Abstract

To evaluate the mechanical stress and elastic deformation exercised in the thread/shaft transition of Schanz screws in assemblies with different screw anchorage distances in the entrance to the bone cortex, through the distribution and location of tension in the samples.

An analysis of 3D finite elements was performed to evaluate the distribution of the equivalent stress (triple stress state) in a Schanz screw fixed bicortically and orthogonally to a tubular bone, using two mounting patterns: (1) thread/shaft transition located 20 mm from the anchorage of the Schanz screws in the entrance to the bone cortex and (2) thread/shaft transition located 3 mm from the anchorage of the Schanz screws in entrance to the bone cortex. The simulations were performed maintaining the same direction of loading and the same distance from the force vector in relation to the center of the hypothetical bone. The load applied, its direction, and the distance to the center of the bone were constant during the simulations in order to maintain the moment of flexion equally constant. The present calculations demonstrated linear behavior during the experiment. It was found that the model with a distance of 20 mm between the Schanz screws anchorage in the entrance to the bone cortex and the thread/shaft transition reduces the risk of breakage or fatigue of the material during the application of constant static loads; in this model, the maximum forces observed were higher (350 MPa). The distance between the Schanz screws anchorage at the entrance to the bone cortex and the smooth thread/shaft transition of the screws used in a femoral distractor during acute distraction of a fracture must be farther from the entrance to the bone cortex, allowing greater degree of elastic deformation of the material, lower mechanical stress in the thread/shaft transition, and minimized breakage or fatigue. The suggested distance is 20 mm.

Keywords: Finite element analysis, Bone nails, Femoral fractures, External fixators, Treatment outcome

Resumo

Avaliar o comportamento do estresse mecânico e da deformação elástica exercida na transição rosca-talo liso dos pinos de Schanz do distrator femoral de fraturas em montagens com diferentes distâncias de ancoragem dos pinos na cortical óssea de entrada através de estudo da distribuição e da localização de tensões no corpo de prova.

Feita análise de elementos finitos 3D para a avaliação da distribuição das tensões equivalentes em um pino de Schanz fixado de modo bicortical e ortogonal a um osso tubular, em dois padrões de montagem: (1) transição rosca-talo liso distante 20 mm da ancoragem dos pinos de Schanz na cortical de entrada e (2) transição rosca-talo liso distante 3 mm da ancoragem dos pinos de Schanz na cortical de entrada. Foram feitas simulações e manteve-se a mesma direção da carga e a mesma distância do vetor força em relação ao centro do osso hipotético. A carga aplicada, sua direção e a distância ao centro do osso foram constantes durante as simulações para manter o momento fletor igualmente constante. Os cálculos apresentados demonstraram comportamento linear durante todo o experimento. Verificou-se que o modelo com uma distância de 20 mm entre a ancoragem dos pinos de Schanz na cortical óssea de entrada e a transição rosca-talo liso reduziu o risco de ruptura ou fadiga do material durante a aplicação de cargas estáticas constantes. Nesse modelo, as forças máximas observadas foram superiores (350 MPa). A análise do comportamento do estresse mecânico e da deformação elástica exercida na transição rosca-talo liso dos pinos de Schanz do distrator femoral de fraturas mostrou que distâncias maiores entre a ancoragem dos pinos na cortical óssea de entrada e a transição rosca-talo liso dos pinos de Schanz permitem menor estresse mecânico na transição rosca-talo liso e maior grau de deformação elástica do material e minimizam quebra ou fadiga. A distância sugerida é de 20 mm.

Palavras-chave: Análise de elementos finitos, Pinos ortopédicos, Fraturas do fêmur, Fixadores externos, Resultado do tratamento

Introduction

In the management of various orthopedic situations related to trauma, such as diaphyseal fractures of long bones of the lower limbs and consolidation disorders, the use of indirect reduction tools such as femoral fracture distractor, developed by the AO Group1 to be used as an adjuvant tool for fracture alignment, is an important advantage during surgery. Its applicability goes beyond the gain of length during surgery; it is possible to make simultaneous or isolated angular and rotational corrections. After the desired adjustments, it serves to maintain the bone fragments in position until definitive osteosynthesis is achieved. Several studies have demonstrated its application in highly varied situations of orthopedic trauma.2, 3

According to the technique used, the fixation of Schanz screws – one in the main proximal fragment and another in the main distal fragment, perpendicularly to the long axis of the operated bone – allows the distractor's threaded body to be positioned parallel to the bone. Protective sleeves are slid over the screws for both biological and mechanical protection at the soft tissue-pin-bone interface. During distraction of the fracture line, pseudoarthrosis, or osteotomy, the highest stress is observed in the cortical adjacent to the entry site of the pins, which is also the area of greater frequency of failure and loosening.4

Numerous factors have been studied to understand the best way to improve bone anchorage of Schanz screws, in order to reduce rates of complications in the pin-bone interface.5, 6, 7 Nonetheless, no studies that evaluated the mechanical stress in the smooth thread/shaft transition of Schanz screws at different distances between the anchorage of screws in the entrance into cortical bone and the smooth thread/shaft transition were retrieved. The greatest concentration of forces is observed precisely in this transition, mainly due to compression and shear loads.1, 8 In the more classical technique descriptions from clinical or experimental trials, the screws are inserted manually until the thread is fixated through the cis (input) and trans (opposite) cortical bone and the shaft is fully supported in the cis cortical.9

The present hypothesis was that the smaller the distance between the thread/shaft transition and the Schanz screw anchorage point in the entrance to the cortical bone, the greater the mechanical stress generated in the transition, and therefore the greater the risk of rupture or fatigue.

The present study was designed to evaluate the distribution of mechanical stress and the elastic deformation of the material in the Schanz screws during a gradual distraction in mountings with different anchor lengths in the entrance to the cortical bone, assessing the distribution and location of the stresses in the test specimen.

Methods

Study design

After Institutional Review Board approval, under the number 0347-2015, a 3D monobody finite element analysis was performed to assess the distribution of the equivalent stress (triple stress state) in a Schanz screw fixated to a hypothetical tubular bone. The bone model used was virtually mapped from a long bone, in its diaphyseal portion, through a finite element computational study.

Within the studied scenario, the Schanz screw was fixated bicortically and orthogonally to the hypothetical bone, and presented two mounting patterns.

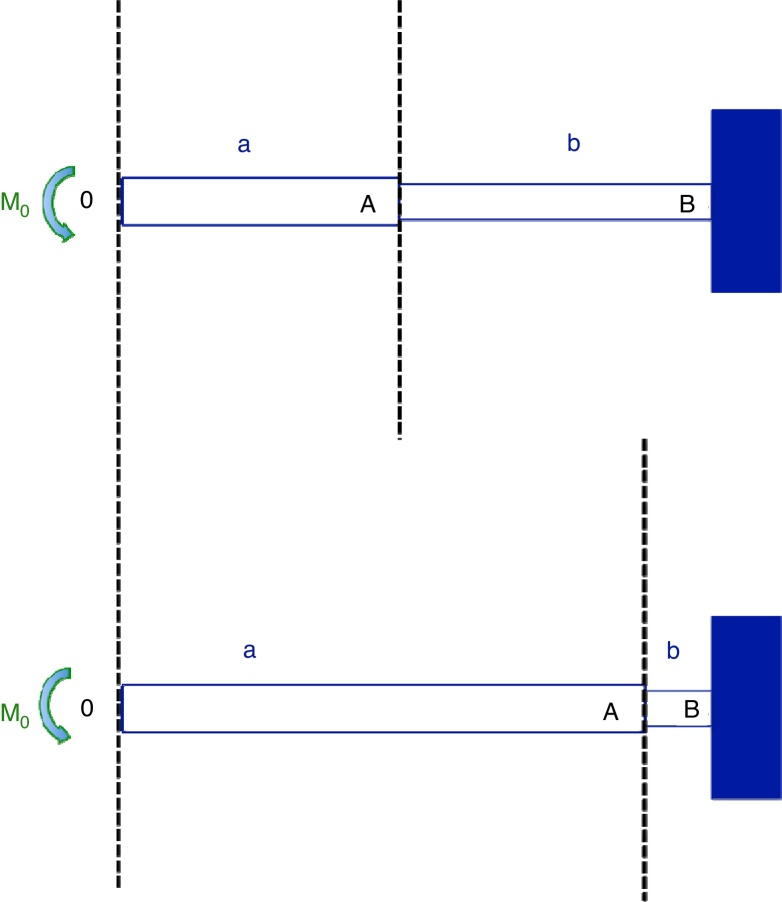

Mounting 1 (M1): the thread/shaft transition was 20 mm from the entrance to the cortical bone (Fig. 1).

Mounting 2 (M2): the thread/shaft transition was 3 mm from the entrance to the cortical bone (Fig. 1).

Fig. 1.

Diagrams used for the analysis of finite elements of the distribution of equivalent stresses.

A, shaft; b, thread; F0, initial flexion momentum; 1A-M1, the thread/shaft transition is distanced 20 mm from the entrance to the cortical bone; 1B-M2, the thread/shaft transition is distanced 3 mm from the entrance to the cortical bone.

In the analysis software, the model for Schanz screw was simplified, graphically eliminating its threaded part, represented by its inner diameter. This procedure aimed to facilitate the understanding of the graphical presentation of the simulation.

Assays

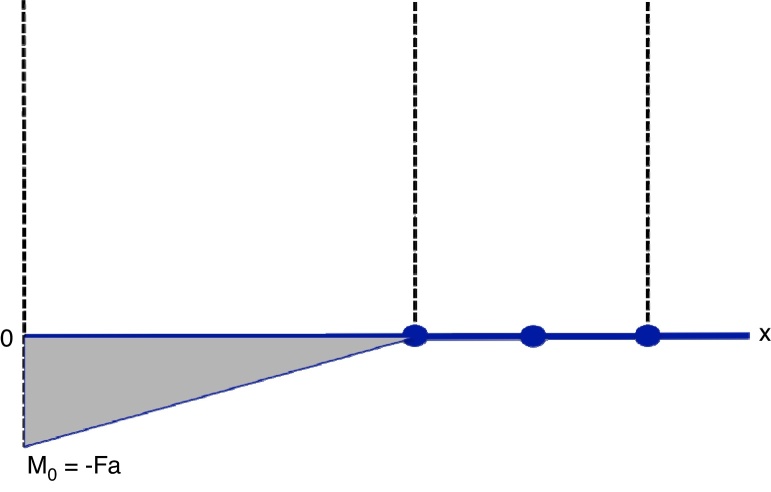

Two simulations were performed, changing the position of the Schanz screw and maintaining the same load direction and the same distance from the force vector in relationship to the center of the hypothetical bone. The applied load, its direction, and the distance to the center of the bone were constant during both simulations, in order to keep the flexion momentum equally constant. The construction of the flexion momentum diagram is shown in Fig. 2.10

Fig. 2.

Construction of the flexion-momentum diagram. Throughout the study, the flexion load remained constant.

The distribution of the equivalent stress on the Schanz screw during the flexion momentum in the two mountings studied was measured in MPa. The graphical representation of the stress concentration zones was computer-generated and used to illustrate this study.

Results

Within the two situations studied, we observed that the thread/shaft transition region of the Schanz screw presented the greatest fatigue sensitivity throughout the analysis. All calculations showed a linear behavior throughout the experiment.

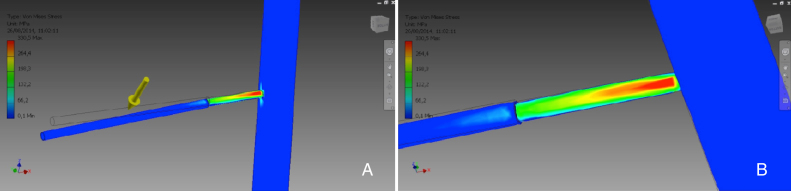

Mounting 1

In the graphs from the initial mounting condition (distance of 20 mm between the thread/shaft transition and the entrance to the cortical bone), we observed that the stress was concentrated in the area closest to the bone, in the traction side. The maximum stress recorded was 330.5 MPa. Due to the greater exposed area of the Schanz screw thread, greater stress dissipation was observed until the transition region with the shaft. The graphical representation of the zones of stress concentration and the illustration of this test are shown in Fig. 3.

Fig. 3.

Graphical representation of the areas of stress concentration (A) and illustration of the deformation (B) in the M1 Schanz screw. Note that the stress dissipation occurred along the thread, there was no greater risk of fatigue in the thread/shaft transition.

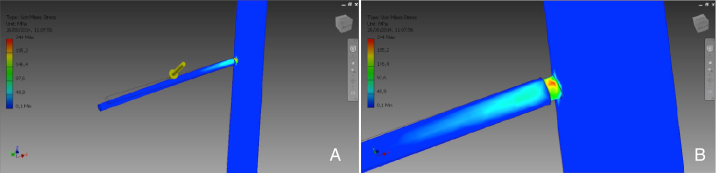

Mounting 2

In the graphs from the initial mounting condition (distance of 3 mm between the thread/shaft transition and the entrance to cortical bone), we observed that the stress was concentrated in the area closest to the bone, in the traction side. Maximum stress observed was 244 MPa. Due to the small exposed area of the Schanz screw thread, there was almost no stress dissipation, and great deformation was observed in the transition region with the shaft. The graphical representation of the zones of stress concentration and the illustration of this test are shown in Fig. 4.

Fig. 4.

Graphical representation of the areas of stress concentration (A) and illustration of the deformation (B) in the Schanz screw in mounting 2. Note the great concentration of force.

Discussion

The femoral distractor is one of the most useful tools for indirect fracture reduction in various cases of skeletal trauma.2, 3 Its versatility and ease of application have made it a major surgical adjuvant, with a low complication rate. One factor that may complicate its use, specifically at the time of fracture line distraction, is the loosening or rupture of the Schanz screws, which sometimes leads to increased surgical time, larger access route, and possible change in surgical procedure. Thus, screw placement is one of the critical points of the procedure; it must be perfectly executed, since it has been demonstrated that the greatest concentration of stress occurs in the entrance to the cortical bone.4, 5, 6

Although biological and mechanical implications of screw failure are debatable, the host's adequate response to osseointegration with the metallic material and the stability in the fracture focus are paramount in the durability of Schanz screws. Nonetheless, unlike external fixators, the relationship between metal screws and the histological response of bone is not observed when a fracture distractor is used, especially for extended periods, such as during stretching and bone transport. The lack of biological bone integration mechanism accentuates the need for maximum mechanical strength at the pin-bone interface during static loading conditions, which are observed when distraction is applied for the correction of shortening, for example.5

In the authors’ opinion, the basic concept that the coaxial unit may maintain the loads exerted in the direction of the long axis of deformation extrapolates the bone (cis cortical) and metal screw interface.7, 11 As failures related to screw ruptures during the use of fracture distractors can be clinically observed, the thread-shaft interface of the Schanz screw appears to contribute, to a certain extent, to the mechanical strength of the construction. Studies with external fixators have shown that screws can support a large amount of flexion force, and that the thread/shaft transition is the point of least resistance of the implant.9, 12, 13

In the present study, which used finite element analysis, the optimal anchoring distance of the thread/shaft transition of Schanz screws in the entrance to the cortical bone was evaluated under constant loads. Contrary to expected, we observed that the greater the exposed area of the Schanz screw thread, the greater the stress dissipation to the transition region with the shaft, hypothetically reducing the risk of material breakage or fatigue during constant static loads, although the observed maximum forces were higher in this model – 350 MPa. When the exposed area of the Schanz screw thread was small (3 mm), a large concentration of stress was observed in the thread/shaft transition in the test monobody. In practice, since the highest concentration of compression and shear loads are observed exactly in the transition regions of the Schanz screws (thread/shaft and shaft/entrance to the cortical bone), it can be inferred that there is a higher risk of material fatigue during flexion-momentum, which occurs in a sharp distraction of the fracture focus.1, 8

In parallel with the concept of the work area in osteosynthesis and according to the relative stability principle, the greater the elastic deformation capacity of the Schanz screw used in the fracture distractor, the lower the risk of breakage or fatigue.14 As this is an extrinsic property, the elastic limit that Schanz screws can undergo during acute distraction of a fracture site, for example, depends basically on their diameter, shape, and properties of the material.14 Oni et al.4 suggested that the use of Schanz screws made of titanium and with short shaft generates less stress and, therefore, less risk of failure. Mercadante et al.9 observed a greater resistance to flexion forces when the screw shaft was smaller (15 mm).

A potential criticism to the present study is that it did not directly study material properties of the Schanz screws. Although this aspect is extremely relevant in assessing the mechanical strength of these implants, the analysis would require more elements, and results would be more complicated to understand. The authors had established a very specific objective, which was to determine, through the study of the distribution and location of stresses in the specimen, the best anchorage distance from the entrance to the cortical bone to the thread/shaft transition of the Schanz screws. By maintaining a constant force and regular deformation ratio, the authors believe that all variables were totally controlled, regardless of the extrinsic properties of the material. Another critical point was that the ideal distance from the thread/shaft transition to the cis cortical was not determined. Based on the models studied, it can be suggested that it is at least 20 mm. However, new experiments should be made to precisely determine this distance.

The authors believe that the data from the present study have clinical applicability regarding the placement of Schanz screws during acute distraction of fractures using the femoral distractor. As the end of the shaft approached the entrance to the cortical bone, it was observed that the stress was concentrated in the area of this implant that is most susceptible to the high-cycle fatigue of metallic materials. This demonstrates that the introduction of the screw until its shaft is inside the bone or very close to it leads to a greater susceptibility to fatigue.

Conclusion

The analysis of the mechanical stress behavior and the elastic deformation exerted on the thread/shaft transition of the Schanz screws of the femoral fracture distractor demonstrated that greater distances between the anchorage of the Schanz screws in the entrance to the cortical bone and the thread/shaft transition led to a lower mechanical stress in this transition and a higher degree of elastic deformation of the material, which minimizes rupture or fatigue. The suggested distance is 20 mm.

Conflicts of interest

The authors declare no conflicts of interest.

Footnotes

Study conducted at the Departamento de Ortopedia, Hospital Miguel Couto, Rio de Janeiro, RJ, Brazil, and at the Departamento de Ortopedia e Traumatologia, Faculdade de Medicina, Universidade de São Paulo, São Paulo, Brazil.

References

- 1.Synthes; West Chester, PA: 2006. The AO ASIF Large Distractor – Femur. Technique guide. Fracture reduction and provisional stabilization. Available from: http://www.rch.org.au/uploadedFiles/Main/Content/ortho/Large_Distractor_-_Femur.pdf. [Google Scholar]

- 2.Baumgaertel F., Dahlen C., Stiletto R., Gotzen L. Technique of using the AO-femoral distractor for femoral intramedullary nailing. J Orthop Trauma. 1994;8(4):315–321. doi: 10.1097/00005131-199408000-00007. [DOI] [PubMed] [Google Scholar]

- 3.Rosenkranz J., Babst R. A special instrument: the LISS tractor. Oper Orthop Traumatol. 2006;18(1):88–99. doi: 10.1007/s00064-006-1164-4. [DOI] [PubMed] [Google Scholar]

- 4.Oni O.O., Capper M., Soutis C. Factors which may increase stresses at the pin-bone interface in external fixation: a finite element analysis study. Afr J Med Med Sci. 1999;28(1–2):13–15. [PubMed] [Google Scholar]

- 5.Karnezis I.A., Miles A.W., Cunningham J.L., Learmonth I.D. Axial preload in external fixator half-pins: a preliminary mechanical study of an experimental bone anchorage system. Clin Biomech (Bristol, Avon) 1999;14(1):69–73. doi: 10.1016/s0268-0033(98)00047-3. [DOI] [PubMed] [Google Scholar]

- 6.Pettine K.A., Chao E.Y., Kelly P.J. Analysis of the external fixator pin-bone interface. Clin Orthop Relat Res. 1993;(293):18–27. [PubMed] [Google Scholar]

- 7.Schell H., Reuter T., Duda G.N., Lienau J. The pin-bone interface in external fixator: a standardized analysis in a sheep osteotomy model. J Orthop Trauma. 2011;25(7):438–445. doi: 10.1097/BOT.0b013e3181ecf856. [DOI] [PubMed] [Google Scholar]

- 8.Ruiskes R., Chao E.Y. Guidelines for external fixation from rigidity and stress. J Orthop Res. 1986;4(1):68–75. doi: 10.1002/jor.1100040108. [DOI] [PubMed] [Google Scholar]

- 9.Mercadante M.T., Christian R.W., Kojima K.E., Hungria J.O.S., Francisco L.N.F.L., Yamaguti D.O. Resistência mecânica às forças de tração e flexão: proposta de novo desenho para os pinos de Schanz dos fixadores externos monolaterais. Rev Bras Ortop. 2008;43(6):248–255. [Google Scholar]

- 10.Kreith F. CRC Press, LLC; Boca Raton: 1999. Frontmatter – mechanical engineering handbook. [Google Scholar]

- 11.Hyldahl C., Pearson S., Tepic S., Perren S.M. Induction and prevention of pin loosening in external fixation: an in vivo study in sheep tibiae. J Orthop Trauma. 1991;5(4):485–492. doi: 10.1097/00005131-199112000-00017. [DOI] [PubMed] [Google Scholar]

- 12.Evans M., Spencer M., Wang Q., White S.H., Cunningham J.L. Design and testing of external fixator bone screws. J Biomed Eng. 1990;12(6):457–462. doi: 10.1016/0141-5425(90)90054-q. [DOI] [PubMed] [Google Scholar]

- 13.Halsey D., Fleming B., Pope M.H., Krag M., Kristiansen T. External fixator pin design. Clin Orthop Relat Res. 1992;(278):305–312. [PubMed] [Google Scholar]

- 14.Black J. Churchill Livingstone; New York: 1988. Orthopaedic biomaterials in research and practice. [Google Scholar]