Abstract

Healthcare is a significant contributor to environmental impact but this has received little attention. The typical laboratory uses far more energy and water per unit area than the typical office building. There is a need to sensitise laboratories to the importance of adopting good environmental practices. Since this comes at an initial cost, it is vital to obtain senior management support. Convincing management of the various tangible and intangible benefits that can accrue in the long run should help achieve this support. Many good environmental practices do not have a cost but will require a change in the culture and mind-set of the organisation. Continuing education and training are important keys to successful implementation of good practices. There is a need to undertake a rigorous cost-benefit analysis of every change that is introduced in going green. The adoption of good practices can eventually lead to ISO certification if this is desired. This paper provides suggestions that will allow a laboratory to start going green. It will allow the industry to enhance its corporate citizenship whilst improving its competitive advantage for long-term.

Introduction

Human activity has a deleterious impact on the environment. The consequences include global warming as a result of energy usage, the rise of seas levels, changes in the ecology and disease patterns. They also involve, inter alia, the loss of irreplaceable resources, a reduction of biodiversity, consumption of energy and water, production of heat, the ever-increasing production of waste and resultant contamination of sites by runoff or landfill. The changes of the various parameters that contribute to and which indicate global warming have been summarised by the National Aeronautical and Space Administration (NASA) of the United States.1

Healthcare practices have a significant impact on the environment. Hospitals operate around the clock, every day and have large environmental footprints. They impact the environment by:

Generating large quantities of waste (including infectious, hazardous, and solid wastes)

Using material that may have toxic effects: including but not limited to: polyvinyl chloride (PVC), diethylhexyl-phthalate (DEHP), cleaning materials, heavy metals in electronics, pesticides, batteries, mercury in medical devices, equipment and light bulbs.

Consuming large amounts of energy, thereby generating significant greenhouse gas emissions

Consuming copious amounts of water.2

In the United States (USA), health-care buildings account for 9% of total primary energy consumption for all commercial buildings. The average health-care facility can use up to and over 2.7 times the annual energy consumption of a typical commercial building.3 Hospitals in the USA produce more than 30 pounds of CO2 emissions per square foot. USA hospitals spend over $5 billion annually on energy, often equalling 1 to 3% of a typical hospital’s operating budget or an estimated 15% of profits.4 According to the World Health Organization (WHO), Brazilian hospitals account for 10.6% of the country’s total commercial energy consumption; in the USA, health-care buildings are the second most energy-intensive buildings in the commercial sector. In the United Kingdom, the National Health Service (NHS) has calculated its carbon footprint at more than 18 million tonnes of CO2 each year which is approximately 25% of total public sector emissions.5

Laboratories are highly energy intensive. The typical laboratory uses 3 to 6 times more energy per unit surface area than the typical office building.6–8 While much of this is due to specialised equipment, a significant amount of energy consumption, (about 50 to 80%), is due to ventilation systems.7,9 The high-energy consumption maybe attributable to the density of high usage equipment; the hours of operation and the need for temperature as well as humidity control.7

Besides energy, laboratories are also significant consumers of water and producers of waste and making the chemicals or emissions of them. It has been estimated that most existing laboratories can reduce their energy consumption by 30 to 50% using existing technology, which is significant given their $1 to 2 billion annual energy costs in the USA.7 Yet, few clinical laboratories have plans in place to address this situation, though most would like guidance if it were available.10 If this excessive, perhaps unconscious, consumption and waste production can be reduced significantly, it can lead to real cost savings as well as an improved environmental footprint.

This commentary is a follow-up to the guidelines on good environmental practice for clinical laboratories that were published in 2012.10 Its purpose is to sensitise laboratories to the importance of such practices. While laws on good practice exist in many countries, especially in regard to waste management, there is a need for laboratories to go beyond existing legislation and take positive steps to identify and reduce their environmental impact.

An Environmental Policy

Rationale for an Environmental Management System (EMS)

Environmental factors are the root cause of a significant burden of morbidity and mortality, particularly in developing countries. The resulting impact is estimated to cause about 25% of death and disease globally, reaching nearly 35% in regions such as sub-Saharan Africa.11 Thus all organisations including laboratories have a societal obligation to do their part to alleviate the harm they do to the environment. However, at this stage, the awareness of the environmental impact of clinical laboratories is limited.10

An organisation may implement an EMS for a variety of reasons. Even if the awareness of their environmental impact may be limited, some organisations may consider implementation of an EMS as an opportunity for innovation and differentiation from competitors. Besides being good for business by attracting new customers who want to buy products and services from an environmentally friendly organisation, such awareness should be useful as a recruiting tool in making the company a more attractive place to work in an age where job seekers increasingly tend to question employer ethics. Such moves will improve corporate image both among the employees and externally among clients and the public at large.

The adoption of an environmental policy tends to be controversial. Firstly, there are up-front costs involved. Furthermore, there is the perception that they do not provide visible benefits for the additional costs, and this belief is exacerbated by the many environmental issues which are beset by scientific uncertainty.

Development of an Environmental Policy

The first step for the introduction of good environmental practices is for a laboratory to make a commitment to reduce its environmental impact. The support of senior management to achieve this goal is imperative. Once this is obtained, the next step will be to develop, enunciate and implement an environmental policy, an example of which is given in reference 10. The environmental policy is essentially a statement of intent, which should aim to instil in the staff awareness and commitment to the goal. Its key features should be the desire to:

Establish and maintain procedures which specify environmental objectives and targets, and, direct efforts towards continual improvement

Minimise consumption of energy and water by appliances12

Reduce waste through the reduction in the use, reuse or recycling of materials13

Review environmental practices at least annually

Engage in advocacy by encouraging customers, suppliers and other stakeholders to mirror the organisation’s commitment to environmental responsibility.10

An important means of achieving the support of senior management will be to demonstrate long-term cost savings, besides the social benefits and the subsequent good public relations that will accrue upon implementation of good environmental practices. Upon approval, there is also the need to assemble a team that will implement the task and to ensure their motivation and involvement. In addition, key stakeholders of the laboratory such as the share holders, senior management, employees, customers of the laboratory such as doctors, suppliers and contractors should be identified for participation in the endeavour.

The Plan-Do-Check-Act Approach for an Action Plan

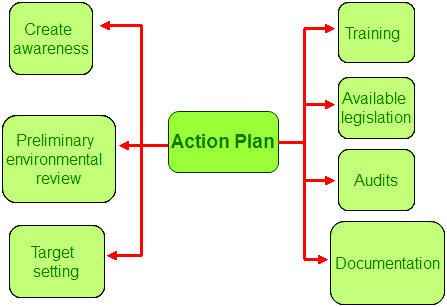

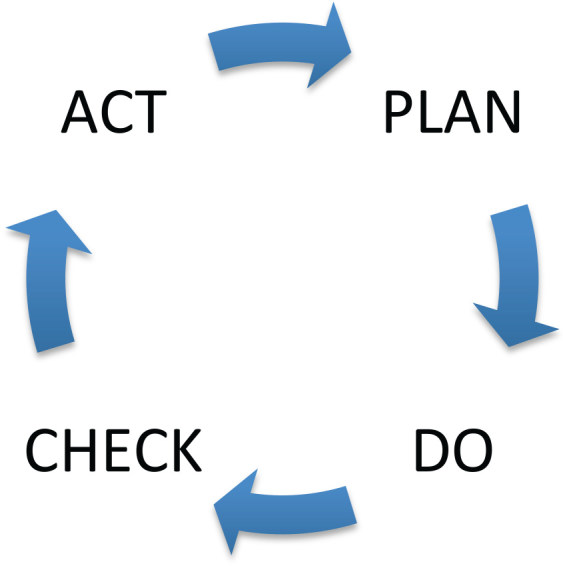

The formulation of a corporate environmental policy should be followed by an action plan (Figure 1). The implementation of the action plan should follow the general tenets of the plan, do, check, act (PDCA) or Deming cycle (Figure 2). This strategy ensures that continual improvement becomes integral to the implementation of the plan.14,15

Figure 1.

Action plan for implementation of good environmental practices in a laboratory

Figure 2.

The PDCA cycle

The 4-stage PDCA cycle provides a simple but effective approach for problem solving and managing change, ensuring that ideas are appropriately tested before committing to full implementation. The PDCA cycle begins with the Plan step which identifies the problem, formulates a specific problem statement and sets attainable and measurable and goals. Do means to “test” where a specific experimental intervention is undertaken, on a pilot basis. A key component of the Do phase is to document important new and changed policies such as Green-Purchasing and a supplier-relationship policy. In the Check phase, the team should gather and analyse data on the solution then evaluate the results. The Act phase is where the full-scale implementation begins. Several factors account for the successful implementation of a PDCA cycle. Team members should decide on data collection tools, be data-driven and evidence-based. Solutions should be not be predetermined. It is important to provide continuous feedback to staff and management. Management support and on-going training are essential, with management review at every phase.14,15

Introduction of Good Environmental Practices

The steps necessary for the implementation of an EMS are common to the implementation of any quality system but with an emphasis on environmental issues. Laboratories may aim for certification under the ISO 14000 standard for environmental management. There is also a need to examine national and local statutory requirements and legislation pertaining to environmental issues specific to a product or service, which could include the storage and disposal of dangerous goods, the licence to discharge wastes to sewer, fire and building laws and permits.

Potential Targets for the Application of Good Environmental Practices

Underlying the application of good environmental practices are three basic principles to reduce, reuse and recycle materials, especially consumables.10 Each application of good environmental practices may involve one of more of these principles.

The laboratory should initially set achievable targets for the introduction of good environmental practices. These involve the reduction of energy and water consumption, consumables and waste generation, and the recycling of waste, where possible. In addition, the laboratory should engage in advocacy of good environmental practices with all its stakeholders.10 A list of specific targets for the application of such practices is presented in Table 1. It is not comprehensive but does give the key areas for the laboratory to focus on at the initial stages. The guidelines previously discussed10 could be used to achieve this goal. Environmental targets and action plans that are agreed to should be reviewed regularly. Where possible, these goals should be linked to cost reduction.

Table 1.

Initiation of sustainable environmental practices - examples of targets for laboratories to initiate sustainable environmental practices.

| Area | Action |

|---|---|

| Laboratory materials | Reduce the use of SST and other plastics where feasible |

| Reuse specimen collection bags and urine collection bottles | |

| Purchase recycler for xylene and formalin recycling | |

| Reduction of energy consumption |

|

| Green purchasing policies* | Pre-purchase considerations for instruments, equipment:

|

Packaging:

| |

Reagents:

| |

| Purchase items that are manufactured locally or as nearby as possible to reduce carbon footprint | |

| Use recycled and recyclable lab furniture where possible | |

| Wastes | Chemical Wastes - implement a hazardous and overall waste reduction plan which should include:

|

| Purchase a Styrofoam compressor | |

| Reduction of water consumption |

|

| Xeriscaping of surroundings | |

| Pollution | Reduce pollution:

|

| Building |

|

| Staff |

|

| Administration | Reduce paper usage:

|

e.g. See the Abington Memorial Hospital Green Hospital Pilot Best Practice: Environmental Purchasing Guidelines: http://www.hcifonline.org/content/document/detail/933

Key Targets within the Laboratory

While several opportunities exist for reducing or reusing materials, the following key areas should be examined for immediate attention:

Reduction of tests: audits should be undertaken with the aim to reduce unnecessary testing by removing out-dated tests and rejecting unnecessary test requests.10

Reduction of serum-separation tubes (SST): Blood specimens for most tests can be collected using a single SST. This follows from fewer daughter tubes required from more consistent and thoughtful tube collection requirements combined with sequential rather than parallel processing in laboratories. One study showed that an increase in the number of single SST tubes collected per episode from 62.64% in March 2006 to 85.15% in July 2009 meant that 600,000 fewer tubes were used in 2009 i.e. that were collected, transported, refrigerated and disposed of in the laboratory.16

Reuse: Laboratories should identify items that can be reused. The reuse needs to be limited to a specific number of recycles in order to ensure the integrity of materials. A key target will be the reuse of plastic specimen bags that are often discarded after single use. These can be reused without compromising laboratory safety. The same applies to 24 h urine bottles.

Organic solvents: Xylene and formalin should be targeted for recycling on-site. While there is an initial cost attached to the purchase of the recycler, this has been shown to be offset in about 2 years by cost savings from reduced solvent purchase and waste disposal.17

Solid wastes: Laboratories can negotiate with suppliers to take back and reuse packaging materials such as Styrofoam and all packaging paper and cardboard products. Electrical and electronic wastes such as fluorescent tubes, batteries, phones, computers, etc. should be recycled or disposed of in accordance with local regulations.

Green purchasing: The application of good environmental practices should not be confined to only the clinical laboratory but should include its suppliers. A green purchasing policy should be implemented which suppliers and contractors are made aware of. Some manufacturers are fully aware of the importance of good environmental practices both for the laboratory and in their manufacturing processes. They should be persuaded of the importance of the development of analysers and reagents that are environmentally friendly in terms of: energy and water consumption, heat generation, biodegradable reagents, packaging and low solid waste production.

Administration: Several opportunities exist to reduce the usage of materials in administration. Paper usage is a target and it may be reduced by using both sides. Paper audits should be instituted.

General recycling: Laboratories should adopt financially feasible recycling programmes. It could begin with separate bins for different kinds of solid wastes, shredding confidential waste paper as it is generated, then send it for recycling.

Reduced energy consumption and waste production: Conducting an energy and waste audit can highlight opportunities for good practice.

Much of the literature focusses on reducing the carbon footprint and sometimes environmental considerations may conflict with existing legislation and regulations (for example, recycling specimen plastic bags, infection control issues in reducing air-conditioning, staff safety vs reducing lighting). These matters need to be borne in mind and it is likely matters that are legislated or regulated take priority, however, this is only one aspect of an environmental policy and the low-hanging fruit listed above are an easier place to start. It is salutary to consider the total waste disposal process, particularly beyond the laboratory (e.g. what is the end-process of sharps disposal?).

Targets Involving Stakeholders of the Laboratory

Advocacy of good environmental practices requires the involvement of stakeholders.

Staff should be appraised to the goals of good environmental practices such as reduced energy consumption. In addition, they should be provided with incentives to use transportation that reduces their individual carbon footprint such as public transport, car-pooling or bicycles. There is better chance of success if senior management sets the example.

Suppliers: All components of the clinical laboratory supply chain should be invited to participate in the efforts to reduce an organisation’s carbon footprint. Suppliers and contractors should be co-opted into the laboratory’s attempts to introduce good environmental practices. A supplier-relationship policy should be formulated.

Targets Involving Laboratory Infrastructure

The renovation of existing laboratories or construction of new laboratories presents the occasional opportunity for the application of good environmental practices. Leadership in Energy and Environmental Design (LEED) is a green building certification program that recognises best-in-class building strategies and practices. LEED certified buildings save money and resources, and have a positive impact on the health of occupants. The use of a LEED certified architect should help achieve this goal.18,19

Fittings: Good environmental practice can be applied when installing or changing the fittings of a building and the laboratory through the use of refurbished equipment and recycled materials manufactured using environmentally sustainable practices.19–21

Costs and Benefits

The implementation of an EMS should always take into account the costs that will be incurred. However, the adoption of some practices involve only a change of the mind-set and culture of a laboratory and only cost the organisation the effort of educating staff.

Where significant costs are involved, it is necessary to perform a rigorous cost-benefit analysis of the various changes that are being considered. Capital and conversion costs should be monitored together with recurrent expenses, where this is appropriate. The sources of information for such monitoring include quotations for goods and services, corporate payables, information of stocks and all other relevant records. As with quality assurance, the use of graphs which monitor the usage of tubes, paper, energy and water, for example, provides crucial feedback to staff and management (Table 2).

Table 2.

Examples of targets and action plans in the implementation process.

| Programmes and procedures | Frequency (monthly) | Associated records |

|---|---|---|

| Monitor plain paper usage | 3 |

|

| Monitor SST usage | 3 |

|

| Monitor energy and water usage | 12 |

|

| Train staff in EMS | As required | Training records, assessment forms, certificates for staff who have been trained |

| Report for corporate management review meeting | 6 | Meeting minutes |

Infrastructure that is green is often more expensive. A new recently constructed environmentally-friendly healthcare centre in Indonesia was estimated to cost 30% higher than a building without these features.19 Environmentally friendly products are often sold at a premium. Though the higher price of green versions of freezers or biosafety cabinets has sometimes deterred laboratories, it should be weighed against the reduced operating cost over the life of the equipment.22

There have been a few published case studies of the implementation of ISO 1400023,24 and some restricted cases have been presented.24,25 Specific savings flowing from the adoption of a green approach have also been published which detail significant savings in blood collection volumes and tubes that flow from a careful assessment of required serum volumes and the impact of collecting, processing and storing redundant tubes.16,25

Changing an automated laboratory system offers the opportunity to make significant enhancements to good environmental practices. As an example, the switch to the Siemens’ ADVIA® LabCell® Automation System for one laboratory brought about benefits for both patients and the laboratory. Each patient was only required to give half of the previous amount necessary for a blood sample. In addition, the number of blood tubes collected from each patient was cut by half. This was extremely important from both a financial and an environmental standpoint as it involved lower material costs, decreased water usage and lessened waste. As a result, the laboratory was able to reduce overall costs by 30 percent. The new system also meant that the laboratory operations generated 30 tons less material waste each year, with nearly a million sample tubes saved in a single year, as well as a reduction in solid waste volume by 61% and liquid waste by 74%. Its in-house water production and consumption were also cut back by 40% due to the reduction in the quantity of blood tubes needed from each patient.25

Waste Management

The definition of waste is still largely internal to an organisation. While the impact of each source of waste may seem relatively minor, their potential cumulative effect can be significant on large ecosystems and the planet.

Waste usage needs to be measured and managed. There are four tiers to waste management, these being (i) to reduce its environmental impact i.e. pollution prevention and source reduction; (ii) reuse or redistribution of unwanted, surplus materials; (iii) treatment, reclamation, and recycling of materials within the waste; and (iv) disposal through incineration, treatment, or land burial. The best strategy for managing laboratory waste is to maximise safety and minimise environmental impact. These objectives should be considered from the time of purchase. The overriding principle governing the prudent handling of laboratory waste is that no activity should begin unless a plan for the disposal of non-hazardous and hazardous waste has been formulated. Application of this simple principle ensures that the numerous state and federal regulatory requirements for waste handling are met and unexpected difficulties, are avoided such as the generation of a form of waste (e.g., chemical, radioactive, biological) that the institution is not equipped to deal with.26

Future Developments in Biodegradable Plastics

Single-use plastics in the laboratory are an important potential target for change. Though not widely available at present, several companies have been working to develop plastics that are made from renewable and biodegradable sources. These include BASF and NatureWorks (Innetonka, Minnesota, USA).27,28 BASF has developed a compostable polyester film called “Ecoflex®” and are making and marketing fully biodegradable bags, “Ecovio®,”made of this film along with cassava starch and calcium carbonate.

Implementation Strategies

Not all staff may support the EMS principle, although the concepts of an EMS are more easily understood than many other ‘quality’ initiatives. While staff may agree with the concept of greater environmental responsibility they may see the documentation and the audit rigor required as an excuse for cost cutting or as being overly bureaucratic. Any organisational change as significant as implementing an EMS needs sustained management input.23

As with any such cultural change there are a number of different approaches to the implementation, particularly in an organisation that may be large, complex and or have a potentially broad geographical spread. If we consider the ultimate target as being the point in time when the entire organisation is certified to the ISO 14000 Environmental Standard, it is possible to plan the implementation as one major step, where there is training of all staff, wholesale changes to procedures across the organisation and then a move to get the organisational certification.24 Another approach is to consider the certification as a series of steps where individual departments or laboratories in a network achieve certification in a somewhat piecemeal way. The first parts of the organisation that move on the implementation will be those where there is a champion or good staff support for the concept. This approach allows demonstration projects to be undertaken which can be used to prove the benefits of the implementation and convert other staff. Such a technique can be very successful and although it may be slower than the first approach it may be more sustainable in changing cultural values. There are of course implementation strategies that lie between these extremes and they should be adopted depending on the organisation and its staff and their willingness to make the necessary behavioural changes.

Conclusion

The key to greater adoption of an EMS is awareness of what it entails and of the benefits it brings. An EMS is a fiscally appropriate approach that leads to innovation that reduces the environmental impact and meets the social responsibilities of clinical laboratories and those organisations that are involved with them. Many practices involve a change of culture. There are numerous steps which can be taken, some at modest costs, but many at minimal or none at all. Some of the steps needed to implement a successful environmental management system may be complex or overly expensive and they will require senior management leadership and support. Convincing management of the benefits including cost-savings in the long-term are crucial. What is described in this paper is a basis for the green or sustainable toolbox that will allow a laboratory to enhance its corporate citizenship whilst improving its competitive advantage for long-term growth.

Footnotes

Competing Interests: None declared.

References

- 1.Global Climate Change. http://climate.nasa.gov (Accessed 10 October 2016)

- 2.Sustainable Healthcare. https://archive.epa.gov/region03/green/web/html/healthcare.html (Accessed 19 February 2016)

- 3.Sustainable Energy for All. https://www.accenture.com/us-en/~/media/Accenture/Conversion-Assets/DotCom/Documents/Global/PDF/Strategy_5/Accenture-Sustainable-Energy-for-All-The-Business-Opportunity.pdf (Accessed 19 February 2016)

- 4.Department of Energy Announces the Launch of the Hospital Energy Alliance to Increase Energy Efficiency in the Healthcare Sector. http://energy.gov/articles/department-energy-announces-launch-hospital-energy-alliance-increase-energy-efficiency (Accessed 19 February 2016)

- 5.World Health Organization and Health Care Without Harm. Healthy Hospitals – Healthy Planet - How the health sector can reduce its climate footprint. http://cape.ca/wp-content/uploads/2013/10/Climate-Footprint-of-Hospital-Report-June-09.pdf (Accessed 19 February 2016)

- 6.Hopkinson L, James P, Lenegan N, McGrath T, Tait M. http://www.goodcampus.org/files/files/60-SLab_Energy_Audits_of_HE_Labs_final_v15_4_7_11.pdf (Accessed 19 Feb 2016); also available at http://www.docfoc.com/s-lab-energy-audits-of-he-labs-final-v15-4-7-11.

- 7. Laboratories for the 21st Century: Best Practice Guide – Optimizing Laboratory Ventilation Rates. http://www.i2sl.org/documents/toolkit/bp_opt_vent_508.pdf (Accessed 20 February 2016)

- 8.Hospitals: Healthy budgets through energy efficiency. http://www.carbontrust.com/media/39216/ctv024_hospitals.pdf (Accessed 20 February 2016)

- 9.Neuman V. Optimizing Laboratory Exhaust Systems. The Lab Manager. 2013 http://www.labmanager.com/lab-design-and-furnishings/2013/04/optimizing-laboratory-exhaust-systems?fw1pk=2#.VZTnrIcxFAY (Accessed 21 February 2016) [Google Scholar]

- 10.Lopez JB, Badrick T. Proposals for the mitigation of the environmental impact of clinical laboratories. Clin Chem Lab Med. 2012;50:1559–64. doi: 10.1515/cclm-2011-0932. [DOI] [PubMed] [Google Scholar]

- 11.Smith KR, Corvalán CF, Kjellstrom T. How much global ill health is attributable to environmental factors? Epidemiology. 1999;10:573–84. [PubMed] [Google Scholar]

- 12.Green Lab Facilities – Steps Toward Sustainability. https://www.downloads.siemens.com/download-center/d/Green-Lab-Facilities---Steps-Toward-Sustainability--Technology-Report_A6V10305003_usen.pdf?mandator=ic_bt&segment=HQ&fct=downloadasset&pos=download&id1=A6V10305003 (Accessed 11 January 2017)

- 13.Less is Better – Guide to minimizing waste in laboratories. Task Force on Laboratory Environment, Health, & Safety. American Chemical Society; 2002. http://www.acs.org/content/dam/acsorg/about/governance/committees/chemicalsafety/publications/less-is-better.pdf. [Google Scholar]

- 14.The W. Edwards Deming Institute: PDSA Cycle. https://www.deming.org/theman/theories/pdsacycle (Accessed 23 February 2016)

- 15.Plan-Do-Check-Act (PDCA). https://www.mindtools.com/pages/article/newPPM_89.htm (Accessed 23 February 2016)

- 16.Hobson P, Badrick T. The impact on costs and efficiency of reducing the number of collected tubes. Clin Chem Lab Med. 2013;51:e53–4. doi: 10.1515/cclm-2012-0447. [DOI] [PubMed] [Google Scholar]

- 17.Grushka MJ, Spark RP. Recycling xylene saves money and the environment. MLO Med Lab Obs. 1991;23:55–6. 58, 60. [PubMed] [Google Scholar]

- 18.Leadership in Energy and Environmental Design. http://www.usgbc.org/leed (Accessed 23 February 2016)

- 19.Lopez JB, Hoyaranda E, Priatman I. The first green diagnostic centre and laboratory building in Indonesia. eJIFCC. 2016;27:84–87. ( http://www.ifcc.org/media/406628/eJIFCC2016Vol27No1pp084_087.pdf; Accessed 23 February 2016). [Google Scholar]

- 20. Thermo Scientific Hamilton – Laboratory Furniture and Air Flow Products – Environmental Responsibility. https://static.thermoscientific.com/images/D16527~.pdf (accessed 23 Feb 2016)

- 21. Examples of Green Chemistry. http://www.acs.org/content/acs/en/greenchemistry/what-is-green-chemistry/examples.html (Accessed 23 February 2016)

- 22. Going Green Economically. http://www.laboratoryequipment.com/article/2009/08/going-green-economically (Accessed 11 January 2017)

- 23.Reid E, Kehrer S, Badrick T. Outcomes and challenges of implementing an ISO 14001:2004 environmental management system in a clinical laboratory. Aust J Med Sci. 2012;33:88–95. [Google Scholar]

- 24.Badrick T, Kehrer S, Reid E. For the greater good: a laboratory reduces waste, enhances efficiency and staff engagement with ISO 14001. Quality Progress. 2013;46:25–31. [Google Scholar]

- 25.Meyer M. Sustainable change. Medical Solutions. 2010 Sep; http://www.siemens.com/about/pool/de/unser_geschaeft/healthcare/diagnostics/medical-solutions-sustainable-change.pdf (Accessed 10 October 2016) [Google Scholar]

- 26.Prudent Practices in the Laboratory: Handling and Management of Chemical Hazards: Updated Version. 8. Management of Waste. https://www.ncbi.nlm.nih.gov/books/NBK55885/ (Accessed 30 September 2016)

- 27.Biodegradable and compostable packaging solutions with ecoflex®. http://product-finder.basf.com/group/corporate/product-finder/en/brand/ECOFLEX (Accessed 23 February 2016)

- 28. From Plants to Plastics. http://www.natureworksllc.com/The-Ingeo-Journey/Eco-Profile-and-LCA/How-Ingeo-is-Made (Accessed 23 February 2016)