Abstract

The international cut flower industry is strongly criticized because of its environmental impacts and unsafe working conditions. Increasing certification of cut flowers is used to improve the growers’ environmental and social performance. But what is the impact of this private governance instrument on regulating the use of pesticides? This paper assesses the potential of private certification on governing the environmental and social problems from pesticide use along the global cut flower supply chain. We use detailed farm-level data to analyse the environmental and social impacts of flower certification in Ethiopia by comparing different national and international certification schemes. Our analysis does not show significant differences between these different private standards for most environmental and health and safety variables. The Ethiopian cut flower industry remains far from improving its sustainability performance through private certification. However, certification schemes may enable farmers to have access to international markets and keep up their reputation.

Electronic supplementary material

The online version of this article (doi:10.1007/s13280-017-0914-x) contains supplementary material, which is available to authorized users.

Keywords: Cut flower, Ethiopia, Pesticide, Private certification

Introduction

The floriculture sector is booming in Ethiopia making the country the second largest flower exporter in Africa and the fourth largest supplier of flowers globally. Over the last ten years, the expansion of floriculture in Ethiopia has been remarkable. It was only in 1997 that the first private floriculture farms, Meskel Flower and Ethio-Flora, started their activities on only a few hectares. By 2007, the number of companies involved in flower production and export reached 67 (Mano and Suzuki 2011). Today, there are around 84 companies growing cut flowers, mostly roses followed by summer flowers and cuttings. Out of these, 52 are funded through foreign direct investment (FDI), while 26 are local companies and six are joint ventures (EHPEA 2015).

The rapid growth of floriculture in Ethiopia is due to the country’s favourable climate, natural resources, the extensive support from the government and the abundant availability of labour. Currently, the floriculture industry occupies about 2000 hectares of greenhouses and open fields. Cut flowers have become the country’s second largest source of foreign exchange in agriculture (next to coffee). The value increased from USD 660 000 in 2001 to USD 211.89 million in 2012/2013. In 2013, the sector generated total earnings of about USD 265.7 million and this is expected to reach USD $550 million by the end of 2016 (The Reporter 2014; EHPEA 2016). For Ethiopian flowers, the EU is the main export destination. Currently, more than 70% of Ethiopia’s floriculture products go to the Dutch market and from there these flowers are re-exported to other EU countries and beyond. Other markets are Germany, Britain, Russia and the Middle East (Getu 2009; EHPEA 2015). The sector provides employment for 180 000 workers, of whom about 80% are women (Mano and Suzuki 2011).

Despite the enormous economic advantages resulting from the Ethiopian floriculture industry, environmental and social problems are growing. There is increasing evidence that the economic benefits from the flower industry come at the expense of farm workers’ health and the environment (Sisay 2007; Getu 2009; Tamirat 2011; Tilahun 2013). Flower growers are among the heaviest users of agrochemicals in the country, starting before seed germination and continuing until after harvesting. For instance, the Ethiopian rose cultivators use more than 212 different pesticides with various active ingredients (Sahle and Potting 2013). The intensive use of pesticides is deteriorating the health and safety of the workers and a large proportion of these pesticides ends up in non-target destinations via drift, volatilization, leaching and run-off (Mmochi and Mberek 1998; Damalas and Eleftherohorinos 2011).

Environmental pollution from pesticides in Ethiopia is investigated in different studies. In particular, Sisay (2007) and Sahle and Potting (2013) describe how chemicals released from flower farms in Ethiopia negatively affect the quality of water and aquatic life. Tamiru (2007) also identified the negative impacts of pesticides on the depletion of macro-invertebrates and the disappearance of sensitive taxa downstream of the flower-producing areas. The negative effects of pesticide use on water and soil quality on non-target organisms like soil organisms, aquatic animals, human beings, and the increase of pesticide resistance of targeted pests are reported by Tamirat (2011), Tilahun (2013), Mekonen et al. (2014) and Teklu et al. (2016). With regard to workers’ health and safety, different studies (Mekonnen and Agonafir 2002; Negatu et al. 2016) highlight problems causing the workers’ feet to swell due to standing for many hours in the greenhouse. Working in the flower industry also causes kidney problems and other health problems such as headaches, coughing, skin rushes, respiratory problems, blood vein problems, pneumonia, bronchitis, sinus, vomiting and others. The absence of adequate toilet facilities, clean drinking water and showers, maternity leave as well as lack of first aid on Ethiopian flower farms was also reported.

The situation of the floriculture industry in Ethiopia does not differ from the rest of the Global South. There are similar experiences reported in other countries such as Ecuador (Jakobasch 1998; Mena and Proaño 2005), China (Kargbo et al. 2010), Costa Rica, Columbia (David 2002) Kenya (Dolan et al. 2002) and Tanzania (PAN UK 2008). Most cut flowers are grown in the Global South (Colombia, Ecuador Ethiopia, Kenya, Uganda Zambia, Zimbabwe) where environmental regulation is limited and states have not been very effective in enforcing policies on pesticide distribution and use (PAN UK 2008; Stadlinger et al. 2013; Mengistie et al. 2015a, b). In addition to this, in Ethiopia, the cut flower industry is not properly regulated. There is (i) a lack of specific laws; (ii) there is an absence of commitment to enforce the relevant laws; and (iii) the government provides long-term credits on very generous terms (Getu 2009; Gebreeyesus and Iizuka 2010). In general, the government’s desire to attract foreign investors is manifested in the deregulation of the sector. In importing countries, the flower sector is also regulated weakly because flowers are not edible (WRI 2016) and international regulatory standards are generally weak.

For these problems, different private standards have been developed by business coalitions and NGOs (Riisgaard 2008; Raynolds 2012). The majority of these standards have been developed in Europe, and exporting countries, such as Kenya, Ethiopia, Uganda and others, have recently developed their own standards. Overall, at least 20 different social and environmental standards exist in the cut flower industry (Ponte et al. 2011). These standards used in Ethiopia are the Horticulture Producers Exporters Association (EHPEA) Code of Practice (at three levels: Bronze, Silver and Gold), MPS-ABC, MPS-SQ, MPS-GAP, Fair trade, Ethical Trading Initiative (ETI), Fair Flower Fair Plants (FFP) and Global-GAP (BTC 2010; Raynolds 2012). Several studies have been conducted on the Ethiopian floriculture industry (Joosten 2007; Belwal and Chala 2008; BTC 2010; Gebreeyesus and Iizuka 2010; Mano and Suzuki 2011). However, much attention has not been paid to the existence of multiple sustainable standards and nothing has been known about the positive impacts of these standards on the environment and on workers’ health and safety. Hence, in this article, we analyse (i) whether there are differences between growers complying with advanced standards and the minimum standard required for export; (ii) whether or not private standards contribute to the improvement of the environment and working conditions.

This article begins with outlining our conceptual framework and then explains the research methods applied. Then, we assess the potential impact of certification on fostering sustainable production practices, on strengthening workers’ well-being and on reducing the risks and impacts of pesticide use for the environment.

Background

Private certification as global pesticide governance instrument

Nowadays, producing certain products for the international market requires meeting certain quality standards. Agricultural products are faced with stricter rules on residues and pest management than in the past. Many of these standards are private, non-state-mandated and transnational (Ponte et al. 2011; Raynolds 2012) and they may take different forms: NGO-initiated standards addressing a vast array of environmental, labour, product safety and other issues; codes of conduct promulgated by corporations and industry associations; and even self-regulation by corporations under the banner of corporate social responsibility (CSR) (Humphrey and Schmitz 2001; Gereffi et al. 2005). This study focuses on the use of certification schemes as a non-state regulatory mechanism. We are especially interested in schemes whereby an independent third party provides assurance that a product, a process or a service is in conformity with the standards.

Global supply chain analysis helps us to understand how pesticide governance through certification may take place. This perspective underlines that the introduction of environmental and social standards in the international flower supply chain, which is buyer-driven, should be seen as complementing the wider shift in the power balance towards the downstream end of the global value chain. Growing consumer concerns create a more demanding regulatory setting for importers, exporters, wholesalers and retailers and oblige growers to manage their practices more carefully, to avert negative publicity and to have their products shown to be of high quality. Social and environmental standards are a prominent governance strategy for global buyers who seek to reduce risk (Riisgaard 2008, 2011). Standards may set entry barriers for newcomers in the supply chain, and create challenges for developing country suppliers (e.g. on safety/working conditions, pesticide residues and toxins). On the other hand, standards may also provide the opportunity for selected suppliers to add value, integrate new functions, improve their products and even spur new or enhanced forms of cooperation among the actors in the industry (Gibbon and Ponte 2005; Tanner 2000). Blackman and Naranjo (2010) found out that eco-certification of coffee significantly reduces chemical input use and increases adoption of some environmentally friendly management practices. Most studies focused on the role of labour organizations to address workers’ safety and rights. Previous studies on the flower industry, such as Riisgaard (2008, 2011) in Kenya and Raynolds (2012) in Ecuador, found that labour organizations’ ability to seriously challenge the prevailing governance structure of the cut flower value chain is extremely limited. Issues of fairness and safety have slowly entered the industry with some countries’ producers and exporters now adopting voluntary codes.

Environmental and social standards and certifications in floriculture

Associations of flower producers in developing countries are increasingly active in introducing standards and codes of practice (Joosten 2007; BTC 2010). In 2007, the EHPEA developed the EHPEA Code of Practice (EHPEA-CoP). This is a voluntary standard developed to guide, monitor and communicate the social and environmental performance of flower farms engaged in export production. The code set requirements for good agricultural practices, protection of the environment, worker welfare and employment practices at three levels: Bronze, Silver and Gold. The Bronze-Level Certification includes basic legal requirements and key issues relevant for the market and local stakeholders; the Silver-Level Certification is broadly similar to Global-GAP for flowers and ornamentals and contains social components equivalent to the Good Social Compliance of the ETI standard and MPS-SQ. EHPEA Gold-Level Certification requires a farm to be active in the implementation of Corporate Social Responsibility (CSR), product quality management and capacity building for the sector.

EHPEA-CoP is adopted by 90% of the sampled farms (See Table 1), with the majority at the Bronze Level. The international standards that are adopted most are MPS-ABC and MPS-SQ, with 65 and 52% of all farms, respectively. The survey also shows that more certifications are adopted by farms that are foreign-owned, older, larger-sized and involved in direct sales channels than by farms that are nationally owned, new, small-sized and involved in auction sales (Table 2). According to this survey, 34% of flowers farms are Dutch-owned, 22% Indian and 12% Israeli while the remaining 32% are fully or (through joint venture) owned (EHPEA 2015). During the period of the survey, about 62% of the growers exported to the EU through auctions (mainly Dutch) combined with direct sales to supermarkets and retailers and 21% used only auction, while the remaining (mainly Indian-owned) 17% exported to the Middle East. Nearly all (92%) farms perceived certification to be a requirement from European supermarkets (especially for direct sale). However, this is not the case when selling through the auction. Many Indian and Russian growers in the ‘Holleta’ cluster selling directly to the Middle East doubted the added value of certification and they were not ready to pay the additional expenses (estimated to be about 100 000–150 000 Ethiopian Birr, or USD 5000). Compliance to standards, however, not only provided a perceived ‘gateway’ to the main markets, but—according to the perceptions of the farms—also improved human and material resource management (87% of the farms), environmental performance (73%) and workers’ safety (68%) (Fig. 1).

Table 1.

Sustainability standards in the interviewed cut flower farms (n = 29)

| Certifications | Full specification | No of certified growers included |

|---|---|---|

| EHPEA-CoP | Growers/suppliers code of practices in standards (bronze, silver and gold level), certified by independent external audits | Bronze (16), Silver (7) Gold (3) |

| MPS-ABC | Environmental certification: reduction of pesticide, water, fertilizer, waste and energy use | 17 |

| MPS-SQ | Socially qualified certification: occupational health and safety aspects | 15 |

| Global-GAP | Good agricultural practices with a small section on workers’ health, safety and welfare | 7 |

| Ethical Trade Initiative (ETI) | Labour/promoting respect for workers’ rights | 4 |

| Fairtrade | Fairtrade flower: mainly occupational health and safety standards and small section on environmental issues | 3 |

| Fair Flower Fair plants (FFP) | Contain ecological and social certification scheme of floriculture | 3 |

Source Ethiopian Horticulture Producer Exporters Association (EHPEA 2015)

Table 2.

Detail of sample flower growers

| Number of farm | Nationality | Production area (ha) | Size work force | # Sprayers | Export destination | Certification |

|---|---|---|---|---|---|---|

| Farm 1 | Dutch | 22 | 600 | 30 | Netherlands, Japan | Silver, GAP, MPS A, SQ, FFP, ETI |

| Farm 2 | Ethiopian | 12 | 400 | 16 | Netherlands, UK, Germany, Middle East | Silver, MPS A, MPS-SQ |

| Farm 3 | Ethiopian | 15 | 340 | 15 | Netherlands | Silver, MPS A, SQ, GAP, ETI, |

| Farm 4 | Belgium | 14 | 22 | Europe, USA, Asia | Silver, on process for GAP | |

| Farm 5 | Dutch | 37 | 1150 | 48 | Netherlands, America, Japan | Silver, GAP, MPS A, SQ, FT, FFP |

| Farm 6 | Ethiopian | 15 | 420 | 22 | Netherlands, Middle East | Silver, MPS A, MPS-SQ |

| Farm 7 | Dutch | 25 | 500 | 20 | Netherlands | Silver, MPS-SQ, MPS-ABC |

| Farm -8 | Dutch | 325 | 10 000 | 250 | Netherlands | Gold, FFP, FT, ETI, Global-GAP, MPS A, MPS-SQ, |

| Farm 9 | German/Dutch | 41 | 1827 | 40 | Europe and USA | Gold, Global-GAP, FT, ETI, MPS A, MPS-SQ |

| Farm 10 | Dutch | 14.5 | 800 | 30 | Europe | Gold, MPS A, MPS-SQ |

| Farm 11 | Dutch | 12 | 200 | 21 | Netherlands | Bronze, MPS A, MPS-SQ, GAP |

| Farm 12 | Indian | – | Middle East | Bronze | ||

| Farm 13 | Russian | 10 | 260 | 13 | Middle east and Russia | In process |

| Farm 14 | Israel | 70 | 1400 | 40 | UK, France, Germany, Norway | Bronze, Global-GAP |

| Farm 15 | Dutch | 40 | 1200 | 62 | Netherlands | Bronze, MPS A, MPS-SQ |

| Farm 16 | Indian | – | Middle East | Bronze | ||

| Farm 17 | Ethiopian | 10 | 340 | 18 | Netherlands | Bronze, MPS A, MPS-SQ |

| Farm 18 | Ethiopian | 18 | 450 | 26 | Netherlands, German | Bronze, MPS A, SQ, Fairtrade |

| Farm 19 | Dutch | 15 | 474 | 22 | Netherlands, Germany, Middle East, Russia | Bronze |

| Farm 20 | Ethiopian | 12 | 300 | 19 | Netherlands | Bronze |

| Farm 21 | Indian | – | – | Middle East | Bronze, MPS A, | |

| Farm 22 | Belgium | 15.6 | 278 | 13 | Belgium, Netherlands, South Africa | In process |

| Farm 23 | Multinational | 18 | 700 | 40 | Europe | Bronze, Global-GAP |

| Farm 24 | Israel | 14.6 | 270 | 14 | Netherlands, Dubai | Bronze, MPS A |

| Farm 25 | Joint venture | 20 | 350 | 7 | Netherlands | Bronze |

| Farm 26 | France | 9.2 | 220 | 12 | France, Rome Middle East and South Africa | In process |

| Farm 27 | Ethiopian | 15 | 260 | 13 | Netherlands, Middle East and German | Bronze, MPS A. |

| Farm 28 | Indian | – | Middle East, Europe | Bronze, MPS A, MPS-SQ | ||

| Farm 29 | Indian | – | Middle East | Bronze |

Farms 12,16, 21 28 and 29 have 950 workers, 40 ha and 22 sprayers together. Handover to ANSA Group during fieldwork

Source Field survey, 2015; Ethiopian Horticulture Development Agency, 2012 and MPS database/websites, 2015

Fig. 1.

Certification of flowers posted at one of the sample farms

Materials and Methods

This study takes flower farms as its main object of research and assesses the impact of private certification on the environment and workers’ health and safety in the floriculture sector in Ethiopia. In 2015, 84 flower farms were operational in different agro-ecological zones in Ethiopia. Of these, 29 farms were selected on the basis of the following criteria: the distribution among different geographical regions/clusters, the origin of the owner’s country, accessibility of data, membership and consultation of EHPEA1 and certification status of growers. In-depth interviews were conducted at these 29 farms in five regions i.e. Ziway, Koka, DebreZeit, Sebeta and Holleta.

An important assumption for this research was that farms that comply with higher standards are more likely to perform better than farms certified according to the minimal standard. Therefore, the farms were categorized into two groups. First, the farms with only EHPEA bronze-level certification (the minimum requirement for exporting) together with the farms in the process of auditing for this bronze-level certification and the farms with only bronze and a single international certification (MPS) (the ‘de facto’ minimum requirement for the floricultural sector in the EU). This category included 19 farms. Second, the farms that have EHPEA silver or gold and/or two or more international certifications (Global-GAP, MPS, ETI, FFP or FT). EHPEA silver and gold levels contain higher requirements for social and environmental performance compared to bronze, and equate with various international labels for the sector. This category included 10 farms (see Table 2 for details). The names of the farms are not included to secure anonymity.

The study combined qualitative and quantitative research methods. Data were collected using structured and semi-structured questionnaires adapted from an audit check sheet. Furthermore, open interviews were held with key informants supplemented with personal observations between August and December 2015. To examine the impact of certification on environmental aspects of pesticide use, 29 farm managers were asked about registration, selection and types of pesticides, strategies with regard to minimizing pesticide use (implementation of IMP), obsolete pesticides, empty containers, solid and liquid waste disposal, audit/certification status, distribution channels and experience of rejection due to certification or pesticide residues. To examine the impact of certification on occupational health and safety, interviews were carried out with 180 randomly selected pesticide sprayers (from a total of 835). Interviews took place outside the farm and dealt with the quality and availably of protective gears, (im)proper use, training on safety, medical check-up (cholinesterase test), labour union and experience with accidents in relation with pesticide application.

All pesticide sprayers were regular workers in Ethiopian flower farms. To investigate re-entry intervals, accidents in relation with pesticides and the availability of protective gears, interviews were carried out with 32 randomly selected pack house workers and 30 flower harvesters (cutters). To examine the influence of certification and labelling along with the supply chain, interviews were also carried out with buyers in the Netherlands (3 wholesalers, 1 from the auction Flora Holland, 3 supermarkets, 18 florists and 48 consumers) using convenience sampling method. A convenience sample is made up of informants who are easy to reach. The Netherlands plays an important role in the international flower trade, and is the main importer from Ethiopia. Use of pesticides in the flower industry can be exercised through buyers’ requirements, stringent standards and distribution channels. Concerned consumers may also exercise their influence more indirectly through boycotts (Micheletti 2003) and demand reliable information about the way the product is produced. Finally, interviews were held with the Ethiopian Horticulture Producer Exporters Agency (EHPEA), the Ministry of Agriculture (MOA), and the Ethiopian Horticulture Development Agency (EHDA) to examine their interactions with flower growers in supporting, regulating and monitoring pesticide use and workers’ health and safety. Observations were used to enhance information on, for instance, the quality of spraying suits, the pesticide storage and the conditions of pesticide incinerators. The information was recorded by means of a structured questionnaire administered via interviews. The questionnaire contained both closed- and open-ended items about common pesticide use practices. Existing documents and pictures of important observations were included as supportive qualitative information. This is then accompanied by the interpretation of pesticide use, practices in textual data and determines how these patterns and themes help answer the research questions at hand.

The quantitative data were coded, entered in SPSS (version 20) and analysed using the Chi-square test to determine the presence of significant differences.

Results and discussion

The impact of certification on environmental safety

Cut flowers are among the commodities most sensitive to diseases and pests (Eshetu et al. 2009). According to the survey, spider mites, aphids, trips, powdery mildew, downy mildew, botrytis, nematodes, mealy bugs and caterpillars are the most common problems. To control these pests and diseases, pesticides (insecticides, fungicides, nematicides, herbicides, growth regulators) are being applied and their use has increased over the years. According to PAN UK (2007), Tamiru (2007), Vieira and Abarca (2009), Tilahun (2013) and MoA (2014) between 2007 and 2014, flower farms in Ethiopia have imported 96 types of insecticides and nematicides and 105 types of fungicides. Of these, 37 were not officially registered in Ethiopia. For roses alone, more than 212 types of pesticides with different active ingredients were used (Joosten 2007; Sahle and Potting 2013). Most growers rank pesticides second on their list of expenditures, next to international (air)transport costs. Table 3 reports the results of environmental impact assessment of pesticide use according to a set of variables such as the degree of certification of the grower. These different variables are further elaborated below.

Table 3.

The impact of certification on selected environmental aspects of pesticides (n = 29)

| Environmental variable | Response category | Bronze-certified growers | Silver/gold and MPS-ABC, GAP, certified growers |

|---|---|---|---|

| Legal/registration status of pesticide | Both registered and unregistered/untested | 19 | 10 |

| Only registered | 0 | 0 | |

| Types of pesticide currently used | Class II | 19 | 10 |

| Class III and above | 19 | 10 | |

| Strategies of alternative pest management | IPM | 0 | 3 |

| Only chemical pesticides | 19 | 7 | |

| Interval of pesticide application | Every three day | 11 | 5 |

| Every week | 8 | 6 | |

| Spraying is only carried out when justified/depending on scouting | 14 | 10 | |

| Does the farm have obsolete pesticides? | Yes | 15 | 8 |

| No | 4 | 2 | |

| Conducted EIA before starting farm operation | Yes | 0 | 0 |

| No | 19 | 10 | |

| Have a policy on environment, waste disposal, risk assessment | Yes | 16 | 10 |

| No, but we have plans to do so | 3 | 0 | |

| Pesticide store inspection | Yes | 3 | 3 |

| No | 16 | 7 | |

| Audit procedure | Announced | 19 | 10 |

| Unannounced | 0 | 0 |

According to the official Ethiopian pesticides registration and control proclamation (PRCP) No. 674/2010, before their use, all pesticides must undergo registration procedures that are implemented under the Plant Health Regulatory Directorate (PHRD) of the MoA. However, the Ethiopian government made an interim arrangement allowing flower growers to import unregistered pesticides which they themselves consider essential for their farms. As a result, flower growers and/or agents representing flower companies, such as Agri Sher, Greenlife and HortiCop, have been importing many different kinds of pesticides (see Table S1).

When comparing Bronze-certified growers with growers certified with higher-level standards, we do not observe differences with respect to registration or the type of active ingredients used. Both categories reported the use of pesticides that the WHO classifies as Class II (highly toxic) and III (moderately toxic). Although none of the growers reported the use of Class I pesticides (extremely hazardous), some growers nevertheless still use WHO class I-active ingredients such as Dichlorvos 1000G/L, Cadusafos 100 G/L (Tamiru (2007), Vieira and Abarca (2009). Besides, some pesticides that entered the flower industry are found on the WHO negative pesticide list [prohibited/unknown on the European Union Pesticide Database (EUPDB 2015)] (Table 4).

Table 4.

Some imported pesticides not approved for use in the EU (import data for flowers in Ethiopia, 2014)

| Trade name | Active ingredients | Environmental fate | Human health issue | WHO class |

|---|---|---|---|---|

| Evisect | Thiocyclam Hydrogen Oxalate 50% | High | Skin and eye irritant | II |

| Ace | Acephate SP 25% | High | Endocrine disrupter, Cholinesterase inhibitor, Neurotoxic | II |

| Dexon | Fenaminosulf SP 45% | High | N/A | II |

| Orthene | Acephate SP 70 G/KG | High | Endocrine disrupter, Cholinesterase inhibitor, Neurotoxic | II |

| Rugby | Cadusafos 100 G/L | Moderate | Cholinesterase inhibitor | Ib |

| Orthene | Acephate 170 GR/KG | High | Endocrine disrupter, Cholinesterase inhibitor, Neurotoxic | II |

| Divipan | Dichlorvos 1000G/L | High | Mutagen, Cholinesterase inhibitor, Neurotoxic, Skin and irritant | Ib |

| Diazol 60 EC | Diazinon 600GM/L | Moderate | Reproduction effects, Cholinesterase inhibitor, Neurotoxic, Respiratory tract irritant, skin irritant | II |

| Starchlor 100 EC | Dichlorvos 1000G/L | High | Mutagen, Cholinesterase inhibitor, Neurotoxic, Skin and eye irritant | Ib |

| Evisect 5 | Thiocyclam Hydrogen Oxalate 50% | High | Skin and irritant | II |

Source European Union pesticide properties database EUPDB (2016) : http://sitem.herts.ac.uk/aeru/ppdb/en/. Last accessed 26-3-2016

The results show that farms certified with higher-level standards differ in applying Good Agricultural Practices/IPM compared to those certified at lower levels. The farms applying IPM have a large number of pesticide sprayers compared to Bronze-level certified farms. Farmers not using IMP argued that although IPM has a positive effect on controlling spider mite (Tetranychus urticae), other pests are becoming a bigger problem, especially trips, aphids and mealy bugs. Most interviewed growers carried out on-farm trials to evaluate the efficacy of biological control in the local context. The progress differed per farm but predatory mites proved able to control spider mites. However, farmers rarely resort to this alternative because they fear the risks associated with possible outbreaks and rapid spread of other pests. Informants from MoA and EPA pointed at the shortage of well-qualified IPM experts, limited access to IPM inputs and difficulty/complexity of implementing IPM compared with conventional pesticide management as the main obstacles hindering IPM adoption. EHPEA reports its strong support to IPM and offers trainings for the flower industry.

Most growers stored their pesticides in a separate room, but appropriate warning signs and indications of their class are often missing. One farm that is certified with Silver and two other international standards stored pesticides, fertilizers and hoses together. ln the accumulation of obsolete pesticides and in the act of reducing risks, higher-level certified growers did not differ from the bronze-level certified ones (Table 3).

Another environmental concern in the flower industry is unsafe management of pesticide containers. Empty containers are usually burnt on the farm in an on-farm incinerator, often an old steel barrel. Higher- and lower-level certified farmers are equally burning empty pesticide containers together with damaged cloths used for spraying, cartons, boxes and plastics (Fig. 2).

Fig. 2.

Unsafe empty pesticide containers management

Liquid pesticide waste mainly consists of effluent and wastewater from flushing drip lines or cleaning spraying equipment and is diluted and disposed of in soak away pits, a practice that may not prevent chemical residues entering the environment. Three certified growers (with Bronze, Silver and Gold) in Ziway use a wetland wastewater treatment system. Although the effectiveness of a wetland is questioned by some growers, this is an example where growers who are certified with Bronze resemble those growers certified with higher standards.

None of the flower farms had performed an Environmental Impact Assessment (EIA) to reduce risks before starting their operation. Hence intensive and unsustainable water use remains an important problem around all farms. In 2009–2010, Alterra conducted a water quality study at three sites near the floriculture complex around Lake Ziway. They tested 200 pesticides and found 30 with concentrations of 0.1 μg/l or higher; five of which are classified as high-risk pesticides (Jansen and Harmsen 2011). While lower- and higher-level certified growers did not differ in having a policy on environment, waste disposal and risk assessment, the latter category had more plans to develop one.

Unannounced audits by certifiers or visits from flower importers might increase the level of compliance. However, none of the farms received unannounced audits and when announced, the grower is informed about issues which are considered most important and documents which need to be prepared. Finally, few growers’ pesticide stores have been inspected by MOA or other state regulatory bodies over the past two years.

Impact of certificates on improvements in workers’ health and safety conditions

Work on Ethiopian flower farms is divided in greenhouse, pack house, spraying and other work. Most activities are exclusively done by female workers between 18 and 25 years, while jobs that demand more muscular force are left to male workers (spraying, irrigation and maintenance). This study focuses on sprayers because the influence of private certification standards should be most noticeable (Table 5). Pesticides are applied every day both in greenhouses and in open fields. All pesticide sprayers are men with an average age of 32 years (range 18–46) and most (87%) had 8–10 years of education. On average, they had four years experience in pesticides spraying (range 6 months–11 years).

Table 5.

The impact of certifications on selected health and safety issues of workers between two categories of growers, n = 180

| Variables | Response | Single and double certified growers (Bronze level) n = 74 | Triple and more certified growers (silver/gold and SQ, ETI, FT, FFP) n = 106 | χ 2 test |

|---|---|---|---|---|

| n (%) | n (%) | |||

| Are you informed on the EHPEA Code of practice? | Yes | 3 (4) | 12 (11) | 3.01 |

| No | 71 (96) | 94 (89) | ||

| Did you receive training on the safe handling of pesticides? | Yes | 41 (55) | 87 (82) | 15.09* |

| No | 33 (45) | 19 (18) | ||

| Can you read pesticide labels and safety information? | Yes | 29 (39) | 55 (52) | 2.82 |

| No | 45 (61) | 51 (48) | ||

| Is the personal protective equipment (PPE) adequate and appropriate? | Yes | 25 (34) | 47 (44) | 2.02 |

| No | 49 (66) | 59 (56) | ||

| Is PPE changed/replaced when necessary? | Yes | 18 (24) | 34 (32) | 1.27 |

| No | 56 (76) | 72 (68) | ||

| Is your cholinesterase level checked quarterly? | Yes | 58 (78) | 99 (93) | 8.82* |

| No | 16 (22) | 7 (7) | ||

| Have there been incidents after application (pesticide-related health symptoms)? | Yes | 65 (88) | 98 (92) | 1.09 |

| No | 9 (12) | 8 (8) | ||

| Are there shifts in the sprayer’s position when the result of blood tests is out of normal range? | Yes | 8 (11) | 18 (17) | 1.34 |

| No | 66 (89) | 88 (83) | ||

| Is a re-entry period applied? | Yes | 33 (45) | 40 (38) | 0.85 |

| No | 41 (55) | 66 (62) | ||

| Are basic safety facilities (shower, toilet, eating) available? | Yes | 29 (39) | 95 (90) | 51.72* |

| No | 45 (61) | 11 (10) | ||

| Are you satisfied with the labour committee? | Yes | 21 (28) | 38 (36) | 1.10 |

| No | 53 (72) | 68 (64) |

* Significant at P < 0.05, df. (2 − 1) × (2 − 1) = 1, critical value = 3.841

No significant difference (χ 2 = 3.01) was observed between the two categories of growers with respect to sprayers’ knowledge of the EHPEA-CoP and their ability to read safety instructions. A discussion with sprayers showed that safety data sheets are available but they are written in English or other languages like Dutch, Chinese and Kiswahili which are not familiar to the store manager, the sprayer and other workers. However, there was a significant difference (χ 2 = 15.09) between the two categories of growers with respect to the training on pesticide use that sprayers received.

Personal protective equipment (PPE) is provided for all farms except for 6 out of 18 farms where workers use their own clothes, old and torn gloves. Most sprayers were provided with spray suits (overalls) (71%), rubber boots (68%), respirators (62%) and impermeable gloves (57%). However, only 13% of the sprayers were provided with impermeable goggles. Some PPE items were rarely used since they hindered the speed of spraying (47%); they were also uncomfortable in the humid climate (53%) or they made it difficult to breathe properly. Seven Bronze-certified and four higher-certified growers provided workers with cheap safety gears like polyester sheets to cover their body and disposable cotton masks that were not manufactured for pesticide spraying; so the effects their protection are unknown. The majority of sprayers reported that their PPEs were inappropriate for their work; in this regard, there was no significant difference (χ 2 = 2.02) between lower- and higher-level certified growers. Periodic monitoring and replacement of PPE was challenging both categories of growers.

All sprayers reported incidents of pesticide-related health symptoms including eye irritation, permanent sight reduction, skin irritation, headache and abdominal pain after routine pesticides application. All sprayers were offered ‘compensation’ in cash or kind (milk and soap), with no significant differences between the two groups of growers.

According to the standards, a quarterly blood test for cholinesterase should be included in the medical check if organophosphate pesticides and/or carbamate insecticides are being used. Cholinesterase is an essential enzyme required for the proper function of the nervous system (normal range 5100–1700 U/L). The large majority of the workers were provided free medical care for occupational illnesses and injuries on site and there was no difference observed between the groups However, the frequency of cholinesterase testing for sprayers differed significantly (χ 2 = 8.818) between the two categories of growers. The majority (83%) of the sprayers working on higher-level certified farms reported that they were tested on a quarterly basis, while the majority of the workers (63%) working at lower-certified farms reported these tests were unscheduled. Although the results of cholinesterase tests were not accessible for all farms, we obtained 5719 tested samples of sprayers’ blood (between 2011 and 2014) from five farms that complied with multi safety (SQ) certification. About 10% of these samples were found to be out of the normal range (<5000 U/L). Standards require sprayers to rotate their work when their cholinesterase level is out of the normal range but in practice this rarely seems to happen at farms in both categories.

The majority (76%) of growers certified with higher standards had a health and safety officer on site as well as a management health and safety committee. Even most lower-certified farms had either one of these. This is a positive result of certification. Nevertheless, their impact should not be overestimated as a health officer reported: “Farm owners are not comfortable when we write about real pesticide exposure”. Another informant added that as a member of health and safety committee’’ I “experienced in signing minutes for the purpose of audit without conducting actual meetings”.

Other workers exposed to pesticides are harvesters and pack house workers who are predominantly female. All interviewed workers reported that injuries caused by scissors, skin pain and fingers pricked by thorns are common since only 28% of the workers were provided gloves. Some workers complained that their protective clothes were not suitable because they wore torn gloves made from cotton. Bunch makers in the pack house are often not provided gloves since it is believed that this affects the quality of the flowers. According to safety standards, this is unacceptable because of the persistent nature of some chemicals. Personal observations showed that there is no much difference between farms with lower- and higher-level certification.

Standards in the cut flowers sector prescribe that greenhouses should not be entered by other people when pesticides are being applied and that re-entry warning signals should be placed outside the sprayed areas. However, according to the interviewed harvesters and sprayers, 42% of the farms the official re-entry period is not applied, similar for both groups of farms. Harvesters complained that their supervisor asks them to enter a greenhouse when the chemical pesticides are still wet. We also observed that while harvesting is going on in one side of a greenhouse, chemicals were being sprayed in another side. A manager in a Silver-Certified farm reported that: “On other farms, they do not have good personal protective equipment: in fumigating they do not have boots, or masks and filters; in production they have no gloves. They go back in an hour after spraying. Here no one enters the greenhouses during fumigating, (…) and spraying is done in late evening. Some farms are exposing workers and the environment; they use pesticides on the red list. Here it is better because of the certifications”.

There is a significant difference χ 2 = 51.717) between the two categories in the provision of basic facilities (toilets, shower and canteen) for the workers. Few farms complying with lower standards had canteens and this is a major health threat. On the other hand, first aid and warning signs (“water not for drinking” or “hazardous chemicals”) were easily spotted while walking in greenhouses of higher-level certified farms (Fig. 3).

Fig. 3.

Workers washing without PPE and hanging their lunchbox at the metal poles of the entrance of greenhouse

Social standards call for the formation of a workers’ committee to negotiate with management. All growers reported that they have a workers’ union and 81% of the workers said that they are members of such associations. The functioning of these workers’ unions varies in their operations. Some are virtually non-existent whereas others strive actively to change the working conditions. Many workers, from lower-certified growers (72%) as well as from higher-level certified farms (64%), were not satisfied with the effectiveness of the union. After putting a lot of effort in identifying problems at work (as required from workers’ committee, gender committee, health and safety committee, HIV/AIDS committee among others), committee members feel discouraged when the management is not taking action. The leader of a workers’ committee in one farm said it openly: “They push us so much for the audit…but after a while no one remembers it”.

With regard to wage, the industry is paying the workers very low wages. The majority of workers earned between 18 and 30 ETB (approximately $0.9–$1.5) for an 8 h working day and 468–780 ETB (approximately $24–$40) for 208 working hours during a month. All (100%) respondents are dissatisfied with their wage and most workers found it difficult to meet their daily needs. One of the factors behind this problem may be the government’s policy to attract foreign investors by pointing at cheap labour. The owners argued that there is no legal minimum wage in the country. Interestingly, some growers with higher-level certifications built hospitals to the community, and supported schools. In Ethiopia, there is no system for certification and licensing of pesticide sprayers. Being licensed would impact positively on their health and safety, and salary. A certified (licensed) sprayer may only apply pesticides according to the prescribed conditions and he/she negotiates such matters(such as wage) in a standard way.

In terms of regular testing on cholinesterase levels and trainings on safe use of pesticides, farms with higher-level certification do not differ from farms with lower-level certification on health and safety issues. Nevertheless, key informants from EHPEA, EHDA, MoA and most farm managers agreed that there is a little progress brought by certifications. As one of them argued: “The entire Ethiopian flower sector has seen substantial improvements in safety conditions. When the industry started, there were many problems in relation to worker safety, and the use of chemicals. But later, the farms have improved a lot. Certifications have been essential in showing the way forward, showing what protective equipment is needed”. But a farm manager compliant with higher-level standards mentioned: “In spite of these improvements, even certified farms hurt human and environmental health.”

Buyer and consumer power in the flower supply chain

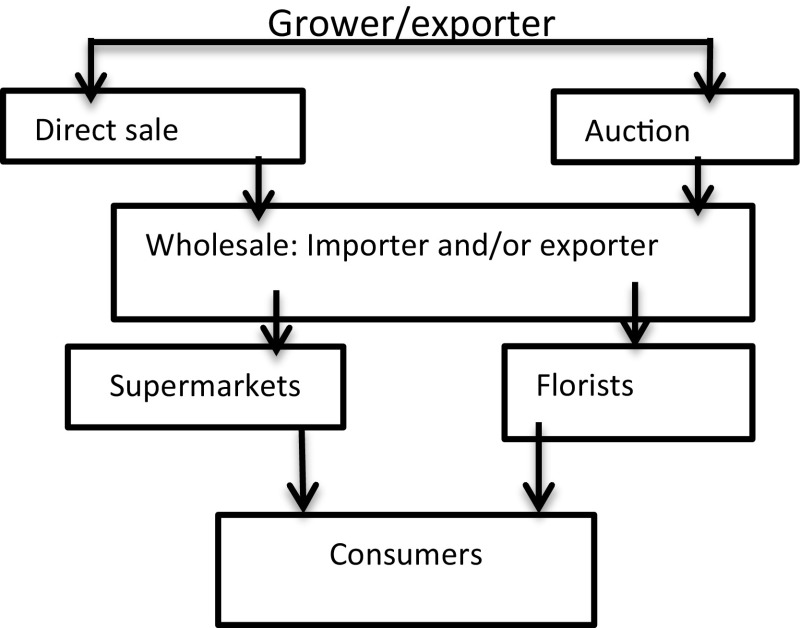

Pesticides governance through buyers’ requirements may compensate weak governance at the side of production. The Netherlands plays an important role in the international flower trade, as the main importer (from Ethiopia) and exporter to the different EU countries (Statistics Netherlands, 2015). Trade between Ethiopia and the Netherlands may take different routes (See Fig. 4).

Fig. 4.

Different channels for Ethiopian flowers entering the EU market

The auction is characterized by relatively loose trading relationships based on a market-based form of co-ordination between grower and buyer. The auction serves both as a market place and as a distribution hub through which cut flowers coming from all over the world including Ethiopia are distributed to wholesalers and supermarkets. Their main customers are wholesalers who typically focus on export. According to a key informant at FloraHolland, the world’s largest flower auction, participation in any certification scheme is not a mandatory requirement for supplying flowers to the auction. Quality control inspectors make sure that flowers meet the standards of quality information such as freshness and maturity, variety, country of origin, quality (damage and diseases), length and number of stems per bunch. Only a small number of the wholesalers who buy at the auction clock pass information about certification to their customers. Nonetheless, most auction suppliers adhere to one or more standards, with MPS-ABC being by far the most popular one. Hence, growers often consider obtaining MPS environmental certification a good way to enhance the farm’s reputation.

Growers and buyers may also do business directly when wholesalers link the growers to retail (supermarkets and florists). Most wholesalers purchase flowers from certified and uncertified growers through agents (or at auctions) in order to obtain the best flowers at the best prices. Some large wholesalers even import themselves following demand from large buyers and some even have their company certified. Social and environmental certificates have become a real license to export in the direct sales channel, especially through supermarket chains. As the chain is strongly buyer-driven, wholesalers, supermarkets and retailers want to be seen as “responsible companies”. Interviewed Dutch wholesalers revealed that to be successful, one should have “good certifications for good marketing”, whereby the wholesaler’s choice of certification depends on customer interest which is country specific. MPS is employed largely for the Dutch auction system, FLP cater mostly for the German flower market and ETI is for UK retailers. For Ethiopian growers supplying several markets this means fulfilling demands from several (2–7) different standards.

None of the wholesalers pays random visits to the farm or checks imported flowers on pesticide residues or active ingredients. Wholesalers rely on the certification report handed in by the supplier. Informants confirmed that an entire shipment can be rejected because of the presence of a single botrytis of fungus, but no grower experienced import rejection due to the presence of the incidence or above-standard active ingredient residues.

The demand for social and environmental certification differs significantly between the florist channel and the supermarket channel. Florists dominate the distribution of flowers in most EU countries and they are supplied by wholesalers. Social and environmental certification is less important in this segment: 14 out of the 18 interviewed Dutch florists do not ask for certification (see also BTC 2010). Interviewed wholesalers confirmed that although MPS certification is transferred through the auction system, they do not incorporate this information in their communication to customers and florists hardly ever ask for certification.

Much more than florists, supermarkets have an interest in standards and certification schemes. Supermarkets have a lot to lose in case of negative publicity about labour conditions and environmental impacts. This would not only affect their flower sales but may harm their entire business reputation. Supermarkets, therefore, use consumer labels to differentiate themselves from others and to make their efforts visible. Our interviewees believe that supermarkets have more leverage to enforce standards than the auction but even they do not inspect suppliers on whether or not they actually meet the social and environmental requirements.

In Dutch supermarkets, such as Albert Heijn, Lidl and Jumbo, consumer sustainability labels are printed on the flower sleeve. However, most environmental and social standards in the flower sector are not communicated to the consumers, as standards like MPS-ABC, Global-GAP and ETI are only used in the business-to-business environment. Florists and supermarkets found that public awareness on the sustainability impact of flowers is limited and so the willingness of Dutch consumers to pay higher prices for labelled flowers is relatively low. For example, the large majority of the interviewed Dutch consumers (48) had no idea what Fair trade certified flowers are, where the flowers come from and how they are produced. Many responded that flowers are a luxury product and not edible so they did not worry about environmental and social issues.

Conclusion

This article presents the results of a study on the impact of certification on the safe use of pesticides on the environment and workers health and safety in Ethiopia’s cut flower industry. These findings show that flower certifications and labels have limited effects on workers’ health and safety conditions and on the environment. No significant difference could be observed between farms certified with lower-level standards compared with higher-level standards with respect to the use of registered pesticides, their toxicity level, re-entry period, accumulation of obsolete pesticides, solid and liquid waste disposal, disposal of empty containers, PPEs and exposure to chemicals. Differences were found on some aspects of workers’ rights (reduction in working hours, formation of labour unions, provision of medical services) and support to the surrounding community for higher-level certified growers. Although only three of the 29 farms, IPM practices can also be identified as a positive impact from certification. The administration and documentation on farms have greatly improved through certification. The adoption of certification plays a positive role in promoting the image of flower farms and acts as reputation insurance. Farms that have adopted more strict certifications have a better and professional outlook than farms without these. Most growers participated in certification schemes to comply with international buyer requirements and to ensure access to international markets.

Private certification schemes are designed to address concerns among supply chain actors, particularly consumers, and to support failing state regulation at the sites of production. In such arrangements producers are expected to comply with the quality and safety indicators embedded in the standards. However, realizing these intentions for non-food commodities like flowers proves a challenge. Buyers have no solid evidence on the active ingredients and maximum residue level that guarantees a positive impact on the environment and workers’ health and safety. They can only rely on audit reports and once an audit is completed, little is done until the next audit, and this confines certification to a one or two-day event per annum.

In the EU, flower imports are not inspected for pesticide residues because they are not edible items; on the other hand, since flowers are considered an agricultural product, they must be free from pests when imported. As a result, over-spraying and the use of more toxic pesticides are encouraged. In addition, cut flowers are produced by independent producers without ties with specific buyers, so no buyer pays random visits to check whether a mismatch exists between the standard and the reality on the farm. Document tracing is applied instead of physical tracing; so consumers cannot be assured that their bunch of flowers is indeed produced in a sustainable way. Most certification schemes are foreign-controlled and lack the local ownership that is necessary for their success.

There are clear limits to what private certification schemes can be expected to accomplish and there is little known about whether this actually affects producers’ environmental and social performance. Standards can solve information asymmetries between trading partners, reduce transaction costs and promote consumer confidence, thereby acting as a catalyst to trade while government agencies may also engage in implementing them (unclear). This might be the case for food crops (which are exposed to MRL testing when imported in the EU), but the flower industry still has a long way to go as they are not tested on MRL but have an equally pesticide-intensive production process.

In becoming more successful and effective, scholars such as Ponte (2008), Büthe (2010), Mayer and Gereffi (2010), and Riisgaard (2011) argue that private governance through certification has two options. One option is to focus on stronger public regulation in developing countries to reinforce—rather than replace—private governance, and promote multi-stakeholder initiatives involving both public and private actors. A second option is to build an effective societal pressure and collective action. Growers are aware that their market may get smaller unless they are committed to adopt certification and improve their environmental performance and the working conditions of their staff. Therefore, new patterns of consumption, media pressure, and campaigns by NGOs may promote consumer interest in the conditions under which their flowers are being produced.

We conclude that certification has emerged as a private governance mechanism in the cut flower industry. However, certification and labels alone may not effectively improve the workers’ safety conditions and reduce the environmental impacts at the production site. Our findings suggest that establishing impacts through certification requires co-ordination among all players in related to the supply chain. Arguably, in developing countries effective government intervention at different levels (including the farm) remains important as well, because governments have a legitimate role to safeguard public interests and collective public goods. Some government functions may be delegated to private enterprises, given the limited capacity of government institutions in many developing countries. However, it is essential to develop a more systematic analysis and strategy of delegating governmental powers to private actors. The failure to do so may undermine the legitimacy of future distribution of governance roles among public and private authorities. Both private enterprises and governments are accountable and responsible for unsustainable cut flower production.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

Authors are thankful to the participants especially flower farm managers/and owners and pesticide sprayers. We would also like express our gratitude to anonymous referee(s) and editor of the journal for their valuable comments and suggestions on the earlier draft of the paper. This study was financially supported by the by the pesticide risk reduction programme (PRRP)-Ethiopia and Alterra, part of Wageningen UR. Additional support was provided by the Netherlands Fellowship Programme (NFP).

Biographies

Belay T. Mengistie

is a PhD research fellow at environmental policy group of Wageningen University. He worked as a lecturer at different universities in Ethiopia. He has authored a number of journal articles in the areas of agricultural geography, pesticide governance, rural livelihoods and development, and environmental governance.

Arthur P. J. Mol

is a professor at Wageningen University and also a professor of environmental policy at Renmin University, China, at Tsinghua University, China, and at the National University of Malaysia UKM. He is joint editor of the journal Environmental Politics, and book series editor of New Horizons in Environmental Politics. His main fields of interest and publications are in environmental studies, globalization, social theory and the environment, informational governance, ecological modernization, China, sustainable (food) production and consumption and urban environmental governance. Currently, he is Rector Magnificus and vice-president of Wageningen University.

Peter Oosterveer

is a professor of sociology at Environmental policy group of Wageningen University in the Netherlands. His research and teaching is in the field of globalization and sustainability of food production and consumption. His interests are in particular on global public and private governance of food towards sustainability, including labelling and certification of food. His research focuses on shifts in global sustainable food governance and their consequences for the organization of the supply chain and the roles of different social actors therein.

Footnotes

The Ethiopian Horticulture Producer Exporter Association (EHPEA) was established in 2002 to promote the expansion of the horticulture sector as well as to address workers’ health and safety and environmental sustainability in the sector. About 90% of all producers are member of the EHPEA.

Electronic supplementary material

The online version of this article (doi:10.1007/s13280-017-0914-x) contains supplementary material, which is available to authorized users.

Contributor Information

Belay T. Mengistie, Phone: +31649935129, Email: belay.mengistie@wur.nl, Email: belaytizazu@yahoo.com

Arthur P. J. Mol, Phone: +31 317 484061, Email: arthur.mol@wur.nl

Peter Oosterveer, Phone: +31 (0)317 485038, Email: peter.oosterveer@wur.nl.

References

- Belwal R, Chala M. Catalysts and barriers to cut flower export: A case study of Ethiopian floriculture industry. International Journal of Emerging Market. 2008;3:216–235. doi: 10.1108/17468800810862650. [DOI] [Google Scholar]

- Belgian Development Agency, Trade for Development Centre, BTC . The European market for fair and sustainable flowers and plants. Brussels: BTC; 2010. [Google Scholar]

- Blackman A, Naranjo MA. Does eco-certification have environmental benefits? Organic coffee in Costa Rica. Ecological Economics. 2010;83:58–66. doi: 10.1016/j.ecolecon.2012.08.001. [DOI] [Google Scholar]

- Büthe T. Private regulation in the global economy: A (P)Review. Business and Politics. 2010;12:2. [Google Scholar]

- Damalas A, Eleftherohorinos G. Pesticide exposure, safety issues, and risk assessment indicators. International Journal of Environmental Research & Public Health. 2011;5:1402–1419. doi: 10.3390/ijerph8051402. [DOI] [PMC free article] [PubMed] [Google Scholar]

- David T. The Bloom on the rose, looking into the floriculture industry: Environmental health perspectives. Focus. 2002;110:240–247. [Google Scholar]

- Dolan, C., M. Opondo, and S. Smith. 2002. Gender, rights & participation in the Kenya cut flower industry. Natural Resource Institute. NRI Report No: 2768 SSR Project No. R8077 2002-4. https://assets.publishing.service.gov.uk/media/57a08d49ed915d622c0018d5/R8077a.pdf.

- EHPEA. 2015. Export horticulture in Ethiopia, Ethiopian horticulture producers export association code of Practices, Version 4. Unpublished official document, Addis Ababa, Ethiopia.

- Eshetu, S., B. Belete, D. Goshu, B. Kassa, D. Tamiru, E. Worku, Z. Lema, A. Delelegn, and J. Tucker. 2009. Income diversification through improved irrigation schemes: Evidence from Gorogutu Woreda, Eastern Ethiopia. Research Report. Addis Ababa: RiPPLE.

- Ethiopian Horticulture Producer Exporters Association (EHPEA). 2016. EHPEA resource centre. http://www.ehpea.org/.

- EUPDB. 2015. European Union pesticide properties database: http://sitem.herts.ac.uk/aeru/ppdb/en/. Accessed 26 March 2016.

- EUPDB. 2016. European Union pesticide properties database: http://sitem.herts.ac.uk/aeru/ppdb/en/.

- Gebreeyesus, M., and M. Iizuka. 2010. Discovery of the flower industry in Ethiopia: Experimentation and coordination. UNU-MERIT working paper series, no. 2010-025.

- Gereffi G, Humphrey J, Sturgeon TJ. The governance of global value chains. Review of International Political Economy. 2005;12:78–104. doi: 10.1080/09692290500049805. [DOI] [Google Scholar]

- Getu M. Ethiopian floriculture and its impact on the environment: Regulation, supervision and compliance. Mizan Law Review. 2009;2:240–270. [Google Scholar]

- Gibbon P, Ponte S. Trading down: Africa, value chains, and the global economy. Philadelphia: Temple University Press; 2005. [Google Scholar]

- Humphrey J, Schmitz H. Governance in global value chains. IDS Bulletin. 2001;32:19–29. doi: 10.1111/j.1759-5436.2001.mp32003003.x. [DOI] [Google Scholar]

- Jakobasch, S. 1998. Sag, wo sind die Blumen her? In: MorgenWelt Magazin. http://www.morgenwelt.de/magazin/repo55.htm.

- Jansen, H.C., and J. Harmsen. 2011. Pesticide monitoring in the central rift valley 2009–2010: Ecosystems for water in Ethiopia. Alterra Wageningen UR, 44.

- Joosten, F. 2007. Development strategy for the export-oriented horticulture in Ethiopia. http://library.wur.nl/way/bestanden/clc/1891396.pdf.

- Kargbo A, Mao J, Wang C. The progress and issues in the Dutch, Chinese and Kenyan floriculture industries. African Journal of Biotechnology. 2010;9:7401–7408. doi: 10.5897/AJB10.740. [DOI] [Google Scholar]

- Mayer F, Gereffi G. Regulation and economic globalization: Prospects and limits of private governance. Business and Politics. 2010;12:1–25. doi: 10.2202/1469-3569.1325. [DOI] [Google Scholar]

- Mano, Y., and A. Suzuki. 2011. Agglomeration economies for industrial development: The case of the Ethiopian cut flower industry. Foundation for advanced studies on international development national graduate research institute for policy studies.

- Mekonen S, Ambelu A, Spanoghe P. Pesticide residue evaluation in major staple food items of Ethiopia using the QuECHERS method: A case study from the Jimma zone. Environmental Toxicology and Chemistry. 2014;33:1294–1302. doi: 10.1002/etc.2554. [DOI] [PubMed] [Google Scholar]

- Mekonnen Y, Agonafir T. Pesticide sprayers’ knowledge, attitude and practice of pesticide use on agricultural farms of Ethiopia. Journal of Occupational Medicine. 2002;52:311–315. doi: 10.1093/occmed/52.6.311. [DOI] [PubMed] [Google Scholar]

- Mena N, Proaño S. Acoso Sexual Laboral en La Floricultura. Quito: International Labor Rights Forum; 2005. [Google Scholar]

- Mengistie BT, Mol APJ, Oosterveer P. Information, motivation and resources: The missing elements in agricultural pesticide policy implementation in Ethiopia. International Journal of Agricultural Sustainability. 2015;13:240–256. doi: 10.1080/14735903.2014.959330. [DOI] [Google Scholar]

- Mengistie BT, Mol APJ, Oosterveer P. Private environmental governance in the Ethiopian pesticide supply chain: Importation, distribution and use. NJAS-Wageningen Journal of Life Sciences. 2015;76:65–73. doi: 10.1016/j.njas.2015.11.005. [DOI] [Google Scholar]

- Micheletti M. Political virtue and shopping: Individuals, consumerism, and collective action. New York: Palgrave; 2003. [Google Scholar]

- Ministry of Agriculture (MoA)-Ethiopia. 2014. Pesticide imported for flower production. PHRD of MoA. Unpublished official reports.

- Mmochi AJ, Mberek RS. Trends in the types, amounts, and toxicity of pesticides used in Tanzania: Efforts to control pesticide pollution in Zanzibar, Tanzania. Ambio. 1998;27:669–676. [Google Scholar]

- Negatu B, Kromhout H, Mekonnen Y, Vermeulen R. Use of chemical pesticides in Ethiopia: A cross-sectional comparative study on knowledge, attitude and practice of farmers and farm workers in three farming systems. Annals of Occupational Hygiene. 2016;60:551–566. doi: 10.1093/annhyg/mew004. [DOI] [PubMed] [Google Scholar]

- PAN UK. 2007. The deadly chemicals in cotton. Exposing the human health and environmental cost of pesticide use in global cotton production. A report in collaboration with Environmental Justice Foundation. http://ejfoundation.org/report/deadly-chemicals-cotton.

- PAN UK (2008), Flower farming: Ethiopian NGOS work to improve conditions for flower producers. Pesticide news, 82.

- Ponte S, Gibon P, Riisgaard L. Competition, best practices’ and exclusion in the market for social and environmental standards. In: Ponte S, Gibbon P, Vestergaard J, editors. Governing through standards: Origins, drivers, and limitations. London: PalgraveMacmillan; 2011. pp. 236–265. [Google Scholar]

- Ponte, S. 2008. Developing a vertical dimension to chronic poverty research: Some lessons from global value chain analysis, Paper 9/2007. Trade law centre for southern Africa, Stellenbosch.

- Raynolds LT. Trade flowers: Global certification, environmental sustainability, and labor standards. Rural Sociology. 2012;77:493–519. doi: 10.1111/j.1549-0831.2012.00090.x. [DOI] [Google Scholar]

- Riisgaard, L. 2008. Localizing private social standards standard initiatives in Kenyan cut flowers. DIIS working paper 2008: 20.

- Riisgaard L. Towards more stringent sustainability standards? Trends in the cut flower industry. Review of African Political Economy. 2011;38:435–453. doi: 10.1080/03056244.2011.598344. [DOI] [Google Scholar]

- Sahle A, Potting J. Environmental life cycle assessment of Ethiopian rose cultivation. Science of the Total Environment. 2013;443:163–172. doi: 10.1016/j.scitotenv.2012.10.048. [DOI] [PubMed] [Google Scholar]

- Sisay, T. 2007. Assessment of the ecological impacts of floriculture industries using physico-chemical parameters and benthic macro invertebrates metric index along Wedecha River, Debrezeit, Ethiopia.

- Stadlinger N, Mmochi AJ, Kumblad L. Weak governmental institutions impair the management of pesticide import and sales in Zanzibar. Ambio. 2013;42:72–82. doi: 10.1007/s13280-012-0338-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tamirat, A. 2011. Toxication in bits. Flower industry threatens right to water in Ethiopia: Cut flower production practices, the sector‘s socio-economic contribution and environmental Standards, FIAN, Germany.

- Tamiru, S.M. 2007. Assessment of the ecological impacts of floriculture industries using physico-chemical parameters and benthic macro invertebrates metric index along Wedecha river, Debrezeit, Ethiopia. MSc thesis. Addis Ababa University, Ethiopia.

- Tanner B. Independent assessment by third-party certification bodies. Food Control. 2000;1:415–417. doi: 10.1016/S0956-7135(99)00055-9. [DOI] [Google Scholar]

- Teklu BM, Retta N, Van den Brink PJ. Sensitivity analysis of Ethiopian aquatic macroinvertebrates to the pesticides endosulfan and diazinon, compared to literature data. Ecotoxcology. 2016;25:1226–1233. doi: 10.1007/s10646-016-1676-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tilahun, A. 2013. Environmental impacts of floriculture industry in Debrezeit Town: A need for strategic environmental assessment, M.Sc. thesis, AAU University, Ethiopia

- The Reporter. 2014. Ethiopian flower sector: Bloomer or gloomier? English newspaper, Version 1 March 2014.

- Vieira, S., and L. Abarca. 2009. Floriculture waste management practices to Ethiopia. https://repositorio.ufsc.br/bitstream/handle/123456789/124459/171.pdf?sequence=1.

- World Recourse Institute (WRI). 2016. What are the environmental costs of Valentine’s Day flowers? http://www.wri.org/blog/2016/02/what-are-environmental-costs-valentines-day-flowers. Accessed 13 April 2016.

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.