Abstract

Poly(3-hydroxybutyrate-co-4-hydroxybutyrate) (P(3HB-co-4HB)) is a biodegradable plastic that is extensively utilized in many fields. In this work, P(3HB-co-4HB) powder was degraded by Pseudomonas mendocina for the preparation of low-molecular-mass (LMW) P(3HB-co-4HB). After degradation, the remaining P(3HB-co-4HB) powder was analyzed via gel permeation chromatography (GPC), differential scanning calorimetry (DSC), X-ray powder diffraction (XRD), Fourier transform infrared (FTIR) spectroscopy, and proton nuclear magnetic resonance (1H NMR) spectroscopy. The degradation of P(3HB-co-4HB) by P. mendocina occurred in two stages: the fast degradation stage (0–8 h) and the slow degradation stage (8–24 h). GPC analysis showed that the molecular weight of P(3HB-co-4HB) gradually decreased with degradation time. After 24 h of degradation, the weight-average molecular weight of P(3HB-co-4HB) was reduced to 4–5 kDa. DSC and XRD analyses both verified that the degree of crystallinity decreased with prolonged degradation time. The melting temperature of the degraded powder, however, remained unchanged. FTIR and 1H NMR analyses of the degraded powder showed that no new material was produced during degradation. Thus, the degradation of P(3HB-co-4HB) by P. mendocina could be used to produce LMW P(3HB-co-4HB) for use in various applications, such as the synthesis of amphiphilic block copolymers.

Keywords: Poly(3-hydroxybutyrate-co-4-hydroxybutyrate), Pseudomonas mendocina, Biodegradation, Biodegradable plastic

Introduction

Polyhydroxyalkanoates (PHAs) are natural polyesters that are intracellularly synthesized and accumulated during the unbalanced growth of various microorganisms (Khanna and Srivastava 2005). In the past few decades, PHAs have attracted commercial attention in the production of green plastics given their biodegradability, and biocompatibility, as well as the similarity of their mechanical properties to those of petrochemical-derived plastics, such as polypropylene (Numata et al. 2009; Wang et al. 2012). The PHA family includes polyhydroxybutyrate (PHB), poly(hydroxybutyrate-co-hydroxyvalerate), poly(3-hydroxybutyrate-co-4-hydroxybutyrate) (P(3HB-co-4HB)), poly(hydroxybutyrate-co-hydroxyhexanoate), and polyhydroxyoctanoate. P(3HB-co-4HB) is one of the most well-known members of the PHA family.

The increasing application of PHAs, however, may cause ecological problems given the incomplete degradation of PHAs within the desired time frame or the formation of intermediates during their degradation in the environment (Tokiwa et al. 2009). Therefore, research on the mechanisms of PHA degradation is necessary to formulate guidelines for their appropriate use. Wen and Lu (2012) investigated the microbial degradation of P(3HB-co-4HB) copolymers with different 4HB molar fractions in soil for 60 days. Their results showed that the rate of degradation of P(3HB-co-4HB) is highly dependent on its crystallinity and surface morphology. Furthermore, its amorphous interspherulitic regions and crystal center are prone to degradation. Faezah et al. (2011) degraded P(3HB-co-4HB) using a depolymerase from Cupriavidus sp. USMAA1020 and observed that enzymatic degradation enhanced 4HB composition in the copolymer. Hsieh et al. (2006) hydrolyzed P(3HB-co-4HB) with depolymerase from Ralstonia pickettii T 1 (Hsieh et al. 2006) and reported that the molecular weights of the crystals decreased during enzymatic degradation, thus suggesting that the enzymatic hydrolysis of chain-folding regions at the crystal surfaces occurred in addition to enzymatic degradation at crystal laterals or edges. Alejandra et al. (2012) hydrolyzed P(3HB-co-4HB) with two kinds of commercial lipases. After enzymatic degradation for 72 h, they obtained low-molecular mass (LMW) P(3HB-co-4HB) with a molecular mass (M w) of 3–5 kDa.

Wang et al. isolated Pseudomonas mendocina DS04-T, which has a remarkable degrading activity for PHB, P(3HB-co-4HB), and other PHAs (Wang et al. 2011). In this work, the degradation of P(3HB-co-4HB) powder by P. mendocina was investigated by analyzing P(3HB-co-4HB) powder after degradation.

PHAs produced from bacteria have a high M w of approximately 200–3000 kDa (Sudesh et al. 2000; Ravenelle and Marchessault 2002). The molecular mass of P(3HB-co-4HB) exceeds 200 kDa (Rahayu et al. 2008). High M w is unsuitable for the molecular design of special polymers, such as amphiphilic block copolymers for drug release or organ transplantation. For such applications, low values of M w (i.e., 1–5 kDa) are required. In this study, the degradation of P(3HB-co-4HB) by P. mendocina DS04-T was studied for the sustainable production of LMW P(3HB-co-4HB) with M w of 4–5 kDa for simple industrial-scale applications.

Materials and methods

Materials

P(3HB-co-4HB) containing 12 mol% 4-hydroxybutyrate was obtained from Shandong Ecomann Technology Co. Ltd. (Zoucheng, China). The average M w of P(3HB-co-4HB) was approximately 520 kDa. Unless otherwise stated, all chemicals used were analytical grade (Mao et al. 2015).

Strain cultivation

Pseudomonas mendocina DS04-T was cultivated in mineral medium that contained 0.15% (w/v) P(3HB-co-4HB) with or without agar (2%, w/v). The mineral medium contained MgSO4·7H2O (0.5 g), NH4Cl (1.0 g), CaCl2·2H2O (0.005 g), KH2PO4 (5.54 g), and Na2HPO4·12H2O (11.94 g) in 1000 mL deionized water, with the pH adjusted to 8.

Biodegradation of P(3HB-co-4HB)

P. mendocina DS04-T strains were first inoculated into liquid mineral medium containing 0.5% (w/v) P(3HB-co-4HB) powder and incubated at 30 °C (Defroidt et al. 2009). Then, P(3HB-co-4HB) powder were collected at different incubation times (4, 8, 12, 16, 20, and 24 h). A blank control without the strain was set up. After degradation, the powder was collected and thoroughly washed with double-distilled water and ethanol to remove medium components and bacterial cells that remained on the powder surface (Allen et al. 2012). Finally, the powder was dried at 60 °C under vacuum to a constant weight (Zhou et al. 2009).

Gel permeation chromatography (GPC)

After degradation, P(3HB-co-4HB) powder was analyzed using GPC, which provided relative molecular mass and molecular mass distribution. GPC measurements were performed at room temperature using the Agilent 1200 system and Agilent ChemStation software (Agilent Technologies, USA). An Agilent 1200 refractive index detector was used at a working temperature of 35 °C with a temperature controller and tungsten lamp. Chloroform was used as the eluent at a flow rate of 0.80 mL/min with a stabilization pressure of 35 bar and a sample concentration of 1.5 mg/mL (Ramachandran et al. 2011). A Waters Styragel HT column (Waters Corporation, Milford, USA) was used. Polystyrene with different molecular masses was used as standards.

Differential scanning calorimetry (DSC)

DSC was performed on a Perkin–Elmer Pyris 1 DSC (Perkin–Elmer, USA) under a dry nitrogen gas flow of 50 mL/min. The apparatus was calibrated using high-purity indium. Approximately 5 mg of sample was sealed in an aluminum planchet and analyzed. Melting temperature (T m), melting enthalpy (), and glass transition temperature were determined using previously described methods (Puglia and Fortunati 2014). Crystallinity degree (X c %) of P(3HB-co-4HB) was calculated with the assumption that the value of 100% crystalline PHB was 146 J/g (Wang et al. 2010). Scans were started at 30 °C and were ramped to 230 °C at 10 °C/min.

X-ray powder diffraction (XRD)

XRD analysis of the samples was conducted on a PAnalytical X’pert Pro X-ray Diffractometer with CuKα radiation (λ = 1.54,178 A°) and operated at 40 kV and 40 mA (Song et al. 2012).

Fourier transform infrared (FTIR) spectroscopy

Chemical structure was characterized using a Perkin–Elmer Fourier transform infrared spectrometer (PerkinElmer, USA) and optical Perkin–Elmer software. The line-scan spectra were based on 32 scans and a resolution of 4/cm (Fu et al. 2015).

Proton nuclear magnetic resonance (1H NMR) spectroscopy

1H NMR spectra were recorded at 25 °C on a Bruker AM300 spectrometer (Bruker, Germany). Polymer samples were dissolved in chloroform, and a drop of tetramethylsilane was added as the reference. The 10-mg samples were dissolved in 1 mL deuterated solvent. Proton spectra were recorded at 300.1 MHz with a spectrum of 32 K data points. A total of 64 scans were performed with a relaxation delay of 1 s.

Results and discussion

Change in Mw of P(3HB-co-4HB) after degradation

Table 1 lists the changes in the M w distributions of P(3HB-co-4HB) after different durations of degradation by P. mendocina DS04-T. Before degradation, P(3HB-co-4HB) had a relatively high weight-average M w of approximately 500 kDa and number-average molecular weight (M n) of approximately 80 kDa. The molecular weight of P(3HB-co-4HB) decreased as degradation progressed. M w of P(3HB-co-4HB) showed a linear downward trend before 8 h of degradation, after which degradation slowed. After 24 h of degradation, M w and M n of P(3HB-co-4HB) decreased to 4–5 kDa and to approximately 2 kDa, respectively. As shown in Table 1, M w /M n decreased rapidly during the first 12 h of degradation and negligibly changed after 12 h of degradation, indicating that the polymer had a homogeneous M w after this period. However, the M w distribution of the polymer changed slightly after 12 h.

Table 1.

Molecular weight distribution of P (3HB-co-4HB) degraded by P. mendocina

| Degradation time (h) | M w | M n | M w /M n |

|---|---|---|---|

| 0 | 523016 | 85152 | 6.14 |

| 4 | 184568 | 35841 | 5.15 |

| 8 | 36741 | 15215 | 2.42 |

| 12 | 9829 | 6542 | 1.50 |

| 16 | 4740 | 2393 | 1.98 |

| 20 | 4805 | 2155 | 2.23 |

| 24 | 4361 | 2085 | 2.09 |

Compared with the results of Alejandra et al. who applied a commercial lipase and obtained LMW P(3HB-co-4HB) after 72 h of enzymatic hydrolysis, the current work obtained LMW P(3HB-co-4HB) from P(3HB-co-4HB) after approximately 16 h of degradation by P. mendocina DS04-T, as revealed by the GPC analyses (Table 1). In the previous study, lipases hydrolyzed P(3HB-co-4HB) to LMW P(3HB-co-4HB), whereas in the present study, P. mendocina DS04-T metabolized P(3HB-co-4HB) to LMW P(3HB-co-4HB). In addition, the rate of production was fast, thus, LMW P(3HB-co-4HB) could be obtained within a short period.

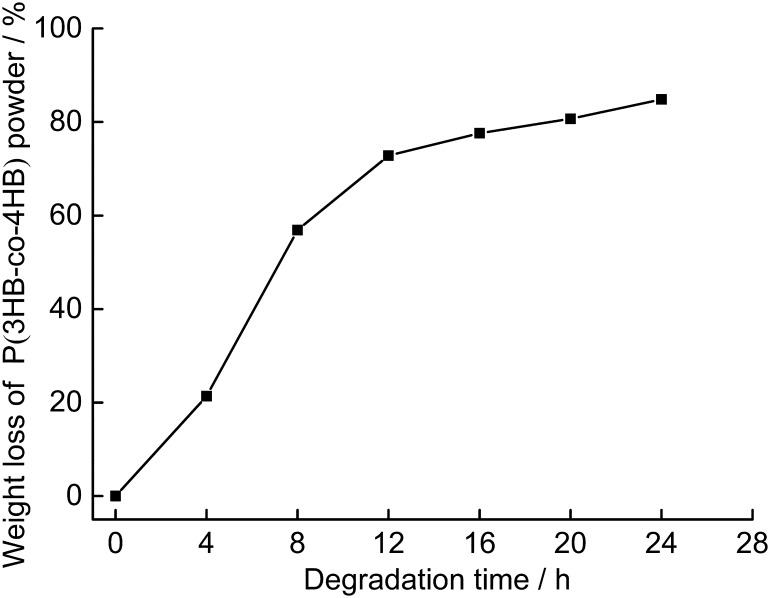

Weight loss, nonisothermal crystallization, and melting behavior

Figure 1 shows the weight loss of P(3HB-co-4HB) after different durations of degradation by P. mendocina DS04-T. The results of gravimetric analysis suggested that degradation rate increased with degradation time. The gravimetric method followed a two-step degradation mechanism with an initially rapid increase from 0 to 8 h that then slowed to a gradual increase from 8 to 24 h. The initial rapid weight loss could be attributed to the large surface area of P(3HB-co-4HB) powder that retained adequate numbers of bacteria or amounts of enzymes. With sufficient nutrient and carbon sources from P(3HB-co-4HB), the bacterial strains and degrading enzymes rapidly accumulated. Therefore, the molecular chain of P(3HB-co-4HB) was broken down rapidly. The second step showed no apparent increase in weight loss for two reasons: first, after a period of accumulation under batch culture conditions, nutrient depletion could inhibit the growth and enzymatic yield of bacterial strains. Second, a large amount of acidic substance (3HB), which could also affect the reproduction, activity, and enzymatic yield of the bacterial strain, was produced during degradation (Li et al. 2013).

Fig. 1.

Weight losses of P(3HB-co-4HB) degraded by P. mendocina DS04-T

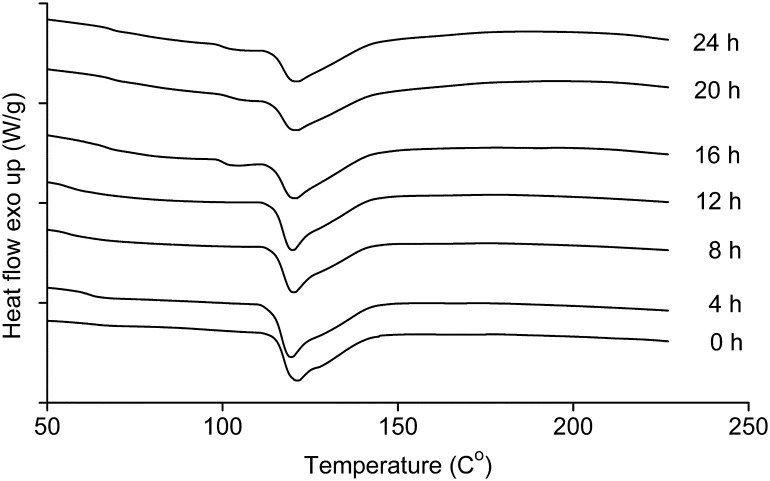

The thermal properties of the samples were determined via DSC. The results of DSC analyses are shown in Fig. 2 and Table 2. The melting point of P(3HB-co-4HB) before degradation was approximately 115.3 °C. After 24 h of degradation, the melting point of P(3HB-co-4HB) showed a decreasing trend. This change, however, was not statistically significant. Huong et al. posited that P4HB is more likely than P3HB to be decomposed through lipase-mediated enzymatic degradation (Huong et al. 2014). The P4HB unit in the molecular chain of P(3HB-co-4HB) was preferentially degraded, because its melting point was lower than that of P3HB (the melting point of P3HB was 171–182 °C, whereas that of P4HB was 60 °C, thus decreasing the degradation product of the molecular chain of P4HB unit content; increasing the relative content of P3HB unit, and increasing the melting point of the system. Alejandra et al. (2012) reported that T m significantly decreases with time when hydrolyzed by two kinds of commercial lipases. This decrease results from the low molecular mass of P(3HB-co-4HB), which in turn is a direct consequence of the chain-scission reactions that occur during enzymatic hydrolysis. P(3HB-co-4HB) powder degradation by extracellular P3HB depolymerase from R. pickettii T 1 showed that the melting point decreases as the duration of degradation is prolonged (Hsieh et al. 2006). Wen et al. (2012) and Chanprateep et al. (2010) also obtained a similar conclusion. The results of these previous studies were different from those of the present study results, because the mechanism of the degradation of the materials by P. mendocina DS04-T was different from that of the pure enzyme.

Fig. 2.

DSC of P(3HB-co-4HB) powder after degraded different times by P. mendocina DS04-T

Table 2.

Weight loss, melting temperature, and crystallinity degree of P(3HB-co-4HB) powder degraded different times by P. mendocina

| Degradation time (h) | Melting temperature (°C) | (J/g) | Xc (%) |

|---|---|---|---|

| 0 | 115.30 | 35.83 | 24.54 |

| 4 | 114.35 | 32.66 | 22.37 |

| 8 | 114.88 | 31.07 | 21.28 |

| 12 | 114.86 | 29.16 | 19.97 |

| 16 | 114.41 | 25.64 | 17.56 |

| 20 | 114.33 | 24.72 | 16.93 |

| 24 | 114.60 | 24.24 | 16.60 |

Two melting peaks appeared after 16 h of bacterial degradation, because the portion of enriched 4HB increased as degradation progressed. Therefore, the melting peak of P4HB appeared.

As shown in Table 2, the melting enthalpy () of P(3HB-co-4HB) decreased as degradation time was prolonged. Crystallinity also decreased as degradation time was prolonged. This observation was consistent with the XRD results. However, this finding differed from that for the biodegradation of PHB films by P. mendocina DS04-T (Wang et al. 2013). When PHB films are degraded by P. mendocina DS04-T, crystallinity increases with degradation time and the amorphous region of the PHB is degraded prior to the crystalline region. Moreover, in this work, P. mendocina DS04-T should simultaneously degrade the crystalline and amorphous regions of P(3HB-co-4HB), with the crystalline region being continuously converted into amorphous phases during degradation.

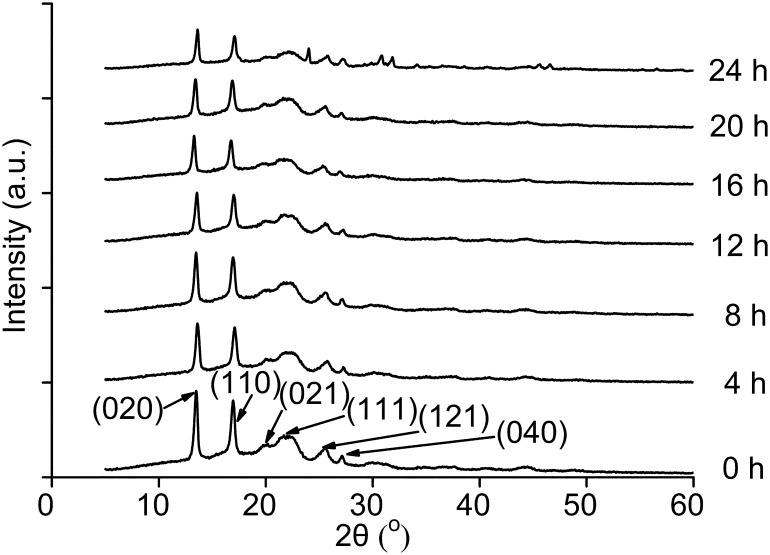

XRD of P(3HB-co-4HB) after different degradation times

The crystal structure of degraded P(3HB-co-4HB) was also investigated via XRD (Fig. 3). As shown in Fig. 3, all samples exhibited almost similar diffraction patterns. Diffraction peaks were all located at approximately 13.57°, 16.96°, 19.87°, 21.49°, 25.53°, 27.13°, and 29.98°, which corresponded with (020), (110), (021), (111), (121), (040), and (002), respectively (Ning et al. 2016; Kunioka et al. 1989). The XRD spectrum of the P(3HB-co-4HB) powder was formed by two parts of a simple superposition: one part was produced by a crystalline sharp peak (diffraction peak) and the other part with a hump arch was produced by a noncrystalline dispersion peak. The two parts indicated that the crystalline and amorphous random copolymer materials are significantly different. The degradation degree of the relative crystallinity of the powder material gradually decreased, as also shown in Fig. 3. This result was consistent with that of DSC analysis. Ou et al. (2011) concluded that the crystallinity of the polymer powder increases as degradation time is prolonged, because the noncrystalline region of P(3HB-co-4HB) is degraded before the crystalline region. Alejandra et al. (2012) also proposed that the crystallinity degree of P(3HB-co-4HB) increases with degradation. However, in this work, P(3HB-co-4HB) crystallinity decreased after 24 h of degradation. This result is consistent with the conclusion reported by Dagnon et al. (2010). The decreased crystallinity degree of PCL (Khatiwala et al. 2008) and PHB (Wang et al. 2013) under biodegradation has also been reported. Theoretically, P. mendocina DS04-T preferentially degrades disordered regions. Thus, the degree of the crystallization of P(3HB-co-4HB) powder should increase as degradation progressed. However, the actual experimental results showed the opposite result, which could be related to the doping of the 4HB monomer (García and Hueso (2010); Hsieh et al. 2009). Given that the crystal structure of the P(3HB-co-4HB) random copolymer is more complex than that of a polymer and that the melting enthalpy is proportional to the degree of crystallinity, the composition of the copolymer remarkably affects polymer crystallinity. The physical properties of P(3HB-co-4HB) were considerably influenced by the incorporation of the 4HB monomer. 3HB and 4HB, however, did not cocrystallize. Under isothermal crystallization, P3HB had a repulsive effect on the 4HB unit in copolymer chains (Faezah et al. 2011). To date, the nonregulatory components of the copolymer, which was excluded from the crystallization group, are unclear and are difficult to explain based solely on DSC results. DSC results revealed that the melting point and relative crystalline degree of P(3HB-co-4HB) powder slightly changed after degradation, confirming that the P. mendocina DS04-T strains can degrade P(3HB-co-4HB) powder.

Fig. 3.

XRD of P(3HB-co-4HB) powder after degraded different times by P. mendocina DS04-T

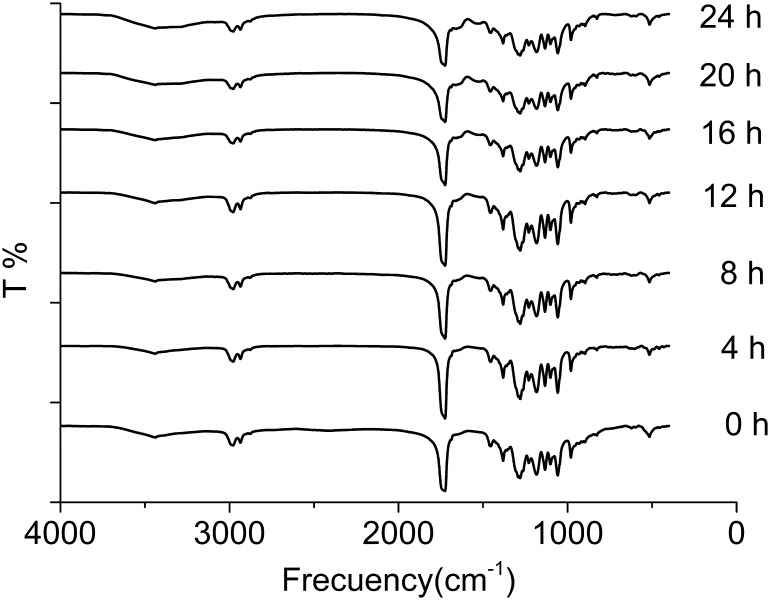

FTIR of P(3HB-co-4HB) after different degradation times

The FTIR spectra of P(3HB-co-4HB) after different durations of degradation with P. mendocina DS04-T are shown in Fig. 4. The FTIR spectra did not reveal significant differences between different P(3HB-co-4HB) samples that were biodegraded by P. mendocina DS04-T. After 24 h of degradation, M w of P(3HB-co-4HB) in all samples significantly decreased without the formation of new substances. Concurrently, all samples showed the corresponding peaks of the main P(3HB-co-4HB) chemical groups: bands at approximately 1727/cm that belonged to the carbonyl group; bands at approximately 2934/cm that represented methylene C–H vibrations; and bands located between 1187 and 1277/cm that represented ester C=O vibrations. The bands at 1228 and 1179/cm were assigned to the chain conformation and the stretching vibration of C–O–C, respectively. The analysis revealed variations in the shape and intensity of the bands at 1179, 1228, and 1277/cm. These changes are associated with the variation in the crystallinity degree of the polymer (Bayari and Severcan 2005). FTIR results showed that no new material was produced.

Fig. 4.

FTIR of P(3HB-co-4HB) powder after degraded different times by P. mendocina DS04-T

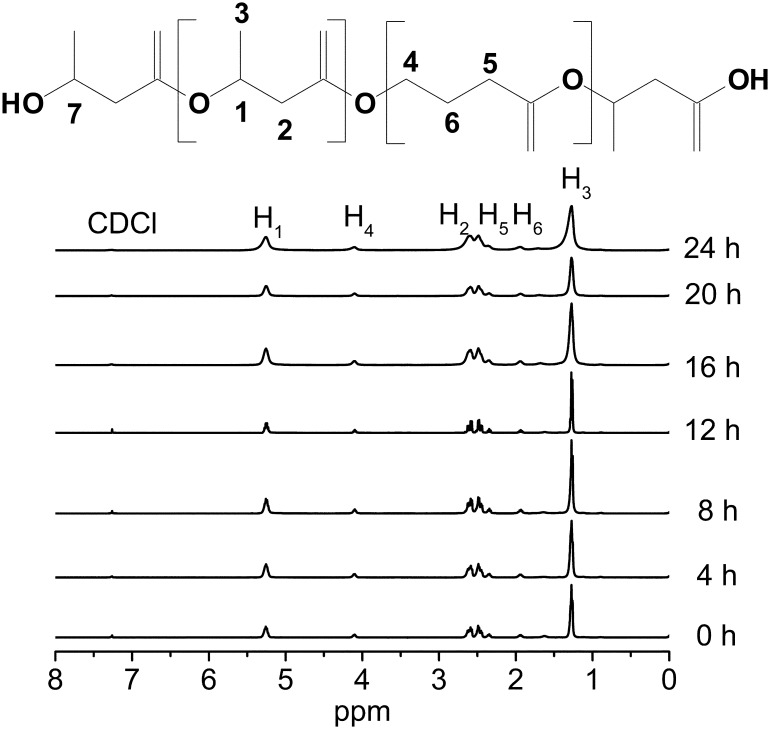

1H NMR of P(3HB-co-4HB) after different durations of degradation

1H NMR results revealed the changes in the molecular structure of P(3HB-co-4HB) as a consequence of degradation by P. mendocina DS04-T. The 1H NMR spectra for P(3HB-co-4HB) after different degradation times are shown in Fig. 5. All samples presented the three characteristic groups of signals for P(3HB-co-4HB): a doublet at 1.26 ppm (Fig. 5, signal H3), a doublet or quadruplet at 2.62 ppm (Fig. 5, signal H2), and a multiplet at 5.27 ppm (Fig. 5, signal H1). All spectra also showed low-intensity signals that corresponded to the 4HB fraction: a triplet at 4.10 ppm (Fig. 5, signal H4) and two multiplets at 2.48 and 1.94 ppm (Fig. 5, signals H5 and H6). The 4HB monomer constituted 12% of the polymer structure, as calculated through the representative peak areas of both fractions: at 5.27 ppm for the 3HB signal and at 4.10 ppm for the 4HB signal. Moreover, the three signals that corresponded to the 4HB fraction decreased with degradation time. NMR results further confirmed that the peak of each unit decreased with the degradation of P(3HB-co-4HB).

Fig. 5.

1H NMR of P(3HB-co-4HB) powder after degraded different times by P. mendocina DS04-T

Conclusions

This work investigated the degradation of P(3HB-co-4HB) powder by P. mendocina. The powder was characterized after degradation. The crystallinity of P(3HB-co-4HB) powder decreased as the duration of degradation increased, whereas T m remained unchanged. The M w of P(3HB-co-4HB) gradually decreased with degradation time. After 24 h of degradation, M w of P(3HB-co-4HB) decreased to approximately 4–5 kDa. Therefore, the degradation of native P(3HB-co-4HB) powder by P. mendocina can produce specific LMW P(3HB-co-4HB). Studies on the conditions for the controllable degradation of P(3HB-co-4HB) and the immobilization of the degraded strain are in progress. Further applications of P(3HB-co-4HB) degradation by P. mendocina in the production of LMW P(3HB-co-4HB) are forthcoming.

Acknowledgements

The authors gratefully acknowledge the financial supports by the National Natural Science Foundation of China (Grant No. 31100099).

Compliance with ethical standards

Conflict of interest

All the authors declare that they have no conflict of interest.

References

- Alejandra RC, Margarita CM, María SMC. Enzymatic degradation of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) by commercial lipases. Polym Degrad Stabil. 2012;97:597–604. doi: 10.1016/j.polymdegradstab.2012.07.042. [DOI] [Google Scholar]

- Allen AD, Daley P, Ayorinde FO, Gugssa A, Anderson WA. Characterization of medium chain length (R)-3-hydroxycarboxylic acids produced by Streptomyces sp. JM3 and the evaluation of their antimicrobial properties. World J Microb Biotechnol. 2012;28:2791–2800. doi: 10.1007/s11274-012-1089-z. [DOI] [PubMed] [Google Scholar]

- Bayari S, Severcan F. FTIR study of biodegradable biopolymers: P(3HB), P(3HB-co-4HB) and P(3HB-co-3HV) J Mol Struct. 2005;744:529–534. doi: 10.1016/j.molstruc.2004.12.029. [DOI] [Google Scholar]

- Chanprateep S, Buasri K, Muangwong A, Utiswannakul P. Biosynthesis and biocompatibility of biodegradable Poly(3-hydroxybutyrate-co-4-hydroxybutyrate) Polym Degrad Stabil. 2010;95:2003–2012. doi: 10.1016/j.polymdegradstab.2010.07.014. [DOI] [Google Scholar]

- Dagnon KL, Thellen C, Ratto JA, D’Souza NA. Physical and thermal analysis of the degradation of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) coated paper in a constructed soil medium. J Polym Environ. 2010;18:510–522. doi: 10.1007/s10924-010-0231-y. [DOI] [Google Scholar]

- Defroidt T, Boon N, Sorgeloos P, Verstraete W, Bossier P. Short-chain fatty acids and poly-β-hydroxyalkanoates: (New) Biocontrol agents for a sustainable animal production. Biotechnol Adv. 2009;27:680–685. doi: 10.1016/j.biotechadv.2009.04.026. [DOI] [PubMed] [Google Scholar]

- Faezah AN, Rahayu A, Vigneswari S, Majid MIA, Amirul AA. Regulating the molar fraction of 4-hydroxybutyrate in Poly(3-hydroxybutyrate-co-4- hydroxybutyrate) by biological fermentation and enzymatic degradation. World J Microb Biotechnol. 2011;27:2455–2459. doi: 10.1007/s11274-011-0697-3. [DOI] [Google Scholar]

- Fu XB, Chen J, Song XL, Zhang YM, Zhu Y, Yang J, Zhang CW. Biodiesel production using a carbon solid acid catalyst derived from β-cyclodextrin. J Am Oil Chem Soc. 2015;92:495–502. doi: 10.1007/s11746-015-2621-8. [DOI] [Google Scholar]

- García MC, Hueso DKB. Simultaneous kinetic determination of 3-hydroxybutyrate and 3-hydroxyvalerate in biopolymer degradation processes. Talanta. 2010;80:1436–1440. doi: 10.1016/j.talanta.2009.09.049. [DOI] [PubMed] [Google Scholar]

- Hsieh WC, Mitomo H, Kasuya KI, Komoto T. Enzymatic degradation and aminolysis of microbial Poly(3-hydroxybutyrate-co-4-hydroxybutyrate) single crystals. J Polym Environ. 2006;14:79–87. doi: 10.1007/s10924-005-8710-2. [DOI] [Google Scholar]

- Hsieh WC, Wada Y, Chang CP. Fermentation, biodegradation and tensile strength of poly(3-hydroxybutyrateco-4-hydroxybutyrate) synthesized by Delftia acidovorans. J Taiwan Inst Chem E. 2009;40:143–147. doi: 10.1016/j.jtice.2008.11.004. [DOI] [Google Scholar]

- Huong KH, Yahya ARM, Amirul AA. Pronounced synergistic influence of mixed substrate cultivation on single step copolymer P(3HB-co-4HB) biosynthesis with a wide range of 4HB monomer composition. J Chem Technol Biotechnol. 2014;89:1023–1029. doi: 10.1002/jctb.4195. [DOI] [Google Scholar]

- Khanna S, Srivastava AK. Recent advances in microbial polyhydroxyalkanoates. Process Biochem. 2005;40:607–619. doi: 10.1016/j.procbio.2004.01.053. [DOI] [Google Scholar]

- Khatiwala VK, Shekhar N, Aggarwal S, Mandal UK. Biodegradation of Poly(ecaprolactone)(PCL) film by Alcaligenes faecalis. J Polym Environ. 2008;16:61–67. doi: 10.1007/s10924-008-0104-9. [DOI] [Google Scholar]

- Kunioka M, Tamaki A, Doi Y. Crystalline and thermal properties of bacterial opolyesters: poly(3-hydroxybutyrate-co-3-hydroxy-valerate) and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) Macromolecules. 1989;22:694–697. doi: 10.1021/ma00192a031. [DOI] [Google Scholar]

- Li LL, Gao J, Jiang HS, Wang ZY. Production of 3-Hydroxybutyrate monomers by Pseudomonas mendocina DS04-T biodegraded polyhydroxybutyrate. J Polym Environ. 2013;21:826–832. doi: 10.1007/s10924-012-0553-z. [DOI] [Google Scholar]

- Mao HL, Liu HF, Gao ZY, Su TT, Wang ZY. Biodegradation of poly(butylene succinate) by Fusarium sp. FS1301 and purification and characterization of poly(butylene succinate) depolymerase. Polym Degrad Stabil. 2015;114:1–7. doi: 10.1016/j.polymdegradstab.2015.01.025. [DOI] [Google Scholar]

- Ning ZG, Xin SY, Wu XY, Xu K, Han CY, Dong LS. Crystallization behavior, mechanical properties, and enzymatic degradation of biosourced poly(3-hydroxybutyrate-co-4-hydroxybutyrate)/graphene nanocomposites. J Therm Anal Calorim. 2016;124:1705–1715. doi: 10.1007/s10973-016-5247-7. [DOI] [Google Scholar]

- Numata K, Abe H, Iwata T. Biodegradability of poly(hydroxyalkanoate)materials. J Mater Chem A. 2009;2:1104–1126. [Google Scholar]

- Ou W, Qiu H, Chen Z, Xu K. Biodegradable block poly (ester-urethane)s based on poly(3-hydroxybutyrate-co-4-hydroxybutyrate) copolymers. Biomaterials. 2011;32:3178–3188. doi: 10.1016/j.biomaterials.2011.01.031. [DOI] [PubMed] [Google Scholar]

- Puglia D, Fortunati E. Influence of organically modified clays on the properties and disintegrability in compost of solution cast poly(3-hydroxybutyrate) films. Polym Degrad Stabil. 2014;99:127–135. doi: 10.1016/j.polymdegradstab.2013.11.013. [DOI] [Google Scholar]

- Rahayu A, Zaleha Z, Yahya ARM, Majid MIA, Amirul AA. Production of copolymer poly(3-hydroxybutyrate-co-4-hydroxybutyrate) through a one-step cultivation process. World J Microb Biotechnol. 2008;24:2403–2409. doi: 10.1007/s11274-008-9764-9. [DOI] [Google Scholar]

- Ramachandran H, Iqbal NM, Sipaut CS, Abdullah AA. Biosynthesis and characterization of poly(3-hydroxybutyrate-co-3-hydroxyvalerate-co-4- hydroxybutyrate) terpolymer with various monomer compositions by Cupriavidus sp. USMAA2-4. Appl Biochem Biotechnol. 2011;164:867–877. doi: 10.1007/s12010-011-9180-8. [DOI] [PubMed] [Google Scholar]

- Ravenelle F, Marchessault R. One-step synthesis of amphiphilic diblock copolymers from bacterial poly([R]-3-hydroxybutyric acid) Biomacromol. 2002;3:1057–1064. doi: 10.1021/bm025553b. [DOI] [PubMed] [Google Scholar]

- Song XL, Fu XB, Zhang CW, Huang WY, Zhu Y, Yang J, Zhang YM. Preparation of a novel carbon based solid acid catalyst for biodiesel production via a sustainable route. Catal Lett. 2012;142:869–874. doi: 10.1007/s10562-012-0840-2. [DOI] [Google Scholar]

- Sudesh K, Abe H, Doi Y. Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog Polym Sci. 2000;25:1503–1555. doi: 10.1016/S0079-6700(00)00035-6. [DOI] [Google Scholar]

- Tokiwa Y, Calabia BP, Ugwu CU, Aiba S. Biodegradability of Plastics. Int J Mol Sci. 2009;10:3722–3742. doi: 10.3390/ijms10093722. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wang XJ, Chen ZF, Chen XY, Pan JY, Xu KT. Miscibility, crystallization kinetics, and mechanical properties of Poly(3-hydroxybutyrate-co-3- hydroxyvalerate) (PHBV)/Poly(3-hydroxybutyrate-co-4-hydroxybutyrate) (P3/4HB) blends. J Appl Polym Sci. 2010;117:838–848. doi: 10.1002/app.31215. [DOI] [Google Scholar]

- Wang ZY, Wang Y, Guo ZQ, Li F, Chen S. Purification and characterization of poly(L-lactic acid) depolymerase from Pseudomonas sp. strain DS04-T. Polym Eng Sci. 2011;51:454–459. doi: 10.1002/pen.21857. [DOI] [Google Scholar]

- Wang ZY, Gao J, Li LL, Jiang HS. Purification and characterization of an extracellular poly(3-hydroxybutyrate-co-3-hydroxyvalerate) depolymerase from Acidovorax sp. HB01. World J Microb Biot. 2012;28:2395–2402. doi: 10.1007/s11274-012-1048-8. [DOI] [PubMed] [Google Scholar]

- Wang ZY, Lin XD, An J, Ren C, Yan X. Biodegradation of Polyhydroxybutyrate film by Pseudomonas mendocina DS04-T. Polym Plast Technol. 2013;52:195–199. doi: 10.1080/03602559.2012.735738. [DOI] [Google Scholar]

- Wen X, Lu XP. Microbial degradation of Poly(3-hydroxybutyrate-co-4- hydroxybutyrate) in Soil. J Polym Environ. 2012;20:381–387. doi: 10.1007/s10924-011-0387-0. [DOI] [Google Scholar]

- Wen X, Lu XQ, Peng Q, Zhu FY, Zheng N. Crystallization behaviors and morphology of biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate) J Therm Anal Calorim. 2012;109:959–966. doi: 10.1007/s10973-011-1768-2. [DOI] [Google Scholar]

- Zhou HL, Wang ZY, Chen S, Liu DB, Xia HM. Purification and characterization of extracellular Poly(β-hydroxybutyrate) Depolymerase from Penicillium sp. DS9701-D2. Polym Plast Technol. 2009;48:58–63. doi: 10.1080/03602550802539627. [DOI] [Google Scholar]