Abstract

Present study was undertaken to optimize the process conditions for development of food grains (maize, defatted soy flour, sesame seed)-banana based nutritious expanded snacks using extrusion processing. Experiments were designed using Box–Behnken design with banana pulp (8–24 g), screw speed (300–350 rpm) and feed moisture (14–16% w.b.). Seven responses viz. expansion ratio (ER), bulk density (BD), water absorption index (WAI), protein, minerals, iron and sensory acceptability were considered for optimizing independent parameters. ER, BD, WAI, protein content, total minerals, iron content, and overall acceptability ranged 2.69–3.36, 153.43–238.83 kg/m3, 4.56–4.88 g/g, 15.19–15.52%, 2.06–2.27%, 4.39–4.67 mg/100 g (w.b.) and 6.76–7.36, respectively. ER was significantly affected by all three process variables while BD was influenced by banana pulp and screw speed only. Studied process variables did not affected colour quality except ‘a’ value with banana pulp and screw speed. Banana pulp had positive correlation with water solubility index, total minerals and iron content and negative with WAI, protein and overall acceptability. Based upon multiple response analysis, optimized conditions were 8 g banana pulp, 350 rpm screw speed and 14% feed moisture indicating the protein, calorie, iron content and overall sensory acceptability in sample as 15.46%, 401 kcal/100 g, 4.48 mg/100 g and 7.6 respectively.

Keywords: Extrusion, Banana, Physical properties, Colour quality, Protein

Introduction

Snack foods are the essential dietary part of today’s consumers as a substitute of quick meal. Nowadays consumers demand healthier and flavourful snack foods options in the market. Extrusion processing is emerging as a promising technology for developing snack foods with desired nutritional properties. The heated barrel as well as thermal energy generated by viscous dissipation during extrusion cooking with combination of shearing effect cooks the raw food materials quickly and modified the physico-chemical properties of the biopolymers (Thymi et al. 2005). Extrusion processing brings gelatinization of starch, denaturation of proteins, inactivation of enzymes, microbes and many antinutritional factors (Bhattacharya and Prakash 1994). Hence, extrusion processing of raw foods is a feasible technique to produce extruded snack foods and has been the object of studies to enhance the nutritional and functional properties of extrudates (Hernandez-Diaz et al. 2007; Gonzalez-Soto et al. 2006; Sacchetti et al. 2005).

Banana (Musa sapientum), an important fruit crop in India, being grown in more than 150 countries, producing 105 million tonnes of fruit per year (Post harvest profile of banana: 2015). Banana production was found maximum in India, contributing about 25.58% in world’s production, followed by China, Philippines and Ecuador (Post harvest profile of banana 2015). Banana is generally consumed as ripe fruit but processed banana products such as puree, juice, chips, powder etc. are also making an important place in food market. However, banana supplemented extruded products are hardly available in India. Banana is nutritious, easily digestible fruit and liked by consumers due to its aroma, texture, and easy to peel and eat, besides rich in potassium and calcium, and low in sodium content (Wall 2006; Anhwange 2008; Adisa and Okey 1987). Banana is rich in phenolic compounds and flavanoids, which have antioxidant properties. This fruit is rich in dopamine, an antioxidant (Kanazawa and Sakakibara 2000; Alothman et al. 2009). Potassium is most abundant mineral followed by magnesium, calcium, and phosphorus in edible portion of banana. Banana pulp is also rich in iron content where as copper is found very small quantity (Jenny et al. 1990). Extruded products are available in plenty but with poor nutritional quality due to cereals being the main ingredients in those products. Maize, being an economical grain and rich in starch component, play an important role in expansion of product during extrusion cooking. Defatted soy flour and grits are rich in protein and minerals with negligible amount of fat thus valuable food materials for enhancing the protein quantity as well as overall nutritional quality of the cereal based food products (Berk 1992). Being rich in calcium content, sesame seeds can also be considered for enhancing of calcium content of snack foods. Being a nutritious fruit, processed banana when accompanied with some legume based products can be useful for development of baby food and snack food products (Jenny et al. 1990) with enhanced flavour and mineral content. Extruded snack foods, one of the most commonly accepted snack foods amongst children and adults if enriched with protein and mineral rich food materials, will certainly be helpful in enhancing the nutritional quality of the product and thus consumers’ demand of health foods. In view of this, the present study was carried out to optimize the extrusion parameters and level of banana pulp for development of banana pulp incorporated nutritious extruded snack food.

Materials and methods

Raw materials

Maize, defatted soy flour, sesame seed and banana were procured from local market, Ludhiana, India. The maize sample was pulverized in hammer mill (Shriram Industries, Indrapuri, Bhopal, India) and sieved using BSS sieve no. 18 to get the grits of 0.954 mm grits (selected on a pre-trial basis). Sesame seeds were coarsely ground in a household grinder and sieved to get the particle size 0.954 mm. Defatted soy flour (Allegro brand, Super Foods, Chandigarh, India) was used to enhance the protein content of the product. Ripe banana pulp was prepared using a pulping machine (capacity 20 kg/h). Feed material was prepared by blending the coarsely ground raw materials i.e. maize (78.5%), sesame seeds (7.5%) with defatted soy flour (14%). This feed material (sample size: 500 g) was used to prepare the extrudates with each level of banana pulp as per the experimental plan. Experimental feed samples were adjusted to the desired moisture level as per the experimental plan (Table 1) by evaporating or by adding the required quantity of water and then allowed to stand at room temperature for 3 h to equilibrate the moisture content prior to extrusion cooking (Mridula et al. 2011).

Table 1.

Experimental design with values of independent and dependent variables of banana incorporated extrudates

| S. no. | Independent variables | |||||

|---|---|---|---|---|---|---|

| Banana pulp (g) | Screw speed, rpm | Feed moisture (%) | ||||

| Coded | Actual | Coded | Actual | Coded | Actual | |

| (a) | ||||||

| 1 | 0 | 16 | 0 | 325 | 0 | 15 |

| 2 | 0 | 16 | −1 | 300 | −1 | 14 |

| 3 | 0 | 16 | 1 | 350 | −1 | 14 |

| 4 | 0 | 16 | 0 | 325 | 0 | 15 |

| 5 | 0 | 16 | −1 | 300 | 1 | 16 |

| 6 | −1 | 8 | 1 | 350 | 0 | 15 |

| 7 | −1 | 8 | 0 | 325 | −1 | 14 |

| 8 | 0 | 16 | 1 | 350 | 1 | 16 |

| 9 | 0 | 16 | 0 | 325 | 0 | 15 |

| 10 | −1 | 8 | −1 | 300 | 0 | 15 |

| 11 | −1 | 8 | 0 | 325 | 1 | 16 |

| 12 | 0 | 16 | 0 | 325 | 0 | 15 |

| 13 | 1 | 24 | 0 | 325 | 1 | 16 |

| 14 | 0 | 16 | 0 | 325 | 0 | 15 |

| 15 | 1 | 24 | 0 | 325 | −1 | 14 |

| 16 | 1 | 24 | 1 | 350 | 0 | 15 |

| 17 | 1 | 24 | −1 | 300 | 0 | 15 |

| S. no. | Responses | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Expansion ratio | Bulk Density (kg/m3) | Water Absorption (g/g) | Water solubility index (%) | L value | a value | b value | Colour difference | Whiteness index | Yellowness index | |

| (a) | ||||||||||

| 1 | 3.03 | 193.26 | 4.72 | 23.58 | 79.95 | 3.20 | 20.36 | 2.24 | 71.25 | 57.63 |

| 2 | 3.11 | 192.20 | 4.80 | 23.46 | 78.23 | 2.60 | 18.00 | 5.15 | 71.63 | 51.62 |

| 3 | 3.24 | 192.03 | 4.71 | 23.39 | 77.01 | 4.25 | 18.08 | 6.03 | 70.45 | 54.05 |

| 4 | 3.08 | 188.70 | 4.76 | 23.38 | 76.64 | 2.91 | 19.40 | 5.36 | 69.50 | 54.79 |

| 5 | 2.87 | 191.22 | 4.83 | 23.37 | 81.92 | 2.42 | 19.42 | 2.88 | 73.36 | 52.73 |

| 6 | 3.34 | 156.65 | 4.84 | 22.65 | 81.01 | 3.39 | 20.94 | 1.34 | 71.53 | 58.41 |

| 7 | 3.36 | 153.43 | 4.86 | 22.17 | 81.55 | 3.24 | 19.99 | 2.23 | 72.60 | 55.25 |

| 8 | 2.98 | 195.62 | 4.65 | 23.36 | 81.98 | 3.06 | 19.27 | 3.00 | 73.44 | 52.9 |

| 9 | 3.05 | 191.88 | 4.77 | 23.36 | 79.95 | 3.21 | 20.61 | 2.04 | 71.07 | 58.08 |

| 10 | 3.22 | 161.00 | 4.87 | 22.25 | 80.97 | 2.82 | 20.37 | 1.82 | 71.98 | 56.51 |

| 11 | 3.20 | 160.83 | 4.88 | 22.26 | 81.85 | 2.72 | 20.02 | 2.24 | 72.84 | 54.81 |

| 12 | 3.02 | 194.88 | 4.82 | 23.34 | 81.35 | 3.05 | 20.03 | 2.15 | 72.46 | 55.39 |

| 13 | 2.69 | 238.83 | 4.56 | 23.88 | 79.91 | 3.33 | 20.44 | 2.22 | 71.15 | 57.01 |

| 14 | 3.09 | 192.83 | 4.69 | 23.38 | 80.88 | 2.94 | 19.76 | 2.44 | 72.35 | 54.9 |

| 15 | 3.07 | 232.94 | 4.58 | 23.76 | 79.68 | 3.17 | 20.01 | 2.67 | 71.31 | 56.6 |

| 16 | 3.02 | 238.28 | 4.62 | 23.96 | 77.01 | 4.8 | 18.86 | 5.69 | 69.88 | 56.76 |

| 17 | 2.96 | 236.97 | 4.59 | 23.85 | 79.84 | 3.37 | 19.61 | 2.95 | 71.67 | 55.65 |

| Experiments | Independent variables | Responses | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Banana pulp (g) | Screw speed, rpm | Feed moisture (%) | Protein content, [%] (w.b.) | Total minerals, [%] (w.b.) | Iron content, mg/100 g (w.b.) | Calcium content [mg/100 g] (w.b.) | Overall acceptability | ||||

| Coded | Actual | Coded | Actual | Coded | Actual | ||||||

| (b) | |||||||||||

| 1 | 0 | 16 | 0 | 325 | 0 | 15 | 15.38 | 2.20 | 4.51 | 111 | 7.15 |

| 2 | 0 | 16 | −1 | 300 | −1 | 14 | 15.33 | 2.14 | 4.49 | 110 | 7.12 |

| 3 | 0 | 16 | 1 | 350 | −1 | 14 | 15.39 | 2.18 | 4.52 | 111 | 7.02 |

| 4 | 0 | 16 | 0 | 325 | 0 | 15 | 15.36 | 2.16 | 4.53 | 112 | 7.11 |

| 5 | 0 | 16 | −1 | 300 | 1 | 16 | 15.41 | 2.18 | 4.52 | 110 | 7.11 |

| 6 | −1 | 8 | 1 | 350 | 0 | 15 | 15.52 | 2.07 | 4.46 | 91 | 7.35 |

| 7 | −1 | 8 | 0 | 325 | −1 | 14 | 15.51 | 2.07 | 4.44 | 90 | 7.24 |

| 8 | 0 | 16 | 1 | 350 | 1 | 16 | 15.43 | 2.13 | 4.48 | 111 | 7.12 |

| 9 | 0 | 16 | 0 | 325 | 0 | 15 | 15.40 | 2.13 | 4.54 | 116 | 7.10 |

| 10 | −1 | 8 | −1 | 300 | 0 | 15 | 15.49 | 2.06 | 4.39 | 92 | 7.36 |

| 11 | −1 | 8 | 0 | 325 | 1 | 16 | 15.48 | 2.07 | 4.43 | 91 | 7.33 |

| 12 | 0 | 16 | 0 | 325 | 0 | 15 | 15.42 | 2.12 | 4.49 | 113 | 7.12 |

| 13 | 1 | 24 | 0 | 325 | 1 | 16 | 15.28 | 2.27 | 4.65 | 153 | 7.00 |

| 14 | 0 | 16 | 0 | 325 | 0 | 15 | 15.31 | 2.12 | 4.57 | 113 | 6.82 |

| 15 | 1 | 24 | 0 | 325 | −1 | 14 | 15.26 | 2.26 | 4.59 | 148 | 6.764 |

| 16 | 1 | 24 | 1 | 350 | 0 | 15 | 15.22 | 2.27 | 4.67 | 147 | 6.88 |

| 17 | 1 | 24 | −1 | 300 | 0 | 15 | 15.19 | 2.26 | 4.59 | 155 | 7.05 |

Experimental design

Box–Behnken design was used to design the experiments with three independent process variables using Design expert 8.0.5 software. Seventeen sets of experiments (Table 1) were performed taking into account three independent variables viz., feed moisture 14–18%, screw speed 330–350 rpm and banana pulp 8, 16, 24 g. Response variables were expansion ratio, bulk density, colour quality (‘L’, ‘a’, ‘b’ value, Colour difference (ΔE), whiteness index (WI), Yellowness index (YI)), water absorption index, water solubility, protein content, total minerals, iron content, calcium content and overall acceptability. Difference between variables was tested for significance using one way Anova analysis procedure.

Extrusion processing

Extrudates samples were prepared using a co-rotating twin screw extruder (Basic Technologies Private Ltd., Kolkata, India) using 3.0 mm die for this study. This twin screw extruder has three barrel zones with 350 mm length with length to diameter ratio of 5:1. The extruder was operated at 10.5 kg/h feed rate and 110 ± 2 °C die head temperature. The extruder barrel was heated or cooled as per requirement at two sections by a separate water circulation system. The temperature of barrel wall was measured by thermocouples and displayed on the electric panel. Steady-state conditions of extruder were assumed to have been reached when there were no visible drift in the barrel temperature for at least 5 min. The feeder and cutter were controlled with 0.5 hp motor, separately. Extrudate rods coming out through die were cut through a constant cutter speed (15 rpm), dried at 50 °C for 2 h (Mridula et al. 2011) in a tray dryer to about 4.5% moisture content (w.b.). The velocity of drying air in tray dryer was 0.5 m/s. The samples were packaged in polyethylene bags (thickness 65μ), sealed properly using heat sealing machine and stored at ambient conditions (25±2 °C) for further quality analysis.

Bulk density and expansion ratio

Expansion Ratio of extrudates was determined as per the method suggested by Ryu and Ng (2001). The diameter of randomly selected extrudates samples was measured at ten different positions along the length of each sample using digital vernier calliper (Model no. CD-8 CSX, Mitutoyo Corp., Kawasaki, Japan). The mass of these extrudate pieces was determined by electronic weighing balance with a least count of 0.0001 g. Expansion Ratio of extrudates and bulk density was calculated by using the following formula, assuming cylindrical shape of extrudates (Asare et al. 2004; Thymi et al. 2005).

| 1 |

| 2 |

where, w is mass, kg; d is diameter, m; and l is length of extrudate, m

Water absorption index (WAI) and water solubility index (WSI)

WAI and WSI were determined in triplicate following the method described by Ding et al. (2005). Ground sample (3 g) was dispersed in 30 mL of distilled water and stirred using a vortex mixer for 30 s at 150 rpm. This dispersion was allowed to stand for 30 min in a water bath at 30 °C. Subsequently, the dispersion was centrifuged at 3000 rpm (rotor radius 29 mm) for 15 min using the Centrifuge (Eltek, Electrocraft (India) Pvt. Ltd., Mumbai, India). The supernatants were decanted into an evaporating dish of known weight, dried at 110 °C and weighed. The WSI of extrudates was considered as the weight of dry solids in the supernatant expressed as percentage of the original weight of sample. WAI and WSI were calculated using following equations:

| 3 |

| 4 |

Instrumental colour quality

Colour (L, a and b values) of the extrudate samples was determined by using Hunter Colorimeter (model no. 45/0 L, made in U.S.A). Before measuring, the colorimeter was calibrated using a white reference tile and a black reference tile. ‘L’ is known as the lightness and extends from 0 (black) to 100 (white), ‘a’ values and ‘b’ values indicates redness (+a) to greenness (−a) and yellowness (+b) to blueness (−b), respectively. Yellowness index was computed by the instruments itself and the yellowness index readings showed by the colorimeter were recorded for evaluating this parameter. The measurements were performed repeatedly four times per sample. An important factor characterizing the variation of colour in the test sample is the total colour difference (ΔE) or TCD (Chakrborty et al. 2011). The total colour difference of samples (ΔE) was defined by the Minolta equation (Amirdivani and Baba 2011) and whiteness index (WI) of extrudates samples was calculated as follows (Prasert and Suwannaporn 2009):

| 5 |

where, ΔL = L − L0, Δa = a − a0, Δb = b − b0; L, a, and b are the measured values of extrudate samples; L0, a0, and b0 are the values of extrudates without banana pulp.

| 6 |

Proximate composition

The moisture, protein, fat, crude fibre, total mineral content, iron and calcium content of extrudate samples were determined using AOAC methods nos. 925.10, 960.52, 920.39, 962.09, 923.03, 944.02 and 944.03, respectively (AOAC 2000). Carbohydrate content was calculated by subtracting the sum of moisture, protein, fat and total minerals from 100 (Hira et al. 1996). Total calories were calculated by multiplying protein, carbohydrates (excluding crude fibre) and fat content by factor of 4, 4 and 9, respectively (Hira et al. 1996). All reagents used for chemical analysis of extrudate samples were of analytical grade.

Sensory characteristics

Sensory characteristics of extruded snack food, such as appearance, colour, sensory texture, odour, flavour, taste and overall acceptability were evaluated on nine point hedonic scale (BIS 1971) by a group of 17 semi-trained panellists. Before sensory evaluation, each sample of extrudates (100 g) was mixed with 2 mL refined oil (Fortune refined soybean oil), 1.5 g salt and 0.2 g green chilli powder for flavouring purposes. Samples (20 g each) were served to each panellist in paper plates identified by random three digits codes for sensory evaluation. Care was taken to maintain the sensory environment at 25 ± 2 °C.

Statistical analysis

Response surface methodology was adopted for experimental design and analysis of the results (Khuri and Cornell 1987) using a commercial statistical package, Design-Expert software version 8 (Stat-Ease Inc, Minneapolis, MN, USA). Multiple regression analysis was used to fit the model, represented by an equation, to the experimental data. The response surfaces for the models were plotted as a function of the two variables while keeping the other one at optimum level.

Numerical optimization technique of the Design–Expert software was used for simultaneous optimization of the multiple responses. The optimization of the food materials aimed at finding the level of independent variables viz. banana pulp (g), screw speed (rpm) and moisture content (%), which could give maximum expansion, protein content, total minerals, iron content, overall acceptability, and minimum bulk density. Responses obtained were analyzed to visualize the interactive effect of independent parameters on quality attributes of the extruded product. Adequacy of the model was considered based on coefficient of correlation (R2), F-ratio and lack of fit. The models were considered adequate when the calculated R2 value was more than 0.80 and lack of fit test was insignificant (Henika 1982).

Results and discussion

Effect of process variables on physical properties of extrudates

Physical properties are important for consumer acceptability of the extruded snack foods. The expansion ratio and bulk density of extruded snack foods have been reported as the most valuable indicator of quality in expanded food products. Expansion index, bulk density, water absorption and water solubility index (WSI) of different extrudate samples ranged between 2.69–3.36, 153.43–238.83 kg/m3, 4.56–4.88 g/g and 22.17–23.96%, respectively (Table 1). Regression analysis for studying the effect of independent variables on physical parameters namely, expansion index, bulk density, water absorption and WSI of extrudates suggested that the model was significant at p ≤ 0.05. Therefore, the second order model was adequate to predict the responses and interpret the effect of independent variables on the responses using the following equations:

where A—Banana; B—Screw speed, C—Moisture.

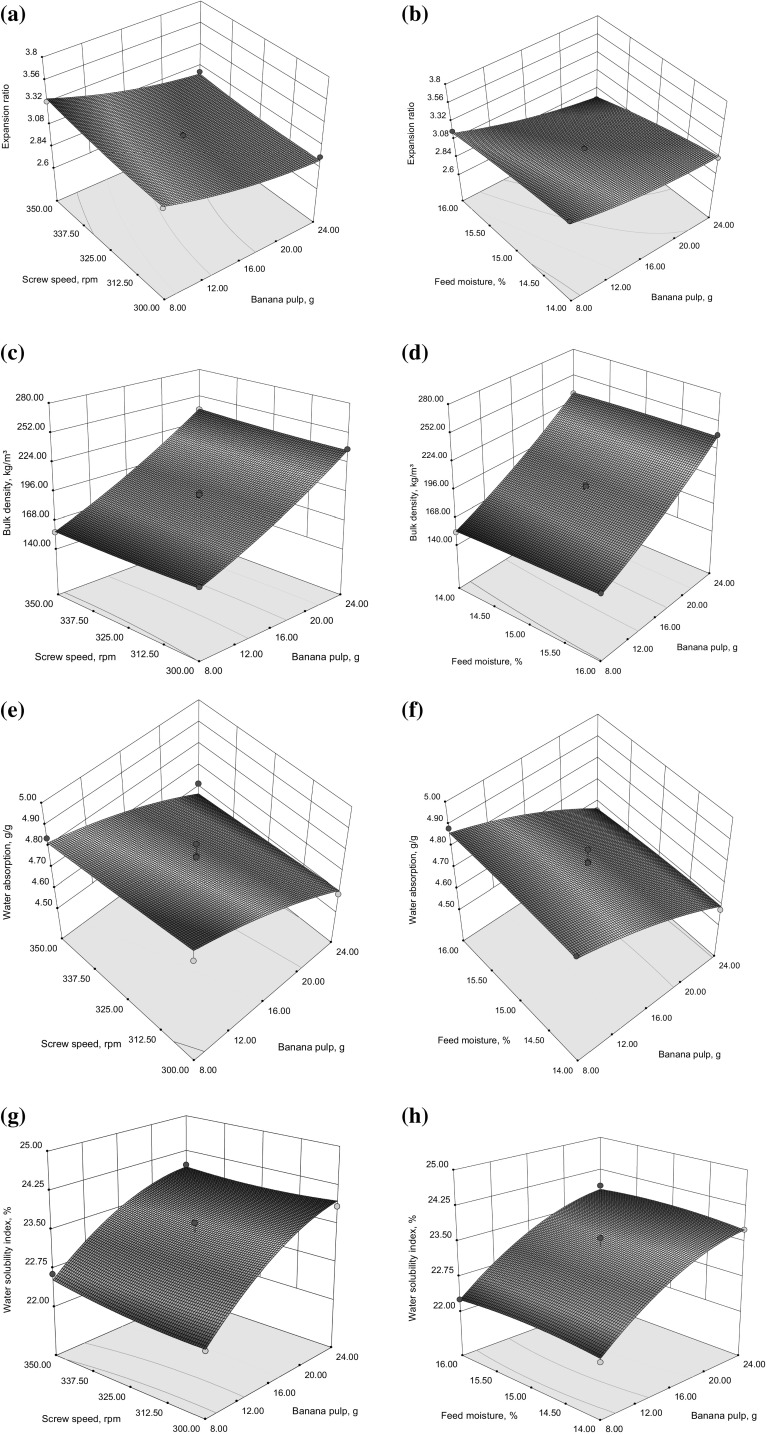

The coefficient of determination (R2) of the models for expansion index, bulk density, water absorption and WSI were found to be 0.9766, 0.9967, 0.8901 and 0.979, respectively, which further indicated that the model was suitable for adequately describing the real relationships among the selected independent variables (Table 1). Non-significant lack of fit indicated a good agreement with the fitted model. The expansion ratio was most significantly (p ≤ 0.05) affected by level of banana pulp followed by moisture content and screw speed (Fig. 1a–b). A negative linear interaction with banana pulp and feed moisture content indicated a reduction in expansion ratio with increasing level of banana pulp and moisture content. This might be attributed to the dilution effect to starch on account of addition of banana pulp (Altan et al. 2008a). A reduction in expansion ratio was also observed by Chiu et al. (2013) in corn extrudates fortified with yam flour. Bulk density was significantly (p ≤ 0.05) affected by level of banana pulp and screw speed. An increase in bulk density was observed with increasing levels of banana pulp and screw speed with a maximum value of 238.28 kg/m3 at 24% level of banana pulp and 350 rpm screw speed (Fig. 1c–d). There is an inverse relation between bulk density and expansion ratio of the extrudates. An increase in bulk density of extrudate was also been observed by Altan et al. (2008b) with increasing level of grape pomace may be attributed to the presence of fiber. Water absorption and WSI were found affected (p ≤ 0.05) by the level of banana pulp only (Fig. 1e–h) with no significant (p ≥ 0.05) effect of screw speed and moisture content (Table 2). Higher levels of banana pulp resulted in an increased WSI whereas water absorption of extrudates was found decreased with increasing level of banana pulp (Fig. 1e–h). This might be due to higher sugar content in banana pulp that limited the gelatinization due to competition between sugar and starch molecules for available moisture as also indicated in other study (Lund 1984). Similar observations had also been indicated by Dhungana et al. (2014) in extrudates prepared with sweet potato flour and tomato pomace. Addition of banana pulp significantly increased the WSI of extrudates. WSI increased progressively with increase in the banana pulp and may be attributed to the amount of soluble solids present in ripened banana pulp. An increase in WSI and decrease in WAI was also reported by Kaur et al. (2015) in banana flour added corn extrudates.

Fig. 1.

Effect of banana pulp, screw speed and feed moisture on expansion ratio (a–b), bulk density (c–d), water absorption (e–f) and water solubility index (g–h) of extrudates

Table 2.

Analysis of variance of linear, quadratic and interactive terms of banana incorporated extrudates process variables on physical properties and nutritional quality responses

| Particulars | Expansion ratio | Bulk density | Water absorption | WSI | ‘a’ value | Whiteness index | Colour difference | Protein content | Total minerals | Iron content | Calcium content | Overall acceptability |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | 32.50** | 233.11** | 6.30** | 37.79** | 7.98** | 0.98 | 1.12 | 9.35** | 12.62** | 9.25** | 222.76** | 3.76** |

| A-Banana | 163.37** | 2072.65** | 51.52** | 307.84** | 11.66* | 2.45 | 2.12 | 79.60** | 108.89** | 76.59** | 1904.03** | 27.80** |

| B-Screw speed | 14.72** | 0.029** | 3.05 | 1.50 | 34.32** | 1.12 | 0.65 | 1.32 | 0.033 | 2.07 | 1.63 | 0.80 |

| C-Moisture | 92.34** | 5.28 | 0.052 | 0.087 | 5.58 | 2.30 | 2.01 | 0.98 | 6.134E−003 | 0.19 | 1.20 | 1.89 |

| A*B | 0.75 | 1.34 | 0.18 | 1.32 | 2.76 | 0.36 | 1.26 | 3.984E−003 | 1.850E−003 | 0.058 | 4.27* | 0.62 |

| A*C | 8.45** | 0.095* | 0.13 | 0.024 | 1.72 | 0.031 | 0.027 | 0.45 | 0.097 | 1.14 | 1.67 | 0.47 |

| B*C | 0.039 | 0.87 | 0.63 | 0.066 | 3.81 | 0.32 | 0.070 | 0.23 | 2.55 | 1.11 | 0.067 | 0.24 |

| A*A | 8.83** | 16.38 | 1.03 | 25.65** | 5.02 | 0.077 | 1.69 | 0.40 | 1.28 | 0.59 | 90.95** | 0.77 |

| B*B | 1.84 | 0.83 | 3.428E−003 | 1.42 | 3.93 | 0.029 | 2.11 | 0.091 | 0.14 | 0.75 | 1.12 | 1.05 |

| C*C | 2.32 | 0.28 | 0.066 | 2.11 | 3.32 | 2.17 | 0.34 | 1.20 | 0.43 | 0.78 | 1.75 | 0.19 |

| Lack of fit | 2.4 | 1.33 | 1.51 | 2.27 | 6.58 | 0.69 | 1.06 | 0.92 | 0.045 | 1.30 | 1.17 | 0.15 |

| C.V. % | 1.24 | 1.26 | 1.16 | 0.53 | 8.08 | 1.56 | 46.42 | 0.27 | 1.27 | 0.70 | 1.67 | 1.50 |

| R2 | 0.9766 | 0.9967 | 0.8901 | 0.979 | 0.9112 | 0.5584 | 0.5906 | 0.9232 | 0.9420 | 0.9224 | 0.9965 | 0.8286 |

Significance: ** (p ≤ 0.05), * (p ≤ 0.1)

Effect of process variables on colour quality of extrudates

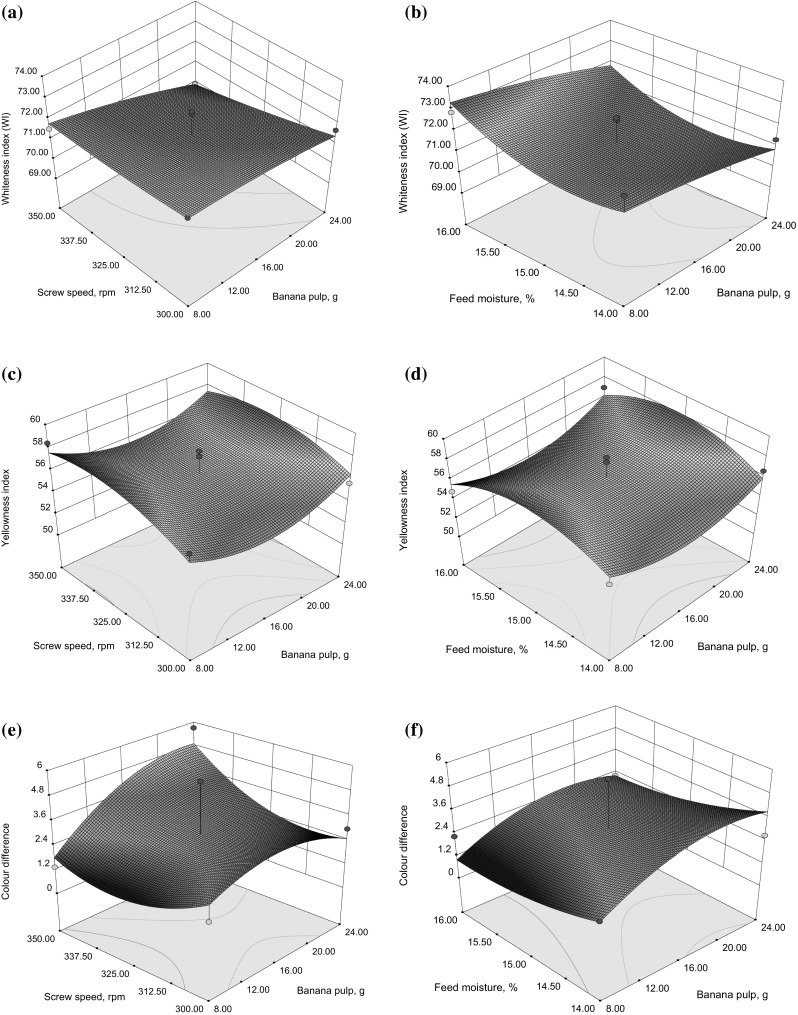

The selected processing variables did not influence the colour quality i.e. ‘L’ value, ‘b’ value, whiteness index (Fig. 2a–b), yellowness index (Fig. 2c–d) and colour difference (Fig. 2e–f) significantly (p > 0.05) whereas, ‘a’ value was significantly affected by level of banana pulp and screw speed at linear level (Table 2). Increase in ‘a’ value i.e. increase in degree of redness was observed with increasing levels of banana pulp and screw speed. This increase in ‘a’ value of colour index as obtained by instrumental colour analysis is probably due to the occurrence of Maillard reaction products, melanoidins, which are responsible for the browning of extrudates (Soria and Villamiel 2012). Maillard reaction is characterized by the interaction between carbonyl group of reducing sugars with the amine group of proteins, peptides or amino acids, occurring in the presence of heat. Therefore, higher the levels of banana pulp in feed formulation of the extrudate, greater the occurrence of Maillard reaction, leading to high ‘a’ value or redness in the final product. In addition, enzymatic browning might also contribute in increased ‘a’ value to a certain degree due to enzymatic reaction during preparation of banana pulp under atmospheric conditions.

Fig. 2.

Effect of banana pulp, screw speed and feed moisture on whiteness index (a–b), yellowness index (c–d) and colour difference (e–f) of extrudates

Predictive equations for colour quality values are as follows:

where A—Banana; B—Screw speed, C—Moisture

Effect of process variables on nutritional quality of extrudates

The experimental results of nutritional quality by a Box–Behnken design, with five replications at the central point are shown in Table 1b. Based on the experimental responses, protein, total minerals, iron and calcium content of extrudates ranged from 15.19–15.52%, 2.06–2.27%, 4.39–4.67 mg/100 g and 90–155 mg/100 g, respectively. Analysis of variance for protein, total minerals, iron and calcium content showed that these nutrients in extrudates were significantly affected by the levels of banana pulp (Table 2). The R2 value for all the responses was greater than 0.90 suggesting more than 90% variability has been explained by models. Fisher’s F test also showed that the models were significant at p < 0.05. Thus, all the responses were considered adequate to describe the effect of process variables on protein, total minerals, iron and calcium content of extrudates.

The protein, total minerals, iron and calcium content of extrudates were significantly (p < 0.05) affected by linear level of banana pulp (Fig. 3a–h). The protein content was negatively affected by addition of banana pulp (Fig. 3a–b). A decrease in protein content with increasing level of banana pulp was observed, may account to the dilution effect of banana pulp on feed formulation. Positive linear coefficients indicated increase in total minerals, iron and calcium content with the increasing levels of banana pulp. Calcium content was also significantly affected by quadratic level of banana pulp and interaction between level of banana pulp and screw speed. The increase in total minerals, iron and calcium content with increasing levels of banana pulp is due to banana pulp being rich in these minerals.

Fig. 3.

Effect of banana pulp, screw speed and feed moisture on protein content (a–b), Total minerals (c-d), iron content (e-f), calcium content (g-h)

Effect of process variables on overall acceptability of extrudates

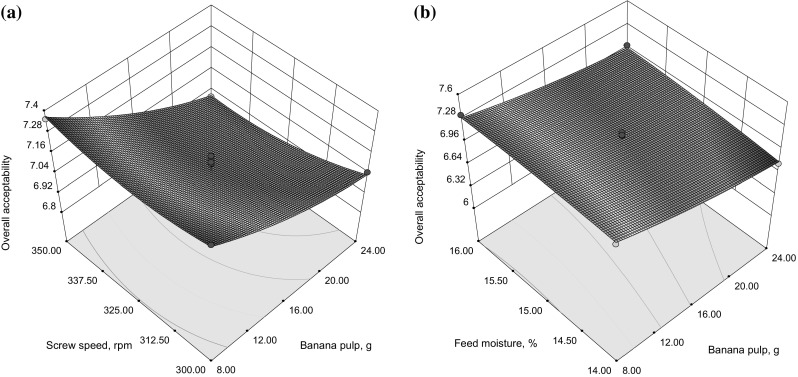

Overall sensory acceptability of extrudates was obtained by compounding contributory scores of all the sensory attributes, the optimum levels for the former satisfy the all individual sensory scores. The overall acceptability score of extrudates varied from 6.76 to 7.36. Maximum overall acceptability score was obtained at 8 g level of banana pulp, 300 rpm screw speed and 15% feed moisture content. Table 2 showed that the coefficient of determination (R2) of the regression model for overall acceptability of extrudates was 0.8286. Therefore, model can be considered adequate as it had a high R2 value. Lack of Fit F-value was non-significant relative to pure error. Predictive equation for overall acceptability is as follows:

The overall sensory acceptability was significantly affected by linear level of banana pulp only (Fig. 4a–b). The significant (p < 0.05) negative coefficient at linear level indicated a decrease in overall acceptability with increasing level of banana pulp. This effect was attributed to the increase in bulk density and decrease in expansion ratio of extrudates hence, affected the sensory texture and appearance of the product also, increasing levels of banana pulp resulted in deviation of colour index of extrudates as compared to control hence, negatively affecting the sensory scores for appearance and colour of the product but for all the experiments performed, the sensory score of banana extrudates were found to be in acceptable limits by the sensory panel.

Fig. 4.

Effect of banana pulp, screw speed (a) and feed moisture (b) on overall acceptability of nutritious extruded snacks

Optimization and validation of parameters

Optimum conditions were determined based upon maximizing expansion ratio, water absorption index, protein content, total minerals, iron content and overall acceptability and minimizing bulk density, whereas independent variables were kept within the range. Based upon the statistical analysis of data, optimized conditions with maximum desirability level (=0.805) were 8 g ripe banana pulp, 350 rpm screw speed and 14% feed moisture. This optimized solution was further validated by analyzing the responses for the sample prepared following the above optimized conditions (Table 3). The extrudates prepared using optimized conditions were found to have 15.46% protein, 2.11% total minerals, 4.48 mg/100 g iron and 92 mg/100 g calcium with an overall acceptability score of 7.60. It was observed that the experimental values of the responses were not statistically different from the predicted values and hence confirmed the validity of optimum conditions.

Table 3.

Constraints, criteria for optimization and optimized solutions with predicted and actual experimental values of banana incorporated extrudates

| Particulars | Target | Experimental range | Importance | Optimum value | Desirability | |

|---|---|---|---|---|---|---|

| Min | Max | |||||

| Banana pulp | Range | 8 | 24 | 3 | 8.00 | 0.805 |

| Screw speed (rpm) | Range | 300 | 350 | 3 | 350.00 | |

| Feed moisture (%) | Range | 14 | 16 | 3 | 14.00 | |

| Responses | Predicted values | Experimental values | ||||

| Expansion ratio | Maximize | 2.69 | 3.36 | 5 | 3.42 | 3.44 |

| Bulk density (kg/m3) | Minimize | 153.43 | 238.83 | 5 | 153.43 | 153.86 |

| Water Absorption (g/g) | Maximize | 4.56 | 4.88 | 5 | 4.83 | 4.80 |

| Total minerals (%) | Maximize | 2.06 | 2.27 | 1 | 2.09 | 2.11 |

| Protein content (%) | Maximize | 15.19 | 15.52 | 5 | 15.54 | 15.46 |

| Iron content (mg/100 g) | Maximize | 4.39 | 4.67 | 2 | 4.46 | 4.48 |

| Overall acceptability | Maximize | 6.76 | 7.36 | 5 | 7.30 | 7.60 |

Conclusion

Response surface methodology is successfully used for optimization of extrusion variables for development of food grains-banana pulp based nutritious snacks food and evaluation of impact of process conditions on extruded snack properties. All the properties were affected by the variation in the level of banana pulp, screw speed and feed moisture content indicating the importance of optimizing extrusion variables for developing a new product in order to achieve optimum product quality. The optimum conditions for preparation of nutritious expanded snack utilizing ripe banana are 8 g banana pulp (per 100 g feed material), 350 rpm screw speed and 14% feed moisture. The fat, carbohydrates, crude fibre, total minerals, iron and calcium content in this nutritious expanded snack with banana was 3.86%, 73.83%, 2.29%, 2.1%, 4.48 mg/100 g and 92 mg/100 g, respectively. The protein and calories in this banana incorporated nutritious snack was 15.46% and 391 kcal/100 g, which could fulfil about 50% of protein and 20% of calorie requirement of a 7–9 years old child. The high protein and significant amount of calories and mineral content in the developed snack food also showed the great potential in combating protein-calorie malnutrition.

Acknowledgements

Authors express sincere thanks to Director, ICAR-CIPHET, Ludhiana for providing funds & facilities for conducting this study.

References

- Adisa VA, Okey EN. Carbohydrate and protein composition of banana pulp and peel as influenced by ripening and mold contamination. Food Chem. 1987;25:85–91. doi: 10.1016/0308-8146(87)90057-4. [DOI] [Google Scholar]

- Alothman M, Bhat R, Karim AA. Antioxidant capacity and phenolic content of selected tropical fruits from Malaysia, extracted with different solvents. Food Chem. 2009;115:785–788. doi: 10.1016/j.foodchem.2008.12.005. [DOI] [Google Scholar]

- Altan A, McCarthy KL, Maskan M. Evaluation of snack foods from barley-tomato pomace blends by extrusion processing. J Food Eng. 2008;84(2):231–242. doi: 10.1016/j.jfoodeng.2007.05.014. [DOI] [Google Scholar]

- Altan A, McCarthy KL, Maskan M. Twin-screw extrusion of barley-grape pomace blends: extrudate characteristics and determination of optimum processing conditions. J Food Eng. 2008;89(1):24–32. doi: 10.1016/j.jfoodeng.2008.03.025. [DOI] [Google Scholar]

- Amirdivani S, Baba AS. Changes in yogurt fermentation characteristics, and antioxidant potential in vitro inhibition of angiotensin-1 converting enzyme upon the inclusion of peppermint, dill and basil. Food Sci Technol-LWT. 2011;44:1458–1464. doi: 10.1016/j.lwt.2011.01.019. [DOI] [Google Scholar]

- Anhwange BA. Chemical Composition of Musa sapientum (Banana) peels. J Food Sci Technol. 2008;6:263–266. [Google Scholar]

- Asare EK, Sefa-Dedeh S, Sakyi-Dawson E, Afoakwa EO. Application of response surface methodology for studying the product characteristics of extrudated rice-cowpea-groundnut blends. Int J Food Sci Nutr. 2004;55:431–439. doi: 10.1080/09637480400003238. [DOI] [PubMed] [Google Scholar]

- Association of Official Analytical Chemist (AOAC) (2000). Official methods of analysis of AOAC International, 17 edn. Published by AOAC International, Maryland, USA

- Berk Z (1992) Technology of production of edible flours and protein products from soybeans. FAO agricultural services bulletin no. 97. Food and Agriculture Organization of the United Nations, Rome

- Bhattacharya S, Prakash M. Extrusion of blends of rice and chickpea flours: a response surface analysis. J Food Eng. 1994;21:315–330. doi: 10.1016/0260-8774(94)90076-0. [DOI] [Google Scholar]

- BIS . Indian Standard IS: 6273 part I and part II. Guide for sensory evaluation of foods. New Delhi: Indian Standard Institution (BIS), Manak Bhawan; 1971. [Google Scholar]

- Chakrborty R, Bera M, Mukhopadhyay P, Bhattacharya P. Prediction of optimal conditions of infrared assisted freeze-drying of aloe vera (Aloe barbadensis) using response surface methodology. Sep Purif Technol. 2011;80:375–384. doi: 10.1016/j.seppur.2011.05.023. [DOI] [Google Scholar]

- Chiu HW, Peng JC, Tsai SJ, Tsay JR, Lui WB. Process optimization by response surface methodology and characteristics investigation of corn extrudate fortified with yam (Dioscorea alata L.) Food Bioprocess Technol. 2013;6:1494–1504. doi: 10.1007/s11947-012-0894-6. [DOI] [Google Scholar]

- Dhungana PK, Chauhan A, Singh S. Evaluation of extrudate from sweet potato flour and tomato pomace blend by extrusion processing. Afr J Food Sci. 2014;8(5):264–277. doi: 10.5897/AJFS2013.1074. [DOI] [Google Scholar]

- Ding QB, Ainsworth P, Tucker G, Marson H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice based expanded snacks. J Food Eng. 2005;66:284–289. doi: 10.1016/j.jfoodeng.2004.03.019. [DOI] [Google Scholar]

- Gonzalez-Soto RA, Sanchez-Hernandez L, Solorza-Feria J, Nunez-Santiago C, Flores-Huicochea E, Bello-Perez LA. Resistant starch production from non-conventional starch sources by extrusion. Food Sci Technol Int. 2006;12:5–11. doi: 10.1177/1082013206060735. [DOI] [Google Scholar]

- Henika RG. Use of response surface methodology in sensory evaluation. Food Technol. 1982;36:96–101. [Google Scholar]

- Hernandez-Diaz JR, Quintero-Ramos A, Barnard J, Balandran-Quintana RR. Functional properties of extrudates prepared with blends of wheat flour/pinto bean meal with added wheat bran. Food Sci Technol Int. 2007;13(4):301–330. doi: 10.1177/1082013207082463. [DOI] [Google Scholar]

- Hira CK, Kawatra BL, Sadana B, Sharma KK. A manual of laboratory techniques for nutrition research. Ludhiana: Punjab Agrricultural University; 1996. p. 10. [Google Scholar]

- Jenny R, Pólit P, Nair BM. Evaluation of the nutritional quality of flakes made of banana pulp and full-fat soya flour. Food Chem. 1990;36(1):31–43. doi: 10.1016/0308-8146(90)90005-O. [DOI] [Google Scholar]

- Kanazawa K, Sakakibara H. High content of dopamine, a strong antioxidant, in cavendish banana. J Agric Food Chem. 2000;4:844–848. doi: 10.1021/jf9909860. [DOI] [PubMed] [Google Scholar]

- Kaur A, Kaur S, Singh M, Singh N, Shevkani K, Singh B. Effect of banana flour, screw speed and temperature on extrusion behaviour of corn extrudates. J Food Sci Technol. 2015;52(7):4276–4285. doi: 10.1007/s13197-014-1524-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Khuri AI, Cornell JA. Response surfaces: designs and analysis. New York: Marcel Dekker; 1987. [Google Scholar]

- Lund D. Influence of time, temperature, moisture, ingredients, and processing conditions on starch gelatinization. Crit Rev Food Sci. 1984;20:249–273. doi: 10.1080/10408398409527391. [DOI] [PubMed] [Google Scholar]

- Mridula D, Jain D, Singh KK, Patil RT, Gupta MK. Physico-chemical and sensory quality of extruded snack foods developed from rice and defatted soy flour/chickpea splits supplemented with dried beetroot. J Agic Eng. 2011;48(4):17–23. [Google Scholar]

- Post Harvest Profile of Banana (2015) Government of India, Ministry of Agriculture (Department of Agriculture & Cooperation), Directorate of Marketing & Inspection, Branch Head Office, Nagpur, MRIN. http://agmarknet.dac.gov.in/Others/CPBANANA.pdf/. Accessed 31 May 2016

- Prasert W, Suwannaporn P. Optimization of instant jasmine rice process and its physic chemical properties. J Food Eng. 2009;95:54–61. doi: 10.1016/j.jfoodeng.2009.04.008. [DOI] [Google Scholar]

- Ryu GH, Ng PKW. Effects of selected process parameters on expansion and mechanical properties of wheat flour and whole cornmeal extrudates. Starch. 2001;53:147–154. doi: 10.1002/1521-379X(200104)53:3/4<147::AID-STAR147>3.0.CO;2-V. [DOI] [Google Scholar]

- Sacchetti G, Pittiam P, Pinnavaia GG. The effect of extrusion temperature and drying tempering on both of kinetics of hydration and the textural changes in extruded ready-to-eat breakfast cereals during soaking in semi-skimmed milk. Int J Food Sci Tech. 2005;40:655–663. doi: 10.1111/j.1365-2621.2005.00976.x. [DOI] [Google Scholar]

- Soria AC, Villamiel M. Non-enzymatic browning in cookies, crackers and breakfast cereals. In: Simpson BK, Nollet LML, Toldra F, Benjakul S, Paliyath G, Hui YH, editors. Food biochemistry and food processing. 2. London: Wiley; 2012. pp. 584–593. [Google Scholar]

- Thymi S, Krokida MK, Papa A, Maroulis ZB. Structural properties of extruded corn starch. J Food Eng. 2005;68:519–526. doi: 10.1016/j.jfoodeng.2004.07.002. [DOI] [Google Scholar]

- Wall MM. Ascorbic acid, vitamin A, and mineral composition of Banana (Musa sp.) and papaya (Carica papaya) cultivars grown in Hawaii. J Food Compost Anal. 2006;19:434–445. doi: 10.1016/j.jfca.2006.01.002. [DOI] [Google Scholar]