Abstract

Recent advances in optical tweezers have greatly expanded their measurement capabilities. A new generation of hybrid instrument that combines nanomechanical manipulation with fluorescence detection—fluorescence optical tweezers, or “fleezers”—is providing a powerful approach to study complex macromolecular dynamics. Here, we describe a combined high-resolution optical trap/confocal fluorescence microscope that can simultaneously detect sub-nanometer displacements, sub-piconewton forces, and single-molecule fluorescence signals. The primary technical challenge to these hybrid instruments is how to combine both measurement modalities without sacrificing the sensitivity of either one. We present general design principles to overcome this challenge and provide detailed, step-by-step instructions to implement them in the construction and alignment of the instrument. Lastly, we present a set of protocols to perform a simple, proof-of-principle experiment that highlights the instrument capabilities.

Keywords: Optical tweezers, Optical trapping, Single-molecule fluorescence, Förster resonance energy transfer, FRET, Confocal microscopy, Fleezers

1 Introduction

Optical traps—or “optical tweezers”—utilize the momentum of light to exert forces on microscopic objects. By tightly focusing a laser beam, a dielectric object such as a micron-sized polystyrene bead can be trapped stably in three dimensions near the focus of light [1]. Beyond its ability to manipulate microscopic objects, an optical tweezer setup is a sensitive quantitative tool. The trap behaves as a linear, “Hookean” spring near its center, and can be used to measure displacements of a trapped bead and the forces exerted on it with sub-nanometer and sub-piconewton (pN) resolution, respectively. This sensitivity range has made optical tweezers a powerful tool to study biological macromolecules at the single molecule level. Optical traps have been used to stretch nucleic acids and proteins, probing their mechanical properties and how secondary and tertiary structures unravel under force [2, 3]. Stretching individual molecules of DNA or RNA has also become a powerful approach to study protein–nucleic acid interactions [4, 5]. Optical tweezers are particularly amenable to the study of molecular motors, which generate forces on pN scales. They have been instrumental in deciphering the mechanism of a wide range of molecular motors involved in cytoskeletal transport, the central dogma, and beyond (reviewed in refs. [6, 7]). Recent advances in design have improved the resolution of these instruments to where it is now possible to observe directly molecular motion on the scale of a single base pair (bp) of DNA. High-resolution optical tweezers [8, 9] now provide unprecedented access to the stepping dynamics of nucleic acid motors (reviewed in ref. [10]): transcription by RNA polymerase with 1 bp resolution [8, 11], translation codon by codon by the ribosome [12], RNA and DNA unwinding by heli-cases at the bp scale [13, 14], and hierarchical bp-scale stepping in translocases [15].

Despite such advances, optical traps have important limitations. Macromolecular dynamics involve conformational changes that are inherently three-dimensional in nature. Most optical trap measurements are ill-equipped to capture this complexity of motion, projecting all movement onto a single axis, along the direction of applied force [16]. As a result, only a limited view of the underlying dynamics is provided. In addition, optical trap measurements have often been limited to investigating systems involving few components, examined in isolation. Many cellular processes, however, involve highly coordinated, multicomponent assemblies. Optical trap assays can be ill-suited to study larger complexes because they typically measure only a single dynamical observable, which does not reveal internal dynamics or coordination within these complexes. These limitations have motivated the development of new single-molecule techniques that can measure complex macromolecular dynamics.

A new generation of hybrid optical tweezers has allowed simultaneous measurement of multiple observables. Optical torque traps exert and measure force and torque simultaneously [17], and several fluorescence optical tweezers (or fleezers) combining fluorescent imaging capabilities with mechanical manipulation have been developed [18–21]. In this chapter, we describe the design of an instrument that combines high-resolution optical tweezers with single-molecule fluorescence microscopy (Fig. 1) [16]. A unique aspect of this instrument, which contrasts with other optical trap/fluorescence designs, is that neither fluorescence detection nor optical trap sensitivity is sacrificed in combining the techniques. The high-resolution fleezers can simultaneously detect fluorescence signals with single-molecule sensitivity, mechanical displacements with sub-nm resolution, and forces with sub-pN resolution [16].

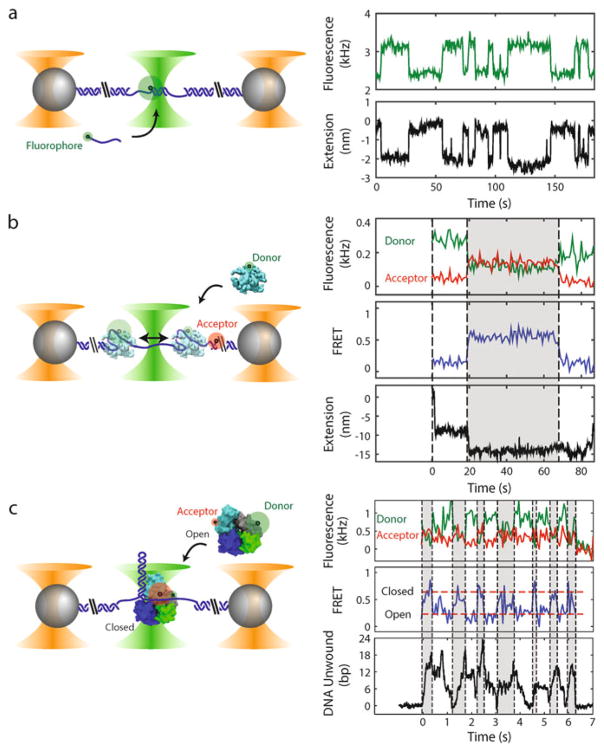

Fig. 1.

Examples of experiments with combined high-resolution optical trap and fluorescence (not to scale). Left panels: Polystyrene microspheres (grey) are held in optical traps (orange cones), tethered by an engineered DNA molecule (blue) containing a variable central segment flanked by long double-stranded DNA (dsDNA) handles. Fluorophores are excited by a green laser (green cone). Right panels: Time traces showing simultaneous measurement of fluorescence and tether extension. (a) Oligonucleotide hybridization. Short oligonucleotides (blue line) labeled with a fluorophore (green disk) bind and unbind to a complementary ssDNA section in the center of the tethered DNA. The fluorescence and change in tether extension upon hybridization are recorded simultaneously. (b) Single-stranded DNA binding protein wrapping dynamics. A tethered DNA molecule containing a short ssDNA region is labeled with a FRET acceptor at the ss-dsDNA junction (red disk). An E. coli single-stranded DNA binding protein (SSB, cyan) labeled with a FRET donor (green disk) binds to and wraps ssDNA around itself. Simultaneous measurement of FRET efficiency and tether extension enables determination of both the position of SSB along the tether and the amount of ssDNA wrapped. The SSB can transiently wrap and unwrap ssDNA under tension (e.g., t = 20 s), and can diffuse one-dimensionally along the ssDNA by reptation (t = 70 s) (data reproduced from ref. [22] with permission from eLife Sciences Publications). (c) UvrD helicase conformational and unwinding dynamics. A tethered DNA molecule contains a hairpin and short ssDNA protein loading site. E. coli UvrD helicase (cyan, blue, grey, and green) is labeled with FRET donor and acceptor pair to differentiate between two possible conformational states: “Open” and “Closed.” Simultaneous measurement of FRET efficiency and number of DNA base pairs of the hairpin unwound by the helicase enables correlation of the conformation with the activity of the helicase. Changes in UvrD conformational state correspond to switches between unwinding and rezipping of the DNA hairpin (reproduced from ref. [23] with permission from AAAS). The proteins in this figure were prepared with VMD [48] using PDB entries 1EYG, 2IS2, and 3LFU

Figure 1 displays three examples of measurements feasible with this instrument. The confocal microscope can either be used to count dye-labeled molecules or to detect dynamics by single-molecule Förster Resonance Energy Transfer (smFRET), while the traps detect mechanical displacements and forces from the DNA molecule stretched between the two trapped beads. In the first example (Fig. 1a), fluorescence is used to detect a dye-labeled oligonucleotide binding to a complementary DNA sequence tethered between trapped beads, while the trap detects the change in extension upon hybridization, as single-stranded (ss)DNA is converted to double-stranded (ds) DNA [16]. In the second (Fig. 1b), E. coli single-stranded DNA binding protein labeled with a single donor fluorophore wraps ssDNA labeled with an acceptor dye. The combination of trap and smFRET is used to distinguish between protein wrapping/unwrapping ssDNA and its diffusion along ssDNA [22]. Finally (Fig. 1c), internal conformational dynamics of E. coli UvrD helicase labeled with a donor and acceptor dye are detected by smFRET simultaneously with detecting its unwinding of a DNA hairpin by optical trap [23].

Stability and sensitivity are key to this instrument’s performance. We use a dual trap design (Fig. 1), in which both traps are formed from the same laser, as it provides exceptional stability [9]. As a consequence, trapping is done away from the sample chamber surface, and we detect fluorescence using confocal microscopy (as opposed to total internal reflection microscopy often used in surface-based assays). An important technical challenge is that fluorophores photobleach very quickly near an optical trap. This results from the fluorophore absorbing trap infrared photons while in the excited state, leading to a transition into a dark state [24]. Since this mechanism requires absorption of both fluorescence excitation and trap light, one solution is to separate the optical trap and fluorophore by a large distance, preventing simultaneous exposure of the dye to both light sources [19]. However, this approach is not conducive to high-resolution measurement. It necessitates long molecules to tether to the trapped beads, which are compliant and poor transducers of mechanical signals. High resolution requires close proximity between trap and fluorophore, and the solution is to separate the two light sources in time [25]. By interlacing the two light sources at a high rate, i.e., turning them on and off out of phase, it is possible to attain a 20-fold improvement in photobleaching lifetime over exposing the fluorophore simultaneously to fluorescence excitation and trapping light [25].

In this chapter, we describe in detail the design and construction of our hybrid high-resolution optical trap/confocal microscope (for an overview, see Fig. 2). We note that many protocols for building and aligning optical traps have been discussed elsewhere [26–28], and we do not repeat these here. Instead, we focus on the complexities specific to combining single-molecule fluorescence detection with optical traps. We provide a detailed parts list, optical layout, and general design principles to build the instrument. Since interlacing is an essential feature of the instrument, we devote much of the chapter to the materials and protocols for precise timing and synchronization of the light sources and data acquisition. We also provide detailed protocols for aligning the confocal microscope to the optical traps. Lastly, materials and protocols are given for doing a simple, proof-of-principle experiment to measure the binding of a fluorescently labeled oligonucleotide to a complementary single-stranded DNA molecule tethered between trapped beads (Fig. 1a).

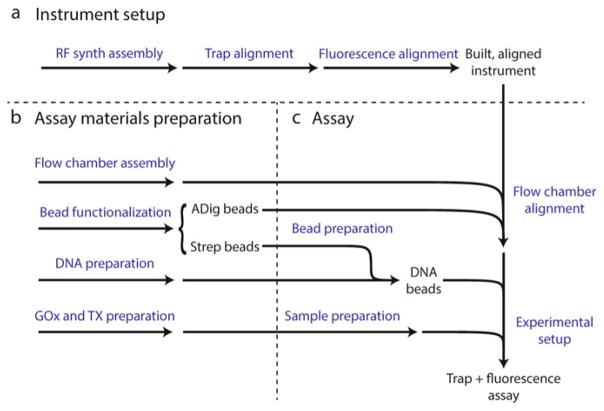

Fig. 2.

Protocol summary. (a) Sequence of major steps involved in assembling and aligning the instrument. (b) Materials for the trap + fluorescence assay are prepared in parallel, including two sets of functionalized beads: anti-digoxigenin (ADig) beads and streptavidin (Strep) beads, and stock solutions of glucose oxidase + catalase (GOx) and trolox (TX). (c) Major steps involved in setting up a trap + fluorescence assay

2 Materials

2.1 Optical Trap Setup

There are many considerations in designing and constructing an optical trap, many of which are beyond the scope of this chapter. We refer the reader to the many excellent resources on this topic [26, 28, 29]. The combined optical trap/confocal microscope layout relies on general design principles that maximize stability, spatial and temporal resolution, and control. The instrument is housed in a temperature-regulated, acoustically isolated room, and built on a thick optical table levitated on pneumatic isolators. All optical components that the trap or fluorescence lasers impinge on are mounted to the optical table by 1″-thick pedestals. Wherever possible, high-performance optomechanical components (e.g., kinematic mirror mounts, translation stages) are used and are equipped with locking screws so that they can be fixed after alignment. We also adhere to the general philosophy of “less is more,” i.e., the fewest components should be used to achieve a specific purpose. Our experience is that more components increase the coupling of noise into the instrument. In contrast to many optical trap designs, we also do not integrate the traps into an inverted microscope body. This provides us with complete control over all instrument components and more flexibility in design.

The overall optical layout consists of three separate “modules”: one for the optical trap, one for the fluorescence confocal microscope, and one for the bright-field imaging system (Fig. 3 and 4). We discuss the optical trap module first. General construction and alignment procedures are not discussed in detail, as these can be found elsewhere [26, 27]. Instead, we focus only on those features unique to the instrument and on its essential components: (1) trapping laser, (2) acousto-optic modulator, (3) objective, and (4) detectors.

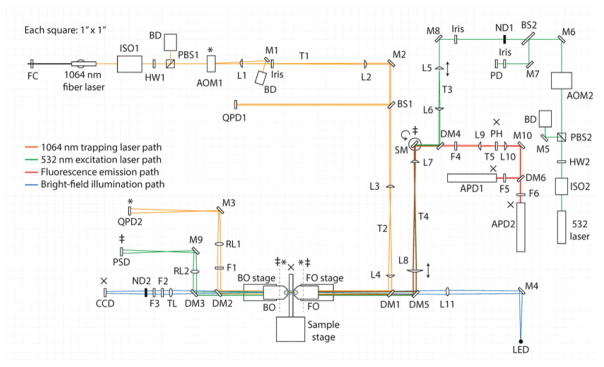

Fig. 3.

Detailed layout of the instrument (to scale). FC fiber clamp; ISO optical isolator; HW half-wave plate; PBS polarizing beam-splitting cube; BD beam dump; AOM acousto-optic modulator; L lens; M mirror; BS beam-splitter; QPD quadrant photodiode; DM dichroic mirror; FO front objective; BO back objective; F filter; RL relay lens; TL tube lens; ND neutral density filter; PD photodiode; SM steerable mirror; PSD position-sensitive detector; PH pinhole; APD avalanche photodiode. Planes conjugate to AOM1 are indicated by an asterisk (*), those conjugate to SM are indicated by a double cross (‡), and those conjugate to the sample plane are indicated by an x (×). Double-sided arrows at L5 and L8 indicate adjustable translational stages. The circular arrow at SM indicates a steerable mirror. Dotted lines indicate the front and back focal planes of FO and BO

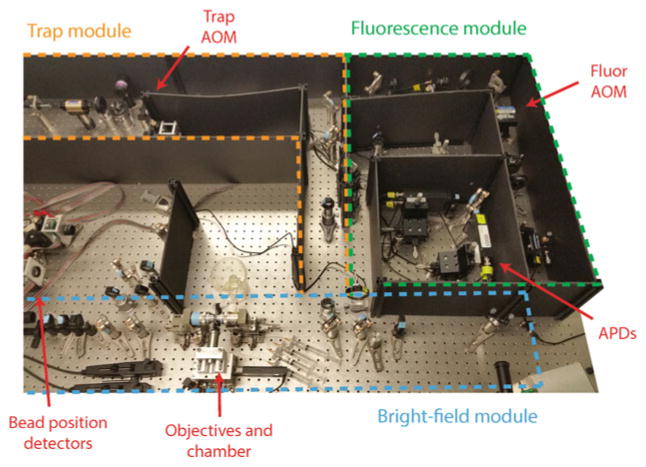

Fig. 4.

Photograph of instrument. The instrument is organized into three separate “modules” (Trap, Fluorescence, and Bright-field), indicated by the colored dotted lines. Major components of the instrument (AOMs, objectives, bead position detectors, and APDs) are labeled

The traps are generated by a 5-W, 1064-nm fiber laser. The advantage of this type of laser is that the single-mode, polarization-maintaining fiber is also the laser cavity, which provides an optimal (Gaussian) beam profile and pointing stability. The emitted infrared (IR) light first passes through an optical isolator (ISO1), which eliminates back-reflection into the laser cavity, followed by a power modulation stage consisting of a half-wave plate (HW1) on a rotary stage and polarizing beamsplitter (PBS1) cube. These components are used to divert power from the trapping beam by rotating its polarization axis prior to the PBS. Excess light is reflected into a high-power beam dump (BD). This stage is used for coarse adjustment of the laser power as needed typically for initial alignment protocols. The trap acousto-optic modulator (AOM1) controls the laser power once the trap laser is aligned.

The AOM is used in the next stage to switch the IR light on and off for interlacing with the fluorescence excitation, as described above. The rate of switching is an important design consideration. If a trap is turned off for too long, forces on the once-trapped bead will pull the bead away from its initial position, out of the trapping region, and the bead may escape. Thus, it is necessary to modulate at a high rate, comparable to or faster than the relaxation timescales of the bead under tension (>10 kHz; we interlace at 66 kHz) to maintain a viable trap [25]. This is possible using AOMs, which function by diffracting the incident laser beam by a sound wave propagating in a crystal. The sound wave is produced by a piezo element adhered to the crystal oscillating via a radio frequency (RF) source. The first diffraction beam (First order) is used for trapping, and the amplitude of the sound wave determines its intensity. When using an AOM to control the trap intensity, one important factor to consider is the trapping beam diameter. The beam must be small enough to fit into the AOM “active area,” defined by the size of the sound field in the crystal (3 mm in this setup). If the beam diameter is too large, additional lenses will be required to shrink it to the appropriate size, which occupy unnecessary space on the optical table and introduce extraneous components. In addition, the rate at which an AOM can modulate the trap intensity is ultimately limited by the speed of sound in the crystal divided by the beam diameter (~2 MHz for a 1.5 mm beam waist). Therefore, smaller beam diameters are advantageous; we chose a fiber laser with 1.5-mm diameter beam collimation for these reasons.

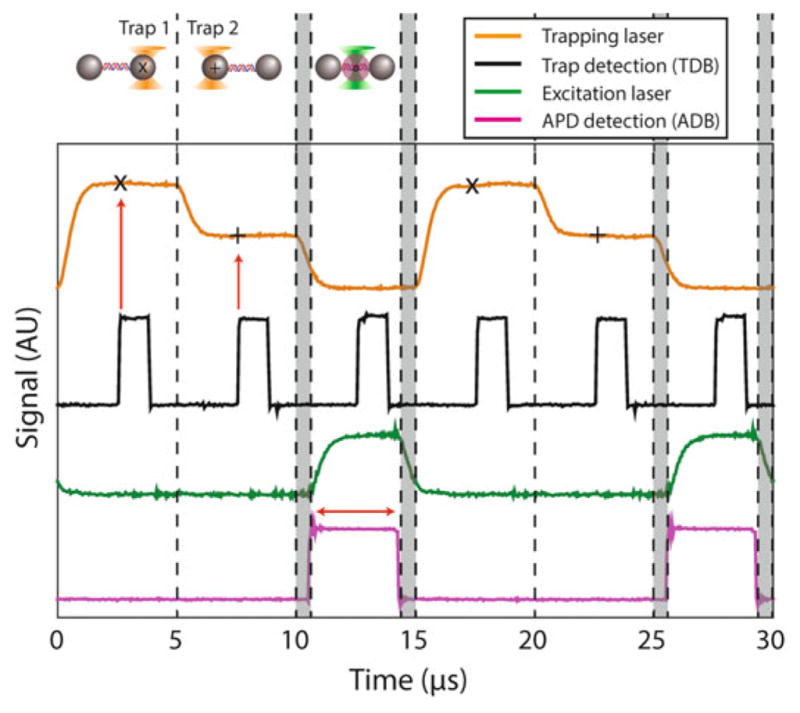

Since the sound wave in the AOM crystal acts as a diffraction grating for the incident trapping beam, the sound frequency determines the angle at which the beam diffracts. We exploit the ability to modulate the beam angle in this instrument for two purposes: (1) to steer the trapping beam, and (2) to form two traps by timesharing, in which the trapping beam is deflected rapidly (faster than the relaxation time of trapped beads) between two angles, generating stable traps at two positions in the specimen plane [30, 31]. This design provides notable advantages. In some dual trap layouts, the two traps are formed by splitting the IR laser beam into two orthogonally polarized beams, with the angle of one beam controlled by a steerable mirror [9]. Previous work showed that any differential optical path between the two trapping beams increases the noise in the instrument, because each beam travels through different environments susceptible to local fluctuations [26]. In the polarization-based design, the two beams must be spatially separated, leading to residual noise even when the differential path is kept to a minimum. However, in the time-sharing approach, beams share identical optical elements and an almost identical beam path, and the instrument is much less sensitive to environmental noise. Thus, during one interlacing cycle, the two traps are formed by timesharing for 1/3 of the cycle each, then turned off for the remaining 1/3 cycle (Fig. 5).

Fig. 5.

Interlacing and timesharing of optical trap and fluorescence excitation lasers, and synchronization of lasers with data acquisition timing. Two optical traps (orange) are created in sequence during two thirds of the interlacing period by time-sharing. The trap AOM (AOM1) switches between two deflection angles (traps in each interval are set to different intensities for clarity in the figure). Trap data acquisition occurs at time points centered on each trap interval. “×” and “+” denote the time points for the first and second trap, respectively. The rising edge of a digital pulse (black) is synchronous with the trap data acquisition timing (red vertical arrows). The fluorescence excitation (green) is only ON during the last third of the interlacing period while the trap is OFF. There are 625-ns delays (grey shaded regions) between turning OFF (ON) the optical traps and turning ON (OFF) the fluorescence excitation. A digital pulse (magenta) synchronous with the APD data acquisition timing is centered on the excitation laser interval. Fluorescence emission signals are only collected during this third time interval (red horizontal arrow). Laser intensities in the plot are measured by feedback photodetectors QPD1 and PD (see Fig. 3), and digital pulses synchronous with data acquisition timing are output directly from the DAQ card trap input timing debug (TDB) and APD gate timing debug (ADB) lines (see Fig. 10). All are recorded using a digital oscilloscope

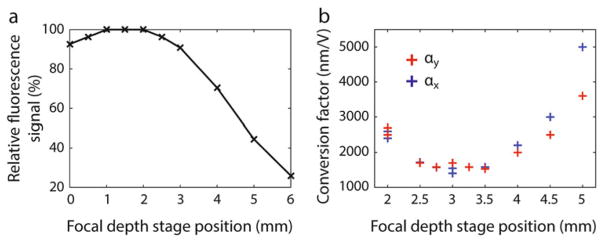

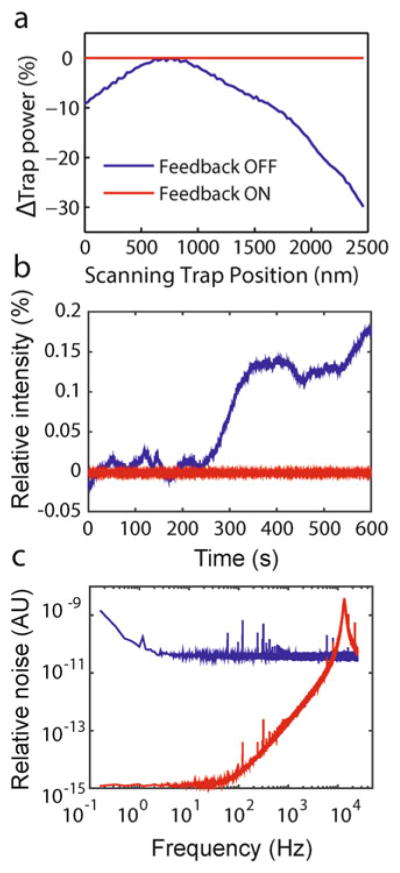

We note that acousto-optic deflectors (AOD) are more commonly used for beam steering than modulators. AODs work by the same principle as AOMs, but have been optimized to provide a larger deflection range. However, we have found that AODs adversely affect the quality of the trapping beam and also introduce fluctuations in beam power over small deflection angles. These can affect trap performance. We thus use an AOM to control temporally both the trapping beam intensity and deflection angle. The price of using an AOM is a smaller beam deflection range. We note that all acousto-optic devices exhibit some degree of variation in diffraction efficiency with deflection angle (Fig. 6a). This is problematic as it means that trap stiffness varies with trap position. To counteract this effect, we implement a feedback system to keep the beam intensity within a narrow range for optimal trap performance. Picking off a small fraction (1–2 %) of the trapping beam after the AOM using a high quality wedged beam sampler (BS1), an IR enhanced photodiode (QPD1) monitors the laser intensity (seeNote 1). The signal from QPD1 is passed to the instrument control system, which then uses a standard Proportional-Integral-Derivative (PID) feedback loop to modulate the RF sound wave amplitude driving the AOM to maintain constant beam intensity no matter where the traps are positioned (see Subheading 2.5). This feedback system is effective in stabilizing laser power fluctuations regardless of source, reducing intensity noise by up to six orders of magnitude (Fig. 6b and c) [16].

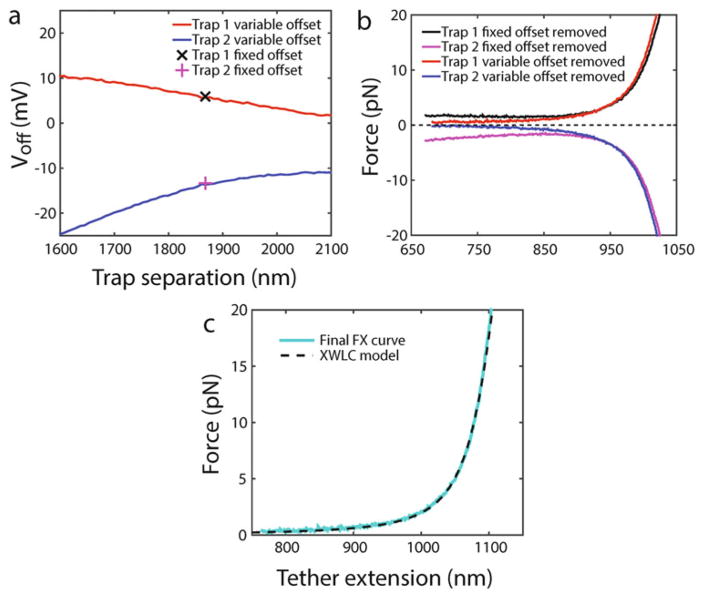

Fig. 6.

Effect of intensity feedback on trap performance. (a) The trapping beam power changes significantly as the trapping AOM deflects the beam over a range of distances in the specimen plane (blue), but remains constant with feedback ON (red). (b) Feedback stabilizes the trap laser intensity against drift over long time periods (red, feedback ON; blue, feedback OFF). (c) Noise power spectrum of laser intensity. Use of feedback reduces low-frequency noise from the trapping laser by up to six orders of magnitude (red, feedback ON; blue, feedback OFF) (reproduced from ref. [16] with permission from Nature Publishing Group)

The trapping light next passes through two telescopes (T1 and T2), which expand the beam (by 3× and 2×, respectively) to overfill slightly the aperture of the front objective (FO, adjusted to approximately 9 mm beam waist at FO aperture) [29]. The telescopes also make the plane about which the trapping beams pivot inside the AOM conjugate telecentric to the back-focal plane of the objective (denoted by * in Fig. 3). This ensures that deflection of the trapping beam by the AOM produces a displacement of the focused traps in the specimen plane while not clipping the beam on the FO aperture (seeNote 2).

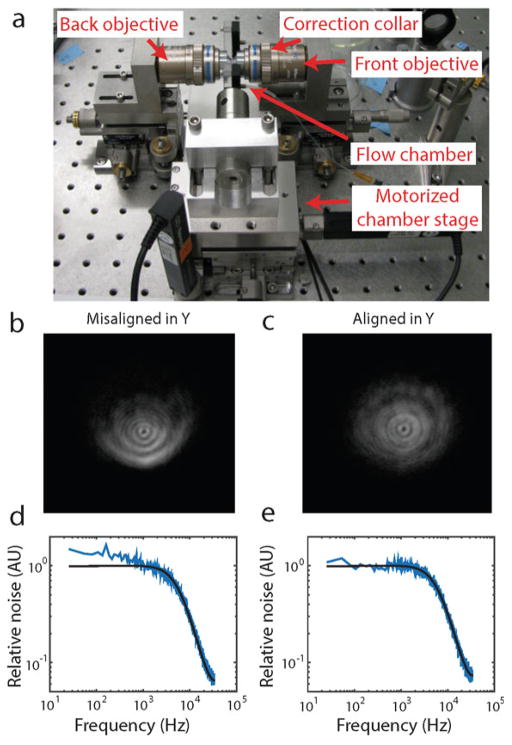

Next, a dichroic mirror (DM1) reflects the trapping light into the front objective (FO). We recommend using a high-quality dichroic that reflects trapping light and transmits fluorescence light efficiently and has a flat surface (<λ/10) and thick (>3 mm) substrate to avoid trap beam distortions prior to entering the objective. FO focuses the IR light, forming the optical traps inside the sample chamber. Considerations for selecting objectives for optical trapping have been described at length elsewhere [26, 29]. Here, we note the use of water-immersion objectives. Oil-immersion objectives generate traps close to the coverslip surface, and the trap stiffness is dependent on the depth of the trap within the chamber. As a result, drift of the surface or focal depth couples to the trap stiffness. An advantage of water- over oil-immersion objectives is that the traps are formed far away from the surface of the flow chamber, where the trap stiffness is decoupled from surface drift, improving stability [26, 32]. However, this comes at a price of a smaller numerical aperture (NA), which leads to moderately weaker traps and affects fluorescence detection (see Subheading 3.5). An identical back objective (BO) is used as a condenser to collect the trapping light. Although an objective is not essential for this purpose, we also use BO as the objective in the bright-field imaging system as it allows directly imaging the traps, which is convenient for alignment (see Subheadings 2.3 and 3.3). An identical dichroic (DM2) reflects the trap light into the detection stage after BO.

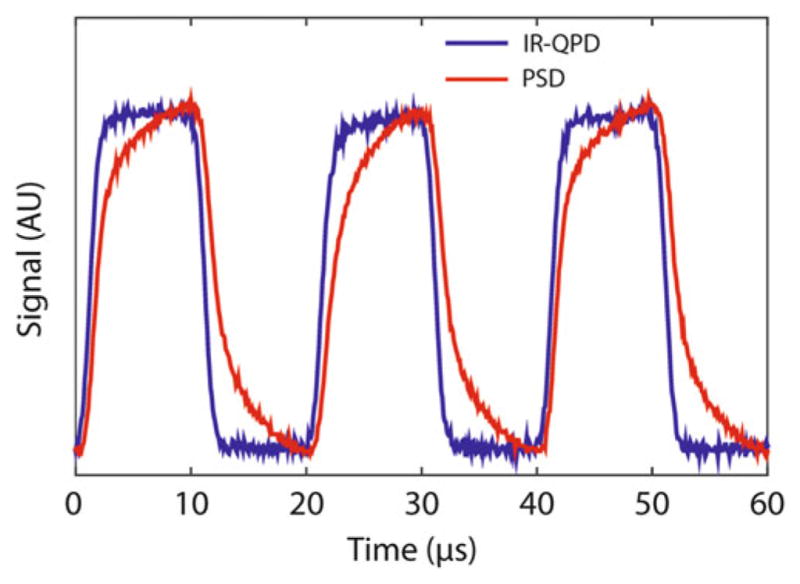

Finally, the positions of the beads in the optical traps are monitored by back-focal plane interferometry of the trapping light [33, 34]. In contrast to other groups, we do not use a separate detection laser during normal operating procedures. A relay lens (RL1) collects the light forward-scattered by the trapped beads at the back-focal plane of BO and images it onto a position-sensitive quadrant photodetector (QPD2). QPD2 outputs voltages proportional to the lateral position, x and y, of the centroid of the collected light and to the total light intensity. The positions of the beads in both traps are monitored with the same QPD; which signal comes from which trapped bead is resolved temporally by the data acquisition system (see Subheadings 2.5 and 3.2). The choice of photo-detector is an important consideration in the design of this instrument. At the 1064-nm trapping wavelength, widely used silicon-based position-sensitive detectors (PSD) exhibit parasitic filtering above ~10 kHz [35]. This low-pass filtering leads to signal inaccuracies during interlacing and timesharing at 66 kHz (Fig. 7). We have found that IR-enhanced quadrant photodetectors are accurate at rates >100 kHz at 1064 nm and are essential for proper operation of the instrument.

Fig. 7.

Comparison of IR-enhanced QPD to PSD for IR laser detection. The trapping laser power measured by an IR-enhanced QPD (blue) and PSD (red) during its ON/OFF interlacing cycle is shown. The PSD exhibits parasitic low-pass filtering, characterized by long rise and fall times (reproduced from ref. [16] with permission from Nature Publishing Group)

Components of interest

5-W, 1064-nm fiber laser (IPG Photonics, YLR-5-1064-LP) (seeNote 3).

Fiber clamp (FC; Newport, CCL-1 cable clamp).

1064 nm optical isolator (ISO1; Thorlabs, item formerly from Optics for Research, IO-3-1064-VHP).

1064 nm zero-order half-wave plate (HW1; Newport, 05RP-02-34).

Continuous rotation mount for wave plate (Thorlabs, RSP1).

1064 nm laser line polarizing beam-splitting cube, 12.7 mm (PBS1; Newport, 05BC16PC.9).

Three-axis optic tilt mount for PBS cube (Newport, UGP-1).

Laser beam dumps (2 each: BD; Kentek, ABD-075NP).

1064 nm acousto-optic modulator (AOM) (AOM1; IntraAction, ATM-803DA6B).

Five-axis alignment stage for AOM (Newport, item formerly from New Focus, 9081).

-

Lenses (all are 1064 nm anti-reflection coated, 25.4 mm diameter):

Plano-convex lens, 88.3 mm EFL (L1; Newport, KPX091AR.33).

Plano-convex lens, 250 mm EFL (L2; Newport, KPX109AR.33).

Plano-convex lens, 100 mm EFL (L3; Newport, KPX094AR.33).

Plano-convex lens, 200 mm EFL (L4; Newport, KPX106AR.33).

Bi-convex lens, 150 mm EFL (RL1; Newport, KBX070AR.33).

Iris (Thorlabs, SM1D12C).

Laser line dielectric mirrors, 1064 nm (2 each: M1 and M2; Newport 10Z40DM.10).

Broadband beam sampler, 1010–1550 nm (BS1; Newport, 10Q20NC.3).

Short-pass dichroic beamsplitters, reflected wavelength = 1064 nm, transmitted wavelength = 415–700 nm (2 each: DM1 and DM2; CVI, SWP-45-RP1064-TUVIS-PW-1025-UV) (seeNote 4).

IR-enhanced quadrant photodiodes (QPDs) (2 each: QPD1 and QPD2; First sensor, formerly Pacific Silicon, QP154-Q-HVSD).

Precision stages for QPDs (2: Newport, 460A-XYZ).

60× water-immersion microscope objectives, NA = 1.2 (2 each: FO and BO; Nikon, CFI Plan APO VC 60XWI).

Precision stages for microscope objectives (2 each; Newport, Ultralign 561D-XYZ [right-handed] and 561D-XYZ-LH [left-handed]).

1064 nm laser line filter (F1; Newport, 10LF25-1064).

2.2 Fluorescence Confocal Microscope

Much of the fluorescence confocal microscope module layout is similar to that of the trap, with some important distinctions. A 532-nm 30-mW laser is used for excitation. Although only micro-watts of power are necessary for typical single-molecule confocal microscopy, we also use the excitation laser for alignment (see Subheadings 3.3 and 3.4), which requires increased power.

As shown in Fig. 3, the excitation beam passes through an optical isolator, power stage, and AOM. Here, the AOM only modulates the laser intensity for interlacing with the optical trap. As in the optical trap module, a fraction (approximately 1 %) of the excitation light intensity is diverted (pellicle beam splitter BS2) and monitored by a photodiode (PD) and stabilized via a feedback loop.

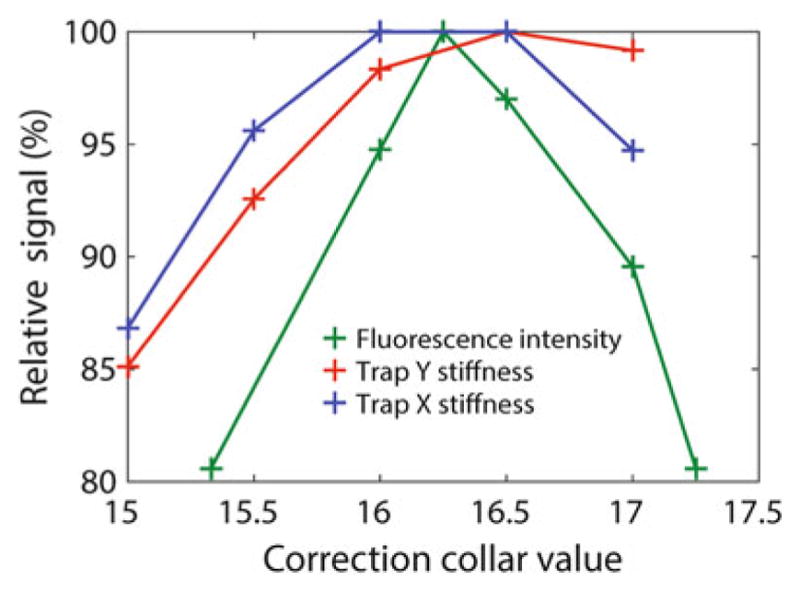

Two telescopes (T3 and T4) expand the beam by 4× and 1.3×, respectively (approximately 6 mm final beam waist, slightly less than the FO aperture, to ease the co-alignment of trap and fluorescence beams) (seeNote 5). We recommend using achromatic doublet lenses for all fluorescence imaging in this module to maintain consistent focusing across the fluorescence spectrum. The excitation beam next enters the front objective FO. There are a few important characteristics for the objectives to keep in mind when trapping simultaneously with fluorescence. First, since water-immersion objectives have a lower NA than oil-immersion objectives, the fluorescence collection efficiency in this setup will be slightly lower than that for standard confocal microscopes. Second, chromatic aberrations in FO require adjusting the fluorescence excitation beam collimation so that it is focused in the same plane as the trapped beads. This is achieved via two translation stages that displace the first and second lenses of T3 and T4, respectively, along the optical axis. These provide coarse and fine control over the focal depth of the fluorescence excitation, respectively (see Subheading 3.4). In addition, a piezo-actuated tip-tilt mirror stage (SM) between T3 and T4 is used to adjust the lateral position of the excitation relative to the traps in the specimen plane. The pivot plane of the mirror is made conjugate with the back-focal plane of FO (denoted by ‡ in Fig. 3) by T4.

Fluorescence emission from the excitation focus at the specimen plane is collected by FO, traveling back along the same path as the excitation, but passing through a long-pass dichroic mirror (DM4) and into the confocal pinhole stage. This consists of a telescope (T5), the first lens of which focuses the emission light onto the pinhole (PH, generally 20–100 μm diameter, depending on lens selection and background rejection requirements) (seeNote 6) that rejects out-of-focus light, and the second of which collects the transmitted light. The fluorescence signals are monitored by two avalanche photodiodes for measuring donor (APD1) and acceptor fluorescence (APD2). These detect individual photons and output a single digital pulse per photon to the data acquisition system (see Subheading 3.4).

The 532-nm excitation light transmitted through the sample chamber is also collected by BO and imaged onto a position-sensitive detector (PSD). This detection system is used during alignment, utilizing the excitation as a detection beam for a trapped bead for accurate positioning of the confocal spot laterally in relation to the trapped beads (see Subheadings 3.3 and 3.4).

In general, it is best to keep fluorescence and trap modules well-separated and partitioned to prevent stray trap light from reaching the fluorescence detectors and producing a background signal. We recommend enclosing the instrument modules in blackout boxes containing multiple turns to maximize absorption of stray light (Fig. 4).

Components of interest:

532 nm laser (World Star Tech, TECGL-30) (seeNote 7).

532 nm laser mount and coarse adjustment stage (Newport, VB-1).

532 nm optical isolator (ISO2; Thorlabs, item formerly from Optics for Research, IO-3-532-LP).

532 nmzero-order half-waveplate(HW2; Newport, 05RP02-16).

Continuous rotation mount for wave plate (Thorlabs, RSP1).

532 nm PBS cube (PBS2; Newport, 05BC16PC.3).

Three-axis optic tilt mount for PBS cube (Newport, UGP-1).

Laser beam dump (BD; Kentek, ABD-075NP).

532 nm AOM (AOM2; IntraAction, AOM-802AF1).

AOM driver electronics for excitation laser (IntraAction, ME-801.5-6).

Pellicle beamsplitter (BS2; Newport, PBS-2C).

Iris (2 each; Thorlabs, SM1D12C).

QPD or non-position-sensitive photodiode (PD; QPD: First sensor, QP154-Q-HVSD. Non-position sensitive photodiode: Thorlabs, PDA36A).

Motorized filter flip mount (ND1; Thorlabs, MFF101).

Assortment of neutral density filters (ND1 and ND2; e.g., Thorlabs, NE05A).

Laser line dielectric mirrors, 532 nm (5 each: M5, M6, M7, M8, and M9; Newport, 10Z40DM.11).

Compact linear lens positioning stages for coarse and fine positioning of fluorescence confocal depth (2 each; Newport, item formerly from New Focus, 9066-COM) (seeNote 8)

-

Lenses (all are 430–700 nm anti-reflection coated, 25.4 mm diameter unless otherwise stated):

Visible achromatic doublet lens, 100 mm EFL (L5; New-port, PAC052AR.14).

Plano-convex lens, 100 mm EFL (L6; Newport, KPX094AR.14).

Visible achromatic doublet lens, 150 mm EFL (L7; New-port, PAC058AR.14).

Visible achromatic doublet lens, 50.8 mm diameter, 200 mm EFL (L8; Newport, PAC087AR.14).

Bi-convex lens, 150 mm EFL (RL2; Newport, KBX070AR.14).

Visible achromatic doublet lens, 50.80 mm EFL (L9; Newport, PAC040AR.14).

Plano-convex lens, 25.4 mm EFL (L10; Newport, KPX076AR.14).

-

Dichroic mirrors:

532 nm long-pass dichroic mirror (DM4; Semrock, LPD02-532RU-25).

532 nm short-pass dichroic mirror (DM5; CVI, SWP-43-RU532-TUVIS-PW-1025-C) (seeNote 9).

590 nm edge dichroic mirror (DM6; Chroma, 590dcxr).

Two-axis piezoelectric mirror tip/tilt actuator (SM; Mad City Labs, Nano-MTA2 Invar).

Three-axis tip/tilt mount for piezoelectric mirror (SM; New-port, item formerly from New Focus, 9411).

QPD or position-sensitive detector (PSD) (PSD; QPD: First Sensor, formerly Pacific Silicon, QP154-Q-HVSD. PSD: First Sensor, DL100-7-PCBA3).

Precision stage for PSD (Newport, 460A-XYZ).

-

Filters:

Mounted precision pinhole (PH; e.g., Thorlabs, P100S).

Precision three axis translation stage for pinhole (Newport, 461-XYZ-M).

Avalanche photodiodes (APDs) (2 each: APD1 and APD2; Excelitas, formerly PerkinElmer, SPCM-AQRH-14).

Precision stages for APDs (2 each; Newport, 460A-XYZ).

2.3 Bright-Field Imaging System

The instrument is equipped with a bright-field imaging system (Fig. 3 and 4) that serves two purposes: (1) to visualize directly the sample chamber and beads during experiments, and (2) to image the trap and fluorescence excitation laser beams during some alignment protocols. The specimen plane is imaged by an IR-enhanced CCD camera using Kohler illumination from a blue LED (seeNote 13). Band-pass filters on flip mounts are used to cut out IR trapping and green excitation light during normal instrument operation. The camera signal is recorded and displayed on the instrument computer using a frame-grabbing PC card. PCI-express video cards such as the one listed below should be used, as they provide sufficient data bandwidth to maintain a continuous video stream without interfering with other instrument measurements and control operations.

465 nm blue LED (LED; e.g., Kingbright, 604-WP7113VBC/D).

Visible mirror (M4; Thorlabs, PF10-03-P01).

Bi-convex lenses, 25.4 mm diameter, 200 mm EFL (2 each: L11 and TL; Newport, KBX076).

1000 nm shortpass filter (F2; Thorlabs, FES1000).

532 nm single-notch filter (F3; Semrock, NF01-532U-25).

IR-enhanced CCD camera (CCD; Watec, WAT-902-B).

Frame-grabbing PC card (Matrix Vision, mvDELTAe-BNC).

Video monitor with BNC inputs for viewing inside instrument room (e.g., Ganz, ZM-L17A, distributed by Reytec).

Reticle calibration stage micrometer (Edmund Optics, 59–280).

2.4 Trap AOM RF Synthesis

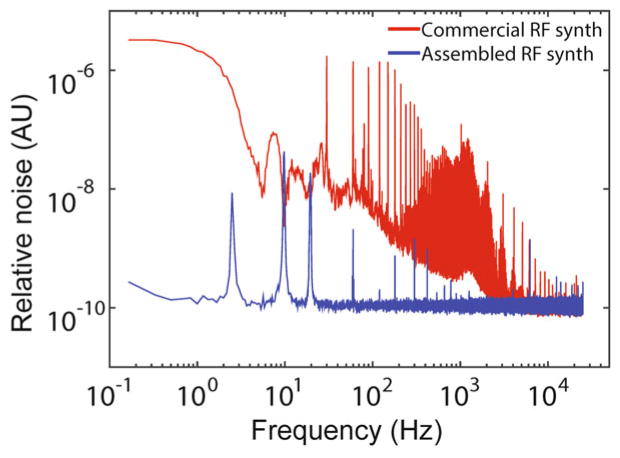

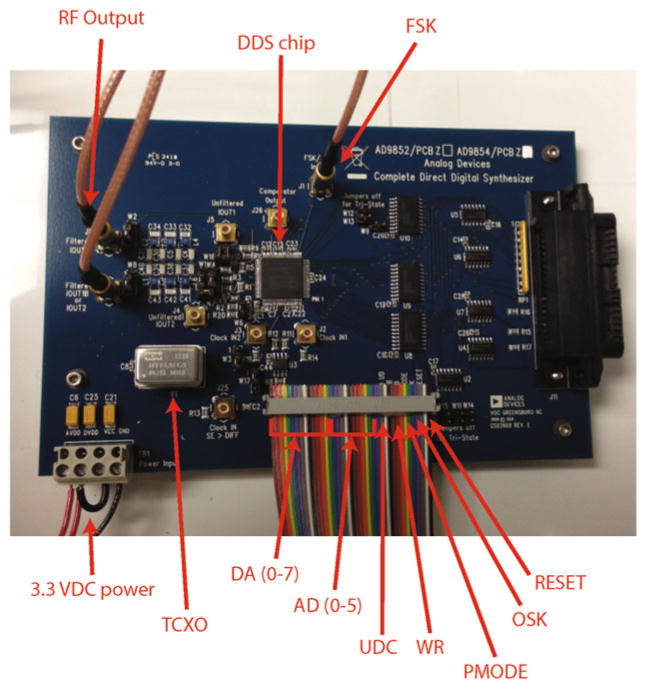

The trap laser intensity and deflection angle are both controlled via AOM. Since the sound wave that determines both is driven by an RF source, precise and stable RF generation is key for stable, high-resolution trapping. Although the AOM RF signal can be produced from an integrated commercial source, we have found that an RF synthesizer custom-built from a direct digital synthesis (DDS) RF source chip provides much lower noise [16] (Fig. 8). The frequency of the RF output is referenced to a clock signal that must be supplied to the board. The stability of the clock directly affects the stability of the RF output frequency and therefore the stability of trap positioning. The synthesizer itself generates a variable low power signal that we amplify by a low-noise, fixed-gain RF power amplifier to drive the AOM. Care must be taken not to exceed the damage threshold of the AOM with RF power >2–3 W (Fig. 9). A DC-block is inserted inline between the RF synthesizer and amplifier as the amplifier is very susceptible to damage by a DC input. We recommend the following parts to assemble such an RF synthesizer and amplifier. The specifications for the AOM modulating the fluorescence intensity are less stringent, and a commercial RF source is sufficient in this case.

Fig. 8.

Noise power spectra from commercial and custom-built RF synthesizers. The custom-built RF synthesizer (blue) exhibits lower noise than the commercial synthesizer (red) by up to four orders of magnitude (reproduced from ref. [16] with permission from Nature Publishing Group)

Fig. 9.

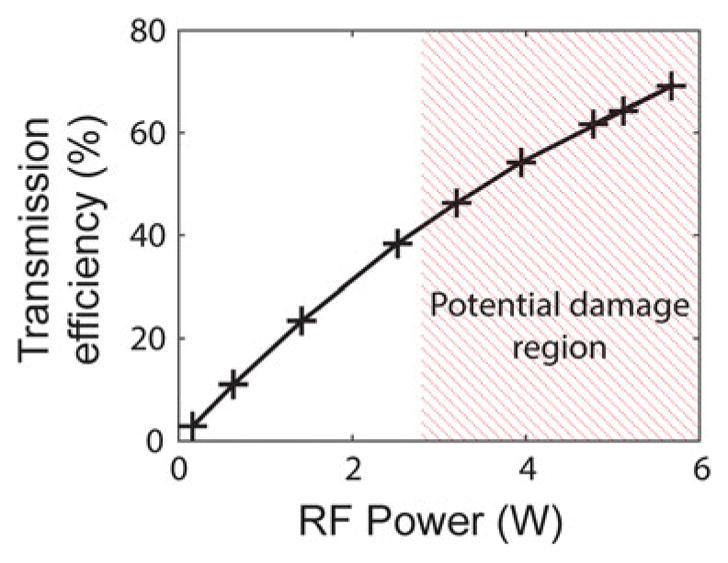

Transmission efficiency of trapping AOM as a function of input RF power. The intensity of the first-order diffracted beam relative to the total intensity input to the AOM increases with RF power. High input RF power can damage the AOM (red hatched region)

Direct digitally synthesized (DDS) integrated circuit (IC) RF source chip on “evaluation” PC board (Analog Devices, AD9852/PCBZ or AD9854/PCBZ).

14-pin DIP, 49.152 MHz fixed output, HCMOS logic, temperature compensated crystal oscillator (TCXO) with 1 ppm stability (Conner-Winfield, HTFL5FG5-049.152 M) (seeNote 14).

14-pin DIP socket.

3.3 V regulated linear power supply for RF synthesizer (Acopian, A3.3NT350).

Standoffs to mount RF board to chassis, 4–40, f-f, 0.375″ long (4 each; e.g., Mouser, 534–2202).

#4 flat insulating washers to mount RF board to chassis (4 each; e.g., Mouser, 534–3368).

40 line ribbon cable (e.g., Mouser, 517–3302/40FT).

40 pin ribbon cable plug (e.g., Mouser, 517–3417–7000).

12″ long SMB plug coaxial test cable (2 each; e.g., Allied, 528–0255).

SMB to BNC adaptor (2 each; e.g., Allied, 319–0409).

BNC jack to jack isolated bulkhead adaptor (2 each; e.g., Allied, 713–8028).

RF synthesizer chassis, 19″ rack box (e.g., Mouser, 563-NHC-14155).

Low-noise, fixed-gain RF power amplifier, 5 W maximum output, 40 dB gain (Mini-Circuits, ZHL-5 W-1) (seeNote 15).

24 V linear regulated power supply for RF power amplifier (Acopian, 24PH15AM) (see Table 1).

Low-noise RF cables (Mini-circuits, CBL-25FT-SMSM+).

DC-block (Mini-circuits, BLK-89 S+).

RFRMSpower meter(Mini-circuits, ZX47-40-S+)(see Note16).

Assortment of RF attenuators (e.g., Mini-circuits, HAT-10+) (seeNote 17).

Combined DPO oscilloscope and RF spectrum analyzer (Tektronix, MDO4000B) (seeNote 18).

Table 1.

Linear regulated low noise DC voltage sources from Acopian

| DB15-10 | +/− 15 V, 100 mA | For the QPD/PSD detectors |

| 5EB50 | 5 V, 500 mA | For wide-field microscope LED |

| A24MT210-M | 24 V, 2.1 A | For NI current analog out control |

| 50EB03 | 50 V, 30 mA | For QPD reverse bias |

| A3.3NT350 | 3.3 V, 3.5 A | For RF DDS synthesizer board supply |

| 24PH15AM | 24 V, 15 A | For RF power amplifier supply |

2.5 Data Acquisition and Instrument Control System

Key components of the instrument, including the trap and fluorescence excitation AOMs, single-photon counting APDs, the bead position measuring QPD, and laser feedback detectors, must be controlled and synchronized to trap interlacing with μs-level precision. PC-based data acquisition (DAQ) cards have historically been unable to achieve this level of timing and control easily, suffering from operating system interference. However, recent Field Programmable Gate Array (FPGA)-based PC DAQ cards circumvent this problem by moving all key timing operations from the PC “host” to a programmable chip on the DAQ card. The FPGA chip runs precisely and consistently as programmed with 40 MHz (25 ns) timing resolution and is isolated from interference from the PC. The FPGA is the “brain” behind all time-sensitive instrumentation control and data acquisition. Data are transferred from the FPGA to the host PC for non-time critical operations such as data analysis, plotting, and saving (seeNote 19 for computer build). Custom LabVIEW (National Instruments) software is used to control the instrument and is separated into FPGA and host PC portions (seeNote 20).

Figure 10 displays the input/output architecture of the FPGA and all the components with which it communicates. There are eight synchronously sampled analog input (AI) channels in total: the x, y, and sum voltages of QPD2 that monitors the trapped bead positions; the x, y, and sum voltages of PSD that monitors the fluorescence excitation beam during alignment protocols; and two sum voltages from the trap and fluorescence feedback detectors QPD1 and PD. Note that the first seven channels are measured directly by the FPGA DAQ card AI. However, the fluorescence feedback detector intensity is measured by an additional AI card installed in an expansion chassis. This additional AI card is directly controlled by the FPGA and adds four more independently sampled AI. This design eases future expansion of the number of fluorescence excitation lasers and data channels. Two digital inputs (DI) collect photon pulses from APD1 and APD2. Two analog outputs (AO) control the two-axis steering mirror (SM) that scans the fluorescence excitation laterally in x and y at the specimen plane. A number of digital output (DO) channels are used to communicate with the custom-built RF source that drives the trap AOM (Figs. 10 and 11). Three additional “debugging” DO are used to indicate APD gating (ADB), trap laser (TDB), and fluorescence excitation laser (EDB) AI timing during interlacing synchronization protocols (see Subheadings 3.2, 3.3, and 3.4). One digital output controls a motorized flip mount to insert or remove a neutral density (ND) filter from the excitation beam path to easily switch between fluorescence excitation (low beam intensity) and bead detection beam (high beam intensity) methods (see Subheading 3.3).

Fig. 10.

Input/output architecture of the FPGA-based DAQ card. Thicker lines refer to groups of wires. The FPGA uses 20 DO lines to communicate with the trap RF synthesizer, including six for individual bits denoting the address byte (AD) and eight for individual bits denoting the data byte (DA). The output RF signal from the synthesizer goes to an amplifier and then to the trap AOM. Three separate debugging DO lines (TDB, EDB, and ADB) are used for synchronizing detection input timing with the interlacing cycle (see Subheadings 3.2, 3.3, and 3.4). One of the FPGA-controlled AO lines is used to output an analog fluorescence signal (AFL) for aligning the instrument (see Subheading 3.4). The FPGA controls an additional set of AIO lines in an expansion chassis. This chassis has one AI line used for the fluorescence feedback PD, and one AO line that is used, along with a DO line from the FPGA, to control the fluorescence RF synthesizer

Fig. 11.

Assembled RF synthesizer board. A ribbon cable (bottom, digital lines labeled) and a coaxial cable (FSK, top) carry digital signals to the board directly from the FPGA (see Fig. 10). The temperature-compensated crystal oscillator (TCXO) is mounted to a 14-pin DIP socket on the board. A coaxial cable carries the filtered RF output signal from the board to the amplifier (top left, labeled IOUT1 on board; the second cable is ignored). Power is supplied to the board from a single 3.3 VDC source (bottom left)

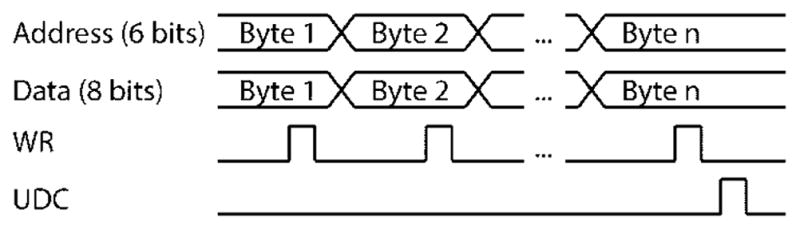

The trap AOM RF synthesizer chip is configured in part (e.g., the RF frequency and amplitude output values) by writing digital bytes (data) to specific locations (addresses) in the chip memory (Fig. 12). We utilize the high-speed parallel data communication method (set by PMODE signal (PM) DO line) of the RF synthesizer board. With this method, a single 8-bit byte of information is sent to a single 6-bit address location in a single data transfer cycle. In general, multiple bytes must be sent in sequence to specify the RF synthesizer board configuration fully (e.g., 6 bytes fully determine the RF frequency). Therefore, in order for all RF chip properties to change synchronously, the board employs a buffered memory process whereby changes are made first to an inactive copy of the chip memory (the buffer). Multiple bytes of data are sequentially transferred to the buffer. This is done by first setting data and address DO lines and then sending a TTL pulse to the write (WR) line. After all necessary changes are made, they are all activated simultaneously by sending a pulse to the update clock (UDC) signal line, which initiates a simultaneous transfer of the buffer memory to the active memory (Fig. 12). The reader should refer to the RF synthesizer chip manual for a complete table of address/configuration settings (Table 9 of ref. [36]) for a more detailed description of operation.

Fig. 12.

Scheme for writing data to RF synthesizer board. Multiple bytes of data are sequentially transferred to a buffer by setting data and address DO lines and then sending a TTL pulse to the write (WR) line. After all necessary changes are made, they are all activated simultaneously by sending a pulse to the update clock (UDC) signal line, which initiates a simultaneous transfer of the buffer memory to the active memory

There is one key exception to the above. It turns out that changes in RF amplitude and frequency output from a simultaneous UDC-initiated buffer transfer are not timed sufficiently synchronously for our high-resolution trapping requirements. To compensate for this time delay, we devised a method by which we can invoke two independent FPGA DO lines to time and synchronize RF frequency and amplitude switching independently. We utilize the frequency shift keying (FSK) method of the RF synthesizer chip, whereby two separate RF frequencies can be stored on the chip (serving as the “active” and “inactive” trap) and the RF output can be switched between the two frequencies using the RF chip FSK digital input. We specify the next trap frequency in the “inactive” memory location and the amplitude in the usual buffer and control the switching of frequency via the RF chip FSK input and the amplitude via the usual RF chip UDC input. By specifying a delay in the FPGA timing between the switching of the FSK and UDC, we can synchronize RF frequency and amplitude switching (see Subheading 3.1).

The fluorescence excitation AOM driver is controlled by one AO channel (analog scaling) and one DO (digital gating) channel. Using both the analog and digital controls together allows maximally extinguishing the fluorescence beam when it should be off. The analog input of the IntraAction AOM driver we use is low impedance and the analog out channels built into the FPGA DAQ card cannot provide sufficient current to drive it. Therefore we use a special high current analog out card installed in the expansion chassis to provide the analog signal to the fluorescence AOM driver.

It is helpful to use a robust desktop computer with up-to-date multi-core processors (e.g., Intel quad-core i7) and as much memory as possible (32 GB suggested). We also highly recommend using at least two storage drives: a small (e.g., 512 GB) fast solid state drive containing the operating system and all software used (including LabVIEW) and a larger (e.g., 2 TB) conventional hard disk drive (seeNote 21) for saving data. Separating these two drives prevents conflicts during high-speed data acquisition and streaming from the FPGA to the PC and saving to the hard disk.

750 kHz sampling rate FPGA-based multi-function DAQ PC card (National Instruments, NI PCIe-7852R).

C-series expansion chassis (National Instruments, NI 9151).

C-series high current analog output card (National Instruments, NI 9265).

C-series analog input expansion card (National Instruments, NI 9215).

Breakout box (2 each; National Instruments, SCB-68).

Cable to mixed IO breakout box (National Instruments, SHC68-RMIO).

Cable to digital IO breakout box (National Instruments, SHC68-68-RDIO).

Cable to expansion chassis (National Instruments, SH68-C68-S).

Custom LabVIEW software (download here: http://www.pa.msu.edu/people/comstock/software.html).

2.6 Optical Tweezers and Confocal Microscope Alignment

10 μm fluorescent polystyrene microspheres, excitation max = 540 nm, emission max = 560 nm (Thermo, F-8833).

1.0 μm fluorescent polystyrene microspheres, excitation max = 540 nm, emission max = 560 nm (Thermo, F-8820).

1.0 μm fluorescent polystyrene microspheres, excitation max = 535 nm, emission max = 575 nm (Thermo, F-8819).

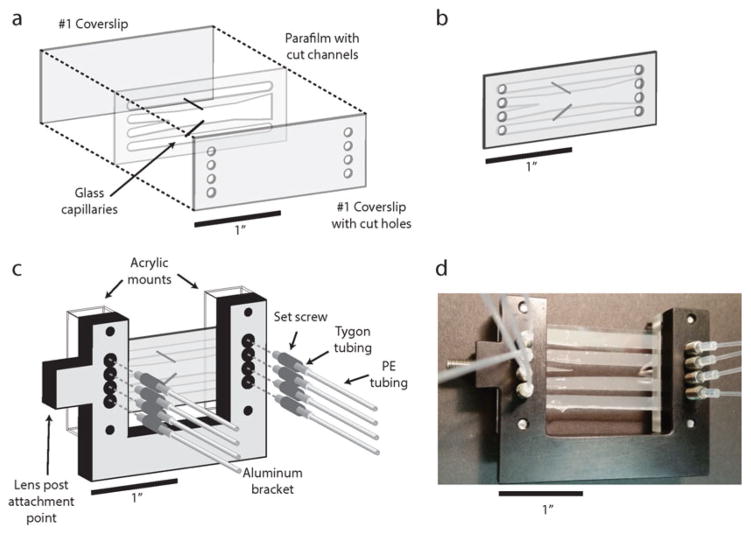

2.7 Sample Flow Chamber Assembly

Laser engraver (Universal Laser Systems, VLS2.30).

CorelDRAW X4 (CorelDRAW).

1.5 HP portable dust collector motor blower (Penn State Industries, DC3XX).

Dust collection hose and clamps (Penn State Industries, D50C and DBC4).

Movable stage for chamber (Newport, Ultralign 562-XYZ).

Movable stage controller (Newport, ESP301-3N).

Closed loop DC servo stage motors (3 each; Newport, TRA12CC).

Joystick (Newport, ESP300-J).

Remote infuse/withdraw syringe pumps for bead channels (2 each; Harvard, PHD Ultra Nanomite 703601).

Remote infuse/withdraw syringe pump for sample channels (Harvard, PHD Ultra Remote Infuse/Withdraw Programmable 703107).

Microscope coverslips (Fisher, 12-548-5P).

Parafilm M (Pechiney Plastic Packaging, PM996).

Glass capillaries with ID = 0.0250 mm, OD = 0.10 mm (King Precision Glass, custom order).

Anodized aluminum bracket (machined in house, see Fig. 13).

Polished acrylic mounts (2 each; machined in house, see Fig. 13).

4/40 × 1/2″ screws for assembling bracket and acrylic mounts (4 each; see Fig. 13).

8/32 × 3/8″ set screws with 1/16″ holes drilled through centers (8 each; McMaster, see Fig. 13).

26G × 3/8 in intradermal bevel needles (BD, 305110).

Tygon tubing with ID = 1/32″, OD = 3/32″, Wall = 1/32″ (Fisher, ABW00001).

Polyethylene tubing with ID = 0.015″, OD = 0.043″ (BD, 427406).

N-(2-aminoethyl)-3-aminopropyltrimethoxysilane (United Chemical Technologies, A0700).

Methoxy-PEG-succinimidyl valerate, MW 5000 (Laysan Bio, MPEG-SVA-5000-1g).

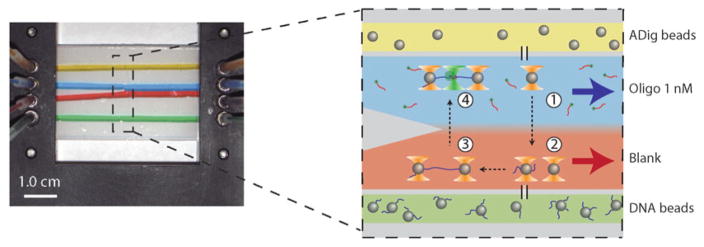

Fig. 13.

Assembly of laminar flow chamber. (a) Expanded view of the “Parafilm sandwich” that comprises the chamber. A piece of Parafilm with flow channels cut into it is placed on a coverslip with eight holes cut into it. Two glass capillaries span the Parafilm to connect the bottom and top channels to the large central channel. A coverslip with no holes is then placed on top of the Parafilm to form the assembled chamber. (b) A fully assembled flow chamber. (c) A flow chamber mounted on an anodized aluminum bracket, held in place by two acrylic mounts. Four holes on either side of the mount are aligned with the holes of the coverslip. A short length of Tygon tubing is threaded through a set screw, and a longer stretch of polyethylene (PE) tubing is inserted into the Tygon tubing. Eight threaded set screws are prepared and screwed into the eight holes in the aluminum bracket to serve as inlet and outlet channels for the flow chamber. (d) Photograph of an assembled and mounted flow chamber

2.8 Functionalization of Beads

Standard benchtop microcentrifuge with Rotor FA-45-30-11 (Eppendorf, 022620601).

Sample rotator (e.g., VWR, 10136-084).

Analog vortex mixer (Fisher, 02-215-365).

1× PBS buffer (10 mL): 137 mM NaCl, 2.7 mM KCl, 4.3 mM Na2HPO4, 1.47 mM KH2PO4, pH = 7.4.

Protein G-coated polystyrene microspheres, 880 nm nominal diameter (Spherotech, PGP-08-5).

Anti-digoxigenin (Roche, 11333089001).

Streptavidin-coated polystyrene microspheres, 810 nm nominal diameter (Spherotech, SVP-08-10).

2.9 Construction of DNA

Standard thermal cycler for DNA PCR reactions (e.g., Bio-Rad T100, 1861096).

Electrophoresis cell with power supply, 8- and 15-well combs, gel caster, and 7 × 10 cm tray (Bio-Rad Mini-Sub Cell GT Cell and PowerPac Basic Power Supply, 1640300).

UV lamp (Laboratory Products Sales, ENF-240C).

Blue light source gel transilluminator (Clare Chemical Research, Dark Reader Transilluminator DR89X).

Nanodrop 2000 UV-Vis spectrophotometer (Thermo Scientific).

pBR322 vector (New England Biolabs, N3033S).

Lambda phage DNA template (NEB, N3011S).

Primers (Integrated DNA Technology) (see Table 2).

Phusion high-fidelity polymerase PCR master mix (NEB, M0531S).

QIAquick PCR purification kit (Qiagen, 28104).

5× stock of TBE buffer (1 L): 400 mM Tris–HCl, 450 mM boric acid, 10 mM EDTA, pH = 8.3.

6× gel loading dye (NEB, B7021S).

1 kb DNA ladder (NEB, N0468S).

Pre-cast 1 % agarose gels in TBE with ethidium bromide (Bio-Rad, 1613010).

PspGI restriction enzyme (NEB, R0611S).

TspRI restriction enzyme (NEB, R0582S).

UltraPure low melting point agarose (ThermoFisher, 16520-050).

GelGreen nucleic acid gel stain, 10,000× in water (Biotium, 41005).

QIAEX II gel extraction kit (Qiagen, 20021).

T4 DNA ligase (NEB, M0202S).

Table 2.

Oligonucleotides used in example experiment

| Oligonucleotide | Sequence (IDT format, 5′ to 3′) |

|---|---|

| LH forward primer | /5Biosg/TGA AGT GGT GGC CTA ACT ACG |

| LH reverse primer | CAA GCC TAT GCC TAC AGC AT |

| RH forward primer | /5DigN/GGG CAA ACC AAG ACA GCT AA |

| RH reverse primer | CGT TTT CCC GAA AAG CCA GAA |

| Ins | /5Phos/CCT GGT TTT TAG GAC TTG TTT TTT CCC ACT GGC |

| Probe | ACA AGT CCT/3Cy3Sp/ |

2.10 Oxygen Scavenging System/Fluorescence Imaging Buffer

There exist numerous methods for improving fluorescence signal quality in single-molecule experiments, and many of these can be easily adapted for use in these experiments. In particular, oxygen scavenger systems such as the glucose oxidase/catalase mixture are known to increase the photobleaching lifetime of fluorophores [37]. Since singlet oxygen species also tend to cause tether breakage [38], such a system has the effect of improving both tether and fluorophore quality. Additionally, a triplet state quencher like Tro-lox can be used to both prevent fluorophore blinking and photo-bleaching [39].

T50 buffer (50 mL): 10 mM Tris–HCl, 50 mM NaCl, pH = 8.0.

Glucose oxidase from Aspergillus niger (Sigma, G7141).

Pyranose oxidase from Coriolus sp. (Sigma, P4234).

Catalase from Aspergillus niger (EMD Millipore, 219261).

Trolox (Sigma-Aldrich, 238813).

0.22 μm centrifugal filters (EMD Millipore, UFC30GV0S).

0.22 μm syringe filters (EMD Millipore, SLMP025SS).

2.11 Preparation of Beads and Sample for DNA Hybridization Experiment

Gastight glass syringes, 1 mL, PTFE Luer Lock (4 each; Hamilton, 81320).

Fluorescently labeled probe DNA (Integrated DNA Technology) (see Table 2).

3 Methods

3.1 Setup of RF Synthesizer for Trapping AOM

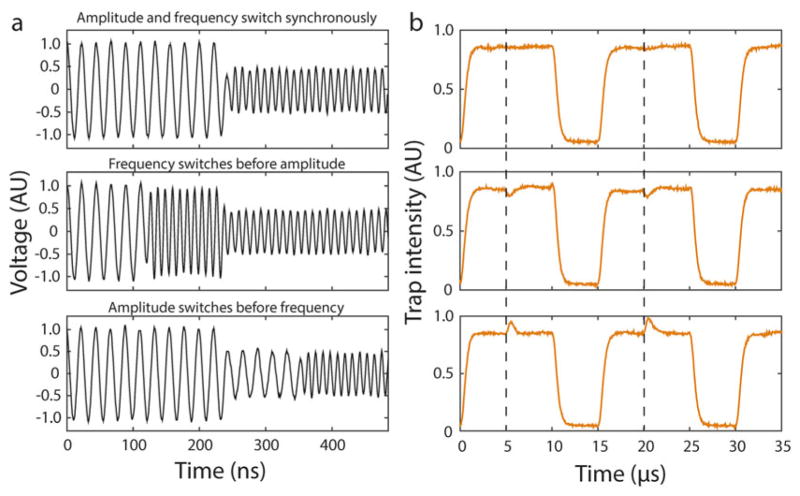

The first component to be assembled and configured is the RF synthesizer that drives the trapping AOM (Fig. 11). An important step in this process is synchronizing the times at which the frequency and amplitude of the RF signal switch. A delay between the RF amplitude and frequency switch will result in a sudden change in one trap stiffness, effectively “kicking” the trapped bead. To avoid this, we require direct and independent timing control of both the RF amplitude and frequency in order to make small timing adjustments to make them synchronous. We do this by tuning a delay into the FPGA timing between the triggering of these two inputs. The proper delay time can be determined by visualizing the RF signal switching directly on an oscilloscope with a sufficient time resolution to resolve individual RF oscillations clearly. This delay time is robust, so this procedure only needs to be performed once.

The following steps describe the assembly of the RF synthesizer board:

-

1

Prepare chassis by drilling holes in bottom panel for RF board standoffs and holes in front panel for signal (RF output and FSK input) and power (3.3 VDC) feedthroughs. We find that the ribbon cable used for digital communication between the FPGA and the RF board can be easily slid out underneath the chassis lid (i.e., no need for a feedthrough).

-

2

Install standoffs on bottom panel of chassis.

-

3

Install BNC signal feedthroughs and banana jack power feed-throughs on front panel.

-

4

Ground yourself with an anti-static strap and perform all RF board assembly work on top of a grounded, anti-static mat. Handle all components by their edges and do not touch component pins or exposed circuitry.

-

5

Mount RF board onto chassis standoffs. Do not over tighten screws.

-

6

Install 14-pin DIP socket onto RF board. Most sockets we have found have all 14 pins, whereas the board only has the 4 corner holes. In this case trim off the inner 10 pins with a wire cutter. Given the tight fit of the socket pins we have installed, we have not needed to solder this connection.

-

7

Install the 14-pin DIP TCXO directly into the 14-pin DIP socket now on the board (see Fig. 11) (seeNote 22).

-

8

Set the jumpers on the board to the following:

W9, W11, W12, W13, W14, W15 jumpers OFF (tri-state jumpers are only set to ON when using the printer port for communication).

W7, W10, W16 jumpers ON (to enable filtered output).

W1, W2, W3, W4, W8 jumpers on the bottom two pins (to enable filtered output).

W17 jumper on the upper two pins (to use the TCXO clock chip).

W6 OFF (to use a single resistor for the output).

-

9

Connect coaxial signal cables between RF board and panel feedthroughs (2 each for RF output and FSK input, use adaptors).

-

10

Connect RF board power inputs to chassis front panel power feedthroughs: first solder wires to panel banana jack feed-through, then screw wires into board inputs. We use a single 3.3 VDC source for all three RF board power inputs.

-

11

Start the RF board by turning on its power supply.

-

12

Initialize (configure) the RF board once after turning it on. This begins with a reset of the board (RESET) followed by a series of digital data transfers using the parallel communications method all performed by the custom LabVIEW software (seeNote 23). Set the following on the board: 6× system clock, phase locked loop (PLL) range low, PLL enabled, output shape keying (OSK) enabled, unramped frequency shift keying (FSK) mode, manual update clock. This RF board reset and initialization is performed whenever the custom LabVIEW software is restarted. The board can remain powered on.

The following steps describe how to synchronize the switching of RF amplitude and frequency for precise interlacing:

-

13

Connect the RF synthesizer output directly to an oscilloscope. Set the scope input impedance to 50 Ω OR use a “T” divider to split the signal between a 50 Ω terminator and the scope set to high input impedance (typically 1–10 MΩ) (seeNote 24).

-

14

Set two easily distinguishable frequencies and amplitudes, corresponding to the two traps. It is easiest to set the second trap amplitude to be ~2× larger or smaller than the first.

-

15

With no programmed delay between the frequency and amplitude triggers, either the frequency or amplitude will typically switch before the other (Fig. 14 middle and bottom panels). Adjust the delay between amplitude and frequency switching until amplitude and frequency switching occur simultaneously (Fig. 14 top panel). 125–250 ns is a typical delay (or 5–10 FPGA clock cycles, for a 40 MHz clock).

-

16

Make this delay the default value in LabVIEW. On startup of the instrument, the amplitude and frequency will be now be synchronized. We have found that this delay remains constant for a given RF board.

Fig. 14.

Synchronization of frequency and amplitude switching of the RF signal. (a) RF signals for the two traps are shown with both frequency and amplitude different by a factor of 2 for clarity (trap 1, 45 MHz; trap 2, 90 MHz). With an appropriately programmed delay between amplitude and frequency signals from the FPGA, the switch happens synchronously (top panel). When there is no programmed delay, the frequency can switch before (middle panel) or after (bottom panel) the amplitude. (b) Traps 1 and 2 during the interlacing cycle, where the RF amplitude is chosen such that both traps have the same intensity. The dotted line indicates when the transition between trap 1 and trap 2 occurs. With the programmed delay between amplitude and frequency switching, the change from trap 1 to trap 2 occurs without any change in intensity (top panel). With no programmed delay, the intensity of trap 2 either drops (middle panel) or rises (bottom panel) to effectively “kick” the bead held in this trap

3.2 Setup of Optical Trap Module

Most of the alignment procedures for the optical trap module have been described in detail previously [26], so we will not repeat these protocols here. The reader can use Fig. 3, which displays a schematic of the instrument drawn to scale, to guide construction of the module. We also refer the reader to the excellent resources on general considerations for aligning optical traps [26, 27, 29]. Here, we focus instead on special considerations required by the use of an AOM and interlacing: how to align the AOM with the trapping beam, how to synchronize trap signal acquisition with the interlacing cycle, and how to locate the plane conjugate to the AOM for positioning the objectives.

Synchronizing data acquisition with interlacing is a particularly important protocol. Since the AOM switches the two traps ON/OFF during the interlacing cycle, measurements of bead positions in each trap must be synchronized with this cycle. Moreover, each bead will be displaced away from the trap center during the OFF cycle of its trap, and will be displaced toward the trap center during the ON cycle (seeNote 25). The pair of trapped beads thus oscillate during interlacing. It is necessary to sample the bead position in the center of each trap ON interval, as it provides the true average bead position (and force) [16] (Fig. 5).

The following steps describe the alignment procedure for the trap AOM. It is important to keep in mind that the first-order diffracted beam coming out of the AOM is the one that will ultimately form the traps, so all alignment must be done for this first-order beam:

-

1

Mount the AOM on the five-axis stage. We recommend machining an adapter plate made of invar or stainless steel to attach the AOM rigidly to the stage, and to minimize drift due to heating of the AOM.

-

2

Elevate the stage using two 1″ height adjustable pedestals for extra stability. Choose pedestal heights such that the trapping beam will pass approximately through the center of the AOM aperture.

-

3

Set the stage to the middle of its range of motion.

-

4

Connect the RF output signal from the synthesizer to a DC block. A DC offset can damage the RF amplifier, so it is important to filter DC signals out.

-

5

Connect this RF signal to the low-noise, fixed-gain RF amplifier.

-

6

Connect the amplified RF output to the trapping AOM using a low-noise RF cable.

-

7

Clamp down the RF cable to the optical table in such a way as to relieve any strain on it. Any shaking of this cable will in turn shake the AOM to which it is attached, so it must be firmly set in place.

-

8

Drive the AOM in the center of its scan range (80 MHz) at low power (~1 W) (seeNote 26).

-

9

Align the AOM by hand such that the trapping beam is roughly centered on the input and output apertures. The beam will pass straight through.

-

10

To achieve an approximate alignment, slowly rotate the angle of the AOM in either direction by hand until a diffraction pattern can be observed coming out of it (see Fig. 15). There are numerous angles that will produce a diffraction pattern, but the optimal angle is the one that produces a pattern with highest intensity. This will be the first angle beyond an incidence angle of 0° as the AOM is rotated either clockwise or counterclockwise (Other sets of diffraction spots will appear if you continue rotating the AOM, and they will be less intense than the first set.).

-

11

Clamp down the base of the AOM stage when this optimal (but still approximate) diffraction pattern appears.

-

12

Place an iris downstream of the AOM to block out all but the first-order diffracted beam. Keep in mind that it is this first-order beam that will ultimately form the traps. Failure to block out the other orders may result in the creation of additional interfering traps.

-

13

Using either a power meter or photodetector to record the output beam intensity, rotate the AOM using the fine-adjustments of the stage until the intensity of the first-order beam reaches a maximum.

-

14

In order to align with the center of the AOM active area, translate the AOM in one of the directions orthogonal to the beam path, finding the two stage positions at which the intensity of the first-order beam reaches half of its maximum intensity (seeNote 27).

-

15

Position the stage in the middle of these two positions.

-

16

Repeat steps 14 and 15 for the other direction.

-

17

Adjust the rotation again to maximize intensity (it is easy to change the angle slightly while translating).

-

18

Attach a ½″ diameter 1064-nm laser line mirror (with very high reflection efficiency) to a post, and deflect the zeroth order beam to a high power beam dump (Fig. 3) (seeNote 28).

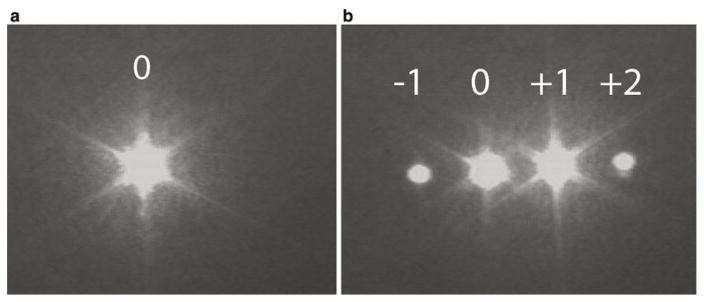

Fig. 15.

Diffraction pattern produced by an AOM (either trap or fluorescence AOM). (a) When the AOM is OFF, only the zeroth order (undiffracted) beam is observed. (b) When the AOM is ON, several orders of diffracted beams are observed. The +1 order beam is the one used for trapping

The steps below describe how to synchronize the input timing of the DAQ card with the trap interlacing cycle using the feedback QPD (QPD1 in Fig. 3):

-

19

After the AOM has been aligned, continue to align optics up to the feedback detector QPD1 (Fig. 3).

-

20

Send the total intensity signal of QPD1 to an oscilloscope, and turn on interlacing with both traps ON (seeNote 29). It is best to adjust the amplitudes for each trap to be different so that the center of each can more easily be distinguished (Fig. 5, orange).

-

21

Output from the DAQ card a digital pulse that is synchronous with the analog input timing (TDB line, Fig. 10), and visualize this pulse on the oscilloscope together with the trapping laser intensity signal (Fig. 5, black).

-

22

In LabVIEW, adjust the phase of the analog input timing until it is centered on the trapping laser intervals (seeNote 30).

-

23

Record this phase shift, and set the “initial phase” to this value in the instrument software (make it a default value).

-

24

Upon startup of the instrument, this phase will always be automatically adjusted to the correct value (seeNote 31).

-

25

Trap laser intensity feedback can now be turned on.

The following steps locate the plane conjugate to the trapping laser AOM deflection axis (Fig. 3). The conjugate planes will not be as well-defined when the beam is steered by an AOM instead of a movable mirror. Because there is no true single pivot plane for the deflected beam in the AOM, the conjugate plane will be smeared over a certain distance, typically ½″ for our optics:

-

26

Connect a QPD x, or horizontal, output to an oscilloscope, and center the QPD on the beam near the location you expect the conjugate plane to be.

-

27

Turn off interlacing, and oscillate one trap in the x direction.

-

28

Turn on trap intensity feedback or else the x signal will be difficult to interpret.

-

29

Translate the QPD in the z or axial direction until the oscillations on the scope reach a minimum. They will not reach zero. The conjugate plane will not be sharply defined, so it is sufficient to find the minimum.

3.3 Setup of Fluorescence Confocal Microscope Module: Excitation Laser Path

The following protocol describes the alignment of the fluorescence excitation and emission paths and the synchronization of the excitation and the trapping interlacing cycles (Figs. 3 and 5). It is important to note that all the synchronization and alignment is done relative to the trapping laser, so it is important that the trapping module be optimally aligned before continuing.

The synchronization steps are essential for proper interlacing. Not only must the fluorescence excitation be switched ON during the OFF interval of the traps, but the excitation intensity signal from the feedback detector (PD) and the fluorescence emission signals from the APDs must also be sampled at the appropriate times in the interlacing cycle (Fig. 5). Since fluorescence is only emitted during the excitation laser ON interlacing period, photons should only be counted during this period to reject background. One way to do this is to “gate” the APDs ON/OFF using the APD gate digital inputs. However, we have found that this method often produces false counts, which grow increasingly worse as the APDs age. A preferable option is to keep the APDs ON continuously and instead program the FPGA to record photon counts only during the excitation laser ON interval. The FPGA “recording interval” must still be aligned temporally with the excitation laser ON interval.

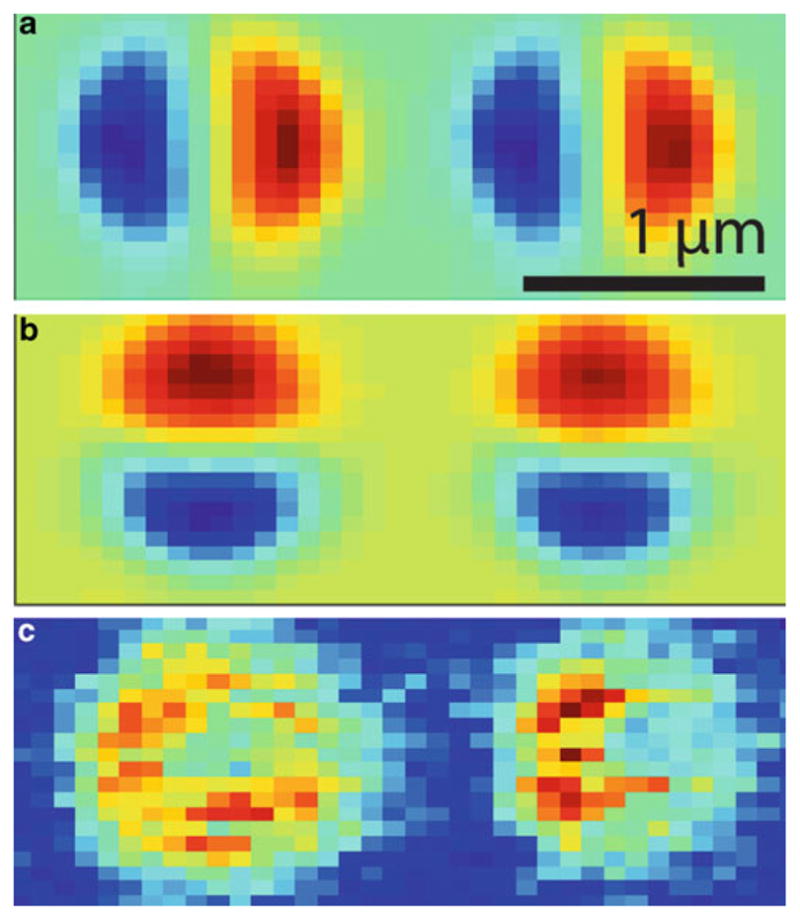

The optical alignment procedures include adjusting the lateral (x and y) and axial (z) position of the confocal excitation spot relative to the optical traps in the specimen plane. For a preliminary, coarse adjustment, we use the CCD camera from the visible bright-field imaging system to image the trapping and fluorescence beams. Fine adjustments are made in one of two ways: (1) imaging a trapped fluorescent bead by raster-scanning the confocal excitation across it and using the APDs to record the fluorescence emission, or (2) using the fluorescence excitation as a “detection beam” [29], scanning it across a trapped bead and recording the beam deflection with the PSD. We provide protocols for each option.

The following steps describe how to synchronize the switching of the fluorescence excitation to the trapping laser to achieve precise time-sharing:

-

1

Align the excitation beam path initially without regard to the trapping beam up to the excitation intensity feedback detector (PD, Fig. 3).

-

2

As done previously with the feedback detector for the trapping laser, send the total intensity signal of PD to an oscilloscope (seeNote 29), and turn on interlacing with both the excitation laser and trapping laser ON (Fig. 5, green and orange).

-

3

In LabVIEW, adjust the phase of the AOM interlacing timing until it is positioned between the trapping intervals as in Fig. 5. We set additional 625-ns delays between turning OFF (ON) the optical traps and turning ON (OFF) the fluorescence excitation (Fig. 5, grey shaded regions).

-

4

Record this phase shift, and set the “initial phase” to this value.

-

5

Make this initial phase value the default in LabVIEW. Upon startup of the instrument, this phase will then always be adjusted to the correct value (seeNote 31).

The following steps describe the synchronization of the feedback detector (PD) signal acquisition with the excitation laser during interlacing. Although the excitation laser and trapping laser are synchronized in steps 1–5, the DAQ card will not sample PD at the appropriate time. This problem arises because the analog output of this detector is connected to an expansion input card with a time delay. The procedure is similar to that described above:

-

6

Send the total intensity signal of PD to the oscilloscope, and turn on interlacing with the excitation laser ON (Fig. 5, green).

-

7

Output from the DAQ card a digital pulse that is synchronous with the analog input timing (EDB line, Fig. 10), and visualize this pulse on the oscilloscope together with the excitation laser intensity signal (Fig. 5, green).

-

8

In LabVIEW, adjust the phase of the excitation laser feedback detector analog input timing until it is centered on the excitation laser ON interval.

-

9

Record this phase shift, and set the “Initial phase” to this value.

-

10

Make this initial phase value the default in LabVIEW. Upon startup of the instrument, this phase will then always be adjusted to the correct value (seeNote 31).

-

11

Excitation laser intensity feedback can now be turned on.

These steps describe the coarse alignment of the excitation laser path in x, y, and z relative to the trapping beam using an image of the beam profile on the CCD camera:

-

12

Immediately after the pellicle beam-splitter (BS2), insert a motorized flip mount for adding neutral density (ND) filters. The flip mount is motorized so that the filters can be flipped out of the beam path when the excitation laser is used as a detection laser, which requires high intensity. Adding ND filters here will roughly control the excitation laser intensity. The AOM along with the feedback system provide fine control over the intensity.

-

13

When setting up the steerable mirror (SM), make sure it is set to the center of its scan range (5 V in both x and y directions).

-

14

Center the excitation beam on the front objective (FO) back aperture and make certain it is collimated.

-

15

Translate the front objective stage until the front apertures of both objectives are a few millimeters apart, and place a few drops of water between them.

-

16

Adjust the trap intensity and camera location to visualize the trap in the CCD image as a focused spot.

-

17

Adjust the first movable lens (L5) of the telescope T3 to adjust the excitation laser collimation and roughly focus the fluorescence excitation beam with the trap.

-

18

Roughly co-align the trapping and excitation beams laterally in the x and y directions by observing them on the CCD camera and adjusting the excitation beam angle (using the coarse adjustment stage beneath the steerable mirror) until it is approximately at the same location as the trapping beam. The fluorescence excitation and trap lasers are now roughly focused to the same sample chamber location (laterally and axially).

-

19

Set up the remaining components of the excitation laser path (RL2, M9, and PSD).

-

20

Place the PSD at a plane conjugate to that of the steerable mirror. The procedure for this is essentially the same as that for the trapping laser AOM (Subheading 3.2, steps 26–29), except in this case the procedure must be repeated for both the x and y directions. The conjugate plane should be at the same location for both.

3.4 Setup of Fluorescence Confocal Microscope Module: Emission Path

The following steps describe the alignment of the fluorescence emission path. This requires trapping a fluorescent bead in a flow chamber. Refer to the protocols on assembling laminar flow sample chambers (Subheading 3.9) and mounting the chamber in the instrument (Subheading 3.12) below for details:

-

1

Set up a flow chamber and trap a large fluorescent bead (~10 μm).

-

2

Roughly position the lateral focal spot of the excitation laser on the trapped bead by scanning in the x and y directions with the steerable mirror (SM) and observing the bright spot from fluorescence emission on the CCD camera.

-

3

Adjust the excitation intensity (adjust ND filters and AOM) so that the bead fluorescence emission can be visualized directly by eye. If the room is dark, we have found we can directly observe the emission path for many minutes before the bead photobleaches.

-

4

Align all optics involved in fluorescence detection (everything downstream of dichroic mirror DM4) using the visible fluorescence emission beam from this bead. Leave the pinhole out for now. It may be necessary to trap more than one bead if they bleach too quickly.

The steps below describe the alignment procedure for the APDs. APDs require special care, as the ambient light in a room is intense enough to damage them. As a general rule, APDs should remain off until it is time to make fine adjustments to them, at which point the lights in the instrument room must be turned off:

-

5

Mount the APDs on three-axis precision stages.

-

6

Align the APDs until the fluorescence emission spot from the large beads is visible near the middle of the detector. The APDs must remain off during this step to prevent damage.

-

7

Output an analog signal from the DAQ card that is proportional to the measured fluorescence to the oscilloscope (AFL line, Fig. 10), so the fluorescence signal can be observed in the instrument room during fine adjustment.

-

8

Add ND filters to the motorized flip mount in the excitation laser path, and be sure the filters are flipped in. The intensity of the fluorescence can be high enough to damage the APDs, so it is best to begin with lower intensity (higher ND) and increase it carefully as the need arises. Keep the intensity well below the damage threshold (~1 MHz count rate) at all times (seeNote 32).

-

9