Abstract

Chocolate milk is one of the most commonly used non-fermentative dairy products, which, due to high level of sucrose, could lead to diabetes and tooth decay among children. Therefore, it is important to replace sucrose with other types of sweeteners, especially, natural ones. In this research, response surface methodology (RSM) was used to optimize the ingredients formulation of prebiotic chocolate milk, date syrup as sweetener (4-10%w/w), inulin as prebiotic texturizer (0-0.5%w/w) and carrageenan as thickening agent (0-0.04%w/w) in the formulation of chocolate milk. The fitted models to predict the variables of selected responses such as pH, viscosity, total solid, sedimentation and overall acceptability of chocolate milk showed a high coefficient of determination. The independent effect of carrageenan was the most effective parameter which led to pH and sedimentation decrease but increased viscosity. Moreover, in most treatments, date syrup and inulin variables had significant effects which had a mutual impact. Optimization of the variables, based on the responses surface 3D plots showed that the sample containing 0.48% (w/w) of inulin, 0.04% (w/w) of carrageenan, and 10% of date syrup was selected as the optimum condition.

Keywords: carrageenan, chocolate milk, date syrup, inulin, RSM

Introduction

Chocolate milk is the most widely recognized beverage among flavored milks (Spreer and Misa, 1998) which is made of milk, sugar, cocoa, and some hydrocolloids (which improve thickness and prevent precipitation of cocoa particles) using pasteurization or sterilization processes (Yanes et al., 2002b).

A high level of sugar in the formulation of chocolate milk is one of the major disadvantages of the product (Thabet et al., 2010). On the other hand, due to increased public awareness and more attention to nutrition, people are more likely to use healthy and natural food with less sugar content. Due to high level of sweetness and economic efficiency, dates could be a good alternative to sugar. Replacement of date syrup in the formulation of foods not only could be a good alternative to sugar, but also could lead to improve the nutritional properties of the foods (AACC, 1999).

Date syrup is a high energy food source and a good source of minerals. It also contains a very complex mixture of saccharides, amino acids, antioxidants, polyphenols, and carotenoids, which would meet the needs to micronutrients. Since children are end consumers of chocolate milk there are growing needs, to decrease sugar consumption, and related diseases such as diabetes.

Prevention of physical instability of chocolate milk is a major challenge in dairy industry; settlement of cocoa particles at the bottom is undesirable. Therefore, use of stabilizers are recommended (Yanes et al., 2002b). Among chocolate milk stabilizers, carrageenan is widely used; this is because of the unique behavior of carrageenan and milk casein micelles interactions (Acero-Lopez et al., 2010; Tijssen et al., 2007; Yanes et al., 2002a). Numerous studies have shown increased stability and decreased sedimentation of chocolate milk caused by carrageenan (Prakash et al., 2010).

Inulin is another hydrocolloid which creates stability and thickness (Cruz et al., 2013). Using shear force, inulin particles absorb water and form a gel with favorable features (Ronkart et al., 2010). Inulin is classified as water-soluble dietary fiber, as well (Flamm et al., 2001). Researches have suggested that inulin has prebiotic and bifidogenic properties. Inulin enters the colon without any change and is fermented by β fructosidase (inulinase) produced by Bifidobacteria which results in the production of short-chain fatty acids (SCFA) and increased intestinal bacterial count (Guarner, 2005). The desirable effect of inulin on physical properties of chocolate milk and decreased sedimentation are reported, as well (Homayouni Rad et al., 2012).

The purpose of this research is to optimize the formulation of functional chocolate milk, which contains inulin as a prebiotic texturizer, and date syrup as natural sweetener accompanying with carrageenan as stabilizer. Such product is expected to have desirable physical, chemical and sensory attributes.

Materials and Methods

Pasteurized milk with 1.5% (w/w) fat was bought from Pegah Co. (Iran). Other ingredients were cocoa powder (Inci Co., Turkey), date syrup (Soheil, Pars Co., Iran), inulin (Tex, Sensus Co., Netherlands), and carrageenan (Palsgard Co., Denmark).

Chocolate milk preparation

Low fat pasteurized milk was prepared and inulin was added in the ratios provided in Table 1 at 20°C. After that, carrageenan, cocoa powder, and date syrup were added at 40°C as being stirred. Pasteurization was performed at 80°C for 5 min and accordingly, cooling down to 4°C. The samples were kept in the refrigerator for 24 h before the sensory and physicochemical tests were been conducted.

Table 1. Design matrix of central composite design.

| Date syrup (%, w/w) | Inulin (%, w/w) | Carrageenan (%, w/w) | Sample |

|---|---|---|---|

| 10.00 | 0.5 | 0.04 | 1 |

| 4.00 | 0.5 | 0.04 | 2 |

| 4.00 | 0.5 | 0.00 | 3 |

| 7.00 | 0.25 | 0.02 | 4 |

| 10.00 | 0.00 | 0.04 | 5 |

| 7.00 | 0.25 | 0.04 | 6 |

| 7.00 | 0.5 | 0.02 | 7 |

| 4.00 | 0.00 | 0.04 | 8 |

| 7.00 | 0.25 | 0.00 | 9 |

| 10.00 | 0.00 | 0.00 | 10 |

| 7.00 | 0.25 | 0.02 | 11 |

| 7.00 | 0.00 | 0.02 | 12 |

| 7.00 | 0.25 | 0.02 | 13 |

| 10.00 | 0.25 | 0.02 | 14 |

| 7.00 | 0.25 | 0.02 | 15 |

| 10.00 | 0.5 | 0.00 | 16 |

| 4.00 | 0.25 | 0.02 | 17 |

| 7.00 | 0.25 | 0.02 | 18 |

| 7.00 | 0.25 | 0.02 | 19 |

| 4.00 | 0.00 | 0.00 | 20 |

pH measurement

pH was measured using a pH Meter (Mettler, Swiss) which was calibrated before the test (AOAC, 1997).

Total solid

Total solid was determined using a laboratory oven at 102±2°C for 2 h to reach a fixed weight. It was then weighted (AOAC, 1990).

Sedimentation

The samples were centrifuged at 5,600 rpm (3,015 g) for 15 min. The sedimentation was separated from the solution and dried at 120°C in the oven for 36 h. It was weighted after cooling down and the results were reported as sedimentation present (Prakash et al., 2010).

Viscosity

The Viscosity of the chocolate milk samples was measured using a Viscometer (Brookfield-DVII, USA) at ambient temperature, with spindle No. 5, and rotation speed of 60 rpm (Sahan et al., 2008).

Sensory evaluation

Sensory evaluation was tested as the overall acceptability of chocolate milk considering colour, flavour, smell, and texture by 50 selected assessors using five–point hedonic test (1= unacceptable, 2 = relatively satisfactory, 3 = average, 4 = good and 5 = excellent). Mean scores of each sample were used as responses for optimization.

Statistical analysis method

Design Expert software (7.1.5), Response Surface Methodology (RSM) with Central Composite Design (CCD) was used for optimization, which involved the design of the experiment, selection of variable levels in experimental runs, fitting mathematical models and finally selection of optimum levels of variables by optimizing the responses and validation the optimum model. Independent variables were inulin (A) (0-0.5%, w/w), date syrup (B) (4-10%, w/w), and carrageenan (C) (0-0.04%, w/w). Each variable had three levels, encoded as low (−1), medium (0), and high (+1) while alpha was selected as face centered to be omitted. The design matrix of CCD is shown in Table 1 and as is shown, twenty runs of experiments were formulated. Viscosity (Y1), pH (Y2), sedimentation (Y3), total Solid (Y4) and sensory acceptability (Y5) were the response variables (dependent) for optimization using RSM as Eq. 1. Responses obtained after each trial were also analysed to visualize the interactive effect of various parameters on Physico-chemical and sensory attributes of chocolate milk.

| (1) |

Where: Y = responses; β0 = constant; β1, β2, β3 = linear regression; β11, β22, β33 = interaction regression; X1, X2, X3 = variables.

Validation of the optimized condition was carried out producing according to the optimum model in triplicate. Mean comparison was carried out by T-test. The significance level was p<0.05 for all of the statistical analysis.

Results and Discussion

Effect of different treatments on the viscosity

Using response surface statistical method, fitted equation was obtained as Eq. 2 for viscosity response.

| (2) |

The coefficient of determination (R2) was 0.98. Adequate precision was 24.41 and greater than 4, as desired. Viscosity was ranged from 570 to 1395 cp. The model was significant (p<0.05). Analysis of variance for all the responses is presented in Table 2.

Table 2. Analysis of variance (ANOVA) of the response variables.

| Source | Sum of squares | Degree of freedom | Mean square | F-value | p-value |

|---|---|---|---|---|---|

| Viscosity | |||||

| Model | 1.137E+006 | 9 | 1.263E+005 | 61.12 | <0.0001 |

| Residual | 20668.81 | 10 | 2066.88 | ||

| Lack of fit | 20668.81 | 5 | 4133.76 | ||

| Pure error | 0.000 | 5 | 0.000 | ||

| Total | 1.158E+006 | 19 | |||

| R2=0.9821 | |||||

| pH | |||||

| Model | 0.21 | 13 | 0.016 | 11.96 | <0.0030 |

| Residual | 8.250E-003 | 6 | 1.375E-003 | ||

| Lack of fit | 8.250E-003 | 1 | 482.55 | 8.250E-003 | |

| Pure error | 0.000 | 5 | 0.000 | ||

| Total | 0.22 | 19 | |||

| R2=0.9628 | |||||

| Sedimentation | |||||

| Model | 0.31 | 13 | 0.024 | 10.31 | 0.0045 |

| Residual | 0.014 | 6 | 2.324E-003 | ||

| Lack of fit | 0.014 | 1 | 0.014 | ||

| Pure error | 0.000 | 5 | 0.000 | ||

| Total | 0.33 | 19 | |||

| R2=0.9571 | |||||

| Total solids | |||||

| Model | 28.42 | 9 | 3.16 | 10.39 | 0.0005 |

| Residual | 3.04 | 10 | 0.30 | ||

| Lack of fit | 3.04 | 5 | 0.61 | ||

| Pure error | 0.000 | 5 | 0.000 | ||

| Total | 31.45 | 19 | |||

| R2=0.9034 | |||||

| Overall acceptability | |||||

| Model | 0.49 | 13 | 0.038 | 7.05 | 0.0124 |

| Residual | 0.032 | 6 | 5.351E-003 | ||

| Lack of fit | 0.032 | 1 | 0.032 | ||

| Pure error | 0.000 | 5 | 0.000 | ||

| Total | 0.52 | 19 | |||

| R2=0.9385 |

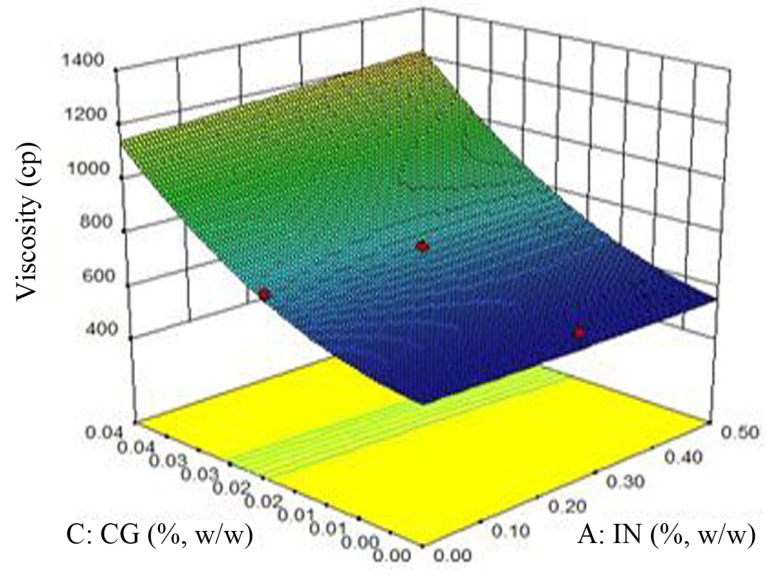

Fig. 1 shows the effect of concentration of carrageenan and inulin on the viscosity of chocolate milk samples. It can be seen that carrageenan concentration had significant effect on viscosity. Since, carrageenan has sulphate groups, it is well hydrated, and such hydrophilic property causes it to be surrounded by the water molecules. On the other hand, the sulphated or anionic moieties interact with casein and form a gel, which led to increased viscosity (Spagnuolo et al., 2005).

Fig. 1. Response surface plot of the effect of inulin (A) and carrageenan (C) on the viscosity of chocolate milk samples.

Increase of inulin and carrageenan increase had positive effect on viscosity, as well. The reason is that, the rheological properties of inulin solution are roughly similar to those of sucrose solution. Due to synergistic reactions, using low amount of inulin with other polysaccharides and gums such as xanthan, waxy starch, etc. leads to considerable increase in viscosity (Gennaro et al., 2000).

Effect of different treatments on pH

Using response surface statistical method, fitted equation was obtained as Eq. 3 for pH response.

| (3) |

The coefficient of determination (R2) was 0.96. Adequate precision was 14.1 and greater than 4, as desired. Value of pH was ranged from 6.6 to 7. The model was significant (p<0.05).

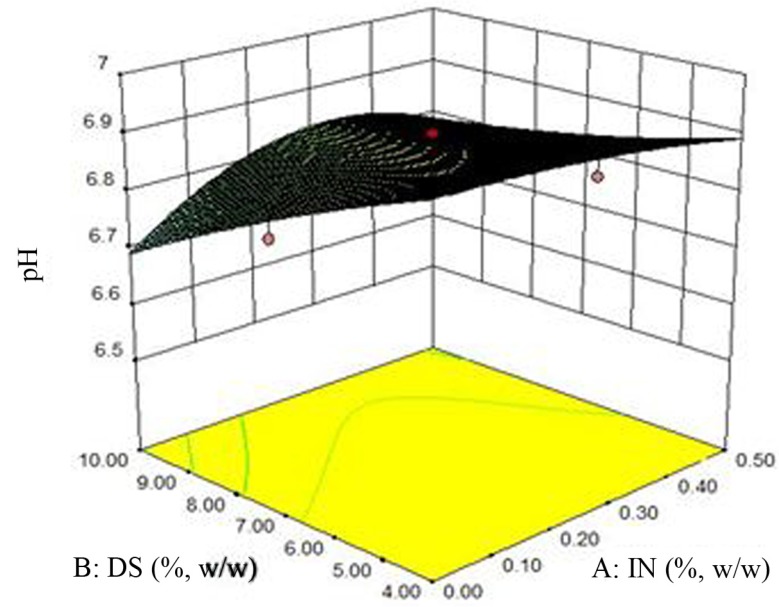

Fig. 2 shows the effect of the concentration of inulin, date syrup, and carrageenan on pH. The independent effect of carrageenan and interaction between inulin and date syrup and inulin, date syrup and carrageenan on pH was significant.

Fig. 2. Response surface plot of the effect of date syrup (B) and inulin (A) on the pH of chocolate milk samples.

According to Fig. 2, as the carrageenan increased, pH increased. This can be the result of the fact that carrageenan with cross - linking properties maintains hydrogen ions in a three dimensional network in the milk and links with milk proteins which led to pH increase (Yanes et al., 2002a). While, as shown in Fig. 2, simultaneous increase of date syrup and inulin caused lower pH due to the intrinsic lower pH of both inulin (pH = 6-6.5) (Pappa et al., 2007) and date syrup (pH = 4.2-6) than milk.

Effect of different treatments on Sedimentation

Using response surface statistical method, fitted equation was obtained as Eq. 4 for sediments response.

| (4) |

The coefficient of determination (R2) was 0.96. Adequate precision was 10.41 and greater than 4, as desired. Sedimentation was ranged from 0.78 to 1.2% w/w. The model was significant (p<0.05).

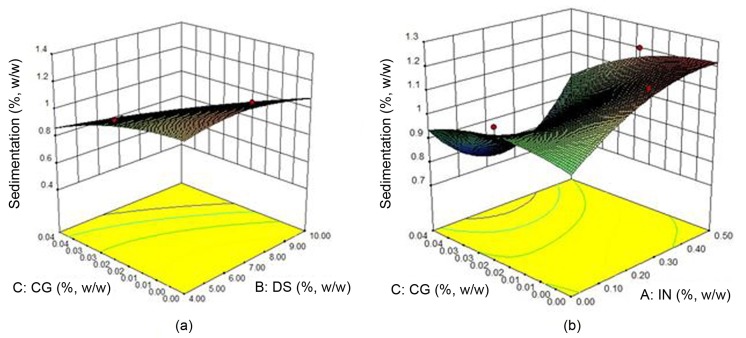

Carrageenan, as an independent variable, and the interactions between the date syrup and carrageenan as well as the interactions among inulin, date syrup, and carrageenan had significant impacts on sedimentations.

According to Fig. 3, as the concentration of carrageenan increases, substantial reduction of sedimentation was observed. Interaction between the negatively charged sulphate groups of carrageenan, positive ions of milk proteins, and the hydrophobicity of carrageenan are the factors affecting the stabilization of the chocolate milk by this stabilizer (Tijsen et al., 2007). Reduction of chocolate milk sedimentations by carrageenan was reported by other researchers, which correspond to the results of the present study (Pangborn et al., 1978).

Fig. 3. Response surface plot of inulin (A) and carrageenan (C) (a); date syrup (B) and carrageenan (C) (b) effect on the sedimentation of chocolate milk samples.

According to the Fig. 3, solely increase of inulin had negative effect on sedimentation, which increased non-linearly. This result could be related to the dependency inulin solubility to temperature. The solubility of inulin at 10°C and at 90°C is 60% and 35% respectively, and as the samples were kept at refrigerated temperature, solubility decreased and the sedimentation increased as inulin concentration increased (Kim et al., 2001).

Effect of different treatments on total solids

Using response surface statistical method, fitted equation was obtained as Eq. 5 for total solids response.

| (5) |

The coefficient of determination (R2) was 0.90. Adequate precision was 10.23 and greater than 4, as desired. Total solid was ranged from 13 to 16.9%. The model was significant (p<0.05).

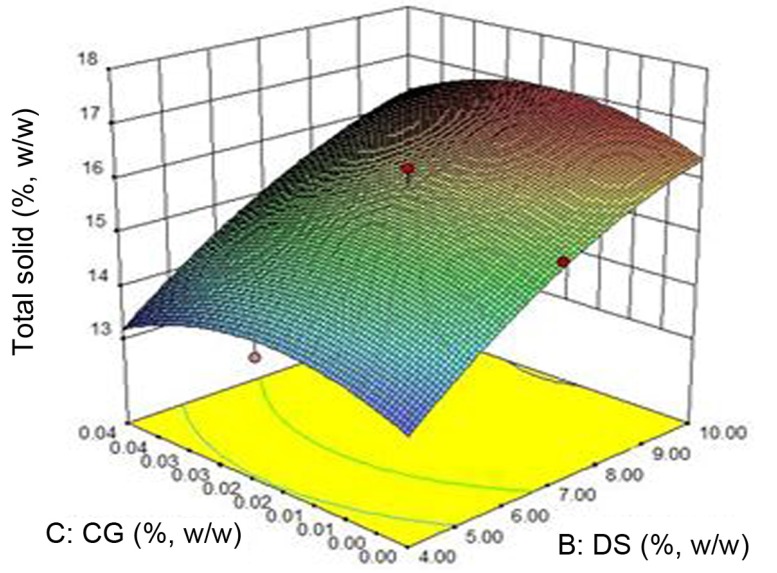

Fig. 4 shows the impact of date syrup concentration on the amount of the total solids in chocolate milk samples. The applied concentrations of date syrup range from 4% to 10% (w/w) were higher compared to inulin and carrageenan. In fact, small amounts of inulin and carrageenan did not show significant effects on the total solids, while date syrup increased the total solids significantly due to the initial added concentrations.

Fig. 4. Response surface plot of the effect of carrageenan (C) and date syrup (B) on the total solids of chocolate milk samples.

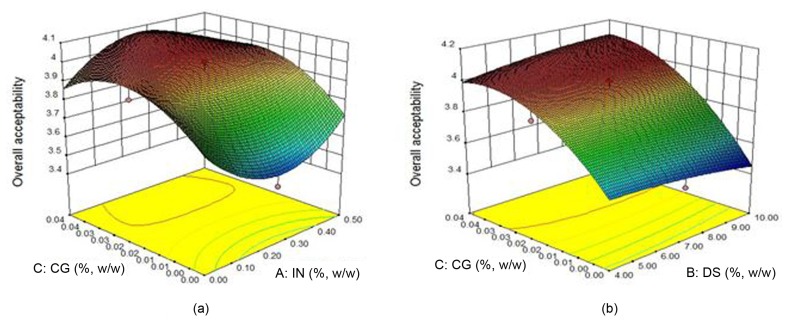

Effect of different treatments on overall acceptability

Using response surface statistical method, fitted equation was obtained as Eq. 6 for overall acceptability response.

| (6) |

The coefficient of determination (R2) was 0.93. Adequate precision was 8.82 and greater than 4, as desired. Sensory acceptability scores were ranged from 3.47 to 4.02% w/w. The model was significant (p<0.05).

Fig. 5 shows the effect of the concentration of inulin, date syrup, and carrageenan on the overall acceptance of the chocolate milk samples. According to the figure, carrageenan content increase in the presence of inulin showed increased acceptability. The results were the same as those reported by Salimian et al. (2012) which showed positive effect of carrageenan due to increased viscosity. According to the figure, as the date syrup along with carrageenan concentration increase, the overall acceptability increased.

Fig. 5. Response surface plot of inulin (A) and carrageenan (C) (a); date syrup (B) and carrageenan (C) (b) effect on the overall acceptability of chocolate milk samples.

Optimization

After the models were determined, optimization was done in order to achieve the levels of independent variables, which led to the best formulation of prebiotic chocolate milk sweetened by date syrup. Maximum viscosity and sensory acceptability with minimum sedimentation were used for optimization while, pH and total solid were in range. Based on the response surface 3D plots, the optimum formulation was the sample with 0.04% (w/w) carrageenan, 10% (w/w) date syrup and 0.48% (w/w) inulin with the predicted viscosity of 1223 cp, total solid: 16.63 (%, w/w), pH: 6.83, Sedimentation: 0.74 (%, w/w) and overall acceptability: 4.02. The desirability of the optimum sample was 0.925.

The optimum mixture was produced in triplicate for validation of the predicted model. As is shown in Table 3, there were no significant differences in viscosity, pH and sedimentation between the predicted and actual optimal conditions while total solid and acceptability were a bit different. The results imply validation of the predicted optimal conditions.

Table 3. Validation results for the optimum product.

| Terms | Actual optimal sample | Predicted optimal conditions |

|---|---|---|

| Viscosity (cp) | 1235±34a | 1223a |

| pH | 6.91±0.12a | 6.83a |

| Sedimentation (%) | 0.80±0.04a | 0.74a |

| Total solids (%) | 16.87±0.04a | 16.63b |

| Overall acceptability* | 4.15±0.08a | 4.02b |

Data of actual sample are mean±SD (n=3).

*5-point hedonic test using 20 selected assessor (n=20).

Conclusions

RSM was successfully optimized the formulation of prebiotic chocolate milk containing date syrup as sugar replacer. Carrageenan improved the viscosity of the samples while decreased the sedimentation. Using of stabilizers is inevitable in order to have acceptable physical properties in chocolate milk. Inulin accompanying with carrageenan could compensate the defect of sugar elimination on texture, as well. The optimum formulation can be for replacement of sugar in chocolate milk with date syrup which is a natural and cost effective.

Acknowledgments

We kindly acknowledge supports from the AzarTarla Dairy Plant (Tabriz, Iran) and Tabriz Branch, Islamic Azad University, Tabriz, Iran.

References

- 1.AACC. Approved method of the American Association of Cereal Chemists. 11th ed. American Association of Cereal Chemists; St. Paul: 1999. [Google Scholar]

- 2.Acero-Lopez A., Alexander M., Coorredig M. Diffusing wave spectroscopy and rheological studies of rennet- induced gelation of skim milk in the presence of pectin and k-carrageenan. Int. Dairy J. 2010;20:328–335. doi: 10.1016/j.idairyj.2009.12.011. [DOI] [Google Scholar]

- 3.AOAC. Official Method of Analysis. 15th ed. Association of Official Analytical Chemists; Washington, DC: 1990. [Google Scholar]

- 4.AOAC. Official Methods of Analysis. 16th ed. Association of Official Analytical Chemists; Washington, DC: 1997. [Google Scholar]

- 5.Cruz A. G., Cavalcanti R. N., Guerreiro L. M. R., Santana A. S., Nogueira L. C., Oliveira C. A. F., Deliza R., Cunha R. L., Faria J. A. F., Bolini H. M. A. Developing a prebiotic yogurt: Rheological, physico-chemical and microbiological aspects and adequacy of survival analysis methodology. J. Food Eng. 2013;114:323–330. doi: 10.1016/j.jfoodeng.2012.08.018. [DOI] [Google Scholar]

- 6.Flamm G., Glinsmann W., Kritchevsky D., Prosky L., Roberfroid M. Inulin and oligofructose as dietary fiber: A review of the evidence. Crit. Rev. Food Sci. 2001;41:353–362. doi: 10.1080/20014091091841. [DOI] [PubMed] [Google Scholar]

- 7.Gennaro S. D. G., Birch G., Parke S. A., Stancher B. Studies on the physicochemical properties of inulin and inulin oligomers. Food Chem. 2000;68:179–183. doi: 10.1016/S0308-8146(99)00173-9. [DOI] [Google Scholar]

- 8.Guarner F. Inulin and oligofructose: Impact on intestinal diseases and disorders. Br. J. Nutr. 2005;93:61–65. doi: 10.1079/BJN20041345. [DOI] [PubMed] [Google Scholar]

- 9.Homayouni Rad A., Delshadian Z. S., Arefhosseini R., Alipour B., Jafarabadi M. A. Effect of inulin and stevia on some physical properties of chocolate milk. Health Promot. Perspect. 2012;2:42–47. doi: 10.5681/hpp.2012.005. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Kip P., Meyer D., Jellema R. H. Inulin improves sensory and textural properties of low-fat yogurts. Int. Dairy J. 2006;16:1098–1103. doi: 10.1016/j.idairyj.2005.10.011. [DOI] [Google Scholar]

- 11.Pangorn R. M., Gibbs Z. M., Tasan C. Effect of hydrocolloids on apparent viscosity and sensory properties selected beverages. J. Texture Stud. 1978;9:415–436. doi: 10.1111/j.1745-4603.1978.tb01216.x. [DOI] [Google Scholar]

- 12.Pappa E. C., Kandarakis I., Mallatou H. Effect of different types of milks and cultures on the rheological characteristic of Teleme cheese. J. Food Eng. 2007;79:143–149. doi: 10.1016/j.jfoodeng.2006.01.038. [DOI] [Google Scholar]

- 13.Prakash S., Huppertz T., Karvchuk O., Deeth H. Ultra-high-temperature processing of chocolate flavored milk. J. Food Eng. 2010;96:179–184. doi: 10.1016/j.jfoodeng.2009.07.008. [DOI] [Google Scholar]

- 14.Ronkart S. N., Paquot M., Deroanne C., Fougnies C., Besbes S., Blecker C. S. Development of gelling properties of inulin by micro fluidization. Food Hydrocolloid. 2010;24:318–324. doi: 10.1016/j.foodhyd.2009.10.009. [DOI] [Google Scholar]

- 15.Sahan N., Yasar K., Hayaloglu A. Physical, chemical and flavour quality of non-fat yogurt as affected by a β-glucan hydro colloidal composite during storage. Food Hydrocolloid. 2008;22:1291–1297. doi: 10.1016/j.foodhyd.2007.06.010. [DOI] [Google Scholar]

- 16.Salimian S., Khosrowshahi A., Zomorodi S. H. The effect of type and amounts of three different stabilizers on stability, rheological and sensory properties of chocolate milks. Res. J. Food Sci. 2012;22:167–173. [Google Scholar]

- 17.Spagnuolo P. A., Dalgleish D. G., Goff H. D., Morris E. R. Kappa-carrageenan interactions in systems containing casein micelles and poly-saccharide stabilizers. Food Hydrocolloid. 2005;19:371–377. doi: 10.1016/j.foodhyd.2004.10.003. [DOI] [Google Scholar]

- 18.Spreer E., Mixa A. Milk and dairy product technology. Marcel Dekker; NY, USA: 1998. pp. 182–189. [Google Scholar]

- 19.Thabet B., Besbes S., Masmoudi M., Attia H., Deroanne C., Blecker C. Compositional, physical, antioxidant and sensory characteristics of novel syrup from date palm (Phoenix dactylifera L.) Food Sci. Technol. Int. 2010;15:583–590. [Google Scholar]

- 20.Tijssen R. L. M., Canabady-Rochelle L. S., Mellema M. Gelation upon long storage of milk drinks with carrageenan. J. Dairy Sci. 2007;90:2604–2611. doi: 10.3168/jds.2006-854. [DOI] [PubMed] [Google Scholar]

- 21.Yanes M., Duran L., Costell E. Rheological and optical properties of commercial chocolate milk beverages. J. Food Eng. 2002a;51:229–234. doi: 10.1016/S0260-8774(01)00061-9. [DOI] [Google Scholar]

- 22.Yanes M., Duran L., Costell E. Effect of hydrocolloid type and concentration on flow behavior and sensory properties of milk beverages model systems. Food Hydrocolloid. 2002b;16:605–611. doi: 10.1016/S0268-005X(02)00023-1. [DOI] [Google Scholar]