Abstract

Jam like product was prepared using high pressure (HP) processing technology and was compared with thermally processed one for quality attributes. Strawberry pulp was mixed with pectin (1%) and sugar and packed in low density polyethylene pouches (50 g pack size) and processed at 200, 400 and 600 MPa for 30 min at 50 °C. Ascorbic acid, anthocyanins, phenolics, flavonoids and antioxidant activities were found to be significantly retained to a better extent in HP processed jams as compared to thermally processed one. The CIE L*, a* and b* values decreased significantly with increase in pressure, the decrease being of much lesser extent compared to thermally processed one. Increase in pressure was found to increase the sensory attributes for colour, appearance, flavour, texture and overall acceptability significantly; however, the scores were comparatively lesser than that of thermally processed jam. The sample processed at 600 MPa showed a shelf-life of 3 months on the basis of physico-chemical, sensory and microbial attributes when stored at ambient storage conditions (28 ± 5 °C).

Keywords: Jam, High pressure processing, Quality, Sensory, Microbiology, Storage

Introduction

Now-a-days consumers demand for high quality foods with fresh like nature and free from additives is increasing without compromising the microbiologically safety and shelf life. This is possible only by application of newer alternative food processing technologies such as high pressure processing. Application of high pressure (HP) processing has not only shown considerable potential as an alternative technology to heat treatments, in terms of assuring safety and retention of quality attributes in food products (Palou et al. 2002), but also facilitated the production of foods that have the quality of fresh foods with retention of nutrients to a greater extent (McClements et al. 2001). High pressure process applies the pressure in the range of 400–600 MPa at ambient temperatures to inactivate enzymes and vegetative microorganisms. Pressure is transmitted uniformly and instantaneously throughout the food, which results in a homogenous processing impact. High pressure processing is successfully used on a larger scale for pasteurisation of a different food products, e.g. fruit juices, guacamole, oysters, ham, etc. Various quality aspects of high pressure sterilised food products are superior to conventional ones (Unni et al. 2011). However, there is limitation in shelf life of pressure processed food products as they deteriorate rapidly during ambient storage (Kimura et al. 1994).

Strawberries are packed with essential vitamins, fibre, potassium and phytonutrients and it is a classic example of a sought after quality fruit, but highly perishable in nature. Fresh strawberries have a very short life as they are easily bruised and quickly spoil due to fungal attack, mainly by Botrytis cinerea (Guichard et al. 1992). The attractive red colour of preserve made from it also destroys rapidly which may be due to ascorbic acid degradation and polymerisation of anthocyanins with other phenolics (Garcia-Viguera et al. 1999). There is a need to develop technologies for preservation of strawberries that could help to extend the range of processed food products made out of it. Such process would retain the organoleptic properties of the raw fruits (i.e. taste, color, aroma and texture) and phyto-nutrients such as vitamins (Lambert et al. 1999). Use of high pressure for stabilising and preserving foodstuffs with retention of a flavour, colour, taste and other natural properties has been reported earlier (Cheftel 1995). Several reports also exist with regards to development of various value added fruit products using high pressure technology such as orange juice (Polydera et al. 2005), grape juice (Palou et al. 2002), black grape juice (Chauhan et al. 2011), etc. Jam is a traditional fruit product and is liked worldwide. Optimal concentration of sugar, pectin and acid is compulsory for proper jam setting. Gelling also requires precise water dispersability of pectin and it is suggested that high methoxy pectins can gel following HP processing (Gustin et al. 1997). Jam preparation from strawberry pulp had been tried earlier using high pressure processing where effect of pectin concentration on textural and colour attributes of jam processed by HP processing was studied (Dervisi et al. 2001). However, the literature is as such scarce with regards to the quality of jam prepared by using high pressure technology. Therefore, the present work was undertaken to develop a jam type of product using HP technique and its quality evaluation vis-a-vis thermally processed one during storage.

Materials and methods

Raw material and processing

Fresh, mature and ripe strawberries were procured from the local market of Mysore, India. The sugar and pectin used in the processing of strawberries were of food grade. The fruits were washed with potable water, cut into small pieces and made into pulp. The pulp was mixed thoroughly with finely powdered sugar (55%), citric acid (0.5%) and pectin (1%). The obtained mixture was packed in polyethylene pouches (50 µ thickness, 50 g pack size) and subjected to high hydrostatic pressure treatment (200, 400 and 600 MPa for 30 min at 50 °C). Jam was also prepared through conventional boiling method using the same composition of pulp, sugar, pectin and citric acid, where the pulp was taken in an open stainless steel pan and required amount of sugar was added and heated continuously on a gas stove under low flame. When the TSS reached 60 ºbrix, calculated amount of pectin (1%) and citric acid (0.5%) was added and the pulp-pectin-sugar-acid mixture was mixed thoroughly and stirred continuously using a steel ladle. Heating was stopped when the TSS reached 67–68 °brix and the mixture was hot filled into 300 ml capacity previously sterilized glass bottles (200 g) and cooled under ambient conditions. The jam prepared using HP as well as conventional thermal processing was stored at ambient temperature (28 ± 2 °C) away from light and evaluated over a period of 3 months.

High pressure treatment

A laboratory scale high pressure food processing equipment (ISO-LAB FPG9400, Stansted Fluid Power Ltd., Stansted, UK) was used for processing of jam. The HP system had a high pressure vessel (2 litre capacity) with dual pressure pumps and pressure intensifiers. The system had a maximum operating pressure of 1000 MPa with provisions for temperature and time variation. The high pressure vessel was surrounded by a liquid circulating jacket connected to a heating/cooling system. The pressure transmitting fluid used was 30% mono-propylene-glycol. The ramp rate for pressurization was set at 600 MPa/min, whereas decompression was done at a ramp rate of 2000 MPa/min. The initial temperature increase during pressure build-up (about 2–3 °C/100 MPa) was taken into consideration in order to achieve the desired operating temperature during pressurization. Inbuilt SCADA based software (Stansted Fluid Power Ltd., Stansted, UK) was used to monitor pressure and temperature during the process.

Chemical parameters

Total soluble solids were measured using a hand refractometer (ERMA, Tokyo, Japan) and expressed as °brix. The pH of samples was measured using a microprocessor based digital pH meter (Century, Model CP931, Bangalore, India). Reducing and total sugar contents were determined using Lane and Eynon method as described by Ranganna (1999). Ascorbic acid was measured as per the method described by Ranganna (1999) using 2, 6-dichlorophenol-indophenol dye method. Anthocyanin content was measured using spectroscopic method as described by Dangles et al. (1992). Antioxidant activity of the jam was estimated according to the procedure described by Benzie and Strain (1996). Whereas, total phenolics as mg gallic acid equivalents per 100 g of jam were estimated colorimetrically in methanolic extracts using Folin–Ciocalteu reagent as per the method described by Singleton and Rossi (1965). Total flavonoids were estimated using the method described by Zhishen et al. (1999). Polyphenol oxidase (PPO) activity was measured by a spectroscopy method (Gonzalez et al. 2000) and calculated as the change in absorbance/min/ml and one unit of enzyme activity equals 0.001 absorbance/min/ml.

Colour coordinates

Surface colour of the samples were recorded using a colour meter (Mini Scan XE Plus, Model 45/0-S, Hunter Associates Laboratory, Inc., Reston, VA, USA) as reflected in CIELAB (L* a* b*) colour space. All the measurements were referenced to the CIE (Commission Internationale de 1′Eclairage) using the standard illuminant D65 and 10º observer and the equipment was calibrated using white and black standard ceramic tiles.

Microbiological quality

Jam samples were analyzed for total plate counts (TPC), yeast and mould counts and total coliform counts according the procedures given in APHA (1992).

Sensory quality

The quality of the jams in terms of sensory colour, appearance, flavour, texture and overall acceptability of the product were measured by a sensory panel of 30 members including both male and female scientific staff of the institution on 9 point hedonic scale (Larmond 1977).

Storage studies

The variously processed strawberry jam samples were kept at room temperature (28 ± 5 °C) for a period of 3 months and were analysed periodically at an interval of 1 month for physico-chemical, microbiological and sensory attributes.

Statistical analysis

All the physico-chemical and microbiological analyses were done in triplicate and the data obtained were analyzed statistically by one-way ANOVA with least significant difference (LSD) at p < 0.05, using Statistica 7 software (Stat Soft, Tulsa, OK, USA).

Results and discussion

Physico-chemical attributes of pressure and thermal processed jams

The effect of HHP and thermal processing on various physico-chemical parameters including pH, total soluble solids (TSS), total sugars, reducing sugars, ascorbic acid, total phenolics, flavonoids and antioxidant activity are given in Table 1. The total soluble solids (°Brix) were found to be 68 °brix in pressure processed jams and 68.5 °brix in thermal processed one (data not shown). Similarly, no significant difference in pH values was observed in pressure and thermal processed jams. The reducing sugar was found to increase significantly (p < 0.05) with increase in pressure. However, the highest reducing sugar content was observed in thermally processed sample (21.32%). The thermal processed sample showed a total sugar content of 66.45% which was significantly (p < 0.05) higher than that of pressure processed ones. The ascorbic acid content decreased significantly (p < 0.05) from 14.48 mg/100 g in the case of 200 MPa pressure processed sample to 7.38 mg/100 g in thermally processed one. Polydera et al. (2005) observed no changes in ascorbic acid content in orange juice treated at 500 MPa pressure for 5 min at 28 °C. Patras et al. (2009) observed that the thermal processing of strawberry puree results in 21% thermal degradation of ascorbic acid. The anthocyanin content was about 23% lesser in thermally processed samples as compared to pressure processed one at 200 MPa. A slight decrease was observed in anthocyanin content from 6.14 to 5.89 mg/100 g with increase in pressure from 200 to 600 MPa. Degradation of anthocyanin pigments in strawberry juice might have been catalysed by the presence of oxidase enzymes during or after processing, as has been demonstrated earlier in several fruit systems (Speers et al. 1987). Verbeyst et al. (2010) observed that with increase in pressure and temperature, anthocyanin degradation also increases. A drastic reduction in polyphenol oxidase (PPO) enzyme activity (about 79.8%) was recorded when pressure of 600 MPa was used as compared to fresh strawberry pulp and the similar results were also obtained in strawberry pulp indicating its sensitivity towards high pressures (Terefe et al. 2010). No enzymatic activity was observed in the thermally processed samples. The phenols were found to be pressure stable with the retention of 92.6, 91.7, and 90.8% at 200, 400, and 600 MPa pressure, respectively, as compared to fresh strawberry pulp (48.56 mg gallic acid eq./100 g). Whereas, about 40.56% reduction in phenolic content was observed in thermally processed jam as compared to fresh pulp. The total flavonoids content was found to be 19.15 mg/100 g in fresh strawberry samples. During pressure processing the total flavonoids content decreased to 18.46, 18.37, 18.32 mg catechin eq./100 g in samples pressurized at 200, 400 and 600 MPa, respectively. The thermal processed sample showed the least flavonoids content at 15.58 mg catechin eq./100 g. Antioxidant activity was found to decrease slightly with increase in pressure. At 600 MPa the antioxidant activity decreased to 92.56 from 93.80 (% RSA) as in the case of fresh strawberry samples. Thermal processed jam showed significantly (p < 0.05) lowest antioxidant activity (63.13% RSA). High pressure processing has been found to decrease the enzymatic activity of grapefruit jam without affecting the bioactive content (Igual et al. 2013).

Table 1.

Effect of high pressure and thermal processing on some physico-chemical attributes of strawberry jam

| Attributes | Type | |||

|---|---|---|---|---|

| 200 (MPa) | 400 (MPa) | 600 (MPa) | Thermal | |

| pH | 03.13a | 03.13a | 03.14a | 03.12a |

| Reducing sugar (%) | 18.88a | 19.05b | 13.20b | 21.32c |

| Total sugars (%) | 65.98a | 65.94a | 65.72a | 66.45b |

| Ascorbic acid (mg/100 g) | 14.48a | 14.36a | 14.30a | 07.38b |

| Anthocyanin (mg/100 g) | 06.14a | 06.02a | 05.89b | 04.74c |

| PPO activity (unit/g/min) | 418.80a | 256.60b | 108.87c | Absent |

| Total phenolics (mg gallic acid eq./100 g) | 48.56a | 48.12a | 47.64b | 31.19c |

| Total flavonoids (mg catechin eq./100 g) | 18.46a | 18.37a | 18.32a | 15.58b |

| Antioxidant activity (% RSA) | 93.08a | 92.87a | 92.56a | 63.13b |

| L* | 17.45a | 16.24b | 15.34c | 10.01d |

| a* | 10.94a | 10.59a | 10.13b | 14.84c |

| b* | 05.70a | 03.03b | 02.13c | 00.37d |

Values with different superscripts in same row differ significantly (p < 0.05)

CIE colour values of pressure and thermal processed jams

The effect of high pressure and thermal processing on CIE colour values in terms of L*, a* and b* values of strawberry jam is presented in Table 1. The L* values were found to decrease significantly (p < 0.05) with increase in pressure during pressure processing of jams, whereas, thermal processed jam showed lowest L* value indicating darkening of colour during thermal processing. High a* value (14.84) was observed in thermal processed jam when compared to pressure processed samples whose values were found to be 10.94 at 200 MPa, 10.59 at 400 MPa and 10.13 at 600 MPa. Patras et al. (2009) observed that the redness of the strawberry puree was well retained by high pressure processing compared to thermal processing. The b* value also decreased significantly (p < 0.05) during pressure processing and thermal processing showing highest decrease in b* values indicating shift in colour from yellow to blue side. Holzwarth et al. (2013) reported that pigments and colour were best retained immediately after processing, when strawberry jams were cooked at 70 °C under reduced pressure depending on pectin type and water activity of the jams. Garcia-Viguera et al. (1999) found no effect of pressure on anthocyanin content and the jam made was found to retain its original colour. However, ascorbic acid degradation and polymerization of anthocyanins with other phenolics can be responsible for colour decrease and pH and fruit type can also affect the colour loss.

Sensory attributes of pressure and thermal processed jams

The samples treated at 600 MPa pressure showed significantly (p < 0.05) highest sensory score for colour followed by samples treated at 400 and 200 MPa. The thermal processed sample showed least sensory colour score (Table 2). The thermal treated sample obtained significantly (p < 0.05) higher sensory value for appearance as compared to pressure treated samples. The sensory scores for flavour showed non-significant decrease with increase in pressure from 200 to 600 MPa. The thermal processed sample showed significantly (p < 0.05) highest sensory score for texture, whereas, the lowest score was showed in 200 MPa treated one. The sensory score for texture was found to differ significantly (p < 0.05) with increase in pressure. The thermal processed sample was found to have significantly (p < 0.05) highest overall acceptability value followed by 600 MPa treated one. The sensory score for overall acceptability was found to increase significantly (p < 0.05) with increase in pressure which may be attributed to improvement in gelling characteristics of the jam due to application of higher pressures. Dervisi et al. (2001) reported that best texture in strawberry jam can be achieved at pectin concentration in the range of 2.5–5.0% (w/w). Similarly, colour of jam was affected by increase in pectin concentration as the absorbance intensity increased with increase in pectin concentration suggesting a relationship between pectin and anthocyanin degradation.

Table 2.

Effect of high pressure and thermal processing on sensory attributes (on nine point hedonic scale) and microbial quality of strawberry jam

| Type | Colour | Appearance | Flavour | Texture | Overall acceptability | TPC (log cfu/g) | Yeasts and moulds (log cfu/g) |

|---|---|---|---|---|---|---|---|

| 200 MPa | 7.85a | 7.25a | 7.50a | 7.00a | 7.20a | 2.54a | 2.17a |

| 400 MPa | 7.90a | 7.40ab | 7.50a | 7.50b | 7.50b | 2.30b | 2.00b |

| 600 MPa | 7.95a | 7.50b | 7.55a | 7.95c | 7.75c | 1.40c | 1.00c |

| Thermal | 7.50b | 8.50c | 8.00b | 8.50d | 8.00d | Absent | Absent |

Values with different superscripts in same column differ significantly (p < 0.05)

Microbial characteristics of pressure and thermal processed jams

Total plate count and yeast and mould counts were found to decrease with increase in pressure from 200 to 600 MPa, whereas, no growth was observed in thermal processed sample (Table 2). No coliforms were observed among all the samples. No growth was observed in 600 MPa pressure processed samples as well as thermal processed samples. Several reports exist with regards to microbial inactivation using high hydrostatic pressure (Li et al. 2010; Unni et al. 2011). The cell membrane is one of the key sites for microbial inactivation which is known to undergo microporation, adversely affecting the permeability characteristics. The other factors may be inhibition in protein synthesis and enzyme inactivation leading to ultimate death of microbial cells.

Changes in physico-chemical attributes during storage

There was non-significant change in the pH, reducing and total sugars during storage of pressure and thermal processed jams (data not shown). The pH of the pressure processed jams was found to decrease slightly during storage at 28 ± 5 °C. Thermal processed samples also showed a slight but not significant decrease in pH. As a fact that organic acids are the second contributors (after sugars) to the total soluble solids of strawberries, they possess equal importance while processing of fruit pulps into jam as they affect the gelling properties of pectin (Pilgrim et al. 1991). The reducing sugars content was found to increase during storage in all pressure processed samples (Butz et al. 2003). The increase in reducing sugar content in thermal processed samples was found to be comparatively higher than in pressure treated samples. Not much change in total sugars was observed in pressure processed and thermal samples during storage at low temperature. Similar changes have also been reported in coconut jam during storage (Chauhan et al. 2012).

The CIE L* values were observed to decrease during storage in all the samples, however, the changes were found to be of lower magnitude. The samples processed at lower pressures, i.e. 200 MPa, showed significantly (p < 0.05) higher decrease as compared to other samples. The CIE a* values were found to increase significantly (p < 0.05) in all samples during storage. Similarly, the CIE b* values decreased significantly (p < 0.05) during storage in all the samples, the trend being the same as in the case of L* values. The changes in CIE L*, a* and b* values were non-significant up to 1 month of storage, however, the changes were found to be significant (p < 0.05) thereafter. The red colour of the strawberry jam is due to the anthocyanins content in the fruits. The changes in colour might be due to polymerization and/or co-pigmentation of anthocyanins with themselves and other co-pigments (Dervisi et al. 2001). Remaining enzymatic activities and dissolved oxygen in high pressure processed samples may also be responsible for anthocyanin degradation during storage causing changes in colour attributes (Cano et al. 1997). Kimura et al. (1994) were also of the opinion that oxidative reactions may be responsible for the decrease in colour values during storage of jams produced by HPP. Browning reactions have also been reported responsible for colour deterioration during storage of jams (Garcia-Viguera et al. 1999).

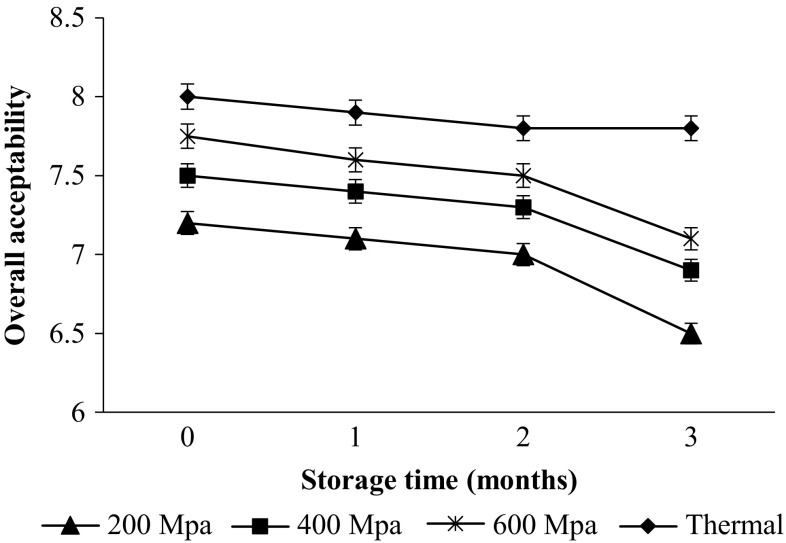

Changes in microbial counts and sensory overall acceptability during storage

The total plate count in high pressure processed samples increased during storage, whereas, no growth was observed among thermal processed samples (data not shown). The yeasts and moulds count also increased significantly (p < 0.05) in pressure processed samples. The samples processed at higher pressures showed significantly (p < 0.05) lesser increase in total plate count as well as yeast and mold counts. Coliforms were found absent during entire storage period in all the samples. Among the pressure processed samples, the sample treated at 600 MPa pressure was found to be acceptable after 3 month storage, although, there was a significant (p < 0.05) reduction in sensory scores during storage but the sample was found in the acceptable range (Fig. 1). The samples processed at 400 and 200 MPa showed significantly (p < 0.05) higher decrease in sensory acceptability as compared to one processed at 600 MPa. In the thermal processed samples, overall sensory acceptability values also decreased significantly (p < 0.05) when stored at room temperature conditions. The decrease in overall sensory acceptability was found to be non-significant up to 1 month of ambient storage, but later on the changes were found to be significant (p < 0.05). Storage temperature has found to have an effect on the ageing of the pectin gels leading to decrease in sensory perceptions (Lopes da Silva and Goncalves 1994). High pressure applications at low to moderate temperatures (<50 °C) causes inactivation of vegetative microbial cells and some enzymes without spoiling the organoleptic qualities of the foods (Cheftel 1995). The pressure processed samples were found to be acceptable on the basis of sensory attributes after 3 months of ambient storage (28 ± 5 °C).

Fig. 1.

Changes in overall sensory acceptability during storage of strawberry jam

Conclusion

High pressure processing retained phenolic, flavonoid, ascorbic acid and anthocyanin contents as well as antioxidant activity in strawberry jam to a better extent as compared to thermal processed ones besides maintaining the sensory and microbiological qualities of the product. The product processed at 600 MPa at 50 °C for 30 min had shown good sensory appeal and was found to be stable for a period of 3 months under ambient storage conditions (28 ± 5 °C). Use of lower pressures during jam making retained the physico-chemical attributes but failed to yield jam like gelling characteristics in the products. High pressure processing could be used in commercial production of high quality products such as jams having superior physico-chemical characteristics as compared to thermal processed counterparts.

References

- APHA (1992) Compendium of methods for the microbiological examination of foods. In: Speck ML (ed), 16th edn. American Public Health Association, Washington

- Benzie IFF, Strain JJ. The ferric reducing ability of plasma (FRAP) as a measure of ‘antioxidant power’: the FRAP assay. Anal Biochem. 1996;239:70–76. doi: 10.1006/abio.1996.0292. [DOI] [PubMed] [Google Scholar]

- Butz P, Fernandez Garcia A, Lindauer R, Dieterich S, Bognar A, Tauscher B. Influence of ultra high pressure processing of fruit and vegetable products. J Food Eng. 2003;56:233–236. doi: 10.1016/S0260-8774(02)00258-3. [DOI] [Google Scholar]

- Cano MP, Hernandez A, De Ancos B. High pressure and temperature effects on enzyme inactivation in strawberry and orange products. J Food Sci. 1997;62:85–88. doi: 10.1111/j.1365-2621.1997.tb04373.x. [DOI] [Google Scholar]

- Chauhan OP, Raju PS, Ravi N, Roopa N, Bawa AS. Studies on retention of antioxidant activity, phenolics and flavonoids in high pressure processed black grape juice and their modelling. Int J Food Sci Technol. 2011;46:2562–2568. doi: 10.1111/j.1365-2621.2011.02783.x. [DOI] [Google Scholar]

- Chauhan OP, Archana BS, Singh A, Raju PS, Bawa AS. Utilization of tender coconut pulp for jam making and its quality evaluation during storage. Food Bioprocess Technol. 2013;6:1444–1449. doi: 10.1007/s11947-012-0920-8. [DOI] [Google Scholar]

- Cheftel JC. Review: high pressure microbial inactivation and food preservation. Food Sci Technol Inst. 1995;1:75–90. doi: 10.1177/108201329500100203. [DOI] [Google Scholar]

- Dangles O, Wigand MC, Brouillard R. Anthocyanin anti-copigment effect. Phytochemistry. 1992;31:3811–3812. doi: 10.1016/S0031-9422(00)97533-2. [DOI] [Google Scholar]

- Dervisi P, Lamb J, Zabetakis I. High pressure processing in jam manufacture: effects on textural and colour properties. Food Chem. 2001;73:85–91. doi: 10.1016/S0308-8146(00)00289-2. [DOI] [Google Scholar]

- Garcia-Viguera C, Zafrilla P, Romero F, Abellan P, Artes F, Tomas-Barberan FA. Colour stability of strawberry jam as affected by cultivar and storage temperature. J Food Sci. 1999;64:243–247. doi: 10.1111/j.1365-2621.1999.tb15874.x. [DOI] [Google Scholar]

- Gonzalez EM, de Ancos B, Cano MP. Partial characterization of peroxidase and polyphenol oxidase activities in blackberry fruits. J Agri Food Chem. 2000;48:5459–5464. doi: 10.1021/jf000169w. [DOI] [PubMed] [Google Scholar]

- Guichard E, Chambroy Y, Reich M, Fourneir N, Souty M. Influence de la concentration en dioxide de carbone sur la qualite aromatique des fraises après entreposage. Sci Aliment. 1992;12:83–100. [Google Scholar]

- Gustin D, Bera F, Dumont de Chassart Q, Mertens B. Pectin gelification under HPP: gel properties and formation mechanisms. In: Heremans K, editor. High pressure research in the biosciences and biotechnology. Leuven: University Press; 1997. pp. 195–200. [Google Scholar]

- Holzwarth M, Korhummel S, Siekmann T, Carle R, Kammerer DR. Influence of different pectins, process and storage conditions on anthocyanin and colour retention in strawberry jams and spreads. LWT Food Sci Technol. 2013;52:131–138. doi: 10.1016/j.lwt.2012.05.020. [DOI] [Google Scholar]

- Igual M, Sampedro F, Martínez-Navarrete N, Fan X. Combined osmodehydration and high pressure processing on the enzyme stability and antioxidant capacity of a grapefruit jam. J Food Eng. 2013;114:514–521. doi: 10.1016/j.jfoodeng.2012.09.006. [DOI] [Google Scholar]

- Kimura K, Ida M, Yosida Y, Ohki K, Fukumoto T, Sakui N. Comparision of keeping quality between pressured-processed jam and heat-processed jam: changes in flavour components, Hue, and nutrients during storage. Biosci Biotech Biochem. 1994;58:1386–1391. doi: 10.1271/bbb.58.1386. [DOI] [Google Scholar]

- Lambert Y, Demazeau G, Largeteau A, Bouveir JM. Changes in aromatic volatile composition of strawberry after high pressure treatment. Food Chem. 1999;67:7–16. doi: 10.1016/S0308-8146(99)00084-9. [DOI] [Google Scholar]

- Larmond E. Laboratory methods for sensory evaluation of foods. Ottaw: Canada Department of Agriculture Publication; 1977. [Google Scholar]

- Li L, Feng L, Yi J, Hua C, Chen F, Liao X, Wang Z, Hu X. High hydrostatic pressure inactivation of total aerobic bacteria, lactic acid bacteria, yeasts in sour Chinese cabbage. Int J Food Micro. 2010;142:180–184. doi: 10.1016/j.ijfoodmicro.2010.06.020. [DOI] [PubMed] [Google Scholar]

- Lopes da Silva JA, Goncalves MP. Rheological study into the ageing of high methoxy pectin/sucrose aqueous gels. Carbohydr Polym. 1994;24:235–245. doi: 10.1016/0144-8617(94)90068-X. [DOI] [Google Scholar]

- McClements JMJ, Patterson MF, Linton M. The effect of growth stage and growth temperature on high hydrostatic pressure inactivation of some psychrotrophic bacteria in milk. J Food Prot. 2001;64:514–522. doi: 10.4315/0362-028X-64.4.514. [DOI] [PubMed] [Google Scholar]

- Palou E, Lopez-Malo A, Welti-Chanes J. Innovative fruit preservation using high pressure. In: Welti-Chanes J, Barbosa-Canovas GV, Aguilera JM, editors. Engineering and food for the twenty first century. Food preservation technology series. Boca Raton: CRC Press; 2002. pp. 715–726. [Google Scholar]

- Patras A, Brunton NP, Da Piev S, Butler F. Impact of high pressure processing on total antioxidant activity, phenolic, ascorbic acid, anthocyanin content and colour of strawberry and blackberry purees. Innov Food Sci Emerg Technol. 2009;10:308–313. doi: 10.1016/j.ifset.2008.12.004. [DOI] [Google Scholar]

- Pilgrim GW, Walter RH, Oakenfull DG. Jams, jellies and preserves. In: Walter RH, editor. The chemistry and technology of pectin. New York: Academic Press; 1991. pp. 23–49. [Google Scholar]

- Polydera AC, Stoforos NG, Taoukis PS. Effect of high pressure treatment on post processing antioxidant activity of fresh navel orange juice. Food Chem. 2005;91:495–503. doi: 10.1016/j.foodchem.2004.04.040. [DOI] [Google Scholar]

- Ranganna S. Handbook of analysis and quality for fruit and vegetable products. New Delhi: Tata McGraw-Hill Publishing Company Limited; 1999. [Google Scholar]

- Singleton VL, Rosi JA. Colorimetry of total phenolics with phosphomolybdic-phosphotungustic acid reagent. Am J Enol Vitic. 1965;16:144–158. [Google Scholar]

- Speers RA, Tung MA, Jackman RL. Colour stability of blueberry, raspberry and strawberry juice. Can Inst Food Sci Technol J. 1987;20:318. doi: 10.1016/S0315-5463(87)71262-0. [DOI] [Google Scholar]

- Terefe NS, Yang YH, Knoerzer K, Buckow R, Versteeg C. High pressure and thermal inactivation kinetics of polyphenol oxidase and peroxidase in strawberry puree. Innov Food Sci Emerg Technol. 2010;11:52–60. doi: 10.1016/j.ifset.2009.08.009. [DOI] [Google Scholar]

- Unni LE, Chauhan OP, Raju PS, Bawa AS. High pressure processing of foods: present status and future strategies. Int J Food Ferment Technol. 2011;1:49–62. [Google Scholar]

- Verbeyst L, Oey I, Van der Plancken I, Hendrickx M, Loey AV. Kinetic study on the thermal and pressure degradation of anthocyanins in strawberries. Food Chem. 2010;123:269–274. doi: 10.1016/j.foodchem.2010.04.027. [DOI] [Google Scholar]

- Zhishen J, Mengcheng T, Jianming W. The determination of flavonoids content in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999;54:555–559. doi: 10.1016/S0308-8146(98)00102-2. [DOI] [Google Scholar]