Abstract

Now a day’s meat and meat products are not only generating convenience trends; they have been recognized as core of meat industry. Meat spread is a convenience cooked spreadable product prepared with meat and non-meat additives. Response surface methodology was used to investigate the effects of three different levels of honey (10, 15, 20 g), vinegar (2.0, 6.0, 10.0 ml) and tomato powder (0.5, 1.0, 1.5 g) on response variables viz. color/appearance, flavor, spreadability, texture, after taste, adhesiveability, overall acceptability, while standardizing the process of development of sweet and sour chicken meat spread box-behnken experimental design was used in which 17 different runs with 5 trials of three similar centre point. A second order polynomial was fitted to all the response variables and surface plots as well as equations were conducted. All the processing variables significantly affected the response variables either linearly or quadratically whereas the “Lack of Fit” was non-significant relative to the pure error. For optimization, target values were set in the form of ranges of all the processing and response variables. While applying multiple regression analysis, a total of 43 workable solutions was found, out of which the product with 14.28% honey, 5.38% vinegar and 1.39% tomato powder was selected. The responses for color/appearance, flavor, spreadability, texture, after taste, adhesiveability, overall acceptability, were predicted at 7.11, 6.72, 7.00, 6.99, 6.61, 6.94 and 6.79 respectively, with a desirability value of 1.

Keywords: Chicken meat spread, Sensory evaluation, Response surface methodology, Spent hen

Introduction

India’s poultry sector represents one of the biggest success stories of the country over the past decade. India is the second largest egg producer and third largest broiler chicken producer in the world with production estimates of 74,752 million eggs and 3 million tonnes of broiler meat per year (DAHD 2015).

With the expeditious growth in poultry sector, availability of layers and broiler hens as culls has elevated, which could be beneficially utilized for product processing for the account of producers and consumers (Kondiah 2010). Even though spent hen meat is a sound source of proteins and omega-3 fatty acids, the meat is genuinely tough and chewy (Chueachuaychoo et al. 2011). Spent hens after the end of economic laying cycle, also contribute a significant amount of meat for human consumption (Mendiratta et al. 2012).

Spreadable products are a kind of convenience product meant to be spread on or sandwich in a base like bread. Many such products like cheese spread, mayonnaise, jam, jelly are present in the market Meat spread is a cooked spreadable product, contains ingredients like meat, fat, spices, condiments and other food additives. As far as India is concerned, no spreadable meat product is available in the market till date. Thus, spreadable meat product can add a new dimension to convenience food processing and marketing. Because of unsatisfactory toughness and brittle bones, the use of spent hen meat for preparation of spreadable meat product can add a new breakthrough to convenience food processing and marketing. There is exigency to enumerate properties in the product which can complement the sensory quality, acceptability as well as stability of the product.

Honey is the natural humectants which contribute for functional characteristics like humectancy, viscosity, flavor enhancement, color, hygroscopicity, miscibility, and spreadability (LaBell 1988; Veronique and Sanders 1988). Traditionally, vinegar was used to marinade meat for preservation and to improve juiciness, odour and flavor or to develop distinctive sensory characteristic pleasant for a particular cuisine. Tomato products are now used as functional and color additives in nitrite reduced meat products.

Various research studies are cited for the development of convenience and shelf-stable meat products based on honey as humectants, vinegar as acidifier and tomatoes as functional additive for enhancing the existing characteristics and to develop a new product aswell. Some examples are honey in restructured duck jerky (Triyannanto and Lee 2016); dry honey in turkey slices (Antony et al. 2000); honey marinades in fried beef steak and chicken breast (Shin and Ustunol 2004); dry honey in beef sausages (Mohammed et al. 2013) vinegar as acidifier in Auricularia auricula mushroom pickle (Khaskheli et al. 2015); vinegar in spent chicken meat pickle (Das et al. 2013); vinegar in Korean beef product (Jang 2006); tomato powder in Fresh Pork Patties (Kang et al. 2010); tomato powder in low fat cooked pork sausages (Kim et al. 2013); tomato powder as natural color additive for reducing the nitrite level in Frankfurter (Eyiler and Oztan 2011), mortedella (Doménech-Asensi et al. 2013) and meat batter (Bázan-Lugo 2012).

Post cook grinding and mixing process during processing of spread makes the product prone to oxidative and microbial spoilage so there is need to incorporate ingredients that provides unfavourable environment to microbial growth and simultaneously cause enhancement of sensory quality. Combination of ingredients (honey, vinegar and tomato powder) used in the presents study provides health benefits as well as increases product stability on account of their humectantcy, antimicrobial properties, reduced pH, antioxidant content and functional benefits. The product was previously technologically standardized taking into account the rest of the ingredients of the formulation. In the present study addition of these new ingredients (honey, vinegar and tomato powder) in order to improve the sensory quality was optimized using response surface methodology to develop a product of sweet and sour taste as well as attractive color.

Material and method

Fourteen white Leghorn layer spent hen of approximately 72–100 week old was procured from CARI, Izatnagar and slaughtered using the halal method in the experimental abattoir of division of LPT, IVRI, Izatnagar. After that carcasses were manually deboned in and kept for conditioning for 24 h at 4 °C followed by storage at −18 ± 1 °C till further use. Spice ingredients and condiments (ginger, garlic and onion) used in the study were procured from the local market. For preparation of condiments mix, onion, ginger and garlic were peeled off, cut into small pieces and homogenized in a mixer to obtain a fine paste and mix at (3:2:1) ratio. The spice ingredients in desired ratio were procured from local market and dried at 50 ± 2 °C for 2 h followed by grinding and sieving through 100mesh. The spice mix was stored at ambient temperature in a PET container (Godrej Cold Gold, India). The formulation contained anise 8%, black pepper 10%, caraway 10%, cardamom 6%, red chili 8%, cloves 3%, cinnamon 6%, cumin 12%, dry ginger 10%, mace 1%,, nutmeg 1% turmeric 10% and coriander 15% (w/w). Honey of pH 4.02 and water activity 0.61 (Dabur Pvt. Ltd.) and vinegar of pH 3.17 (Tops India) were also procured from local market. Tomato powder was prepared in laboratory using pre-standardized procedure of Jayathunge et al. (2012) with slight modification. Fresh ripened tomatoes were washed and blanched at 60 °C for 1 min then sliced into thin pieces of about 5–8 mm. Pieces were subjected to drying in hot air oven at 70 °C initially followed by drying at 50 °C for 68 h with turning in between. Dried tomatoes were pulverized to form powder and packed in laminated pouches.

The deboned-frozen meat was thawed overnight in refrigerator and cut into small chunks and minced twice in a meat mincer (Mado Eskimo Mew-714, Mado, Germany) through 8 and 4 mm plates. Five hundred grams of chicken meat spread was prepared for each combination given in Table 1. Minced meat mixed with all the ingredients was cooked via braising in oven (Sunflame regalia FSCR01) to an internal temperature of 73 °C. Honey and vinegar were added at the end of cooking and cooked mix was chopped in a chopper (Seydelmann K20, Ras, Germany) to fine pasty consistency.

Table 1.

Initial formulation used to prepare sweet and sour chicken meat spread

| Ingredients | (w/w) |

|---|---|

| Meat level | 57a |

| Oil level | 12a |

| Spices mix. | 3a |

| Condiments (onion:ginger:garlic) (3:2:1) | 5a |

| Potato starch | 2a |

| STTP | 0.4 |

| Honey | X1 (10/15/20) |

| Vinegar (v/w) | X2 (2/6/10) |

| Tomato powder | X3 (0.5/1.0/1.5) |

a Ingredients calculated on the % basis

X1 is coded independent variable for honey level (g), X2 is coded independent variable for vinegar level (ml), X3 is coded independent variable for tomato powder (g)

On the basis of sensory attributes, series of preliminary trials were conducted to optimize the level of meat, salt spices and condiments as well as processing technique. For optimization of level of honey vinegar and tomato powder levels were obtained from response surface methodology. Three levels of honey, vinegar and tomato powder were selected on the basis of preliminary trial and on consultation with literature where it was observed that 10–20 g honey/100 g, 2–10 ml vinegar/100 g and 0.5–1.5 g tomato powder/100 g gave acceptable product.

Product was manually packed hot in glass containers and temperature for sensory analysis was performed.

Statistical analysis and experimental design

A 3-factor-3-level Box-Behnken experimental design (Box and Behnken 1960) with five replicates at the centre point was adopted for the optimization of levels of ingredients in which a total of 17 different trials were conducted in Table 2. Preliminary trials were conducted to select the levels of independent variables viz. honey, vinegar and tomato powder for the development of sweet and sour chicken meat spread. Coded values and uncoded values of independent variables obtained from experimental design were given in Table 2. The data generated for different responses were analysed using the “Design Expert” software (Version 8.0.4.1, Stat-Ease, Inc., Minneapolis, USA) statistical package. After conducting the runs, a second order polynomial of the following form was fitted and the data was analysed employing multiple regression technique to develop a response surface model.

Table 2.

Second order design matrix used to evaluate the effects of process variables and values of experimental responses for the sensory attributes of sweet and sour chicken meat spread

| Runs | Coded variables | Uncoded variables | Response | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 (g) | X2 (ml) | X3 (g) | H (g) | V (ml) | TP (g) | C/A | Flv | Spr | Tex | AT | Adh | OA | |

| 1 | 1 | 0 | 1 | 20 | 06 | 1.5 | 7.26 | 6.53 | 7.40 | 7.46 | 6.73 | 7.30 | 6.63 |

| 2 | 0 | 0 | 0 | 15 | 06 | 1.0 | 7.16 | 7.16 | 7.23 | 7.03 | 7.33 | 7.03 | 7.26 |

| 3 | 0 | 0 | 0 | 15 | 06 | 1.0 | 7.33 | 7.40 | 7.10 | 7.23 | 7.30 | 7.06 | 7.43 |

| 4 | −1 | 1 | 0 | 10 | 10 | 1.0 | 7.06 | 6.36 | 6.86 | 7.06 | 5.90 | 6.96 | 5.86 |

| 5 | 0 | −1 | 1 | 15 | 02 | 1.5 | 7.13 | 5.93 | 6.83 | 6.83 | 5.60 | 6.70 | 5.93 |

| 6 | 0 | 0 | 0 | 15 | 06 | 1.0 | 7.13 | 7.26 | 7.10 | 7.13 | 7.36 | 7.03 | 7.26 |

| 7 | −1 | −1 | 0 | 10 | 02 | 1.0 | 6.66 | 6.30 | 6.6 | 6.8 | 6.53 | 6.63 | 6.56 |

| 8 | 1 | −1 | 0 | 20 | 02 | 1.0 | 7.30 | 5.13 | 7.36 | 7.16 | 5.00 | 7.26 | 5.06 |

| 9 | 0 | −1 | −1 | 15 | 02 | 0.5 | 7.13 | 5.66 | 7.03 | 7.16 | 5.50 | 7.10 | 5.73 |

| 10 | −1 | 0 | 1 | 10 | 06 | 1.5 | 7.1 | 6.90 | 7.03 | 7.03 | 6.86 | 6.93 | 6.90 |

| 11 | 1 | 0 | −1 | 20 | 06 | 0.5 | 7.13 | 6.16 | 7.43 | 7.2 | 6.43 | 7.33 | 6.33 |

| 12 | 1 | 1 | 0 | 20 | 10 | 1.0 | 7.43 | 6.36 | 7.43 | 7.03 | 6.76 | 7.50 | 6.40 |

| 13 | 0 | 1 | 1 | 15 | 10 | 1.5 | 7.30 | 7.06 | 7.33 | 7.13 | 6.90 | 7.06 | 6.90 |

| 14 | 0 | 0 | 0 | 15 | 06 | 1.0 | 7.16 | 7.20 | 7.13 | 7.13 | 7.20 | 7.10 | 7.20 |

| 15 | 0 | 1 | −1 | 15 | 10 | 0.5 | 7.10 | 6.90 | 7.26 | 7.03 | 6.87 | 6.93 | 6.90 |

| 16 | 0 | 0 | 0 | 15 | 06 | 1.0 | 7.16 | 7.36 | 7.16 | 7.13 | 7.30 | 7.20 | 7.33 |

| 17 | −1 | 0 | −1 | 10 | 06 | 0.5 | 7.10 | 6.70 | 7.06 | 7.06 | 6.70 | 7.06 | 6.83 |

H honey, V vinegar, TP tomato powder, CA color/appearance, Flv flavor, Spr spreadability, Tex texture, AT after taste, Adh adhesiveability, OA overall acceptability

From the equation presented, Y is the estimated response; where β0 is constant, βi, βii and βij are linear, quadratic and interaction coefficients, respectively. Xi and Xj defined as the coded independent variables.The F-values, R2 values and CV were computed for all the responses (Table 3). Equations and 3-D surface graphs were developed which showed effect of interaction of two variables on each response. The effect of the independent variables individual responses were described at P < 0.05 level of significance.

Table 3.

Significance of the regression models (F values) and the effects of processing variables

| Source of variance | CA | Flv | Spr | Tex | AT | Adh | OA |

|---|---|---|---|---|---|---|---|

| R2 = 0.5876 | R2 = 0.9700 | R2 = 0.8072 | R2 = 0.8472 | R2 = 0.9584 | R2 = 0.6772 | R2 = 0.9543 | |

| F value | F value | F value | F value | F value | F value | F value | |

| Linear | |||||||

| β 1 | 13.35a | 19.06a | 42.84a | 13.16a | 03.00 | 22.12a | 08.18a |

| β 2 | 04.16 | 59.01a | 11.23a | 01.46 | 37.87a | 03.90 | 21.11a |

| β 3 | 01.01 | 04.41 | 00.36 | 00.00 | 00.91 | 01.25 | 0.89 |

| Cross product | |||||||

| β 12 | – | 12.06a | – | 04.94 | 29.96a | – | 22.74a |

| β 13 | – | 00.25 | – | 02.73 | 00.10 | – | 00.29 |

| β 23 | – | 00.11 | – | 06.01a | 0.026 | – | 00.22 |

| Quadratic | |||||||

| β 11 | – | 41.17a | – | 00.14 | 13.71a | – | 23.86a |

| β 22 | – | 75.17a | – | 09.79a | 64.80a | – | 61.39a |

| β 33 | – | 04.64 | – | 00.93 | 04.43 | – | 01.20 |

| Lack of fit | 02.57 | 04.98 | 05.72 | 02.26 | 29.39 | 04.87 | 12.48 |

| C.V. | 01.62 | 02.55 | 01.57 | 01.24 | 03.31 | 01.92 | 03.23 |

| Total model | 06.17a | 25.16a | 18.15a | 04.31a | 17.93a | 9.09a | 16.25a |

P < 0.05; R2—Coefficient of determination

C.V. coefficient of variation, CA color/appearance, Flv flavor, Spr spreadability, Tex texture, AT after taste, Adh adhesiveability, OA overall acceptability

a Significant (P < 0.05)

Sensory evaluation

Sensory attributes for sweet and sour chicken meat spread were evaluated using 8 point descriptive scale (Keeton 1983). Where 8 score was given for extremely good and 1 was given for extremely poor. Panellist consisting of scientists and post graduate students of the LPT Division were make familiarized with the nature product without disclosing the identity of the product and also briefed about for the product attributes viz color and appearance, flavor, spreadability, texture, after taste, adhesiveability and overall acceptability. Out of the 17 combinations obtained using second order design matrix of Box-Behnken experimental design of response surface methodology 4, 4, 4 and 5 number of product were evaluated in 4 consecutive trials by 7 numbers of judges in each trial. Products were evaluated at ambient temperature with and without spreading over a piece of bread. Plain water was provided to rinse the mouth in between the samples. In all trials mean value of observation was taken as response variable.

Results and discussion

The optimized sweet and sour chicken meat spread were developed using Box-Behnken experimental design with minimum possible number of points. The experimental design with the three factors and the seven responses viz; color/appearance, flavor, spreadability, texture, after taste, adhesiveability and overall acceptability is presented in Table 2. The responses selected influenced the sensory quality of the product and their values were dependent on the three factors chosen for the present design. Perusal of Table 3 revealed that for all the responses, F-values for the "model" were significant (P < 0.05) and “All of the lacks of fit” tests were not significant (P > 0.05), which also showed a validity between the experimental data and the model. The R2 value reflects the suitability of the model to represent the real relationship between the selected reaction parameters. The model adequacies were checked by R2, adjusted R2 and coefficient of variance (CV) (Myers and Montgomery 1995). The present analysis indicated that optimum value for the responses of sweet and sour chicken meat spread processing with the addition of honey, vinegar and tomato powder can be achieved using a honey concentration of 14.36 g, 3.40 ml vinegar and tomato powder of 1.40 g. The responses for color/appearance, flavor, spreadability, texture, after taste, adhesiveability, overall acceptability, were predicted at 7.11, 6.72, 7.00, 6.99, 6.61, 6.94 and 6.79 respectively, with a desirability value of 1.

Sensory properties of any food are the major part of important attributes that affect the consumer choice. Knowledge of these sensory attributes is of prime impotence for development and evaluation of food products as such they have been summarised as under:

Color/appearance

Color is one of the most important attribute since it is the first aspect of a product that affect the consumer acceptance, purchasing decisions and satisfaction of meat products. Muscle micro-structure, concentration and state of the haem pigments, myoglobin (Mb) and haemoglobin (Hb) determined the meat color and appearance of meat products.

The second order polynomial equation generated relating dependent variable CA and three independent variables (honey, vinegar and tomato powder) as under,

From the above equation, it was seen that the effect of honey (X1), vinegar (X2) and tomato powder (X3) level gave rise to linear effect only. As per this model only one variable i.e. honey level was found to show significant effect (P < 0.05) on CA ofspread (Table 3). The “Pred R-Squared” of 0.2075 is not as close to the “Adj R-Squared” of 0.4924 as one might normally expect and it may indicate a large block effect. Analysis indicated that with increase in honey level, CA of spread, increased linearly. At the highest level of tomato powder level (1.5 g), CA of spread was improved. Color improving effect of tomato paste can be attributed to the pigment, lycopene, which is present in tomato paste, due to its red color and antioxidant effect (Candogan 2002). Triyannanto and Lee (2016) reported that differences in color properties of restructured duck jerky remained insignificant between 6 and 10% honey concentrations. Kang et al. (2010) observed that pork patties with 0.75 and 1.0% of tomato powder with olive oil scored higher in color scores than the control. However lower color score was observed for 4.5 and 6% dried tomato peel added hamburger as compared to control 1.5 and 3% level (García et al. 2009).

Flavor

Flavor is a complex sensation of meat which comprises mainly of taste and odour. It has been shown to have a profound effect on the overall acceptability of meat product. It depends on species, sex, age, diet, management and cooking methods. The response surface analysis (Table 3) demonstrated a high coefficient of determination (R2 = 0.9700) showed the relationship between Flv and independent variables viz. honey, vinegar and tomato powder as follows.

In the present study, it was found to fit with the three independent variables as per quadrtic model that explained by the following equation,

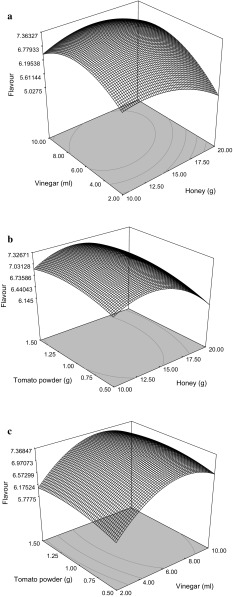

This shows that honey and vinegar (linear and quadratic effect), honey and vinegar interaction significantly (P < 0.05) imporoved the flavor of product (Table 3). The Model F-value of 25.16 implies the model is significant (Table 3). There is only a 0.02% chance that a “Model F-Value” this large could occur due to noise. With increase in honey, vinegar and tomato powder level, flavor of product first increased and then decreased (Fig. 1a–c). However, the interaction of honey with vinegar and tomato powder and vinegar with tomato powder shown increased and decreased flavor score respectively (Fig. 1a–c).

Fig. 1.

Surface plot (3-D) for flavor

Na et al. (2012) optimized level of tomato powder and starch in pork sausages using central composite response surface design, and observed that the optimized product showed significantly higher preference in color as well flavor as compared to control. García et al. (2009) reported that the odour score of hamburger enriched in lycopene with 1.5, 3, 4.5 and 6% tomato peel added hamburger was not significantly different among the treatment batches (P > 0.05). Intense sweetness of honey combined with the sourness of vinegar might have masked the flavor effect of tomato powder. Honey has been known for decades to enhance sweetness, and confer functional advantages, nutritional value, and unique flavors in wide array of food products (Antony et al. 2000). Alabdulkarim et al. (2012) observed that higher mean sensory scores of frozen chicken patties incorporated with different honey level as compared to control.

Spreadability

Spreadability of food like jam, jelly and mayonnaise refer to the capability to being spread on a surface in a layer as a result of distributing or extending. In the present study, it was found to fit with the three variables as per linear model and the second-order polynomial equation predicting effect of processing variables is as follows:

Above equation analysis shows that linear term of honey and vinegar had significant (P < 0.05) effect on the Spr score of the spread (Table 3). Spr of spread increased linearly, with increase in honey and vinegar level. But with increased tomato powder, Spr score decreased.

Texture

Texture is the structural-conformational quality of food that is also an index of quality. The texture of a food can change as it is stored, for various reasons. Thus texture encompasses all properties of food which are perceived by the kinaesthetic and tactile senses in mouth i.e. mouth feel. The following second order polynomial equation was found to fit with the three variables as per quadratic model for the texture,

It was seen that the effect of honey level (linear effect), vinegar level (quadratic effect) and vinegar and tomato powder interaction showed significant effect (P < 0.05) on texture of spread (Table 3). In this case, the coefficient of determination (R2 = 0.8472) indicated that only 15.28% of the total variations were not explained by the regression model (Table 3). With increase in honey level, texture of spread increase linearly (Fig. 2a, b) and with increase in vinegar, texture of spread/jam, first increased and then decreased by showing interaction with honey and tomato powder (Fig. 2a, c). Salem (2013) reported that the tenderness of the beef sausages was decreased when the tomato peel level were increased whereas, findings of Kim et al. (2011) suggested that addition of tomato powder did not cause any negative effect in the textural properties of sausages.

Fig. 2.

Surface plot (3-D) for texture

After-taste

After-taste is the taste intensity for a food which is perceived immediately after that food or meat product is removed from the mouth (Neely and Borg, 1999). The second order polynomial equation generated showed a quadratic relationship between the independent uncoded variables X1, X2 and X3 and the dependent variable AT.

The analysis of variance showed that vinegar (linear effect), honey and vinegar (quadratic effect) and honey and vinegar interaction had significant effect (P < 0.05) on AT of spread (Table 3). With increase in honey, vinegar and tomato powder level, AT of product first increased and then decreased. However, the interaction of honey with vinegar and tomato powder and vinegar with tomato powder shown increased and decreased AT score respectively.

Adhesiveability

Adhesivability for spreadable food product indicates the ability to stick to a surface or base like bread. It was found to have linear relationship with the three process variables as described by the following equation,

The analysis of variance showed that honey level (linear term)showed significant effect (P < 0.05) on Adh of spread (Table 3). However, the coefficient of variation being 1.92%, indicated better precision of the experiment (Table 3). Adh of spread increased linearly, with increase in honey and vinegar level. But with increased tomato powder, Adh value decreased.

Overall acceptability

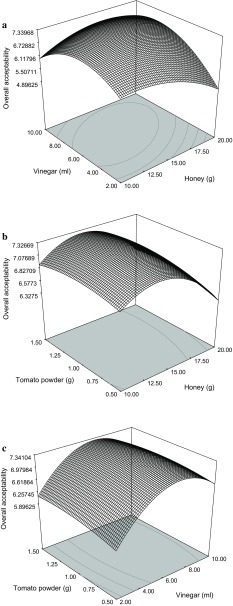

Overall acceptability of spread was found to have quadratic relationship with the three process variables as per the following equation,

As per this modal, honey and vinegar (linear and quadrartic term) and honey and vinegar interaction was found to be significant effect (P < 0.05) on OA of spread. With increase in honey, vinegar and tomato powder level, OA of product first increased and then decreased (Fig. 3a–c). However, the interaction of honey with vinegar and tomato powder and vinegar with tomato powder shown increased and decreased OA score respectively (Fig. 3a–c). Hoe et al. (2006) observed that low-fat emulsion type sausages containing 5.0% ground raw tomato paste and 0.5% freeze dried tomato powder during storage had a slightly higher score regarding color, aroma, tenderness and overall acceptability. Whereas, Kim et al. (2011) observed that the addition of 0.5% tomato powder did not affect the sensory profile of emulsion type sausages. Findings of Savadkoohi et al. (2014) suggested that addition of tomato pomace greater than 5% (w/w) in cooked beef frankfurter, beef ham and meat-free sausages decreased the acceptability of the sausages. Kang et al. (2010) added 0.25, 0.55, 0.75 and 1.0% tomato powder in pork patties and observed that on sensory evaluation, the scores of color, flavor and overall acceptability in 0.75 and 1.0% tomato powder added patties scored higher (P < 0.05) than those of control at days 1 and 3 of storage.

Fig. 3.

Surface plot (3-D) for overall acceptability

Conclusion

Results concluded that sweet and sour chicken meat spread can be successfully prepared using the response surface methodology, optimizing the level of honey, vinegar and tomato powder in the formulation. Ingredients used in the study did not adversely affected any of the sensory characteristics rather combination of honey with vinegar, contributed to desirable sweet and sour taste. Greater stability and product quality for chicken spread with added honey, vinegar and tomato powder can lead to better consumer acceptance, as well as plausible health benefits of a diet rich these functional products.

Acknowledgements

The authors are obliged for providing necessary facilities and funds to carry out the research by the Director, Joint Director (Research) and Joint Director (Academics) of Indian Veterinary Research Institute.

References

- Alabdulkarim B, Bakeet ZAN, Arzoo S. Effect of frying oils on quality characteristics of frozen chicken patties incorporated with honey. Afr J Biotechnol. 2012;11(12):2985–2992. [Google Scholar]

- Antony S, Rieck JR, Dawson PL. Effect of dry honey on oxidation in turkey breast meat. Poult Sci. 2000;79(12):1846–1850. doi: 10.1093/ps/79.12.1846. [DOI] [PubMed] [Google Scholar]

- Bázan-Lugo E, García-Martínez I, Alfaro-Rodríguez RH, Totosaus A. Color compensation in nitrite-reduced meat batters incorporating paprika or tomato paste. J Sci Food Agr. 2012;92(8):1627–1632. doi: 10.1002/jsfa.4748. [DOI] [PubMed] [Google Scholar]

- Box GEP, Behnken DW. Some new three level designs for the study of quantitative variables. Technometrics. 1960;2:455–475. doi: 10.1080/00401706.1960.10489912. [DOI] [Google Scholar]

- Candogan K. The effect of tomato paste on some quality characteristics of beef patties during refrigerated storage. Eur Food Res Technol. 2002;215(4):305–309. doi: 10.1007/s00217-002-0567-1. [DOI] [Google Scholar]

- Chueachuaychoo A, Wattanachant S, Beenjakul S. Quality characteristics of raw and cooked spent hen’s pectoris major muscles during chilled storage: effect of salt and phosphate. Int Food Res J. 2011;18:593–605. [Google Scholar]

- DAHD (2015) Basic animal husbandry & fisheries statistics. Department of animal husbandry, dairying and fisheries. http://dahd.nic.in/sites/default/files/BAH_%26_FS_Book.pdf

- Das A, Nath DR, Hazarika M, Laskar SK. Studies on certain quality attributes of meat pickle prepared from spent chicken. Vet World. 2013;6(3):156–158. doi: 10.5455/vetworld.2013.156-158. [DOI] [Google Scholar]

- Doménech-Asensi G, García-Alonso FJ, Martínez E, Santaella M, Martín-Pozuelo G, Bravo S, Periago MJ. Effect of the addition of tomato paste on the nutritional and sensory properties of mortadella. Meat Sci. 2013;93(2):213–219. doi: 10.1016/j.meatsci.2012.08.021. [DOI] [PubMed] [Google Scholar]

- Eyiler E, Oztan A. Production of frankfurters with tomato powder as a natural additive. LWT-Food Sci Technol. 2011;44(1):307–311. doi: 10.1016/j.lwt.2010.07.004. [DOI] [Google Scholar]

- García ML, Calvo MM, Selgas MD. Beef hamburgers enriched in lycopene using dry tomato peel as an ingredient. Meat sci. 2009;83(1):45–49. doi: 10.1016/j.meatsci.2009.03.009. [DOI] [PubMed] [Google Scholar]

- Hoe SK, Park KH, Yang MR, Jeong KJ, Kim DH, Choi JS, Kim IS. Quality characteristics of low-fat emulsified sausage containing tomatoes during cold storage. Korean J Food Sci Anim Resour. 2006;26(3):297–305. [Google Scholar]

- Jang JD, Seo GH, Lyu ES, Yam KL, Lee DS. Hurdle effect of vinegar and sake on Korean seasoned beef preserved by sous vide packaging. Food control. 2006;17(3):171–175. doi: 10.1016/j.foodcont.2004.09.017. [DOI] [Google Scholar]

- Jayathunge KGLR, Kapilarathne RANS, Thilakarathne BMKS, Fernando MD, Palipane KB, Prasanna PHP. Development of a methodology for production of dehydrated tomato powder and study the acceptability of the product. J Agr Technol. 2012;8(2):765–773. [Google Scholar]

- Kang SN, Jin SK, Yang MR, Kim IS. Changes in quality characteristics of fresh pork patties added with tomato powder during storage. Korean J Food Sci Anim Resour. 2010;30(2):216–222. doi: 10.5851/kosfa.2010.30.2.216. [DOI] [Google Scholar]

- Keeton JT. Effect of fat and NaCl/phosphate levels on the chemical and sensory properties of pork patties. J Food Sci. 1983;48:878–881. doi: 10.1111/j.1365-2621.1983.tb14921.x. [DOI] [Google Scholar]

- Khaskheli SG, Zheng W, Khaskheli AA, Liu Y, Wang YF, Huang W. Effect of processing techniques on the quality and acceptability of Auriculari aauricula mushroom pickle. J Food Nutr Res. 2015;3(1):46–51. doi: 10.12691/jfnr-3-1-8. [DOI] [Google Scholar]

- Kim IS, Jin SK, Mandal PK, Kang SN. Quality of low-fat pork sausages with tomato powder as color and functional additive during refrigerated storage. J Food Sci Technol. 2011;48(5):591–597. doi: 10.1007/s13197-010-0182-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim IS, Jin SK, Yang MR, Chu GM, Park JH, Rashid RHI, Kim JY, Kang SNI. Efficacy of tomato powder as antioxidant in cooked pork patties. Asian Australin J Anim Sci. 2013;26(9):1339–1346. doi: 10.5713/ajas.2013.13079. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kondiah N (2010) Challenges and issues for development in Processed Meat Sector. Training manual on requirements and developments in processed meat sector for better utilization of meat animal resources, NRC Hyderabad, 7–16 Dec 2010, pp 1–6

- LaBell F. Honey: traditional food finds new uses. Food Process. 1988;11:111–114. [Google Scholar]

- Mendiratta SK, Sharma BD, Majhi M, Kumar RR. Effect of post-mortem handling conditions on the quality of the spent hen meat curry. J Food Sci Technol. 2012;49:246–251. doi: 10.1007/s13197-011-0409-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mohammed RA, Mashair A, Sulieman Elgasim EA. Effect of bee honey in safety and storability of beef sausage. Pakistan J Nutr. 2013;12(6):560–566. doi: 10.3923/pjn.2013.560.566. [DOI] [Google Scholar]

- Myers RH, Montgomery DC (1995) Response surface methodology, process and product optimization using designed experiments, 2nd ed. Wiley, New York

- Na Y, Kim S, Eun-Kyung K, Joo N (2012) Processing optimization and antioxidant activity of sausage prepared with tomato powder. In: International conference on clean and green energy IPCBEE, vol 27. IACSIT Press, Singapore

- Neely G, Borg G. The perceived intensity of caffeine after-taste: tasters versus non-tasters. Chem Senses. 1999;24:19–21. doi: 10.1093/chemse/24.1.19. [DOI] [PubMed] [Google Scholar]

- Salem RH. Quality characteristics of beef sausages with tomato peel as a color and functional additive during frozen storage. World Appl Sci J. 2013;22(8):1085–1093. [Google Scholar]

- Savadkoohi S, Hoogenkamp H, Shamsi K, Farahnaky A. Color, sensory and textural attributes of beef frankfurter, beef ham and meat-free sausage containing tomato pomace. Meat Sci. 2014;97(4):410–418. doi: 10.1016/j.meatsci.2014.03.017. [DOI] [PubMed] [Google Scholar]

- Shin HS, Ustunol Z. Enfluence of honey-containing marinades on heterocyclic aromatic amine formation and overall mutagenicity in fried beef steak and chicken breast. J Food Sci. 2004;69(3):147–153. [Google Scholar]

- Triyannanto E, Lee KT. Evaluation of honey and rice syrup as replacements for sorbitol in the production of restructured duck jerky. Asian Australas J Anim Sci. 2016;29(2):271–279. doi: 10.5713/ajas.15.0431. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Veronique L, Sanders SW. Honey in cereal-based new food products. Cer Food World. 1988;33:833–835. [Google Scholar]