Abstract

Additive manufacturing (AM) alias 3D printing translates computer-aided design (CAD) virtual 3D models into physical objects. By digital slicing of CAD, 3D scan, or tomography data, AM builds objects layer by layer without the need for molds or machining. AM enables decentralized fabrication of customized objects on demand by exploiting digital information storage and retrieval via the Internet. The ongoing transition from rapid prototyping to rapid manufacturing prompts new challenges for mechanical engineers and materials scientists alike. Because polymers are by far the most utilized class of materials for AM, this Review focuses on polymer processing and the development of polymers and advanced polymer systems specifically for AM. AM techniques covered include vat photopolymerization (stereolithography), powder bed fusion (SLS), material and binder jetting (inkjet and aerosol 3D printing), sheet lamination (LOM), extrusion (FDM, 3D dispensing, 3D fiber deposition, and 3D plotting), and 3D bioprinting. The range of polymers used in AM encompasses thermoplastics, thermosets, elastomers, hydrogels, functional polymers, polymer blends, composites, and biological systems. Aspects of polymer design, additives, and processing parameters as they relate to enhancing build speed and improving accuracy, functionality, surface finish, stability, mechanical properties, and porosity are addressed. Selected applications demonstrate how polymer-based AM is being exploited in lightweight engineering, architecture, food processing, optics, energy technology, dentistry, drug delivery, and personalized medicine. Unparalleled by metals and ceramics, polymer-based AM plays a key role in the emerging AM of advanced multifunctional and multimaterial systems including living biological systems as well as life-like synthetic systems.

1. Introduction

First introduced during the 1980s to serve the highly specialized needs of model making and rapid prototyping (RP), additive manufacturing (AM) alias 3D printing has emerged as a versatile technology platform for computer-assisted design (CAD) and rapid manufacturing. AM allows the production of customized parts from metals, ceramics, and polymers without the need for molds or machining typical for conventional formative and subtractive fabrication. Today 3D printers are commercially available for less than $500, enabling desktop fabrication of 3D objects even at home. In the same way that the development of digital 2D printing together with desktop publishing has revolutionized communication and information technology, the development of AM technologies in conjunction with the “internet of things” has the potential to revolutionize computer-guided fabrication of both complex objects and multifunctional materials systems. Whereas conventional fabrication is governed by processing constraints related to industrial mass production, AM is inherently agile enabling faster turnaround on design and manufacturing of customized objects tailored to meet the demands of individuals and specific applications. In literature, the terms additive manufacturing, rapid prototyping, layered manufacturing, solid freeform fabrication, 3D fabbing, and 3D printing are used more or less synonymously. While “additive manufacturing” is preferred by most engineers, the term “3D printing” is far more common particularly in the popular media. In this work, the terms “additive manufacturing” (AM) and 3D printing are both used to describe the same general manufacturing principle.

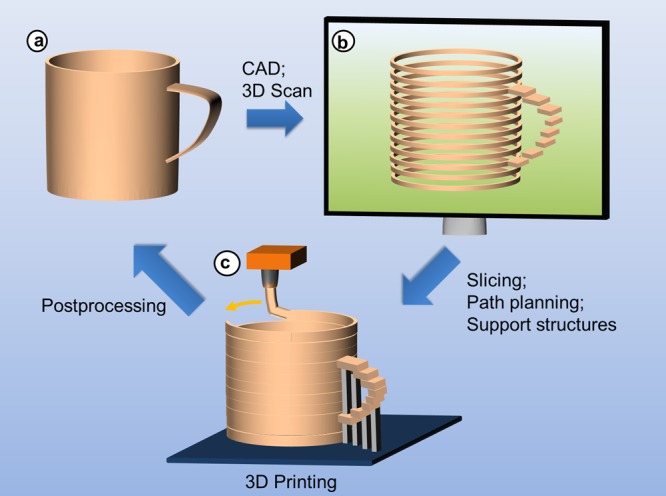

AM allows the production of 3D structures with high shape complexity. Although a coffee mug is not very complex, it provides a convenient object to demonstrate the concepts of AM (Figure 1). In the first step, CAD is used to create a virtual object, which is then digitally sliced. Objects with overhanging portions (i.e., the coffee mug handle) are designed with temporary support structures to prevent collapse during the build process. The coordinates of the virtual object and digital slices are then used to steer the motors, which control the position of the building device or the 3D-dispenser orifice, respectively. For practical purposes, this type of computer-aided manufacturing (CAM) is normally performed layer by layer with typical layer thicknesses ranging from 15 to 500 μm. When the layer thickness is below 50 μm, the naked eye will in most cases not be able to recognize the stair-steps associated with a layered manufacturing approach. For thicker layers or in demanding applications, postprocessing may be used to remove support structures or to improve surface properties. As compared to conventional polymer processing (see Figure 2) by formative techniques like injection molding and subtractive techniques like CNC machining, AM is slower but enables CAD-guided fabrication of multifunctional material systems with complex shapes and functionalities, including bio systems.

Figure 1.

Basic principles of additive manufacturing. (a) Development of product idea that is transformed into digital data by means of CAD, or analysis of geometric data by means of 3D scanning; (b) preprocessing of model data: slicing of virtual model into layered data, adjustment of support structures to stabilize craning structures, path planning, and successive transfer of layered data to 3D printer; (c) and additive manufacturing of model or product, for example, by melt extrusion, postprocessing to remove typical artifacts including support structures and surface roughness due to staircase effects.

Figure 2.

Comparison of (a) subtractive, (b) additive, and (c) formative manufacturing techniques.

With the development of easy-to-use systems exhibiting sufficiently fast build-speeds and decreased system prices, AM has moved from the arena of niche-manufacturing processes into the spotlight of a much larger audience. Despite the significant progress that has been achieved in recent years, there are still a number of challenges that need to be tackled to establish AM as a manufacturing tool on a large scale. Many of these challenges are related to the insufficient material properties (thermomechanical properties, anisotropy, porosity, long-term stability, cost, corrosion properties, creep, etc.) of the currently used build materials. With a focus on polymeric materials, this Review describes the different AM processes that use polymers along with the technical requirements of the utilized materials. Critical points, which currently limit the further use of AM in manufacturing, will be pointed out, and possible strategies for overcoming these issues will be discussed.

The increasingly large number of AM processes can be categorized employing different criteria, ranging from the application (visual prototyping, functional prototyping, rapid tooling, and rapid manufacturing) to the initial condition of processed materials or the physical principle underlying the mostly layerwise solidification process.1 In 2009 the ASTM International Committee F42 on Additive Manufacturing Technology defined a number of terms to distinguish additive manufacturing technologies from their formative and subtractive competitors (Figure 2) and to classify different additive manufacturing processes.2,3 We aim to follow this nomenclature in the course of this Review:

Material extrusion is an additive manufacturing process in which material is selectively dispensed through a nozzle. Fused deposition modeling (FDM), fused filament fabrication (FFF), 3D dispensing, and 3D bioplotting fall into this category.

Material jetting is an additive manufacturing process in which droplets of build material (such as photopolymer or thermoplastic materials) are selectively deposited. Systems based on inkjet-printing fall into this category.

Binder jetting is an additive manufacturing process in which a liquid bonding agent is selectively deposited to fuse powder materials.

Sheet lamination is an additive manufacturing process in which sheets of material are bonded together to form an object.

Vat photopolymerization is an additive manufacturing process in which liquid photopolymer in a vat is selectively cured by light-activated polymerization. Many of the lithography-based AM approaches (e.g., multiphoton polymerization (2PP), digital light processing (DLP), and stereolithography (SLA)) can be grouped into this category.

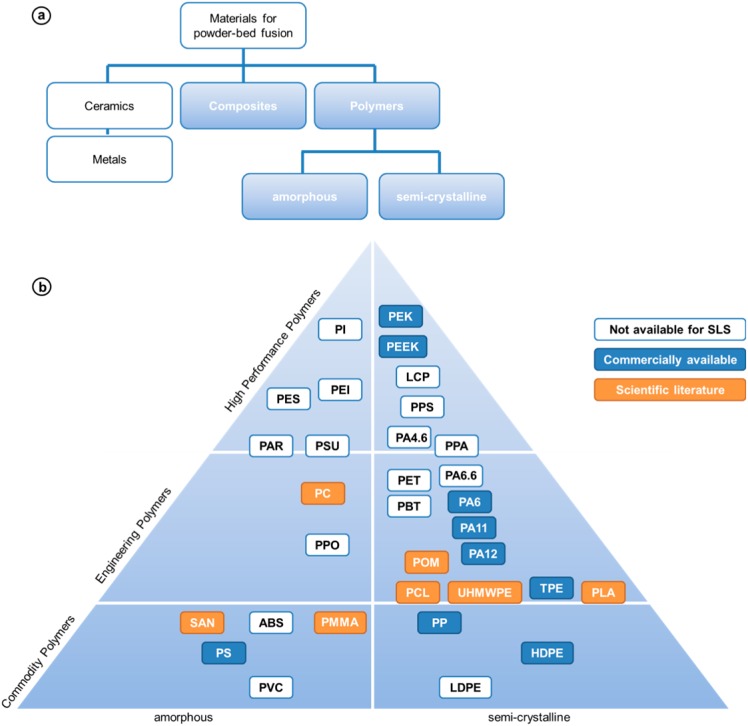

Powder bed fusion is an additive manufacturing process in which thermal energy (provided, e.g., by a laser or an electron beam) selectively fuses regions of a powder bed. Selective laser sintering (from 3D Systems) and laser sintering (from EOS), both of which are abbreviated in this Review as SLS, and electron beam machining (EBM) fall into this category. These processes are used for metals as well as polymers.

Directed energy deposition is an additive manufacturing process in which focused thermal energy (e.g., laser or plasma arc) is used to fuse materials by melting as they are being deposited. This process is currently only used for metals.

Table 1 lists the AM techniques covered in this Review with some of their more pertinent features and limitations. The typical and largest build volumes for commercially available instruments are also listed and named in parentheses.

Table 1. Categorized AM Techniques for Polymers along with Advantages and Disadvantages.

| categorized techniques | typical and largest build volume | typical feature resolution | typical materials | advantages | disadvantages |

|---|---|---|---|---|---|

| Vat Photopolymerization | |||||

| exposure from top | 250 × 250 × 250 mm3 | 50–100 μm | acrylates/epoxides | excellent surface quality and precision | limited mechanical properties |

| 800 × 330 × 400 mm3 (Prodways) | |||||

| CLIP | 150 × 80 × 300 mm3 | 75 μm | acrylates | high build speed | low-viscosity resins required |

| exposure from bottom | 100 × 100 × 100 mm3 | 25–100 μm | acrylates/epoxides | low initial vat volume; better surface quality | limited mechanical properties |

| 300 × 300 × 300 mm3 (DigitalWax 30X) | |||||

| multiphoton lithography | 5 × 5 × 1 mm3 | 0.1–5 μm | acrylates | very high resolution | low build speed; limited materials |

| 100 × 100 × 3 mm3 (Nanoscribe) | |||||

| Powder Bed Fusion | |||||

| polymer SLS | 250 × 250 × 250 mm3 | 50–100 μm | PA12, PEEK | best mechanical properties; less anisotropy | rough surfaces; poor reusability of unsintered powder |

| 1400 × 1400 × 500 mm3 (Huake 3D HKS1400) | |||||

| Material and Binder Jetting | |||||

| polyjet | 300 × 200 × 150 mm3 | 25 μm | acrylates | fast; allows multimaterial AM | low viscosity ink required |

| 1000 × 800 × 500 mm3 (Objet 1000) | |||||

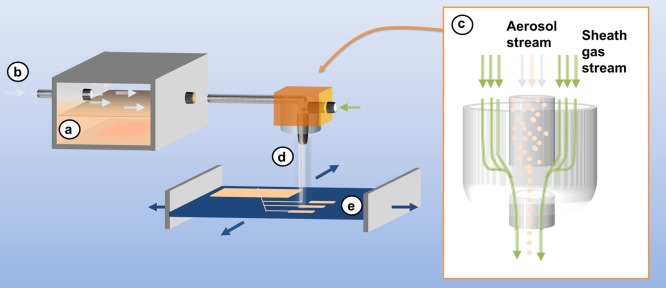

| aerosol jet printing | 200 × 300 × 200 mm3 (Aerosol Jet 5X) | 10 μm | conductive inks/dielectrics | high resolution; low temp process | low viscosity ink required |

| 3D printing (binder jetting) | 200 × 250 × 200 mm3 | 100 μm | starch, PLA, ceramics | fast; allows multimaterial AM; low temp | limited strength of parts; rough surfaces |

| 1000 × 600 × 500 mm3 (Voxeljet) | |||||

| Sheet Lamination | |||||

| laminated object manufacturing | 170 × 220 × 145 mm3 (Solidimension SD300) | 200–300 μm | PVC, paper | compact desktop 3D printer | limited materials; low resolution; high anisotropy |

| Material Extrusion | |||||

| FDM | 200 × 200 × 200 mm3 | 100–150 μm | ABS, PLA, PC, HIPS | inexpensive machines and materials | rough surfaces; high temperature process |

| 1005 × 1005 × 1005 mm3 (BigRep One) | |||||

| 3D dispensing | 150 × 150 × 140 mm3 (3D Bioplotter) | 100 μm to 1 cm | thermo-plastics, composites, photoresins, hydrogels, biomaterials | broad range of materials | rough surfaces; narrow viscosity process window |

1.1. Scientific and Technological Impact

The scientific and technological impact of AM has steadily increased since the first commercial instruments were introduced in the late 1980s. Figure 3 represents this trend graphically by tracing the yearly number of scientific publications and patents from 1985 to 2016 using the terms “additive manufacturing” and “rapid prototyping” (Figure 3). As testimony to these developments, references for books and review articles from this time period on AM and RP are provided here.1,4−9 Whereas interest in “additive manufacturing” has grown steadily for the last 25 years, the comparatively younger field of bioprinting (which is based on AM) has witnessed a comparatively impressive increase in patents and publications within the past decade. This growth (expressed in units on the right-hand side of Figure 3 for better comparison) is expected to continue and may in the near future reach the levels of AM and RP.

Figure 3.

Research interest in rapid prototyping, 3D printing, additive manufacturing and bioprinting, as indicated by the number of hits per annum for the respective terms (data from Web of Science, accessed July 27, 2017).

1.2. Economic Impact

The initial economic motivation for the development of AM in the 1980s (better known as RP at that time) was to accelerate and lower the costs related to product development. In comparison to subtractive manufacturing technologies such as computerized numerical control (CNC) machining, AM is less wasteful (in terms of both construction material and replacement machine tools) and enables the incorporation of more complex internal substructures and undercuts. By providing designers with novel processes enabling them to efficiently create and amend physical models for validation purposes, design mistakes could be identified earlier. Resulting amendments were shifted to earlier stages of product development, enabling design security and eliminating the need for expensive corrections at later stages.6,10,11

AM finds application in manufacturing of custom-made parts, including prototypes, and small series parts. AM is not only by far more flexible than conventional formative molding or casting processes, but may as well be considered economically favorable in cases where the high financial and time expenditure necessary for the production of molds and tools for formative manufacturing exceeds the usually higher production costs per part in AM.

In recent years, the overall market situation for AM was characterized by significant growth rates, as indicated by Figure 4. Revenues from services as well as products (systems and materials) have grown since the 2008 crisis, and worldwide numbers surpassed the value of 5 billion USD in 2015.7 This significant growth spurred a lot of interest in AM-related activities, and major players in the manufacturing industry (aerospace, energy, automotive, consumer products, and medical/dental) have started activities in the field.

Figure 4.

Worldwide revenues from AM products and services between 1995 and 2016. Data from ref (12).

AM is currently able to fabricate parts made of metals, polymers, and ceramics. As indicated in Figure 5, the revenues from material sales passed the value of 900 million USD in 2016. Interestingly, the largest fraction of these material sales still goes into photopolymers (350 million USD), despite the fact that, with a few exceptions, photopolymers are currently mostly used for molding and prototyping applications. AM metals worth 127 million USD were sold in 2016, and an estimated amount of 225 million USD was spent on polymer powders for laser sintering.13 The remaining revenues mostly come from sales of polymer filaments for fused deposition modeling (FDM). Polymers are therefore clearly the most widely used material class for AM.

Figure 5.

Worldwide revenues from AM material sales between 2000 and 2016. Data from ref (12).

As AM became more established, and the quality of processes and materials reached a higher level, applications have widened to include prototypes for functional testing (functional prototyping). In parallel, the increasingly competitive accuracy of CAD reproduction and surface quality has enabled the use of AM in the tooling sector (rapid tooling), either by directly producing molds or by combining additive manufacturing with postprocessing techniques like CNC-machining or electro-discharge machining.1,6,14,15

The economic feasibility of additive manufacturing for end-user parts is mainly dependent on the number and bulk speed of identical parts that are to be produced. While impractical for mass production of simple objects, AM can outrun conventional, especially formative, manufacturing techniques in applications with a high level of individuality. There are some clinical applications that serve as examples where direct fabrication for the consumer is well-established. In osteoplastics, prosthetic dentistry, and orthodontics, precisely fitting implants or supports are often manufactured by AM. In these cases, end-user parts can be produced directly according to tomographic patient data.16−23 Further fields with commercial relevance include architecture, urban development, and jewelry.24,25

1.3. Challenges in Process and Materials Development for 3D Printing and Customized Additive Manufacturing

With the increasingly widespread use of AM in ever more challenging applications, increased demands are placed on the parameters of the build process and on the performance of the finished object.26 Generally the shortcomings of AM can be looked at as areas of opportunity, and indeed it is in response to these problems where the majority of new developments in the field have arisen. Listed are the more serious of these shortcomings.

1.3.1. Build Speed

The term rapid prototyping, which is commonly used synonymously with AM, can be somewhat misleading with regards to the build speed. Although AM processes facilitate a much faster product development by reducing the time necessary for design validations and enabling the production of functional prototypes already at early stages in development, AM is still slow in comparison to mass production technologies such as injection molding. Up to now, this has been acceptable in a multitude of applications such as customized manufacturing that take advantage of the flexibility of AM processes. Nevertheless, the struggle to broaden the scope of application in the future has been a key motivator for research activities, for example, ranging from advanced path planning procedures for SLA in the 1990s to the development of continuous liquid interface production (CLIP) in 2015 by DeSimone et al.4,27 Videos of the CLIP process are available online displaying both its speed and its continuous nature, which is likened to the shapeshifting robot from the movie Terminator 2.28,29

1.3.2. Mechanical Properties

As application of AM progresses from (visual) prototyping to manufacturing of end-user parts, the functionality of these parts is expected to match or surpass the performance of products fabricated using subtractive and formative technologies. Despite numerous research activities, products produced by AM are inferior with respect to mechanical properties in many cases. Depending on the specific process employed, this weakness may be due to a limited choice of materials suited for a process (e.g., photocurable vinyl- or epoxy-functional oligomers for photopolymerization in the case of SLA)30 or to an unavoidable porosity of parts derived from powder bed fusion or material extrusion.31,32 Moreover, due to the layered production process, mechanical properties of parts tend to be anisotropic, with the boundary between adjacent layers representing weak regions with maximum residual stresses in applications where mechanical integrity is a major concern.33 Kotlinski conducted an in-depth analysis of the mechanical properties of commercial AM materials and techniques and found anisotropy to be the worst for LOM and least critical with SLS.34 Mechanical properties and anisotropy for FDM were found to be highly dependent on material and process parameters.35 Anisotropy is also a problem with lithographic AM, where postcuring has been found to provide improvements.36 Improving the mechanical properties of AM formed objects is an active area of research, where the development and application of composite materials can provide unique solutions.37

1.3.3. Resolution

Another major concern influenced both by the specific AM technique and by the processed material is spatial resolution. Insufficient resolution can have a dramatic influence on the quality and functionality of an object. While the formed object is expected to have high fidelity with the CAD virtual object, limitations of the technique and of the build material mean that some degree of dimensional inaccuracies is to be expected. Most prominently, stair step surfaces (Figure 1) are an inherent feature of layer by layer manufacturing, which may require postprocessing (coating, solvent treatment, sanding, or milling).

Resolution requirements set by advanced applications of AM have triggered a lot of research in the fields of engineering and materials science. Using vat photopolymerization as an example, material parameters governing resolution include the absorption and curing characteristics of the respective material. Both are strongly dependent on the monomers used along with the presence of initiator and inhibitor. Where the initiator induces photo-cross-linking and thus solidification within irradiated regions, the inhibitor causes termination on the borderline to dark regions.5 Process parameters influencing the x–y resolution of vat-photopolymerization techniques include the minimum resolution of the light source employed and path planning operations for processes based on laser-scanning. Resolution in the z-direction as described by the minimum layer thickness is dependent on the accuracy of the step motor operating the build platform and on the efficiency of the recoating process (which is dependent on viscosity of the photoresin). It was only very recently that 3D carbon’s novel continuous liquid interface production (CLIP) overcame this drawback by eliminating the need for stepwise processing.27

Similar considerations have to be made for other AM processes, for example, the minimum strand thicknesses tolerable in material extrusion processes, which depend on the rheological properties of the processed materials, or the minimum size of powder particles in powder bed fusion and powder binding-based manufacturing processes, the latter being determined by safety considerations and the limits set by powder production processes.

1.3.4. Multimaterial Parts

AM is prevalently used for prototypes and models, where the option to print in multiple colors is interesting for aesthetic and for demonstration purposes. Commercial multicolor 3D printers have become increasingly common, with entry-level FDM printers starting below $1000.38 These printers use different color filaments from the same material (typically PLA or ABS). By comparison, processing two or more different materials within a single print job is more complicated due to differences in reactivity, in thermal and rheological behavior, and due to incompatibilities either from the materials themselves or from the different techniques used to process them.39 Almost all AM techniques have been modified in some form to allow multimaterial AM (MMAM), but only a few of these modified techniques have actually been commercialized. MMAM is possible by vat photopolymerization by using multiple vats and transferring the object between vats during building.40,41 Powder bed MMAM has also been demonstrated, where one powder material is exchanged for another during building.42 These MMAM techniques are limited though due to contamination issues, slow transfer from one material to another, and more fundamentally by the fact that material exchange is possible only between layers (1D multimaterial) and not within layers (3D multimaterial). Material jetting MMAM based on drop on demand (DOD) technology, by comparison, allows rapid exchange between build materials at each 1D point within a 3D print job.43 This technique is also limited due to the narrow process window of the ink jet actuator. Hope is offered by multi actuator jetting systems, which allow printing of materials with different viscosities and electrical properties. To build free-standing objects from two fundamentally different materials (i.e., metals and polymers), multiprocess 3D printing uses a robot to transfer the object between two or more different AM machines during fabrication.44 MMAM plays an important role in AM for bioprinting and applications in medicine and life sciences.

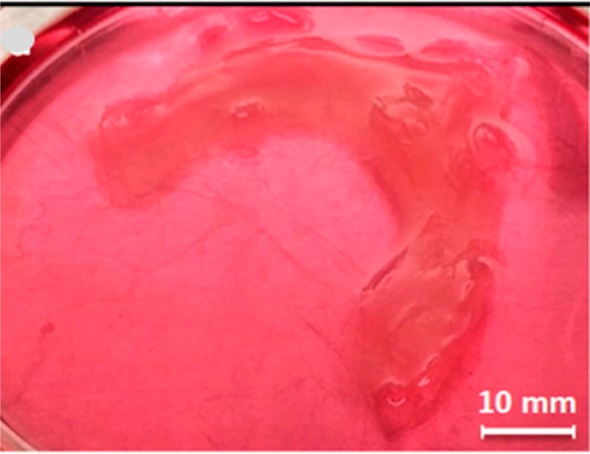

1.3.5. Biocompatibility and Other Concerns for Medical Applications

One of the most promising applications for AM is in the field of personalized medicine, where tomographic images (from X-ray, MRI, etc.) can be used to print objects contoured specifically for the patient. AM is used in surgical planning, in building prosthetics, in dentistry, and in tissue engineering.45−51 Using AM to build tissue grafts and other surgical implants is an intense area of research, where special consideration for both the build material and the AM technique must be considered. For example, acrylates, which are used in all lithographic AM methods (SLA, Polyjet), are cytotoxic but can be replaced by less reactive methacrylates, thiol–ene systems, and other photoreactive monomers.52,53 PLA, which is one of the most commonly used materials for FDM, is also FDA approved for human implantation but has poor mechanical properties.54 Moreover, FDM is a melt extrusion process and does not allow incorporation of living cells or growth factors. Bioplotting is a versatile room-temperature AM method, which can process hydrogels with cells and growth factors.55,56 Control of temperature and of other process parameters, particularly for multimaterial bioplotting, is not straightforward, and research groups are investigating different approaches to alleviate these issues.

2. Vat Photopolymerization

2.1. Techniques

2.1.1. Stereolithography

In the early 1980s, Kodama described methods for building solids by selectively exposing photopolymers either with masks or with optical fibers manipulated by an X–Y plotter.58,59 At about the same time, Herbert presented similar methods using a plotter to direct a laser beam and a lab jack to control the z-direction.60 In 1984, two independent patents (one in France by André et al. and the other in the United States by Chuck Hull) were filed describing layer by layer lithographic fabrication of solids.61 While the French patent was abandoned for business reasons, Hull’s patent both coined the term “stereolithography” (SLA) and laid the groundwork for this technique and for commercial additive manufacturing.57

Figure 6 illustrates the principal components of an SLA device and how they fit together to allow layer by layer fabrication. In the late 1980s, SLA instruments became commercially available first in the U.S. by Hull’s 3D Systems and not long after in Japan by CMET.62 In SLA systems, coherent light sources (usually lasers emitting in the UV-range) are used to induce polymerization and cross-linking of the initially liquid resin. One of the main advantages of SLA is the high spatial resolution provided by the spot size of the focused laser beam. With SLA, light exposure is performed sequentially by scanning the laser beam within the plane on the surface of the photosensitive material. The time necessary to produce one slice of the structure therefore depends on the speed with which the laser beam is scanned and on the illuminated area. The lateral position of the laser beam is usually controlled by a pair of mirrors within a galvanoscanner. As with most other AM technologies, the process is executed in a layer by layer manner. The slice information is presented in the form of a set of coordinates, defining the tilt angle of the two mirrors, which guide the position of the laser beam along the plane. The fact that every pixel of the layer is irradiated sequentially would theoretically allow adjustment of exposure dose for every pixel separately, by controlling the laser intensity. This enables SLA to process grayscale patterns. Vertical resolution is dependent on the light penetration depth, which can be controlled by addition of suitable absorbers to the photopolymer resin. The curing depth also depends on the exposure dose (light intensity and illumination time), which might be the main reason why the grayscale capability of SLA is not utilized in practice. It is worth noting that the main time-consuming step in SLA is not the laser-scanning itself, but the deposition of the new layer of photosensitive material. Here, the viscosity of the material plays an important role. Very often nonreactive additives or solvent must be used to decrease the viscosity of the photopolymer resin.

Figure 6.

Image from U.S. Patent 4575330 introducing the term and the concept of stereolithography.57 Description of components using the numbering scheme from the patent: (21) container, (22) UV curable liquid, (23) working surface, (26) UV light source, (27) UV light spot, (28) computer, (29) movable elevator platform, (30) three-dimensional object, and (30a–c) integrated laminae of the object.

An extension of traditional SLA is provided by microstereolithography, which is impractically slow for large objects but offers lateral resolution usually in the range of a few micrometers.63

2.1.2. Digital Light Processing

Digital light processing (DLP) is similar to SLA in that both techniques utilize light to selectively cross-link a photoresin in a layer by layer fashion to build a free-standing object. Different from SLA, each layer is exposed not point-by-point but rather all-at-once with a selectively masked light source (Figure 7).64

Figure 7.

Digital light processing (DLP) consisting of (a) vat filled with photopolymer resin, (b) light source, (c) micromirror array, (d) vertically movable building platform, and (e) tilting device to replenish the uncured bottom layer.21

DLP closely resembles classical lithography, and is often referred to as dynamic mask photolithography. The information for each layer of the structure is provided in the form of black and white images. Such binary patterns are presented via a digital micromirror device (DMD), a technology also used in overhead projectors.65,66 Because the whole layer (slice) of the structure is produced in one exposure step, the build time is considerably shorter than SLA. By the same virtue, the build time is the same whether the whole available illumination field or only a part of it has been exposed. Therefore, DLP processing speed is most often expressed in cm h–1, that is, the height of the structure (number of layers) per unit time. Furthermore, DLP is less affected by oxygen inhibition as compared to SLA, because the layer of resin being polymerized is always on the bottom of the vat and not in direct contact with air. The utilized light sources have rapidly evolved from classical lamps to modern light-emitting diodes (LED) covering a wavelength range from deep UV to visible. The lateral resolution of DLP systems is usually in the range of 10–50 μm depending on the number of pixels/mirrors provided by the DMD and the optics used to project the patterns onto the build platform. The vertical resolution, that is, the smallest possible layer thickness, mainly depends on the light penetration depth into the material and the resulting curing depth. Vertical resolution can be adjusted with light absorbing additives, such as naphthol-based dyes, which in addition help to reduce the unwanted effects associated with scattered light. In addition to nonfilled photopolymers, slurries containing, for example, ceramic or metal particles can be processed with DLP.67 In this case, the photosensitive polymer matrix acts as a binder material, while the fillers are usually photochemically passive. Further discussion of ceramics is provided in the materials section.

2.1.3. Continuous Liquid Interface Production (CLIP)

Continuous liquid interface production (CLIP) is a variety of vat photopolymerization AM pioneered by DeSimone et al., which uses an oxygen permeable film to inhibit polymerization at the surface close to the UV source and as a result remove the need for an intermediate recoating step for each layer.27,68 CLIP is schematically described in Figure 8 and can also be witnessed in videos online, which better capture the dynamics of the process.28 CLIP has several advantages to other forms of SLA and has been commercialized by the company Carbon 3D, Inc., which sells instruments, materials, and services.69

Figure 8.

Continuous liquid interface production (CLIP). Reprinted with permission from ref (27). Copyright 2015 the American Association for the Advancement of Science.

Because the resin recoating step is the most time-consuming operation of the DLP lithography process, CLIP is considerably faster than traditional DLP, allowing production of objects with features below 100 μm at z-axis growth rates of 30 cm h–1. Lower resolution objects can be grown at rates beyond 100 cm h–1. A CLIP device is similar to a DLP device without a tiltable stage and instead with a UV and oxygen permeable window at the bottom of the vat. Oxygen concentration at the bottom of the vat is thus sufficiently high to create a “dead zone” where radical polymerization does not occur. The thickness of this “dead zone” is defined by the following equation, where ϕ0 is photon flux, αPI is the absorption coefficient of the photoinitiator, and Dc0 is the resin curing dosage:

| 1 |

C is a proportionality constant for the oxygen permeable window (30 for a 100 μm thick Teflon AF film with air on the underside). A dead zone thickness of 20–30 μm was generally optimal for fast and precise CLIP. Just above the dead zone, cross-linking occurs in areas illuminated by the imaging unit. Feature resolution in the z direction is improved by increasing the concentration of a passive light absorber. Lowering the concentration of absorber allows deeper light penetration and thus faster production. Although CLIP is fairly new, Carbon 3D has been quick to develop commercial instruments and improved resins allowing the production of objects from hard to elastic polymers as well as ceramics.70,71

2.1.4. Multiphoton Polymerization

The simultaneous absorption of two photons (TPA) was first described theoretically by Maria Göppert-Mayer in 1931,72 and for this her name is given to the unit for quantifying TPA cross section (1 GM = 1 × 10–50 cm4 s molecules–1 photon–1). Although experimental validation of TPA first came in the 1960s,73 it was not until the 1980s that solid-state femtosecond pulsed lasers became available to provide sufficient light intensities to allow TPA in the laboratory. For TPA to occur, photons must be present in sufficiently high concentration to drive a transition via a very short-lived (fs) intermediate virtual state to the excited state (S2) having energy roughly equal to twice that of the excitation wavelength (E = hν). TPA can be represented on a Jablonski diagram next to the traditional one-photon absorption (OPA) process (Figure 9).74 As a consequence, the probability of TPA is proportional not directly (as with OPA) but rather to the square of light intensity. TPA is thus effectively confined to the narrow focal volume of the laser (∼60 nm in three dimensions),75 which is well below the diffraction limit of the excitation laser wavelength (∼780 nm for a fs pulsed Ti:sapphire laser).

Figure 9.

Simplified Jablonski diagram showing OPA and degenerate (one color) TPA excitation processes. S0 is the ground state and S1 is an excited state reached directly by OPA or indirectly by TPA via a very short-lived higher energy state (S2); ω1 and ω2 are incident light frequencies, and ω3 is a fluorescent emission frequency. Reproduced with permission from ref (74). Copyright 2008 Elsevier.

TPA was used to induce polymerization already in the 1960s, although with limited success.76 Thirty years later, with more powerful lasers and more sensitive photoresins, two-photon polymerization (2PP) began to be explored as a lithographic technique.77 Maruo and co-workers developed 2PP stereolithography further by using a pulsed Ti:sapphire laser with computer-driven galvano-mirrors to direct the beam within a vessel of photoresin and in the process build free-standing microscopic structures with feature sizes orders of magnitude beyond that of other lithographic techniques.78,79 2PP is defacto an AM technique and may also be referred to as two-photon-absorbed photopolymerization,80 two-photon induced polymerization,81,82 two-photon lithography,83 two-photon laser scanning lithography,84,85 multiphoton-excited microfabrication,86 3-D multiphoton lithography,87 3D laser lithography,88 or simply direct laser writing.89,90 The term “multi-photon” acknowledges that the simultaneous absorption of three or more photons can also occur (although with very low probabilities) and contribute to photo-cross-linking. Different from traditional stereolithography, multiphoton polymerization (MPP) is not a layer by layer technique because the focal point of the laser can be moved in any direction within the resin.91 Because the photoresin is transparent to NIR, cross-linking will occur only within the focal volume of the laser.92 MPP is thus considered a true 3D writing method allowing complex and in-cut structures not possible with layer by layer SLA.

To trigger the nonlinear two-photon absorption process, light sources with very high photon density are required. Most currently used MPP setups are based on pulsed femtosecond-lasers with pulse durations between 50 and 150 fs. Amplified laser systems allow benefits such as tunable wavelength, pulse duration and intensity, but are limited with regard to maximum repetition rate, which is typically on the order of several kHz. The low repetition rate limits the maximum writing speed of MPP, because at least one laser pulse is required per voxel to trigger polymerization. For this reason, nonamplified lasers are more common for MPP, based either on Ti:sapphire or on fiber lasers. Laser powers vary between 10 and 700 mW, with pulse durations typically around 100 fs and repetition rates of 10–100 MHz.

A typical setup for MPP is depicted in Figure 10. The laser beam passes first through a collimator and then through an acousto-optical modulator (AOM), which disperses the beam into zero- and first-order diffractions. The first-order output can be turned on and off by switching the AOM. The first-order output is fed through a λ/2 wave-plate, which can be rotated to adjust the laser power. The beam is finally directed through a microscope objective to focus it into the sample holder containing the photopolymerizable formulation. A camera can be positioned behind a semitransparent mirror to allow online-observation of the polymerization process. By illuminating the sample with the appropriate lighting (e.g., red light emitting diodes), imaging of the sample is further improved.

Figure 10.

Schematic setup of MPP microfabrication.93 License CC BY 4.0.

Positioning of the laser focus for MPP can be achieved by two different methods: (1) The positioning of the laser beam in the xy-plane is controlled with piezo-actuated or linear air-bearing stages. Alternatively, (2) the laser beam passes through a galvanoscanner, which is positioned before the microscope objective. Galvanoscanners have the advantage that the laser beam can be positioned precisely allowing a more dynamic movement of the beam. The drawbacks are mostly related to the limited build size: For high-resolution structures, immersion-oil objectives with high magnification (typically 100×) have to be used. In combination with a galvanoscanner, this setup is limited to build sizes of approximately 30 × 30 μm. Piezo-actuated stages allow slightly larger scan areas (around 200 × 200 μm), while high-precision air-bearing stages cover significantly larger build areas (up to 100 × 100 mm). Scan speeds up to 1000 mm s–1 are possible when using highly reactive resins with suitable photoinitiators and appropriate optics. For parts that require very high resolution and precision, 100 μm s–1 up to 1 mm s–1 are commonly used writing speeds.

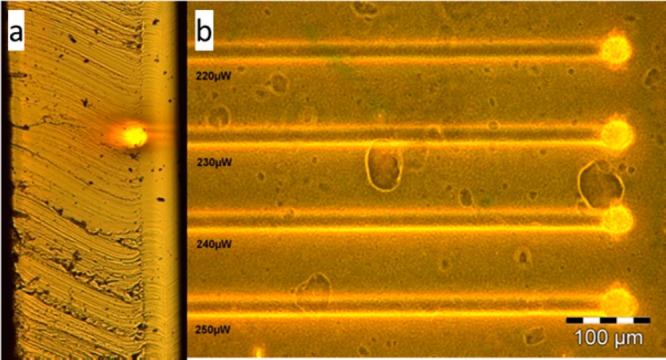

The spatial resolution of microstructures built by MPP is unrivaled, with feature sizes well below 100 nm being common.94Figure 11 illustrates the relation of laser intensity and voxel size on feature resolution defined by the volume in which polymerization occurs. Two important power boundaries are defined: the polymerization/fabrication threshold (Pth) and the damage threshold (Pdam), which dictate the useful range of power for the laser.95 For clarification, the resin will polymerize as soon as the density of initiating radicals exceeds a certain minimum concentration but will be destroyed when the laser power is too high. Pth is lower in resins with efficient photoinitiators, and Pdam will depend on heat transport and stability of the resin. Feature resolution may be further reduced (to roughly 65 nm) with the addition of radical quenchers, which limit propagation and thus spatially confine polymerization.96,97 More recently, repolymerization techniques have been used to lower feature sizes to 22 nm.98

Figure 11.

Relation between laser intensity, voxel size, and success of polymerization. Reproduced with permission from ref (95). Copyright 2008 Cuvillier Verlag.

Yet another method for improving the resolution of MPP is based on stimulated emission depletion (STED).24,99 STED makes use of two light beams: the first is the excitation beam, and the second, which is preferably at a longer wavelength, is used to counteract the effects of exposure and depopulate excited chromophores via stimulated emission. Figure 12 presents the photophysics of the STED process.100 First, TPA is used to excite a molecule from the ground state, S0, to a vibrationally excited state of the first excited electronic state, S1. Fast (∼ps) intramolecular vibrational redistribution (IVR) brings the molecule to the ground vibrational state of S1, from which it can undergo intersystem crossing (ISC) to the reactive triplet state T1 or undergo stimulated emission to a vibrationally excited state of S0. Excited-state/excited-state absorption (EEA) is a competing process, which is particularly problematic when traditional one-photon initiators are applied to STED.101,102 Instead, chromophores with high fluorescence quantum yield such as rhodamine 6G are preferred.103 As another example, the laser dye 7-diethylamino-3-thenoylcoumarin (DETC) was used with a photoresist and appropriate two-photon excitation (fs pulsed 780 nm) and deactivation (continuous wave 532 nm) light sources to build structures with feature sizes of 55 nm at a 120 nm pitch.104

Figure 12.

Jablonski diagram of STED for 2PP.17 Reproduced with permission from ref (105). Copyright 2014 Royal Society of Chemistry.

MPP has been used to structure various solid material samples, such as Zr-based hybrids and photosensitive modified gelatin.106,107 The resin and its principal components have important roles in dictating process parameters as well as resolution.108 This is further discussed in the MPP initiator section. Where MPP is often based on lasers emitting in the NIR, this radiation tends generally to scatter less and can permeate through living tissue without denaturing proteins. This advantage is further elaborated in section 8.3.3.

2.2. Photoresins for AM Processes

2.2.1. Background

The first photocurable materials to be utilized for AM were not intended for use in AM. In Hull’s 1984 patent where he first describes SLA,57 he uses a resin from Loctite and cites an earlier patent for details on its composition.109 This resin, which had been originally intended for use as a UV curable adhesive, consisted of a urethane dimethacrylate with a small fraction of acrylic acid, benzophenone as photoinitiator, and methyl ethyl hydroquinone (MEHQ)/triallyl phosphate to inhibit premature polymerization. Hull used a 350 W mercury short arc lamp light source focused through a 1 mm fiber optic bundle giving an irradiance of 1 W cm–2 at the cure surface. In subsequent patents, the He–Cd laser became the principle light source for SLA, which is considerably more efficient but only for resins that absorb at 325 nm.110 As photobased AM methods matured, formulators sought to provide resins that required a smaller dose of energy to reach gelation, which relate to faster writing speeds and thus “rapid” prototyping.5,111 For SLA, the critical exposure Ec to cause gelation as measured in mJ cm–2 can be defined as

| 2 |

where E0 is the dose at the surface, Cd is the curing depth, and Dp is the penetration depth as defined by

| 3 |

This equation assumes that absorption of light is dependent solely on photoinitiator concentration [I] and molar extinction coefficient (ε) at the utilized wavelength.112 This becomes invalid for resins with inorganic fillers that scatter or with UV–vis absorbing additives. Both classes of additives will be described further in latter sections.

While Ec is an important value, the strength and modulus of a polymer at the gel point are normally too low to survive the build and development processes.1 It is worth noting that Flory’s equation predicts that gelation occurs at ever lower conversion as the functionality of the monomer is increased: 33% conversion in the case of a diacrylate, 20% for a triacrylate, and 14% for a tetraacrylate.113 To compensate, Jacobs defines the excess energy (Ex) required to cross-link the polymer to an extent to provide sufficient green strength. “Green” refers here to the initially formed photopolymerized object as opposed to the final object, which very commonly is subjected to additional thermal curing after AM.

| 4 |

Excess energy is directly proportional to the critical exposure and inversely proportional to the cure depth. This means that green strength can be improved either by increasing the energy dosage or by lowering penetration depth. Addition of UV or visible absorbers, which do not participate in initiation, can thus improve resolution by allowing thinner layers and concomitantly improve strength. The obvious disadvantage of this methodology is a longer build time.

Another important criteria for any photopolymer used in AM is the recoating depth or layer thickness before cure.114 The limits to recoating are dependent both on the build method and on the resin. Viscosity and wetting behavior of the resin onto the solidified part are both of critical importance here. The higher molecular weight multifunctional acrylates that are commonly used for AM thus must often be thinned with a smaller but still multifunctional acrylate. More on viscosity is discussed in the application section.

2.2.2. Radical Systems

2.2.2.1. Radical Photoinitiators

Radical generation, initiation, and propagation are all relatively rapid processes and are thus commonly used for rapid prototyping. The first step in cross-linking of a photoresin is absorbance of light, and it is the photoinitiator or photoinitiator system that converts photolytic energy into reactive species to induce polymerization. Generally speaking, radical photoinitiators may be classified as either Norrish Type I or Type II.115 Type I initiators are single molecules that cleave into radical fragments when exposed to light of an appropriate wavelength. Benzil ketals are common Type I initiators with fairly low energy n → π* transitions (equivalent to roughly 350–360 nm). The mechanism for photocleavage of Darocur 1173 (a common Type I initiator) is given in Scheme 1. The initially formed excited singlet state may cleave directly or undergo intersystem crossing to give an excited triplet. Because the triplet is similar in energy to the singlet and longer lived, radical generation via the triplet predominates.10 Other commonly used benzil ketal initiators, which undergo similar photocleavage reactions, include Irgacure 184, Irgacure 651, and Irgacure 369 (Figure 13).116

Scheme 1. Norrish Type I Photocleavage of Darocur 1173.

Figure 13.

Type I radical photoinitiators commonly cited in stereolithography patents.

Acyl phosphine oxides (such as TPO and BAPO in Figure 13)117 are another class of Type I radical initiators and may be preferred with AM devices based on higher wavelength lamps (such as DLP). The phosphorus atom adjacent to the carbonyl group lowers the energy level of the π* state, thus shifting the maximum of the n → π* transition toward 400 nm. Most essentially, these and the new generation of long wavelength germanium initiators (Ivocerin in Figure 13) have excellent photobleaching behavior (as the heteroatom is separated from the carbonyl group), thus allow curing of highly filled systems.118

Type II photoinitiation systems are two-component systems consisting of a light absorbing molecule (or sensitizer) along with a co-initiator (or synergist) (Scheme 2). Upon irradiation, the synergist donates a hydrogen atom to the excited sensitizer and in the process provides the initiating radical. Tertiary amines with at least one alkyl substituent are the most commonly used Type II co-initiators.119,120 They react via electron transfer from the amine to the excited ketone. The subsequent step of proton transfer from the amine radical cation to the initiator radical anion is the speed limiting factor, and back electron transfer has to be considered as a competitive reaction. Although Type II sensitizers (such as benzophenone and isopropylthioxanthone) are commonly cited in SLA patents,121 amine synergists are not recommended. One reason is that many modern day SLA resins are based on mixtures of radical and cationic-based systems, and amines can inhibit the latter. In fact, benzyl-N,N-dimethylamine (a very effective hydrogen donor) is listed as a cationic stabilizer in a few patents,122 and used at a concentration of less than 0.01 wt % (too low to be of use as a synergist). While Type II systems are more effective with reactive synergists, Type II sensitizers may still contribute to radical polymerization via direct hydrogen donation from monomer or solvent.123 Hydrogen abstraction from alkyl carbons adjacent to oxygen can occur with many monomers including those containing propylene glycol or ethylene glycol units.124 An advantage of using oligoether or oligoester acrylate monomers with abstractable hydrogens is that they tend to cure better in air than analogous alkyl monomers, and yet they do not inhibit cationic polymerization such as amines.

Scheme 2. Radical Generation from Type II Photoinitiators.

Performance of the utilized radical photoinitiator will depend on the utilized light source. Classical benzoyl-based photoinitiators such as I651 but also D1173 and I184 require UVA or UVB light sources to initiate polymerization. This makes these initiators appropriate for stereolithography based on He–Cd lasers (325 nm) or frequency tripled Nd:YAG sources (355 nm) or UVA/B-based DLP.125,126 With higher wavelength light sources, acyl phosphine oxide photoinitiators are superior. For AM instruments based on blue light curing, bisacylgermanium photoinitiators (Ivocerin in Figure 13) can be considered.127 The use of multiple radical photoinitiators is also fairly common in resins intended for AM, and the success of this strategy will depend largely on the breadth of wavelength of the light source.

2.2.2.2. (Meth)acrylate Monomers

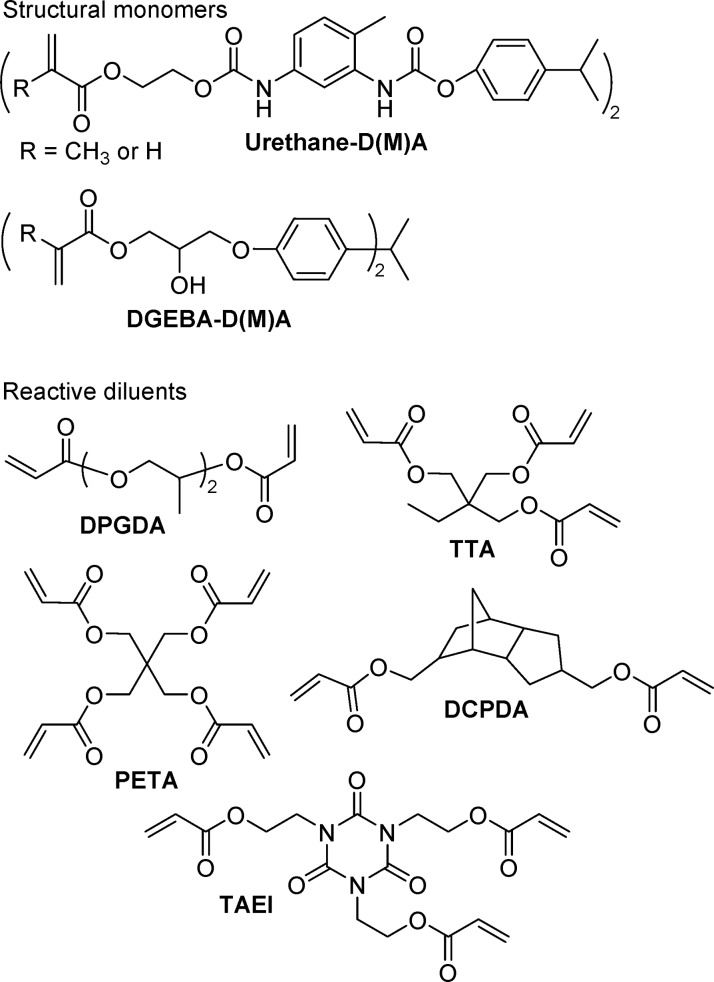

Because the exact composition of most commercial resins used in photo based AM is proprietary, examples from patents are used to provide insight on utilized monomers and potential concentrations thereof. As a good early example of monomers intended for SLA, Murphy et al. filed a patent in 1988 describing a resin consisting of a combination of a high viscosity oligomeric diacrylate or dimethacrylate dissolved in a liquid acrylate or methacrylate and an N-vinyl monomer (preferably N-vinylpyrrolidone (NVP) as reactive diluent).128 They state that a system consisting of both an acrylate and a methacrylate is preferable because methacrylates cure too slowly on their own and because the pure acrylate system leads to distortions in the printed object. In their examples, they describe a resinous diacrylate (either urethane- or epoxy-based) dissolved in trimethylol propane trimethacrylate (TTMA) or hexane diol dimethacrylate. NVP is rapid curing and provides “green strength”, which refers to the combined mechanical properties required to maintain fidelity during the development process. The ideal ratio of resinous acrylate:liquid methacrylate:NVP was found between 7:6:6 and 14:3:3. Darocur 1173 (D1173) and Irgacure 184 (I184) (Figure 13) were listed as photoinitiators.

Resins based on urethane acrylates129 and DGEBA (bisphenol A diglycidyl ether) are commonly cited in SLA patents due to the mechanical strength that these functional groups help provide.130 Urethane acrylates are synthesized from the reaction of hydroxy acrylates (such as HEA or HEMA) with isocyanates, where the latter is oftentimes an oligomeric polyurethane formed in a prior step from a polyol reacted with excess small molecule diisocyanate.131 An array of urethane acrylate monomers is available commercially, defined as either aliphatic or aromatic and with degree of functionality from one to six. Structural monomers, on their own, are often too viscous to be processed directly by AM and require thinning with a lower viscosity reactive diluent.132 To facilitate rapid cross-linking of the resin, multifunctional reactive diluents such as dipropylene glycol diacrylate (DPGDA) or pentaerythritol tetraacrylate (PETA) are often used (Figure 14). Tris[2-(acryloyl)ethyl] isocyanurate (TAEI) is a reactive liquid acrylate monomer with a heterocycle core that should also help improve product mechanical properties.133 Diacrylates with cycloaliphatic cores (such as DCPDA) are claimed in a few SLA patents as they tend to undergo less shrinkage than other acrylate monomers and help contribute to a higher final modulus.134

Figure 14.

Meth(acrylate) monomers for AM.

Although they have their advantages, acrylates, as with all other vinyl monomers, undergo shrinkage during polymerization. The amount of shrinkage is dependent on molecular structure, with cycloaliphatic and aromatic acrylates shrinking less than common diluents (i.e., bisphenol-based dimethacrylate bis-GMA shrinks 5%, while diluent triethylene glycol dimethacrylate shrinks 12%).135 Preorganization of monomers (e.g., by hydrogen bridges) can help to reduce shrinkage stress. Another strategy is to change the polymerization mechanism from a chain growth polymerization toward a radical step growth mechanism (elaborated further in subsequent sections). Polymerization shrinkage and associated stress cause particular problems in layer by layer fabrication where inhomogeneous stress results in curling and other deformation problems.136 Hull et al. describe 3D printing techniques including the use of dashed and curved lines for vertical structures, which develop less strain versus straight continuous structures. One of the more common chemical methods of reducing shrinkage (and thus curl) is to use higher molecular weight oligomeric acrylates.137 The problem of increased viscosity can be compensated by heating the resin during processing, although this solution is not universally applicable.

2.2.2.3. Thiol–Ene and Thiol–Yne Systems

Shrinkage is not the only problem from which acrylates suffer. Notably propagating carbon radicals are inhibited by molecular oxygen dissolved in the resin.138 The problem is further exacerbated in open vat SLA setups where the curing surface is in constant contact with ambient air. Traditional additives for mitigating oxygen inhibition such as tertiary amines retard cationic polymerization and are not appropriate for mixed epoxy/acrylate resins. Fast curing alternatives to acrylates are to be considered. One of the first alternate monomer systems to be investigated for SLA was based on “thiol–ene” chemistry.139,140 In this case, the -ene component was actually a dinorbornene, which was formed by Diels–Alder cycloaddition of a diacrylate (various diol acrylates including hexanediol diacrylate) with cyclopentadiene. In equimolar ratio with a polythiol (pentaerythritol tetramercaptopropionate is cited in the example), the formulation cures with a much lower radiation dosage in comparison to DGEBA DA (2 vs 13 mJ cm–2). The authors blame the poor response of DGEBA DA on oxygen inhibition.141 Thiols can alleviate oxygen inhibition by donating a hydrogen atom to a formed peroxyl radical and in the process providing a reactive thiyl radical (Scheme 3). Other additives that have been tested to reduce oxygen inhibition in SLA include triphenylphosphine,111 where the authors specify resins with Ec values below 1 mJ cm–2. Although thiols and phosphines can both improve in-air photo curing, they tend not to remain stable for extended times in formulations with acrylates. In the case of thiols at least, storage stability can be significantly improved by proper use of a buffer with a radical inhibitor.142 While improved in-air curing is generally desirable for stereolithography, it does exclude the use of thiol–ene resins for CLIP (section 2.1.3), where oxygen inhibition is needed to prevent adhesion to the bottom of the vat.27

Scheme 3. Thiol–Ene Reactions.

Thiol–ene-based formulations undergo less polymerization shrinkage and exhibit reduced shrinkage stress relative to acrylate-based formulations.143 Acrylate/methacrylate-based resins containing thiols were found to shrink significantly less during photopolymerization than those without and as a result provide sharper structures.144 Explanation for the lower shrinkage stress is given by the delay of the gel point toward higher conversion. Pure (meth)acrylate resins gel already at conversions as low as 20%. Up to the final conversion of about 70%, the material is no longer able to flow, and shrinkage stress is increased with each newly formed bond. Because of the step growth mechanism of thiol–ene systems, the kinetic chain length is significantly shorter (thiol–(meth)acrylate systems) or even not existent (thiol–nonhomopolymerizable ene), thus shifting the gel point well beyond 30% double bond conversion.

Thiol–ene polymers also tend to be less brittle than acrylate networks, although the materials are in some cases too soft for many applications.145 Lower brittleness can be explained by the more homogeneous polymer architecture (Scheme 4). (Meth)acrylates undergo a radical chain growth polymerization with a rather long kinetic chain length in the initial phase. Having potential cross-linking points on every second carbon atom of the primary chain, the network is not efficient in dissipating stress and cracks will propagate more readily.146 Thiol–ene networks, which form by step growth kinetics, are comparatively more regular in structure. Unfortunately, flexible thiol-bridges in thiol–ene networks lead to significant softening and lower the useful temperature range of the material.

Scheme 4. Network Formation with Thiol–Ene Monomers versus Network Formation with Acrylate Monomers.

Adapted with permission from ref (146). Copyright 2016 the Royal Society of Chemistry.

Dias et al. address the problem of low modulus by synthesizing oligourethanes end-capped with norbornene and polymerizing these with trimethyloylpropane tris(mercaptopropionate). Hydrogen bonding between urethane chains increases the rigidity of an otherwise loose thiol–ene network.147 Another approach to improving thiol–ene mechanical properties has been to use ternary monomer systems such as thiols with allyl ethers and methacrylates.148 Resultant polymers exhibit higher modulus and reduced shrinkage stress.

Leonards et al. demonstrated the importance of stoichiometry in thiol–ene resins for AM. They used Raman spectroscopy to confirm that thiols remained on the surfaces of cross-linked polymers and used these to immobilize fluorescent dyes. Using an SLA instrument with a 266 nm laser, thiol-vinyl ether resins without photoinitiator were selectively structured with feature sizes below 50 μm.149

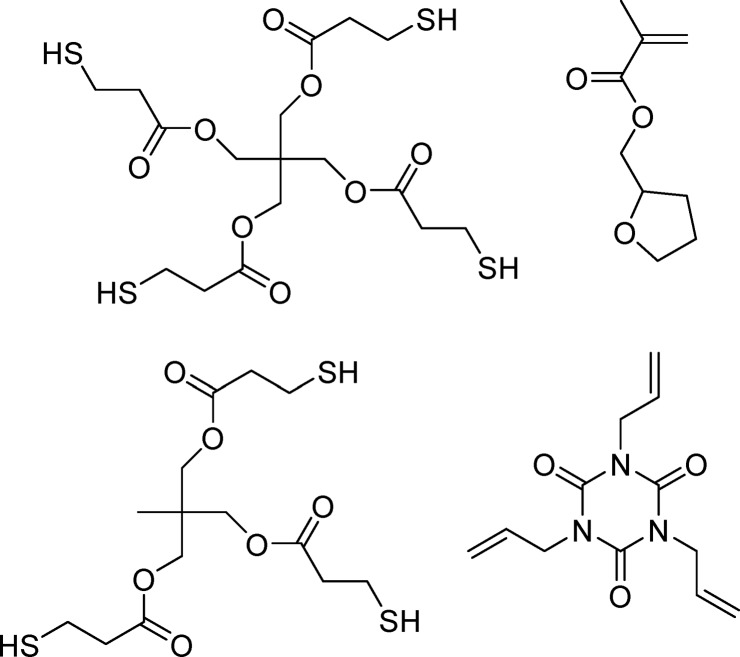

Commercial thiol–ene resins from Norland Optical Adhesives have been used by a few research groups for SLA and for 2PP. The resins cure well with lamps with outputs from 320 to 380 nm.150 Joshi et al. added a two-photon chromophore (6-benzothiazol-2-yl(2-naphthyl) diphenylamine) to NOA 72 (a resin based on mercapto esters and tetrahydrofuran methacrylate) and used this to pattern microscopic optical components.151,152 NOA thiol–ene-based resins are optically transparent and provide polymers with refractive indices higher than those of acrylate-based resins (1.62–1.64 vs 1.32–1.48). Triallyl isocyanate (Figure 15) is mentioned as a component in multiple resins including NOA 61, which was used by Sun et al. to fabricate optical lenses.153 Also of interest for AM applications, shrinkage of these thiol–ene resins is very low (1.5% with NOA 61).

Figure 15.

Thiol–ene components in commercial photocurable resins.

Alkyl thiols undergo addition reactions with terminal alkynes at rates comparable to those of alkenes. The advantage of thiol–yne chemistry is that two thiols can react per alkyne group providing a material with a much higher Tg than most thiol–ene networks.154 Thiol–yne systems also tend to exhibit reduced shrinkage stress; however, final conversion in thiol–yne systems may not as high as expected. For whatever reason, thiol–yne chemistry has received limited attention for use in photobased AM.

2.2.2.4. Addition–Fragmentation Chain Transfer for Controlled Polymer Architecture

Although thiols show great promise as resin components for AM (less shrinkage stress, tougher materials), disadvantages such as poor storage stability, bad odor, and lower modulus of the final material remain as issues. Recognizing the relationship between well-defined polymer architecture and improved material properties, addition–fragmentation chain transfer (AFCT) reagents are being investigated in photocurable formulations. From the literature, a broad variety of AFCT reagents is known, although they were investigated primarily for narrowing polydispersity of linear polymers.14 Recently, Gorsche et al. have tested β-allyl sulfones (Figure 16) with dimethacrylate monomers and found them to be very efficient in regulating network formation.155 With chain transfer constants close to unity, they “copolymerize” in a statistical manner. Thereby the gel-point is significantly shifted toward higher conversion, thus reducing shrinkage stress in a manner similar to that of thiols. β-Allyl sulfones also improve impact strength of methacrylate networks, but without reducing room-temperature modulus as is observed with thiols (Figure 17).156,157 Odor and storage stability of the ß-allyl sulfone AFCT reagents are not issues, although a slight retardation in polymerization may occur. This issue has recently been circumvented with a structurally similar sulfone ester AFCT reagent (VSE in Figure 16).

Figure 16.

β-Allyl sulfone AFCT reagents (MAS and DAS) and sulfone ester AFCT reagent (VSE).

Figure 17.

Mechanical properties of dimethacrylate polymers with 20 wt % thiol additive (DT) and with 20 wt % AFCT reagent (DAS). Reprinted with permission from ref (155). Copyright 2015 Royal Society of Chemistry.

2.2.3. Cationic Systems

2.2.3.1. Photoacid Generators (PAGs)

Cationic photopolymerization was first developed in the 1970s chiefly in response to some of the shortcomings of radical polymerization. The first successful cationic photoinitiators (Figure 18) were aryl iodonium salts (Ar2I+X–) with non-nucleophilic counterions (BF4–, PF6–, AsF6–, and SbF6–).158 These compounds are thermally stable and upon exposure to UV radiation will decompose to form a mixture of cations, radical cations, and radical intermediates. Further reaction of the reactive intermediates with solvent or monomer leads to the formation of super acid HMXn, which acts as the principal initiator for cationic polymerization.159 Where toxicity of early photoacids was a concern, substitution of the diaryl iodonium with an alkyloxy group was found to significantly improve rat LD50 (>5 g kg–1) and in the process increase solubility and red shift absorbance. Aryl iodoniums with alkyl substituents on both rings were found to significantly improve solubility in otherwise immiscible silicone epoxides.160

Figure 18.

Representative cationic photoinitiators and a schematic for generation of the primary initiating species.

Not long after the discovery of diaryl iodonium photoinitiators, triaryl sulfonium salts were synthesized and found to exhibit similar photoreactivity.161 Sulfonium photoinitiators tend to have even better thermal stability than aryl iodoniums and generally absorb better beyond 300 nm. Further conjugated aryl sulfonium mixtures with absorbance up to 350 nm were developed in the early 1980s.162 Beyond these wavelengths, aryl iodonium photoacids may be a better option because they are more readily sensitized. This may be done with a variety of dyes such as anthracene,163 thioxanthones, and coumarins and extends the use of these cationic initiators up to 400 nm.164 Type I radical initiators can also be used in combination with cationic initiators, where radical intermediates from the former can react with iodonium or sulfonium reagents to give radical cations. Cationic polymerization can also be induced with visible light by use of a metallocene initiator such as Irgacure 261 (I261).

2.2.3.2. Epoxides

Epoxides are one of the most commonly used classes of monomers for photobased AM. One reason is that epoxides undergo significantly less shrinkage (2–3% volumetric) than acrylates during photo-cross-linking.165 This can be explained by the ring opening reaction of the epoxide group. Another reason is the generally good mechanical properties of the resultant polymers. The most commonly used epoxide monomers for SLA include diglycidyl ether derivatives of bisphenol A (DGEBA), 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexanecarboxylate (ECC), and epoxides of aliphatic alcohols such as trimethyloyl propane (Figure 19).134 The reactivity of an epoxide monomer is dependent on molecular structure, where cycloaliphatic epoxides with high double ring strain like VCDE cross-link most rapidly. Epoxy monomers with nucleophilic groups including ester moieties, which may be protonated, have reduced reactivity. Thus, photo-cross-linking of ECC is about 10 times slower than that of other cyclohexene derived epoxides without nucleophilic groups. Complexation of the ester group of ECC both intra- and intermolecularly with oxiranium intermediates can retard the desired reaction.166 Ether groups such as those found in epichlorohydrin derived epoxides (e.g., DGEBA) can also form bi- or multidentate proton coordination, which explains the lower reactivity of these monomers.167

Figure 19.

Epoxide monomers and polyol chain extenders for cationic photopolymerization.

N-Glycidyl ethers (derived from the reaction of amines with epichlorohydrin) are mentioned in many SLA patents although never cited in examples.168 Rath et al. performed photo-DSC with formulations containing cationic initiator and N-glycidyl ethers and witnessed no exotherm, which they attributed to the basicity of the amine inhibiting cationic polymerization.169 Epoxidized plant oils and in particular soy bean oil (ESBO) serve as reactive internal plasticizers and work particularly well in combination to soften DGEBA networks.170 Cyclopentene oxides (such as CPDE) are mentioned in patents and according to the literature ring open under cationic conditions at rates intermediate to cyclohexene oxide and simple linear alkene oxides.171

Cationically cured epoxides are polymers that are fundamentally different from the more common amine cured epoxy resins. While cationic curing proceeds in a chain growth manner, the amine curing is based on a step growth polymerization. This leads to a significantly different polymer architecture (Scheme 5). The cationic cured network has a quite high number of cross-linking points along the polymer backbone (in theory every third atom), leading to increased brittleness. To counteract this high cross-link density, alcohols are often used as chain transfer agents. Polyester and polyether diols are cited in patents and used at concentrations from 5 to 20 wt %, where modulus becomes undesirably low at higher concentrations. Steinmann et al. use ethoxylated derivatives of bisphenol A in some of their examples.132 Simple diols such ethylene glycol or butane diol used at concentration of 3–5 wt % can also increase the cure speed of DGEBA by 30–50%.115 Trimethyloylpropane triol has low viscosity and yet provides high cross-link density per added weight percent.

Scheme 5. Cationic Chain Growth of Diepoxide Monomers and Chain Transfer with Diols.

Although lithography as it is used for the production of integrated circuits is not the same as stereolithography, commonly used negative photoresists have been applied by a number of researchers for SLA. For reference, photoresists are classified as positive if they become more soluble in solvent on exposure to light and negative if they become less soluble. The most commonly used negative photoresist for lithography is SU-8, a bisphenol A Novolak monomer with on average eight epoxide moieties in solution with a cationic photoinitiator.172 SU-8 is sold as a 40–75 wt % solution, with solution viscosity and spin speed being used to control layer thickness between 2 and 200 μm.173,174 Soft prebaking of SU-8 at 95 °C is used prior to photoexposure to remove solvent and thus decrease lateral movement during polymerization. SU-8 has also been used by a number of groups for 2PP, where longer prebaking corresponds to greater feature widths.175,176 UV filtered at 350 nm has been found advantageous due to improved penetration, which translates to high aspect ratios (feature height/width) and better vertical profiles.172 Following irradiation, the unexposed resin is washed away with a suitable solvent such as acetone or propylene glycol methyl ether acetate. As with some other AM methods, post development baking of SU-8 at 200 °C is recommended. As an aromatic epoxide polymer, cured SU-8 has good thermal and chemical stability, which may or may not be advantageous depending on the application. In particular, copper, which has become an increasingly popular alternative to aluminum for IC connections, can be damaged by strong acids or high temperatures used to remove SU-8, in which case, an acrylate-based negative photoresist such as Ordyl (Elga Europe, Italy) or DiaPlate (HTP, Switzerland)177 may be preferred because it can be stripped fairly mildly with 3% NaOH at 50 °C.178

2.2.3.3. Oxetanes and Vinyl Ethers

Epoxide monomers photopolymerize much slower than acrylate monomers, and for this reason, epoxides are rarely used on their own in photoresins intended for AM. In fact, the first application of epoxides for SLA was in combination with much more reactive but also cationic polymerizable vinyl ether monomers.165 The syntheses of vinyl ethers and epoxides are complementary because they both use the same feed stock diols (i.e., bisphenol A), triols, and polyols.179 This gives rise to products such as 1,4-cyclohexane dimethanol divinyl ether (CDVE), bisphenol A divinyl ether, polyurethane divinyl ethers,180 and trimethyloyl propane trivinyl ether (TTVE) (Figure 20). The advantage of using vinyl ethers in combination with epoxides is that the first will rapidly polymerize and harden sufficiently during the AM build process while the latter will minimize shrinkage during the post cure process. Disubstituted oxetane (DSO) monomers are more reactive than epoxides and offer similar low shrinkage advantages.181 Oxetanes provide an additional advantage by imparting improved water resistance to cross-linked materials.182 For resins with a restrictively high cross-link density, a long or short chain diol can be used as a chain transfer agent.183 While (meth)acrylate-based resins tend only to be postcured with light, the cationic system can be post cured either with light or with heat.

Figure 20.

Vinyl ether and oxetane monomers commonly cited in SLA patents.

2.2.4. Hybrid (Dual-Cure) Formulations

The advantages of using resins consisting of multiple types of monomers with different rates of reaction had been recognized already in the early days of SLA. Resins based solely on a highly reactive monomer (acrylate or vinyl ether) exhibited catastrophic curl distortions due to rapid and inhomogeneous shrinkage. Mixtures with less reactive monomers (acrylate/methacrylate or vinyl ether/epoxide) had significantly lower curl factors and could be further cured after building.128,179 Relative to these purely radical and purely cationic mixtures, hybrid formulations containing both radical and cationic monomers and initiators began to be studied in the early 1990s and have become standard ever since.184 Acrylates and epoxides undergo different modes of polymerization and do not appreciably react with one another. The resultant polymer is thus not a copolymer (as is the case with acrylate/methacrylate and vinyl ether/epoxy mixtures) but rather an interpenetrating network (IPN). With systems consisting of DGEBA DA and ECC, the acrylate portion reacts significantly faster while the epoxy portion undergoes significant “dark cure”, continuing to polymerize after the light is turned off.185 An advantage of these systems is a significant reduction in sensitivity toward oxygen inhibition. Incompatibility of the two monomers can however be a problem, which Steinman et al. address with urethane-based macromers containing both acrylate and epoxide moieties.131 Commercially available hybrid monomers include glycidyl methacrylate and 3,4-epoxy-cyclohexyl-methyl methacrylate (GMA and ECMA in Figure 21).186 The benefits of covalently binding the acrylate and epoxide moieties is not clear however because these compounds are less common in patent examples. A more typical hybrid resin formulation for SLA is provided in a patent from Ito et al.: 53.7 wt % ECC, 14.9 wt % DGEBA DA, 9 wt % tetra acrylate, 9 wt % 3-methyl-3-hydoxymethyloxetane, 9 wt % polyol chain extender, 2.7 wt % aryl sulfonium cationic initiator, and 1.8 wt % Irgacure 184 radical initiator.187 Such a formulation is reasonably representative, although variations in composition will be made to adjust cross-link density and thus influence mechanical properties or to lower water uptake for certain applications.

Figure 21.

Hybrid (meth)acrylate/epoxy monomers from patent literature and commercially available.131

2.2.5. Two-Photon Initiators

A resin commonly used in early 2PP work was SCR500 from Japan Synthetic Rubber, which consists of a proprietary blend of urethane acrylates and a free radical initiator (either Irgacure 369 or Irgacure 184).188 Microstructure resolution and processing parameters of such resins are not optimal, however, due to low two-photon absorption (TPA) of traditional photoinitiators.101,189,190 The TPA cross section (σTPA) is a value analogous to the molar extinction coefficient (ε), which quantifies a molecule’s propensity for one-photon absorption. As with ε, the σTPA can predict the probability for formation of an excited state, but does not give any information about subsequent photochemistry. As an example, Schafer et al. examined Irgacure OXE01 (Figure 22a) with z-scan analysis and measured a σTPA of less than 40 GM (1 GM = 1 × 10–50 cm4 s molecules–1 photon–1).102,191,192 More importantly, TPA at 800 nm, which is close to the output of most commonly used Ti:sapphire lasers, was particularly low. Nevertheless, the quantum yield for radical formation and initiation of such initiators is high, and several research groups prefer them.74,193 Fluorescent dyes such as coumarin and rhodamine B (Figure 22b) have slightly higher σTPA values than traditional photoinitiators and have thus also been investigated for two-photon applications.194

Figure 22.

TPA photoinitiators with TPA cross-section (σTPA).

Real progress came with the recognition that molecules with extended planar π-conjugated cores connecting electron-donating (D) and -accepting (A) moieties have lower energy excited states with large dipolar transitions, which increases the likelihood for multiphoton events. TPA of dipolar, quadrupolar, and octapolar chromophores are found to be orders of magnitude better than traditional photoinitiators (Figure 23).195 While larger multipolar TPA chromophores (even polymeric and dendritic TPA active compounds) are also investigated, quadrupolar and octapolar molecules have been favored. The increased chromophore density of such molecules relative to dipolar chromophores has a positive influence on σTPA, and synthetic preparation is generally less complicated than that of higher branched derivatives. Extended π-conjugation tends to increase σTPA and to red shift λmax. While higher σTPA is always desirable for 2PP, optimal λmax will depend on the laser source (approximately 800 nm in the case of Ti:sapphire).

Figure 23.

Schematics of different TPA chromophores classified by substitution pattern (D = electron donor, π = π-conjugated bridge, A = acceptor moiety).195

Rational design of molecules with high TPA has advanced greatly in the last 20 years (Scheme 6).196 Substituted derivatives of stilbene are some of the simplest organic dipolar and quadrupoloar chromophores. Related chromophores based on the bis(styryl)benzene core have received attention in 2PP applications. Common modifications have been to use stronger electron-donating groups, to incorporate acceptors on the core and even multiple acceptors on the ends of the molecule.

Scheme 6. Evolution of Multipolar Chromophores from Stilbene.