Soft materials, such as hydrogels, elastomers, and plastics, are pervasive in nature and society. For example, except for teeth, nails, and bones, all other components of the human body are hydrogels, and we eat, wear, and use soft materials as foods, clothes, shoes, and car tires, just to name a few, in our daily life. Although amorphous polymer chains endow soft materials with high flexibility or “softness,” they can also lead to inferior mechanical performances, such as low fracture toughness and low strength, frequently hampering applications and innovations of soft materials. Over recent years, intensive efforts have been devoted to the development of soft materials that possess extraordinary mechanical properties, especially by seeking inspiration from nature and biology. For instance, synthetic hydrogels can now be made much tougher than articular cartilages (1, 2) and more adhesive than mussel glues (3, 4). In PNAS, Wu et al. (5) report the fabrication of bioinspired fibers with both high toughness and high strength by drawing from a hydrogel at ambient temperatures and pressures. This nascent progress in the field raises a generic question. What are the fundamental principles for the design of soft materials to achieve certain mechanical properties in nature and engineered systems? Compared with hard materials such as steels and ceramics, which have been explored over centuries, such principles are still elusive in the field of soft materials.

The goal of this commentary is to elucidate the design principles for soft materials that are both tough and strong, such as natural silks (6) and the hydrogel fibers synthesized by Wu et al. (5). I will show that three design principles are required for soft materials to achieve both high toughness and high strength: (i) high mechanical dissipation and stretchability, (ii) below flaw-sensitive length scale, and (iii) simultaneous stiffening and fracture of significant polymer chains at failure. By drawing from a multiphase self-assembled hydrogel, Wu et al. (5) exploited all three principles to fabricate fibers that were both tough and strong. In control cases, when any principle was violated, the resultant fibers turned out to be brittle and/or weak (5). In the following sections, I will elaborate on these principles and propose possible designs for future soft materials with extraordinary mechanical properties and beyond.

High Mechanical Dissipation and Stretchability

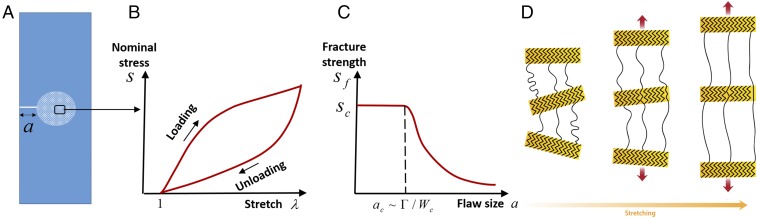

The intrinsic fracture toughness of polymer networks, defined as the energy required to fracture a single layer of polymer chains (7), is on the order of 1∼100 Jm−2, which is much lower than the fracture toughness of articular cartilage (over 1,000 Jm−2). The intrinsic fracture toughness alone cannot give a tough soft material. To design tough soft materials, one needs to induce significant mechanical dissipation in the process zone around the crack tip (Fig. 1A). The total fracture toughness of the soft material can be expressed as (8, 9)

where is the intrinsic fracture toughness and is the contribution from dissipation in the process zone. The mechanical dissipation manifests as a hysteresis loop in the nominal stress-stretch curve of the material (Fig. 1B). Although the failure strengths of soft materials are typically much lower than the failure strengths of hard materials, one can design high stretchability of a soft material to achieve a large area of the hysteresis loop, as shown in Fig. 1B. The mechanisms for dissipating mechanical energy in soft materials include fracture of polymer chains, reversible cross-links, and domain transformations, and the mechanisms for achieving high stretchability include interpenetration of long-chain networks, hybrid physical and chemical cross-links, and high-functionality cross-links (8). A combination of mechanisms for high dissipation and stretchability can give various designs of tough soft materials (8). For example, in Wu et al.’s work (5), reversible cross-links and high-functionality cross-links have been used to give dissipative, stretchy, and thus tough hydrogels (5).

Fig. 1.

Schematic illustration of the design principles for soft materials to be tough and strong. (A) Soft material contains a crack of size a and a process zone around the crack tip. (B) Toughening. High mechanical dissipation in the process zone, manifested as a hysteresis loop in the curve of nominal stress vs. stretch , toughens the material. (C) Flaw-insensitive strength. The fracture strength of a material increases with the decrease of flaw size until the flaw reaches a critical length scale below which the fracture strength is flaw-insensitive . (D) High strength. High-functionality cross-links that accommodate hidden polymer chains can promote simultaneous stiffening and fracture of significant polymer chains, which gives soft material high fracture strength.

Below Flaw-Insensitive Length Scale

The high fracture toughness of a material does not guarantee its high fracture strength. For one thing, the fracture strength can be significantly affected by flaws presented in the material, such as cavities, cracks, and impurities. A critical length scale has been defined as (10, 11)

where is the work to rupture of a material with no flaw or only flaws that do not affect its fracture strength and is a dimensionless parameter that accounts for geometrical and nonlinear effects. If the size of any flaw in the material is larger than , the fracture strength decreases significantly with the flaw size, but if all flaws are smaller than , the fracture strength reaches a plateau value insensitive to flaws (Fig. 1C). This flaw-sensitivity principle applies to both hard and soft materials, and the critical length scale ranges from tens of nanometers for ceramics and glass (11) to millimeters for elastomers and gels (10). Although eliminating flaws from materials is difficult, one can design materials to make all possible flaws smaller than to achieve . In general, enhancing the fracture toughness of a material tends to increase its ; for example, toughening of ceramics (12), elastomers (13), and hydrogels (1, 2) makes them more flaw-tolerant. Another simple approach to achieve flaw-insensitive strength is by making the characteristic length of a material smaller than , such as drawing fibers with diameters equal to or less than (5).

Simultaneous Stiffening and Fracture of Significant Polymer Chains

A flaw-insensitive fracture strength still does not mean a high fracture strength, particularly in soft materials. For instance, the flaw-insensitive fracture strengths of tough hydrogels are usually lower than 1 MPa (1, 2). On the other hand, the ideal fracture strength of soft materials can be extremely high. Let us consider an ideal polymer network with uniform chain lengths and no defect or entanglement (14). By assuming all chains reach extension limit and rupture simultaneously, we can evaluate the ideal fracture strength of the network (in terms of nominal stress) to be

where is the number of polymer chains per unit volume, is the number of Kuhn monomers per chain, is the length of a Kuhn monomer, and is the rupture force of a polymer chain. For a polymer network with a shear modulus of 100 kPa, where is around and , , and are taken as typical values of 100, 1 nm (15) and 4 nN (16), the ideal fracture strength can be estimated to be 1 GPa. (Note the ideal fracture strength in terms of true stress is , which is even higher.) This theoretical limit indicates that it is possible to design extremely strong soft materials, but such design requires a significant amount of polymer chains to reach the extension limit and to rupture simultaneously. However, the polymer networks in real soft materials usually have nonuniform chain lengths and defects; thus, the polymer chains tend to stiffen and fracture in a sequential manner, leading to low fracture strength. One method to promote simultaneous stiffening and fracture of multiple polymer chains is to introduce high-functionality cross-links that accommodate hidden chains (17), such as crystalline domains and nanoparticles with segments of polymer chains embedded in or attached on them. Multiple polymer chains with different lengths bridge two adjacent high-functionality cross-links (Fig. 1D). Under deformation, the shorter chains can pull hidden segments from the cross-links, and eventually reach the extension limit and fracture simultaneously with longer chains (Fig. 1D). In Wu et al.’s hydrogel (5), both silica nanoparticles and crystalline domains were used as high-functionality cross-links. Another possible method for simultaneous stiffening and fracture of polymer chains is to use slidable cross-links that automatically adjust chain lengths during deformation to achieve uniform chain forces throughout the network (18).

Although this commentary has discussed the principles for designing soft materials that are both tough and strong, more and more questions are emerging in this rapidly evolving field. For example, it is equally important to elucidate the design principles for soft materials to achieve other mechanical properties, such as antifatigue, high adhesiveness (3, 4), and low surface friction (19). Beyond mechanical properties, intensive efforts have been devoted to making soft materials responsive to external stimuli, such as temperature, pH, light, and electromagnetic field. What are the design principles for responsive soft materials to achieve high actuation strain and stress, high energy efficiency, and fast response? Furthermore, as soft materials are enabling future electronics, medicine, robots, and machines (20), how can we harness the designed properties of soft materials most effectively to help address societal challenges in relevant areas, such as health care, food, water, and energy?

Acknowledgments

I thank Hyunwoo Yuk for help in drawing the schematic figure. My research is supported by National Science Foundation Grant CMMI-1661627, Office of Naval Research Grant N00014-14-1-0619, and the MIT Institute for Soldier Nanotechnologies.

Footnotes

The author declares no conflict of interest.

See companion article on page 8163.

References

- 1.Gong JP, Katsuyama Y, Kurokawa T, Osada Y. Double‐network hydrogels with extremely high mechanical strength. Adv Mater. 2003;15:1155–1158. [Google Scholar]

- 2.Sun J-Y, et al. Highly stretchable and tough hydrogels. Nature. 2012;489:133–136. doi: 10.1038/nature11409. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Yuk H, Zhang T, Lin S, Parada GA, Zhao X. Tough bonding of hydrogels to diverse non-porous surfaces. Nat Mater. 2016;15:190–196. doi: 10.1038/nmat4463. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Yuk H, Zhang T, Parada GA, Liu X, Zhao X. Skin-inspired hydrogel-elastomer hybrids with robust interfaces and functional microstructures. Nat Commun. 2016;7:12028. doi: 10.1038/ncomms12028. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Wu Y, et al. Bioinspired supramolecular fibers drawn from a multiphase self-assembled hydrogel. Proc Natl Acad Sci USA. 2017;114:8163–8168. doi: 10.1073/pnas.1705380114. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Keten S, Xu Z, Ihle B, Buehler MJ. Nanoconfinement controls stiffness, strength and mechanical toughness of beta-sheet crystals in silk. Nat Mater. 2010;9:359–367. doi: 10.1038/nmat2704. [DOI] [PubMed] [Google Scholar]

- 7.Lake G, Thomas A. The strength of highly elastic materials. Proc R Soc Lond A Math Phys Sci. 1967;300:108–119. [Google Scholar]

- 8.Zhao X. Multi-scale multi-mechanism design of tough hydrogels: Building dissipation into stretchy networks. Soft Matter. 2014;10:672–687. doi: 10.1039/C3SM52272E. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Zhang T, Lin S, Yuk H, Zhao X. Predicting fracture energies and crack-tip fields of soft tough materials. Extreme Mechanics Letters. 2015;4:1–8. [Google Scholar]

- 10.Chen C, Wang Z, Suo Z. Flaw sensitivity of highly stretchable materials. Extreme Mechanics Letters. 2017;10:50–57. [Google Scholar]

- 11.Gao H, Ji B, Jäger IL, Arzt E, Fratzl P. Materials become insensitive to flaws at nanoscale: Lessons from nature. Proc Natl Acad Sci USA. 2003;100:5597–5600. doi: 10.1073/pnas.0631609100. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.McMeeking R, Evans A. Mechanics of transformation‐toughening in brittle materials. J Am Ceram Soc. 1982;65:242–246. [Google Scholar]

- 13.Ducrot E, Chen Y, Bulters M, Sijbesma RP, Creton C. Toughening elastomers with sacrificial bonds and watching them break. Science. 2014;344:186–189. doi: 10.1126/science.1248494. [DOI] [PubMed] [Google Scholar]

- 14.Sakai T, et al. Design and fabrication of a high-strength hydrogel with ideally homogeneous network structure from tetrahedron-like macromonomers. Macromolecules. 2008;41:5379–5384. [Google Scholar]

- 15.Rubinstein M, Colby RH. Polymer Physics. Oxford Univ Press; New York: 2003. [Google Scholar]

- 16.Beyer MK. The mechanical strength of a covalent bond calculated by density functional theory. J Chem Phys. 2000;112:7307–7312. [Google Scholar]

- 17.Fantner GE, et al. Sacrificial bonds and hidden length dissipate energy as mineralized fibrils separate during bone fracture. Nat Mater. 2005;4:612–616. doi: 10.1038/nmat1428. [DOI] [PubMed] [Google Scholar]

- 18.Okumura Y, Ito K. The polyrotaxane gel: A topological gel by figure‐of‐eight cross‐links. Adv Mater. 2001;13:485–487. [Google Scholar]

- 19.Gong JP. Friction and lubrication of hydrogels—Its richness and complexity. Soft Matter. 2006;2:544–552. doi: 10.1039/b603209p. [DOI] [PubMed] [Google Scholar]

- 20.Bauer S, et al. 25th anniversary article: A soft future: From robots and sensor skin to energy harvesters. Adv Mater. 2014;26:149–161. doi: 10.1002/adma.201303349. [DOI] [PMC free article] [PubMed] [Google Scholar]