Abstract

Cheese is an extremely versatile food product that has a wide range of flavor, textures and end uses. The vast majority of cheese is eaten not by itself, but as part of another food. As an ingredient in foods, cheese is required to exhibit functional characteristics in the raw as well as cooked forms. Melting, stretching, free-oil formation, elasticity and browning are the functional properties considered to be significant for Mozzarella cheese. When a cheese is destined for its end use, some of its unique characteristics play a significant role in the products acceptability. For instance pH of cheese determines the cheese structure which in turn decides the cheese shredability and meltability properties. The residual galactose content in cheese mass determines the propensity of cheese to brown during baking. Development of ‘tailor-made cheese’ involves focusing on manipulation of such unique traits of cheese in order to obtain the desired characteristics for its end use application suiting the varied consumer’s whims and wishes. This comprehensive review paper will provide an insight to the cheese maker regarding the factors determining the functional properties of cheese and also for the pizza manufacturers to decide which age of cheese to be used which will perform well in baking applications.

Keywords: Mozzarella cheese, Functional properties, Shred, Stretch, Melt, Free-oil

Introduction

Cheese, a highly nutritious and palatable food, is of significant value in the diet since it comprises of almost all of the protein, fat, essential minerals, vitamins and other nutrients. Cheese is primarily used for its organoleptic contribution to food; however, it provides nutrition and functionality to an array of foods. As an ingredient in food system, cheese is expected to exhibit functional characteristics in the raw (e.g. sliceability, shredability, grateability) and cooked (e.g. flowability, mouthfeel, flavour and/or stretchability) forms (Rohit and Metzger 2008; Lucey 2008). There is a growing demand for cheeses and/or cheese toppings possessing customized functional attributes in the pizza, burger, and sandwich trade (Atanu 2001). Since cheese is an integral part of food products, it is becoming increasingly important for the cheese manufacturers to produce their cheese according to the functionalities required for the end use (Atanu 2001).

Cheese is an extremely versatile food product that has a wide range of flavours, textures, and end-uses. The physical properties of cheese are largely determined by the casein content, the type, number and strength of casein interactions, proximate cheese composition and ripening conditions (Lucey et al. 2003; Banville et al. 2013).

Sensory evaluation of cheese presents a considerable challenge since there are numerous cheese varieties. The modern consumer is more affluent and aware of nearly all aspects of cheese quality. Thus to survive in the competitive market, the manufacturer must control the cheese characteristics by evaluating the pertinent properties and understanding how such characteristics are influenced by a range of factors.

Types of cheeses

More than 400 different varieties of cheese are available worldwide (National Dairy Council 2000). However, the cheeses are classified (Table 1) into specific categories based on several criteria like firmness (moisture content), type of culture, ripened or otherwise, etc. (Fox et al. 2016).

Table 1.

Classification of cheese based on hardness/moisture content.

| Cheese type | Moisture content (%) | Examples |

|---|---|---|

| Soft cheese | 50–80 | Cottage, Quark, Baker’s, Mozzarella, Camembert, Feta |

| Semi-soft cheese | 39–50 | Blue, Limburger, Provolone, Tilsiter |

| Hard cheese | Max. 39 | Cheddar, Colby, Edam, Swiss, Gouda |

| Very hard cheese | Max. 34 | Parmesan, Romano, Sardo, Grana |

Functionality of cheeses

The term ‘functionality’ for cheese refers to ‘capable of performing’. It is applied to wide varieties of cheese; the characteristics of significance include flavor, physical properties and stability. When a cheese is destined for its end use, some of its unique characteristics play a significant role in the products acceptability. Development of ‘tailor-made cheese’ involves laying a stress on manipulation of such unique traits of cheese in order to obtain the desired characteristics for its end use application. The definition of terms related to cheese functionality is provided in Table 2.

Table 2.

Definition of terms related to cheese functionality.

Source: Mc Mahon et al. (1993), Guinee (2002), Childs et al. (2007) and Rohit and Metzger (2008)

| Cheese functionality | Definition |

|---|---|

| Melting | Liquefaction of cheese by heat |

| Stretching | Formation of fibrous strands that elongate without breaking yet resist permanent elongation |

| Oiling-off | Tendency of free oil separation from melted cheese. Such property is also referred to as fat leakage |

| Cook colour/Browning/Blistering | Blisters are trapped pockets of heated air and steam that may be preferentially scorched during baking. It occurs at the cheese surface during high temperature baking |

| Whitening/Decolourization | Bleaching of cheese |

| Spreadability | Ability to spread over a surface on application of slight force to form a layer, thin enough to form a coating |

| Grating | Property of cheese to be divided into small particles on rubbing |

| Slicing | Property of cheese to be divided into slices or blocks |

| Dicing | Property which enables user to cut cheese into cubes |

| Shredding/Mincing | Property enabling cheese to cut or chop into very small pieces |

Mozzarella cheese

Mozzarella cheese belongs to a class of ‘Pasta filata’ family which involves the principle of skilful stretching of the curd in hot water to obtain smooth texture in cheese. The cheese is soft, white, unripened, that may be consumed shortly after manufacture. The specific melting and stretching characteristics of Mozzarella cheese is highly appreciated in the manufacture of Pizza in which it is a key ingredient (Atanu 2001).

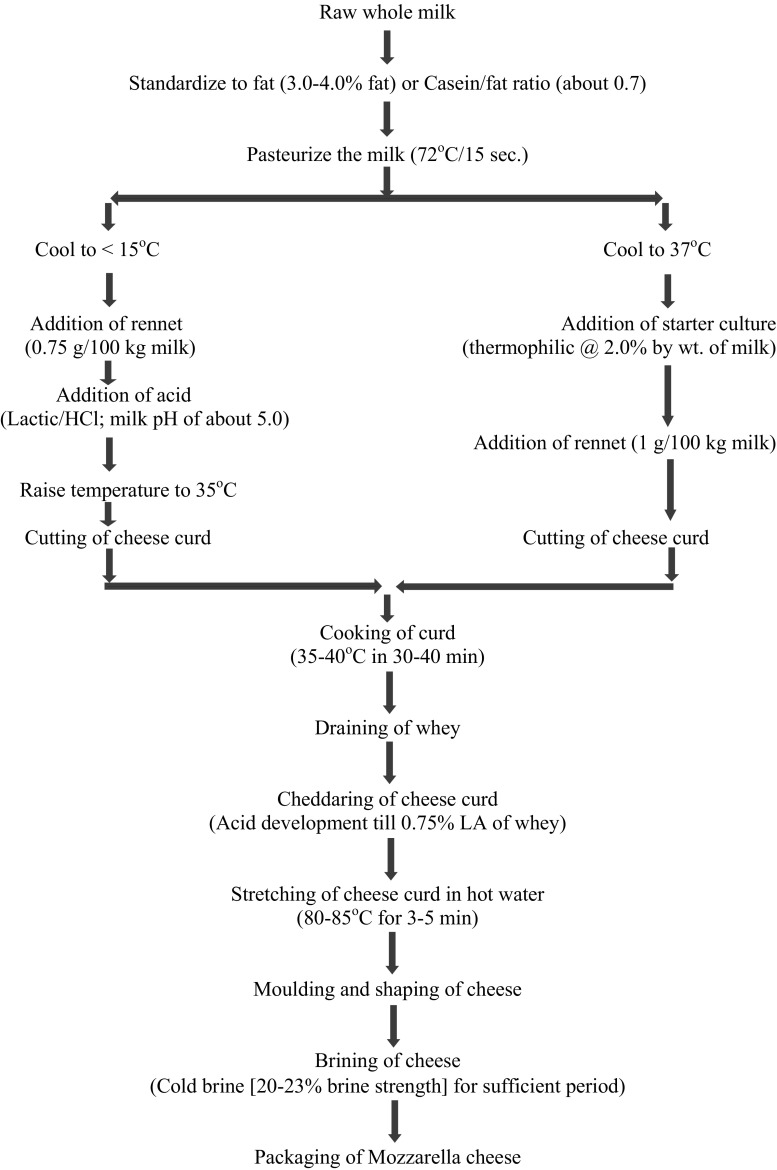

The flow chart for the production of Mozzarella cheese by ‘Starter culture’ and ‘Direct acidification’ methods is depicted in Fig. 1.

Fig. 1.

Flow chart for preparation of Mozzarella cheese.

This cheese’s clean, mild flavor, shredability and appealing melt and stretch make it ideal for pizza. Low moisture part-skim Mozzarella (LMPSM) finds greater application than traditional Mozzarella (up to 60% moisture) on pizza owing to its superior slicing qualities. LMPSM is associated with a moisture content ranging from 45 to 52% and a fat on dry matter (FDM) content ranging from 30 to 45% (Jana and Mandal 2011). Such lower moisture content of LMPSM confers superior shredability and the moderate fat content provides desired fat leakage during its baking applications. The composition of Mozzarella cheese reported in literature is depicted in Table 3.

Table 3.

Proximate composition of Mozzarella cheeses made from cow and buffalo milk by different methods

| Constituents | Proximate composition of Mozzarella cheese | |||

|---|---|---|---|---|

| Karuna and Bajwa (2015)a | Andreatta et al. (2009)b | El-Alfy et al. (2008)c | El-Alfy et al. (2008)d | |

| Moisture, % | 49.21 | 50.1 | 48.70 | 45.94 |

| Fat, % | 26.17 | 28.60 | 21.70 | 20.60 |

| Total protein, % | 22.32 | 17.90 | 26.22 | 29.41 |

| Lactose, % | – | – | 1.08 | 1.44 |

| Ash, % | 4.51 | 1.90 | 2.30 | 2.61 |

| Acidity, % LA | – | 0.48 | 0.66 | 0.59 |

a Direct acidification using lactic acid

b Starter culture (SC) method

c From cow milk retentate using SC method

d From buffalo milk retentate using SC method

The ranges of functional characteristics attributable to melted Mozzarella cheese are wide and varied, and are largely responsible for consumer perception. Melting, stretching, free-oil formation, elasticity and browning are usually the properties considered to be of significance when used as a pizza topping (Atanu 2001).

Production and consumption of Mozzarella cheese

USA leads the global consumption of Pasta filata cheeses at 54.5% of volume, followed by Brazil (6.6%), Italy (5.2%), Germany (5.2%) and Canada (3.7%) (GEA 2016). Mozzarella is America´s favorite cheese accounting for nearly a third of the consumption, since it is one of the main ingredients of pizza (http://www.pmfood.dk/upl/9735/WCMINFORMATION.pdf). In Argentina, Soft/fresh types (Mozzarella, Cremoso, Saint Paulin) dominate the cheese categories comprising 50% of the market (http://www.pmfood.dk/upl/9735/WCMINFORMATION.pdf). Since 2010, cheese imports in China have tripled which involves fresh and curd type cheese including mozzarella; such cheese type accounted for 58% of cheese imports in 2014 (http://www.hoogwegt.com/media/1589/horizons-july-2015.pdf).

The major players in India for cheese are Amul, Britannia and Dabon International. Other major brands include Vijaya, Verka, Parag Milk Foods Pvt. Ltd. (Gowardhan brand), Nandini and Vadilal (http://www.aavinmilk.com/dairyprofile.html). Mozzarella cheese has a share of about 20% of total cheese consumed in India (Food and Agribusiness Advisory and Research 2016).

Factors affecting the functionality of Mozzarella cheese

The protocol for manufacture of Mozzarella cheese by ‘Starter culture’ and ‘Direct acidification’ techniques is furnished in Fig. 1. Several factors affect the functionality of Mozzarella cheese. These include type of milk used for cheese making (cow, buffalo, mixed milks), manufacturing protocol (starter culture or direct acidification method), type of starter culture and rennet enzymes used, plasticizing treatment, method of salting, etc. (Rowney et al. 1999; Jana and Mandal 2011). Contemplating variations in the cheese manufacturing technology offers an opportunity for the cheese maker to enhance the functionality of the finished cheese (Rowney et al. 1999). The cheese manufacturing parameters that can have an influence on the cheese characteristics are discussed hereunder.

Type of milk and stage of lactation

Mozzarella cheese maker should avoid late-lactation milk since the higher concentration of plasmin in such milk hydrolyses casein, which makes the cheese unsuitable for pizza applications (Lucey et al. 1992).

The physical and sensory quality of Mozzarella cheeses prepared from cow and buffalo milk were found to be similar. Buffalo milk Mozzarella (BMM) cheeses were associated with higher fat, protein, ash (including calcium) and total solids as compared to cow milk cheese (Bhattarai and Acharya 2010; Mijan et al. 2010). Use of buffalo milk led to Mozzarella cheese possessing whiter colour, more piquant and aromatic flavor as compared to that prepared from cow’s milk (Sabikhi and Kanawjia 1992). Few reports point at buffalo Mozzarella cheese possessing harder body, being less watery possessing reduced meltability and greater oiling-off as compared to cow milk counterpart (Ghosh and Singh 1996; Mostafa et al. 1996).

The cow milk Mozzarella (CMM) cheese tended to be softer, more flexible and contained slightly higher moisture, fat and salt content unlike BMM cheese which were associated with higher protein content. BMM cheese showed lower soluble nitrogen content as well as total volatile fatty acids (TVFA) during refrigerated storage than did cheese made from cow’s milk (Zedan et al. 2014). The proteolysis in cheese influenced the cheese texture as well as meltability. TVFA content contributes to the flavor of Mozzarella cheese.

Cheese made from cow milk had superior meltability and stretchability as compared to buffalo counterpart. Cheese made from cow milk had superior overall sensory score as compared to buffalo milk cheese. As a result, cow milk cheese was preferred over buffalo milk cheese for pizza topping (Bhattarai and Acharya 2010; Zedan et al. 2014).

Effect of starter cultures

Different starter cultures have varying proteolytic activity can influence the functionality of Mozzarella cheese (Oberg et al. 1991b; Hong et al. 1998). Lactobacillus helveticus when used as adjunct starter with Streptococcus thermophilus is reported to provide superior functional properties (especially melt) compared to use of Lb. delbrueckii ssp. bulgaricus (Oberg et al. 1991b).

Mozzarella cheese, aged 1 month, prepared using mixed culture (S. thermophilus and Lb. helveticus) exhibited 3–4 times greater meltability (compared to fresh cheese) as against only 2 times greater meltability of cheese made using S. thermophilus culture singly (Dave et al. 2003a). The synergistic effect between coagulating enzyme and starter culture is reported to enhance the melt and flow properties of Mozzarella cheese (Dave et al. 2003b).

The cocci starter were dominant in the curd at milling, regardless of the rod:coccus ratios (i.e. Lb. delbreuckii ssp. bulgaricus: S. thermophilus; 9:1, 1:1 and 1:9) employed in Mozzarella cheese making and such starter survived the stretching of curd (at 57 °C). Proteolysis was rapid in case of stored Mozzarella cheese especially when prepared using rod:coccus (9:1). The springiness and apparent viscosity were lower for cheese prepared using rod:coccus (9:1) compared to cheese made using other two ratios of starter; the hardness, meltability and free oil properties of cheese were unaffected (Yun et al. 1995).

Effect of rennet type

Different coagulating enzymes are known to have different specificity towards casein (Chaves and Grosso 1999). Protease from Cryphonectria parasitica is more proteolytic and specific towards β-casein compared to chymosin; the latter is less proteolytic and more specific towards αs-casein (Yun et al. 1993d). The highest percentage breakdown of αs-casein was ~ 75% in 1 month old Mozzarella cheeses made with mixed culture using chymosin rennet, while breakdown of β-casein was ~ 50% in similar aged cheese prepared utilizing rennet from Cryphonectria parasitica. The meltability of Mozzarella cheese was reported to correlate mainly with the hydrolysis of β-casein (Dave et al. 2003a).

The rate of proteolysis in Mozzarella cheese during storage was greater when Mucor miehei rennet (Fromase) was used as against use of calf rennet and fermentation derived chymosin. Use of Fromase rennet resulted in cheese having superior flavor as well as body and texture attributes; an improvement was noted in such sensory scores with ageing of cheese. The type of rennet used failed to influence the TVFA content nor did it affect the meltability and fat leakage characteristics of Mozzarella cheese (Ahmed et al. 2011).

Cheese composition

Moisture content

Controlling the moisture content of Mozzarella cheese is economically important. However, variation in the moisture content of cheese may adversely affect its functionality. Increasing the moisture content of Mozzarella cheese from 47 to 52% resulted in a softer texture (poor shredding) and led to increase in the melting property of cheese (Jana and Upadhyay 1992). Low pressure homogenization (2.45–4.90 MPa) of buffalo milk yielded Mozzarella cheese possessing greater moisture content, culminating in retarded stretch and melt, poor shredability but with superior whiter color, flavor and fat leakage (i.e. reduced) (Jana and Upadhyay 1992).

Fat content

The fat content of Mozzarella cheese is determined by adjusting the casein-to-fat ratio of milk. The fat-in-dry-matter (FDM) of Mozzarella is kept typically ≥ 35% in India. As the fat content of Mozzarella cheese increases, the softness and meltability of the cheese improves, while shred quality tends to be impaired (Tunick et al. 1991). Decreasing the fat content of cheese invariably results in physical and flavour changes that leads to poorer quality products (Mc Mahon et al. 1993). The low-fat Mozzarella cheeses often tend to be tough and rubbery.

Homogenization of milk in the preparation of low-fat mozzarella cheese yielded product having desirable meltability (Tunick et al. 1993b; Merrill et al. 1994); low-fat cheese usually suffers from poor melting. The use of exopolysaccharide producing cultures helped in obtaining low-fat cheese with increased moisture content leading to improved meltability (Perry et al. 1997, 1998).

Many of the undesirable functional characteristics of low-fat Mozzarella cheese are partly due to the lack of fat leakage, thereby allowing the casein matrix to dehydrate, leading to intense browning and limited meltability (Rudan and Barbano 1998a, b). Application of a thin hydrophobic surface coating (such as vegetable oil) to the Mozzarella cheese shreds serves as a physical barrier to dehydration resulting in desirable melting and browning characteristics during baking on a pizza base.

Lactose/galactose content

Accumulation of galactose in Mozzarella cheese leads to cheese having greater propensity to browning, since such sugar plays a role in Maillard browning (Johnson and Olson 1985). Galactose-fermenting and galactose-non-releasing strains have been in use to especially manufacture low-browning mozzarella cheese (Matzdorf et al. 1994; Mukherjee and Hutkins 1994). Mozzarella cheese made by direct acidification undergoes lower extent of proteolysis culminating in cheese that remains white during cooking, even though lactose is present (Oberg et al. 1991a).

pH of curd (at milling) and cheese

The pH at whey drain has a profound impact on curd functionality than the pH at milling, since the former pH is critical in deciding the amount of lactose partitioned into the curd (Yun et al. 1993a). Mozzarella cheese characteristics in melted state such as meltability and free oil formation were unaffected by varying the milling pH in the range 5.1 to 5.4 (Yun et al. 1993a). Kiely et al. (1992) and Maldonado et al. (2013) reported that the optimum condition for Mozzarella cheese curd melting and stretching was adjusting the final curd pH in the range 5.2–5.5. Cheeses stretched at pH 5.2 and 5.3 were criticized for being sticky and easily chewable, not springy, and having low disintegration. However, cheeses stretched at pH 5.6 and 5.7 were firm, springy and chewier (Maldonado et al. 2013).

Processing conditions affecting Mozzarella cheese functionality

Several pre-treatments and processing conditions meted out to cheese milk can have a bearing on the resultant functional properties of cheese made thereof. These are discussed herein.

Pasteurization of cheese milk

Heat treatment of milk (72 °C, no hold) meant for Mozzarella cheese making yielded soft-bodied cheese with superior sensory flavor and keeping quality compared to cheese made from raw milk (Patel et al. 1986). Increasing the severity of milk pasteurization (i.e. from 72 to 82 °C temperature) significantly reduced the flowability and stretchability of the melted Mozzarella cheese (Rynne et al. 2004).

Homogenization

Homogenization of milk causes the formation of new fat/water interface, predominantly containing caseins (Sharma and Dalgleish 1993); such interface provides greater stability to cheese against free oil formation. Homogenization of cheese milk or of cream (referred to as ‘partial homogenization’) at low pressures (2.45–4.90 MPa) is advantageous in reducing fat leakage in cheese during baking (Jana and Upadhyay 1993). The size of the fat globule and its dispersion in the casein matrix influences the meltability and fat leakage of resultant cheese (Tunick 1994; Rowney et al. 1998).

Cheese milk homogenized at high pressures (6700 kPa) tended to reduce the stretching and melting properties, while low pressure homogenization (400 kPa) did not impair such properties of resultant Mozzarella cheese (Lelievre et al. 1990).

Cooking of cheese curd

With an increase in the cooking temperature (i.e. from 32 to 46 °C), there was an increase in the hardness and decrease in the meltability of Mozzarella cheese (Tunick et al. 1993b); the effect was ascribed to lower moisture content of cheese and retarded proteolysis during storage. Varying the cooking temperature in the range 38–44 °C did not significantly change the meltability and fat leakage properties of cheese. However, apparent viscosity of melted cheese was greater when employing higher cooking temperature (Yun et al. 1993c).

Stretching of cheese curd

The stretching step in the manufacture of mozzarella cheese is important in developing the functional characteristics of the finished cheese. At pH 5.2, when curd is typically transferred to the cooker/stretcher, a large proportion of casein is dissociated from the micelles forming longitudinal microstructure. Curd stretched at pH 5.3 has a more structured texture, when fresh and during ageing, compared to Mozzarella cheese made from curd stretched at pH 5.0; the adoption of former pH also yielded cheese that took longer time to age (Yun et al. 1993b).

Increasing the stretching temperature of the curd from 57 to 75 °C somewhat impaired the elastic properties of Mozzarella cheese (Mulvaney et al. 1997). Use of stretching temperature on higher side affected the survival of proteolytic organisms in cheese. The primary as well as secondary proteolysis of mozzarella cheese was found to decrease during ageing, when the stretching water temperature was raised from 62 to 66 °C (Yun et al. 1994). Proteolytic changes in Mozzarella cheese curd have a bearing on the melt, stretch and fat leakage characteristics.

As compared to Mozzarella cheese made in a conventional cooker/stretcher, cheese produced in a high-pressure, twin-screw extruder yielded product having retarded meltability and free-oil formation (Apostolopoulos et al. 1994). Renda et al. (1997) reported that twin-screw cooker/stretcher operated at lower screw speed (5 rpm) produced a cheese with significantly higher fat leakage as compared to use of relatively higher (12–19 rpm) screw speed.

Method of salting and salt content

The brining step in Mozzarella cheese manufacture not only affected the salt content of the cheese but also affected the rate at which the cheese is cooled through thermal equilibration in the cold brine. There exists salt gradient in a block of cheese soon after brining. The moisture content and calcium levels of cheese are significantly lower at the product surface. Such locational differences lead to variations in the melting characteristics within the same block of cheese (Kindstedt et al. 1989). Free-oil formation is significantly greater at the surface of the cheese and apparent viscosity significantly lower as a consequence of brining (Kindstedt et al. 1992). The pizza maker should exercise care in blending the shredded brined cheese properly so that the cheese performs satisfactorily during baking.

The functionality of Mozzarella cheese is affected by the salt content of the cheese. Mozzarella cheese with a higher salt content (i.e. 1.78%) is reported to be less meltable and less stringy than cheese having lower (1.06%) salt content (Olson 1982). Mozzarella cheese having 3.0% salt was reported to have significantly lower fat leakage than cheese having 0.4% salt (Kindstedt et al. 1992). Increased salt content in Mozzarella cheese decreased the melting quality of resultant product (Olson 1982), but increased the melting of non-fat Mozzarella cheese (Paulson et al. 1998). Kindstedt et al. (1992) postulated that sodium might be getting exchanged with calcium in the casein matrix thereby enhancing the ability of casein to emulsify fat, yielding cheese having a firmer texture. The proteolysis in Mozzarella cheese remained unaffected by the varying levels of salt in the product (Everett et al. 2004); salting operation was carried out using a combination of dry and brine salting. Partial salting of the cheese curd, prior to brining, enables the brining period to be reduced and minimises the salt gradient in the cheese. Dry salting had a greater impact on the final moisture content of non-fat Mozzarella cheese than did brine salting (Paulson et al. 1998).

Quality of Mozzarella cheese dictating its end use application in food system

Cheese is one of the favoured ingredients for use on pizza. Mozzarella cheese’s clean, mild flavour, shredability, and appealing melt and stretch make it ideal for pizza.

The specific functional properties of Mozzarella cheese appear to develop in two distinct, but inter-dependent phases. The first phase occurs during manufacture, when the basic curd structure is being developed. The second occurs during storage, when functionality and curd structure gets altered. The fresh Mozzarella cheese is typically firm and is associated with poor melting properties and, although it stretches, the overall texture is invariably unacceptable. During storage (1–3 weeks) of cheese, there is an improvement in the functional characteristics (viz., meltability, fat leakage, stretch), favouring its end use as a topping on pizza (Lucey et al. 2003). There are reports indicating decrease in the extent of stretch with ageing of the cheese (Rowney et al. 1999). Exceeding 3–4 weeks of ageing, the cheese may become ‘soupy’ (upon melting) and the strands become ‘short’ and ‘weak’ (Rowney et al. 1999; Lucey et al. 2003).

Mozzarella cheese quality as defined and interpreted by the restaurant trade is based on the unique requirements of pizza. Quality of cheese as desired at the restaurant may be quite different from that at the cheese plant or the supermarket (Pilcher and Kindstedt 1990). Table 4 depicts the definition of various physical properties of Mozzarella cheese applicable for its end use functionality.

Table 4.

Major unmelted and melted textural properties associated with cheese and their end-use functionality.

| Descriptor terms | Properties | Importance |

|---|---|---|

| Shredability | Physical attributes such as the ease of machinability, the shape and integrity of shreds, the propensity of shreds to mat | 1. For application as pizza topping, the cheese needs to be shredded 2. Commercially available packaged shredded cheese for convenience |

| Meltability | Tendency of the cheese to soften upon heating | 1. Toasted sandwiches, burgers, and so on. Ability to maintain a uniform softening with minimal oiling-off when used in toasted sandwiches and other heated food preparations 2. Shredded cheese on pizza, in breaded cheese sticks, cheese insets in bratwurst, and burger patties |

| Viscosity/flow | Tendency of the cheese to spread and flow when completely melted | 1. Cooker ‘drop-down’ viscosity after manufacture 2. Optimum hot-fill ability into loaves during packaging 3. Restricted flow during toasting (food preparation) |

| Stretching ability | Tendency of the heated cheese to form strings when extended | 1. Shredded cheese on pizza, in breaded cheese sticks |

Functionality of cheese suitable for its end use application

Some of the important functionality of Mozzarella cheese in which a pizza maker maybe interested is discussed in depth under suitable headings.

Shredability of cheese

The shredded cheese is a value-added product. Pizza Mozzarella cheese is invariably shredded, cut or diced to improve its handling (Gunasekaran and Ak 2002). Shredability is a broad term that includes physical attributes such as the ease of machinability, the shape and integrity of cheese shreds, the propensity of shreds to mat, and excessive production of fines during shredding (Childs et al. 2007). Shredding offers improved functionalities owing to faster melting than is available with other forms of cheese. Conventional shredded cheese is 3.2 or 1.6 mm (1/8″ or 1/16″) square cross-section, while newer fancy shreds are 0.8 or 0.4 mm (1/32″ or 1/64″). Shredded cheese should appear appetizing and eye-appealing for inclusion in salads or desserts or even for use as a garnish. Use of uniformly shredded cheese permits it to melt easily and evenly when included in hot dishes or when used as a topping (Dubuy 1980).

The primary textural attributes associated with acceptable shredding of Mozzarella cheese are firmness and adhesiveness. The firmer and less adhesive the Mozzarella, the higher the shred grade (an indicator of shredded cheese quality). At a period of 2-weeks, Mozzarella cheese shredded at lower temperatures (i.e. − 1.1, 1.7 °C) were firmer and led to significantly higher shred grade scores. At 6 weeks, in spite of cheese remaining firm at low temperature, the cheese shredding quality remained unaltered, irrespective of the shredding temperature (Lim et al. 2005).

Soft cheese usually exhibits poor shredding characteristics since it sticks to the blade, forms gummy balls of cheese, and eventually gives shreds that tend to mat together. Conversely, firm and dry Mozzarella cheese easily shatters into fines (Kindstedt 1995). Free-flowing and degree of matting of cheese shreds could be considered as good quality indices for shredded cheeses (Ni and Gunasekaran 2004). Cheese with moderate moisture content (45–48% moisture) provides desired shredability. The shredding behaviour of pizza Mozzarella cheese was strongly affected by cheese-making conditions. Lowering the pH of milk at renneting and aging the cheeses tended to decrease the fines production during shredding (Banville et al. 2014).

Meltability of cheese

Melting qualities are related to the ability of the cheese to melt to a uniform, homogenous and smooth consistency without becoming watery and releasing oil. Cooked Mozzarella cheese should melt uniformly, so that no individual cheese shred particles are visible upon melting (Mc Mahon et al. 1993). Melted cheese has found an array of applications, such as a pizza topping, cheese slices on hamburgers, toasted sandwiches, fillings, layers in lasagna and sauces. The cheese manufacturers can manipulate cheese performance to consistently meet the melt specifications.

Cheese meltability is a functional trait reflecting closely the functional quality of cheese and is dictated by the consumers’ requirements. Meltability of cheese was aided by utilizing milk with higher fat content and by extended period of storage, while it was hindered by fat reduction, homogenization of milk and use of higher cooking temperature (Tunick et al. 1993b). Superior meltability is associated with higher moisture in non-fat substances (MNFS) and lower cheese pH. The progressive increase in proteolysis during ageing of cheese promotes the meltability of cheese. The meltability correlated better with fat on wet matter basis than on dry matter basis, indicating that moisture plays a significant role in cheese meltability (Lefevere et al. 2000).

Cow milk Mozzarella showed significantly higher meltability compared to buffalo milk cheese. Addition of whey protein concentrate (47.88% protein) powder (at 0.3%) to buffalo milk in the manufacture of Mozzarella cheese improved its meltability by twofold (Salama 2015). Even addition of cow milk or goat milk to buffalo milk improved the meltability of the resultant Mozzarella cheese (Sabikhi and Kanawjia 1992; Mostafa et al. 1996; Sameen et al. 2008).

Meltability of Mozzarella cheese has been reported to correlate with hydrolysis of β-casein and was comparable to soluble nitrogen but had least correlation with hydrolysis of αs-casein (Dave et al. 2003a, b). An increase in the moisture content of low-fat Mozzarella is aimed at by the cheese manufacturer to improve upon its meltability and to prevent undesirable scorching or browning.

Fat leakage of cheese

Free-oil formation is the tendency of liquid fat to separate from melted cheese and accumulate in pockets or pools, particularly at the cheese surface. In case of Mozzarella cheese, both excessive free-oil and limited free-oil are considered to be serious defects (Jana and Mandal 2011).

Abd El-Gawad (1998) and Ghosh and Singh (1996) reported that cow milk Mozzarella cheese exhibited greater fat leakage than buffalo milk cheese; both made from milk of same fat content. A direct relation between fat content of milk and the fat leakage in Mozzarella cheese has been reported. Ageing of cheese led to marked increase in fat leakage (Richoux et al. 2008). Varying amount of free oil may be produced by Mozzarella cheese prepared using different starter cultures, which in turn, affects the browning of cheese (Ma et al. 2013a). Homogenization of milk is advantageous in reducing the fat leakage of cheese during baking; it is especially of greater significance in case of buffalo milk Mozzarella cheese since buffalo milk fat is comprised of fat globules that are larger in size than that of cow milk fat (Breene et al. 1964; Jana and Upadhyay 1993). The extent of free oil formed may influence cheese dehydration and affect cheese browning during baking (Richoux et al. 2008).

Stretchability

Under tension, Mozzarella cheese should form fibrous strands in hot condition and should elongate without breaking. The ability of Mozzarella cheese to form such fibrous strands is quantified as stretchability (Kindstedt et al. 1989). Stretch quality is considered to be an important aspect during its end usage in baking applications. Thus, the length, tension and type of stretch (strings, feathering or fibrous) are important quality attributes of such cheese. Retention of stretch in Mozzarella cheese is related to the extent of inactivation of the residual milk coagulant (Barbano et al. 1993).

As per United States Department of Agriculture (2013) Mozzarella cheese topped on pizza base when baked at 425 °F for 12 min in a conventional oven should stretch to a minimum of 3 inches of unbroken string (http://www.fsa.usda.gov/Internet/FSA_File/dmoz4.pdf). Consumers may have varied preferences relating to the stretchability of Mozzarella cheese.

The stretch quality of buffalo milk Mozzarella cheese is reported to be slightly superior to that of cow milk cheese. The soft and fine threads of cow milk cheese was ascribed to lower protein content in former cheese as compared to buffalo milk cheese (Ghosh and Singh 1996). The calcium content of cheese is reported to determine the stretchability of non-fat Mozzarella cheese (Wadhwani et al. 2011).

Guinee et al. (2000) noted a marked increase in the stretchability of Mozzarella cheese during ageing of 1 month at refrigeration temperature; beyond this period the stretch quality was impaired. The initial improvement in the stretchability of Mozzarella with ageing was ascribed in part to the age related reduction in the concentration of intact para-casein and the increased water binding capacity of the casein. The latter aspect was conductive to better retention of moisture during baking of pizza, which in turn limited the occurrence of defects associated with excessive dehydration (i.e. burning, crusting and poor flowability) (Zedan et al. 2014).

Browning and blistering

Blistering and browning are considered to be essential quality attributes for the pizza baking performance of Mozzarella cheese. Blisters are trapped pockets of heated air and steam that may be preferentially scorched during baking. Blistering and browning of cheese may occur, however a burnt appearance should be avoided (Rudan and Barbano 1998a, b; Wang and Sun 2002). Since many pizza retailers bake pizza at temperatures above 260 °C, the tendency of the cheese to brown excessively has become a concern to the Mozzarella cheese industry.

Colour and blister development in Mozzarella is often a function of starter culture selection, sugar utilization, and manufacturing protocols that promote removal of sugars. The browning of Mozzarella cheese, resulting from Maillard reaction, is associated with its cooking (Johnson and Olson 1985; Ma et al. 2013a). The elastic and stretching resistances prevent blisters from growing, resulting in smaller blisters on the pizzas post baking (Ma et al. 2013b). Mozzarella cheeses with higher salt (thus having higher salt in moisture content) were associated with lower water activity. The water activity of Mozzarella cheese affects the transition temperature, which further influences the blistering of cheese (Ma et al. 2013b).

Progress of proteolysis may result in formation of higher concentration of available amino groups that can participate in the Maillard browning reaction. The use of adjunct starter cultures (i.e. Lactobacillus helveticus) over and above the conventional ones resulted in fermentation of residual galactose in cheese, retarding the browning tendency of the cheese (Matzdorf et al. 1994; Mukherjee and Hutkins 1994).

Influence of freezing of cheese on cheese functionality

Freezing of cheese can prolong the shelf life of Mozzarella cheese, while still maintaining the desired functionality. However, studies have shown that freezing increases the hardness (Diefes et al. 1993), stretch (Oberg et al. 1992), while it decreased its meltability (Oberg et al. 1992) and fat leakage (Bertola et al. 1996) characteristics. Allowing frozen (− 20 °C) cheese to ripen up to 21 days at 4 °C did not cause any loss of free-oil formation and meltability as was the case with unfrozen cheese samples (Bertola et al. 1996). Shredding of the cheese, before freezing led to improvement in the stretchability but decreased the meltability of cheese (Oberg et al. 1992). Such cheese, in absence of ageing, exhibited good melt and low blistering and maintained such functionality up to 1 year of storage. Kuo and Gunasekaran (2003) reported that the structural changes in cheese during freezing and frozen storage led to an improvement in the meltability of cheese; however, there was some impairment in the stretchability of cheese. The formation of ice crystals in cheese as a result of freezing might be causing local dehydration of proteins, resulting in breaks in the protein structure. Recrystallization of ice crystals during frozen storage might be responsible for the extensive breakdown of the cheese structure.

Microflora of Mozzarella cheese affecting the cheese functionality

Lactic acid bacteria (LAB) help in developing the physical properties of cheese, especially body and texture. The use of starter cultures possessing varying proteolytic activity can alter the stretch, melt and color of Mozzarella cheese (Oberg et al. 1991b). LAB produces several metabolic products such as organic acids, fatty acids, hydrogen peroxide and bacteriocins that have antimicrobial activity resulting in inhibition of pathogenic and even spoilage bacteria (Abdalla and Ibrahim 2010). A high concentration of LAB in the raw materials and in the whey starter ensured safe and good quality Mozzarella cheese. A high LAB concentration (~ 107) ensured high quality of Mozzarella cheese with regard to sensory quality, shelf life and safety (Losito et al. 2014).

Mozzarella cheese prepared using direct acidification (without whey culture) technique exhibited rapid sensorial quality loss during refrigerated storage as compared to the one made using whey culture (Faccia et al. 2013).

Buffalo milk Mozzarella produced using natural whey starter cultures exhibited higher microbial diversity with lower psychrotrophic bacteria. Cow Mozzarella prepared using commercial starters had high count of S. thermophilus and consequently had greater levels of galactose and phenylalanine. Cow milk Mozzarella made using direct acidification method had lower microbial count and higher levels of urea and sugars. The LAB count was reported to be 7.08, 3.50 and 4.82 log10cfu/g for cow milk Mozzarella cheese made using starter culture, cow milk cheese made using direct acidification and buffalo milk cheese respectively (Pisano et al. 2016).

Cheese functionality as affected by refrigerated storage

Proteolytic changes in cheese during storage

Proteolysis in cheese may result from the activity of residual coagulant (rennet), indigenous milk proteases and starter culture enzymes. Primary proteolysis results from the action of the residual rennet in the cheese. This is followed by secondary proteolysis of peptides by the enzymes of starter culture into smaller peptides and free amino acids which aids in controlling the fat leakage in cheese (Barbano et al. 1993). The melting characteristics of cheese showed a positive correlation (r = 0.51–0.80) with proteolysis, whereas it showed negative correlation (r = − 0.48 to − 0.81) with textural characteristics of cheese (Imm et al. 2003).

Water-binding capacity of cheese

Fresh mozzarella (first few days of refrigerated storage) often exudes free moisture at the block surfaces and freshly cut surfaces, making it unsuitable for shredding and melting (Guo and Kindstedt 1995). However, as ageing proceeds, the surface moisture is absorbed back into the block and the cheese develops desirable melting characteristics. It is postulated that during ageing of cheese, the insoluble casein matrix swells and forms a hydrated gel which leads to improved water binding capacity in the product (Rowney et al. 1999). The water-binding capacity of Mozzarella cheese is also influenced by the salt content of the serum (Guo and Kindstedt 1997). Improved hydrated protein structure facilitates the proteins to slip past one another with ease and coupled with the lubricating properties of the fat, it results in improved meltability of the cheese product (Tunick et al. 1993a).

Conclusion

Changing habits of diet and use of newer appliances for cooking and processing of cheese product demands specific tailor-made functionalities expected from such cheese product. Cheese making has changed from a closely guarded craft to science because of better understanding and advances in the fields of chemistry, technology and bacteriology of milk and cheese. Thus, today’s cheese maker is in a better position to exploit such knowledge in producing ‘tailor-made’ cheese product, suiting the consumer’s whims and wishes. The pizza maker should specifically use the Mozzarella cheese that has been aged for 1–1.5 weeks to permit improvement in the melting and stretching properties of cheese suitable for its end use on pizza. Developing accurate tests to evaluate the functional properties of cheese and correlating such data with the varying end-use applications for cheese is the need of the day.

References

- Abd El-Gawad MAM (1998) Manufacture and properties of mozzarella cheese from buffaloes milk. Ph.D. Thesis, Faculty of Agriculture, Cairo University, Egypt

- Abdalla OMM, Ibrahim NNM. Chemical and microbiological evaluation of Mozzarella cheese during storage. Austr J Basic Appl Sci. 2010;4:532–536. [Google Scholar]

- Ahmed NS, Abd El-Gawad Mona AM, El-Abd MM, Abd-Rabou NS. Properties of buffalo Mozzarella cheese as affected by type of coagulant. Acta Sci Pol Technol Aliment. 2011;10:339–357. [Google Scholar]

- Andreatta E, Fernandes AM, Santos MV, Mussarelli C, Marques MC, de Oliveira CAF. Composition, functional properties and sensory characteristics of Mozzarella cheese manufactured from different somatic cell counts in milk. Braz Arch Biol Technol. 2009;52:1235–1242. doi: 10.1590/S1516-89132009000500022. [DOI] [Google Scholar]

- Apostolopoulos C, Bines VE, Marshall RJ. Effect of post cheddaring manufacturing parameters on the meltability and free-oil of Mozzarella cheese. J Soc Dairy Technol. 1994;47:84–87. doi: 10.1111/j.1471-0307.1994.tb01526.x. [DOI] [Google Scholar]

- Atanu Jana. Mozzarella cheese and pizza–the compatible partners. Beverage Food World. 2001;28:14–19. [Google Scholar]

- Banville V, Morin P, Pouliot Y, Britten M. Physical properties of pizza Mozzarella cheese manufactured under different cheese-making conditions. J Dairy Sci. 2013;96:4804–4814. doi: 10.3168/jds.2012-6314. [DOI] [PubMed] [Google Scholar]

- Banville V, Morin P, Pouliot Y, Britten M. Shreddability of pizza Mozzarella cheese predicted using physico-chemical properties. J Dairy Sci. 2014;97:4097–4110. doi: 10.3168/jds.2014-8040. [DOI] [PubMed] [Google Scholar]

- Barbano DM, Chu KY, Yun JJ, and Kindstedt PS (1993) Contribution of coagulant, starter and milk enzymes to proteolysis and browning in Mozzarella cheese. In Proceedings of 30th Annual Marschall Italian Cheese Seminar, Madison, pp 65–79

- Bertola NC, Califano AN, Bevilacqua AE, Zaritsky NE. Effect of freezing conditions on functional properties of low moisture Mozzarella cheese. J Dairy Sci. 1996;79:185–190. doi: 10.3168/jds.S0022-0302(96)76349-X. [DOI] [Google Scholar]

- Bhattarai RR, Acharya PP. Preparation and quality evaluation of mozzarella cheese from different milk sources. J Food Sci Technol Nepal. 2010;6:94–101. [Google Scholar]

- Breene WM, Price WV, Ernstrom CA. Manufacture of Pizza cheese without starter. J Dairy Sci. 1964;47:1173–1180. doi: 10.3168/jds.S0022-0302(64)88877-9. [DOI] [Google Scholar]

- Chaves WHV, Grosso CRF. Proteolysis and functional properties of Mozzarella cheese as affected by refrigerated storage. J Food Sci. 1999;64:202–205. doi: 10.1111/j.1365-2621.1999.tb15865.x. [DOI] [Google Scholar]

- Childs JL, Daubert CR, Stefanski L, Foegeding EA. Factors regulating cheese shreddability. J Dairy Sci. 2007;90:2163–2174. doi: 10.3168/jds.2006-618. [DOI] [PubMed] [Google Scholar]

- Dave RI, Sharma Pragati, Mc Mahon DJ. Melt and rheological properties of mozzarella cheese as affected by starter culture and coagulating enzymes. Le Lait. 2003;83:61–77. doi: 10.1051/lait:2002050. [DOI] [Google Scholar]

- Dave RI, Sharma P, Muthukumarappan K. Effects of starter culture and coagulating enzymes on viscoelastic behavior and melt of Mozzarella cheese. J Food Sci. 2003;68:1404–1410. doi: 10.1111/j.1365-2621.2003.tb09657.x. [DOI] [Google Scholar]

- Diefes HA, Rizvi SSH, Bartsch JA. Rheological behavior of frozen and thawed low-moisture part-skim Mozzarella cheese. J Food Sci. 1993;58:764–769. doi: 10.1111/j.1365-2621.1993.tb09354.x. [DOI] [Google Scholar]

- Dubuy MM. The French art of shredding cheese. Food Proc Ind. 1980;49:52–53. [Google Scholar]

- El-Alfy MB, Shenana ME, Hassaan HM, Abdou SM, and Nasr WI (2008) Using ultrafiltered (UF) retentate in Mozzarella cheese making. Alex J Food Sci Technol Spec Conf Vol, pp 45–60

- Everett DW, Rowney MK, Hickey MW, Roupas P. Salt-induced structural changes in mozzarella cheese and the impact upon free oil formation in ripening cheese. Le Lait. 2004;84:539–549. doi: 10.1051/lait:2004029. [DOI] [Google Scholar]

- Faccia M, Mastromatteo M, Conte A, Del Nobile MA. Influence of the milk bactofugation and natural whey culture on the microbiological and physico-chemical characteristics of Mozzarella cheese. J Food Process Technol. 2013;4:218–225. doi: 10.4172/2157-7110.1000218. [DOI] [Google Scholar]

- Food and agribusiness advisory and research (2016) Dairy Sector in India: Opportunities in key states and products. October 2016. Yes Bank Ltd. and Embassy of the Kingdom of the Netherlands (http://www.agroberichtenbuitenland.nl/india/wp-content/uploads/sites/25/2016/10/Final-DAIRY-REPORT-Updated-file-12-oct-16.pdf

- Fox PF, Guinee TP, Cogan TM, and Mc Sweeney PLH (2016) In: Fundamentals of cheese science. Principal families of cheese. Chapter 3, Springer, New York, pp 27–69

- GEA (2016) Global pasta filata cheese market trends. GEA business area solution—Application center dairy, Dirk Dubiel, Bardolino–Italy (http://www.clal.it/downloads/news/Dubiel-EN.pdf)

- Ghosh BC, Singh S. A comparison of cow and buffalo milk Mozzarella cheese. Indian J Dairy Sci. 1996;49:38–41. [Google Scholar]

- Guinee TP. The functionality of cheese as an ingredient: a review. Aust J Dairy Technol. 2002;57:79–91. [Google Scholar]

- Guinee TP, Auty MAE, Fenelon MA. The effect of fat content on the rheology, microstructure and heat-induced functional characteristics of cheddar cheese. Int Dairy J. 2000;10:277–288. doi: 10.1016/S0958-6946(00)00048-0. [DOI] [Google Scholar]

- Gunasekaran S, Ak MM. In: Cheese rheology and texture. Boca Raton: CRC Press LLC; 2002. p. 243. [Google Scholar]

- Guo MR, Kindstedt PS. Age-related changes in the water phase of Mozzarella cheese. J Dairy Sci. 1995;78:2099–2107. doi: 10.3168/jds.S0022-0302(95)76836-9. [DOI] [Google Scholar]

- Guo MR, Kindstedt PS. Effect of sodium chloride on the serum phase of Mozzarella cheese. J Dairy Sci. 1997;80:3092–3098. doi: 10.3168/jds.S0022-0302(97)76279-9. [DOI] [Google Scholar]

- Hong YH, Yun JJ, Barbano DM, Larose KL, Kindstedt PS. Mozzarella cheese: impact of three commercial strains on composition, proteolysis and functional properties. Aust J Dairy Technol. 1998;53:163–169. [Google Scholar]

- Imm JY, Oh EJ, Han KS, Oh S, Park YW, Kim SH. Functionality and physico-chemical characteristics of bovine and caprine mozzarella cheeses during refrigerated storage. J Dairy Sci. 2003;86:2790–2798. doi: 10.3168/jds.S0022-0302(03)73876-4. [DOI] [PubMed] [Google Scholar]

- Jana AH, Mandal PK. Manufacturing and quality of Mozzarella cheese—a review. Int J Dairy Sci. 2011;6:199–226. doi: 10.3923/ijds.2011.199.226. [DOI] [Google Scholar]

- Jana AH, Upadhyay KG. Homogenization of milk for cheese making—a review. Aust J Dairy Technol. 1992;47:72–79. [Google Scholar]

- Jana AH, Upadhyay KG. A comparative study of the quality of Mozzarella cheese obtained from unhomogenized and homogenized buffalo milks. Cult Dairy Products J. 1993;28:16–22. [Google Scholar]

- Johnson ME, Olson NF. Non-enzymatic browning of Mozzarella cheese. J Dairy Sci. 1985;68:3143–3147. doi: 10.3168/jds.S0022-0302(85)81219-4. [DOI] [Google Scholar]

- Karuna Seth, Bajwa Usha. Effect of acidulants on the recovery of milk constituents and quality of Mozzarella processed cheese. J Food Sci Technol. 2015;52:1561–1569. doi: 10.1007/s13197-013-1176-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kiely LJ, Kindstedt PS, Hendricks GM, Levis JE, Yun JJ, Barbano DM. Effect of draw pH on the development of curd structure during the manufacture of mozzarella cheese. Food Struct. 1992;11:217–224. [Google Scholar]

- Kindstedt PS. Factors affecting the functional characteristics of unmelted and melted Mozzarella cheese. In: Malin EL, Tunick MH, editors. Chemistry of structure-function relationships in cheese. New York: Plenum Press; 1995. pp. 27–41. [DOI] [PubMed] [Google Scholar]

- Kindstedt PS, Rippe JK, Duthie CM. Application of helical viscometry to study commercial mozzarella cheese melting properties. J Dairy Sci. 1989;72:3123–3128. doi: 10.3168/jds.S0022-0302(89)79469-8. [DOI] [Google Scholar]

- Kindstedt PS, Kiely LJ, Gilmore JA. Variation in composition and functional properties within brine-salted Mozzarella cheese. J Dairy Sci. 1992;75:2913–2921. doi: 10.3168/jds.S0022-0302(92)78053-9. [DOI] [Google Scholar]

- Kuo MI, Gunasekaran S. Effect of frozen storage on physical properties of pasta filata and non-pasta filata Mozzarella cheeses. J Dairy Sci. 2003;86:1108–1117. doi: 10.3168/jds.S0022-0302(03)73693-5. [DOI] [PubMed] [Google Scholar]

- Lefevere I, Dewttinck K, Huyghebaert A. Cheese fat as driving force in cheese flow upon melting. Milchwissenschaft. 2000;55:563–566. [Google Scholar]

- Lelievre J, Shaker R, Taylor MW. The role of homogenization in the manufacture of Halloumi and Mozzarella cheese from recombined milk. J Soc Dairy Technol. 1990;43:21–24. doi: 10.1111/j.1471-0307.1990.tb02759.x. [DOI] [Google Scholar]

- Lim K, Bostley A, Chen C (2005) The effect of cheese temperature on the texture and shredding of mozzarella. Wisconsin Center for Dairy Research, Madison, WI, p 234. J Dairy Sci 88 (Suppl. 1) (http://www.jtmtg.org/JAM/2005/abstracts/05abs232.pdf)

- Losito F, Arienzo A, Bottini G, Priolisi FR, Mari A, Antonini G. Microbiological safety and quality of Mozzarella cheese assessed by the microbiological survey method. J Dairy Sci. 2014;97:46–55. doi: 10.3168/jds.2013-7026. [DOI] [PubMed] [Google Scholar]

- Lucey JA. Some perspectives on the use of cheese as a food ingredient. Dairy Sci Technol. 2008;88:573–594. doi: 10.1051/dst:2008010. [DOI] [Google Scholar]

- Lucey JA, Kindstedt PS, Fox PF (1992) Seasonality: its impact on the production of good quality Mozzarella cheese. In Proceedings, 3rd Cheese Symposium, Moorepark, Cogan TM (ed), National Dairy Products Research Centre, Moorepark, pp 41–47

- Lucey JA, Johnson ME, Horne DS. Perspectives on the basis of the rheology and texture properties of cheese. J Dairy Sci. 2003;86:2725–2743. doi: 10.3168/jds.S0022-0302(03)73869-7. [DOI] [PubMed] [Google Scholar]

- Ma X, James B, Balaban MO, Zhang Lu, and Emanuelsson P (2013a) Quantifying blistering and browning properties of Mozzarella cheese. Part I: Cheese made with different starter cultures. Food Res Int 54:912–916 (http://www.dx.doi.org/10.1016/j.foodres.2013.06.007)

- Ma X, James B, Balaban MO, Zhang Lu, Emma AC, Emanuelsson P. Quantifying blistering and browning properties of Mozzarella cheese. Part II: cheese with different salt and moisture contents. Food Res Int. 2013;54:917–921. doi: 10.1016/j.foodres.2013.05.029. [DOI] [Google Scholar]

- Maldonado R, Melendez B, Arispe I, Boeneke C, Torrico D, Prinyawiwatku W. Effect of pH on technological parameters and physico-chemical and texture characteristics of the pasta filata cheese telita. J Dairy Sci. 2013;96:7414–7426. doi: 10.3168/jds.2013-6887. [DOI] [PubMed] [Google Scholar]

- Matzdorf B, Cuppett SL, Keeler L, Hutkins RW. Browning of Mozzarella cheese during high temperature pizza baking. J Dairy Sci. 1994;77:2850–2853. doi: 10.3168/jds.S0022-0302(94)77224-6. [DOI] [Google Scholar]

- Mc Mahon DJ, Oberg CJ, Mc Manus W. Functionality of Mozzarella cheese. Aust J Dairy Technol. 1993;48:99–104. [Google Scholar]

- Merrill RK, Oberg CJ, Mc Mahon DJ. A method for manufacturing reduced fat mozzarella cheese. J Dairy Sci. 1994;77:1783–1789. doi: 10.3168/jds.S0022-0302(94)77119-8. [DOI] [Google Scholar]

- Mijan MA, Haque MA, Habib MA, Wadud MA. Evaluation of quality of Mozzarella cheese. The Bangladesh Veterinarian. 2010;27:36–42. [Google Scholar]

- Mostafa MBM, Shahein NM, Abdel-Kader YI, El-Zoghby AS. Properties of mozzarella cheese as affected by milk type. II.–proteolysis, physical properties and organoleptic quality of cheese. Egyp J Dairy Sci. 1996;24:289–296. [Google Scholar]

- Mukherjee KK, Hutkins RW. Isolation of galactose fermenting thermophilic cultures and their use in the manufacture of low browning Mozzarella cheese. J Dairy Sci. 1994;77:839–2849. doi: 10.3168/jds.S0022-0302(94)77223-4. [DOI] [Google Scholar]

- Mulvaney S, Rong S, Barbano DM, Yun JJ. Systems analysis of the plasticization and extrusion processing of Mozzarella cheese. J Dairy Sci. 1997;80:3030–3039. doi: 10.3168/jds.S0022-0302(97)76270-2. [DOI] [Google Scholar]

- National Dairy Council (2000) Cheese. p 1–3 Cited from http://www.hilmarcheese.com/wp-content/uploads/2015/10/cheeseinformationsheet.pdf

- Ni H, Gunasekaran S. Image processing algorithm for cheese shred evaluation. J Food Eng. 2004;61:37–45. doi: 10.1016/S0260-8774(03)00186-9. [DOI] [Google Scholar]

- Oberg CJ, Merrill R, Moyes LV, Brown RJ, Richardson GH. Effect of Lactobacillus helveticus cultures on physical properties of Mozzarella cheese. J Dairy Sci. 1991;74:4101–4107. doi: 10.3168/jds.S0022-0302(91)78604-9. [DOI] [Google Scholar]

- Oberg CJ, Wang A, Moyes LV, Brown RJ, Richardson GH. Effects of proteolytic activity of thermolactic cultures on physical properties of Mozzarella cheese. J Dairy Sci. 1991;74:389–397. doi: 10.3168/jds.S0022-0302(91)78180-0. [DOI] [Google Scholar]

- Oberg CJ, Merrill R, Brown RJ, Richardson GH. Effects of milk-clotting enzymes on physical properties of Mozzarella cheese. J Dairy Sci. 1992;75:669–675. doi: 10.3168/jds.S0022-0302(92)77802-3. [DOI] [Google Scholar]

- Olson NF (1982) The effect of salt levels on the characteristics of Mozzarella cheese before and after frozen storage. In: Proceedings of 19th Annual Marschall Italian Cheese Seminar, Madison, WI, pp 14–21

- Olson NF (2008) Cheese. In: Rehm HJ, Reed G (eds) Biotechnology, Vol 9, 2nd edn. Wiley-VCH Verlag GmbH, Germany, pp 353–384

- Patel GC, Vyas SH, Upadhyay KG. Evaluation of Mozzarella cheese made from buffalo milk using direct acidification technique. Int J Dairy Sci. 1986;39:394–403. [Google Scholar]

- Paulson BM, Mc Mahon DJ, Oberg CJ. Influence of sodium chloride on appearance, functionality and protein arrangements in non-fat Mozzarella cheese. J Dairy Sci. 1998;81:2053–2064. doi: 10.3168/jds.S0022-0302(98)75780-7. [DOI] [Google Scholar]

- Perry DB, Mc Mahon DJ, Oberg CJ. Effect of exopolysaccharide-producing cultures on moisture retention in low fat mozzarella cheese. J Dairy Sci. 1997;80:799–805. doi: 10.3168/jds.S0022-0302(97)76000-4. [DOI] [Google Scholar]

- Perry DB, Mc Mahon DJ, Oberg CJ. Manufacture of low fat Mozzarella cheese using exopolysaccharide-producing starter cultures. J Dairy Sci. 1998;81:563–566. doi: 10.3168/jds.S0022-0302(98)75608-5. [DOI] [Google Scholar]

- Pilcher SW, Kindstedt PS. Survey of mozzarella cheese quality at restaurant end use. J Dairy Sci. 1990;73:1644–1647. doi: 10.3168/jds.S0022-0302(90)78835-2. [DOI] [Google Scholar]

- Pisano MB, Scano P, Murgia A, Cosentino S, Caboni P. Metabolomics and microbiological profile of Italian mozzarella cheese produced with buffalo and cow milk. Food Chem. 2016;192:618–624. doi: 10.1016/j.foodchem.2015.07.061. [DOI] [PubMed] [Google Scholar]

- Renda A, Barbano DM, Yun JJ, Kindstedt PS, Mulvaney SJ. Influence of screw speeds of the mixer at low temperature on characteristics of Mozzarella cheese. J Dairy Sci. 1997;80:1901–1907. doi: 10.3168/jds.S0022-0302(97)76130-7. [DOI] [Google Scholar]

- Richoux R, Aubert L, Roset G, Briard-Bion V, Kerjean JR, Lopez C. Combined temperature-time parameters during the pressing of curd as a tool to modulate oiling-off in Swiss cheese. Food Res Int. 2008;41:1058–1064. doi: 10.1016/j.foodres.2008.07.021. [DOI] [Google Scholar]

- Rohit Kapoor, Metzger LE. Process cheese: scientific and technological aspects—a review. Comp Rev Food Sci Food Saf. 2008;7:194–214. doi: 10.1111/j.1541-4337.2008.00040.x. [DOI] [Google Scholar]

- Rowney M, Roupas P, Hickey M, Everett D. Milk fat structure and free-oil in Mozzarella cheese. Aust J Dairy Technol. 1998;53:94–110. [Google Scholar]

- Rowney M, Roupas P, Hickey MW, Everett DW. Factors affecting the functionality of Mozzarella cheese. Aust J Dairy Technol. 1999;54:94–102. [Google Scholar]

- Rudan MA, Barbano DM. A model of Mozzarella cheese melting and browning during pizza baking. J Dairy Sci. 1998;81:2312–2319. doi: 10.3168/jds.S0022-0302(98)75812-6. [DOI] [Google Scholar]

- Rudan MA, Barbano DM. A dynamic model for melting and browning of Mozzarella cheese during pizza baking. Aust J Dairy Technol. 1998;53:95–97. [Google Scholar]

- Rynne NM, Beresford TP, Kelly AL, Guinee TP. Effect of milk pasteurization temperature and in situ whey protein denaturation on the composition, texture and heat-induced functionality of half-fat Cheddar cheese. Int Dairy J. 2004;14:989–1001. doi: 10.1016/j.idairyj.2004.03.010. [DOI] [Google Scholar]

- Sabikhi L, Kanawjia SK. Effect of admixing of goat and buffalo milks on sensory compositional and textural characteristics of direct acid mozzarella cheese. Indian J Dairy Sci. 1992;45:562–567. [Google Scholar]

- Salama WM. Influence of whey proteins on the characteristics of buffalo mozzarella cheese. Int J Dairy Sci. 2015;10:12–23. doi: 10.3923/ijds.2015.12.23. [DOI] [Google Scholar]

- Sameen A, Anjum FM, Huma N, Nawaz H. Quality evaluation of Mozzarella cheese from different milk sources. Pak J Nutr. 2008;7:753–756. doi: 10.3923/pjn.2008.753.756. [DOI] [Google Scholar]

- Sharma SK, Dalgleish DG. Interactions between milk serum proteins and synthetic fat globule membrane during heating of homogenized whole milk. J Agric Food Chem. 1993;41:1407–1412. doi: 10.1021/jf00033a011. [DOI] [Google Scholar]

- Tunick MH. Effects of homogenization and proteolysis on free-oil in Mozzarella cheese. J Dairy Sci. 1994;77:2487–2493. doi: 10.3168/jds.S0022-0302(94)77190-3. [DOI] [Google Scholar]

- Tunick MH, Mackey KL, Smith PW, Holsinger VH. Effects of composition and storage on the texture of Mozzarella cheese. Neth Milk Dairy J. 1991;45:117–125. [Google Scholar]

- Tunick MH, Mackey KL, Shieh JJ, Smith PW, Cooke P, Malin EL. Rheology and microstructure of low-fat Mozzarella cheese. Int Dairy J. 1993;3:649–662. doi: 10.1016/0958-6946(93)90106-A. [DOI] [Google Scholar]

- Tunick MH, Malin EL, Smith PW, Sheih JJ, Sullivan BC, Mackey KL, Holsinger VH. Proteolysis and rheology of low fat and full fat mozzarella cheeses prepared from homogenized milk. J Dairy Sci. 1993;76:3621–3628. doi: 10.3168/jds.S0022-0302(93)77703-6. [DOI] [Google Scholar]

- USDA (2013) United states department of agriculture community requirements document DM024 Mozzarella cheese for use in domestic programs. Kansas City Community Office, Farm Service Agency, Kansas City, MO, pp 1–8. Cited from www.fsa.usda.gov/Internet/FSA_File/dmoz4.pdf

- Wadhwani R, Mc Manus WR, Mc Mahon DJ. Improvement in melting and baking properties of low-fat Mozzarella cheese. J Dairy Sci. 2011;94:1713–1723. doi: 10.3168/jds.2010-3952. [DOI] [PubMed] [Google Scholar]

- Wang HH, Sun DW. Assessment of cheese browning affected by baking conditions using computer vision. J Food Eng. 2002;56:339–345. doi: 10.1016/S0260-8774(02)00159-0. [DOI] [Google Scholar]

- Yun JJ, Kiely LJ, Kindstedt PS, Barbano DM. Mozzarella cheese: impact of milling pH on functional properties. J Dairy Sci. 1993;76:3639–3647. doi: 10.3168/jds.S0022-0302(93)77708-5. [DOI] [Google Scholar]

- Yun JJ, Barbano DM, Kindstedt PS. Mozzarella cheese: impact of milling pH on chemical composition and proteolysis. J Dairy Sci. 1993;76:3629–3638. doi: 10.3168/jds.S0022-0302(93)77708-5. [DOI] [PubMed] [Google Scholar]

- Yun JJ, Barbano DM, Kindstedt PS. Mozzarella cheese: impact of cooking temperature on chemical composition, proteolysis and functional properties. J Dairy Sci. 1993;76:3664–3673. doi: 10.3168/jds.S0022-0302(93)77708-5. [DOI] [Google Scholar]

- Yun JJ, Barbano DM, Kindstedt PS. Mozzarella cheese: impact of coagulant type on chemical composition and proteolysis. J Dairy Sci. 1993;76:3648–3656. doi: 10.3168/jds.S0022-0302(93)77708-5. [DOI] [PubMed] [Google Scholar]

- Yun JJ, Barbano DM, Larose KL, Kindstedt PS. Effect of stretching temperature on chemical composition, microstructure, proteolysis and functional properties of Mozzarella cheese. J Dairy Sci. 1994;77(Suppl. 1):34. [Google Scholar]

- Yun JJ, Barbano DM, Kiely LJ, Kindstedt PS. Mozzarella cheese: impact of rod:coccus ratio on composition, proteolysis, and functional properties. J Dairy Sci. 1995;78:751–760. doi: 10.3168/jds.S0022-0302(95)76686-3. [DOI] [Google Scholar]

- Zedan IA, Abou-Shaloue Z, Zaky SM. Quality evaluation of Mozzarella cheese from different milk types. Alexandria Sci Exc J. 2014;35:162–177. [Google Scholar]