” shape and the capacitance minimum is about 2 µF cm–2 at the PZC. In mid‐1980s, Gerischer et al. proposed an interpretation of the capacitance of graphite electrode in relation to its electronic DOS. The basic idea was to divide the capacitance contribution into two parts: (1) the electrolyte contribution from both Helmholtz layer (CH) and diffuse layer (Cdiff); (2) the space charge contribution from the DOS of the graphite electrode (CSC):197, 198

| (8) |

By measuring the total capacitance (Cexpt) and the electrolyte contribution (CH and Cdiff), CSC and then DOS can be obtained. The DOS indirectly measured by this way showed good agreement with the theoretical DOS of graphite. In other words, CSC proposed by Gerischer et al. is closely related to what we now call the quantum capacitance.

The term “quantum capacitance” was first used by Luryi in 1988, as a general physical quantity to describe the DOS‐related charging behavior in 2D materials used for solid‐state electronic devices.199 In solid‐state physics, the electrons in metal can be treated as electron gas. Thus, when the metal layer is atom‐thin, it could behave as a 2D electron gas (2DEG) in a quantum well; when charging such a 2DEG system, quantum capacitance (CQ) arises due to the limited electronic DOS at the Fermi level. CQ of 2DEG200 and graphene have been obtained analytically and used in study of solid‐state devices.201 Below we focus our discussion of CQ in the context of EDLCs, i.e., a 2D material in contact with a liquid electrolyte.

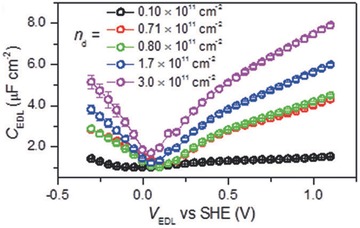

5.2. Experimental Measurement of Quantum Capacitance

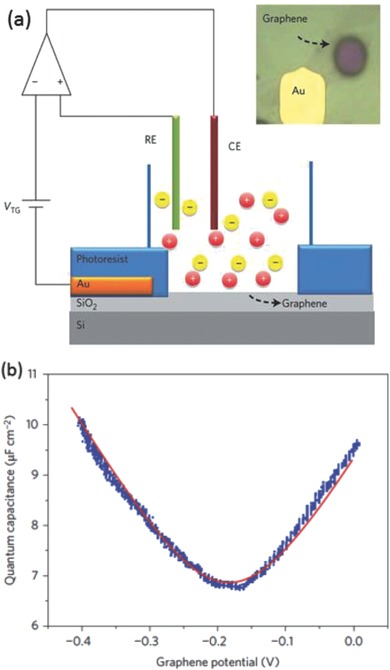

Tao et al. first measured CQ of a single layer graphene in an electrochemical cell that showed good agreement with theoretical prediction (Figure 17 ).202 The measurement is based on the “two‐contribution” model of interfacial capacitance: 1/Ctot = 1/CEDL +1/CQ. Ctot is experimentally measured in the electrochemical cell. CEDL can be roughly treated as a constant from one electrode to another due to the dominant contribution of the Helmholtz layer in aqueous electrolyte. CEDL can be measured by using a metal electrode such as Pt instead of a graphene electrode in the same experimental condition. By subtracting the measured CEDL from Ctot, one can obtain CQ. Using a similar approach, Ruoff et al. studied the layer effect on the capacitance for few‐layer graphene electrodes,203 and Downard et al. measured CQ of aryldiazonium modified few‐layer graphene electrodes.204

Figure 17.

(a) Setup and (b) result of quantum capacitance measurement of graphene against an ionic liquid electrolyte, 1‐butyl‐3‐methylimidazolium hexafluorophosphate (BMIMPF6). Reproduced with permission.202 Copyright 2009, Nature Publishing Group.

5.3. Simulating Quantum Capacitance in Single‐Layer Graphene EDLC

Since CQ arises from the electrode DOS, one can directly compute the electrode's electronic structure and then derive CQ. If one assumes that the electronic structure is unchanged during charging, this is called the fixed‐band approximation.

5.3.1. Fixed Band Approximation

Fixed‐band approximation (FBA) is a simple way to simulate CQ in EDLC. Assuming that the Fermi level is rigidly shifted by bias potential φ and DOS is not affected by charging, the excess charge density Q on the electrode can be written in terms of DOS [D(E)] and the Fermi‐Dirac distribution [f(E)]:

| (9) |

so that

| (10) |

For any electrode system, one first computes its electronic DOS by using an electronic‐structure method such as Kohn‐Sham DFT (KS‐DFT) and then uses Equation (10) to obtain CQ.80 In addition, it is shown that the FBA‐obtained CQ is not affected by the explicit ionic liquid electrolyte.205

5.3.2. Relaxed‐Band Approach

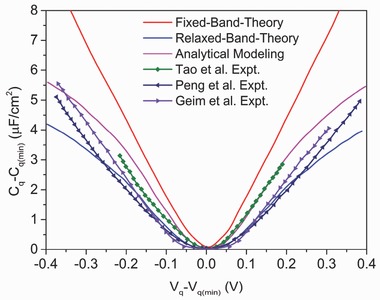

In the relaxed‐band approach, the electronic structure is fully optimized or relaxed after the electrode is charged, hence the name “relaxed band” (RB). One then directly computes the contribution of band emptying/filling, as reflected in the Fermi level shift, to the total potential drop across the interface to compute CQ.129 Wood et al. simulated CQ of graphene in the RB approach through the ESM method. Their simulated CQ compares better to the experimental measurement (Figure 18 ), while the FBA curve overestimates. But overall, both approaches can well capture the main trend of graphene CQ.

Figure 18.

Experimental and theoretical quantum capacitances of single layer graphene. Figure legends from top to bottom are from: Ref. 80, Ref. 129, Ref. 202, Ref. 206, and Ref. 207.

5.4. Modeling Total Capacitance of Graphene Electrodes

As discussed above, quantum capacitance is indirectly obtained experimentally from subtraction from the measured total capacitance, while it can be directly computed theoretically. To compare with the experimental total capacitance, the CEDL contribution from classical simulations needs to be combined with computed CQ to predict the total capacitance.

5.4.1. Two Contribution Model

Hwang and coworkers modeled the capacitance of graphene by combining separately simulated CQ from KS‐DFT and CEDL from CMD,80 based on two serially connected capacitors. The PZC from CMD simulation is treated as the electrode potential reference and used to set the Fermi level in the KS‐DFT calculation. By summing up the potential drops from CQ and CEDL at the same charge density, one can obtain the total potential drop and total differential capacitance curve. They found that the voltage‐dependent Ctot of graphene shows a “U” shape near the PZC and becomes flat when the bias voltage is large. This unique “U” shape of differential capacitance of graphene was also reported by Sun et al. through JDFT simulation that treated the electrode and electrolyte self‐consistently.208 In addition, Ruoff et al. reported a similar trend with both experimental evidence and theoretical interpretation.209 The “U” shape mainly stems from CQ: as shown in Figure 18, CQ of graphene has a “V” shape and a very low value near the Fermi level (PZC), thereby dominating Ctot near the PZC.

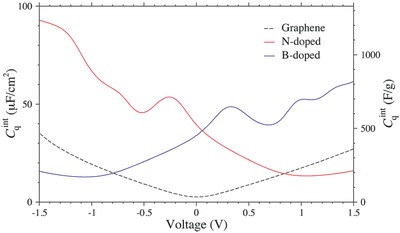

5.4.2. Doping of Graphene

Based on the two‐contribution model, a straightforward approach to increase Ctot of graphene materials is to increase CQ by raising DOS at the Fermi level. Hwang et al. showed that N‐doping can greatly increase CQ of graphene and lead to higher Ctot, which can explain the experimentally observed capacitance increase in N‐doped graphene electrode.210 The doping effect on DOS and CQ can be well understood in some simple cases, such as graphitic N and B doped graphene.211 Replacing one carbon atom by nitrogen in graphene adds one electron to the conduction band and causes the Fermi level shift to the higher energy, while replacing one carbon atom by boron in graphene removes one electron from the valence band and causes the Fermi level shift to the lower energy. In both cases, the DOS at the new “Fermi level” is larger than that of Dirac Point in graphene, leading to a higher CQ (Figure 19 ).

Figure 19.

Quantum capacitance of N‐doped and B‐doped graphene. Reproduced with permission.211 Copyright 2014, American Chemical Society.

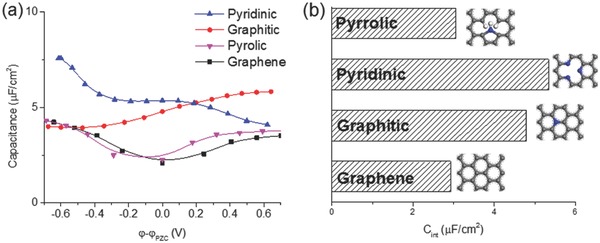

More types of N‐doping were explored later,212 including graphitic, pyridinic and pyrrolic. KS‐DFT calculations showed that graphitic and pyridinic nitrogen can greatly increase CQ monotonically with doping concentration, while pyrrolic nitrogen gives a V‐shaped CQ, similar to pristine graphene. CMD simulation showed that CEDL is significantly affected by nitrogen doping. Ctot from combining the KS‐DFT‐obtained CQ and CMD‐obtained CEDL showed that graphitic and pyridinic N‐doped graphenes exhibit higher Ctot than pristine graphene, while the pyrrolic N‐doped graphene has the same Ctot as pristine graphene (Figure 20 ).212 Moreover, computed formation energy shows that the relative stability follows pyrrolic > pyridinic > graphitic.213 Thus, to effectively improve the capacitance, one should enrich the graphitic and pyridinic nitrogens, and avoid pyrrolic nitrogen. This idea is supported by experimental evidence: Ruoff et al. obtained a U‐shaped differential capacitance on N‐doped carbon and XPS showed that the pyrrolic nitrogen is dominant.214 Choi et al. studied the capacitance of N‐doped graphene synthesized by plasma and found that the capacitive performance is dependent on the relative proportion of nitrogen configurations. As the pyrrolic nitrogen content increases, the capacitance decreases, consistent with our theoretical finding.215 In addition, N‐doping could yield stronger bilayer formation than pristine graphene,216 thereby leading to a potentailly different behavior of capacitance dependence on the layer thickness.

Figure 20.

Simulated total capacitance of N‐doped graphene: a) differential capacitance; b) integral capacitance from –0.6 to 0.6 V. Reproduced with permission.212 Copyright 2016, Royal Society of Chemistry.

Other dopants have also been explored. Hwang et al. studied Ctot of metal‐doped graphene electrode by combining DFT‐obtained CQ and CMD‐obtained CEDL.217 Two types of configuration were studied: monovacancy and divacancy site. The KS‐DFT study shows that most transition‐metal dopants can greatly increase CQ of graphene and have an asymmetric charging behavior. CMD simulation shows that doping causes only a small increase in CEDL. Together, they lead to higher Ctot. Mousavi‐Khoshdel et al. studied CQ of co‐doped graphene (by N, S, Si, and P) and found that most of them exhibit very large CQ, comparing with pristine graphene.218

5.4.3. Defect, Curvature and Geometry

Besides doping effect, the structural modification on carbon itself is also an effective way to improve CQ. Wood et al. showed that defect or vacancy can greatly increase CQ of graphene.211 Hwang el al. found that topological defects with special geometry shows larger CQ than pristine graphene.64 In experiment, vacancies and defects can be created in porous carbons by KOH activation and are expected to have higher capacitance than perfect graphene. Another way of structural modification is surface curvature. Wood et al. showed that strain‐induced ripples can increase CQ.211 Hwang et al. found that CQ of CNT increases as its diameter decreases.84 A strong experimental evidence of defect effect was recently reported, as shown in Figure 21 .63 The TEM image clearly shows that the synthesized graphene contains some topological defects that can be controlled experimentally. Differential capacitance measurement shows that the capacitance increases with the defect concentration. Geometry effect such as surface wrinkles was also investigated from MD simulation.219

Figure 21.

Experimental differential capacitance of a graphene electrode with different topological defect concentrations. Reproduced with permission.63

5.5. Dielectric Screening and Three‐Contribution Model

As discussed in the preceding section, understanding of graphene EDLCs is based on the two‐contribution model that combines CQ from electronic DOS and CEDL from ionic response. This model shows good agreement with the experiment for a single‐layer graphene electrode. However, such a model cannot give a good interpretation on the layer effect for few‐layer graphene (FLG) electrodes. Ruoff et al. measured the capacitance of FLG with different layer number and obtained the Helmholtz layer capacitance (CH) of FLG by subtracting calculated CQ from measured Ctot.203 The obtained CH showed strong dependence on the layer number, which cannot be explained by the traditional EDL theory. As it turned out, dielectric screening becomes important in FLG electrodes.

Uesugi et al. studied the capacitance of FLG in IL electrolyte.220 They treated the dielectric behavior of FLG classically by using the macroscopic dielectric constant of graphite. Simulated capacitance including the dielectric screening contribution shows good agreement with experimentally obtained layer‐dependent total capacitance.220 To take into account the electronic structure of FLG,221 Wood et al. applied KS‐DFT with ESM to study the capacitance of graphene and obtained a contribution that lumped quantum capacitance and dielectric screening contribution together.129

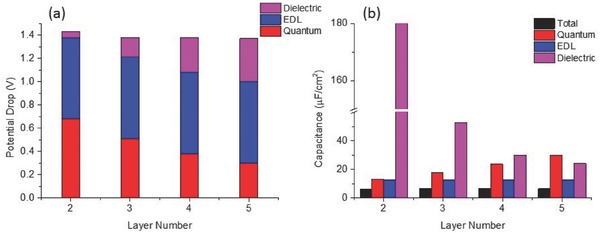

Although the physical origins of quantum capacitance and dielectric screening are closely related, they can be treated and quantified separately in addition to the EDL contribution by separating their contributions from the total potential drop (φ), leading to a three‐contribution model:222

| (11) |

so that

| (12) |

JDFT was used to calculate the capacitance of FLG electrodes in aqueous electrolyte. By separating the electronic chemical potential shift into quantum (CQ), EDL (CEDL) and dielectric (CDielec) contributions (Figure 22 a), one can elucidate how the different parts dominate the total capacitance. CQ from JDFT showed a linear increase with the layer number. The EDL potential drops of FLG are very close to the surface potential drop of a charged Pt surface. The dielectric contribution shows strong dependence on the layer number (n) as shown in Figure 22b: CDielec is very large when n is small and decreases significantly when n increases. Thus, the total capacitance of FLG is dominated by CQ when n is low, and limited by CDielec when n >3, while CEDL is roughly constant with n.222

Figure 22.

Joint DFT simulations of few‐layer‐graphene electrodes with an implicit solvation model: a) Breakdown of the potential drop into quantum, EDL and dielectric screening contributions with the layer number under the same surface charge density of 9 µC cm–2. b) The corresponding integral capacitance contributions. Reproduced with permission.222 Copyright 2016, American Chemical Society.

We note that the above analysis regarding the dielectric contribution focuses on the FLG electrodes for which the thickness is well defined. Single‐layer graphene can also suffer from dielectric screening but its contribution is more difficult to separate from the other contributions due to the difficulty in defining the thickness and the electrode/electrolyte boundary for the single‐layer graphene.

6. From Graphene to Amorphous Carbon

Activated carbon electrodes have diverse structure and form, but most theoretical studies still focus on graphene‐based model. Although the slit pore surface of a porous carbon can be simulated by a graphene basal plane, pore mouth is better represented by an edge plane. Moving beyond the graphene‐based models requires simulating the amorphous structure of a carbon electrode. In this section, we will first introduce several recent experimental and theoretical studies on the edge effect in carbon electrode, and then focus on the reverse Monte‐Carlo and MD techniques for modeling structure and EDL capacitance of amorphous carbon electrodes.

6.1. Edge Planes vs. Basal Planes

The electrochemical behavior of carbon edge planes has been reported in some experimental studies: Endo et al. investigated the capacitive performance of edge‐enriched porous carbon and found that it has much higher capacitance than traditional porous carbon electrodes, while Bashir et al. indicated that the edge plane of graphene has higher electrochemical activity than basal plane through direct electrochemical measurement on the edge of single graphene layer nanopore.223, 224, 225 A recent work reported by Cen et al. provided a clearer view on the edge effect: as the ratio of graphene edge plane decreases, the measured capacitance shows a significant decrease.226 Thus, all of the experimental evidence above shows that introducing more edge sites in carbon EDLCs can improve the capacitance. However, the exact mechanism of edge effect on the capacitance is not clear.

Graphene has two common types of edges: armchair and zigzag. The armchair edge is semi‐conductive, while the zigzag edge is metallic with edge states. Based on the two‐contribution model, Hwang et al. studied the capacitance of graphene edges by combining CQ from DFT and CEDL from CMD and found that Ctot increases for edge plane.227 However, since the graphene edges also exhibit typical dielectric behavior, it is necessary to include the dielectric screening contribution in total capacitance with the three‐contribution model.221 To this end, JDFT was used to study the capacitance of graphene edge planes in contact with an implicit aqueous electrolyte: the electronic chemical potential shift and the electrostatic potential drop across the interface show that armchair and zigzag edges have distinct dielectric screening; the zigzag edge has much higher total capacitance than armchair edge due to its very high CQ; CMD simulation was also used to study the influence of surface morphology on the CEDL.228

6.2. Modeling the 3D Structure of Porous Carbon

To simulate activated carbons used in EDLCs, two most commonly used techniques are reverse Monte Carlo (RMC) and quenched molecular dynamics (QMD). Monte Carlo methods of various sophistication have been employed to generate atomistic structures that reproduce either experimental and/or physically realistic radial distribution functions and pore size distributions.229, 230, 231 But Monte Carlo simulation code tends to suffer from poor parallelization that limits the ability to generate large models.232, 233, 234 Another method for generating such structures is quenched molecular dynamics (QMD) simulations. A liquid‐like configuration of disordered atoms at high temperature is used as the initial state. Then, the system is cooled to a lower temperature until a stable solid structure is formed. Because QMD is a molecular dynamics routine, the temperature is tightly controlled with a thermostat and intra and intermolecular interactions are governed by the selected force field. In contrast to RMC simulations, QMD simulations are able to take advantage of recent advances in parallelization and computational efficiency.235

Previous QMD studies employed force fields specific to the application, such as amorphous carbon, glass, and metalloids.139, 236, 237, 238, 239 Using a more rigorous and generalizable force field would improve the validity of the model and allow extensions to various chemical heterogeneities. To this end, the ReaxFF reactive force field was used with a QMD routine to generate atomistic, scalable models for carbide‐derived carbons (CDC). ReaxFF allows bonds to break and form in the bond order formalism.240 Unlike other reactive force fields, ReaxFF includes electrostatics and two‐, three‐, and four‐body interactions. Interaction parameters are tuned to thermodynamic data from first‐principles calculations.240 A representative structure of this QMD model is shown in Figure 23 . A cubic box of length 25 nm includes 200,000 carbon atoms. Nanopores of various sizes are observed. Nanoporous domains are comprised of graphene‐like sheets, which themselves exhibit a mixture of sheet‐sheet stacking and contain defects such as non‐hexagonal rings and curvature.

Figure 23.

Model of a carbide‐derived carbon (CDC) generated via quenched molecular dynamics with a ReaxFF force field.

6.3. Charging Inside a 3D Porous Carbon from Constant‐Voltage MD

With an appropriate model of porous carbon electrode, one can apply constant‐potential simulation to directly simulate a realistic electrochemical behavior of an electrolyte such as an ionic liquid in the nanopore. Salanne et al. utilized constant‐potential MD to simulate the coarse‐grained IL electrolyte in the nanoporous carbon electrode generated from atomistic QMD simulation of a CDC.139 The simulation results provide a clear view on the capacitance increase by the pore size effect, due to the weakening of overscreening (Figure 24 ).90 Similar work also has been reported by Bhatia et al. through constant‐potential MC in a realistic CDC model.125

Figure 24.

Simulation of an EDLC cell comprising two realistic CDC models at the end with a bulk coarse‐grained ionic‐liquid electrolyte in the middle from a constant‐potential MD simulation. Reproduced with permission.90 Copyright 2013, American Chemical Society.

7. Modeling Pseudocapacitors

Understanding pseudocapacitors is more challenging due to the complexity of interfacial physics and chemistry. There are two main ways to simulate their behavior: (a) numerical solution and scaling analysis of classical equations (such as PNP and PB equations) to describe the solid/liquid interface with specified boundary conditions; (b) atomistic modeling based on quantum mechanics and molecular mechanics.

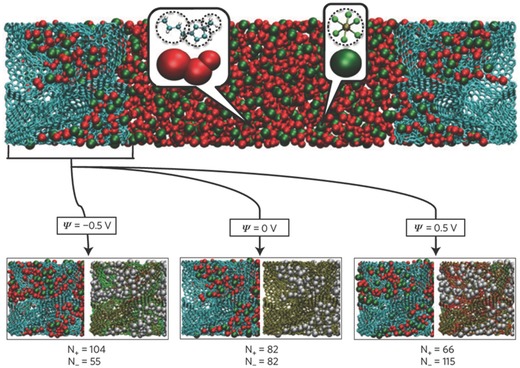

7.1. Numerical Simulation of Intercalation Pseudocapacitors based on a Continuum Model

Pilon et al. proposed a one‐dimensional continuum model to simulate the time‐dependent charging behavior of a hybrid capacitor consisting of a pseudocapacitive metal oxide electrode for lithium‐ion intercalation and a carbon electrode for EDL formation (Figure 25 a).241, 242, 243 Ion diffusion, lithium‐ion intercalation, and redox reaction were simultaneously captured. The numerically simulated CV graph showed good agreement with experiment. In the case of a thin‐film electrode of fast Li‐intercalation, the CV curve suggests that the Faradaic process dominates in the whole voltage range (Figure 25b). In the case of a thick oxide electrode where the kinetics is limited by Li intercalation, they found that the Faradaic region is at more negative potential, while the capacitive region is at high potential and dominated by the EDL formation and that the transition between Faradaic and capacitive behavior occurred between these two regions.241, 242, 243

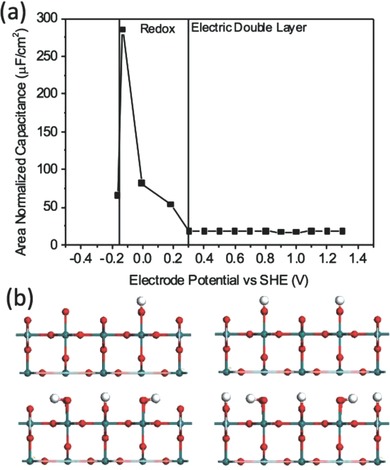

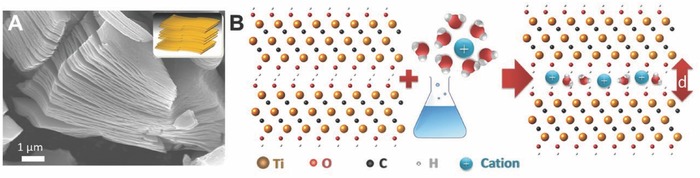

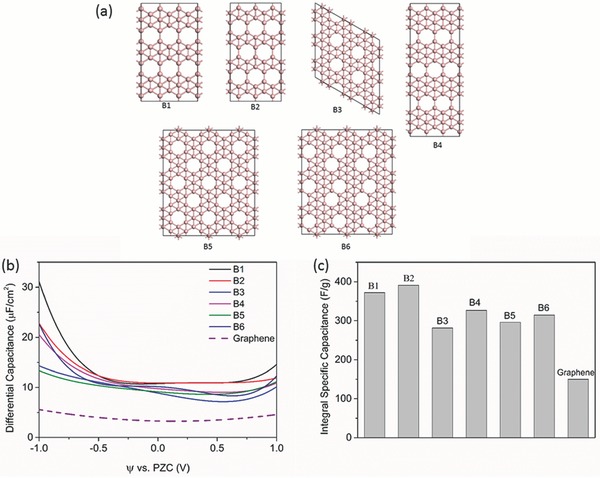

Figure 25.