Abstract

In this study, efforts were made to utilize hulless barley (variety BHS352) to enhance the nutritive value of chapatti and biscuit made from wheat flour. Barley flour was added to wheat flour in different ratios (5 to 30%). Antioxidant activity, total phenolic content and β-glucan content were determined both in flour blends and their products. Changes in physical quality and taste of chapatti and biscuits after blending of hulless barley flour with wheat flour were measured. The chapatti quality score decreased by 15% and biscuit spread factor by 33% after 30% barley flour blending. Significant increase in β-glucan content and antioxidant activity of flour blends and their products was observed at 30% blending level. The phenolic content increased from 63 to 135 µg for biscuits and 237 to 287 ug GAE/g for chapatti with blending of 30% barley flour.

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-017-2669-6) contains supplementary material, which is available to authorized users.

Keywords: Antioxidant activity, β-glucan, Phenolic content, Hulless barley, Wheat

Introduction

Wheat is the staple food for most of the population of the world. It provides around 20% of the daily energy requirement. As such wheat has no food value unless it is converted to flour which can then be used to prepare a large number of products for human consumption. Most of the nutrients in wheat grain are concentrated in the outer bran layer. During milling these nutrients are removed and the flour is left with the starch only. Therefore, instead of the refined flour, the wheat products must be prepared from the whole meal flour which retains most of the nutrients and can provide health benefits. The health benefits of the wheat flour can be further enhanced by blending with the flours of other nutritious grains. People have become more health conscious and now look for additional health benefits besides the basic nutrition from cereal based food products. For this reason more and more multigrain food products are available in the market and attracting more consumers (Otles and Cagindi 2006).

Recently, Noorfarahzilah et al. (2014) discussed about the blending of wheat flour with various sources of tubers, legumes, cereals and fruit flour in different percentages to produce variety of food products. The positive effects of the use of composite flour can be seen in the final product related to the functional and physicochemical properties and health benefits of raw blended flour along with percentage blending. Flours from corn, barley, cassava and chickpea are among the most predominantly studied for the production of composite flour breads (Ali et al. 2000; Skendi et al. 2010). In literature, reports are also available where wheat products have been prepared by partial blending with other cereals (Pourafshar et al. 2015), legumes (Zucco et al. 2011) and oil seeds (Skrbic and Cvejanov 2011).

A great interest has recently risen in the development of “functional” foods, products that may provide a health benefit beyond the traditional nutrients. Foods rich in antioxidants and a low glycemic index (GI) can reduce the risk of increased postprandial oxidative stress, which is one of the constituents of the onset of several chronic diseases (Hou and Jimenez 2013). Barley is considered to be highly nutritive because of high content of soluble fibre β-glucan (Sullivan et al. 2013) and antioxidants (Zhao et al. 2008). Consumption of barley has increased during the recent years because of its ability to control cholesterol and blood glucose levels. Studies also show that bread made with a blend of wheat and barley flour has acceptable sensory properties (Skendi et al. 2010). The β-glucan in barley flour can increase the quality of bread by modifying the glycemic and insulin response (Gujral and Gaur 2005). Barley is being used mostly to prepare malt and beer. Barley is also used in multigrain flours, ready to eat breakfast cereals, muesli, high fiber biscuits, etc. At home, barley flour can be easily blended with the wheat flour in order to make more nutritious and healthy products for daily consumption.

Wheat has very less amount of β-glucan, but when barley is added to it, the β-glucan content of wheat flour and of the final product increases (Holtekjolen et al. 2008; Yamlahi et al. 2013). Likewise, barley is also a store house of a large number of antioxidants (phenolic acids, proanthocyanidins, tannins, flavonols, chalcones, flavones, flavanones, lignans and amino phenolic compounds) and the blending of barley in wheat flour can enhance the nutritive value and the health benefits of wheat flour and its products (Holtekjolen et al. 2008; Sharma and Gujral 2014a). Hulless barley is commonly used for human food. Even though the current usage of hulless barley in human diets and animal feeds is quite small, it has vast potential uses. Lack of acceptance by the food and feed industries and lack of consumer awareness are due partly to the lack of a sufficient volume of hulless barley production and partly to food recognition of its food and feed value (Hou and Jimenez 2013).The processing of hulled barley is quite difficult and laborious. Therefore, the hulless barley can have the additional advantage of the minimal requirement of the processing.

The objective of this study was to improve the nutritional and health benefits of wheat-based food products by blending with hulless barley. IIWBR (ICAR-Indian Institute of Wheat and Barley Research) has identified a hulless barley variety that has high β-glucan content (Kumar et al. 2015), antioxidant activity and phenolics (Narwal et al. 2016). In India, about 90% wheat is used in the form of chapatti and is consumed in all the three meals in many parts of India. This study is the first attempt to use an Indian hulless barley variety for blending with the wheat flour and making blended chapatti and biscuits. These products were then analysed for β-glucan, antioxidant activity and total phenolic content to observe the blending effects.

Materials and methods

Material

Wheat (Triticum aestivum, C306 & HS490) and barley (Hordeum vulgare, BHS352) varieties grown at the research farm of Indian Institute of Wheat and Barley Research, Karnal, India were used in this study. The characteristics of these varieties are provided in Online Resource 1 (ESM1). For chapatti preparation, the barley from 2013–14 harvest and for cookies, barley from 2014–15 harvest was used. DPPH (1,1-diphenyl-2-picrylhydrazyl) and gallic acid were from Sigma (St. Louis, MO, USA). All other chemicals and solvents were of the highest commercial grade.

Preparation of flours

The barley (BHS352) and wheat (C306) whole meal flours were prepared using the Cyclotec Mill (Tecator, Hoganas, Sweden) using 0.5 mm sieve. The wheat variety (HS490) was tempered to 14% moisture and then subjected to roller flour milling (Brabender Quadrument Senior, Germany) to obtain refined flour having an extraction rate of 72%.

Chapatti preparation and quality analysis

Barley flour was added to the whole wheat flour in different ratios to have 5, 10, 15, 20, 25 and 30% barley blending on flour basis. Chapattis were prepared as per the method of Rao and Bharati (1996) with some modifications. 100 g whole wheat flour was kneaded into a dough with hands for around 3 min and the water used was noted. The dough was covered with a moist cloth and allowed to rest for 30 min. The dough was divided into two 40 g balls. These balls were rolled into chapatti of around 15 cm diameter and 2 mm thickness. The chapattis were baked on the heated iron griddle on both the sides and then allowed to puff on the gas burner flame. Chapattis were scored (0–10) subjectively for the following parameters: appearance, colour, taste, aroma, pliability, puffing height. Details of parameters studied for chapatti evaluation are given in Online Resource 2 (ESM2). Sensory qualities of chapatti were assessed by a panel of 6 judges adopting the procedure described by Rao et al. (1986). Chapattis from 100% wheat flour were used as control. Higher the chapatti score, better the quality of chapatti.

Biscuit preparation and quality analysis

Barley flour was added to wheat flour in different ratios to have 5, 10, 15, 20, 25 and 30% barley blending on flour basis. The biscuits were prepared as per the AACC method 10-52 (2010). Two biscuits were prepared from each blend and their spread factors were calculated. Biscuits were also prepared from 100% wheat and barley flours to serve as control.

Sample preparation and extraction

Chapatti and biscuits were dried in oven at 40 °C for 12 h, first grinded in pestle and mortar and then in Cyclotec Mill. Methanol extracts were prepared by adding 1.0 ml methanol to 0.1 g of each sample and shaking for 2 h. After shaking, the contents were centrifuged at 2500×g for 10 min. The supernatants were collected as methanol extracts and used for estimating total antioxidant activity and total phenolic content.

β-glucan content determination

The β glucan content was determined through an enzymatic method and Megazyme β glucan estimation kit was used (Megazyme International, Ireland) following McCleary Enzymic Method for barley (McCleary and Codd 1991).

DPPH radical scavenging activity

The free radical scavenging activity was measured using DPPH, a stable free radical as described by Beta et al. (2005). The methanol extract (0.1 ml) was reacted with 3.9 ml of 6 × 10−5 mol/L of DPPH solution. The absorbance was recorded at 0 and 30 min using methanol as blank at 515 nm. Antioxidant activity was calculated as % discoloration. All the tests were done in duplicate. The data for all antioxidant assays is reported as percent discoloration.

Phenolic content

Phenolic content in the extracts was estimated as described by Singleton et al. (1999). Briefly, 20μl of the extracts were mixed with 1.58 ml water and oxidized with 100μl of the Folin–Ciocalteu reagent. After 1–8 min, the reaction was stopped by adding 300 μl of 20% sodium carbonate solution and incubated in 40°C water bath for 30 min. Absorbance was measured at 765 nm and the content of phenolic compounds were determined against the gallic acid standards. The phenolic content in barley and malt was expressed as the µg of gallic acid equivalent (GAE) per gram of sample.

Statistical analysis

Data were reported as mean ± standard deviation for duplicate determinations of each sample. Analysis of variance (ANOVA) and Tukey’s comparison test were performed using XLSTAT software (2009) to identify differences between the values. Statistical significance was declared at P < 0.05.

Results and discussion

In this study, the potential of hulless barley as health food was utilized to improve the nutritional and health benefits of wheat products (chapatti and biscuit). Indian barley genotypes have high variability in the β-glucan content (2.4–7.2%) (Kumar et al. 2012). BHS352, is a hulless barley genotype with high (6.5%) β-glucan content (Kumar et al. 2015), antioxidant activity and phenolic content (Narwal et al. 2016). Wheat flour was mixed in different ratios with barley flour to make chapattis and biscuits and evaluated for their β-glucan content, antioxidant activity and phenolic content. Wheat variety C306 has the highest chapatti score and HS490 has the highest biscuit spread factor among all the released Indian wheat varieties and thus used in this study (Online Resource 1, ESM1).

Effect of barley blending on chapatti and biscuit quality

Flour from hulless barley variety BHS352 was mixed with whole wheat flour of C 306 in different ratios (5–30%). The chapattis were prepared and their quality scores were calculated. The quality score represents the overall quality of the chapatti including physical, cooking and sensory parameters. It was observed that more water was required to knead the dough with barley flour. Sharma and Gujral (2014b) also reported increase in dough water absorption with the addition of barley flour. The change in the taste of the chapattis started at 5% blending. The overall quality score of chapatti for C306 decreased from 8.6 to 7.25 at 30% barley blending level, which was mainly due to slight change in colour and taste (Table 1). Thus, after 30% blending with barley, the chapatti score decreased only by 15% and the chapattis were still acceptable.

Table 1.

Effect of barley blending on the quality of the wheat product

| % Barley added | Chapatti quality score (Out of 10)* | Biscuit spread factor* |

|---|---|---|

| 0 | 8.58 ± 0.06a | 11.33 ± 0.00b |

| 5 | 8.37 ± 0.06b | 11.98 ± 0.10a |

| 10 | 7.91 ± 0.00c | 10.27 ± 0.08c |

| 15 | 7.08 ± 0.06e | 8.61 ± 0.00d |

| 20 | 7.12 ± 0.06de | 8.13 ± 0.09e |

| 25 | 7.25 ± 0.00d | 7.92 ± 0.07f |

| 30 | 7.25 ± 0.00d | 7.54 ± 0.07g |

| 100 | – | 5.00 ± 0.00h |

* Values are means of two determinations ± standard deviation. Means with the same letters in the same column are not significantly different (P < 0.05)

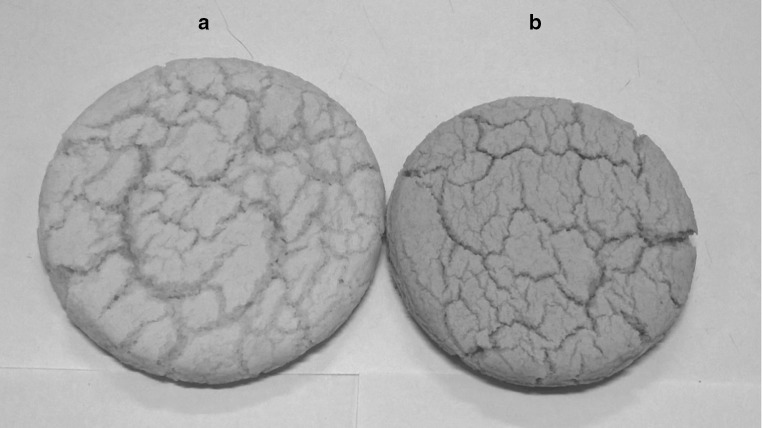

The spread factor of biscuits made from flour HS 490 was 11.33. As the amount of barley flour was increased, the biscuit spread factor decreased and was 7.54 at 30% barley blending which indicates a 33% decrease in the spread factor (Table 1, Fig. 1). The spread factor for the whole barley biscuits was only 5.0. Sharma and Gujral (2014a) observed 31% decrease in the biscuit spread factor when the wheat was completely replaced by barley flour. The colour of the cookies changed from pale cream to golden brown with increasing concentration of barley and the taste was acceptable even up to 30% blending (results not shown).

Fig. 1.

Biscuits prepared from 100% wheat flour (a) and with 30% barley blending (b)

Effect of barley blending on antioxidant activity of wheat flour, chapattis and biscuits

Chapattis were prepared by blending whole meal flour from C306 with hulless barley variety BHS352 in different ratios. The antioxidant activity of barley flour was found to be 60% discoloration. The antioxidant activity of whole wheat flour was however only 14.5% which increased to 32.0% discoloration with the blending of barley flour at 30% level (Table 2). Thus at 30% barley blending around twofold increase was observed in the antioxidant activity of whole wheat flour. The antioxidant activity of whole wheat flour decreased to 9.5% after chapatti making, however the activity increased to 14.0% discoloration with barley flour blending at 30% level. Sharma and Gujral (2014b) reported increase in antioxidant activity after chapatti preparation. These differences might be due to the different methods used for chapatti cooking. In this study, the normal house-hold method of cooking chapatti on a ladle and finally on the fire was used. But, Sharma and Gujral (2014b) used an electric hot plate for the final cooking of the chapattis. In both the studies the chapattis were acceptable with barley up to 30% level. Beyond which there were drastic changes in the taste and colour of the chapatti.

Table 2.

Effect of barley blending on the antioxidant activity of wheat flours, chapatti and biscuit

| % Barley added | Antioxidant activity (% Discoloration)* | |||

|---|---|---|---|---|

| Whole wheat flour: barley blends | Chapatti | Wheat flour: barley blends | Biscuit | |

| 0 | 14.45 ± 0.14g | 9.53 ± 0.72c | 1.41 ± 0.02d | 1.33 ± 0.01e |

| 5 | 17.93 ± 1.01f | 10.55 ± 0.43bc | 2.74 ± 0.04d | 4.51 ± 0.06de |

| 10 | 19.26 ± 0.87ef | 9.32 ± 0.14c | 5.92 ± 0.01cd | 5.12 ± 0.11d |

| 15 | 22.34 ± 0.29de | 10.76 ± 0.14bc | 11.57 ± 0.50bcd | 6.36 ± 0.06cd |

| 20 | 23.67 ± 1.59d | 11.89 ± 0.29 b | 15.72 ± 0.08bc | 8.75 ± 0.03bc |

| 25 | 27.97 ± 1.01c | 14.04 ± 0.43a | 21.91 ± 0.12b | 9.63 ± 0.14bc |

| 30 | 32.07 ± 0.72b | 13.93 ± 0.58a | 22.97 ± 0.06b | 9.89 ± 0.05b |

| 100 | 60.00 ± 0.56a | – | 52.21 ± 0.42a | 28.89 ± 0.23a |

* Values are means of two determinations ± standard deviation. Means with the same letters in the same column are not significantly different (P < 0.05)

Biscuits were prepared by blending refined wheat flour of HS490 with the hulless barley BHS352 in different ratios. The initial antioxidant activity of wheat flour was very less (1.4% discoloration) in comparison to that of barley flour (52.2% discoloration). After blending with 30% barley flour, the antioxidant activity increased considerably up to 23.0% discoloration (Table 2). In the biscuits, the initial activity was 1.3% which increased after 30% barley blending to 9.9%. Gupta et al. (2011) also observed that the incorporation of barley flour increased the antioxidant properties and polyphenolic content and hence increased functional properties of the cookies compared to the control. But, they did not observed a continuous increase in the antioxidant activity in the cookies with the increase in percentage of barley flour. Sharma and Gujral (2014a) studied the cookie making behavior of wheat flour (PBW 343) blended with hulled barley (PL712). They, however reported the increase in the antioxidant activity after cookie making in comparison to the dough and not the flour.

Effect of barley blending on the total phenolic content of wheat flour, chapattis and biscuits

Phenolic compounds are one of the important group of phytochemicals which contribute to the antioxidant activity of the cereal grains and also provide additional health benefits. Hulless barley BHS352 had phenolic content of 854 µg GAE/g. The phenolic content of the whole wheat flour was only 366 µg GAE/g. After 30% barley blending, the phenolic content of whole wheat flour increased to 489 µg GAE/g (Table 3). After chapatti making, the phenolic content of reduced to 238 from 366 µg GAE/g. The phenolic content of chapattis however increased from 238 to 290 µg GAE/g with 30% barley blending. Although the differences between wheat–barley flour blends were not statistically significant, but the phenolic content of the chapattis increased by around 20% when barley was added at 30% level. Increasing the levels of barley flour led to higher decrease in TPC which may be attributed to the longer baking time for chapatti containing barley flour due to increase in water absorption of dough. Also, as a consequence of increased water absorption there was more moist heat that led to greater damage to the TPC (Sharma and Gujral 2014b).

Table 3.

Effect of barley blending on the total phenolic content of wheat flours, chapatti and biscuit

| % Barley added | Total phenolic content (µg GAE/g)* | |||

|---|---|---|---|---|

| Whole wheat flour: barley blends | Chapatti | Wheat flour: barley blends | Biscuit | |

| 0 | 365.56 ± 0.00b | 237.78 ± 23.57a | nd | 63.83 ± 0.0b |

| 5 | 404.44 ± 7.86b | 304.44 ± 86.42a | 53.19 ± 0.0de | 63.83 ± 0.0b |

| 10 | 387.78 ± 47.14b | 243.33 ± 62.85a | 111.70 ± 7.61cde | 94.44 ± 0.63b |

| 15 | 415.56 ± 39.28b | 293.33 ± 7.86a | 143.62 ± 7.61cd | 66.67 ± 0.24b |

| 20 | 432.22 ± 94.28b | 287.78 ± 31.43a | 260.64 ± 2.75bc | 163.36 ± 2.39b |

| 25 | 421.11 ± 62.85b | 276.67 ± 31.43a | 329.79 ± 5.03b | 161.70 ± 7.26b |

| 30 | 448.89 ± 70.71b | 287.78 ± 15.71a | 340.43 ± 5.04b | 135.11 ± 4.65b |

| 100 | 854.44 ± 157.13a | – | 1042.55 ± 0.0a | 439.83 ± 2.91a |

nd not detected

* Values are means of two determinations ± standard deviation. Means with the same letters in the same column are not significantly different (P < 0.05)

Negligible amount of phenolics were observed in refined wheat flour. This is because most of the phenolics are concentrated in the outer bran layers of the grain and which are removed during the milling process. But in case of barley, the whole grain flour was used which had high content of phenolics (1065 µg GAE/g) and the TPC increased significantly as the amount of barley flour added was increased. At 30% barley blending, the phenolic content increased up to 340 µg GAE/g (Table 3). Phenolics are very unstable and reactive compounds and some degradation of phenolics occurs during baking process due to decomposition, volatilization (Hamama and Nawar 1991) and interaction of the phenolics including the tannins content (Dykes and Rooney 2006) with other components of the dough. The initial phenolic content in the wheat biscuits was 63 µg GAE/g which increased up to 135 µg GAE/g in 30% barley blended biscuits. Although the phenolic content of biscuits doubled, but no regular increasing trend was observed after blending. This may be due to the changes in the molecular structure of phenolic compounds as a result of heating which leads to either reduced chemical reactivity or decreases their extractability due to certain degree of polymerization (Altan et al. 2009). However, other reports indicate a gradual increase in the phenolic content of cookies with the increase in percentage of barley (Gupta et al. 2011; Sharma and Gujral 2014a).

Effect of barley blending on the β-glucan content of wheat flour, chapattis and biscuits

Wheat has very low β-glucan content, usually less than 1% (Gebreurs et al. 2008). Barley is a rich source of soluble fibre β-glucan and by adding barley to wheat, the β-glucan levels of different wheat products can be increased. Flours, chapattis and biscuits made from different wheat barley blends were tested for the β-glucan levels. The β-glucan content of hulless BHS352 barley is 6.5%. The β-glucan content of C306 whole wheat flour was only 0.7, which increased significantly up to 2.4% by adding barley at 30% level (Table 4). After chapatti making, β-glucan content remained quite stable. Wheat chapatti has β-glucan content of 0.6% which increased up to 2.3% in chapattis with 30% barley flour.

Table 4.

Effect of barley blending on the β-Glucan content of wheat flours, chapatti and biscuit

| % Barley added | β-Glucan content (%)* | |||

|---|---|---|---|---|

| Whole wheat flour: barley blends | Chapatti | Wheat flour: barley blends | Biscuit | |

| 0 | 0.69 ± 0.09g | 0.60 ± 0.05f | 0.26 ± 0.01g | 0.18 ± 0.00f |

| 5 | 1.07 ± 0.02f | 0.95 ± 0.04e | 0.59 ± 0.01f | 0.38 ± 0.01f |

| 10 | 1.41 ± 0.03e | 1.27 ± 0.09d | 0.81 ± 0.01e | 0.62 ± 0.03e |

| 15 | 1.59 ± 0.05de | 1.56 ± 0.12c | 1.39 ± 0.06d | 0.85 ± 0.01de |

| 20 | 1.80 ± 0.00d | 1.59 ± 0.04c | 1.85 ± 0.03c | 1.07 ± 0.01cd |

| 25 | 2.17 ± 0.07c | 2.00 ± 0.03b | 1.99 ± 0.10c | 1.28 ± 0.04bc |

| 30 | 2.40 ± 0.06b | 2.34 ± 0.04a | 2.22 ± 0.02b | 1.46 ± 0.03b |

| 100 | 6.50 ± 0.04a | – | 6.80 ± 0.09a | 4.13 ± 0.15a |

* Values are means of two determinations ± standard deviation. Means with the same letters in the same column are not significantly different (P < 0.05)

The refined wheat flour had β-glucan content of 0.3% which increased significantly to 2.2% with 30% barley blending. The wheat biscuits had β-glucan content of 0.2%, which increased to 1.3% in biscuits with 30% barley blending (Table 4). Skrbic and Cvejanov (2011) also reported a significant increase in β-glucan content of the cookies to 1.3% made from 30% blending with barley flour. Hassan et al. (2012) also reported an increase in β-glucan content of biscuits supplemented with 30% hulless barley flour to 1.8%.

Conclusion

Wheat has been blended with a number of cereals, legumes, seeds etc. in order to improve the health benefits of different wheat products. The aim of this study was to improve the nutritional and health benefits of wheat-based food products by blending with hulless barley. Barley is a store hose of nutrients but its direct use as food is very limited, but it can be easily blended with other flours to make healthy blended products. This study has shown that adding barley to wheat chapatti and biscuit can considerably enhance the nutritional value of these products in terms of high antioxidant activity, phenolic content and β-glucan content. Moreover, hulless barley requires less processing as compared to hulled barley and is therefore much more useful for blending purpose at house hold level. Thus, BHS352, a hulless barley variety can be a good option to improve the nutritional and health benefits of wheat-based products. By incorporating barley flour into popularly consumed wheat-based products, it could help consumers to improve their health.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

This work was financially supported by the Indian Council of Agricultural Research, New Delhi, India (Project No.DWR/RP/10/10.4).

Footnotes

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-017-2669-6) contains supplementary material, which is available to authorized users.

References

- AACC International (2010) Approved methods of analysis, 11th Ed. Method 10–52. Available online only. AACC International: St. Paul, MN

- Ali HK, Esam HM, Fathy MD. Influence of malt on rheological and baking properties of wheat cassava composite flours. LWT—Food Sci Technol. 2000;33:159–164. [Google Scholar]

- Altan A, McCarthy KL, Maskan M. Effect of extrusion process on antioxidant activity, total phenolics and b-glucan content of extrudates developed from barley-fruit and vegetable byproducts. Int J Food Sci Tech. 2009;44:1263–1271. doi: 10.1111/j.1365-2621.2009.01956.x. [DOI] [Google Scholar]

- Beta T, Nam S, Dexter JE, Sairstein HD. Phenolic content and antioxidant activity of pearled wheat and roller-milled fractions. Cereal Chem. 2005;82:390–393. doi: 10.1094/CC-82-0390. [DOI] [Google Scholar]

- Dykes L, Rooney LW. Sorghum and millet phenols and antioxidants. J Cereal Sci. 2006;44:236–251. doi: 10.1016/j.jcs.2006.06.007. [DOI] [Google Scholar]

- Gebruers K, Dornez E, Boros D, Fraś A, Dynkowska W, et al. Variation in the content of dietary fiber and components thereof in wheats in the HEALTHGRAIN diversity screen. J Agric Food Chem. 2008;56(21):9740–9749. doi: 10.1021/jf800975w. [DOI] [PubMed] [Google Scholar]

- Gujral HS, Gaur S. Instrumental texture of chapatti as affected by barley flour, glycerol monostearate and sodium chloride. Int J Food Prop. 2005;8:377–385. doi: 10.1081/JFP-200059492. [DOI] [Google Scholar]

- Gupta M, Bawab AS, Abu-Ghannam N. Effect of barley flour and freeze–thaw cycles on textural, nutritional and functional properties of cookies. Food Bioprod Process. 2011;89:520–527. doi: 10.1016/j.fbp.2010.07.005. [DOI] [Google Scholar]

- Hamama AA, Nawar WW. Thermal decomposition of some phenolic antioxidants. J Agric Food Chem. 1991;39:1063–1069. doi: 10.1021/jf00006a012. [DOI] [Google Scholar]

- Hassan AA, Ramsey NM, Foda MI, Bahgaat WK. Production of functional biscuits for lowering blood lipids. World J Dairy Food Sci. 2012;7(1):01–20. [Google Scholar]

- Holtekjølen AK, Baevre AB, Rødbotten M, Berg H, Knutsen SH. Antioxidant properties and sensory profiles of breads containing barley flour. Food Chem. 2008;110:414–421. doi: 10.1016/j.foodchem.2008.02.054. [DOI] [PubMed] [Google Scholar]

- Hou GG, Jimenez V (2013) Developing barley–fortified wheat based foods. Web. www.barleyfoods.org/documents/barleybagelsbw.pdf. Accessed 16 September 2013

- Kumar D, Narwal S, Verma RPS, Kharab AS, Kumar V, Sharma I. Genotypic variability in β-glucan and crude protein contents in barley genotypes. J Wheat Res. 2012;4(2):61–68. [Google Scholar]

- Kumar D, Verma RPS, Narwal S, Kharab AS, Malik R, Selvakumar R, Singh J, Kumar V, Sharma I. Barley lines with higher grain beta glucan content identified. Indian J Plant Genet Resour. 2015;28(3):346–347. doi: 10.5958/0976-1926.2015.00046.7. [DOI] [Google Scholar]

- Mc Cleary BV, Codd R. Measurement of (1-3)(1-4)-β-D-glucan in barley and oats: a streamlined enzymic procedure. J Food Sci Agric. 1991;55:303–312. doi: 10.1002/jsfa.2740550215. [DOI] [Google Scholar]

- Narwal S, Kumar D, Verma RPS. Effect of genotype, environment and malting on the antioxidant activity and phenolic content of Indian barley. J Food Biochem. 2016;40:91–99. doi: 10.1111/jfbc.12198. [DOI] [Google Scholar]

- Noorfarahzilah M, Lee JS, Sharifudin MS, Mohd Fadzelly AB, Hasmadi M. Applications of composite flour in development of food products. Int Food Res J. 2014;21(6):2061–2074. [Google Scholar]

- Ötles S, Cagindi Ö. Cereal based functional foods and nutraceuticals. Acta Sci Pol Technol Alignment. 2006;5(1):107–112. [Google Scholar]

- Pourafshar S, Rosentrater KA, Krishnan PG. Using alternative flours as partial replacement of barbari bread formulation (traditional Iranian bread) J Food Sci Technol. 2015;52(9):5691–5699. doi: 10.1007/s13197-014-1640-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rao M, Bharati P. Dough characteristics and chapathi making quality of wheat varieties. Karnataka J Agric Sci. 1996;9:562–564. [Google Scholar]

- Rao HP, Leelavathi K, Shurpalekar SR. Test baking of chapatti—development of a method. Cereal Chem. 1986;63(4):297–303. [Google Scholar]

- Sharma P, Gujral HS. Cookie making behavior of wheat-barley flour blends and effects on antioxidant properties. LWT—Food Sci Technol. 2014;55:301–307. [Google Scholar]

- Sharma P, Gujral HS. Antioxidant potential of wheat flour chapattis as affected by incorporating barley flour. LWT—Food Sci Technol. 2014;56:118–123. [Google Scholar]

- Singleton VL, Orthofer R, Lamuela-Raventos RM. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin–Ciocalteu reagent. Method Enzymol. 1999;299:152–178. doi: 10.1016/S0076-6879(99)99017-1. [DOI] [Google Scholar]

- Skendi A, Biliadenis CG, Papageorgiou M, Izydorczyk MS. Effect of two barley β-glucan isolates on wheat flour dough and bread properties. Food Chem. 2010;119:1159–1167. doi: 10.1016/j.foodchem.2009.08.030. [DOI] [Google Scholar]

- Škrbic´ B, Cvejanov J. The enrichment of wheat cookies with high-oleic sunflower seed and hull-lessbarley flour: impact on nutritional composition, content of heavy elements and physical properties. Food Chem. 2011;124:1416–1422. doi: 10.1016/j.foodchem.2010.07.101. [DOI] [Google Scholar]

- Sullivan P, Arendt E, Gallagher E. The increasing use of barley and barley by-products in the production of healthier baked goods. Trends Food Sci Technol. 2013;29:124–134. doi: 10.1016/j.tifs.2012.10.005. [DOI] [Google Scholar]

- Yamlahi AE, Berny E, Hammoumi A, Ouhssine M. Effect of barley (Hordeum vulgare L.) flour incorporation on the baking quality of wheat (Triticum aestivum L.) flour. J Chem Pharm Res. 2013;5(2):162–170. [Google Scholar]

- Zhao H, Fan W, Dong J, Lu J, Chen J, Shan L, Lin Y, Kong W. Evaluation of antioxidant activities and total phenolic contents of typical malting barley varieties. Food Chem. 2008;107:296–304. doi: 10.1016/j.foodchem.2007.08.018. [DOI] [Google Scholar]

- Zucco F, Borsuk Y, Arntfield SD. Physical and nutritional evaluation of wheat cookies supplemented with pulse flours of different particle sizes. LWT—Food Sci Technol. 2011;44:2070–2076. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.