Abstract

Background

Gavi recommends solar refrigerators for vaccine storage in areas with less than eight hours of electricity per day, and WHO guidelines are more conservative. The question remains: Can solar refrigerators provide value where electrical outages are less frequent?

Methods

Using a HERMES-generated computational model of the Mozambique routine immunization supply chain, we simulated the use of solar versus electric mains-powered refrigerators (hereafter referred to as “electric refrigerators”) at different locations in the supply chain under various circumstances.

Results

At their current price premium, the annual cost of each solar refrigerator is 132% more than each electric refrigerator at the district level and 241% more at health facilities. Solar refrigerators provided savings over electric refrigerators when one-day electrical outages occurred more than five times per year at either the district level or the health facilities, even when the electric refrigerator holdover time exceeded the duration of the outage. Two-day outages occurring more than three times per year at the district level or more than twice per year at the health facilities also caused solar refrigerators to be cost saving. Lowering the annual cost of a solar refrigerator to 75% more than an electric refrigerator allowed solar refrigerators to be cost saving at either level when one-day outages occurred more than once per year, or when two-day outages occurred more than once per year at the district level or even once per year at the health facilities.

Conclusion

Our study supports WHO and Gavi guidelines. In fact, solar refrigerators may provide savings in total cost per dose administered over electrical refrigerators when electrical outages are less frequent. Our study identified the frequency and duration at which electrical outages need to occur for solar refrigerators to provide savings in total cost per dose administered over electric refrigerators at different solar refrigerator prices.

Keywords: Technology assessment, Supply chain, Computational modeling, Vaccine storage, Solar power

1. Introduction

To effectively maintain an adequate supply of life-saving vaccines in low and middle income countries, where electricity supplies can be capricious [1], the World Health Organization (WHO) currently recommends solar refrigerators for regions with less than four hours of electricity per day, on average, and electric mainspowered ice-lined refrigerators (ILRs) for areas with more reliable electricity [2]. Gavi recommends solar refrigerators for locations with fewer than eight hours of electricity per day or power outages that last more than 48 h [3]. The question remains: Do these thresholds identify all locations where solar refrigerators provide value, or can solar refrigerators be a more effective and efficient means of vaccine storage than ILRs in areas with more reliable electricity? To identify additional settings where solar technologies may offer benefits that outweigh their higher price, further evidence is needed.

Efforts to develop and implement new vaccine storage technologies that reduce reliance on the electrical grid have been challenged by the added cost of many new devices, which can be difficult to justify without better understanding their potential value. Though solar direct-drive refrigerators (SDDs) avoid many of the problems associated with the earlier generation of solar refrigerators that require batteries [4], the purchase prices of SDDs remain higher than those of ILRs [5], and uncertainties persist around the useful lifetime of SDDs due to currently insufficient field data [6]. Barriers to proper, timely, and affordable maintenance for SDDs have included limited availability of technicians with the expertise needed to diagnose and repair solar devices in remote regions, as well as lack of personnel willing to climb onto roofs to clean solar panels [4,7]. At the same time, progress has been made in ILR technologies. Newer ILRs can maintain vaccine storage temperatures for over 10 days without electricity [2].

Understanding how unreliable electricity must be in order for solar devices to be favorable over electric mains-powered refrigerators (i.e. on-grid refrigerators, hereafter referred to as “electric refrigerators”) in various settings is important for decision makers to select the most appropriate cold chain equipment for their situation. Computational modeling can help elucidate the potential system-wide implications of changing one or more components in a supply chain prior to deciding whether to invest the resources necessary for implementation [8]. We used simulation modeling to evaluate the impact of SDDs on vaccine supply chain performance and costs under a range of circumstances and to determine the conditions necessary for solar powered storage equipment to be favorable over ILRs.

2. Methods

2.1. HERMES model of the Mozambique vaccine supply chain

Using our HERMES (Highly Extensible Resource for Modeling Event-driven Supply Chains) software platform, our team developed a discrete-event simulation model of the supply chain for WHO Expanded Program on Immunization (EPI) vaccines in Mozambique. As described in previous publications [9–11], HERMES-generated models include virtual representations of every storage and immunization location, storage device, transport route, vehicle, and personnel in the supply chain, as well as each vaccine vial flowing through the system. We populated the model using data from the Mozambique Ministry of Health, the comprehensive multi-year plan, and WHO and UNICEF databases for vaccines and equipment [2,5,12–14]. Supply chain operations follow ordering and shipping policies observed in Mozambique.

Vaccines enter the country supply chain at one national warehouse in the capital city of Maputo, which also serves as a provincial warehouse for Maputo province. Vaccines travel from Maputo to 10 other provincial warehouses by plane or truck. Two provinces supply vaccines directly from their provincial warehouses to all health facilities via monthly distribution loops, in which trucks deliver vaccines to several facilities in a single trip before returning to a warehouse. Seven provinces distribute vaccines monthly to district stores, from which vaccines are either delivered to health facilities or picked up by health workers from the facilities each month. The remaining two provinces use a combination of distribution loops from the provincial warehouses and distribution through intermediary district stores to move vaccines to health facilities. The 1377 health facilities across the country provide routine immunizations each weekday to target groups among the Mozambican population of 26,423,623 [15].

For a baseline comparison between electric and solar powered refrigerators at the district and health facility levels, we modified the supply chain model to relieve storage and transport constraints and assigned only one storage device model per level. The selected device at each level was currently WHO prequalified and had a vaccine storage capacity that most closely matched the storage needs of an average location at that level [2]. This allowed for a comparison between the most suitable ILRs and SDDs for the system, while sensitivity analyses varied characteristics of these devices (as described under Experiments) in order to assess how different devices or future technological developments may impact the results. Every location received a sufficient number of the assigned device to hold the quantities of vaccines needed with a 25% buffer stock, per EPI policy. In all scenarios, the national and provincial warehouses stored vaccines in electric cold rooms. At the lower levels, the baseline comparison assessed ILRs (217 Vest-frost MK 404 across all districts, 1691 Haier HBC 110 across all health facilities) and SDDs (218 Dulas VC 200 SDD across all districts, 1680 SunDanzer BFRV 55 across all health facilities). Table 1 summarizes the characteristics of these refrigerators at baseline and in the following experiments [2,3,5,6].

Table 1.

Characteristics of electric and solar devices studied and sensitivity ranges tested.

| District level refrigerators | Health facility level refrigerators | |||

|---|---|---|---|---|

|

|

|

|||

| Vestfrost MK 404 | Dulas VC 200 SDD | Haier HBC 110 | SunDanzer BFRV 55 | |

| Device type [1] | Electric ice-lined refrigerator | Solar direct drive refrigerator | Electric ice-lined refrigerator | Solar direct drive refrigerator |

| Net vaccine storage capacity, L [1] | 135.0 | 132.0 | 52.5 | 54.5 |

| Purchase price (USD)a [2] | $964 ($482–$1928) | $5060 ($2530–$10,120) | $550 ($275–$1100) | $3235 ($1618–$6470) |

| Holdover time during electrical outage, days [1,3] | 0.97 (0.97–5.34) | N/A | 1.51 (1.02–7.58) | N/A |

Solar refrigerator purchase prices include solar power system.

2.2. Experiments

To identify primary cost drivers of the systems modeled in the baseline comparison, sensitivity analyses compared the selected ILRs and SDDs with varying characteristics and under a broad range of conditions, without electrical outages, to measure the impact of potential changes in device characteristics, real-world deviations from baseline assumptions, and the extent to which cost savings may vary in different settings (for example, many Sub-Saharan African nations have higher costs of electricity than Mozambique [16]). These analyses varied the energy costs, purchase price, maintenance costs (for spare parts as well as labor required for repairs, defrosting and cleaning devices, and cleaning solar panels), and useful lifetime of each device.

Further analyses identified the necessary conditions for a solar refrigerator to offer savings over ILRs with varying holdover times, in scenarios introducing electrical outages of varying durations (one or two days) and frequencies (0–20 times per year). ILR holdover times (i.e. the length of time an electric-powered device can maintain vaccine storage temperatures during an electrical outage, during which the device cannot be opened) varied within the range for currently available ILRs of similar size (Table 1) [3]. Reported results for each scenario are the average over 10 iterations of one simulated year.

3. Results

3.1. Identifying cost drivers

Both systems in the baseline comparison achieved full demand fulfillment due to an absence of electrical outages, with similar non-storage costs ($1,039,751 in labor, $186,512 in building, $3,312,718 in transport for the entire system, on average). We therefore compared the two based on annual storage costs (energy, maintenance, and amortization for storage devices including power system) at the district and health facility levels. Using ILRs at these levels led to $74,066 in energy, $59,226 in maintenance, and $122,838 in amortization costs of storage equipment annually. SDDs at these levels incurred $284,464 in maintenance and $573,313 in amortization costs.

We calculated the annual storage cost savings provided by ILRs as the difference between the annual storage costs accrued when using electric devices at the district and health facility levels and those incurred when using solar refrigerators. Without electrical outages, using ILRs at the district and health facility levels cost $711,351 less in annual storage costs than SDDs ($334,822 as compared to $1,046,173, 2016 USD). In sensitivity analyses (Table 2), varying the purchase price or useful lifetime of solar devices had the greatest impact on cost savings offered by ILRs. Reducing the purchase price by 50% from baseline or doubling the useful lifetime to 20 years for solar devices reduced the annual savings in storage costs to $361,502. Doubling the purchase price from baseline or reducing the useful lifetime to 5 years for solar devices raised the annual storage cost savings to $1,411,049. Cost savings were also relatively sensitive to maintenance costs for solar refrigerators. Reducing annual solar device maintenance costs from the baseline assumption of 5% of the purchase price to 2.5% reduced cost savings to $538,113 annually, while doubling maintenance costs to 10% raised the cost savings to $1,057,826. Varying parameters that influence ILR storage costs (i.e. purchase price, electricity costs, and maintenance costs) had a substantially smaller effect on storage cost savings offered by ILRs.

Table 2.

Cost savings offered by electric refrigerators over solar devices under varying conditions without electrical outages.

| Value (range) | Annual storage cost savings (USD) | |

|---|---|---|

| Baseline | – | $711,351 |

| Sensitivity analyses | ||

| Purchase price of solar devices, as % of current pricea | 100% (50–200%) | $361,502–$1,411,049 |

| Useful lifetime of solar devices, years [3,6] | 10 (5–20) | $361,502–$1,411,049 |

| Maintenance costs of solar devices (annual), as % of purchase pricea [14] | 5% (2.5–10%) | $538,113–$1,057,826 |

| Purchase price of electric devicesa | 100% (50–200%) | $791,263–$551,528 |

| Useful lifetime of electric devices [3,6] | 10 (5–20) | $551,528–$791,263 |

| Electricity costs, per kWh | $0.10 ($0.05–0.20) | $760,581–$612,890 |

| Maintenance costs of electric devices (annual)a [14] | 5% (2.5–10%) | $749,620–$634,813 |

Table 1 lists the purchase price of each device.

3.2. Varying electrical outage frequency and duration

Electrical outages not only caused vaccine spoilage in cases where the outage outlasted the ILR holdover time but also led to missed vaccination opportunities even when using ILRs with longer holdover times. Missed opportunities occurred due to three reasons: the inability to open refrigerators to immunize people during outages at health facilities, stockouts occurring at health facilities when district-level refrigerators could not be opened during outages, and stockouts resulting from vaccine expiry in cases where the outage exceeded ILR holdover times. Simulated people who were turned away from health centers were assumed to not return to the health facility at a later date or seek immunizations at another facility [17–19]. We measured the total cost (for vaccines and supply chain logistics) per dose administered to assess the relative suitability of each type of storage equipment under the conditions in each scenario. This metric captured the reduced number of administered doses, as well as the costs of purchasing and transporting vaccines to replace any vials that may have expired due to temperature excursions (if ILR holdover time was insufficient), during each electrical outage. The total cost per dose administered is calculated as follows:

Logistics costs include the costs of storage (energy, maintenance, amortization), transport (fuel, maintenance, amortization, per diems), buildings (overhead, amortization), and labor (personnel wages for time dedicated to supply chain logistics). Solar refrigerators were deemed cost saving in a given scenario when their use yielded a lower total cost per dose administered than that provided by electric refrigerators under the same conditions. Each threshold at which a solar refrigerator could provide cost savings is reported in terms of the annual cost of each solar device.

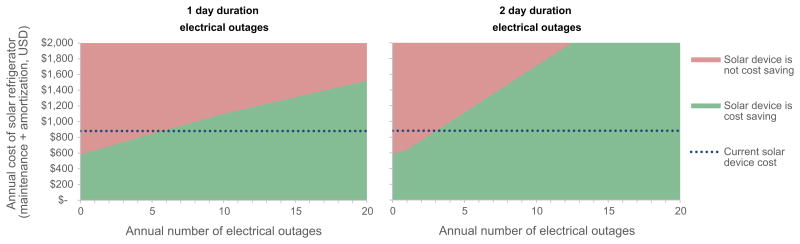

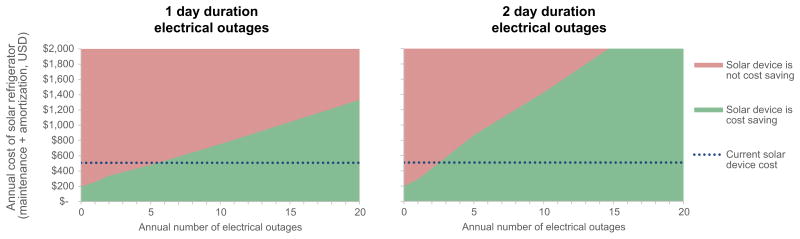

Introducing electrical outages at the district or health facility levels allowed currently available (and substantially more expensive) solar refrigerators to provide a lower total cost per dose administered than ILRs. Even when the ILR holdover time exceeded the duration of the electrical outage, thereby preventing vaccine expiry, the number of doses administered decreased due to missed vaccination opportunities. This phenomenon produced “tipping points” at which the ILRs began performing less effectively and efficiently than solar refrigerators, as measured by savings in the total cost per dose administered. Fig. 1 shows the annual storage cost per district level solar refrigerator necessary to achieve savings under a range of conditions, and Fig. 2 shows the thresholds for the health facility level. The ability of a solar refrigerator at a particular price point to provide cost savings over an ILR varied with the duration and frequency of electrical outages as well as the holdover time of the ILR.

Fig. 1.

Conditions under which solar powered refrigerators can provide savings over electric refrigerators at the district level. The maximum annual cost for each district-level solar device (including amortization and maintenance) that can provide savings over electric mains-powered refrigerators in total cost per dose administered is shown when electrical outages of varying frequency and duration occur at all district level locations. Results assume the electric refrigerator holdover time exceeds the duration of the outage.

Fig. 2.

Conditions under which solar powered refrigerators can provide savings over electric refrigerators at health facilities. The maximum annual cost for each solar device (including amortization and maintenance) that can provide savings over electric mains-powered refrigerators in total cost per dose administered at the health facility level is shown when electrical outages of varying frequency and duration occur at all health facilities. Results assume the electric refrigerator holdover time exceeds the duration of the outage.

Currently available solar refrigerators (costing 132% more in annual storage costs than each electric refrigerator at the district level and 241% more at health facilities) provided a lower total cost per dose administered than electric refrigerators when one-day electrical outages occurred more than five times per year at either level. Current solar refrigerators also provided savings when two-day outages occurred more than three times per year at the district level or more than twice per year at the health facilities. Both levels were sensitive to outage duration, as two-day outages occurring more than three times per year at the district level or more than twice per year at the health facilities also caused solar refrigerators to be cost saving.

If the cost of solar refrigerators decreases from current price points, fewer outages can cause solar refrigerators to provide cost savings. When the annual cost of each solar refrigerator dropped to double that of each ILR, solar refrigerators were cost saving if one-day outages occurred at the district level more than three times per year or at the health facilities more than once annually. Solar refrigerators at this price could also save costs if two-day outages occurred more than twice per year at the district level or more than once annually at the health facilities. More than one annual one-day outage at either level caused solar refrigerators costing 75% more than ILRs to provide cost savings at either level. At this same price, solar refrigerators saved costs when a two-day outage occurred more than once per year at the district level or even once per year at the health facilities. More frequent electrical outages substantially raised the limits on the solar refrigerator costs capable of providing savings. One-day outages occurring 10 times per year allowed a solar device costing 200% more than an electric refrigerator at the district level or 500% more at the health facilities to yield cost savings over ILRs.

3.3. Varying electric refrigerator holdover time

Cost savings thresholds for solar devices were considerably higher when the duration of electrical outages even slightly exceeded the electric refrigerator holdover time. For example, when the district level experienced one-day electrical outages 10 times per year while using electric refrigerators with a holdover time of 0.97 days (the shortest holdover time of similarly sized WHO prequalified ILRs [3]), annual total costs rose by $16,714,073 (from baseline with no outages) and the system administered 890,559 fewer doses, causing the total cost per dose administered to rise from $2.92 to $3.99. In this situation, even a solar refrigerator with an annual cost of $5000 would provide savings over the electric device in terms of the total cost per dose administered. Because the shortest holdover time tested for health facility refrigerators was longer than one day, this trend was observed at the district level only.

4. Discussion

Results suggest that WHO and Gavi guidelines may be appropriate but conservative, as the actual thresholds at which solar refrigerators can provide value may include places with more reliable electricity. Our analysis provides insight into the difference in costs between electric and solar refrigerators, as well as the conditions that produce “tipping points” at which solar refrigerators offer savings in the total cost per dose administered. Though current solar devices were more costly than electric refrigerators when no power outages occurred, introducing even small numbers of daylong electrical outages demonstrated the improvements in performance and efficiency that SDDs can offer over ILRs in areas with substantially more reliable electricity than those indicated by current guidelines. Any cost savings provided by ILRs over SDDs were most sensitive to solar device characteristics, particularly purchase price and useful lifetime. These parameters will likely continue to change with solar technology development and the availability of additional field data. Iterative modeling with updated inputs can continually produce and refine guidelines as to where SDDs may be beneficial.

Though solar refrigerators can offer a reliable option in many settings, especially as they become increasingly more affordable and easy to maintain, other factors may hinder uptake. Current knowledge may be insufficient for decision makers to approve large purchases of solar equipment, as ministries of health may require substantial evidence to support recommendations. As more solar powered options become available, additional data collection will allow further modeling to reveal where new devices would be best suited and ultimately maximize the impact of new storage equipment. To reap the full benefits of solar technology while avoiding pitfalls, immunization programs need to be able to assess the advantages and disadvantages prior to making an investment.

While the WHO and Gavi guidelines may be helpful in identifying places that require off-grid solutions in order to function the majority of the time, these guidelines may not capture all situations where solar devices could offer benefits that outweigh their costs. Computational modeling provides a “virtual laboratory” for testing new technologies with a lower risk of wasting valuable life-saving resources than implementing changes on the basis of trial and error.[20,21] When uncertainties exist around variables such as the useful lifetime of a device, modeling allows in-depth analysis of parameters across a range of scenarios. As available storage equipment evolves, simulation models can continue to test devices in different settings, under different conditions, and with new characteristics. Such analyses can aid public health decision makers in improving vaccine supply chains as well as inform manufacturers regarding the needs of their consumers.

5. Limitations

A model is a simplified representation of reality that cannot capture every feature of a system. This study utilized available data as well as sensitivity analyses to identify where additional data may be most impactful. It is possible that our sensitivity analyses omitted potentially realistic values of the parameters studied, as well as additional factors that may influence cost savings among storage devices. Factors such as installation requirements, access to spare parts, or availability of maintenance technicians were not directly considered but may be represented in sensitivity analyses around the purchase price and maintenance costs. Baseline assumptions entail higher maintenance costs for SDDs than ILRs. As SDDs become increasingly common and the technology develops, maintenance costs will likely decrease and may possibly already rival those of ILRs. If so, this analysis provides a conservative estimate of when SDDs can offer savings. ILRs may display holdover times in the field that exceed WHO estimates.

6. Conclusion

Our study provides support for WHO and Gavi guidelines and in fact shows that solar refrigerators may provide more doses of vaccines at a lower total cost per dose than electrical refrigerators, even when electrical outages are less frequent. The purchase price, useful lifetime, and maintenance costs of solar refrigerators are major drivers of any cost savings offered by ILRs, suggesting a need for additional data and iterative modeling as solar technology advances. We identified thresholds at which solar refrigerators could offer savings over electric refrigerators in order to provide guidance to refrigerator manufacturers, policy makers, funders, and other stakeholders.

Acknowledgments

This work was supported by the Bill and Melinda Gates Foundation, the Agency for Healthcare Research and Quality (AHRQ) via grant R01HS023317, the Eunice Kennedy Shriver National Institute of Child Health and Human Development (NICHD) Office of Behavioral and Social Sciences Research (OBSSR) and the Global Obesity Prevention Center (GOPC) via grant U54HD070725 and NICHD via U01HD086861. Simulations were run on the Olympus High Performance Compute Cluster located at the Pittsburgh Supercomputing Center at Carnegie Mellon University, which is supported by National Institute of General Medical Sciences Modeling Infectious Disease Agent Study (MIDAS) Informatics Services Group grant 1U24GM110707. The funders had no role in the design and conduct of the study; collection, management, analysis, and interpretation of the data; and preparation, review, or approval of the manuscript.

Footnotes

Open Access provided for this article by the Gates Foundation.

References

- 1.VillageReach. Keeping the Cold Chain. Seattle (WA): VillageReach; 2014. [Google Scholar]

- 2.World Health Organization Department of Immunization, Vaccines and Biologicals Quality, Standards and Safety. PQS devices catalogue: prequalified equipment for the Expanded Programme on Immunization (EPI) 2016 Mar 11; [Google Scholar]

- 3.Gavi. Cold chain equipment optimisation platform technology guide. 2016 Feb; [Google Scholar]

- 4.World Health Organization. Introducing solar-powered vaccine refrigerator and freezer systems. Geneva (Switzerland): World Health Organization; 2015. [Google Scholar]

- 5.UNICEF Supply Division. UNICEF supply catalogue. 2016 Apr; Available at: < https://supply.unicef.org/>.

- 6.McCarney S, Robertson J, Arnaud J, Lorenson K, Llyod J. Using solar-powered refrigeration for vaccine storage where other sources of reliable electricity are inadequate or costly. Vaccine. 2013;31:6050–7. doi: 10.1016/j.vaccine.2013.07.076. [DOI] [PubMed] [Google Scholar]

- 7.Van Cuong N. Solar direct drive refrigerators in Vietnam: Summarizing the needs, feasibility, and challenges. TechNet Conference; Bangkok, Thailand: 2015. [Google Scholar]

- 8.Norman BA, Nourollahi S, Chen SI, Brown ST, Claypool EG, Connor DL, et al. A passive cold storage device economic model to evaluate selected immunization location scenarios. Vaccine. 2013;31:5232–8. doi: 10.1016/j.vaccine.2013.08.079. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Assi TM, Brown ST, Djibo A, Norman BA, Rajgopal J, Welling JS, et al. Impact of changing the measles vaccine vial size on Niger's vaccine supply chain: a computational model. BMC Public Health. 2011;11:425. doi: 10.1186/1471-2458-11-425. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Lee BY, Cakouros BE, Assi TM, Connor DL, Welling J, Kone S, et al. The impact of making vaccines thermostable in Niger's vaccine supply chain. Vaccine. 2012;30:5637–43. doi: 10.1016/j.vaccine.2012.06.087. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Lee BY, Connor DL, Wateska AR, Norman BA, Rajgopal J, Cakouros BE, et al. Landscaping the structures of GAVI country vaccine supply chains and testing the effects of radical redesign. Vaccine. 2015;33:4451–8. doi: 10.1016/j.vaccine.2015.07.033. [DOI] [PubMed] [Google Scholar]

- 12.World Health Organization. WHO prequalified vaccines. 2016 Apr; Available at: < https://extranet.who.int/gavi/PQ_Web/>.

- 13.UNICEF. Vaccine price data. 2016 Apr; Available at: < http://www.unicef.org/supply/index_57476.html>.

- 14.Mozambique Ministry of Health. Comprehensive multi-year plan (cMYP) 2012–2016. 2011 [Google Scholar]

- 15.Instituto Nacional de Estatística Moçambique. 2016 Apr; Available at: < http://www.ine.gov.mz/>.

- 16.World Bank. Fact sheet: The World Bank and energy in Africa. The World Bank Group; Available at: < http://web.worldbank.org/WBSITE/EXTERNAL/COUNTRIES/AFRICAEXT/0,,contentMDK:21935594∼pagePK:146736∼piPK:146830∼theSitePK:258644,00.html>. [Google Scholar]

- 17.Favin M, Steinglass R, Fields R, Banerjee K, Sawhney M. Why children are not vaccinated: a review of the grey literature. Int Health. 2012;4:229–38. doi: 10.1016/j.inhe.2012.07.004. [DOI] [PubMed] [Google Scholar]

- 18.Negussie A, Kassahun W, Assegid S, Hagan AK. Factors associated with incomplete childhood immunization in Arbegona district, southern Ethiopia: a case – control study. BMC Public Health. 2016;16:1–9. doi: 10.1186/s12889-015-2678-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Legesse E, Dechasa W. An assessment of child immunization coverage and its determinants in Sinana District, Southeast Ethiopia. BMC Pediatrics. 2015;15:31. doi: 10.1186/s12887-015-0345-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.de Oliveria LH, Danovaro-Holliday MC, Matus CR, Andrus JK. Rotavirus vaccine introduction in the Americas: progress and lessons learned. Expert Rev Vaccines. 2008;7:345–53. doi: 10.1586/14760584.7.3.345. [DOI] [PubMed] [Google Scholar]

- 21.Lee BY, Assi TM, Rookkapan K, Connor DL, Rajgopal J, Sornsrivichai V, et al. Replacing the measles ten-dose vaccine presentation with the single-dose presentation in Thailand. Vaccine. 2011;29:3811–7. doi: 10.1016/j.vaccine.2011.03.013. [DOI] [PMC free article] [PubMed] [Google Scholar]