Abstract

Silicon and glass were the main fabrication materials of microfluidic devices, however, plastics are on the rise in the past few years. Thermoplastic materials have recently been used to fabricate microfluidic platforms to perform experiments on cellular studies or environmental monitoring, with low cost disposable devices. This review describes the present state of the development and applications of microfluidic systems used in cell biology and analyses since the year 2000. Cultivation, separation/isolation, detection and analysis, and reaction studies are extensively discussed, considering only microorganisms (bacteria, yeast, fungi, zebra fish, etc.) and mammalian cell related studies in the microfluidic platforms. The advantages/disadvantages, fabrication methods, dimensions, and the purpose of creating the desired system are explained in detail. An important conclusion of this review is that these microfluidic platforms are still open for research and development, and solutions need to be found for each case separately.

I. INTRODUCTION

Miniaturization of devices and systems by means of microfabrication technologies has become very popular in scientific advances, and the micro-nanofluidics field has thus emerged. Particularly, the electronics and chemical, biological, and medical fields have benefited from developing microscale technologies. Conventional laboratory handling, processing, and analytical techniques have been revolutionized with the help of microfluidics. In the field of microfluidics, there has been much valuable work with materials such as glass, polydimethylsiloxane (PDMS) or thermoplastics, and living cells, but this review deals only with devices made of thermoplastics used in cell biology.

A. Choice of material

In the biochemical and biomedical fields, polymer-based materials are primarily used since their surface can be easily modified.1 Being composed of linear and branched molecules, the thermoplastic materials are durable against temperature and pressure changes and they do not suffer from any structural breakdown. The properties/characteristics of thermoplastics used to fabricate chips are summarized in Table I. Thermoplastic-based materials have good physical and chemical characteristics such as low electrical conductivity and high chemical stability, and they are suitable for mass production at low cost. Thermoplastics can be softened and made to flow by applying heat and pressure. During cooling, the softened polymer hardens and it takes the shape of the container or mold without any chemical change.2,3 Low-cost fabrication methods for high-throughput production can be successfully used in thermoplastics made with microfluidic systems.

TABLE I.

Summary of properties for thermoplastics.5–11

| Thermoplastics | Thermal expansion coefficient [m/(m K)] 10−6 | Young's modulus (GPa) | Tg () | Tm () | Solubility parameter (MPa)1/2 | Water absorption (%) | O2 permeability (x10−13 cm3. cm cm−2 s−1 Pa−1) | Biocompatibility | Transparency | Auto-fluorescence |

|---|---|---|---|---|---|---|---|---|---|---|

| Cyclo olefin (co) polymer (COC/COP) | 60–70 | 1.7–3.2 | 70–180 | 190–320 | 17.7 | 0.01 | NA | Biocompatible | Transparent | Low |

| Polymethyl methacrylate (PMMA) | 7077 | 2.4–3.4 | 105 | 250–260 | 20.1 | 0.1–0.4 | 0.1 | Biocompatible | Transparent | Low |

| Polyethylene terephthalate (PET) | 59.4 | 2–2.7 | 70 | 255 | 20.5 | 0.16 | 0.03 | Biocompatible | Transparent | Medium |

| Polyethylene-low density (LDPE) | 100–200 | 0.11–0.45 | −125 | 105–115 | 17.6 | 0.005–0.015 | 2 | Biocompatible | Both opaque and transparent | Medium |

| Polyethylene-high density (HDPE) | 120 | 0.8 | −80 | 120–180 | 18.2 | 0.005–0.01 | 0.4 | Biocompatible | Both opaque and transparent | Medium |

| Polypropylene (PP) | 72–90 | 1.5–2 | −20 | 160 | 16.3 | 0.01–0.1 | 1.7 | Biocompatible | Both opaque and transparent | Medium |

| Polystyrene (PS) | 70 | 3–3.5 | 95 | 240 | 18.7 | 0.02–0.15 | 2 | Biocompatible | Transparent | High |

| Polycarbonate (PC) | 65–70 | 2.6 | 145 | 260–270 | 19.4 | 0.23 | 1 | Biocompatible | Transparent | High |

| Polyvinyl chloride (PVC) | 54–110 | 2.4–4.1 | 80 | 100–260 | 19.4 | 0.04–0.4 | 0.04 | Biocompatible | Transparent | High |

| Polyamide (Nylon) | 110 | 2.5 | 47–60 | 190–350 | 28 | 1.6–1.9 | 0.03 | Biocompatible | Transparent | High |

| Polysulfone(PSU) | 55–60 | 2.48 | 185 | 180–190 | 18.7 | 0.2–0.8 | NA | Biocompatible | Translucent | High |

| Polylactic acid (PLA) | 740 | 3.5 | 60–65 | 150–160 | 0.68 | NA | Biocompatible (problematic) | Transparent | High | |

| Polytetrafluoroethylene (PTFE) | 112–135 | 0.4 | 115 | 326 | 12.6 | 0.005–0.01 | 3 | Biocompatible | Translucent | High |

| Polyetheretherketone (PEEK) | 26 | 4–24 | 143 | 343 | 21.9 | 0.1–0.5 | 0.1 | Biocompatible | Opaque | NA |

| Acrylonitrile butadiene styrene (ABS) | 72–108 | 1.4–3.1 | 105 | Amorphous | 18.8 | 0.05–1.8 | 0.5 | Not suitable | Both opaque and transparent | High |

It is very important to select the material type by taking the design of the device into consideration, the compatibility of the material with the chemicals, as well as the applied temperature and pressure. Thus, microfabrication techniques and functional components involved in the miniaturized systems should be planned in detail before constructing the microfluidic system.4

The mechanical, chemical, and optical properties of the polymers are listed in Table I. According to this table, it is not convenient to use LDPE or HDPE as a construction material of microfluidic devices due to their high thermal expansion coefficients and low melting point that make the bonding process difficult. Moreover, they are susceptible to stress cracking.12 PVC is largely employed in medical products but its usage is still open to discussion.13 Automotive, electrical/electronic, and industrial applications have benefited from the advantages of polyamide polymers. However, polyamide has disadvantages such as high moisture pick-up with related dimensional instability and high shrinkage in molded sections. Therefore it is not convenient to use this polymer in microfluidic applications.14 PMMA, PET, and PS offer good thermal stability and insulation properties. High mechanical strength, hardness, and rigidity are the advantageous characteristics of the PMMA substrate but COP/COC is better than these polymers.15–18 The COP/COC is a fully saturated olefin polymer and it shows very little interaction with proteins. The material's ring structure provides high stability. The COP/COC polymer has a smaller Young's modulus than PMMA, and its rigidity and strength is higher. This also makes the dimensional stability property of the COP/COC polymer better.19

When the chemical properties are considered, the material used in cell biology must be biocompatible. According to Table I, most of the thermoplastics are biocompatible except ABS and PLA. The oxidative stability of PET might cause problems during the long experiments.20 PCs are classified as linear polymers that include two germinal ether bonds and a carbonyl bond. While this bond is hydrolytically stable, surface erosion might occur during the in vivo applications. In addition, the release of Bisphenol A (BPA), which is very hazardous in food contact situations, might show up during hydrolysis.21 PVC and nylon are also known as biocompatible materials but, PVC can release toxic gases during manufacturing and nylon is a heat sensitive material.13,14 PS is widely used in molecular and cell biology studies due to its biocompatibility. Petri dishes, test tubes, microplates, and other laboratory containers are all made of PS and this material has high resistivity against alcohols, polar solvents, and alkalis.18,22 PMMA has chemical inertness to many solutions and solvents; however, unfortunately it is affected by ethanol, isopropyl alcohol (IPA), acetone, and other important solvents used in microfabrication and sterilization. The polishing of PMMA is also easy and it displays low water absorption and excellent water resistance.15,16 Most importantly, PMMA is a biocompatible polymer, except when its surface is treated with ozone or O2 plasma.17 The COP/COC polymer shows resistance against acids, bases, and almost all solvents including ethanol, IPA, and acetone, and it has the lowest water absorbency among all plastics. This polymer's stability does not change under moisture conditions, exhibiting a good structure for microfluidic device fabrication.1 The high moisture barrier of COP/COC is beneficial; when working with cell cultures, the cells consume more oxygen from water, instead of its absorption onto the surface of the polymers, and the COP/COC material provides an inert low binding surface property.23

In order to follow the changes inside the microfluidic devices under a microscope, the optical properties of the selected material (e.g., transparency) are very important. Therefore PEEK, PP, PSU, and PTFE are not suitable to work with. In addition to transparency, the auto-fluorescence characteristic of a substrate determines the natural fluorescence that appears in it. Although the auto-fluorescent characteristics of LDPE and HDPE are better than most of the other thermoplastics, their bonding is difficult.12 PET also shows medium auto-fluorescence characteristics, but using PET as a fabrication material of a microfluidic device for biological applications is questionable. There are many microfluidic devices made of PC, but its auto-fluorescence is high. Thus, this makes PC difficult to use when working with fluorescently labeled cells or materials. PS has high transparency and the surface of PS is suitable for long-term cell studies.18 Despite all these appealing characteristics, the thermo-compression bonding of PS pieces has rarely been utilized, and not enough attention has been given to directing the research further into such device applications.24 However, compared to COP/COC and PMMA it has higher background auto-fluorescence. PMMA has a low auto-fluorescence background and this material exhibits excellent transparency.15,16 On average, 92% of light in the visible range can pass through a typical PMMA grade and PMMA materials can be found easily at a low-cost.17 COC/COP materials are the best among other thermoplastics in terms of auto-fluorescence.4

Glass is an extensively used material in microfluidic practices. Glass has a good surface stability and solvent compatibility. In addition, glass is also biocompatible, chemically inert, and hydrophilic. It provides superior optical transparency and high-pressure resistance. However, glass microfluidic devices are relatively expensive and they are prone to breaking. PDMS is a widely used soft-elastomer in microfluidic systems. Soft-lithography techniques can be employed easily to create complex fluidic circuits by PDMS. This material is optically transparent and flexible. Furthermore, it is inert, non-toxic, and biocompatible. Unfortunately, organic solvents can be absorbed by PDMS and it is gas permeable. Proteins or small hydrophobic solvents can also be absorbed and this may create cell adhesion problems and clogging in the microfluidic devices. Since PDMS is an inherently hydrophobic material, it requires surface treatments to transform its surface into a hydrophilic surface. Moreover, PDMS is not a durable material for lengthy experiments. Consequently, it is not possible to commercialize the microfluidic systems made of PDMS as it is not a rigid material.25–29

In this review, PMMA, COP/COC, PC or PS made microfluidic devices, which are fabricated mainly to work with living organisms and tissues, will be focused on, and among them PMMA is the most extensively used one for cell biology applications. COP/COC and PS are promising substrates. When publications from the year 2000 are examined, more than 70% of the research belongs to PMMA, and there are only 12 publications (9%) on COP/COC made devices used in work related to cells (WOS). Nevertheless, COP/COC is a rising substrate for the commercialization of microfluidic devices made of thermoplastics.

B. Fabrication

Photolithography, oxidation, e-beam evaporation, wet etching, sputtering, injection molding, micromilling, laser ablation, computer numerical control (CNC) machining, hot embossing, and CO2 laser engraving are some of the methods applied to create the patterns of microfluidic devices. Double sided adhesives, UV/ozone assisted thermal bonding, solvent assisted thermal bonding, pressure sensitive adhesive tapes, laminating adhesives or thermal fusion bonding were some of the common methods to seal these devices. So far, microfluidic devices made from thermoplastics are simple systems lacking active components such as micropumps, microvalves, and sensors.

Interfacial interactions play an important role for the performance of the microfluidic devices. Several surface modification techniques, such as plasma or UV treatment, can be applied to the polymers to control the surface properties.30 A hydrophilic surface is required to have a smooth and consistent flow of analytes within the microchannels to conduct and to monitor the experiments properly. Moreover, cell or tissue interactions with biocompatible materials can be managed by biological recognition. In order to increase this biological recognition, most often the surface of the device is coated with protiens.31 For example, PC12 cell adhesion, proliferation, and differentiation into a microfluidic neural interface platform were enhanced via polypeptide surface treatment.30 In another example, biotinylated- Bovine serum albumin (BSA) was used to treat the surface of the microfluidic device to immobilize the mother yeast cells.32 We have been fabricating microfluidic devices using thermoplastic substrates like PMMA, COP/COC, and PS by hot embossing, chemical etching, and thermal bonding methods. These 1 nl microbioreactors are successfully used for yeast culturing. Fortunately, for yeast cell cultivation, COP/COC, PMMA, and PS made microfluidic devices do not require any modifications on the surface.25

C. Applications and commercialization

Cell or tissue culturing, separation, detection, analysis or reaction-production studies can be conducted in microfluidic devices by using small sample volumes. In addition, high-throughput drug screening, single cell or molecule analysis and manipulation, drug delivery and therapeutics, biosensing, and point-of-care diagnostics are some of the biological applications that can be accomplished via these devices.33–36

Although microfluidic devices are capable of making high-throughput screening by using a small amount of consumables, commercialization of these devices is not at the desired level. This might be the result of challenges encountered such as finding adequate funding for product development and manufacturing during the stages of commercialization. However, a few companies have overcome these steps, and they have introduced their products into the market. Pico-Gen Picodroplet Formation Chips by Sphere Fluidics Ltd., Multiflux by Dolomite Microfluidics or Chips by Microfluidic ChipShop are the examples of commercialized products. Microfluidic products in the market can be increased if industrial partners and academic partners can come together and reach an agreement. Moreover, as the developments increase in both bioMEMS technologies and commercialization of microfluidic equipment, real-world problems can be solved by researchers effectively at high throughput and low cost. At the end, point-of-care diagnostics, rapid, quantitative, and multiplexed immunoassays, biosensors or instruments for rapid detection of pathogens can be more widely produced and individuals suffering from diseases can be treated more quickly and easily.37,38

In this review paper, microfluidic devices made from thermoplastics, that have been used to study living-organisms or tissues are described. This paper includes 4 main titles, which are related to Cultivation: Organism-on-a-chip, Separation/Isolation, Detection and Analysis and Reaction: Microbial Fuel Cells in thermoplastic made microfluidic devices.

II. CULTIVATION: ORGANISM-ON-A-CHIP

Cells, capable of dividing and increasing in size, continue to grow when the appropriate media and conditions are available. It is generally accepted that, a single cell is the building block for human life. Every cell includes a genetic material that holds the secret to inherited diseases. Scientists have improved the methods of studying the behavior of single cells. The effects of the amount and type of the nutrients, temperature, humidity, and gaseous atmosphere on cells can be investigated to provide optimum cultivation conditions. The cell's response in a culture is measured to reveal the relation between other kinds of cells, carcinogenic agents or, eventually, drugs. Nowadays, these experiments can be conducted in precisely controlled micro-environments, where a low volume of sample and energy are needed. High-throughput screening can also be conducted in these microfluidic devices.39,40

A. Culturing of bacterial cells

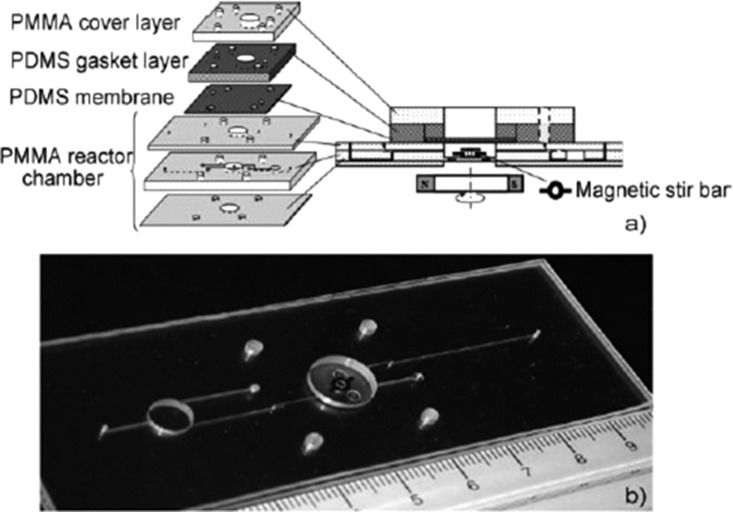

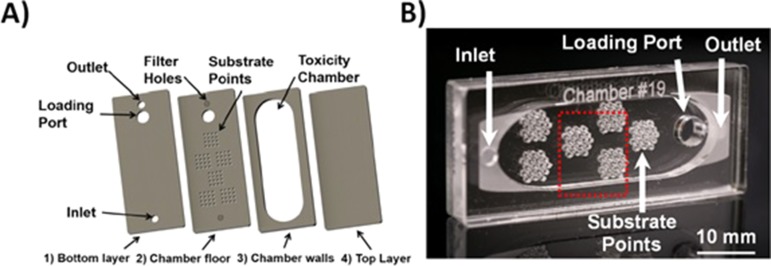

Cell culturing experiments have been conducted with several living organisms. In 2005, Szita and his colleagues fabricated PMMA and PDMS made microbioreactors to monitor bacteria cells, Escherichia coli (E. coli). A multiplexed microbioreactor system including magnetic motors for magnetic stirring and optics to observe the optical density (OD), were used to measure the parameters, dissolved oxygen (DO), and pH, during fermentation. The system can make four parallel microbial fermentations.41 Another study with bacteria cells in a polymer-based microbioreactor system is capable of measuring optical density (OD), pH, and dissolved oxygen (DO) in real-time. Continuous cultivation of E. coli was done in a microbioreactor of 150 μl volume with membrane aeration. The device consists of PMMA and PDMS layers with three connecting microchannels of 250 μm height and 250 μm width (Fig. 1). The surface modification of the PMMA and PDMS parts of the device was conducted via poly(ethylene glycol)-grafted poly(acrylic acid) (PAA) copolymer films to obtain bio-inert surfaces resistant to non-specific protein adsorption and cell adhesion. This surface modification reinforced the cultivation time and prevented wall growth of the cells.42

FIG. 1.

(a) Schematic view of the microfluidic system. (b) Photograph of the PMMA chamber. Reproduced with permission from Zhang et al., Lab Chip 6, 906 (2006). Copyright 2006 Royal Society of Chemistry.

In 2010, glass slides and polymer films were used to create low-cost and detachable microfluidic chips by applying adhesive wax as a bonding material. This biocompatible wax-based microfluidic chips were used to perform PCR tests and to culture GFP-tagged (Green fluorescence protein) E. coli to see the effect of the antibiotic ciprofloxacin concentration on the E. coli migration. The fluorescence expression was found to decrease as the ciprofloxacin concentration increased in the reagent cell. Otherwise, E. coli cells survived 15 days in the chip without any leakage.43 In the same year, Skolimowski and his colleagues built a five layer microfluidic chip allowing gas transition and examined the active oxygen depletion. Simulations were performed via COMSOL Multiphysics 3.5a to follow the relation between O2 generation and measured oxygen concentration. Pseudomonas aeruginosa bacterium was used in the microchip to examine the growth patterns under different oxygen concentrations. A GFP-tagged bacterium was allowed to grow in the flow chambers of the device. The oxygen concentration affected the attachment of bacterium to the substrate.44 The drug resistance of several bacterial strains E. coli, Shigella flexneri, Shigella boydii, Shigella sonnei, and Uropathogenic E. coli was tested using the Resazurin dye reduction method (RRM) as the colorimetric antibiogram in the PMMA microfluidic system and 96-well microtiter plates. Bacteria suspensions were inoculated into the wells of both the 96-well plates and the microfluidic device. Visual and OD620 results of the microfluidic system and 96-well microtiter plates were compared with the standard turbidity tests. The data obtained from both systems were compatible with each other, so the developed microfluidic device can be used in the determination of the antibiogram of the drug-resistant bacteria.45 Recently, the determination of E. coli K12 concentration was done by using positively and negatively charged electrospun poly(vinyl alcohol) (PVA) nanofibers in PMMA made microchannels. Fiber distribution and fiber mat height on analyte retention were also examined. In order to have a large surface area for analyte concentration and to obstruct size-related retention of the E. coli cells, the 3 D morphology of the mats was improved. Positively charged nanofibers showed better performance than the negatively charged ones. Then, the negatively charged nanofibers were customized with anti-E.coli antibodies, and consequently they became capable of specific capturing the bacterial cells.46

B. Fungi cultivation

PMMA made microfluidic devices were also employed for fungi cultivation. As a new approach for the cultivation, monodispersed agar beads were produced by using a temperature-controlled microfluidic device with 5 layers. The dimensions of the agar beads were determined by the flow, which can be dispersed or continuous (Fig. 2). These agar beads were used as the substrate for the Cordyceps militaris cells. This technology is seen as a promising one because several experiments can be performed, like encapsulating biomaterials, enzymes, and drugs into agar beads, for biomedical applications.47 In another study on fungal and bacterial cells, Bolic et al. developed a milliliter-scale bioreactor (0.5–2 ml volume) consisting of gas connections, heater, temperature sensor, optical fibers, magnetic stirrer, and optical sensors. pH, dissolved oxygen, and optical density can be measured and the system is capable of aeration and mixing. The performance of the device was evaluated by considering mixing time, residence time distribution, and oxygen transfer rates in several conditions. The mixing time was determined as 0.4 s - 2 s, and the oxygen transfer rate was 1000 h−1. Bacterial and yeast cells (Lactobacillus paracasei and Saccharomyces cerevisiae (S. cerevisiae) cells) were successfully cultivated in the device.48

FIG. 2.

(a) The 5 layers of the microfluidic device. (b) Assembled view of the temperature-controlled chip. Reproduced with permission from Lin et al., Electrophoresis 32, 3157 (2011). Copyright 2011 Wiley Online Library.

By using ultrasonic hot embossing and welding techniques, microfluidic devices made from PC were fabricated and the functionality of these devices was shown via yeast cultivation experiments. Cells survived at least 22 h in the device and enhanced green fluorescent protein (eGFP) expression was observed with a supply of the inducer galactose. It was proven that, ultrasonic processing can be used for microfluidic device fabrication in the future to conduct microbial analysis.49

C. Zebra fish cultivation

The zebrafish is the most used vertebrate model organism in scientific studies. Zebrafish (Danio rerio), which can be used for drug research and environmental toxicology studies, was investigated for its developmental analysis in a 3 D multilayer microfluidic system. By using this system, one embryo can be kept in one trap and each of these embryos can be encoded. On a large scale, it is possible to make high-throughput docking and recovery of single embryos. The device included conical traps of 2 mm in diameter at the top plane and 1.6 mm in diameter at the bottom plane. Wild type and GFP tagged Tg(fli1a:EGFP) zebrafish embryos were trapped, and kept for 3 days via active suction-based immobilization and then analyzed. 100% trapping of the cells was attained successfully, and these cells kept their positions during the 72 h experiments. This system can also be adapted to the kinetic analysis of pharmacological agents prohibiting blood vessel growth (angiogenesis) in zebrafish.50,51 In 2013, another PMMA made microfluidic device for zebrafish was developed, and Environmental Scanning Electron Microscope (ESEM) imaging was used to observe the zebrafish larvae. There were an engraved reservoir, 36 circular microwells, and 6 microchannels in the chip. The reservoir with the multiple semispherical microwells, located in the device, was to keep the larvae and to drain the excess medium. In order to activate the device, a paper filter was used, and the trapping of the larvae was achieved by the suction of the cells due to water drainage. This microfluidic system was important for the ESEM imaging for prospective laser microsurgery and tissue regeneration. However, the experiments were not successful due to the damaged tissues under a low vacuum environment, and more optimization was needed to make ESEM imaging without tissue damage.52 In 2014, Akagi et al. developed another microfluidic system to trap and immobilize the transgenic zebrafish embryos with the help of low-pressure suction. The PMMA made microchip platform consisted of piezoelectric microdiaphram pumps, embryo-trapping suction manifold, drug delivery manifold, and tin oxide heating element. Gambit 2.3 and Finite-volume-based Fluent 6.3 softwares were used for computational fluid dynamics (CFD) simulations. Embryo loading and recovery were done in the main channel, single embryo trapping and immobilization were conducted in an array of 16 traps, and the drug delivery was done via a drug delivery channel. This system was capable of making rapid and automated manipulation of zebrafish cells for drug discovery.53 A year later, Akagi and his group improved their microfluidic system and this system was able to reveal the morphological features of the zebrafish larvae by employing ESEM imaging technology. Microwells were used to keep the yolk of the zebrafish larvae and microchannels were used to provide immobilization of the larvae.54 In another study on zebrafish, a continuous flow embryo sorter device capable of analyzing, sorting, and dispensing the zebrafish embryos was developed. In order to actuate the system, DC gearmotors with a D-shaped output shaft (3 mm diameter) were integrated into the system. In the main body of the device, a rectangular channel for embryo loading, sorter wheel and suction manifold for keeping the embryos in position during the rotation were located, whereas in the 3 D printed part, a DC motor and stainless steel ball bearings were present. Through this study, a new concept for rapid and automated zebrafish embryo sorting, and a device to do so, was introduced.55 An electronic interface integrated Lab-on-a-chip biomicrofluidic device was used to make automatic immobilization, cultivation, and treatment of zebrafish embryos. The design and optimization of the microfluidic device were done with the Gambit 2.3 CFD simulation program. The main channel for embryo loading, 20 traps for embryo trapping and immobilization, and a plenum suction manifold of 0.7 mm height for creating the drag force to immobilize the cells were located within the device. The Field Programmable Gate Array (FPGA) hardware/software controlled the cell loading and immobilization, flow dynamics, temperature, and image acquisition of zebrafish embryos.56 Furthermore, Zhu et al. fabricated a minimized high-throughput Lab-on-a-Chip microfluidic device to perform a fish embryo toxicity (FET) assay. The device had a 96-well microtiter plate, a main loading channel, and 21 miniaturized embryo traps. Gambit 2.3 and Finite-volume based Fluent 6.3 softwares were used to run CFD simulations. Rapid loading, separating, and immobilizing of the zebrafish cells in the traps, providing continuous perfusion and live imaging were done with this 3 D device. The off-chip interface carried peristaltic pumps, USB-imaging station, and ITO heaters. In addition, anti-angiogenesis drug tests were performed in this device, and the image acquisition was done with an imaging cytometer.57 Fluorescence Ratiometric Imaging (FRIM) technology was employed to develop the zebrafish embryos in a microfluidic device. FRIM technology can make the kinetic quantification of the aqueous oxygen gradients, and the oxygen consumption of the cells can be measured. The device included a main loading channel for embryo loading and toxicant transportation, 18 embryo traps of 1.5 mm × 1 mm sizes for trapping and immobilization, a suction manifold with the interconnecting channels and a sensing manifold with Presens Sensor Foils. This microfluidic system can be used to reveal the metabolism and physiology of the cells in the future.58

D. Fruit fly (drosophila) cultivation

In 2016, a PMMA made microfluidic device for Drosophila was fabricated to study the actions of flies in the system. In the device, the chambers with visual and auditory stimuli were used to manage the liquid food presentations. A behavior chamber and a feeding alcove were placed in the chip for flies to feed from a microchannel. The behavior of the flies and microfluidic food channel were video recorded. According to the repeated experiments, the flies learned to access the food in a more direct way.59

E. Mammalian cell cultivation

For human cell and tissue culturing experiments, PMMA, PS, PC, and COC substrates were investigated as the biocompatible materials alternative to PDMS. In order to decrease the adsorption of hydrophobic compounds, UV-generated ozone or oxygen plasma surface treatments were done on the polymer substrates. The validity of the surface treatment was evaluated via the contact angle of water on the surface. In order to reveal the biocompatibility, human hepatoma (HepG2) cells were used on the treated surfaces of the microfluidic chips. After cultivation of the cells on well-plates, they were exposed to acridine orange and propidium iodide solutions for viability tests. PDMS and PMMA showed a lower recovery of the hydrophobic compounds. After surface treatment, HepG2 cells were stuck to the PMMA substrate due to the unstable peroxides on the PMMA surface after the treatment. PC and COC chips showed good performance about gas permeability and COC is better than PC due to its lower auto-fluorescence. Overall, PC and COC chips were mostly suitable for incorporation of cells and tissues.60 To study the co-cultured cell behavior, human U937 and MG-63 cell lines were employed where monitoring of real-time cytokine release, generation of a linear cytokine gradient for drug discovery, and non-contact co-culturing processes were accomplished.61 Shear-stress acting on the cells may give information about the dissolved oxygen (DO) level. Using HT1080 cells, the transportation of the oxygen through the fabricated microbioreactor was first investigated, then the low-shear stress at the cell level and oxygen tension of the materials and dimensions were regulated. There were two channels inside the microbioreactors, one of them is the culture channel placed in the bottom sheet, and the other one is the oxygen supply channel on the top plate. The number of cells and their viability (fluorescent live/dead staining), the cell density, and the circularity of the cells were investigated.62 HEK-293 T cells were cultivated in PDMS and PMMA microfluidic devices to reveal the optimum conditions for growth under several experimental conditions such as with or without the cell adhesion agent poly-D-lysine. Microchannel geometries, thicknesses, and flow rates in the devices were also evaluated. The PMMA chip had three distinct microchannel structures (linear, zigzag, and square waves) of 40 μm height × 0.4 mm width and 3.68 μl volume. The other chip had 40 μm height with serpentine structures of 100 μm width. The length changed between 10 and 80 mm and the volume was 17.8 μl. Poly-D-lysine increased the cell adhesion and viability under continuous or discontinuous flow. Cell adhesion was mostly seen in the corners of the microchannels and in large channels due to lower flow rate. This recent study provides an insight into the future studies on the microbioreactor design.63 In 2009, the hard top-soft bottom microfluidic devices were fabricated. Polyethylene terephthalate glycol (PETG) and cyclic olefin copolymer (COC) or PS were used as hard tops and the channels were imprinted by hot embossing. The hard tops were bonded to elastomeric PDMS or polyurethane (PU). The device included an X region and the height of this area was 200 μm while the height of other channels was 30 μm. HepG2 cells and C2C12 cells were cultured in the devices, and the cell survival was ∼100%.64 A microfluidic device made of polytetrafluoroethylene (PTFE) was fabricated to conduct the encapsulation of living, therapeutically active cells within monodisperse alginate microspheres. HEK293, U-2 OS, and PC12 cell lines (GFP tagged) were successfully encapsulated and loss of cell viability was minimum. High and medium guluronic acid concentrated alginate samples were more applicable to micro-reaction processes.30 Due to the limited functions of the PDMS polymer, conventional plastics are used to rapidly prototype microfluidic systems. Thermal scribing, a one-step fabrication method, was used to produce the PS made microfluidic devices. The applicability of the system was shown via induction of functional neutrophil extracellular traps (NETs). The experiments were helpful to understand the mechanism of neutrophil culture systems.65

1. 3 D culturing

Nowadays, cell cultures are created in a (3-dimensional) 3 D environment to imitate the in vivo conditions. 3 D cultured cells are more reminiscent of the native tissue from which they originated. They can conceive a more elaborate extracellular matrix and better intercellular communication.66,67 3 D cultured cells are independent of the cell density in contrast to 2 D cultured cells. A 3 D cell culture-based chemosensitivity assay was performed in the microfluidic cell culture chip, which contained 36 microbioreactors. Human colorectal adenocarcinoma cells were loaded to the microfluidic device to obtain information about the micro-scale perfusion of the 3 D cell culture and chemosensitivity assay. This platform provides stable, well-defined, and a biologically more relevant culture environment to perform high-precision and high-throughput 3 D cell-culture based assays.68 Huang et al. developed another high-throughput 3 D microfluidic cell culture system including 30 microbioreactors. The system was capable of implementing durable thermal conditions for cell culturing and efficient sample loading, and contained multiple medium perfusion mechanisms with a waste medium collector for bioassays. The microchannels were used to deliver the medium into the microbioreactors or to the waste reservoirs. In the fabricated device, the chemosensitivity assay, the DNA content detection (via fluorescence labeling) and viability experiments were conducted by using a human oral cancer cell line (OEC-M1).69 High-throughput 3 D cell culture, drug administration, and quantitative in situ assays were conducted in a micro-scaffold array system. The microfluidic device included sponge-like micro-scaffolds for absorption of cell or drug loading as well as for avoiding cell loss during medium exchange. The device had a 96 microwell array with 2 mm diameter on the top layer for culture and drug medium, and had a smaller 96 microwell array with 1.5 mm diameter on the bottom layer for the 3 D cell culture. RFP-labeled NIH3T3 fibroblasts, human fibrosarcoma cells (HT1080), human hepatocellular carcinoma cells (HepG2), and human non-small lung cancer cells (NCI-H460) were cultured in this device, and the cells were stained with fluorescence for imaging. In this system, cancer cells showed higher drug resistance than those on the planar high-density multiwall plates (2 D). These 3 D cultured cells were independent of the cell density in contrast to 2 D cultured cells.70 Nery et al. developed a flow-through sensor array to perform cell viability and cell toxicity tests in a microbioreactor system. Cell toxicity experiments were conducted with A549 cells treated with 1,4-dioxane and 5-fluorouracil. In order to enhance the functionality of the device, rectangular obstacles of 0.35 mm × 1.2 mm dimensions were placed in the microchannel. The comparison of the system with the standard methods indicated that this system can be successfully used to carry out cell culture monitoring and drug testing experiments after toxic treatment.71

2. Nanoparticles (NPs) in microfluidic platforms

Nanoparticle (NP) study is very popular in scientific research. NPs find a place in potential applications of biomedical, optical, and electronic fields. NPs build a bridge between the bulk materials and atomic or molecular structures, and they provide a high specific surface area, high reactivity, and rapid diffusion.72 Koh et al. worked with NPs to examine the Bcl-2 down-regulation at the mRNA and protein levels with cellular uptake and apoptosis by using K562 human erythroleukemia cells and G3139 as the drug, and they produced a multi-inlet microfluidic hydrodynamic focusing (MF) system. The lipopolyplex (LP) nanoparticles produced via the MF method were smaller than those produced by the bulk mixing (BM) method. In addition, Bcl-2 antisense uptake was higher in MF LP nanoparticles and these nanoparticles were more influential in the down-regulation of the Bcl-2 protein level than the BM LP nanoparticles.73 In order to increase the transmission of exogenous oligonucleotides (ODN) in vitro, the semi-continuous flow electroporation (SFE) chip was used with the liposome nanoparticles (LNs) containing the target ligand. K562 cells and transferrin-targeted lipoplex encapsulating ODN G3139 nanoparticles were mixed and incubated to increase the nanoparticle binding. In the fabricated microchip, electric pulses were applied during the mixture flow through the channel and Al pieces were used as both electrodes and channel walls in SFE. Since electroporation application makes cell membranes permeable, ODN transmission efficiency was higher when the non-targeted LNs and SFE were combined rather than utilizing targeted LNs alone.74

3. Electric field (EF)-based microfluidic systems

Electrophoresis, electroosmosis or electroporation are generally applied to manipulate the biological cells and record their responses.75 An electrotaxis study was conducted in a microfluidic cell culture chip. Two types of chips were used: the single-field chip (SFC) consisted of only one microchannel of 3000 μm width, 70 μm height and 15 mm length. The multi-field electrostatic chip (MFC) included a cell culture microchannel of 24 mm length, having three segments of 5000, 1667, and 1000 μm dimensions. In SFC, three distinct electric fields (EFs) were applied and the cellular response was recorded. Numerical simulation was done via the CFD-ACE+ software and the results were compared with those of the measured ones. In the MFC chip, CL1–5 and CL1–0 lung cancer cell lines were used, and these two cancer cell lines gave distinct answers under different Efs.76 A multilayer contactless dielectrophoresis (cDEP) system was developed, where sample and electrode channels were placed on different layers. Several simulations were performed via COMSOL and the results were validated experimentally. The developed device had identical characteristics with the other cDEP devices and was capable of increasing fluid throughput. The limiting elements in these devices were the breakdown voltage of the barrier material and the capability of producing high-voltage/high-frequency signals. The ultimate aim was to immobilize the cells in the saw tooth structure with the application of the electric field. When the electric field was applied, individual cells (MDA-MB-231 human breast cells) began to create the pearl chains, and they travelled through the saw tooth structure for trapping. The difference of this device from other devices was that the fluid electrodes and the sample channels were separated from each other by a thin film.77 For cell trapping, a stable electrode with a salt bridge was combined with the microfluidic sensor chip. HEK293 cells were used in this system and the PMMA device was fabricated. By using FIB milling, the micropores were created at the middle of the cell trapping area to form the incubation-type planar patch clamp. The laser-induced channel currents of channel rhodopsin wide receiver (ChRWR) expressing the HEK 293 sensor cell were measured. The results were compared with the pipette patch clamp design, and they were found to be compatible with each other.78 In another study, a PMMA cell culture microchip and a multichannel lens-free CMOS (complementary metal-oxide semiconductor)/LED imaging system were combined to monitor the cell growth. The LabVIEW program was used to manage the CMOD/LED imaging system. HepG2 cancer cells were tested in this system, and cytotoxicity experiments were conducted by using cyclophosphamide solution at several concentrations. Cell proliferation in the device was monitored, and cell growth was successfully obtained under different environmental conditions.79 In the same year, a 1 D scanning detector and a parallel array of flow channels were coupled to create the parallel microfluidic cytometer (PMC) for cell screening assays. A live-cell translocation assay using a NF-kB/GFP fusion protein in Chinese hamster ovary cells, CD3/CD28 receptor capping in Jurkat cells, and nuclear translocation of NF-kB in Jurkat T-cells employing an antibody label were successfully cultured in this system.80

Micro-optical tweezers (μOTs) were combined with the microfluidic device for trapping as well as for accomplishing the mechanical and chemical spectroscopic analyses of the cells. The microfluidic device was made of hybrid PMMA and glass, and μOT achieved the trapping and exciting of the Raman and fluorescence response of the cells. Microprism reflectors were created by Two Photon Lithography (TPL) on the fiber facets to create optical trapping inside the microfluidic device. Red blood cells (RBCs) and tumor cells were used in the system, and the device was capable of trapping cells by setting the power output at each prism at 5 mW. In addition, monitoring of the single cell response with different environmental stress can be conducted.81

There are several advantages of using microfluidic devices for culturing experiments. Most importantly, scientists can make high-throughput analysis by using a single device. These devices allow one to conduct parallel experiments. Experimental conditions such as temperature, cultivation time, and oxygen or pH level settings can be arranged more precisely. In order to monitor the cell growth during cultivation, several imaging technologies, i.e., ESEM or FRIM, can be integrated into the microfluidic devices. Rapid loading, separating, immobilizing of cells, and continuous perfusion through the device can be realized fairly easily. Cell manipulation and cell response observations can be made instantly via these microfluidic devices. In vivo conditions can be created in the 3 D culturing chips, and experiments can be done in a stable, well defined, and biologically relevant culture environment to obtain high-precision and high-throughput.

F. Tissue engineering (TE)

Since the beginning of the 21st century, bio-based materials have been used in many research fields. Healthcare facilities need continuous innovations and the engineering applications in new materials contribute to the development of such innovations. According to the statistics, 100 000 people are on the donor waiting list and 22 people on an average die every day due to insufficiency in organs or tissues. Over the past decade, tissue engineering has made subtle progress in finding solutions to these problems. The field of TE combines notions of materials science, engineering, medicine, and biology to improve cell, tissue, and organ performance.82–84

The first tissue engineering study involving PMMA in the microfield was developed by Dalby and his colleagues. The reaction between primary human osteoprogenitor cell populations and nanotopographies of 10 nm in size was examined. Colloidal lithography and polymer demixing on silicon was used to generate the topographies and then they were hot embossed on PMMA. The cell morphology, cell cytoskeleton, adhesion formation, cell growth, and differentiation were studied using human bone marrow cells.85 The microfabrication and microcontact printing methods were combined to create a spherical organoid (spheroid) microarray culture system. Cylindrical cavities of 300 μm diameter were placed in the chip and these cavities were characterized as being either a supporter or inhibitor of the cell adhesion. Collagen (Col) and polyethylene glycol were used to generate the adhesive and non-adhesive regions in the chip, respectively. Primary hepatocytes were produced as identical spheroids in the middle of the cavities, and hepatocytes were produced as the cuboidal shaped organoids, similar to the in vivo experiments.86 The chitosan microfibers coated with collagen are necessary for cell cultivation, and can be produced in PMMA made microfluidic devices. One of these devices was fabricated with a 45° cross-junction microchannel to pass the chitosan solution and sodium tripolyphosphate (STPP). Hydrodynamic focusing was used to create the laminar flow. Schwann cells and fibroblast cells were cultured in these chitosan microfibers, which created a satisfying environment for the cells. In tissue engineering applications, they can be used as the scaffold for cell cultures.87 In the study on prosthetic cornea matter, PMMA was treated with the help of polydopamine-based adhesive surface chemistry for the improvement of the biointegration of soft tissues. Polydopamine (PDA) treatment with cell adhesive peptide RGD (PDA-PEG-RGD) increased the corneal epithelial cell proliferation and keratocytes. Adhesion to the collagen gels was achieved by PDA but was not achieved by PDA-PEG-RGD and untreated PMMA. When the subcutaneous implantation was applied, tissue reaction to polydopamine-coated surfaces was benevolent even after 45 days. Tissue integration of implants with soft tissues can be operated with polydopamine-based surface chemistries.88 Microengineering of vascular structures was also investigated in microfield studies by the combination of self-assembled monolayer (SAM)-based cell transfer and gelatin methacrylate hydrogel photopatterning methods. Two SAM desorption tools, which are photoinduced and electrochemically triggered, were displayed during the transfer of human umbilical vein cells (HUVECs) from oligopeptide SAM-coated surfaces to the hydrogel. In order to generate the microvascular structure, a perfusion culture chamber made of PMMA was used. This study can be seen as a good start for more complex, vascularized tissue constructs for regenerative medicine and tissue engineering applications with the combination of SAM-based cell transfer and hydrogel photocrosslinking.89 Microfluidic hydrogels with helical microchannels were produced and their perfusion features were evaluated both experimentally and numerically (COMSOL Multiphysics V4.2). Helical microchannels and straight microchannels were compared with each other by means of cell viability and post-encapsulation. The cooled agarose solution was injected into the PMMA chamber, and fabricated via the laser etcher. In order to have different sized helical microchannels, several helical springs were employed. Rhodamine B solution and the NIH 3T3 cell line were used to reveal the diffusion property and the cell viability under the perfusion culture of microfluidic hydrogels, respectively. Helical microchannels were better than straight microchannels in perfusion ability and oxygen and nutrient delivery to cells.90 Two different kinds of nanoengineered polystyrene surfaces (NPS), including nanopillar (NPS-Pi) or nanopore (NPS-Po) were fabricated to study the topographical effects of surfaces on MC3T3-E1 cells. When compared with the flat substrates, NPS has serious effects on cells in terms of the cell morphology, attachment, proliferation, and osteogenic differentiation. In addition, cell proliferation and osteogenesis differentiation were better in NPS-Po.91 By using the microinjection molding technique, osteoinductive micro-pillared PS surfaces were fabricated for bone replacement operations. Micro topography parameters, pillars diameter, aspect ratio, and spacing, were evaluated according to MC3T3-E1 cell adhesion and proliferation criteria after 1, 3, and 7 days from seeding. It is observed that, micro-pillared surfaces were better than flat surfaces.92 In 2013, another study on tissue engineering was done by Sivashankar et al. A 3 D microfluidic system capable of continuous perfusion was established to monitor liver tissue cultures. The microfluidic device included PMMA microbioreactors which were connected with each other, and poly(ethylene glycol) diacrylate (PEG-DA) microstructures with mesothelial cells were placed in these microbioreactors. The major roles of the mesothelial cells were to contribute to the adhesive surface and help tissue repair. The hematoxylin and eosin (H&E) staining method was used to stain the tissue parts, and the terminal deoxynucleotide transferase (dUTP) nick end labeling (TUNEL) assay was utilized to monitor the DNA fragments. The liver tissue conserved its viability after twelve days of culture.93 Primary human alveolar bone osteoblast (PHABO) morphogenesis was investigated in both microchip-based 3 D-static conditions and 3 D-fluid flow-mediated biomechanical stimulation in perfusion bioreactors. The morphogenesis of the PHABO was evaluated by respective imaging, fluorescence based live/dead staining, and SEM and time-lapse imaging techniques. Cubic microcavities of 300 μm length were placed in the microstructured area in the PMMA made microfluidic device. In static cultures and fluid-flow mediated cultures, PHABO showed different morphogenesis, and mechanobiological studies under hard tissue-specific environments stimulate the osteoblasts to the bone phenotype.94 In 2013, a mechanical microconnector system (mMS) was created to regulate the retracted spinal cord stumps. This system was made of PMMA to fill the spinal cord tissue gap after transection. The two discs consisted of 55 small and 15 large honeycombs. The spinal cord stumps were sent through the honeycomb-structured holes by the negative pressure utilization at the outlet tubing system of the mMS and these stumps kept their location in the mMS walls. Axonal regrowth was achieved after 2, 5, and 19 weeks with the mMS, and in-bleeding or cyst was not observed.95

In 2015, a new cell line was created by combining spheroids and tissues in a microfluidic device without the need for scaffolds or metabolic biosynthesis. Liposome fusion, bio-orthogonal chemistry, and cell surface engineering were used in the device by taking advantage of click chemistry. The device has a Y-shaped channel to mix the cell suspensions including C3H10T1/2 stem cells. By using this system, bio-orthogonal chemical groups with the help of click chemistry were created in a rapid, straightforward, and flexible way.96 In another bone-related study, several parameter effects on the vascularization of bone-mimicking tissues were investigated. The design aims to create a link between the macroscale and microscale tissue engineering studies. Here, the effect of endothelial cell (EC) density, cell ratio among ECs, mesenchymal stem cells (MSCs) and osteo-differentiated MSCs, culture medium, hydrogel type, and tissue geometry parameters were researched. The geometry and oxygen gradient of the hydrogels were optimized by using computational simulations (Rhinoceros and COMSOL), and the analyses of microvascular network features were done. Mcells/ml ECs, 10:1:0 cell ratio, osteo-medium, 2 × 2 × 5 mm3 cage, and 2.5 mg/ml fibrin (60%) + collagen (40%) hydrogels were the best choices to produce bone-mimicking pre-vascularized matrices. Isolation of specific cellular populations and genetic analyses can be conducted in this system.97 Although PDMS is a preferred polymer for cell-based research, it has adverse effects on cells due to high gas permeability and surface hydrophobicity of the material. Therefore, the performance of a PS made microfluidic device was tested and compared to that of PDMS. In this process, COP (at the bottom) and cellulose acetate (CA) were used to flatten the surface and prevent adhesion between PS and COP, respectively. Human umbilical vein endothelial cell (HUVEC) culturing in one application and blood neutrophils under chemoattractant exposure observation in another application were conducted. The results showed that, PS made microfluidic devices can be used for long-term cell studies.98 A microfluidic platform with improved 3 D gel capabilities, controlled surface properties, and better high-volume functions was produced in COC via commercially viable fabrication methods. Human microvascular endothelial cells (hMVECs) were used in the experiments and the results showed that COC has no negative effect on cells like PDMS devices.99 A multi-organ-tissue-flow (MOTiF) biochip including a perfusable membrane was constructed in COC to be used in cell culture experiments. Nutrition medium supply, catabolic cell metabolites removal, and shear stress application on endothelial cells (ECs) can be achieved. The results obtained on cell viability, EC marker protein expression, and adhesion of ECs under low and high shear stress environments were compared with the two-dimensionally perfused flow chambers under a stable environment. The MOTiF biochip provided higher cellular density in monolayer with increased cell layer thickness.100 A body-on-a-chip device was also produced to imitate the drug distribution and metabolism processes in the body. A pumpless 14 chamber (chambers were considered as distinct organs) microfluidic cell culture device was fabricated to conduct the separation between the barrier and nonbarrier cell cultures as well as to reveal the interactive responses between the cell lines. A549 (liver) and Caco2 (GI) represented the barrier lines and HepG2 C3A (liver), Meg01 (bone marrow) and HK2 (kidney) represented the nonbarrier lines. The device, comprised of polycarbonate frame, 0.5 mm thick two layer silicon gaskets for cell/organ chambers, 0.25 mm thick two layers of PMMA gaskets for channels, a porous PC membrane, and 1.6 mm thick silicone gaskets. Cell lines lived 7 days in the device. By using this system, the usefulness of building, managing, and cultivating a multi-organ microphysiological system was proved.101

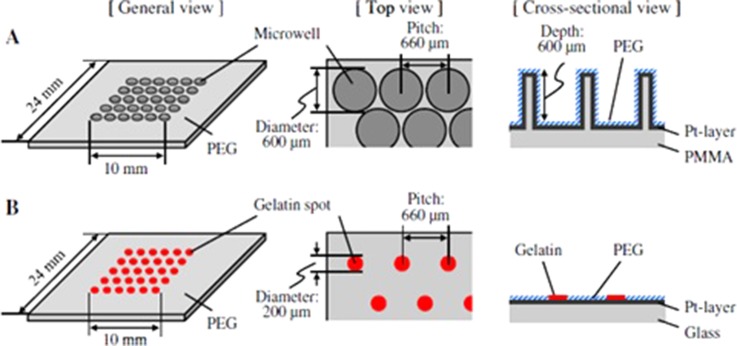

Microwell chip and micropatterned chip were operated and compared by monitoring the proliferation and differentiation characteristics of the embryoid bodies (EB) obtained from the mouse embryonic stem (ES) cells (Fig. 3). The microwell chip had 270 microwells (each 600 μm in diameter and depth). In order to coat the surface with PEG, the chip was immersed into the 50% ethanol solution of 2.5 mM PEG with a thiol group. For the micropatterned chip, 270 gelatin spots (200 μm in diameter) were created on the glass substrate via microcontact printing. The remaining area was again coated with PEG to increase the nonadhesive property. A high cell growth rate and expression of the endotherm as well as an increment in the mesoderm markers were seen in the EBs in the micropatterned chip. The proliferation and differentiation of the EBs may vary from design to design.102 Another microdevice was developed to produce spheroids with almost the same size, and this device was capable of transferring these spheroids from a floating situation to a micropatterned adherent culture. 270 microwells, which were PEG treated to obtain the nonadhesive surface, were located on the PMMA frame and PDMS sheet. On the PMMA frame, the microwells were created via programmable micro-milling technology. On the bottom of the PMMA frame, PDMS was bonded. In this study, first mouse ES cells and then 3T3 cells, HepG2 cells, and primary rat hepatocytes were sequentially produced as spheroids in each microwell chip. This technology can be auspicious in spheroid studies.103 The polymer surfaces, which have changeable cell-attractive and cell-repellent characteristics, were used for local lift-off of the mammalian cells. In order to implement the cell adhesion, colloidal microgels were used to create micropatterned thermoresponsive polymer coatings. The microgels of 200 μm were fabricated through automated nanodispensing or microcontact printing (μCP). The microfluidic device was made of a PMMA plate, a double sided sticky pressure-sensitive adhesive (PSA) foil, and a glass with microgel patterns at the bottom. The microchannel was created on the PSA foil of 86 μm height, 500 μm width, and 1 cm length. L929 mouse fibroblasts were cultivated and the cell detachment was accomplished via both of the coating strategies depending on the temperature shift. The lower limit of the surface coverage was determined by changing the average microgel distance and the cell detachment efficiency.104

FIG. 3.

(a) Microwell designed chip. (b) Micropatterned chip. Reproduced with permission from Sakai et al., J. Biosci. Bioeng. 111, 85 (2011). Copyright 2011 Elsevier.

In another study on cell attachment and alignment using physically microstripped-nanoengineered polystyrene surfaces (PMS-NPS), the PMS-NPS was produced via nano-injection molding, UV-photolithography, and electroforming methods. Controlled MG-63 cell attachment and alignment were conducted by biophysical cue (without biochemical cue) and PMS-NPSs were found to be better than flat PS surfaces.105 In order to study the cell-nanoengineered surface (NES) interactions, PS nano Petri dishes were fabricated. During mass fabrication via nano-injection, the Taguchi method was used to evaluate the fabrication parameters as well as to optimize and conduct efficient and reliable cell culture studies. MG-63 cell attachment and proliferation was examined in nano Petri dishes including nanopore arrays with and without the oxygen plasma treatment. The nanopore array surface gave better performance than the flat surfaces for cell attachment and proliferation.106

The advantages of the microfluidic platforms employed for tissue engineering studies can be summarized as the effective management of multi-organ microphysiological systems, biointegration of soft tissues, tissue integration of implants, microengineering of vascular structures, monitoring parameter effects on the vascularization of bone-mimicking tissues, isolation of specific cellular populations, and imitating the drug distribution and metabolism processes in the body. This part is summarized in Table II.

TABLE II.

Summary table of CULTIVATION: Organism-on-a-Chip part.

| Format | Microorganism | Material used | Fabrication techniques | Dimensions | Comment | Reference |

|---|---|---|---|---|---|---|

| Multiplexed microbioreactor | E. coli | PMMAPDMS | Milling Hermetical sealing | 150 μl reactor chamber | OD, DO and pH measuring 4 parallel microbial fermentation | 41 |

| Microbioreactor | E. coli | PMMAPDMS PAA | CNC milling Thermal bonding | 150 μl reactor chamber | OD, DO, pH measuring Reinforced cultivation time and prevented wall growth of the cells | 42 |

| 3D microfluidic chip | HeLa E. coli | PMMAPC | Laser cutter Wax bonding | 2 mm width and 500 μm height of chamber | PCR, HeLa cell EP and E. coli culturing Effect of ciprofloxacin concentration on E. coli | 43 |

| Microfluidic chip | Pseudomonas aeruginosa | PMMAPDMS | Laser ablation Adhesive tape for sealing | 150 μm thick cell culture chamber | Chip allows the gas transition Active oxygen depletion examination | 44 |

| Microfluidic chip | E. coli Shigella flexneri Shigella boydii Shigella sonnei Uropathogenic E. coli | PMMA | CO2 laser cutter glue bonding | 5 mm in diameter and 800 μm in the height of reservoir | Drug resistance testing of several bacterial strains Comparison of the microfluidic system and 96-well microtiter plates | 45 |

| PMMA made microchannels | E. coli K12 | PMMA | Hot embossing UVO-assisted thermal bonding | 42 μm height, 1 mm width and 20 mm length of microchannels | Positively charged nanofibers were better than negatively charged ones | 46 |

| Microfluidic chip | Cordyceps militaris | PMMA | CO2 laser machine Screw binding | NA | Monodispersed agar beads for cultivation | 47 |

| Milliliter-scale bioreactor | Lactobacillus paracasei S. cerevisiae | PMMAPDMS | CNC machining PDMS for sealing glue for bonding | 0.5–2 ml bioreactor | OD, DO, pH measuring. Aeration and mixing capability | 48 |

| Microfluidic chip | S. cerevisiae | PC | Ultrasonic hot embossing Ultrasonic welding | Microchannels with a depth between 50 μm and 1 mm and a width between 100 μm and 3 mm | eGFP tagged protein monitoring with a supply of the inducer galactose 22 h operation in the device | 49 |

| 3D multilayer microfluidic system | Zebrafish (Danio rerio) | PMMA | Infrared laser machine Thermal bonding | Conical traps of 2 mm in diameter at the top and 1.6 mm in diameter at the bottom planes | One embryo in one trap 100% trapping of the cells 72 h experiments | 50, 51 |

| Microfluidic chip | Zebrafish (Danio rerio) | PMMA | High-speed infrared CO2 laser cutting Thermal bonding | 0.75 mm in diameter and 0.5 mm in height of microwells | ESEM imaging Damaged tissues under a low vacuum environment | 52 |

| 3D microfluidic chip | Zebrafish (Danio rerio) | PMMA | Infrared laser machine Thermal bonding | 1.7 mm × 1.5 mm × 55 mm of main channel | Rapid and automated manipulation of zebrafish cells for drug discovery | 53 |

| Microfluidic chip | Zebrafish (Danio rerio) | PMMA | CO2 laser cutting | 36 circular microwells (0.75 mm in diameter and 0.5 mm in depth | Microwells for keeping zebrafish yolk revealing morphological features of zebrafish via ESEM imaging | 54 |

| 3D multilayer microfluidic chip | Zebrafish (Danio rerio) | PMMA | Infrared laser micromachining Thermal bonding | Suction manifold of 0.5 mm width and 1.8 mm height | Analyzing, sorting and dispensing of cells | 55 |

| 3D multilayer microfluidic chip | Zebrafish (Danio rerio) | PMMA | Laser micromachining Thermal bonding | 20 miniaturized traps and 1.7 mm × 1.5 mm × 55 mm of main channel | Making automatic immobilization, culture and treatment of cells | 56 |

| 3D multilayer microfluidic chip | Zebrafish (Danio rerio) | PMMA | Infrared laser micromachining Thermal bonding | 96-well microtiter plate 21 miniaturized traps of 1.5 mm × 1 mm | FET assay performing Rapid loading separating immobilizing of cells and continuous perfusion Anti-angiogenesis drug tests | 57 |

| 3D multilayer microfluidic chip | Zebrafish | PMMA | Infrared laser micromachining | 18 embryo traps of 1.5 mm × 1 mm | FRIM technology for kinetic quantification of the aqueous oxygen gradients | 58 |

| Small-animal Nutritional Access Control (SNAC) chip | Drosophila melanogaster | PMMA | CNC machining Thermal fusion bonding | Behavior chamber of 20 mm × 15 mm × 2 mm Feeding alcove of 400 μm width | Studying the actions of flies | 59 |

| Microfluidic chip | HepG2 | PMMAPS PC COC | Hot embossing Thermal bonding | 3.5 μl culture chambers | Investigation of biocompatible materials | 60 |

| Microfluidic coculture chip | Human U937 and MG-63 cell lines | PMMA | CO2 laser scriber Thermal bonding | Trenches of 200 μm in height and width | Studying coculture behavior | 61 |

| Microbioreactor | HT 1080 | PMMA | Milling Double sided adhesive tape | Culture channel of 4 cm × 300 μm × 300 μm | DO level and shear-stress acting on the cells investigation | 62 |

| Microfluidic chip | HEK-293T | PDMS PMMA | PDMS: silicon wafer mold + high frequency generator PMMA: CO2 laser etching | Microchannels of 40 μm H × 0.4 mm W Microchannels of 40 μm H × 100 μm W | Revealing optimum conditions for growth under several experimental conditions | 63 |

| Hard-soft hybrid material microfluidic chip | HepG2 C2C12 | PETG COC PS | Hot embossing Soft lithography Argon and oxygen plasma | X region of 200 μm height | Combination of hard and soft materials Cell culturing ∼100% cell survival rate | 64 |

| Microfluidic chip | HEK293 U-2 OS PC12 | PTFE | CNC machining Stainless steel clamping | Fluidic input channels of 500 μm2, opening out of 1000 μm2 | Encapsulation of living, therapeutically active cells within monodisperse alginate microspheres | 30 |

| Microfluidic chip | IMR-90 fetal lung fibroblast Human neutrophils | PS PDMS | Thermal scribing | Microchannel of 500 μm width, 250 μm height and 25 mm length | Understanding the mechanism of neutrophil culture systems | 65 |

| Microfluidic chip | Human colorectal adenocarcinoma cells | PDMS PMMA | CNC machining Replica molding Oxygen plasma | 36 microbioreactors of 1.5 mm in diameter and 1 mm in height | High-throughput 3D cell culture and chemosensitivity assay | 68 |

| Microfluidic chip | Human oral cancer cell line | PDMS PMMA | CNC machining Replica molding Oxygen plasma | 30 microbioreactors of 3 mm in diameter and 2.5 in height | High-throughput 3D cell culture system Chemosensitivity assay DNA content detection Viability experiments | 69 |

| Micro-scaffold array chip and Drug laden chip | NIH3T3 fibroblasts Human fibrosarcoma cells Human hepatocellular carcinoma cells Human non-small lung cancer cells | PMMA | CO2 laser system | 96 microwell array of 2 mm in diameter | 3D cell culture Drug administration Quantitative in situ assays | 70 |

| Microbioreactor | Human lung adenocarcinoma epithelial cell line (A549) | PMMA | Micromilling Screw binding | Rectangle obstacles of 0.35 mm × 1.2 mm in microchannel of 0.8 mm × 0.35 mm | Cell viability and cell toxicity tests Drug testing experiments | 71 |

| Microfluidic chip | K562 human erythroleukemia cells | PMMA | machining Thermal bonding | Microchannel of 254 μm W × 150 μm H | NP study to examine the Bcl-2 down-regulation at the mRNA and protein levels | 73 |

| Semi-continuous flow electroporation (SFE) chip | K562 cells | PMMA | Hot embossing Lamination | Channels of 2 mm width | Increasing the transmission of exogenous oligonucleotides in vitro | 74 |

| Single field chip (SFC) and multi-field electrostatic chip (MFC) | CL1-5 and CL1-0 lung cancer cell lines | PMMA | CO2 laser ablation Double sided adhesive tape | SFC: microchannel of 3000 μm × 70 μm × 15 mm MFC: microchannel of 24 mm in length with 5000, 1667, 1000 μm in width segments | Electrotaxis study Distinct electric fields applications for cellular response | 76 |

| Microfluidic chip | MDA-MB-231 human breast cells | PMMA | NA | Barrier thickness of 60 μm ± 40 μm | Multilayer contactless dielectrophoresis system | 77 |

| Sensor chip | HEK293 cells | PMMA | Hot embossing FIB milling | Micropore of 1.5–2 μm in diameter | Cell trapping | 78 |

| Microfluidic chip | HepG2 cells | PMMA | CO2 laser ablation Double-sided adhesive tape Hot-press bonding | Rectangular cell culture chamber of 8 mm × 6 mm | Monitoring cell growth Cytotoxicity experiments | 79 |

| Parallel microfluidic cytometer (PMC) | Chinese hamster ovary cells Jurkat cells Jurkat T-cells | PMMA | Deep reactive-ion etching | Microchannel of 40 μm × 150 μm | Cell screening assays | 80 |

| Micro-optical tweezers (μOT) | RBC Tumor cells | Glass PMMA | Micromilling Solvent assisted bonding | Channels of 60 μm × 1 mm × 2 cm | Mechanical and chemical spectroscopic analysis | 81 |

| Nanotopography | Primary human osteoprogenitor cells | PMMA | Colloidal lithography Polymer demixing Embossing | 10 nm size topographies | Cell morphology, cell cytoskeleton, adhesion formation, cell growth and differentiation studies | 85 |

| Spheroid microarray chip (SM chip) | Hepatocytes | PMMA | Micromilling Press bonding | Cylindrical cavities of 300 μm | Production of spheroids by hepatocytes | 86 |

| Microfluidic chip | Schwann cells Fibroblast cells | PMMA | CO2 laser machining Screw bonding | Microchannel width of 200 μm, depth of the chip is 1.5 mm | Can be used as scaffold for cell cultures | 87 |

| Surface modification | Human corneal limbal epithelial cells (HCLEs) Human keratocytes | PMMA | Surface modifications with chemicals | NA | Adhesion of collagen gel studies | 88 |

| Microengineering vascular structures | Human umbilical vein cell (HUVEC) | PMMA | Gelatin methacrylate hydrogel photopatterning | NA | More complex, vascularized tissue constructs for regenerative medicine and tissue engineering applications with the combination of SAM-based cell transfer and hydrogel photocrosslinking | 89 |

| Helical and straight microchannels | NIH 3T3 | PMMA | Agarose solution for hydrogel fabrication Laser etcher | Chamber: 24 mm × 12 mm × 5 mm Wire diameter: 300 μm | Helical and straight microchannels comparison Better perfusion ability and oxygen and nutrient delivery to cells in helical microchannels | 90 |

| Surface modification | MC3T3-E1 | PS | Anodization Hot embossing Nickel electroforming | Nanopore structure with a diameter of 200 nm, depth of 500 nm | Studying the topographical effects of surfaces on MC3T3-E1 cells | 91 |

| Surface modification | MC3T3-E1 | PS | Injection molding | Several patterns with 2,3,4 μm diameter holes | Bone replacement operations Microtopography, pillar diameter, aspect ratio and spacing evaluations Micro-pillared surfaces are better than flat surfaces | 92 |

| 3D microfluidic structures | Liver tissue cultures Mesothelial cells | PMMA | Engraving machine UV photo polymerization | PEGDA structures of 60 μm height | PEGDA microstructures with mesothelial cells for contribution of adhesive surface and tissue repair | 93 |

| Microfluidic chip | Primary human alveolar bone osteoblast (PHABO) | PMMA | NA | 300 μm cubic cavities 10 mm × 10 mm device | PHABO morphogenesis investigation in both microchip-based 3D-static conditions and 3D-fluid flow-mediated biomechanical stimulation in perfusion bioreactors | 94 |

| Mechanical microconnector system (mMS) | Spinal cord stumps | PMMA | Vacuum application | Thickness of 350 μm and outer diameters of 1.7 mm and 2.7 mm | Regulation of retracted spinal cord stumps Axonal regrowth was achieved after 2, 5 and 19 weeks with the mMS. | 95 |

| Microfluidic chip | C3H10T1/2 stem cells | PMMA | CO2 laser etching Thermal bonding | 170 μm width, 200 μm height and 1.5 cm length | Application of click chemistry Bio-orthogonal chemical group generation in a rapid, straightforward and flexible way | 96 |

| Microvascular network | Endothelial cell Mesenchymal stem cells | PMMA | Laser cut Silicone glue bonding | 2 × 2 × 2 mm3 and 2 × 2 × 5 mm3 masks | Parameter effects on the vascularization of bone-mimicking tissues Creation a link in between the macroscale and microscale tissue engineering studies | 97 |

| Microfluidic chip | Human umbilical vein endothelial cells (HUVEC) Blood neutrophil | PS COP | Hot embossing Thermal bonding | 3 different aspect ratios: 10, 20 and 50 Height: 10 μm | HUVEC culturing in one application and blood neutrophil culturing under chemoattactant in another PS can be used for long term studies | 98 |

| Microfluidic chip | Human microvascular endothelial cells (hMVECs) | COC | Hot embossing Oxygen plasma Roller-lamination | 50 mm × 4 mm × 100 μm (L×W×H) | No adverse effect of COC material on cells | 99 |

| MOTiF biochip | Endothelial cells | COC | Injection molding Surface oxidation | 140 μm thick | Nutrient medium supply, catabolic cell metabolites removal and shear stress applications | 100 |

| Body-on-a-chip | A549 Caco2 HepG2 C3A Meg01 HK2 | PC Silicone PMMA | Milling Screwing | 2.5 μl volume | Imitation the drug distribution and metabolism processes in the body Building, managing and cultivating of multi-organ microphysiological system | 101 |

| Microwell and patterned chip | Embryoid bodies from mouse embryonic stem cells | PMMA | Micromilling Microcontact printing | 270 microwells of 600 μm in diameter and depth, 270 gelatin spots of 200 μm in diameter | The proliferation and differentiation of EB variation from design to design | 102 |

| Spheroid transfer chip (ST chip) | Mouse ES cells, 3T3 cells, HepG2 cells and primary hepatocytes | PMMA PDMS | Micromilling | 270 microwells of 600 μm in diameter, depth and pitch | Spheroid production Cell proliferation and cell viability in the spheroid and spheroid size monitoring | 103 |

| Microfluidic chip | L929 mouse fibroblast | PMMA | Automated nanodispensing or microcontact printing Double side sticky pressure-sensitive adhesive | Microgel coatings of 200 μm | Cultivation of L929 mouse fibroblast Studying cell detachment | 104 |

| Surface modification | MG-63 | PS | Nano-injection molding UV photolithography electroforming | The width and spacing of microgroove patterns: 50 μm | Cell attachment and alignment using PMS-NPS PMS-NPS are better than flat PS surfaces | 105 |

| Surface modification | MG-63 | PS | Nano-injection | Nanopore array: 20 mm × 20 mm | Cell attachment and proliferation study on NES Nanopore surface is better than flat surface | 106 |

III. SEPARATION/ISOLATION

In biological and biomedical research as well as in clinical therapy, cell separation or cell sorting methods are mostly used to perform analyses. For example; in some cases, circulating tumor cells (CTCs), red blood cells (RBCs), and white blood cells (WBCs) are held together in blood samples and CTCs should be separated to work with. Cell separation with a low risk of contamination is very important to further study a targeted cell or an individual cell in an isolated area. Heterogeneous cell populations can only give lumped averaged data about the populations, but one can obtain an important result from an isolated subpopulation via cell sorting. There are many technologies for cell isolation such as flow cytometry, laser capture microdissection, limiting dilution, manual cell picking or microfluidic devices. In the following parts, studies on cell isolation in microfluidic devices will be discussed in detail.107,108

A. DNA-RNA extraction/isolation

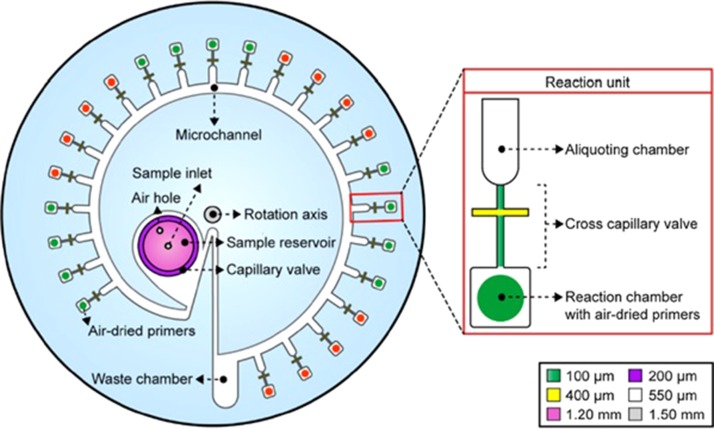

In the prokaryotic cell domain, bacteria cells occupy a large area, and E. coli cells are the most widely used pathogens among all, in many experiments. In 2004, Chung et al. employed immobilized beads in their microfluidic device to extract DNA from lysed cells. The solution in the device flowed back and forth, and the DNA was successfully isolated in the device. The experiments conducted with serum had higher efficiency.109 In 2007, an optimal fuzzy sliding-mode control (OFSMC) bio-microfluidic device was fabricated with 8051 microprocessors. In this system, the collision of molecules was increased via a back and forth process to enhance the biochemical reaction efficiency, and DNA extraction experiment was performed. When the beads were immobilized, the extraction efficiency is higher than that of the free beads.110 Geissler and his group employed Bacillus atrophaeus subsp. globigii spores for the nucleic acid separation. A PMMA made microfluidic device was used to manage the bead-based mechanical cell lysis of the bacteria. The chip was composed of the mechanical slides of PMMA and a metal disk with microbeads in the lysis chamber. Cell destruction was handled via the collisions and frictional forces were created by the metal disk magnetic actuation. Gathered DNA molecules were counted via the PCR method. The composition of the lysis matrix such as the size or amount of the microbeads and the instrumental parameters, like duration and frequency of the agitation, affected the yield of the experiment.111 The isolation and amplification of eukaryotic mRNA from Cryptosporidium parvum (C. parvum) cells were performed in another type of microfluidic device. The surface of the microfluidic channels of the device was carboxylated via the UV/ozone and coated with polyamidoamine (PAMAM) dendrimers to enhance the binding of the thymidine oligonucleotide (oligo(dT)25) for the nucleic acid sequence-based amplification (NASBA) reaction. The device includes 6 microchannels to perform mRNA isolation and amplification. mRNA was successfully separated from C. parvum oocysts.112

Viruses are neither prokaryotic nor eukaryotic pathogens, and duplicate their DNA or RNA only inside the living cells of other organisms. They cause infectious diseases and can affect all type of living forms.113 In 2008, viral RNA extraction from mammalian cells infected with influenza A (H1N1) virus experiments were conducted in a cyclic polyolefin made microfluidic device. A solid-phase extraction system was created for isolation of RNA and separation was done via reversible binding of nucleic acids to the silica particles in the monolith.114 In order to detect the norovirus (NoV) in oysters, cell concentration, lysis (RNA extraction), nucleic acid amplification, and detection operations were assembled in one microfluidic device. The virus concentration and lysis events were conducted by charge switchable microbeads in a shape changeable microchamber. The murine NoVs were adsorbed on the microbeads and their RNA was extracted via bead beating. Then, the extracted RNA was sent to the amplification chamber and finally murine NoVs in the oyster were detected. The microfluidic device was produced from PMMA and PDMS.115

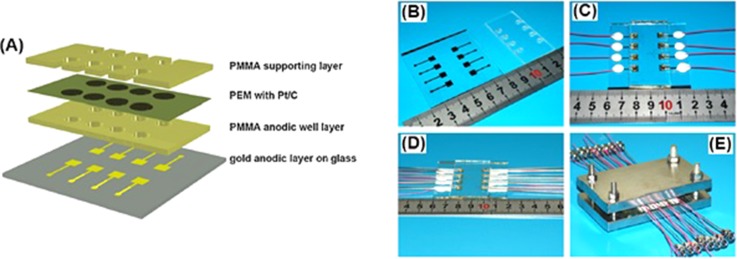

B. Separation/isolation of microorganisms