Abstract

This study was performed to investigate the quality characteristics of noodles made from four different potato varieties: Atlantic, Go-un, Sae-bong, Jin-sun, and wheat flour. Quality characteristics of five noodles were analyzed by general components analysis, cooking quality (rate of water absorption, cooking loss, and volume increase), and mechanical textural properties. Some variations existed in wheat- or potato-based noodles for the general components analysis, but no clear trend was observed. Higher values in the rates of water absorption, cooking loss, and volume increase were observed for the wheat flour noodle, while some variations were observed for potato noodles depending on the variety. The wheat flour noodles exhibited higher values of textural characteristics obtained from the texture profile analysis, except for adhesiveness. Higher gluten contents as well as lower ash contents in the wheat flour noodles compared to the potato noodles are thought to be the two key factors contributing to this finding.

Keywords: potato noodle, wheat flour noodle, texture, texture profile analysis

INTRODUCTION

Potato is the world’s 3rd most important food crop following rice and wheat, producing approximately 300 million metric tons annually, and it is consumed by more than a billion people worldwide (1,2). It is believed that potato was introduced to Korea by China in 1824. Since then, the potato has been used as a complementary crop to rice in Korea and is now mainly used as processed potato products such as snacks (3). It has been reported that there are differences in cell binding capacity, starch content, structural differences, and the amount of protein depending on the varieties of potato (4). Those characteristics of potato enable to select a certain variety of potato depending on the purpose of use. Currently, there are 33 varieties of potato registered in Korea, initially from Nam-jak (1928) to Nam-sun (2015) (5). Go-un, Sae-bong, and Jin-sun are newly developed varieties to redress the disadvantage of Atlantic, which is mostly imported due to its long period of dormancy (6,7).

The utilization rate of imported potato is influenced by harvest yield of potato in Korea, showing utilization rates of 57.1% and 14.1% in 2011 and 2012, respectively (8). A significant increase in the utilization rate in 2011 was attributed to the increase in a temporal import of potato because potatoes in Korea were not sufficiently produced in 2011 (9). Therefore, research for the development of new varieties of potatoes with a short dormancy period in Korea is required. However, most studies related to potatoes are focused on the physicochemical properties of potatoes (10–13), potato starch (14–16), or anti-oxidative effects of potato extracts (17).

The domestic market in the noodle industry has evolved in a variety of ways, ranging from fried noodles to dry noodles, fresh noodles, and frozen noodles, in accordance with the changes in consumers’ interest and needs towards health. In particular, domestic sales of non-fried fresh noodles with low calories are steadily increasing (18). Therefore, the objective of this study was to investigate the quality characteristics of noodles prepared from different varieties of potato produced in Korea, compared to noodles made with only wheat flour.

MATERIALS AND METHODS

Samples and preparation

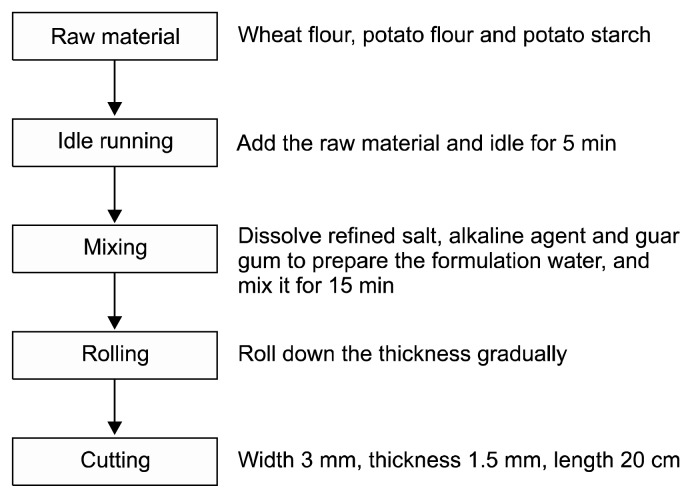

Potatoes (Atlantic, Go-un, Sae-bong, and Jin-sun) harvested in 2016 were obtained from the Highland Agriculture Research Institute, Pyeongchang, Korea. Potato flour was commercially processed by the Chodang Agricultural Association Corporation, Muan, Korea while potato starch was manufactured by a slight modification of the method introduced by Huang et al. (19). The mixing ratio of potato noodles containing potato flour and potato starch is shown in Table 1, and the process for producing noodles is shown in Fig. 1. The processing steps for manufacturing potato noodles are as follows. Wheat flour and different varieties of potato flour in combination with starch were placed in a kneader and allowed to be idle for 5 min ensuring that the water needed was evenly distributed when the compounding water was added to the raw materials. Refined salt (Hanu Corporation, Ulsan, Korea), alkali agent (Alkaline-100STM, SDBNI Co., Ltd., Hwaseong, Korea), and guar gum (Shinwon Chemical, Seoul, Korea) were completely dissolved in water and sprayed evenly to prevent any lumps of the raw materials. After kneading for 15 min, the mixture was rolled by a noodle making machine (HSN-1, Hunwoo, Seoul, Korea). The rolling process was carried out several times so the thickness of the mixture became gradually narrow. Through the rolling processes, the activity of gluten in the wheat flour increased to aggregate the raw materials, finally forming the noodle sheet. Following the repeated rolling processes, the sheet was cut out along the formed surface. Width, thickness, and length of the noodle was 3 mm, 1.5 mm, and 200 mm, respectively. The control noodle was made with wheat flour only.

Table 1.

Formula of noodles prepared from wheat flour and different potato cultivars

| Ingredients (g) | Sample | |

|---|---|---|

|

| ||

| WN | Potato noodles (AN, GN, SN, and JN) | |

| Medium flour | 3,000 | 1,800 |

| Potato flour | – | 900 |

| Potato starch | – | 300 |

| Salt | 30 | 30 |

| Alkaline agents for noodles | 4.5 | 4.5 |

| Guar gum | 2.4 | 2.4 |

| Water | 960 | 1,440 |

WN, wheat flour noodle; AN, Atlantic noodle; GN, Go-un noodle; SN, Sae-bong noodle; JN, Jin-sun noodle.

Fig. 1.

Manufacture process of noodles prepared from wheat flour, potato flours, and starches obtained from different cultivars.

Analysis of general components in potato flours and potato starches

The general components of potato flour and starch were analyzed for moisture, crude protein, crude fat, and crude ash content according to the AACC Approved methods 44–15.02, 46–11.02, 30–25.01, and 08–12.01, respectively (20). Moisture content was analyzed by the atmospheric pressure heating drying method, crude protein was measured by the Kjeldahl nitrogen determination method, crude fat was analyzed by the Soxhlet extraction method, and crude ash was measured by a drying method. All the analyses were conducted in triplicate.

Evaluation of cooking quality of noodles

Water absorption, cooking loss, and volume increase of noodles were measured according to the AACC methods 66–50 (20). The water absorption rate was measured after cooking 20 g of fresh noodles in 300 mL distilled water for a suitable cooking time (wheat flour noodles: 8 min, potato added noodles: 3~4 min to be fully gelatinized), cooling for 1 min in cold water, and removing the water for 30 s. The cooking loss was measured after drying at 105°C for 24 h with the remaining water after measuring the water absorption rate. The volume increase rate was measured by filling 300 mL distilled water in a 500 mL mass cylinder and adding 20 g of fresh noodles and cooked noodles, respectively. All the analyses were conducted in triplicate. The respective formulae used in the calculations are as follow:

Evaluation of textural characteristics of noodles

For the evaluation of textural characteristics of noodles, noodles (30 g) were cooked in 300 g of water using an induction oven (RBE-22H, Rinnai, Incheon, Korea) for 8 min (21,22). The cooked noodles were then cooled in a sieve for 30 s and left for 2 min to remove the remaining water. Noodles of 1.5 mm thickness and 50 mm length were prepared for the analysis of texture profile analysis using a texture analyzer (TA-XTplus, Stable Micro Systems Ltd., Godalming, UK). A cylindrical probe with a diameter of 36 mm was used. The test conditions were as follows: 1 mm/s pre-test speed, 1 mm/s test speed, 5 mm/s post-test speed, 80% strain, and 20 g trigger force. The parameters calculated were hardness, adhesiveness, springiness, cohesiveness, and chewiness. Measurements were replicated 20 times for each treatment.

Statistical analysis

All experimental results were expressed as mean and standard deviation. The results of general components were analyzed using ANOVA followed by Fisher’s least significant differences at P<0.05 by SAS (SAS 9.3, SAS Institute Inc., Cary, NC, USA). The results of textural properties were analyzed using Turkey’s t-test P<0.05 level by Minitab (Minitab 16, Minitab Inc., State College, PA, USA).

RESULTS AND DISCUSSION

General components in potato flours and potato starches

The results of general components for potato flour and potato starch are shown in Table 2. The moisture contents of potato flour were the highest for Go-un (6.36%), while no differences were observed among the other varieties ranging from 5.57 to 5.64%. The crude protein contents were the highest for Sae-bong (7.26%) and Jinsun (7.22%) and the lowest in Atlantic (6.36%). There was no significant difference in crude fat contents (0.31~0.56%) for all varieties. The contents of crude ash for Sae-bong (2.48%) were higher than that of Jinsun (1.96%), whereas no differences were found among varieties (2.14~2.28%). The general components of potato flour showed a similar tendency to the results of Kim et al. (10) with the exception of the crude protein contents. This may be due to the differences in pretreatment conditions, harvest year, and cultivation environment for potatoes in the two different studies.

Table 2.

General components of potato flours and potato starches obtained from different cultivars

| Type | Composition analysis (%) | Sample | |||

|---|---|---|---|---|---|

|

| |||||

| Atlantic | Go-un | Sae-bong | Jin-sun | ||

| Potato flour | Moisture | 5.57±0.15b | 6.36±0.19a | 5.59±0.15b | 5.64±0.14b |

| Crude protein | 6.36±0.03c | 6.56±0.00b | 7.26±0.12a | 7.22±0.06a | |

| Crude fat | 0.52±0.13ns | 0.56±0.21 | 0.31±0.02 | 0.33±0.15 | |

| Crude ash | 2.14±0.33ab | 2.28±0.09ab | 2.48±0.01a | 1.96±0.21b | |

| Potato starch | Moisture | 7.58±0.86a | 6.99±0.34a | 5.22±0.29b | 5.54±0.38b |

| Crude protein | 0.17±0.12ab | 0.34±0.12a | 0.09±0.00b | 0.17±0.00ab | |

| Crude fat | 0.26±0.08ns | 0.28±0.01 | 0.28±0.04 | 0.32±0.02 | |

| Crude ash | 0.95±0.07a | 0.49±0.00c | 0.70±0.14bc | 0.85±0.07ab | |

Values with different letters (a–c) within the same row differ significantly (P<0.05).

Not significant.

The moisture contents of potato starch were high in Atlantic and Go-un (6.99~7.58%). Crude protein contents of Go-un (0.34%) were higher than that of Saebong (0.09%), but there was no difference between the other samples (0.17%). No significant differences were observed in the crude fat contents (0.26~0.32%) among samples.

Cooking quality of noodles

The rate of water absorption, cooking loss, and volume increase of noodles are shown in Table 3. The highest value in water absorption rate was observed for wheat flour noodles (WN: 122.83%), followed by Sae-bong noodle (SN), Jin-sun noodle (JN), Go-un noodle (GN), and Atlantic noodle (AN) ranging from 75.70 to 92.82%. It was interesting to note that significant variations in water absorption rates exist among different varieties of potatoes. Lee and Jung (21) mentioned that the degree of water absorption in noodles during cooking is mainly affected by starch gelatinization as well as protein hydration related to particle size of starch. The fact that potatoes have less protein content and larger particle size than wheat might result in lower water absorption rates for noodles made with potatoes (23). Therefore, the lower protein content of AN (Table 2) might partially explain the low water absorption of noodles prepared with AN. Also, the larger particle size of starch in AN might influence the water absorption of noodles although particle size was not analyzed in this study. A very similar pattern was found in the volume increase rate showing the highest value for WN, followed by SN, JN, GN, and AN. This is because these two attributes are highly associated, indicating the more water absorption to noodles, the more volume increase in noodles.

Table 3.

Cooking quality of noodles prepared from wheat flour and different potato cultivars

| Cooking quality (%) | Sample | ||||

|---|---|---|---|---|---|

|

| |||||

| WN | AN | GN | SN | JN | |

| Water absorption | 122.83±0.09a | 75.70±0.41d | 80.73±0.85c | 92.82±2.02b | 83.02±0.73c |

| Cooking loss | 4.12±0.41a | 6.35±0.29b | 6.51±0.43b | 6.42±0.16b | 6.45±0.12b |

| Volume increase | 175.86±0.00a | 103.45±4.88d | 113.79±0.00cd | 139.66±2.44b | 122.41±2.44c |

WN, wheat flour noodle; AN, Atlantic noodle; GN, Go-un noodle; SN, Sae-bong noodle; JN, Jin-sun noodle.

Values with different letters (a–d) within the same row differ significantly (P<0.05).

The WN showed the best ability to retain water during cooking, showing a cooking loss of 4.12%. Potato noodles, however, showed higher cooking loss than WN, and different potato varieties did not induce significant differences in cooking loss. Cooking loss is related to the structural densities of surfaces, during which the soluble solids are eluted from the surface into the cooking water (24). Lucisano et al. (24) compared the cooking loss of a pasta prepared with durum wheat, rice flour, corn flour, and potato starch. As a result, it was predicted that the cooking loss was affected by the gluten contents of the potatoes in view of the high cooking loss of pasta in products without gluten. In a study by Park and Baik (25), the cooking loss of wheat noodles with 6% gluten decreased by 15% for similar reasons.

According to Giuberti et al. (26), the quality of noodles became lower when a cooking loss exceeded 12%. The cooking loss of the noodles used in this study was between 4 and 6%, indicating guarantee of quality in terms of water retention after being cooked. Water holding capacity is a key attribute for noodles after cooking since this directly contributes to the final yield of noodles. From this point of view, it is important for potato noodles to retain more water during cooking compared to wheat noodles.

Textural characteristics of noodles

The textural characteristics of noodles prepared from wheat flour and different potato varieties are shown in Table 4. There was a clear trend that the WN exhibited higher values for most of the textural attributes except for adhesiveness. Adhesiveness is calculated as the total area under the force-time curve after the first compression. It is suggested that the higher viscosity of potatoes compared to that of wheat could be attributed to the high adhesiveness of potato noodles.

Table 4.

Textural characteristics of noodles prepared from wheat flour and different potato cultivars

| Texture profile | Sample | ||||

|---|---|---|---|---|---|

|

| |||||

| WN | AN | GN | SN | JN | |

| Hardness (g) | 4,389.20±352.20a | 3,263.10±238.30b | 2,969.40±136.20c | 3,192.80±206.50bc | 3,201.20±107.60bc |

| Adhesiveness (g·s) | −69.25±24.0a | −128.15±60.00b | −97.74±29.80ab | −86.59±23.3a | −92.77±29.40a |

| Springiness | 0.98±0.00a | 0.93±0.00b | 0.88±0.10c | 0.95±0.0ab | 0.95±0.00ab |

| Cohesiveness | 0.56±0.10a | 0.44±0.00b | 0.35±0.00d | 0.40±0.0c | 0.43±0.00b |

| Chewiness (J) | 2,408.50±350.50a | 1,329.00±118.40b | 903.60±123.60c | 1,210.10±136.40b | 1,295.90±103.90b |

WN, wheat flour noodle; AN, Atlantic noodle; GN, Go-un noodle; SN, Sae-bong noodle; JN, Jin-sun noodle.

Values with different letters (a–d) within the same row differ significantly (P<0.05).

Cho and Hwang (27) reported that the lower gluten contents or the higher crude ash contents could decrease the viscoelasticity of the dough. A major protein of potatoes is tuberin, a non-gluten protein, while wheat flour has gluten in which gliadin and glutenin are entangled to form a three-dimensional network. Moreover, the crude ash contents of medium flour are 0.5~1.3%, while potato flour contains as high as 1.96~2.48% of ash depending on the variety (27). Therefore, low gluten content and high ash content by replacing wheat flour with potato flour and starch may deteriorate the textural properties of potato noodles compared to the wheat noodles. The study conducted by Park and Baik (25) revealed that hardness and tensile strength of noodles incorporated with gluten increased linearly with the gluten contents regardless of cooking time and storage time after cooking.

In summary, hardness, springiness, cohesiveness, and chewiness of WN were higher than those of potato noodles. Studies have shown that some of the textural properties tend to improve when freeze-dried fish scale collagen power or enzymatically resistant starch was added (28,29). This was because the substitutes in wheat noodles resulted in the decreased binding ability of gluten protein in wheat flour (30). In addition, the substitutes expectedly absorbed a large amount of water during cooking time to soften the texture of the noodles (31).

ACKNOWLEDGEMENTS

This work was carried out with the support of the “Cooperative Research Program for Agriculture Science & Technology Development (Project No. PJ011239032017)” Rural Development Administration, Republic of Korea.

Footnotes

AUTHOR DISCLOSURE STATEMENT

The authors declare no conflict of interest.

REFERENCES

- 1.International Potato Center. [accessed Mar 2017];CIP annual report 2015: roots and tubers improving the lives of the poor. https://cipotato.org/publications/annual-report-2015-roots-tubers-improving-lives-poor-embracing-sdgs-2015/

- 2.Korean Statistical Information Service. [accessed Mar 2017];Agricultural production. http://kosis.kr/statHtml/statHtml.do?orgId=101&tblId=DT_2KAA406&conn_path=I2.

- 3.Cho HM, Park YE, Cho JH, Kim SY. Historical review of land race potato in Korea. J Kor Soc Hort Sci. 2003;44:838–845. [Google Scholar]

- 4.Kim WS, Shin MS, Chung HJ, Lee KA, Kim MJ. Cookery science & experiment. Life Science Publishing Co.; Seoul, Korea: 2006. p. 93. [Google Scholar]

- 5.Rural Development Administration. [accessed Mar 2017];Varieties of potato. http://www.nongsaro.go.kr/portal/search/nongsaroSearch.ps?categoryName=SCH01&menuId=PS00007&option=0&searchWord=%EA%B0%90%EC%9E%90#1.

- 6.Cho JH, Cheon CK, Chang DC, Im JS, Jin YI, Park YE, Kim DU, Yu HS. Potato yield and chip quality by planting and harvest periods in spring season. Presented at 97th Annual Autumn Conference of the Korean Society for Horticultural Science; Jinju, Korea. 2012. p. 56. [Google Scholar]

- 7.Cho JH, Cheon CK, Cho KS, Im JS, Chang DC, Jin YI, Lee KJ, Yu HS. Supply of potato for potato chip processing with double cropping potato varieties. Presented at 101st Annual Autumn Conference of the Korean Society for Horticultural Science; Changwon, Korea. 2014. pp. 56–57. [Google Scholar]

- 8.Korean Statistical Information Service. [accessed Mar 2017];Imported utilization rate. http://kosis.kr/statHtml/statHtml.do?orgId=114&tblId=DT_114_2015_S0003&conn_path=I2.

- 9.Korean Statistical Information Service. [accessed Mar 2017];Reasons for using imported. http://kosis.kr/statHtml/statHtml.do?orgId=114&tblId=DT_114_2015_S0007&conn_path=I2.

- 10.Kim KM, Jung SY, Kim JS, Kim GC, Jang YE, Kwon OK. Nutrient components and physicochemical properties of 23 Korean potato cultivars. Food Eng Prog. 2013;17:346–354. doi: 10.13050/foodengprog.2013.17.4.346. [DOI] [Google Scholar]

- 11.Choi HD, Lee HC, Kim SS, Kim YS, Lim HT, Ryu GH. Nutrient components and physicochemical properties of new domestic potato cultivars. Korean J Food Sci Technol. 2008;40:382–388. [Google Scholar]

- 12.Park HJ, Jeon TW, Lee SH, Cho YS, Cho SM, Chang KS. Studies on characteristics and stability of anthocyanin pigment extracted from Korean purple-fleshed potatoes. J Korean Soc Food Sci Nutr. 2004;33:1544–1551. doi: 10.3746/jkfn.2004.33.9.1544. [DOI] [Google Scholar]

- 13.Jang HL, Hong JY, Kim NJ, Kim MH, Shin SR, Yoon KY. Comparison of nutrient components and physicochemical properties of general and colored potato. Korean J Hortic Sci Technol. 2011;29:144–150. [Google Scholar]

- 14.Kim KA, Kim SM, Jung LH. Comparison of physicochemical properties of several Korean potato starches. Korean J Soc Food Sci. 1989;5(1):53–62. [Google Scholar]

- 15.Kim KA, Kim SM. Comparison of physicochemical properties of several Korean potato starches–physicochemical properties of defatted potato starch–. Korean J Food Cook Sci. 1989;5(2):43–50. [Google Scholar]

- 16.Seog HM, Park YK, Nam YJ, Min BY. Physicochemical properties of several potato starches. J Korean Agric Chem Soc. 1987;30:133–140. [Google Scholar]

- 17.Park YE, Cho HM, Lee HJ, Hwang YS, Choi SSN, Lee SJ, Park ES, Lim JD, Choung MG. Antioxidant and inhibition on angiotensin converting enzyme activity of colored potato extracts. Korean J Crop Sci. 2007;52:447–452. [Google Scholar]

- 18.Korean Statistical Information Service. [accessed Mar 2017];Changes in domestic sales by noodle items. http://kosis.kr/statHtml/statHtml.do?orgId=145&tblId=TX_14503_A056&conn_path=I2.

- 19.Huang TT, Zhou DN, Jin ZY, Xu XM, Chen HQ. Effect of debranching and heat-moisture treatments on structural characteristics and digestibility of sweet potato starch. Food Chem. 2015;187:218–224. doi: 10.1016/j.foodchem.2015.04.050. [DOI] [PubMed] [Google Scholar]

- 20.AACC. AACC International approved methods of analysis. 11th ed. American Association of Cereal Chemists; St. Paul, MN, USA: 2010. [Google Scholar]

- 21.Lee YT, Jung JY. Quality characteristics of barley β-glucan enriched noodles. Korean J Food Sci Technol. 2003;35:405–409. [Google Scholar]

- 22.Kim YS, Ha TY, Lee SH, Lee HY. Effect of rice bran dietary fiber on flour rheology and quality of wet noodles. Korean J Food Sci Technol. 1997;29:90–95. [Google Scholar]

- 23.Jung SH, Shin GJ, Choi CU. Comparison of physicochemical properties of corn, sweet potato, potato, wheat and mungbean starches. Korean J Food Sci Technol. 1991;23:272–275. [Google Scholar]

- 24.Lucisano M, Cappa C, Fongaro L, Mariotti M. Characterisation of gluten-free pasta through conventional and innovative methods: evaluation of the cooking behaviour. J Cereal Sci. 2012;56:667–675. doi: 10.1016/j.jcs.2012.08.014. [DOI] [Google Scholar]

- 25.Park SJ, Baik BK. Quantitative and qualitative role of added gluten on white salted noodles. Cereal Chem. 2009;86:646–652. doi: 10.1094/CCHEM-86-6-0646. [DOI] [Google Scholar]

- 26.Giuberti G, Gallo A, Cerioli C, Fortunati P, Masoero F. Cooking quality and starch digestibility of gluten free pasta using new bean flour. Food Chem. 2015;175:43–49. doi: 10.1016/j.foodchem.2014.11.127. [DOI] [PubMed] [Google Scholar]

- 27.Cho JS, Hwang SY. Food materials. Munundang; Seoul, Korea: 2005. p. 182. [Google Scholar]

- 28.Jung YM, Bang EJ, Kang ST. Quality characteristics of noodles added with freeze-dried fish scale collagen mixture powder. J Korean Soc Food Sci Nutr. 2015;44:449–454. doi: 10.3746/jkfn.2015.44.3.449. [DOI] [Google Scholar]

- 29.Mun SH, Shin MS. Quality characteristics of noodle with health-functional enzyme resistant starch. Korean J Food Sci Technol. 2000;32:328–334. [Google Scholar]

- 30.Jeong CH, Shim KH, Bae YI, Choi JS. Quality characteristics of wet noodle added with freeze dried garlic powder. J Korean Soc Food Sci Nutr. 2008;37:1369–1374. doi: 10.3746/jkfn.2008.37.10.1369. [DOI] [Google Scholar]

- 31.Park SI, Cho EJ. Quality characteristics of noodle added with chlorella extract. Korean J Food Nutr. 2004;17:120–127. [Google Scholar]