Abstract

The aims of the present work were: to calculate lifting energy consumption (LEC) in work activities designed to have a growing lifting index (LI) by means of revised NIOSH lifting equation; to evaluate the relationship between LEC and forces at the L5-S1 joint. The kinematic and kinetic data of 20 workers were recorded during the execution of lifting tasks in three conditions. We computed kinetic, potential and mechanical energy and the corresponding LEC by considering three different centers of mass of: 1) the load (CoML); 2) the multi-segment upper body model and load together (CoMUpp+L); 3) the whole body and load together (CoMTot). We also estimated compression and shear forces. Results shows that LEC calculated for CoMUpp+L and CoMTot grew significantly with the LI and that all the lifting condition pairs are discriminated. The correlation analysis highlighted a relationship between LEC and forces that determine injuries at the L5-S1 joint.

Keywords: Mechanical energy consumption, Biomechanical risk assessment, Lifting index (LI), Work-related low-back disorders (WLBDs), Revised NIOSH (National Institute for Occupational Safety and Health) lifting equation (RNLE)

Introduction

The manual lifting tasks that are found in almost every workplace1) can cause work-related low-back disorders (WLBDs)2, 3, 4, 5, 6, 7, 8, 9), which are the most common musculoskeletal problems5, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21).

An approach widely used for prevention of WLBDs is based on the revised NIOSH (National Institute for Occupational Safety and Health) lifting equation (RNLE), which provides an estimate of the physical stress level associated with the lifting task22, 23, 24). The RNLE defines a safe condition if the LI score is below 1.0, or as stressful and associated with a moderate or high risk of injury if the LI score is higher. The risk of WLBDs has been shown to increase as the LI increases from 1.0 to 3.0, with a significant odds ratio4, 11, 25, 26).

Unfortunately, approximately 35% of lifting tasks and 63% of workers cannot be assessed by means of the RNLE owing to its strict parameters and equation restrictions22, 27, 28, 29, 30, 31, 32, 33).

The development of methodologies based on new technologies for risk assessment may not only reduce the number of cases in which the RNLE cannot be applied, but also avoid job misidentification26, 34). Indeed, the huge technological advances, i.e. increased accuracy and miniaturization, have considerably enhanced the ability to identify the relationship between WLBDs and risk factors16, 35). Furthermore, the possibility to use these technologies connected to electronic smart devices (smartphones, phablets, tablets and smartwatches) via wireless protocols such as Wi-Fi and Bluetooth, would allow a simplified analysis in the worker-centered environments and distributed computing environments.

One such tool could be based on kinematic measurements designed to calculate the mechanical lifting energy consumption (LEC) in relation to the center of mass (CoM) of the system involved in the lifting task. Mechanical energy consumption, previously used in both normal36, 37) and abnormal gait patterns38, 39), provides information on the mechanical energy consumed by the whole skeletal muscle system during the movement task. Higher values are indicative of greater energy expenditure. We hypothesize that this parameter may be used as an index that is sensitive to the LI and is closely related to the compression and shear forces at the L5–S1 joint.

It may be possible to study this approach in the laboratory by means of optoelectronic systems40, 41, 42, 43) and apply it to indoor and outdoor work environments by means of wearable sensors44). Indeed, the recent development of microelectromechanical systems, such as inertial measurement units (IMUs) (i.e. combined accelerometers and gyroscopes), has paved the way for some noteworthy scientific breakthroughs that may be applied to a range of research areas45, 46).

The aims of the present work were: i) to calculate lifting energy consumption (LEC) during the execution of controlled lifting tasks designed on the basis of the RNLE and with an increasing lifting index (LI=l, LI=2 and LI=3); ii) to verify the sensitivity of LEC to the risk level and to evaluate its relationship with forces at the L5–S1 joint.

Subjects and Methods

Subjects

Twenty male subjects (mean age 33.30 ± 7.39 yr, height 1.80 ± 0.07 m, body mass index (BMI) 24.37 ± 2.67 kg/m2) were enrolled in the study. The workers had no history of musculoskeletal disorders, upper limb, lower limb and trunk surgery, or orthopedic and neurological diseases. All the participants gave their informed consent to the study, which complied with the Helsinki Declaration and was approved by the local ethics committee.

Kinematic and kinetic recordings

An eight infrared cameras (sampling frequency 340 Hz) optoelectronic motion analysis system (SMART-DX 6000 System, BTS, Milan, Italy) was used to detect the movements of 33 spherical markers (15 mm in diameter) covered with aluminum powder reflective material placed over the cutaneous projections of the spinous processes of the seventh and tenth cervical vertebrae, suprasternal notch (between the clavicular notches), sternum, sacrum and, bilaterally, over the temple, posterior-superior parietal bone, acromion, olecranon, ulnar styloid and radial processes, head of the third metacarpal bone, anterior superior iliac spine, great trochanter, lateral femoral condyle, fibula head, lateral malleoli, metatarsal head and heel47, 48, 49, 50, 51). Four markers were also placed over the 4 vertexes of a load consisting of a plastic crate.

Ground reaction forces were acquired by using four dynamometric platforms at a sampling rate of 680 Hz (P 6000, BTS, Milan, Italy) embedded in the floor.

Data acquisition from the infrared cameras and force platforms was integrated and synchronized.

Experimental procedures

The environmental data in the laboratory were collected using a portable multi-channel (sampling frequency 0.033 Hz) data logger (Lsi – Lastem, Babuc A, Permenugo, Italy). Air temperature and relative humidity were 23.30 ± 0.95°C and 40.60 ± 5.03% respectively.

Spatial accuracy after the calibration procedure was 0.2 mm in the x, y and z dimensions. A global reference system (GRS) in the laboratory was adopted in accordance with the International Society of Biomechanics47, 48).

The subjects were asked to perform the manual material lifting task standing in a neutral body position and lifting a plastic crate with handles using both hands in three different lifting conditions, according to the RNLE22). The six lifting conditions were chosen in order to obtain LI values of 1, 2 and 3. The task factors were arbitrarily chosen among a large number of combinations to have these three fixed LI values. Table 1 shows, for each lifting condition, the values of the load weight (L), horizontal (H) and vertical (V) locations, vertical travel distance (D), asymmetry angle (A) and lifting frequency (F), as well as the corresponding values of the multipliers. The hand-to-object coupling was defined as “good” for all three lifting conditions. Each participant was required to perform a total of 30 trials (5 repetitions X 6 lifting tasks). The order of each condition was randomly assigned.

Table 1. For each task (A, B, C, D, E and F), the values of the load weight (L), the horizontal (H) and vertical (V) locations, the vertical travel distance (D), the asymmetry angle (A), the lifting frequency (F) and the hand-to-object coupling (C) and the corresponding values of the multipliers and recommended weight limit (RWL).

| Task | LC | H (cm) | HM | V (cm) | VM | D (cm) | DM | A (°) | AM | F (lift/min) | FM | C | CM | L (kg) | RWL | LI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 23 kg | 25 | 1 | 75 | 1 | 25 | 1 | 30 | 0.9 | ≤0.2 | 1 | good | 1 | 23 | 23 | 1 |

| B | 23 kg | 25 | 1 | 75 | 1 | 25 | 1 | 0 | 1 | ≤0.2 | 1 | good | 1 | 20.7 | 20.7 | |

| C | 23 kg | 50 | 0.5 | 75 | 1 | 25 | 1 | 30 | 0.9 | ≤0.2 | 1 | good | 1 | 23 | 11.5 | 2 |

| D | 23 kg | 50 | 0.5 | 75 | 1 | 25 | 1 | 0 | 1 | ≤0.2 | 1 | good | 1 | 20.7 | 10.35 | |

| E | 23 kg | 60 | 0.42 | 30 | 0.87 | 45 | 0.92 | 30 | 0.9 | ≤0.2 | 1 | good | 1 | 22.09 | 7.36 | 3 |

| F | 23 kg | 63 | 0.4 | 30 | 0.87 | 45 | 0.92 | 0 | 1 | ≤0.2 | 1 | Good | 1 | 20.88 | 6.96 | |

Data analysis

Lifting cycle detection

Acquisitions were performed using Smart Capture software (BTS, Milan, Italy), while the tracking procedure and data computing were performed by Smart Tracker (BTS, Milan, Italy), Smart Analyzer (BTS, Milan, Italy) and Matlab (version 8.0.0.783, MathWorks, Natick, MA, USA) software. The vertical displacement and velocity of one of the four markers placed over the vertexes of the crate were evaluated. Velocities were obtained by applying finite difference derivatives and a Butterworth filtered 4-Hz cut-off low-pass frequency. The onset of the lifting task was defined as the time point at which the crate marker velocity exceeded the velocity threshold by 0.025 m/s on the vertical axis. Termination of the lifting task was defined as the point on the graph at which the crate marker velocity fell below the velocity threshold in the opposite direction. Kinematic and kinetic data were time normalized to the duration of the lifting tasks and reduced to 101 samples using a polynomial procedure.

CoM calculation

We calculated three different CoM values referring respectively to the load (CoML), the multi-segment upper body model (head, trunk, upper arms, forearms and hands) and load together (CoMUpp+L) as well as to the whole body (multi-segment upper body model, pelvis, thighs, shanks and feet) and load together (CoMTot). In all the three cases, the CoM was computed as the centroid of a set of elements composed by n body segments and the load. The computation was carried on by considering kinematic and anthropometric data together with the body segment parameters51, 52, 53), according to the weighted average of the individual body segments’ center of mass49, 54).

| (1) |

| (2) |

| (3) |

where CoMx, CoMy and CoMz are, respectively, the instantaneous x, y and z components of the CoM position, m is the mass of the system being considered (load, upper body+load and whole body+load, respectively), n is the number of parts being considered (n=1, n=9 and n=16, respectively), xi, yi and zi are the components of the CoM position of the ith part, and mi is the mass of the ith segment or load.

Lifting energy consumption (LEC)

For each of the CoMs calculated, the kinetic energy (Ek) during the lifting tasks was calculated as the sum of the kinetic energy on the x (Ekx), y (Eky) and z (Ekz) axes as follows:

| (4) |

where m and vx, vy and vz are, respectively, the mass and velocity components on x, y and z of the CoM being considered. Furthermore, the potential energy (Ep) was calculated using the following equation:

| (5) |

where h is the vertical (y) component of the CoM of the system being considered and g is the acceleration of gravity.

Lastly, the mechanical energy (EM) was calculated as the sum of Ek and Ep. For each CoM, the difference between maximum and minimum values of each Ek, Ep and EM within the lifting cycle were considered as LEC (LECk, LECp and LECM, respectively). In particular, we calculated LECk_L, LECp_L, and LECM_L for CoML, LECk_Upp+L, LECp_Upp+L and LECM_Upp+L for CoMUpp+L, and LECk_Tot, LECp_Tot and LECM_Tot for CoMTot.

Force calculation

According to the multi-segment upper body model, the net forces (FL5−S1) at the L5−S1 joint were calculated, in the local reference system (LRS) placed on the trunk in which the y′ axis is oriented as the vector C7-sacrum and x′−z′ represents the orthogonal plane to y, by using the following formula55):

| (6) |

where q is the number of external forces, Fj is the jth external force, p is the number of body segments being considered, mi and ai are respectively the mass50, 51) and the acceleration of the ith segment.

In this LRS, the components of FL5−S1 on the y′ axis and the x′−z′ plane were called compression (FcomprL5−S1) and shear (FshearL5−S1) forces, respectively.

Statistical analysis

All the analyses were performed using SPSS 17.0 software (SPSS Inc. Chicago, IL, USA). The Shapiro-Wilk and Kolmogorov-Smirnov test were used to analyze the normal distribution of the data. For each LECk, LECp and LECM, we performed a one-way repeated-measures ANOVA to determine whether there were any significant differences between the three risk levels. Post-hoc analyses were performed using a paired t test with Bonferroni’s corrections when significant differences were observed in the ANOVA. The Pearson test was used to investigate any correlations between LECk, LECp and LECM and the forces. A p value of less than 0.05 was considered statistically significant.

Results

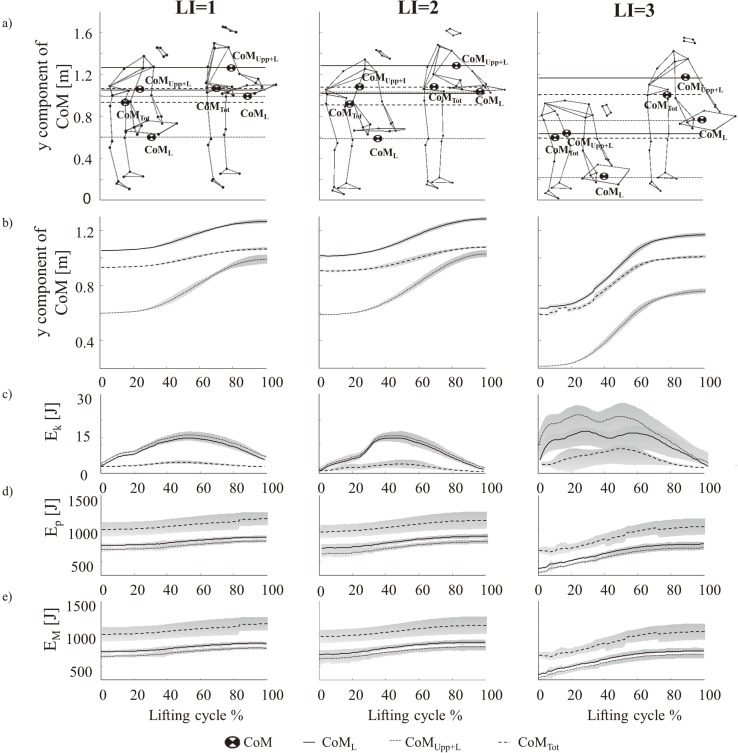

A description of the vertical displacements of the three CoMs considered, Ek, Ep and EM during the execution of the lifting tasks in the three conditions is provided in Fig. 1: the qualitative analysis of energy expenditure revealed differences in both the Ep and EM curves among the three lifting conditions (Fig. 1 (c) and Fig. 1 (d)) for each CoM considered.

Fig. 1.

A qualitative description in a representative subject of vertical displacements of CoML, CoMUpp+L and CoMTot (a) (in meters), Ek (b), Ep (c) and EM (d) (in Joule) for each CoM investigated during the execution of the three lifting conditions (LI=1, LI=2 and LI=3). Black curves represent the mean values, with the SDs of the means shown in grey. Data are normalized to the lifting cycle duration and reduced to 101 samples over the cycle.

Figure 2 shows the means and standard deviation values of LEC.

Fig. 2.

Means and standard deviations of the LECk (a), LECp (b) and LECM (c) calculated while performing manual material lifting tasks in the three different conditions (LI=1, LI=2 and LI=3) for the three CoMs (CoML, CoMUpp+L, CoMTot). * and ** Significant differences at the post hoc analysis with p<0.05 and p<0.001 respectively.

As reported in Table 2, the repeated measures ANOVA revealed a significant effect of the lifting condition on LECp and LECM for all the CoMs considered. Statistically significant effects were also detected for LECk_Upp+L and LECk_Tot. Particularly, post hoc analysis showed significant differences (all p<0.001) between each pair of lifting conditions for LECp and LECM for all the CoMs considered and also for LECk_Upp+L. Furthermore, as regard LECk_Tot significant differences were found between each pair of lifting conditions (LI=1 vs LI=2: p=0.001; LI=1 vs LI=3: p= 0.005; LI=2 vs LI=3: p=0.021).

Table 2. The F, df and p-values of the repeated-measures ANOVA considering the Lk, Lp, and LM in the three lifting conditions for the CoML, CoMUpp+L and CoMTot. Bold type indicates statistical significance.

| CoML | CoMUpp+L | CoMTot | ||

|---|---|---|---|---|

| LECk | F | 3.847 | 73.469 | 16.043 |

| df | 1.118 | 1.081 | 1.047 | |

| p | 0.075 | <0.001 | 0.003 | |

| LECp | F | 150.992 | 173.479 | 65.755 |

| df | 1.349 | 1.027 | 1.049 | |

| p | <0.001 | <0.001 | <0.001 | |

| LECM | F | 126.454 | 146.276 | 67.219 |

| df | 1.154 | 1.012 | 1.050 | |

| p | <0.001 | <0.001 | <0.001 | |

The results of the correlation analysis between each LEC with FcomprL5−S1, FshearL5−S1 (scatter plots, regression line, correlation coefficients and p values) are reported in Fig. 3. Particularly, the correlation analysis highlighted i) a strong correlation (r>0.7) between each LEC relating to CoMUpp+L and FshearL5−S1, ii) a moderate correlation (0.3<r<0.7) between each LEC relating to CoMUpp+L and FcomprL5−S1, iii) a moderate correlation (0.3<r<0.7) between each LEC relating to CoMTot and only FshearL5−S1, iv) a strong correlation (r>0.7) between LECp_L and LECM_L and FshearL5−S1, v) a moderate correlation (0.3<r<0.7) between LECp_L and LECM_L and FcomprL5−S1.

Fig. 3.

Correlation between the LECk_L, LECp_L, LECM_L, LECk_Upp+L, LECp_Upp+L, LECM_Upp+L, LECk_Tot, LECp_Tot and LECM_Tot and the maximum values of FcompL5−S1 (a) and FshearL5−S1 (b). Each plot contains 60 points, which correspond to the 20 subjects performing the three different lifting conditions (LI=1, LI=2 and LI=3). Triangles represent the mean of the twenty points for each lifting condition. Each plot shows the r and p values. Bold type indicates statistical significance.

Discussion

In this study, we investigated energy consumption, the forces at the L5−S1 joint and the relationship among these parameters during the execution of lifting tasks designed in such a way as to exert a growing biomechanical load using the RNLE. The rationale behind this investigation is that an instrumental tool based on energy consumption may be used as risk assessment method to combine with the NIOSH protocol.

Qualitative analysis of our results revealed differences in both the Ep and EM curves among the three lifting conditions for each CoM considered and in Ek curves for the CoMs referred to the upper-body and whole body multi-segments systems (Fig. 1). Furthermore, a significant effect of the lifting condition was found on each lifting energy consumption for the CoMUpp+L and CoMTot and also on LECP and LECM in relation to the CoM referring to the load (Fig. 2).

This is likely to be due to the fact that CoMUpp+L and CoMTot take into account the dynamic body geometry during the execution of the lifting tasks and are, consequently, more sensitive to the RNLE factors that influence the risk level. By contrast, CoML is influenced above all by the motor strategy at the end effectors (hands), and does not take into account the dynamic body geometry during the execution of the lifting tasks. Indeed, for a given L, an equal D and different LI, CoML might not yield any differences in lifting energy consumption because the total movement dynamic would not be considered in the same way as for CoMUpp+L and CoMTot, nor would the relevance of the other RNLE factors be considered, i.e. H and A.

Our results also highlighted that lifting energy consumption grew significantly with the LI and that all the lifting condition pairs are discriminated (Table 2 and Fig. 2): these trends indicate that lifting energy consumption correctly represents the greater energetic requirements due to the increased level of physical stress, and thus suggest that lifting energy consumption may be used as a risk assessment biomechanical index. In particular, it may be possible to use each lifting energy consumption related to CoMUpp+L and COMTot to correctly interpret low-, medium- and high-risk jobs.

Certainly, the validity of lifting energy consumption method depends on the lifting conditions we set so depending on the multipliers of RNLE equation. On the other hand, findings of our study show the presence of a significant effect of LI on lifting energy consumption calculated by considering CoMUpp+L and CoMTot, even if obtained within the boundaries of our experimental setup. These results allow us to comprehend that lifting energy consumption, although calculated by a different equation with respect to LI, is sensitive to the RNLE factors and to the risk level because centers of mass are linked to the dynamic body geometry during the execution of the lifting tasks.

The above considerations are supported by the correlation analysis (Fig. 3), which highlights a close relationship i) between each lifting energy consumption and FshearL5−S1 and FcomprL5−S1 when we considered the CoMUpp+L, ii) between each lifting energy consumption and only FshearL5−S1 when we considered CoMTot and iii) between LECp_L and LECM_L and both the forces FshearL5−S1 and FcomprL5−S1. In particular, these findings point to the need to calculate the CoMUpp+L for the lifting energy consumption analysis. For against a low correlation between LECk and forces was detected when we considered CoML. From a global point of view, mechanical energy expenditure during the execution of lifting tasks is always closely related to the shear forces because spinal loads are affected by lifting dynamics, i.e. flexed lifting56).

Our experimental data allowed us to identify the lifting energy consumption indices that are sensitive to an increasing LI (LI=l, LI=2 and LI=3) designed on the basis of the RNLE. These indices would be particularly useful as an instrumental risk assessment method if referred to the set of conditions studied to support the NIOSH protocol or to evaluate a varied range of conditions in which the NIOSH protocol cannot be used (lifting with one hand, for over eight hours, while seated or kneeling, in a restricted work space, unstable objects, while carrying, pushing or pulling, with wheelbarrows or shovels, in high speed motion, with unreasonable foot-floor coupling, in an unfavourable environment).

In literature, there are many studies considering the mechanical energy consumption and/or the body energy consumption57, 58) during lifting tasks. Furthermore, a linear relationship between mechanical work and body energy consumption was found in different activities59, 60, 61). Particularly, in lifting tasks, for the same increase in absolute mechanical work there is a higher increase in body energy consumption for positive compared with negative work61).

This relationship strengthens the choice of our index to risk assessment during lifting task. Certainly, the mechanical energy consumption method is easier to apply in work environments than the body energy consumption. In fact, measurements of oxygen consumption (VO2) are generally carried out by using a portable system for pulmonary gas exchange measurement. In this kind of measurement, the subject needs to wear a mask that can interfere with the working activities and can introduce psychological stress in the works62).

Indeed, once these indices have been identified in the laboratory in controlled lifting conditions by means of the optoelectronic system, they could be applied in indoor and outdoor work environments by means of IMUs. In addition to being able to measure single- or multi-point motion trajectories of single or multiple body segments of the subject during the movement task, IMUs have become widely used in all activities that address complex motion analysis because of their interconnectivity, light weight, small size, low power consumption, portability and low cost. Moreover, since IMUs are included in smart devices (i.e. smartphones and tablets), which are now used in every walk of life, inertial sensor-based movement recognition has attracted increasing interest in a number of research fields, including biomechanics63, 64, 65, 66, 67, 68, 69). Such research might lead to an IMU-based lifting recognition tool built on data acquired in controlled lifting conditions that would increase the likelihood of detecting the risks associated with WLBDs.

For instance, a LEC-based lifting recognition tool could be designed by considering one criterion of risk classification based on LECM, as shown in Fig. 4.

Fig. 4.

An IMU-based lifting recognition tool designed by considering one criterion of risk classification (LECM_L (a) or LECM_Upp+L (b) or LECM_Tot (c)). The error bars represent the mean ± SD values.

Our LEC-based lifting recognition tool was built considering: low risk jobs as the interval between 0 and [mean+SD of LI=1] (all values under [mean-SD of LI=1] were associated with low risk jobs); medium risk jobs as the interval between [mean-SD of LI=2] and [mean+SD of LI=2]; high risk jobs as the interval between [mean-SD of LI=3] and [mean+SD of LI=3]. The values included in two different intervals or in any interval (Fig. 4), represent ranges for which it is not possible to make a choice because they should be associated with two different type of risk jobs. Whereas values above the high risk zone indicate very high-risk jobs (Fig. 4). In particular, LECM_L values within the range 0-[mean+SD of LI=1], [mean-SD of LI=2]-[mean+SD of LI=2] and [mean-SD of LI=3]-[mean+SD of LI=3] indicate low-, medium- and high- risk jobs, respectively (Fig. 4 (a)). Instead, as regards LECM_Upp+L and LECM_Tot values within the range 0-[mean-SD of LI=2], [mean+SD of LI=1]-[mean+SD of LI=2] and [mean-SD of LI=3]-[mean+SD of LI=3] indicate low-, medium- and high- risk jobs, respectively (Fig. 4 (b and c)). Others ranges for which it is not possible to make a choice are indicated as LI=?. Finally, values above the LI=3 zone indicate very high-risk jobs.

Limitations and future developments

One limitation of this method may be its suitability for the assessment of composite or sequential22, 70) manual lifting jobs in which the lifting tasks are significantly different. Another limitation of this study is the use of only male workers; indeed, gender aspects are important and they may lead to different results.

This study may be developed further by: i) widening the range of lifting task types with the same LI but changing the multiplier values; ii) testing also lifting conditions with LI values lower than 1, between 1 and 2, and between 2 and 3; iii) analyzing changes in the criteria selected due to temperature and humidity, sex, age, work experience, etc. The study could also be extended by using, in addition to the optoelectronic motion analysis system, wearable inertial sensors during manual material lifting tasks in the laboratory in different lifting conditions.

This would allow us to compare the LEC calculated using the optoelectronic system with that calculated by means of inertial sensors, thereby validating and strengthening the applicability of this method in indoor and outdoor work environments, and further supporting the findings of previous noteworthy studies in this field45, 46, 47). An instrumental lifting recognition tool could be further implemented by using surface electromyography-based indices that would provide additional criteria of classification and enhance the power of the test.

Conclusion

Results of our study show that LEC significantly change in relation to the risk levels. In the light of these considerations, we believe that an IMU/Inertial sensor-based lifting recognition tool using LEC indices and designed according to the revised RNLE lends itself to the estimation of risk. It should be noted that the proposed IMU/Inertial sensor-based lifting recognition tool was based on 6 lifting conditions corresponding to three LI levels at 1, 2 and 3. Future research is recommended for validating the risk assessment tool for additional lifting conditions.

Acknowledgments

We are extremely grateful to Simona Del Ferraro and Vincenzo Molinaro for their help with the environmental temperature measurements. This research was funded by INAIL, “Bando Ricerche in Collaborazione 2016”.

References

- 1.Becker L. (2001) Musculoskeletal conditions in the United States, Occup Injury Illnesses, 93–8.

- 2.Kuijer PP, Verbeek JH, Visser B, Elders LA, Van Roden N, Van den Wittenboer ME, Lebbink M, Burdorf A, Hulshof CT (2014) An Evidence-Based Multidisciplinary Practice Guideline to Reduce the Workload due to Lifting for Preventing Work-Related Low Back Pain. Ann Occup Environ Med 26, 16. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Lu ML, Waters TR, Krieg E, Werren D (2014) Efficacy of the revised NIOSH lifting equation to predict risk of low-back pain associated with manual lifting: a one-year prospective study. Hum Factors 56, 73–85. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Garg A, Boda S, Hegmann KT, Moore JS, Kapellusch JM, Bhoyar P, Thiese MS, Merryweather A, Deckow-Schaefer G, Bloswick D, Malloy EJ (2014) The NIOSH lifting equation and low-back pain, Part 1: Association with low-back pain in the backworks prospective cohort study. Hum Factors 56, 6–28. [DOI] [PubMed] [Google Scholar]

- 5.Health Council of the Netherlands, Manual Lifting During Work (2012) http://www.gezondheidsraad.nl/sites/default/files/2136E_Manual_Lifting_during_work.pdf.

- 6.INAIL, Italian Worker’s Compensation Authority Annual Report. Part IV. Statistics, Accidents and Occupational Diseases (2011). [Google Scholar]

- 7.TNO Innovation for Life: Ziekteverzuim in Nederland in 2010. In Dutch: Sick Leave in the Netherlands in 2010. [Google Scholar]

- 8.Hopkinton MA. (2009) Liberty Mutual workplace safety index. Liberty Mutual Research Institute for Safety. [Google Scholar]

- 9.da Costa BR, Vieira ER (2010) Risk factors for work-related musculoskeletal disorders: A systematic review of recent longitudinal studies. Am J Ind Med 53, 285–323. [DOI] [PubMed] [Google Scholar]

- 10.Griffith LE, Shannon HS, Wells RP, Walter SD, Cole DC, Côté P, Frank J, Hogg-Johnson S, Langlois LE (2012) Individual participant data meta-analysis of mechanical workplace risk factors and low back pain. Am J Public Health 102, 309–18. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Waters TR, Lu ML, Piacitelli LA, Werren D, Deddens JA (2011) Efficacy of the revised NIOSH lifting equation to predict risk of low back pain due to manual lifting: expanded cross-sectional analysis. J Occup Environ Med 53, 1061–7. [DOI] [PubMed] [Google Scholar]

- 12.Eurofound (2011) European Foundation for the Improvement of Living and Working Conditions: Work and Health: a Difficult Relationship? http://www.eurofound.europa.eu/pubdocs/2011/17/en/1/EF1117EN.pdf.

- 13.Kwon BK, Roffey DM, Bishop PB, Dagenais S, Wai EK (2011) Systematic review: occupational physical activity and low back pain. Occup Med (Lond) 61, 541–8. [DOI] [PubMed] [Google Scholar]

- 14.Hooftman W, Klein Hesselink J, Van Genabeek J, Wiezer N, Willems D (2011) Working Conditions Overview 2010: Quality of Labour, Consequences and Measures Taken in the Netherlands In Dutch: Arbobalans 2010: Kwaliteit van de Arbeid, Effecten en Maatregelen in Nederland. Hoofddorp (The Netherlands): TNO Innovation for Life. [Google Scholar]

- 15.Wai EK, Roffey DM, Bishop P, Kwon BK, Dagenais S (2010) Causal assessment of occupational lifting and low back pain: results of a systematic review. Spine J 10, 554–66. [DOI] [PubMed] [Google Scholar]

- 16.Marras WS, Lavender SA, Ferguson SA, Splittstoesser RE, Yang G (2010) Quantitative dynamic measures of physical exposure predict low back functional impairment. Spine 35, 914–23. [DOI] [PubMed] [Google Scholar]

- 17.Bakker EW, Verhagen AP, van Trijffel E, Lucas C, Koes BW (2009) Spinal mechanical load as a risk factor for low back pain: a systematic review of prospective cohort studies. Spine 34, E281–93. [DOI] [PubMed] [Google Scholar]

- 18.Lötters F, Burdorf A, Kuiper J, Miedema H (2003) Model for the work-relatedness of low-back pain. Scand J Work Environ Health 29, 431–40. [DOI] [PubMed] [Google Scholar]

- 19.Tubach F, Leclerc A, Landre MF, Pietri-Taleb F (2002) Risk factors for sick leave due to low back pain: a prospective study. J Occup Environ Med 44, 451–8. [DOI] [PubMed] [Google Scholar]

- 20.Hoogendoorn WE, Bongers PM, de Vet HCW, Ariëns GA, van Mechelen W, Bouter LM (2002) High physical work load and low job satisfaction increase the risk of sickness absence due to low back pain: results of a prospective cohort study. Occup Environ Med 59, 323–8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Hartvigsen J, Bakketeig LS, Leboeuf-Yde C, Engberg M, Lauritzen T (2001) The association between physical workload and low back pain clouded by the “healthy worker” effect: population-based cross-sectional and 5-year prospective questionnaire study. Spine 26, 1788–92, discussion 1792–3. [DOI] [PubMed] [Google Scholar]

- 22.Waters TR, Putz-Anderson V, Garg A (1994) Applications Manual for the Revised NIOSH Lifting Equation. Cincinnati, OH: U.S. Department of Health and Human Services. [Google Scholar]

- 23.Lin CJ, Cheng CF (2017) Lifting speed preferences and their effects on the maximal lifting capacity. Ind Health 55, 27–34. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Waters TR, Putz-Anderson V, Garg A, Fine LJ (1993) Revised NIOSH equation for the design and evaluation of manual lifting tasks. Ergonomics 36, 749–76. [DOI] [PubMed] [Google Scholar]

- 25.Waters TR, Baron SL, Piacitelli LA, Anderson VP, Skov T, Haring-Sweeney M, Wall DK, Fine LJ (1999) Evaluation of the revised NIOSH lifting equation. A cross-sectional epidemiologic study. Spine 24, 386–94, discussion 395. [DOI] [PubMed] [Google Scholar]

- 26.Sesek R, Gilkey D, Drinkaus P, Bloswick DS, Herron R (2003) Evaluation and quantification of manual materials handling risk factors. Int J Occup Saf Ergon 9, 271–87. [DOI] [PubMed] [Google Scholar]

- 27.Lavender SA, Li YC, Natarajan RN, Andersson GB (2009) Does the asymmetry multiplier in the 1991 NIOSH lifting equation adequately control the biomechanical loading of the spine? Ergonomics 52, 71–9. [DOI] [PubMed] [Google Scholar]

- 28.Dempsey PG. (2002) Usability of the revised NIOSH lifting equation. Ergonomics 45, 817–28. [DOI] [PubMed] [Google Scholar]

- 29.Elfeituri FE, Taboun SM (2002) An evaluation of the NIOSH Lifting Equation: a psychophysical and biomechanical investigation. Int J Occup Saf Ergon 8, 243–58. [DOI] [PubMed] [Google Scholar]

- 30.Dempsey PG, Fathallah FA (1999) Application issues and theoretical concerns regarding the 1991 NIOSH equation asymmetry multiplier. Int J Ind Ergon 23, 181–91. [Google Scholar]

- 31.Wang MJ, Garg A, Chang YC, Shih YC, Yeh WY, Lee CL (1998) The relationship between low back discomfort ratings and the NIOSH lifting index. Hum Factors 40, 509–15. [DOI] [PubMed] [Google Scholar]

- 32.Nussbaum M, Chaffin D, Page G (1995) A biomechanical investigation of the asymmetric multiplier in the revised NIOSH lifting equation. In Proceedings of the Human Factors and Ergonomics Society 39th Annual Meeting (709–713). Santa Monica, CA, USA: Human Factors and Ergonomics Society.

- 33.Karwowski W, Brokaw N (1992) Implications of the proposed revisions in a draft of the revised NIOSH lifting guide (1991) for job redesign: A field study,” In Proceedings of the 36th Annual Meeting of the Human Factors Society, pp. 659–63, Santa Monica, CA, USA: Human Factors Society.

- 34.Marras WS, Fine LJ, Ferguson SA, Waters TR (1999) The effectiveness of commonly used lifting assessment methods to identify industrial jobs associated with elevated risk of low-back disorders. Ergonomics 42, 229–45. [DOI] [PubMed] [Google Scholar]

- 35.Dempsey PG, Burdorf A, Fathallah FA, Sorock GS, Hashemi L (2001) Influence of measurement accuracy on the application of the 1991 NIOSH equation. Appl Ergon 32, 91–9. [DOI] [PubMed] [Google Scholar]

- 36.Cavagna GA, Thys H, Zamboni A (1976) The sources of external work in level walking and running. J Physiol 262, 639–57. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Cavagna GA, Willems PA, Legramandi MA, Heglund NC (2002) Pendular energy transduction within the step in human walking. J Exp Biol 205, 3413–22. [DOI] [PubMed] [Google Scholar]

- 38.Detrembleur C, Dierick F, Stoquart G, Chantraine F, Lejeune T (2003) Energy cost, mechanical work, and efficiency of hemiparetic walking. Gait Posture 18, 47–55. [DOI] [PubMed] [Google Scholar]

- 39.Don R, Serrao M, Vinci P, Ranavolo A, Cacchio A, Ioppolo F, Paoloni M, Procaccianti R, Frascarelli F, De Santis F, Pierelli F, Frascarelli M, Santilli V (2007) Foot drop and plantar flexion failure determine different gait strategies in Charcot-Marie-Tooth patients. Clin Biomech (Bristol, Avon) 22, 905–16. [DOI] [PubMed] [Google Scholar]

- 40.Della Croce U, Leardini A, Chiari L, Cappozzo A (2005) Human movement analysis using stereophotogrammetry. Part 4: assessment of anatomical landmark misplacement and its effects on joint kinematics. Gait Posture 21, 226–37. [DOI] [PubMed] [Google Scholar]

- 41.Leardini A, Chiari L, Della Croce U, Cappozzo A (2005) Human movement analysis using stereophotogrammetry. Part 3. Soft tissue artifact assessment and compensation. Gait Posture 21, 212–25. [DOI] [PubMed] [Google Scholar]

- 42.Chiari L, Della Croce U, Leardini A, Cappozzo A (2005) Human movement analysis using stereophotogrammetry. Part 2: instrumental errors. Gait Posture 21, 197–211. [DOI] [PubMed] [Google Scholar]

- 43.Cappozzo A, Della Croce U, Leardini A, Chiari L (2005) Human movement analysis using stereophotogrammetry. Part 1: theoretical background. Gait Posture 21, 186–96. [DOI] [PubMed] [Google Scholar]

- 44.Gómez-Galán M, Pérez-Alonso J, Callejón-Ferre ÁJ, López-Martínez J (2017) Musculoskeletal disorders: OWAS review. Ind Health 55, 314–37. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.Taborri J, Palermo E, Rossi S, Cappa P (2016) Gait Partitioning Methods: A Systematic Review. Sensors (Basel) 16, E66. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 46.Sprager S, Juric MB (2015) Inertial Sensor-Based Gait Recognition: A Review. Sensors (Basel) 15, 22089–127. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Wu G, Siegler S, Allard P, Kirtley C, Leardini A, Rosenbaum D, Whittle M, D’Lima DD, Cristofolini L, Witte H, Schmid O, Stokes I; Standardization and Terminology Committee of the International Society of Biomechanics (2002) ISB recommendation on definitions of joint coordinate system of various joints for the reporting of human joint motion–part I: ankle, hip, and spine. J Biomech 35, 543–8. [DOI] [PubMed] [Google Scholar]

- 48.Wu G, van der Helm FC, Veeger HE, Makhsous M, Van Roy P, Anglin C, Nagels J, Karduna AR, McQuade K, Wang X, Werner FW, Buchholz B (2005) ISB recommendation on definitions of joint coordinate systems of various joints for the reporting of human joint motion--Part II: shoulder, elbow, wrist and hand. J Biomech 38, 981–92. [DOI] [PubMed] [Google Scholar]

- 49.Gutierrez-Farewik EM, Bartonek A, Saraste H (2006) Comparison and evaluation of two common methods to measure center of mass displacement in three dimensions during gait. Hum Mov Sci 25, 238–56. [DOI] [PubMed] [Google Scholar]

- 50.Rab G, Petuskey K, Bagley A (2002) A method for determination of upper extremity kinematics. Gait Posture 15, 113–9. [DOI] [PubMed] [Google Scholar]

- 51.Davis RB 3rd, Õunpuu S, Tyburski D, Gage JR (1991) A gait analysis data collection and reduction technique. Hum Mov Sci 10, 575–87. [Google Scholar]

- 52.Zatsiorsky VM, Seluyanov VN, Chugunova LG (1990) Methods of determining mass-inertial characteristics of human body segments. In G.G. Chernyi & S.A. Regirer, Contemporary Problems of Biomechanics, 272–91. [Google Scholar]

- 53.de Leva P. (1996) Adjustments to Zatsiorsky-Seluyanov’s segment inertia parameters. J Biomech 29, 1223–30. [DOI] [PubMed] [Google Scholar]

- 54.Winter DA. (1990) Biomechanics and Motor Control of Human Movement New York: Wiley. [Google Scholar]

- 55.Plamondon A, Gagnon M, Desjardins P (1996) Validation of two 3-D segment models to calculate the net reaction forces and moments at the L5/S1 joint in lifting. Clin Biomech (Bristol, Avon) 11, 101–10. [DOI] [PubMed] [Google Scholar]

- 56.Granata KP, Marras WS (1995) An EMG-assisted model of trunk loading during free-dynamic lifting. J Biomech 28, 1309–17. [DOI] [PubMed] [Google Scholar]

- 57.de Looze MP, Bussmann JB, Kingma I, Toussaint HM (1992) Different methods to estimate total power and its components during lifting. J Biomech 25, 1089–95. [DOI] [PubMed] [Google Scholar]

- 58.Li KW, Yu RF, Han XL (2007) Physiological and psychophysical responses in handling maximum acceptable weights under different footwear–floor friction conditions. Appl Ergon 38, 259–65. [DOI] [PubMed] [Google Scholar]

- 59.Burdett RG, Skrinar GS, Simon SR (1983) Comparison of mechanical work and metabolic energy consumption during normal gait. J Orthop Res 1, 63–72. [DOI] [PubMed] [Google Scholar]

- 60.Cotes JE, Meade F (1960) The energy expenditure and mechanical energy demand in walking. Ergonomics 3, 97–119. [Google Scholar]

- 61.De Looze MP, Toussaint HM, Commissaris DA, Jans MP, Sargeant AJ (1994) Relationships between energy expenditure and positive and negative mechanical work in repetitive lifting and lowering. J Appl Physiol (1985) 77, 420–6. [DOI] [PubMed] [Google Scholar]

- 62.Horwat F, Meyer JP, Malchaire J (1988) Validation of a new pocket computer assisted method for metabolic rate estimation in field studies. Ergonomics 31, 1155–64. [DOI] [PubMed] [Google Scholar]

- 63.Fong DTP, Chan YY (2010) The use of wearable inertial motion sensors in human lower limb biomechanics studies: a systematic review. Sensors (Basel) 10, 11556–65. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 64.Tao W, Liu T, Zheng R, Feng H (2012) Gait analysis using wearable sensors. Sensors (Basel) 12, 2255–83. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 65.Whittle MW. (2008) Gait Analysis: An Introduction. 4th ed. Butterworth-Heinemann, Elsevier: Edinburgh, UK. [Google Scholar]

- 66.Favre J, Aissaoui R, Jolles BM, de Guise JA, Aminian K (2009) Functional calibration procedure for 3D knee joint angle description using inertial sensors. J Biomech 42, 2330–5. [DOI] [PubMed] [Google Scholar]

- 67.Liu T, Inoue Y, Shibata K (2009) Development of a wearable sensor system for quantitative gait analysis. Measurement 42, 978–88. [Google Scholar]

- 68.Klucken J, Barth J, Kugler P, Schlachetzki J, Henze T, Marxreiter F, Kohl Z, Steidl R, Hornegger J, Eskofier B, Winkler J (2013) Unbiased and mobile gait analysis detects motor impairment in Parkinson’s disease. PLoS One 8, e56956. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 69.Muro-de-la-Herran A, García-Zapirain B, Mendez-Zorrilla A (2014) Gait analysis methods: an overview of wearable and non-wearable systems, highlighting clinical applications. Sensors (Basel) 14, 3362–94. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 70.Waters TR, Dick RB, Davis-Barkley J, Krieg EF (2007) A cross-sectional study of risk factors for musculoskeletal symptoms in the workplace using data from the General Social Survey (GSS). J Occup Environ Med 49, 172–84. [DOI] [PubMed] [Google Scholar]