Abstract

The effects of xanthan gum (XG) and hydroxypropyl methylcellulose (HPMC) in sponge cakes were studied. Hydrocolloids enhanced the thickening effect in batter that affected the textural attributes of sponge cakes. During storage, the structural changes in XG-cake resulted in higher hardness compared to HPMC-cake. Similar to XG, HPMC also contributed moistness to cake. The moisture loss of cake containing XG was slower than HPMC-cake. FTIR study showed absorption of OH at region of 3600–2900 cm−1 that explained the strong interaction of water in cake containing XG compared to other cake formulations.

Keywords: Sponge cake, HPMC, Xanthan gum, Moisture loss, FTIR

Introduction

The qualities of cakes should have a fine, uniform, moist crumb structure, tenderness and tolerance to staling. These desired qualities can be predicted or evaluated through properties of batters and baked cake (Sozer et al. 2009). Meanwhile, texture is the organoleptic attributes that influence the acceptance of consumers to the baked product. The texture profiling of baked products includes hardness, chewiness, gumminess, adhesiveness, cohesiveness, springiness and fracture (Shyu and Sung 2010; Li and Nie 2015).

Many studies have related the staling of cake during storage with its textural changes especially the increase in hardness values. Staling is undesirable changes that cause crumb firming and drying which is taking place between the time cakes is baked and consumed. It is mainly caused by changes in the starch structure and moisture migration from the crumb to dry regions through evaporation and redistribution (Angioloni and Collar 2009; Gómez et al. 2007).

The problem of staling requires more attention especially for the bakery products that stored on shelves at room temperature, as it may increase the staling rate of the cake, thus influences texture and moistness of the products during storage (Goesaert et al. 2005). The possible solutions to reduce this process are through the interference of the starch network either through the interaction of the additives with the starch and water; or by disrupting the chain of starch itself. Several studies have shown that using certain additives added into the cake formulation can retard staling process. For examples are emulsifiers (Lee et al. 2014; Ashwini et al. 2009) and hydrocolloids (Gómez et al. 2007).

Addition of hydrocolloids has been reported to improve the quality of gluten free cakes and muffins by increasing the viscosity of batters (Gómez et al. 2007; Singh et al. 2016). However, the effectiveness of hydrocolloids as anti staling agent in bakery products; specifically in improving the texture of cakes during storage requires further investigation as there are several advantages and disadvantages of hydrocolloids that have been highlighted in terms of their contribution in physical properties related to quality of cakes (Hager and Arendt 2013). Therefore, the aim of this study was to determine the effects of hydrocolloids on the physicochemical properties, microstructure, moistness and FTIR analysis of baked sponge cakes during storage.

Materials and methods

Materials

Xanthan gum (XG) and hydroxypropylmethylcellulose (HPMC) were supplied by Sigma Aldrich (USA). Wheat flour (Cap Sauh), corn flour (Cap Bintang), eggs (Nutriplus), butter (Buttercup) and white sugar (Prai) were obtained from the local market (GIANT) in “Materials and methods” section, Shah Alam, Selangor.

Preparation of sponge cakes

The ingredients for sponge cake were wheat flour (23.8 g), corn starch (13.8 g), sugar (47.5 g), eggs (55 g), butter (11 g) and boiled water (11 ml). Hydrocolloids (XG and HPMC) were incorporated into sponge cake formulations at 1% of dry flour basis (w/w). Before the preparation of sponge cake, 1% XG (0.38 g) and 1% HPMC (0.38 g) were solubilized using 11 ml of boiled water (100 °C).

Egg white was beaten using mixer (Panasonic MK-GH1) at high speed (no. 3). Then, sugar was added and the mixture was continuously beaten for 3 min. In other bowl, hydrated hydrocolloid was mixed into yolk mixture and beaten for 1 min. Finally, yolk mixture, dry ingredients and butter were folded in the creamy mixture. Batter was baked in the oven (Revent International) for 30 min at 175 °C and cooled. Cake was stored in zip plastic bag (polyethylene, moisture proof) after cooling for 1 h at room temperature (25 °C) and storage relative humidity (RH = 84%) (Lee et al. 2014). The cake of different formulations with and without addition of hydrocolloids was stored for 6 days and the effectiveness of the hydrocolloids were measured at day 0, 2, 4 and 6.

Batter characteristics

Batter density and specific gravity was determined based on Gómez et al. (2007), while flow behaviour properties were studied using Rheometer (Physica Antor Par MCR 300) (Martínez-Cervera et al. 2012). Before rheological test, batters were kept at room temperature (25 °C) for 1 h to rest the batter and favour the stable network formation. 40-mm diameter plate sensor geometry with a serrated surface and 1-mm gap was employed. A rotational and continuous ramp was applied and apparent viscosity was measured in triplicate as a function of shear rate over the 0.10–100 s−1 ranges at 25 °C for 5 min. By plotting the graph (Fig. 1), all curves were adjusted to Ostwald model following power-law equation: ŋ = Kýn−1, where ŋ = apparent viscosity, K = consistency index, ý = shear rates and n = flow behaviour index. The value of viscosity was constantly taken at shear rate of 0.50 s−1.

Fig. 1.

Flow behaviour properties of batter of control, 1% XG and 1% HPMC based on power law model: ŋ = Kxn−1 where ŋ = apparent viscosity, K = consistency index, ý = shear rates and n = flow behaviour index. The value of viscosity was taken at shear rate 0.50 s−1

Microstructure analysis

Microstructure of cake crumb was determined using scanning electron microscope (Carl Zeiss Subra 40VP German). The preparation of cake sample was done after 1 h of cooling. The cake was cut into a size of 0.8 × 0.8 × 0.3 cm and freeze-dried for 2 days. After that, the sample was sputter-coated with gold and observed under the microscope at 200× magnification (Shyu and Sung 2010).

Cake volume

The volume of cake was measured from 1 to 2 h after cooling. The volume of cake was measured by using rapeseed displacement. Specific volume was divided by sample mass (Cauvain and Young 2011).

Texture profile analysis

The method was based on Shyu and Sung (2010). Two loaf sponge cakes were cut into 16 cubes with a size of 3 mm × 3 mm × 3 mm. Then, the cake was packed into 4 zip plastic bag (polyethylene, moisture proof), separately. Each pack contained 4 cubes and labelled as day 0, 2, 4 and 6 and stored on shelf at 25 °C, RH = 84%. The first measurement for texture was taken after 1 h cooling (day 0), while the next measurements (day 2, 4 and 6) were taken after 48, 96 and 114 h cooling. For each measurement, the outer layer and crust (0.50 cm) of cake was removed to obtain crumb with a size of 25 mm × 25 mm × 25 mm. The measurements were performed using 75 mm aluminium cylindrical probe (P/75), Texture analyser TA-XT2i (Stable Microsystems England). The speed was set at 2 mm/min at distance of 10 mm. The increase of hardness during storage was used as a parameter in the assessment of staling. Staling index or increase of hardness was calculated as follows (Sim et al. 2011):

Moisture content and moisture loss

The preparation, packaging and storage conditions for cake sample were similar to the texture profiling analysis (“Texture profiling (TP) of sponge cake” section). However, the measurement of moisture content was done after 24 h (day 0), 72 h (day 2), 120 h (day 4) and 168 h (day 6). About 0.50 cm of crust and outside layer of cakes was removed and ground using dry blender (Panasonic) for 1 min. About 2 g of ground cake was weighed in aluminium dishes and dried to a constant weight in a Vacuum Drying Oven with Pump Valucell 22 (Germany) at 70 °C for 5 h (Ji et al. 2007). The difference in the weight of the sample before and after drying was used to calculate the moisture content. Moisture losses of the stored cakes for all formulations were calculated by the difference in the moisture content between day 2, 4 and 6 with initial moisture content (day 0).

Water activity

Water activity was measured after 24 h (day 0), 72 h (day 2), 120 h (day 4) and 168 h (day 6) cooling by using Aqualab Dew Point Water Activity Meter 4TE (USA). Prior to the measurement, the instrument was calibrated using the water activity standards (6.0 mol/kg of NaCl, aw = 0.760). Then, about 2 g of crumb was placed in the cup and held at 25 ± 0.1 °C until equilibrium reached. All analyses were conducted in triplicate and the average values were reported (Ji et al. 2007).

Fourier transforms infrared (FTIR) spectroscopy

FTIR spectroscopic measurements were carried out following the method of Sivam et al. (2012) with some modifications. In their study, the bread was freeze-dried to reduce the detection of water absorbance bands. About 32 scan were applied and curve fitting was performed using the grams/32 (version 5) software with Gaussian–Lorenzian mix function to examine the amide bands in the region 1500–1800 cm−1 of the FTIR spectra, which not prefer the presence of moist within samples.

In this study, the crumb was not freeze-dried and the sample was taken from the centre of cake. The study was done after 24 h (day 0), 72 h (day 2), 120 h (day 4) and 168 h (day 6) after baking and cooling. About 2 mg of crumb was mixed with 80 mg potassium bromide, KBr (Sigma Aldrich) to form a disc using the compressor. Triplicates samples were prepared for each formulation and analysed by FTIR on day 0, 2, 4 and 6 of storage. FTIR spectra (4 scans) were recorded at a resolution of 4 cm−1 on a Perkin Elmer spectrum™ 100 FTIR spectrometer equipped with a universal ATR attachment. All spectra obtained from 450 to 4000 cm−1 were subjected to a multipoint linear base-line correction. Then, the data obtained was plotted in terms of transmittance (T) versus wavenumbers (nm) to observe the polysaccharide and water absorption spectra.

Statistical analysis

Duncan multiple comparison tests were performed using SAS version 9.3.1 (USA) to determine significant differences between treated samples.

Results and discussion

Rheological properties of batter

Figure 1 depicts the flow behavior properties of batters using the power law model (ŋ = kýn−1), where ŋ = apparent viscosity, K = consistency index, ý = shear rates and n = flow behavior index. Power law model was chosen for the trend line or regression type in plotted graph because the experimental data did not provide a good fit (R2 = 0.99).

All batters had flow behaviour index (n) of less than 1, thus the model reflected non-Newtonian behaviour in which all cake batters had shear thinning behaviour, which indicated that the viscosity of batter was continuously decreased when subjected to shear stress (Baixauli et al. 2008).

In Table 1, 1% XG batter (0.30) had significant low ‘n’ values followed by control (0.39) and 1% HPMC (0.49) batters. The ‘n’ values for the batters (non-Newtonian fluid) was in agreement with Turabi et al. (2010), Baixauli et al. (2008) and Martínez-Cervera et al. (2012). These authors reported ‘n’ less than 0.6, which proved that the batter was thick emulsion and did not show a physical characteristics of water (if n = 1). The significant high ‘n’ value for HPMC batter may explain that the addition of HPMC thinned down the batter compared to control and xanthan batter. It may be due to its double action as surface active and low thickening properties. Its properties as surface active may had disrupted the network structure within the batter. Meanwhile, the formation of gel network in HPMC batter may have reduced due to low temperature (Hager and Arendt 2013; Damodaran et al. 2008).

Table 1.

Correlation of hardness with batter and cake properties

| Parameters | Control | 1% XG | 1% HPMC | Correlation (r) |

|---|---|---|---|---|

| Cake properties | ||||

| Cake volume (ml) | 350a ± 4.47 | 319b ± 4.92 | 321b ± 5.85 | ns |

| Sp. volume of cake (ml/g) | 2.66a ± 0.03 | 2.40bc ± 0.04 | 2.43b ± 0.04 | ns |

| Moisture content (%) | 32.00a ± 0.33 | 32.11a ± 0.37 | 32.37a ± 0.31 | ns |

| Batter properties | ||||

| Density (g/cm3) | 0.770b ± 0.01 | 0.790a ± 0.01 | 0.780b ± 0.02 | 0.5136* |

| Sp. gravity | 0.799b ± 0.01 | 0.818a ± 0.01 | 0.801ab ± 0.02 | 0.4468* |

| Flow behaviour index, n | 0.393b ± 0.01 | 0.300c ± 0.04 | 0.488a ± 0.03 | −0.5834* |

| Consistency index, K(Pa sn) | 17.30b ± 1.17 | 39.24a ± 5.00 | 15.67b ± 1.13 | 0.7127* |

| Apparent viscosity (Pa sn) | 22.33c ± 1.51 | 72.57a ± 0.74 | 25.23b ± 2.85 | 0.6266* |

Values followed by different letter within the same row were significantly different (p < 0.05)

* p < 0.05; ns not significant (p > 0.05)

The apparent viscosity of 1% XG was significantly higher (p < 0.05) compared to 1% HPMC and control with 72.57, 25.23 and 22.33 Pa s, respectively. The viscosity of control batter can be explained based on results of Martínez et al. (2015) where the amount of water, protein and starch may affect the viscosity of batter through its solubility, gelatinization and unfolding. These processes involved high water absorption that diminishes the free water available in solution, which increased the apparent viscosity.

The same principle can be applied to describe the viscosity of batter containing hydrocolloids where the solubility and gelation of hydrocolloids within the batter also involved the water absorption, which diminish the free water available in solution and increased the apparent viscosity. Besides, an additional interaction of hydrocolloids with the starch, protein and water were proposed since there was an increase in viscosity of hydrocolloids batter. The significant different in batter viscosity of 1% XG batter and 1% HPMC batter was due to its thickening properties and different chemical structures (Damodaran et al. 2008). The native form of xanthan gum below the melting point is a rigid double helix structure stabilized by non-covalent bonds. During the disruption of its chemical structure, more favourable interaction between xanthan gum molecules and ingredients in batter occurred. Then, its conformation change to native forms, which was a rigid and stabilized double helix structure after the removal of shearing effects (Navidghasemizad et al. 2015; Hager and Arendt 2013). For these reason, it thickened the liquid batter and produced high apparent viscosity. Ronda and Roos (2011) also related the increment of apparent viscosity with the presence of hydrocolloids, which contributed by its high water binding capacity. High water binding capacity of ingredients reduced the amount of free water available, thus retarded the movement of particles in batter. From the results obtained, it could be concluded that batter containing 1% XG had high water binding capacity followed by 1% HPMC and control.

The consistency values may provide the idea of the fluid viscosity (Björn et al. 2012). Control (17.30 Pa sn) and 1% HPMC (15.67 Pa sn) had significantly low consistency index (K) compared to 1% XG (39.24 Pa sn). Low K values may be attributed to the weak gel strength of emulsified structure in control and 1% HPMC batter. In 1% XG batter, significant high ‘K’ values (39.24 Pa sn) was observed showing that the strengthening effect was due to the interaction of starch with xanthan gum (Cho and Yoo 2015). In this study, the consistency index (17.30–39.24 Pa sn) was in agreement with the consistency index (10–110 Pa sn) obtained in other studies on cake batters (Barcenas and Rosell 2006; Baixauli et al. 2008; Turabi et al. 2010; Martínez-Cervera et al. 2012).

Microstructure of sponge cake

The micrograph in Fig. 2 shows the inner surface structure of the sponge cakes using a scanning electron microscope (SEM) analysis with 200× magnification. Figure 2a shows some formation of coalesced pores and homogenous distribution of tiny air bubbles, thus resulted in less dense structure in control cake. The surface of control cake was quite rough (not smooth) compared to 1% XG and 1% HPMC. This condition may explain the homogeneous pores distributions in control.

Fig. 2.

SEM micrograph (200x magnifications) for sponge cakes: a control, b 1% XG and c 1% HPMC. White arrows indicate pores and void spaces while black arrows indicate smooth and compact structure. The height of cakes for a control, b 1% XG, c 1% HPMC was 4.5, 4.0 and 4.1; respectively

In 1% XG cake (Fig. 2b), the crumb structure was dense and compact due to its strong polymer interaction with the ingredients in batter. As a result, it forms a dense, compact and thick wall structure (Zhao et al. 2009; Ashwini et al. 2009). The larger and heterogeneous pores distribution in cake was due to rapid coalescence of air bubbles in XG batters.

Coalesced pores formation can also be observed in 1% HPMC cake (Fig. 2c). However, the cake structure was less compact compared to 1% XG cake since there were voids spaces and small arrangement of air bubbles structure. Many have studies suggested that HPMC may exhibit double actions in batter. Low thickening properties of HPMC favours the formation of stable emulsion structure to avoid sedimentation or collapsed cake. It was due to its hydrophilic properties, which interacted with starch (Shohreh et al. 2012). Meanwhile, HPMC also acted as surface-active molecules that weakened the protein network in batter, thus exhibits less strengthening effects than XG (Mohammadi et al. 2014; Hager and Arendt 2013; Zhao et al. 2009).

Texture profile analysis

Hardness of sponge cake

Initial hardening effect in cake texture was due to starch retrogradation, mainly involving amylose recrystallization during cooling (Goesaert et al. 2005; Hager and Arendt 2013). Hardness of XG cake in Fig. 3a was significantly higher than 1% HPMC and control cakes. This indicated that the presence of XG has hardening effect on cakes compared to HPMC and control. XG able to stabilize and support the starch and protein network in batter emulsion thus increases the rigidity of batter. In addition, the strengthening effect could be due to molecular entanglements between XG and gluten proteins, enhanced by ionic interactions of its carboxylate groups and strong polymeric interactions in cake (Mandala and Sotirakoglou 2005).

Fig. 3.

Texture profiles analysis of sponge cakes during storage (day 0, 2, 4 and 6) at room temperature. Mean with different small letters (between different cake) and capital letters (between same cake) indicated significant different (p < 0.05)

The correlations of hardness and cake properties were obtained in Table 1 to determine the significant effects of hydrocolloids in crumb texture of sponge cake. It was found that batter density and specific gravity were positively correlated with hardness (p < 0.05) but the correlations (rdensity = 0.5136 and rsp. gravity = 0.4468) were not strong. Meanwhile, no significant correlation was observed between hardness and cake volume. Another study by Gómez et al. (2011) on effect of batter freezing conditions and resting time on cake quality also produced weak and negative correlation between hardness and cake volumes.

Hardness of 1% XG was significantly higher than 1% HPMC even though no significant difference in cake volume was observed between these two formulations. This may be due to the fact that more dense structure was observed in 1% XG as compared to 1% HPMC. The dense, thick wall and heterogeneous pored structure can be related with the high hardness values. Farzi et al. (2015) reported that highly porous structure and homogenous pore sizes in cakes represent uniform aerated structure while sample that has no bubble expansion shows a quite dense structure. On the other hand, more void spaces within the crumb were observed in 1% HPMC (Fig. 2) that able to explain the low hardness of this cake.

In order to predict the hardness of sponge cakes, new parameters such as flow behaviour properties (viscosity and consistency index) were observed. Table 1 shows that hardness was positively correlated with consistency index (rconsistency index = 0.7127) and viscosity (rviscosity = 0.6266) parameters. Control (17.30 Pa sn) and HPMC (15.67 Pa sn) batters had low consistency index (K) (p < 0.05) compared to XG (39.24 Pa sn) batter. Low K values may be attributed to weak gel strength of emulsified structure in control and HPMC batters. In XG batter, significant high ‘K’ values (39.24 Pa sn) was observed showing that the strengthening effect of XG batter is due to the additional interactions of starch with XG (Cho and Yoo 2015).

On day 2 (Fig. 3a), all cakes showed an increment in their hardness values where 1% XG cake (420.63 g) has significantly highest hardness value compared to 1% HPMC-cake (286.72 g) and control cake (250.62 g) and it is related with starch retrogradation (Gómez et al. 2007). According to Goesaert et al. (2005), amylopectin (72–75%) dominates the content of starch granules compared to amylose (25–28%), and plays a major role to the changes of texture in baked products during storage. Amylopectin slowly recrystallized during storage and caused an increase in crumb firmness (Goesaert et al. 2005). This process involved the progressive association of gelatinized starch segments into more ordered structure (Jia et al. 2008). Jia et al. (2008) attributed the moisture loss from crumb to primary firming process that caused rigidities to the crumb structure while the secondary firming was due to starch retrogradation. During initial days of storage (day 0 and day 2), 1% XG cake had high initial increase of hardness (Fig. 3b) compared to control cake and 1% HPMC cake. Singh et al. (2015) showed that addition of XG increase the volume of gluten-free rice muffins due to an increase of batter viscosity. On the other note, this study was instead found that the increment of batter viscosity in cake batter was reduced. The presence of xanthan gum with other thickening agents such as starch and sugars produce highly viscous batter compared to control batter without hydrocolloid. The highly viscous batter significantly correlated (p < 0.05) with the increase of cake hardness as shown in Table 1.

At day 4 and day 6, increment of hardness in 1% XG cake was slow than 1% HPMC and control. These could be related with its high retention of water as shown by lower moisture loss in cake containing XG during storage (Fig. 4b). For 1% HPMC cake (Fig. 3a), the softening effect of HPMC could maintain the initial hardness values of sponge cake similar to control cake. It also had low (p < 0.05) hardness values compared to 1% XG. However, it failed to maintain the softness of cake since the increased in hardness (Fig. 3b) and moisture loss (Fig. 4b) was observed during storage. Addition of hydrocolloids cannot interfere the starch retrogradation from occurring although it able to form interaction with the starch (Fig. 3b). Meanwhile, their thickening properties only cause an increase in rigidity of cake structures.

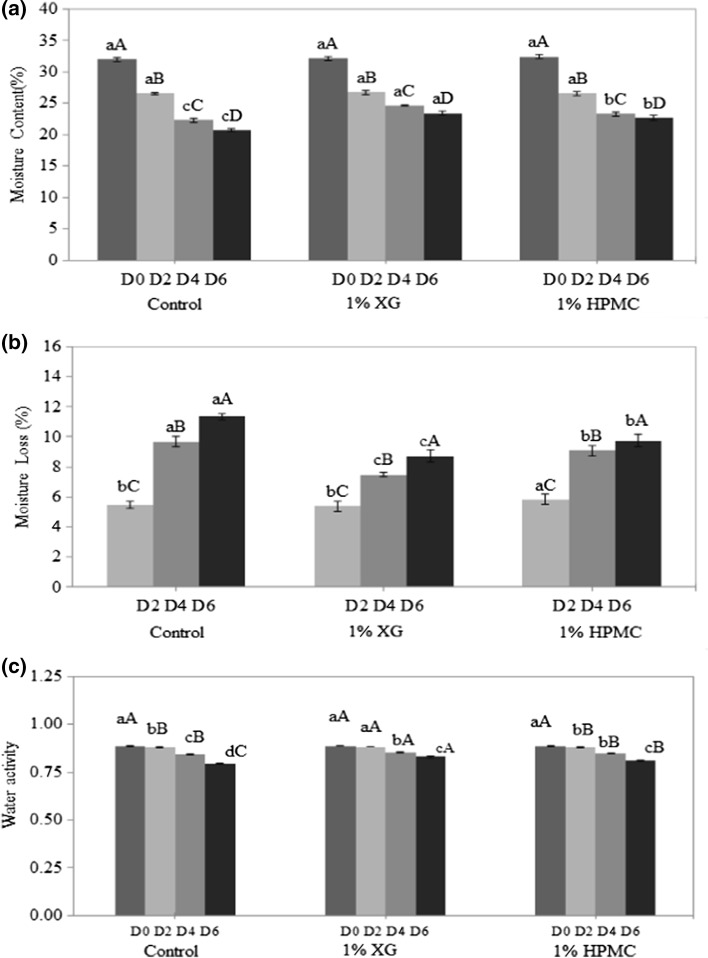

Fig. 4.

a Moisture content, b moisture loss and c water activity of sponge cakes (control, 1% XG and 1% HPMC) during storage at room temperature. Mean with different small letters (between different cake) and capital letters (between same cake) indicated significant different (p < 0.05)

Cohesiveness of sponge cake

Cohesiveness (Fig. 3c) was evaluated to test the resistance of cake to withstand second deformation compared to its behaviour under the first deformation. It is related with the integrity of the cake (Zohng 2013). At day 0, cohesiveness of all cakes was not significantly different. Therefore, the integrity of all cakes was assumed to have stable network formation. Then, the cohesiveness of 1% HPMC started to decrease at day 2 while for control and 1% XG, the cohesiveness decreased at day 4 and day 6, respectively.

In previous study, cakes containing the oat-guar gum show a cohesiveness reduction, due to the disruption within the intermolecular interaction and continuity of network system within the cakes (Gularte et al. 2012; Icoz and Kokini 2007). This may explain the action of HPMC in cake. In control and 1% HPMC cake, the deformation of protein structure may have occurred, thus decreased the value of cohesiveness in sponge cake (Zohng 2013). For 1% XG cake, cohesiveness values of sponge cake were more stable by the addition of xanthan gum, which took longer time to disrupt the cohesiveness of cake. At day 6, the cohesiveness of cake containing XG (0.78) was significantly high (p < 0.05) than control (0.66) and 1% HPMC (0.65). This may be due to its stable emulsified structure as well as the strengthening effects of xanthan gum that were able to support the intermolecular association in cake. This effect could be observed in Fig. 2.

Moisture content and moisture loss of sponge cake

For plain sponge cake, moisture content was reported in range between 25–32% (Cauvain and Young 2011). Figure 4a, b shows moisture content and moisture loss of sponge cake at day 0, 2, 4 and 6. At day 0, moisture content of control (32%), 1% XG (32.1%) and 1% HPMC (32.4%) were not significantly different, which was similar to the finding obtained by Eduardo et al. (2014) where the moisture content of bread containing hydrocolloids (47.9–48%) were slightly higher compared to control bread (47.2%).

At day 2, no significant differences (p > 0.05) of moisture content were observed among all cakes. However, moisture content of all cakes at day 2 was significantly (p < 0.05) lower than day 0 with values of 26.53, 26.72 and 26.55%, respectively. Moisture content also showed continuous decreasing after day 4 and day 6 (Fig. 4b). This indicates that the storage temperature (25 °C) affects the stability of cakes due to water migration and redistribution, thus causes dryness to these cakes (Sozer et al. 2009). This was reflected in the decreasing values of water activity (Fig. 4c) due to moisture loss in all sponge cakes during storage. From these findings, it indicates that hydrocolloids cannot prevent the moisture migration to occur during storage.

However, 1% XG cake had the highest moisture content in comparison to other samples. This might be due to its strong water binding properties that able to entrap and retain more water within the thick wall and compact structure (Fig. 2). High batter consistency and water binding capacity of the hydrocolloids may decrease the degree of crumb degradation or maintain stability of cake structure during storage (Mohammadi et al. 2014).

At day 6 (Fig. 4b), the moisture loss for the cakes treated with hydrocolloids was 8.40–8.70%, which significantly lower (p < 0.06) than control cake (11.41%). These show that the incorporation of hydrocolloids able to retain the moisture through its interaction with starch, which slow the moisture loss. However, no significant correlation was obtained between moisture content and hardness in this study (Table 1). Based on Barcenas and Rosell (2006), the change of moisture content of baked products is contributed by staling through evaporation and water redistribution. There are two circumstances being proposed for moisture loss. First, when there is moisture gradient between the crumb and the surrounding. This can be pronounced as water migration from crumb to crust. Secondly, the moisture loss is due to the changes in starch structure. The moisture migration and distribution is bound to occur as retrogradation of amylopectin of starch occurs (Goesaert et al. 2005).

The second process may explain that the different in moisture loss amongst the cakes containing hydrocolloid might be due to the changes in starch molecules during storage. During baking, starch gelatinization occurs and disrupts the original conformation of starch from order state (crystallized) to disorder state. Cooling process of cake after baking involves the changes of starch from disorder to order state (crystallized), which is also known as retrogradation. The changes in starch during heating and cooling are a reversible process (Angioloni and Collar 2009). During storage, water molecules in crumb might be used by amylopectin to form a stable conformation structure known as double helical structure. Consequently, it reduces the availability of free water molecules and cause dryness to the crumb. This process also causes the firmness of crumb to increase with time (Damodaran et al. 2008).

Water activity of sponge cake

At day 0 (Fig. 4c), all cakes were considered moist since they had high relative humidity of about 88% (aw = 0.88). At day 2, significant decrease in water activity was observed in all cakes except for 1% XG cake. Further decrease in water activity was observed in all cakes formulations at day 4 and day 6. Water activity was positively correlated (0.862, p < 0.01) with moisture content where low water activity indicated low moisture content in cake. Lower water activity indicated rapid loss of moisture occurred within crumb (Cauvain and Young 2011), which may have resulted in tougher cake as reflected in Fig. 3a.

At day 4, 1% XG cake (0.8530) had high water activity compared to 1% HPMC (0.8470) and control cake (0.8430). Further storage at day 6 showed that 1% XG cake still contained the highest water activity compared to all cakes followed by 1% HPMC and control cakes. This finding shows that 1% XG cake has better ability to maintain the moistness as compared to 1% HPMC and control cake.

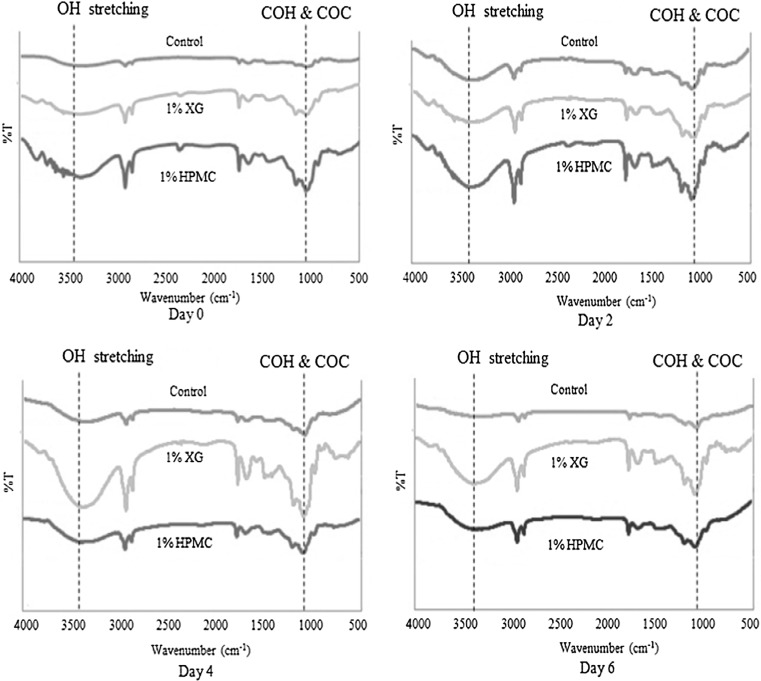

FTIR analysis of crumb during storage

The abundance of water (OH stretching vibration) in cake crumbs are observed using FTIR spectra between 3600 and 3000 cm−1, while a broad envelope at 1200–800 cm−1 was assigned to the polysaccharides bands to observe the change in intensity of functional group due to the polymeric interactions by hydrocolloids (Sivam et al. 2012). At day 0 (Fig. 5), 1% HPMC cake had broad OH stretching vibration at 3500 cm−1 followed by 1% XG and control cake, suggesting that there was a strong molecular interaction (inter/intra) of hydrogen bonds within the crumb structure (Bilanovic et al. 2015; Icoz and Kokini 2007). High absorption bands at 1100–900 cm−1 for hydrocolloids cakes suggested that there was more ordered saccharide conformation structure occurred in hydrocolloid cakes compared to control cake. It showed that there was an additional interaction of alcoholic (–CH2OH groups) of hydrocolloids with ingredients (water, intrinsic phenols in flour), forming H bonding interactions, thus spread the distribution of C–O stretching frequencies and broaden the peaks (Sivam et al. 2012).

Fig. 5.

FTIR spectra of stored sponge cakes (control, 1% XG and 1% HPMC) at day 0, 2, 4 and 6

On day 2 (Fig. 5), the migration of water was assumed to occur within the crumb as aerated cake structures tend to lose its stability or tend to degrade. The arrangement of starch structure through starch retrogradation involves moisture, which affects the stability of cake structure during storage. This could be observed in low values of water activity (Fig. 4c) in sponge cake on day 2 compared to day 0. The changes in cake structure include the decrease in cohesiveness as in Fig. 3c. The crumb of 1% HPMC cake was physically interacted with water as the broad area of OH stretching vibration could be observed at region (3600–2900 cm−1). Meanwhile, on day 4 and day 6 (Fig. 5), the ability of XG to maintain the water in 1% XG cake could be observed as it had the broadest absorption of OH stretching vibration compared to 1% HPMC and control at the region 3500 cm−1. This might be due to strong bonded of water molecules to the active site (carboxylate group) of XG, which indicates that the hydrocolloids can restore the water within the cakes structure during storage. The interaction of loose water–solid interactions at a macromolecular level is important to keep water in immobilize state, so that it can retain the moisture (Curti et al. 2014). XG may physically bond to the water through its carboxyl group (COO−) and OH groups, while HPMC may restore the water through its OH group (Navidghasemizad et al. 2015; Shohreh et al. 2012).

Control cake shows a decrease pattern of water distribution over the storage that is related to the weak absorption of OH stretching vibration at 3500 cm−1. The crumb of control cake was more dried compared to 1% XG and 1% HPMC cakes since control cake had significantly higher moisture loss and lower water activity (Fig. 4b, c) compared to 1% XG cake. The loss of moisture for amylopectin retrogradation was suggested since the storage conditions for all cakes were similar. It was because the availability of sufficient moisture required for the starch recrystallization. The moisture mobilized long polymer chain segments until these chains were gradually aggregated through intramolecular binding (Wang et al. 2015). Without hydrocolloids, the moisture is more available for starch recrystallization. The broad OH vibration stretching of HPMC and XG might be related to its interaction with polymer ingredients and water molecules. These are reflected in smooth, compact and thick wall structure of XG cake in Fig. 2, which may indicate its strengthening effects in cake structure that able to immobilize the water molecules within the cake.

Conclusion

In conclusion, the hardening effect was observed in XG cake where the cake had thick wall, compact structure and more heterogeneous pores distribution as seen in SEM study. The strengthening effects of XG increase the rigidity of batter and crumb hardness of sponge cakes. For stored cake, the mechanism of staling (starch retrogradation and moisture distribution) was continuously occurred in all sponge cakes formulations. The decreasing of moisture content and water activity, increasing of moisture loss and hardness, and the changes in OH distribution in FTIR over the storage from day 0 to day 6 confirmed the staling process occurred in sponge cakes.

The addition of XG and HPMC were able to reduce the staling process by minimizing the water loss that retained more moistness. However, XG and HPMC could not interrupt the starch retrogradation within the cake. Moreover, its interaction with starch resulted in higher values of crumb hardness. The continuity of starch and protein network was undisrupted in XG cake, thus resulted in higher values of crumb hardness compared to HPMC cake. For sponge cake, HPMC is more suitable to be added as additives than XG because it imparts the softening effects in crumb texture.

Acknowledgements

The authors thank Universiti Teknologi MARA, Research Management Institute for Excellent Funds 11/2010, Reference: 600-RMI/ST/DANA 5/3/Dst (122/2010) and MITRANS for the support and assistance throughout this research.

References

- Angioloni A, Collar C (2009) Gel, dough and fibre enriched fresh breads: Relationships between quality features and staling kinetics. J Food Eng 91(4):526–532

- Ashwini A, Jyotsna R, Indrani D. Effect of hydrocolloids and emulsifiers on the rheological microstructural and quality characteristics of eggless cake. Food Hydrocoll. 2009;23:700–707. doi: 10.1016/j.foodhyd.2008.06.002. [DOI] [Google Scholar]

- Baixauli R, Sanz T, Salvador A, Fiszman SM. Muffins with resistant starch: baking performance in relation to the rheological properties of the batter. J Cereal Sci. 2008;47:502–509. doi: 10.1016/j.jcs.2007.06.015. [DOI] [Google Scholar]

- Barcenas ME, Rosell CM. Different approaches for improving the quality and extending the shelf life of partially baked bread: low temperatures and HPMC addition. J Food Eng. 2006;72:92–99. doi: 10.1016/j.jfoodeng.2004.11.027. [DOI] [Google Scholar]

- Bilanovic D, Starosvetsky J, Armon RH. Cross-linking xanthan and other compounds with glycerol. Food Hydrocoll. 2015;44:129–135. doi: 10.1016/j.foodhyd.2014.09.024. [DOI] [Google Scholar]

- Björn A, Karlsson A, Svensson BH, Ejlertsson J, de La Monja PS. Rheological characterization. Rijeka: INTECH Open Access Publisher; 2012. [Google Scholar]

- Cauvain SP, Young LS. The stability and shelf life of bread and other bakery products. In: Kilcast D, Subramaniam P, editors. Food and beverage stability and shelf life. Cambridge: Woodhead Publishing Ltd; 2011. pp. 657–682. [Google Scholar]

- Cho HM, Yoo B. Rheological characteristics of cold thickened beverages containing xanthan gum—based food thickeners used for dysphagia diets. J Acad Nutr Diet. 2015;115:106–111. doi: 10.1016/j.jand.2014.08.028. [DOI] [PubMed] [Google Scholar]

- Curti E, Carini E, Tribuzio G, Vittadini E. Bread staling: effect of gluten on physicochemical properties and molecular mobility. LWT Food Sci Technol. 2014;59:418–425. doi: 10.1016/j.lwt.2014.04.057. [DOI] [Google Scholar]

- Damodaran S, Parkin KL, Fennema OR. Fennema’s food chemistry. 4. Boca Raton: CRC Press; 2008. [Google Scholar]

- Eduardo E, Svanberg S, Ahrne H (2014) Effect of hydrocolloids and emulsifiers on baking quality of composite cassava-maize-wheat breads. Int J Food Sci 1–9 [DOI] [PMC free article] [PubMed]

- Farzi M, Saffari MM, Emam-Djomeh Z. Effects of sugar, starch and HPMC concentrations on textural properties of reduced-sugar sponge cakes. J Food Sci Technol. 2015;52(1):444–450. doi: 10.1007/s13197-013-0965-3. [DOI] [Google Scholar]

- Goesaert H, Brijs K, Veraverbeke WS, Courtin CM, Gebruers K, Delcour JA. Wheat flour constituents: how they impact bread quality and how to impact their functionality. Trends Food Sci Technol. 2005;16:12–30. doi: 10.1016/j.tifs.2004.02.011. [DOI] [Google Scholar]

- Gómez M, Ronda F, Caballero PA, Blanco CA, Rosell CM. Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll. 2007;21:167–173. doi: 10.1016/j.foodhyd.2006.03.012. [DOI] [Google Scholar]

- Gómez M, Ruiz E, Oliete B. Effect of batter freezing conditions and resting time on cake quality. LWT Food Sci Technol. 2011;44(4):911–916. doi: 10.1016/j.lwt.2010.11.037. [DOI] [Google Scholar]

- Gularte MA, de la Hera E, Gómez M, Rosell CM. Effect of different fibres on batter and gluten-free layer cake properties. LWT Food Sci Technol. 2012;48:209–214. doi: 10.1016/j.lwt.2012.03.015. [DOI] [Google Scholar]

- Hager AS, Arendt EK. Influence of hydroxypropylmethylcellulose, xanthan gum and their combination on loaf specific volume crumb hardness and crumb grain characteristics of gluten-free breads based on rice maize teff and buckwheat. Food Hydrocoll. 2013;32:195–203. doi: 10.1016/j.foodhyd.2012.12.021. [DOI] [Google Scholar]

- Icoz DZ, Kokini JL. Probing the boundaries of miscibility in model carbohydrates consisting of chemically derivatives dextran using DSC and FTIR spectroscopy. Carbohydr Polym. 2007;68:68–76. doi: 10.1016/j.carbpol.2006.07.011. [DOI] [Google Scholar]

- Ji Y, Zhu K, Qian H, Zhou H. Staling of cake prepared from rice flour and sticky rice flour. Food Chem. 2007;104:53–58. doi: 10.1016/j.foodchem.2006.10.072. [DOI] [Google Scholar]

- Jia C, Kim YS, Huang W, Huang G. Sensory and instrumental assessment of Chinese moon cake: Influences of almond flour, maltitol syrup, fat, and gums. Food Res Int. 2008;41:930–936. doi: 10.1016/j.foodres.2007.10.006. [DOI] [Google Scholar]

- Lee LY, Chin NL, Lim CH, Yusof YA, Talib RA. Saturated distilled monoglycerides variants in gel-form cake emulsifiers. Agric Agric Sci Procedia. 2014;2:191–198. doi: 10.1016/j.aaspro.2014.11.027. [DOI] [Google Scholar]

- Li JM, Nie SP. The functional and nutritional aspects of hydrocolloids in foods. Food Hydrocoll. 2015;53:46–61. doi: 10.1016/j.foodhyd.2015.01.035. [DOI] [Google Scholar]

- Mandala IG, Sotirakoglou K. Effect of frozen storage and microwave reheating on some physical attributes of fresh bread containing hydrocolloids. Food Hydrocoll. 2005;19:709–719. doi: 10.1016/j.foodhyd.2004.09.001. [DOI] [Google Scholar]

- Martínez MM, Sanz T, Gómez M. Influence of wheat flour subjected to different extrusion conditions on the rheological behaviour and thermal properties of batter systems for coating. LWT Food Sci Technol. 2015;64(2):1309–1314. doi: 10.1016/j.lwt.2015.07.037. [DOI] [Google Scholar]

- Martínez-Cervera S, Sanz T, Salvador A, Fiszman SM. Rheological textural and sensorial properties of low-sucrose muffins reformulated with sucralose/polydextrose. LWT Food Sci Technol. 2012;45:213–220. doi: 10.1016/j.lwt.2011.08.001. [DOI] [Google Scholar]

- Mohammadi M, Sadeghnia N, Azizi MH, Neyestani TR, Mortazavian AM. Development of gluten-free flat bread using hydrocolloids: xanthan and CMC. J Ind Eng Chem. 2014;20:1812–1818. doi: 10.1016/j.jiec.2013.08.035. [DOI] [Google Scholar]

- Navidghasemizad S, Temelli F, Wu J. Phase separation behaviour of egg yolk suspensions after anionic polysaccharides addition. Carbohydr Polym. 2015;117:297–303. doi: 10.1016/j.carbpol.2014.08.117. [DOI] [PubMed] [Google Scholar]

- Ronda F, Roos YH. Staling of fresh and frozen gluten-free bread. J Cereal Sci. 2011;53(3):340–346. doi: 10.1016/j.jcs.2011.02.004. [DOI] [Google Scholar]

- Shohreh A, Movahhed S, Nematti N. Evaluation of addition of xanthan and hydroxypropyl methylcellulose gums on chemical and rheological properties of sponge cakes. Ann Biol Res. 2012;3:589–594. [Google Scholar]

- Shyu Y-S, Sung W-C. Improving the emulsion stability of sponge cake by the addition of y-polyglutamic acid. J Mar Sci Technol. 2010;18:895–900. [Google Scholar]

- Sim SY, Noor Aziah AA, Cheng LH. Characteristics of wheat dough and Chinese steamed bread added with sodium alginates or konjac glucomannan. Food Hydrocoll. 2011;25:951–957. doi: 10.1016/j.foodhyd.2010.09.009. [DOI] [Google Scholar]

- Singh JP, Kaur A, Shevkani K, Singh N. Influence of jambolan (Syzygium cumini) and xanthan gum incorporation on the physicochemical, antioxidant and sensory properties of gluten-free eggless rice muffins. Int J Food Sci Technol. 2015;50(5):1190–1197. doi: 10.1111/ijfs.12764. [DOI] [Google Scholar]

- Singh JP, Kaur A, Singh N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J Food Sci Technol. 2016;53(2):1269–1278. doi: 10.1007/s13197-015-2103-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sivam AS, Sun-Waterhouse D, Perera CO, Waterhouse GIN. Exploring the interactions between blackcurrant polyphenols, pectin and wheat biopolymers in model breads; a FTIR and HPLC investigation. Food Chem. 2012;131:802–810. doi: 10.1016/j.foodchem.2011.09.047. [DOI] [Google Scholar]

- Sozer N, Kokini JL, Bruins R, Dietzel C, Franke W, Trottier B, Harrington S (2009) https://www.researchgatenet/publication/235078314_Quality_Improvement_Project_for_Shelf_Stable_Bakery_Products/. Accessed 16 Apr 2016

- Turabi E, Sumnu G, Sahin S. Quantitative analysis of macro and microstructure of gluten-free rice cakes containing different types of gums baked in different ovens. Food Hydrocoll. 2010;24:755–762. doi: 10.1016/j.foodhyd.2010.04.001. [DOI] [Google Scholar]

- Wang S, Li C, Copeland L, Niu Q, Wang S. Starch retrogradation: a comprehensive review. Compr Rev Food Sci Food Saf. 2015;14:568–585. doi: 10.1111/1541-4337.12143. [DOI] [Google Scholar]

- Zhao Q, Zhao M, Yang B, Cui C. Effect of xanthan gum on the physical properties and textural characteristics of whipped cream. Food Chem. 2009;116:624–628. doi: 10.1016/j.foodchem.2009.02.079. [DOI] [Google Scholar]

- Zohng H (2013) http://www.digitalcommonsusuedu/cgi/viewcontentcgi?article=2501andcontext=etd/. Accessed 3 Apr 2016