Abstract

The effect of microwave heating wheat grains (700 W for 0–60 s) on gluten, farinograph, pasting properties and baking (steamed bread and biscuit) of flour was studied. The lipase (LA) and lipoxygenase (LOX) activities of the microwave-treated wheat were monitored, and the accelerated storage at 35 °C of whole wheat flour was also investigated. The results showed that the gluten, farinograph properties and viscosity were influenced to a small extent when microwave treatment time was less than or equal to 20 s and the temperature of the grains was less than or equal to 56 °C. Texture profile analysis indicated that steamed bread made from wheat treated by microwave for 20 s was softer and of better quality. Microwave treatment for longer periods (≥30 s) increased the temperature ≥68 °C, that damaged the gluten and made wheat unsuitable for making steamed bread; however, suitable for making food with lower gluten requirements, such as biscuits. The results obtained from enzyme activity and accelerated storage experiments demonstrated that microwave treatment could inactivate LA and LOX and extend the shelf-life.

Keywords: Microwave, Whole wheat flour, Functional properties, Texture, Accelerated storage

Introduction

Heat treatments can inactivate enzymes to inhibit rancidity caused by LA and LOX and reduce moisture content to extend the shelf-life of grain (Bucsella et al. 2016). It can also modify starch granules, denature proteins, reduce microbial load and even modify taste and aroma (Gómez and Martínez 2016). Heat treatment of wheat flour (120–130 °C for 30 min) is used as an improver; it increases cake height, bulk density, and fine texture (Neill et al. 2012; Chesterton et al. 2015). However, when heat treatment was used for grain drying, the drying temperature was significant to the quality of the grain, i.e., the quality of wheat was affected significantly when the temperature was above 70 °C (Vazquez-Chavez and Vizcarra-Mendoza 2008).

Heat treatment of cereal grains caused changes in the protein and starch, so rheological characteristics and pasting properties were also investigated. Studies have shown that heating enhanced the water-holding, oil-binding, emulsifying and foaming capacities of the flours (Yalcin et al. 2008; Seema et al. 2012). Moreover, heat could alter the rheological properties of the flour. Heat-treated flour showed higher resistance, viscosity, and rigidity during the mixing process, which contributed to the increase in dough elasticity (Marston et al. 2016; Meza et al. 2011). Rheological changes can be caused by protein aggregation, together with changes in starch-protein and starch–starch interactions (Mann et al. 2013; Bucsella et al. 2016).

Albumins, globulins, glutenins and gliadins are the four major constituent proteins in wheat and were differentiated based on the their different solubilities in different solvents. Gluten proteins are composed of glutenins and gliadins, two functionally distinct groups that give doughs different properties.

Glutenins and gliadins, made up of gluten proteins, allow wheat flour to form dough. Gliadin is a mixture of heterogeneous monomeric proteins. Glutenin is a polymeric protein composed of high-molecular-weight and low-molecular-weight subunits that are linked by inter-chain disulphide bonds (Rahaman et al. 2016; Wieser 2007). The effects of heat treatment on the wheat proteins have been studied by various research groups. The disulphide bonds were rearranged, which made the proteins denature and polymerize. Albumins and globulins denature at 60 °C and bind to high-molecular-weight proteins. Due to the conformational structure and low thiol availability, gliadins were only partially denatured at 90 °C and aggregated into polymers (Lamacchia et al. 2016). When heated, the molecular size of the glutenin aggregates increased. These all lowered the protein extractability (Lamacchia et al. 2010). Miki et al. (2009) showed that dry heating (120 °C, 120 min) wheat flour did not change the structures of its starch.

In addition to being used for grain drying, grain storage stability and quality improving, heat treatment can also be used as a preliminary experimental method to supply celiac disease patients with wheat products (Lamacchia et al. 2016). Celiac disease is a genetically based autoimmune disorder affecting the gastrointestinal system. People with this disease must eliminate gluten from their diet for their entire lives, specifically gliadin in wheat, secalin in rye, and hordein in barley (Capriles and Areas 2014; Sollid and Lundin 2009; Marston et al. 2016). Approximately 1: 200–350 people in Europe and 1: 250–500 in the USA suffer from this disease (Sozer 2009; Thompson and Méndez 2008; Palabiyik et al. 2016). Currently, gluten-free foods are prepared using rice flour (Soto-Jover et al. 2016), sorghum flour (Marston et al. 2016), etc. to replace wheat, rye and barley flours (Ozkoc and Seyhun 2015). Rahaman et al. (2016) suggested that at pH 3 and with heating up to 90 °C, the antigenicity of wheat gluten was reduced by 30%, and further heating to 100 °C increased antigenicity likely because of the exposure of new epitopes. Kwak et al. (2012) investigated the antigenicity of gliadins after microwave treatment (1000 W for 1, 5 and 10 min). Their results indicated that the microwave did not reduce the antigenicity of wheat gliadins, and in fact, the antigenicity increased with increased microwave time. It should be noted that all the antigenicity experiments were carried out with gluten or after the gluten had been already formed. Nevertheless, Lamacchia et al. (2016) proposed that microwave exposure can reduce antigenicity by 99% in wheat kernels. This may be due to the wheat proteins being subjected to microwave heating while in the endosperm; protein chemical changes can occur in different protein bodies in their native form if they are not already formed into gluten. Therefore, microwave treatment of wheat kernels can be used as an alternative method for the production of gluten-free products.

The aim of this paper is to show the effects of microwave treatment of wheat kernels on the activities of enzymes, storage stability, gluten content, farinograph properties, viscosity properties and final products, which might be consumed by celiac disease patients.

Materials and methods

Raw materials and microwave heating

The wheat used in this study was purchased from Rui-Xing Seed Corporation (Zhengzhou, China). The wheat kernels were tempered for 24 h to reach 18–20% moisture content. Then, 40 g wheat kernels were heated in a microwave oven at 700 W for 10, 20, 30, 40, 50 and 60 s. The unheated wheat kernels were used as the control. After heating, the wheat kernels were milled into whole wheat flour over a 40 mesh sieve by a hammer mill.

Gluten properties

The wet gluten content and the gluten index were determined according to GB/T 14608-2003 (Chinese National Standards). Zeleny sedimentation values were determined based on the AACC method 56-61A (AACC 1999).

Farinograph properties

Farinograph characteristics of the doughs were determined using a Brabender Farinograph (300 g) according to the method described by Liu et al. (2015).

Viscosity determination by RVA

The viscosity was investigated using a Rapid Visco Analyser (RVA, Newport Scientific, Sydney, Australia) using the method described by Fierens et al. (2015).

Damaged starch determination

Damaged starch was determined using an SD-matic (Chopin, France) according to the method described by Rogers et al. (1994).

Food preparation and texture tests

Steamed bread preparation

Dehydrated yeast (1.5 g) and 85 to 95 mL warm water were added to 150 g whole wheat flour. After 3 min of stirring in a dough mixer and kneaded by hand, the dough had formed. The dough was then sheeted 8 times and shaped by a dough mould. Then, it was cut into 3 pieces, which were then kneaded by hand until they were round with a smooth surface. The round dough was placed into the fermentation cabinet at 38 °C with 85% relative humidity for 70 min. After that, the proofed dough was steamed for 30 min in a steam tray with boiling water.

Soft biscuit preparation

A mixture of 28.5 g sugar, 4.6 g maltose, 23 g shortening, 12 mL water, 16.7 g egg, 0.07 g salt and 100 g whole wheat flour was stirred to make a dough. The dough was proofed at 30 °C for 30 min and pressed into moulds. The trays were baked at 180 °C for 9 min in the oven. After that, the biscuits were cooled to room temperature.

Texture tests of steamed bread and biscuits

The texture tests were conducted using a texture analyser (TA-XT Plus, Stable Miero System, Britain).

After cooling for 1 h, the texture of the steamed bread was determined using a texture analyser equipped with a P36 probe. The steamed bread was sliced into pieces 20 mm thick using a slicer. The test parameters were as follows: pre-test speed 2.0 mm/s, test speed 1.0 mm/s, post-test speed 1.0 mm/s and trigger force 5 g. Steamed bread pieces were compressed to 50% of their height. The hardness, adhesiveness, resilience, cohesiveness, springiness and chewiness of the steamed bread were determined.

The biscuits were put on the support of the analyser horizontally and measured with SMS P/0.25 s probe. The experimental parameters were as follows: in “Compression” determination mode, test speed 1.0 mm/s, post-test speed 1.0 mm/s and trigger force 5 g. The parameters of hardness, brittleness and tenacity can be obtained from the texture profile analysis (TPA) experiments.

Temperature monitoring

The temperatures of the wheat kernels during heating were monitored using an electronic probe thermometer.

The determination of the activities of enzymes and the free fatty acid value (FFA)

Determination of lipase (LA) activity

The LA activities of the wheat samples were determined using a spectrophotometric assay following the method of Cai et al. (2011). Tris–HCl buffer (10 mL, pH 8.0, 50 mM) was used for extracting the LA from 2.0 g of whole wheat flour. LA extract (200 μL) was reacted with 20 μL of 10 mM p-nitrophenyl octanoate as the substrate in 1780 μL of Tris–HCl buffer. The mixture was allowed to react for 1 min at 37 °C. One unit of lipase activity in this assay was defined as an increase in absorbance of 0.1 at 405 nm within 1 min.

Lipoxidase (LOX) activity assays

The LOX activities were evaluated as described by Cato et al. (2006). To prepare the linoleic acid substrate, 0.5 mL of Tween-20 was dissolved in borate buffer (50 mM, pH 9.0, 10 mL), 0.5 mL of linoleic acid was added to the buffer solution dropwise, and the mixture was stirred. Then, 1 M NaOH was added to clarify the solution. Finally, 90 mL of borate buffer (50 mM, pH 9.0) was added, the solution was diluted to 200 mL with distilled water, and the pH was adjusted to 7.0 with 1 M HCl. The substrate solution was then put in a brown glass bottle and preserved at 4 °C.

To extract the LOX from whole wheat flour, 0.5 g of whole wheat flour was added to 2.5 mL of phosphate buffer (50 mM, pH 7.5), and then the mixture was agitated on ice for 30 min and centrifuged (8000 r/min, 11 min, 4 °C) to obtain the LOX extract.

The activity of LOX was determined spectrophotometrically at 25 °C. The reaction mixture was composed of sodium acetate buffer (50 mM, pH 5.5, 2890 µL), linoleic acid substrate (90 µL) and LOX extract (20 µL). One LOX activity unit was defined as an increase in absorbance of 0.01 at 234 nm within 1 min.

Free fatty acid (FFA) value determination

FFA values were measured by titration according to Chen et al. (2015). Lipids were extracted using benzene and titrated with 0.01 M KOH (95% ethanol as solvent) using phenolphthalein (95% ethanol as solvent) as an indicator. FFA value was expressed as the amount of KOH consumed by a 100 g sample (mgKOH/100 g).

Results and discussion

Microwave effects on wheat gluten

Gluten is necessary for the production of most flour-based products because it provides the supporting framework for flour products, such as bread. Table 1 summarizes the effects of microwave treatment on the wet gluten content (WGC), gluten index (GI) and sedimentation value (SV) of gluten in the whole wheat flour. It can be seen from the data in Table 1 that microwave treatment for 10 s had little impact on WGC compared to the control (0 s), and WGC fell slightly with microwave heating for 20 s. Gluten quality and quantity are of great importance in making wheat flour-based food, and they can be determined by GI and SV tests. GI measures the gluten characteristics and indicates if the gluten is weak, normal or strong. SV reflects the differences in both protein quantity and protein quality. There is a positive correlation between SV and gluten strength, which controls loaf volume. The data in Table 1 showed that the GI and SV were changed very little by 10 s of microwave treatment. The GI increased from 63 to 78, and SV decreased a little from 23.40 to 21.08 after 20 s of microwave treatment. These data indicated that short periods (700 W, ≤20 s) of microwave heating had little impact on the gluten quality; however, the quality improved a little when the wheat was heated for 20 s in the microwave. The trend was in accordance with Diraman (2010). When the microwave heating time was greater than or equal to 30 s, the wet gluten content could not be determined because the gluten scattered and was washed away. This corroborates the findings of Neill et al. (2012) and Warchalewski et al. (2011). Neill et al. (2012) suggested that heat treated gluten broke down into small aggregates of gluten. Warchalewski et al. (2011) reported that the colour, endosperm structure, reducing sugar content and endogenous amylolytic activity of wheat changed significantly when the grain was heated above 64 °C.

Table 1.

The effects of microwave treatments of wheat kernels on wheat gluten and whole wheat dough farinograph properties

| Microwave treatment time (s) | Wet gluten content (WGC) (%) | Gluten index (GI) | Sedimentation value (SV) (mL) | Development time (min) | Stability (min) | Consistency (FU) | Water absorption (mL 100 g−1) | Degree of softening (FU) | FQN (Farinograph quality number) |

|---|---|---|---|---|---|---|---|---|---|

| 0 | 37.22 ± 0.19 | 63 ± 1 | 23.40 ± 0.53 | 3.40 ± 0.17 | 1.84 ± 0.06 | 486 ± 11 | 79.5 ± 1.8 | 114 ± 3 | 48 ± 1 |

| 10 | 38.61 ± 0.20 | 59 ± 1 | 24.35 ± 0.25 | 3.39 ± 0.15 | 2.00 ± 0.07 | 510 ± 9 | 73.2 ± 1.4 | 129 ± 2 | 45 ± 1 |

| 20 | 31.76 ± 0.15 | 78 ± 1 | 21.08 ± 0.26 | 4.47 ± 0.18 | 1.78 ± 0.05 | 489 ± 7 | 75.4 ± 1.4 | 100 ± 2 | 61 ± 2 |

| 30 | – | – | – | – | – | – | – | – | – |

| 40 | – | – | – | – | – | – | – | – | – |

| 50 | – | – | – | – | – | – | – | – | – |

| 60 | – | – | – | – | – | – | – | – | – |

“–” the data could not be determined

Therefore, the WGC, GI and SV could not be determined. This indicated that the gluten proteins denatured, and the gluten structure was damaged when the microwave heating time was greater than or equal to 30 s at 700 W.

The influences of microwave heating on dough farinograph properties

Kaur et al. (2016) and Singh et al. (2016) reported that the farinograph properties, pasting properties, and ratio of monomeric proteins and polymeric proteins were interrelated. Farinograph experiments are usually used to evaluate dough kneading characteristics. The evaluation indexes were development time (DT), stability (S), consistency (C), water absorption (WA), degree of softening (DS) and farinograph quality number (FQN).

The data in Table 1 showed the effects of microwave treatments on dough farinograph properties. The results indicated that when the wheat was heated in a microwave for 20 s, the DT increased from 3.40 to 4.47 min, WA decreased from 79.5 to 75.4 mL/100 g, DS decreased a small amount, and FQN increased from 48 to 61. The increase in DT could be due to gluten denaturation and the effect on the gluten network formation. WA decreased because the altered gluten network changed its the ability to hold water. The increase in FQN also indicated a little improvement in the quality of dough after 20 s of microwave heating compared with the control (0 s). When the microwave treatment time was greater than or equal to 30 s, the farinograph experiments could not be carried out due to the gluten degradation.

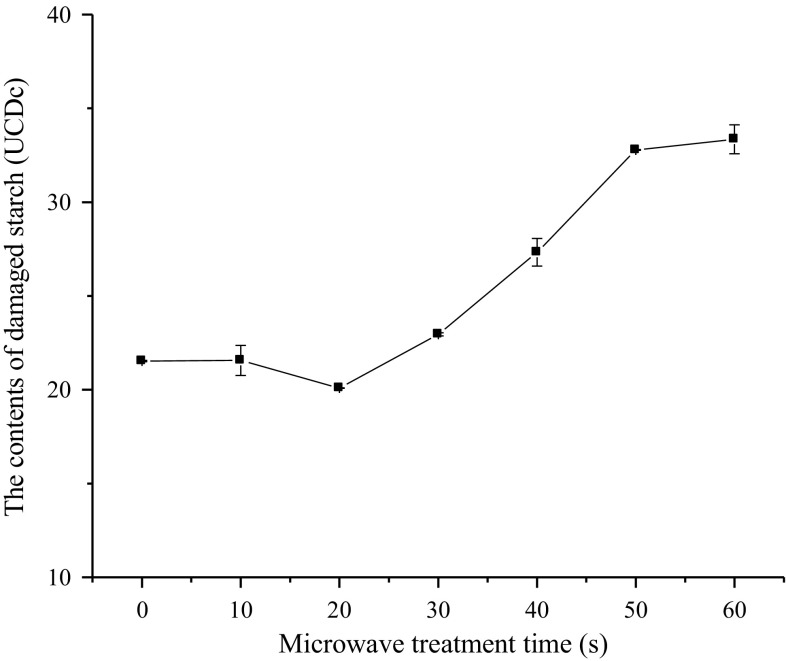

The effects of microwave heating on damaged starch

The data in Fig. 1 showed the changes in the contents of damaged starch after milling. The results showed that longer microwave treatments could cause more mechanical damage to the starch at milling. The damaged starch content was not significantly changed when the microwave heating times were less than 20 s, but it increased gradually after 20 s of microwave heating. This meant that longer microwave treatments at 700 W had an impact on the starch, but the starch was more stable to heat than the protein.

Fig. 1.

The effect of microwave treatments of wheat kernels on the contents of damaged starch

The impacts of microwave heating on viscosity properties

The impacts of microwave on gelatinization properties were presented in Table 2. The results showed that the initial pasting temperature increased as the microwave treatment time increased, from 65.2 °C (control, 0 s) to 85.5 °C (60 s, 700 W). This may be because microwave heating influenced the structures and arrangements of starch molecules, which needed higher temperatures to gelatinize. The peak viscosities were between 1549 and 1732 cP, and the changes were irregular. However, the trough viscosities gradually increased with increased microwave heating time because the microwave heating decreased the breakdown value (breakdown = peak viscosity−trough viscosity). The decreasing breakdown values were described as the resistance of starch granules to thermal treatment (Susanna and Prabhasankar 2011). The reorganization of the solubilized amylose molecules during the cooling process is measured by the final viscosity (Bucsella et al. 2016). Microwave heating destroyed the intermolecular force between the starch and gluten proteins and the increased content of damaged starch, which caused the final viscosity to increase, which indicated the possibility of the setback value increasing and a tendency for starch retrogradation.

Table 2.

The effects of microwave treatments of wheat kernels on whole wheat flour pasting properties

| Microwave treatment time (s) | Initial pasting temperature (°C) | Trough viscosity (cP) | Peak viscosity (cP) | Final viscosity (cP) | Peak time (min) | Setback (cP) | Breakdown (cP) |

|---|---|---|---|---|---|---|---|

| 0 | 65.2 ± 0.3 | 1095 ± 11 | 1645 ± 23 | 2070 ± 35 | 5.92 ± 0.11 | 975 ± 10 | 550 ± 11 |

| 10 | 73.4 ± 1.0 | 1235 ± 15 | 1732 ± 28 | 2161 ± 18 | 5.98 ± 0.06 | 926 ± 8 | 497 ± 13 |

| 20 | 71.7 ± 1.7 | 1125 ± 26 | 1549 ± 31 | 2028 ± 23 | 5.98 ± 0.08 | 903 ± 7 | 424 ± 8 |

| 30 | 78.9 ± 2.1 | 1226 ± 20 | 1665 ± 36 | 2285 ± 30 | 5.78 ± 0.12 | 1059 ± 15 | 439 ± 10 |

| 40 | 69.4 ± 2.5 | 1323 ± 18 | 1659 ± 11 | 2276 ± 47 | 6.32 ± 0.06 | 953 ± 10 | 336 ± 12 |

| 50 | 86.3 ± 2.0 | 1346 ± 21 | 1612 ± 16 | 2415 ± 27 | 5.92 ± 0.06 | 1069 ± 9 | 266 ± 10 |

| 60 | 85.5 ± 1.6 | 1400 ± 20 | 1648 ± 29 | 2457 ± 20 | 5.92 ± 0.13 | 1057 ± 14 | 248 ± 7 |

The effects of microwave heating on food made from whole wheat flour

The steamed breads made from whole wheat flour milled from microwave-heated (0–60 s) wheat kernels had different appearances and structures. The internal pores of the steamed bread were evenly distributed, and the surfaces were smooth when the microwave treatment time was less than 20 s. As the microwave treatment time increased to 30 s, the internal pores in the steamed bread decreased, and the crust separated from the rest of the bread to some extent. At the same time, cracks in the surface of the steamed bread appeared. Once the microwave times were greater than 40 s, the gluten network could not be formed, which made steamed bread more and more firm. Therefore, when microwave treatment was greater than or equal to 30 s, the steamed breads were unfit for human consumption.

The data in Table 3 showed that as the microwave treatment time increased, the hardness, adhesiveness and chewiness of the steamed breads first decreased and then increased. In addition, the three quality indicators were reduced to their minimums at 20 s of microwave treatment. In contrast, the resilience, cohesiveness and springiness of the steamed bread increased first and then decreased, and they reached their maximum values when the wheat was microwave heated for 20 s and wheat kernels reached 56 °C. These results indicated that short periods of microwave heating (700 W, ≤ 20 s) can improve the quality of steamed bread, but long periods of microwave treatment decrease the quality of steamed bread due to the denaturation of the gluten proteins.

Table 3.

The textures of steamed bread and biscuits made from microwave-treated wheat

| Microwave treatment time (s) | Steamed bread | Biscuits | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Hardness (g) | Adhesiveness (g s) | Resilience (%) | Cohesiveness (%) | Springiness (%) | Chewiness | Hardness (kg) | Brittleness (mm) | Tenacity (kg mm−1) | |

| 0 | 14,226 ± 888 | −0.498 ± 0.004 | 39.736 ± 0.177 | 0.747 ± 0.007 | 92.450 ± 0.265 | 981,721.13 ± 4958.67 | 3.736 ± 0.407 | 0.949 ± 0.134 | 3.967 ± 0.511 |

| 10 | 8590 ± 27 | −0.371 ± 0.018 | 42.136 ± 3.640 | 0.774 ± 0.012 | 93.446 ± 0.191 | 621,519.80 ± 1226.41 | 3.775 ± 0.149 | 1.079 ± 0.198 | 3.546 ± 0.513 |

| 20 | 6723 ± 186 | −0.262 ± 0.016 | 47.980 ± 0.057 | 0.789 ± 0.038 | 93.791 ± 0.274 | 497,408.03 ± 8670.71 | 3.545 ± 0.435 | 1.132 ± 0.164 | 3.176 ± 0.536 |

| 30 | 7930 ± 38 | −0.290 ± 0.042 | 38.513 ± 0.191 | 0.777 ± 0.002 | 91.355 ± 0.240 | 562,899.36 ± 126.47 | 2.848 ± 0.574 | 1.167 ± 0.512 | 2.671 ± 0.918 |

| 40 | 10,556 ± 2403 | −4.398 ± 0.295 | 42.411 ± 2.380 | 0.752 ± 0.004 | 83.027 ± 4.852 | 6632.867 ± 1852.37 | 2.612 ± 0.256 | 1.073 ± 0.409 | 2.638 ± 0.805 |

| 50 | 15,804 ± 2059 | −2.531 ± 3.162 | 39.869 ± 4.790 | 0.735 ± 0.047 | 83.888 ± 7.791 | 9728.838 ± 1561.55 | 2.362 ± 0.456 | 1.124 ± 0.319 | 2.198 ± 0.563 |

| 60 | 12,469 ± 3019 | −6.698 ± 0.133 | 41.217 ± 1.738 | 0.735 ± 0.013 | 84.622 ± 5.576 | 7800.906 ± 2252.21 | 2.084 ± 0.061 | 1.433 ± 0.241 | 1.483 ± 0.264 |

Unlike steamed bread, microwave heating showed no effect on the appearances of the biscuits. The hardness and tenacity of the biscuits decreased, and the brittleness increased as the microwave treatment time increased (0–60 s) (Table 3). Hence, microwave heating can increase the brittleness and improve the textures of biscuits.

From above, we can see that short microwave treatments (700 W, ≤20 s) did not change the gluten very much. In addition, wheat treated under these conditions was suitable for the preparation of food with relatively high gluten requirements. However, wheat that was microwave treated for more than 30 s can be used for making food with low gluten requirements.

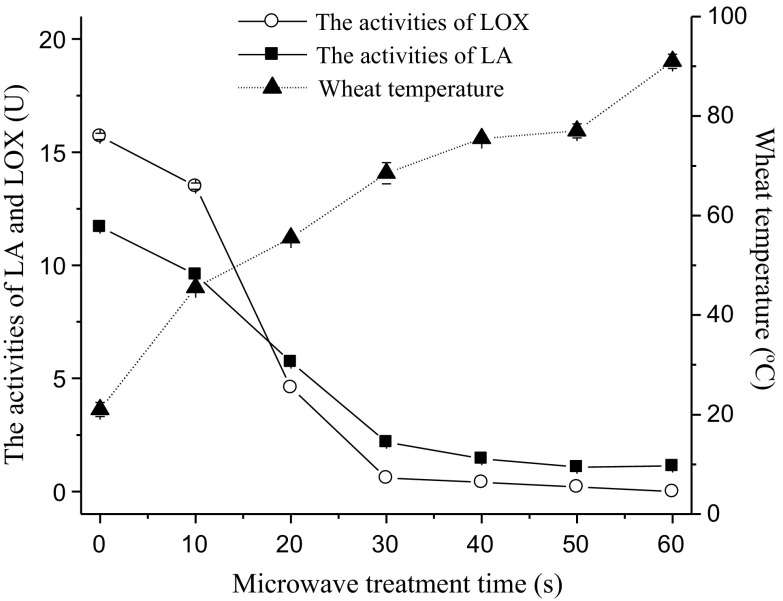

Changes in temperature, LA and LOX activities of microwave heated wheat

It can be seen from the data in Fig. 2 that longer microwave heating times caused the temperatures of the wheat kernels to gradually increase and the LA and LOX activities to decrease. When the wheat kernels were heated in a microwave (700 W) for 10 s, the LA and LOX activities decreased only small amount. Notably, the LA and LOX activities decreased substantially from the 10 s to the 30 s microwave treatment. After 20 s of microwave treatment, LA activity decreased by 50%, the LOX activity decreased by approximately 2/3, and the wheat kernel temperature increased to 56 °C. The LA and LOX activities decreased almost to their minimums after 30 s of microwave treatment when the seed temperature was 68 °C. When the microwave treatment time was more than 30 s, the activities of LA and LOX decreased slowly. Therefore, heating to 68 °C caused substantial decreases in LA and LOX activities. This could be because microwave heating changed the structures or conformations of LA and LOX, and the environment around the LA and LOX active sites changed.

Fig. 2.

The effects of microwave treatment time on the wheat kernel temperature and the activities of LA and LOX

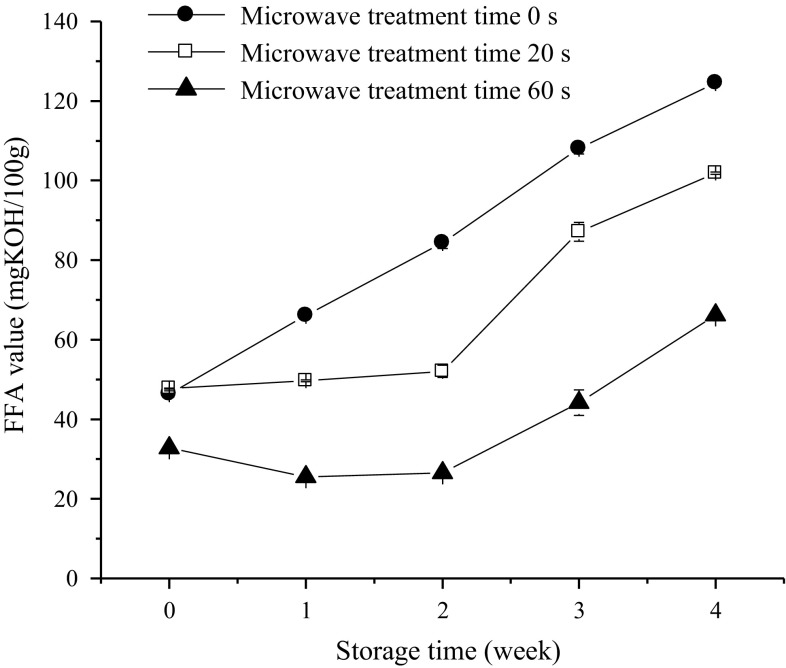

The effects of microwave heating on the accelerated storage of whole wheat flour

Wheat kernels that were microwave heated for 0, 20 and 60 s were milled to produce whole wheat flour. The whole wheat flours were stored at 35 °C for 4 weeks. It can be seen from the data shown in Fig. 3 that 60 s of microwave treatment could reduce the FFA value from 47.81 to 32.56 mgKOH/100 g before storage. This probably meant that the relative high temperature caused the volatilization of low-molecular-weight fatty acids. The data in Fig. 3 also show that the FFA values of the controlled sample (0 s) increased dramatically and reached 124.36 mgKOH/100 g after 4 weeks of storage. The FFA values of the samples subjected to 20 and 60 s of microwave treatment were stable for the first 2 weeks of storage and then increased. After 4 weeks of storage, the FFA values of samples treated for 20 and 60 s reached 102.06 mgKOH/100 g and 65.63 mgKOH/100 g, respectively. GB 1355-86 (Chinese National Standards) prescribed that the FFA values of wheat flour must be below 80 mgKOH/100 g (wet basis). The FFA value of the whole wheat flour made from the control sample reached 80 mgKOH/100 g after 2 weeks of storage at 35 °C, while the sample that was microwave heated for 20 s needed 3 weeks. In addition, after 4 weeks of storage, the FFA value of the 60 s microwave-treated sample had still not reached 80 mgKOH/100 g. Therefore, microwave treatment can significantly slow the lipid rancidity of whole wheat flour.

Fig. 3.

Accelerated storage of the whole wheat flour (milled from wheat following microwave treatment) at 35 °C

Conclusion

Whole wheat flour is more nutritious than ordinary flour because it contains all components in the germ, bran and endosperm. However, lipid rancidity is more likely to occur because of the introduction of more active enzymes and fat in wheat bran and germ. Microwave treatment, as a feasible and effective technique to inactive enzymes, can extend the storage time of whole wheat flour. However, if the wheat is heated for long periods of time (≥30 s, 700 W) and reaches a relative high temperature (≥68 °C), the treatment can also cause the wheat proteins to denature. Fortunately, the protein-denatured samples can be used to make foods with low gluten requirements. Allergies to foods made of protein-denatured wheat flour will be investigated in subsequent experiments.

Acknowledgements

This work was supported by grants from the National Natural Science Foundation of China (Grant No. 31301567) and Fundamental Research Funds for the Henan Provincial Colleges and Universities in Henan University of Technology (2017XTCX03).

References

- AACC 56-61A (1999) Sedimentation test for wheat. pp 1–4

- Bucsella B, Takács Á, Vizer V, Schwendener U, Tömösközi S. Comparison of the effects of different heat treatment processes on rheological properties of cake and bread wheat flours. Food Chem. 2016;190:990–996. doi: 10.1016/j.foodchem.2015.06.073. [DOI] [PubMed] [Google Scholar]

- Cai JG, Xie Y, Song B, Wang YP, Zhang ZM, Feng Y. Fervidobacterium changbaicum Lip1: identification, cloning, and characterization of the thermophilic lipase as a new member of bacterial lipase family V. Appl Microbiol Biotechnol. 2011;89:1463–1473. doi: 10.1007/s00253-010-2971-y. [DOI] [PubMed] [Google Scholar]

- Capriles VD, Areas JG. Novel approaches in gluten-free breadmaking: interface between food science, nutrition, and health. Compr Rev Food Sci Saf. 2014;13:871–890. doi: 10.1111/1541-4337.12091. [DOI] [Google Scholar]

- Cato L, Halmos AL, Small DM. Measurement of lipoxygenase in Australian white wheat flour: the effect of lipoxygenase on the quality properties of white salted noodles. J Sci Food Agric. 2006;86:1670–1678. doi: 10.1002/jsfa.2539. [DOI] [Google Scholar]

- Chen YJ, Jiang WX, Jiang ZQ, Chen X, Cao J, Dong W, Dai BY. Changes in physicochemical, structural, and sensory properties of irradiated brown japonica rice during storage. J Agric Food Chem. 2015;63:4361–4369. doi: 10.1021/jf5047514. [DOI] [PubMed] [Google Scholar]

- Chesterton AKS, Wilson DI, Sadd PA, Moggridge GD. A novel laboratory scale method for studying heat treatment of cake flour. J Food Eng. 2015;144:36–44. doi: 10.1016/j.jfoodeng.2014.07.011. [DOI] [Google Scholar]

- Diraman H. Effect of microwaves on technological and rheological properites of Suni-Bug (Eurygaster spp) damaged and undamaged wheat flour. Food Sci Technol Res. 2010;16:313–318. doi: 10.3136/fstr.16.313. [DOI] [Google Scholar]

- Fierens E, Helsmoortel L, Joye IJ, Courtin CM, Delcour JA. Changes in wheat (Triticum aestivum L.) flour pasting characteristics as a result of storage and their underlying mechanisms. J Cereal Sci. 2015;65:81–87. doi: 10.1016/j.jcs.2015.06.009. [DOI] [Google Scholar]

- Gómez M, Martínez MM. Changing flour functionality through physical treatments for the production of gluten-free baking goods. J Cereal Sci. 2016;67:68–74. doi: 10.1016/j.jcs.2015.07.009. [DOI] [Google Scholar]

- Kaur A, Shevkani K, Katyal M, Singh N, Ahlawat AK, Singh AM. Physicochemical and rheological properties of starch and flour from different durum wheat varieties and their relationships with noodle quality. J Food Sci Technol. 2016;53:2127–2138. doi: 10.1007/s13197-016-2202-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kwak JH, Kim KBWR, Lee CJ, Kim MJ, Kim DH, Sunwoo C, et al. Effects of autoclave and microwave treatments on the antigenicity of gliadin in medium wheat dough. J Food Sci Technol. 2012;44:55–60. [Google Scholar]

- Lamacchia C, Baiano A, Lamparelli S, Notte EL, Luccia AD. Changes in durum wheat kernel and pasta proteins induced by toasting and drying processes. Food Chem. 2010;118:191–198. doi: 10.1016/j.foodchem.2009.04.100. [DOI] [Google Scholar]

- Lamacchia C, Landriscina L, D’Agnello P. Changes in wheat kernel proteins induced by microwave treatment. Food Chem. 2016;197:634–640. doi: 10.1016/j.foodchem.2015.11.016. [DOI] [PubMed] [Google Scholar]

- Liu C, Liu L, Li LM, Hao CM, Zheng XL, Bian K, Zhang J, Wang XX. Effects of different milling processes on whole wheat flour quality and performance in steamed bread making. LWT Food Sci Technol. 2015;62:310–318. doi: 10.1016/j.lwt.2014.08.030. [DOI] [Google Scholar]

- Mann J, Schiedt B, Baumann A, Conde-Petit B, Vilgis TA. Effect of heat treatment on wheat dough rheology and wheat protein solubility. Food Sci Technol Int. 2013;20:341–351. doi: 10.1177/1082013213488381. [DOI] [PubMed] [Google Scholar]

- Marston K, Khouryieh H, Aramouni F. Effect of heat treatment of sorghum flour on the functional properties of gluten-free bread and cake. LWT Food Sci Technol. 2016;65:637–644. doi: 10.1016/j.lwt.2015.08.063. [DOI] [Google Scholar]

- Meza BE, Chesterton AKS, Verdini RA, Rubiolo AC, Sadd PA, Moggridge GD, Wilson D. Rheological characterisation of cake batters generated by planetary mixing: comparison between untreated and heat-treated wheat flours. J Food Eng. 2011;104:592–602. doi: 10.1016/j.jfoodeng.2011.01.022. [DOI] [Google Scholar]

- Miki O, Yukie K, Masaharu S. Investigation of dry-heated hard and soft wheat flour. Starch-Starke. 2009;61:398–406. doi: 10.1002/star.200800142. [DOI] [Google Scholar]

- Neill G, Al-Muhtaseb AH, Magee TRA. Optimisation of time/temperature treatment, for heat treated soft wheat flour. J Food Eng. 2012;113:422–426. doi: 10.1016/j.jfoodeng.2012.06.019. [DOI] [Google Scholar]

- Ozkoc SO, Seyhun N. Effect of gum type and flaxseed concentration on quality of gluten-free breads made from frozen dough baked in infrared-microwave combination oven. Food Bioprocess Technol. 2015;8:2500–2506. doi: 10.1007/s11947-015-1615-8. [DOI] [Google Scholar]

- Palabiyik I, Yildiz O, Toker OS, Cavus M, Ceylan MM, Yurt B. Investigating the addition of enzymes in gluten-free flours—the effect on pasting and textural properties. LWT Food Sci Technol. 2016;69:633–641. doi: 10.1016/j.lwt.2016.01.019. [DOI] [Google Scholar]

- Rahaman T, Vasiljevic T, Ramchandran L. Shear, heat and pH induced conformational changes of wheat gluten—impact on antigenicity. Food Chem. 2016;196:180–188. doi: 10.1016/j.foodchem.2015.09.041. [DOI] [PubMed] [Google Scholar]

- Rogers DE, Gelroth JA, Langemeier JM, Ranhotra GS. Evaluation of Starch damage values determined enzymatically or amperometrically. Cereal Chem. 1994;71:578–581. [Google Scholar]

- Seema A, Ghufran SSM, Asad SS. Impact of microwave treatment on the functionality of cereals and legumes. Int J Agric Biol. 2012;14:365–370. [Google Scholar]

- Singh N, Kaur A, Katyal M, Bhinder S, Ahlawat AK, Singh AM. Diversity in quality traits amongst Indian wheat varieties II: paste, dough and muffin making properties. Food Chem. 2016;197:316–324. doi: 10.1016/j.foodchem.2015.10.035. [DOI] [PubMed] [Google Scholar]

- Sollid LM, Lundin KEA. Diagnosis and treatment of celiac disease. Mucosal Immunol. 2009;2:3–7. doi: 10.1038/mi.2008.74. [DOI] [PubMed] [Google Scholar]

- Soto-Jover S, Boluda-Aguilar M, López-Gómez A. Influence of heating on stability of γ-oryzanol in gluten-free ready meals. LWT Food Sci Technol. 2016;65:25–31. doi: 10.1016/j.lwt.2015.07.058. [DOI] [Google Scholar]

- Sozer N. Rheological properties of rice pasta dough supplemented with proteins and gums. Food Hydrocoll. 2009;23:849–855. doi: 10.1016/j.foodhyd.2008.03.016. [DOI] [Google Scholar]

- Susanna S, Prabhasankar P. A comparative study of different bio-processing methods for reduction in wheat flour allergens. Eur Food Res Technol. 2011;233:999–1006. doi: 10.1007/s00217-011-1589-3. [DOI] [Google Scholar]

- Thompson T, Méndez E. Commercial assays to assess gluten content of gluten-free foods: why they are not created equal. J Am Diet Assoc. 2008;108:1682–1687. doi: 10.1016/j.jada.2008.07.012. [DOI] [PubMed] [Google Scholar]

- Vazquez-Chavez L, Vizcarra-Mendoza M. Fluidized bed drying of wheat and its quality. Rev Mex Ing Quim. 2008;7:131–137. [Google Scholar]

- Warchalewski JR, Gralik J, Grundas S, Kędzior AP, Kędzior Z (2011) Changes in microwave-treated wheat grain properties. In: Grundas S (ed) Advances in induction and microwave heating of mineral and organic materials, InTech, pp 503–530. ISBN: 978-953-307-522-8. Available from: http://www.intechopen.com/books/advances-in-induction-and-microwave-heating-of-mineral-andorganic-materials/changes-in-microwave-treated-wheat-grain-properties

- Wieser H. Chemistry of gluten proteins. Food Microbiol. 2007;24:115–119. doi: 10.1016/j.fm.2006.07.004. [DOI] [PubMed] [Google Scholar]

- Yalcin E, Sakiyan O, Sumnu G, Celik S, Koksel H. Functional properties of microwave-treated wheat gluten. Eur Food Res Technol. 2008;227:1411–1417. doi: 10.1007/s00217-008-0860-8. [DOI] [Google Scholar]