Abstract

This study was performed to investigate the impacts of irradiation sources on quality attributes of low-salt sausage during refrigerated storage. Control sausage was prepared with 1.5% sodium chloride (NaCl), whereas low-salt sausage was formulated with 0.75% NaCl (a 50% reduction; L-control). Sausage samples were vacuum-packaged, and low-sausages were irradiated with gamma-ray, electron-beam and X-ray at 5 kGy, respectively. The samples were stored at 4°C for 28 d to determine changes in quality attributes. The pH of low-salt sausages was unaffected by irradiation at 5 kGy (p>0.05). Higher redness values were found at irradiated low-salt sausages compared to control (p<0.05). The hardness, gumminess and chewiness of control sausage were higher than those of low-salt sausages (p<0.05). However, there were no significant differences in the textural parameters between low-salt sausage treatments. The overall sensory acceptability score of irradiated/low-salt sausages were lower than L-control due to decreased scores for cooked meat flavor but increased radiolytic off-flavor (p<0.05). The initial 2-thiobarbituric acid-reactive substances (TBARS) values of irradiated/low-salt sausages were higher than control and L-control (p<0.05). However, the TBARS values of irradiated treatments were significantly lower than control at the end of storage. Irradiation could effectively inhibit the microorganism growth (total aerobic bacteria, coliforms, Enterobacteriaceae, and Pseudomonas spp.) in low-salt sausages (p<0.05). Therefore, our findings show that irradiation could be to improve microbial safety of low-salt sausages, and suggest that further studies should be necessary to reducing radiolytic off-flavor of irradiated/low-salt sausages.

Keywords: sausage, low-sodium, lipid oxidation, microbial, ionizing source

Introduction

Excessive sodium intake is highly related to the potential risks of cardiovascular diseases, hypertension and stoke in human body (Grossi et al., 2012; Tobin et al., 2013). In this regard, modern consumers have attempted to reduce sodium intake from their daily diet. Processed meat products are regarded as a high-sodium food, since they generally contain 433-1,080 mg of sodium (approximately 1.1-2.7 g of salt) per 100 g of sausage (Desmond, 2006). To meet the consumer’s demand on healthier meat products, thus, the meat industry has been trying to reduce the addition of sodium salts in processed meat products (Ruusunen and Puolanne, 2005).

Sodium chloride (NaCl) is commonly added to processed meat products with multiple purposes, leading to desirable quality attributes of final products (Desmond, 2006; Grossi et al., 2012; Tobin et al., 2013). In particular, a direct reduction in NaCl (less 0.75 g per 100 g) could result in considerable quality defects on technological (emulsion stability, protein solubility, cooking yield), textural, sensory, and microbial properties of emulsion sausage (Desmond, 2006; Song et al., 2014). Recent studies have reported that the technological and textural properties of low-salt emulsion sausage could be improved through the addition of functional ingredients such as hydrocolloids and non-meat proteins (García-García and Totosaus, 2008; Grossi et al., 2012). However, Desmond (2006) indicated that additional preservative methods should be necessary to guarantee the microbial safety of low-salt processed meat products during further storage, thereby controlling the growth of food spoilage and/or food-borne bacteria.

Food irradiation technology has been practically used as an effective preservative method to not only reduce initial microbial contamination, but also delay microorganism growth during storage in meat products (Kim et al., 2012; Park et al., 2010; Roberts, 2014). According to Shin et al. (2014), irradiation dose over 4 kGy could be effective in controlling total aerobic bacteria in emulsion sausage. Thus, it would be reasonable to anticipate that irradiation technology contributes to ensure microbial safety of low-salt emulsion sausage. In practice, previous studies have revealed that irradiation technology could improve microbial property of several low-salt foods, without any adverse impacts on quality characteristics (Byun et al., 2000; Lee et al., 2002; Park et al., 2002). However, the effect of irradiation on microbial property in low-salt emulsion sausage has not been fully investigated.

Codex Alimentarius Commission (CODEX), World Health Organization (WHO), and Food and Agriculture Organization (FAO) have approved gamma-rays, electronbeams, and X-rays as sources for food irradiation (CODEX, 2003; Grégoire et al., 2003). Gamma-rays are electromagnetic waves emitted from radioactive isotopes such as cobalt-60 or cesium-137 that have strong penetration (Shin et al., 2014). Electron-beams are mechanically generated by electron accelerator and directly irradiate products, it has advantages of control convenience and favorable perception consumer acceptance, but weak penetration power compared to gamma-ray (Grégoire et al., 2003; Ham, 2017). Electron accelerators can be transform from the electron beam mode to the X-ray mode, thereby providing a wide range of dose rates (Miller, 2003). X-rays are produced by bremsstrahlung effect when high-energy electrons strike target material and indirectly irradiate products (Ham, 2017; Miller, 2003). It has advantages which are better power utilization, reduced treatment time, improved dose uniformity and strong penetration (Grégoire et al., 2003). However, the major limitation of X-ray irradiation is high cost and low energy efficiency compared to gamma or electron beam irradiation (Ham, 2017). In this regard, the percentage of their use is approximately 80% for gamma rays, and 20% for electron - beams and X-rays (Go, 2016). A recent study has indicated that three irradiation sources (gamma-ray, electron-beam, and X-ray) led to different efficacies on microbial properties as well as color characteristic and lipid oxidation stability (Ham et al., 2017).

Therefore, the objective of this study was to evaluate the irradiation efficacies of three irradiation sources, gammaray (γ-ray), electron-beam (E-beam) and X-ray, on physicochemical, textural, sensory, and microbial properties of low-salt emulsion sausage during 28 d of refrigerated storage.

Materials and Methods

Emulsion sausage processing

Fresh pork ham (M. biceps femoris, M. semitendinosus, and M. semimembranosus) and pork back fat at 48 h postmortem were purchased from a local market. All subcutaneous fat and visible connective tissues were removed from the pork ham muscle. The pork ham and pork back fat were ground using a meat grinder (Optimo MEW 619, Mado, Germany) equipped with an 8-mm plate. Five different groups of emulsion sausages were prepared as follows. The Control group was prepared with 1.5% salt, whereas four low-salt groups, to reduce salt addition by 50% were individually formulated with 0.75% salt. Pork meat, with the targeted amount of NaCl (1.5 or 0.75%), 0.012% sodium nitrite and 0.3% sodium tripolyphosphate were homogenized and ground for 1 min 30 s in a silent cutter (MSK 760-II, Mado, Germany). Then, ice and pork back fat were added and mixed for additional 2 min 30 s. Finally, the meat batter was homogenized with spices (0.05%, ascorbic acid, 0.5% spice, 2% isolated soy protein, 0.5% sugar, 0.1% pepper, 0.3% onion powder, 0.2% garlic powder, and 0.1% ginger powder) for 3 min. The temperature of the meat batter was maintained below 10°C throughout batter preparation. The meat batter was stuffed into collagen casings (#240; NIPPI Inc., Japan; approximate diameter, 25 mm) using a stuffer (Vacuum stuffer Konti A50, Frey, Germany). The raw sausages were heated to 75±1°C (core temperature) for 30 min in a smoke chamber (1900 EL-C-Q, Kerres, Germany). After cooking, the cooked sausages were cooled, vacuum-packaged, and stored in a 4°C refrigerator for one day until the irradiation process. A total of three different batches were prepared on different days.

Irradiation procedure

The vacuum-packaged emulsion sausages (approximately 25-mm thickness) were irradiated at 5 kGy using three different ionizing sources under the an ambient temperature of 22±2°C. Gamma-ray irradiation was conducted in a cobalt-60 irradiator (100 kCi, AECL, IR-79, MDS Nordion Inc., Canada) at the Korea Atomic Energy Research Institute (Korea) with a source strength of approximately 11.1 PBq, at a dose rate of 10 kGy/h. X-ray and E-beam irradiation were performed using an ELV-4 electron-beam accelerator (10 MeV) and X-ray linear accelerator (7.5 MeV), respectively, at EB-Tech Co. (Korea). X-ray and E-beam irradiation were performed with a beam current of 1 mA and dose rate of 5 kGy/h and 2.9 kGy/s, respectively. For dosimetry of samples, alanine dosimeters (5 mm diameter; Bruker Instruments, Germany) were attached to two different positions (top and bottom) of the samples. The absorbed dose was measured with an electron paramagnetic resonance analyzer in accordance with international standards (ISO/ASTM 51607, 2004). The dose uniformity ratios (min/max ratios) of all irradiation sources were less than 1.2 and the actual dose was within ±5% of the target dose. After irradiation, the irradiated samples were stored at 4±1°C for 28 d and weekly analyzed.

pH values

The pH values of samples were measured in a homogenate prepared with 5 g of sample and distilled water (20 mL) using an electric pH meter (Model 340, Mettler-Toledo GmbH, Switzerland). All determinations were performed in triplicate.

Color measurements

The color of each sample was determined using a colorimeter (Minolta Chroma meter CR-210, Minolta Ltd., Osaka, Japan; illuminate C, calibrated with a white plate, L*=+97.83, a*=−0.43, b*=+1.98) from cross-sections selected from five random locations on cross-section of each sample. Lightness (CIE L*- value), redness (CIE a*- value), and yellowness (CIE b*- value) values were recorded.

2-Thiobarbituric acid-reactive substances (TBARS)

Lipid oxidation was assessed in triplicate by the 2-thiobarbituric acid (TBA) method by Hwang et al. (2015). TBARS values of sausage samples were calculated using a standard curve (8-50 nmol) of 1,1,3,3-tetraethoxy propane (TEP) and expressed as mg malondialdehyde per kg sample (mg MDA/kg sample).

Texture profile analysis (TPA)

The texture profile analysis (TPA) of low-salt sausages were measured using a texture analyzer (TA-XT2i, Stable Micro System Ltd., UK). The sausages samples (20 mm in height) were taken from the central portion of each sample. The conditions of texture analysis were as follows: pre- and post-test speed 2.0 mm/s and 5.0 mm/s, head speed 2.0 mm/s, maximum load 2 kg, distance 8.0 mm, force 5 g. The calculation of texture values was obtained by graphing a curve using time and force plots.

Microbial analyses

The bacterial count in each sample was determined after 0, 7, 14, 21, and 28 d of refrigerated storage, using 3 M-Petrifilm for aerobic count plates, E. coli/coliforms and Enterobacteriaceae (AOAC International, 2005; Silbernagel and Lindberg, 2003). The Pseudomonas spp. were determined using Pseudomonas agar base with Cetrimide-Fucidin-Cephaloridine selective supplement (Oxoid), incubated at 30°C for 48 h (Georgantelis et al., 2007).

Sensory evaluation

The sensory evaluations were performed by nine trained sensory panelists (25-31 years old) from the Department of Food Sciences and Biotechnology of Animal Resources at Konkuk University. The selection of trained panelists was performed according to sensory evaluation procedures (Lawless and Heymann, 2010). Sausage sample were evaluated in terms of the intensity of cured/cooked color, the intensity of cooked meat flavor, the intensity of radiolytic off-flavor, juiciness, tenderness, and overall acceptability. The emulsion sausage samples were reheated until the core temperature reached 40°C, cut into 1-cm-thickness slice, and served randomly to the panelists. Each sample was coded with a randomly selected 3-digit number. Sensory evaluations were performed under fluorescent lighting. Panelists were instructed to cleanse their palates with water before tasting the next samples. The cured/cooked color (1 = weak cured/cooked pink-reddish color, 9 = strong cured/cooked pink-reddish color), cooked meat flavor intensity (1 = extremely weak, 9 = extremely strong), radiolytic off-flavor (1 = extremely strong, 9 = extremely weak), tenderness (1 = extremely tough, 9 = extremely tender), juiciness (1 = extremely dry, 9 = extremely juicy), and overall acceptability (1 = extremely rejective, 9 = extremely acceptable) of the cooked samples were evaluated using a 9-point descriptive scale. This analysis was conducted using the hedonic test described by Bergara-Almeida et al. (2002).

Statistical analysis

The experimental design of this study was a completely randomized block design with three different batches. Statistical analysis and comparisons among means were carried out using the statistical package SPSS 18.0 (SPSS Inc., USA). All data were analyzed by ANOVA to test the effects of two fixed factors: storage periods and irradiation type. The Duncan’s multiple range test was applied for comparisons of means; differences were considered significant at p<0.05.

Results and Discussion

pH and color characteristics

Change in the pH value of irradiated/low-salt sausages during refrigerated storage is shown in Table 1. The initial pH of emulsion sausages was not affected by NaCl level and irradiation source (p>0.05). Similar to our result, Hwang et al. (2015) reported that the pH value of chicken sausages irradiated at 0, 2.5 and 5 kGy was not different. In addition, Kim et al. (2012) also revealed that gamma-ray irradiation within 4 kGy had no impact on the pH values of fermented pork sausage. In this current study, the change in pH value during refrigerated storage was observed at only control, in which the pH increased from 6.25 to 6.36 (p<0.05). However, the pH value of low-salt sausages was not changed during refrigerated storage, regardless of irradiation (p>0.05). Thus, our finding indicates that irradiation had little to no impacts on change in pH value of emulsion sausage during refrigerated storage.

Table 1. Changes in pH value and color characteristics of irradiated/low-salt sausage during refrigerated storage.

| Storage (d) | Control (1.5% NaCl) | Low-salt sausages1) (0.75% NaCl) | SEM2) | |||

|---|---|---|---|---|---|---|

| L-control | γ-ray | E-beam | X-ray | |||

| pH | ||||||

| 0 | 6.25a | 6.27 | 6.29 | 6.32 | 6.30 | 0.013 |

| 7 | 6.32ab | 6.34 | 6.34 | 6.34 | 6.34 | 0.012 |

| 14 | 6.32ab | 6.29 | 6.29 | 6.30 | 6.30 | 0.015 |

| 21 | 6.31ab | 6.26 | 6.26 | 6.29 | 6.30 | 0.012 |

| 28 | 6.36b | 6.32 | 6.29 | 6.30 | 6.30 | 0.013 |

| SEM | 0.014 | 0.014 | 0.013 | 0.012 | 0.012 | |

| CIE L*-value (lightness) | ||||||

| 0 | 75.45Bc | 73.59Ab | 73.78Abc | 73.74Abc | 73.39Ab | 0.371 |

| 7 | 75.50Bc | 74.12Ab | 74.28Ac | 74.18Ac | 74.13Ab | 0.266 |

| 14 | 74.43Cb | 73.63ABb | 73.81ABbc | 73.28Ab | 74.19BCb | 0.203 |

| 21 | 75.34Bc | 73.83Ab | 73.27Ab | 73.58Abc | 73.88Ab | 0.357 |

| 28 | 72.88Ba | 71.82ABa | 71.49Aa | 72.14ABa | 71.38Aa | 0.270 |

| SEM | 0.499 | 0.407 | 0.487 | 0.344 | 0.523 | |

| CIE a*-value (redness) | ||||||

| 0 | 7.95A | 9.35Cb | 9.04BCb | 8.98Bab | 9.32BCc | 0.255 |

| 7 | 7.56A | 8.81Ba | 8.48Ba | 8.72Ba | 8.96Bbc | 0.249 |

| 14 | 7.79A | 9.15Cab | 8.80Cab | 8.87Cab | 8.42Ba | 0.236 |

| 21 | 8.12A | 8.90Bab | 8.95Bb | 9.09Bb | 9.19Bc | 0.189 |

| 28 | 8.10A | 9.25Dab | 8.98Cb | 8.69Ba | 8.75Bab | 0.190 |

| SEM | 0.106 | 0.102 | 0.100 | 0.076 | 0.160 | |

| CIE b*-values (yellowness) | ||||||

| 0 | 12.60ABab | 12.97B | 12.53ABa | 12.33Aa | 12.40Aa | 0.112 |

| 7 | 12.75ab | 13.19 | 12.84a | 12.98bc | 12.88b | 0.076 |

| 14 | 13.41bc | 13.05 | 12.81a | 13.20bc | 13.25b | 0.101 |

| 21 | 13.27Bc | 13.24B | 12.91Aab | 12.74Aab | 12.82Ab | 0.109 |

| 28 | 13.42c | 13.45 | 13.38b | 13.37c | 13.25b | 0.035 |

| SEM | 0.172 | 0.084 | 0.138 | 0.183 | 0.158 | |

1)Low-salt sausages were non-irradiated (L-control) or irradiated with gamma-ray (γ-ray), electron-beam (E-beam), X-ray at 5 kGy, respectively.

2)SEM: the standard error of the means (n=3).

A-CMeans with different letters within the same row were significantly different (p<0.05).

a-cMeans with different letters within the same column were significantly different (p<0.05).

CIE L*-value (lightness) of control sausage was significantly higher than that of low-salt sausages during overall storage period. Among low-salt sausage treatments, there was no significant difference in lightness between L-control and irradiated/low-salt sausages. Similarly, Shin et al. (2014) reported that X-ray or E-beam irradiation did not influence the lightness of emulsion sausage. Park et al. (2010) also reported that the lightness of beef sausage patties was not changed by gamma and E-beam irradiation, regardless of irradiation doses within 0-20 kGy.

At initial storage time (0 d), control sausage exhibited significantly lower redness than irradiated/low-salt sausages. Among low-salt sausages, irradiation tended to decrease redness, in which low-salt sausage irradiated E-beam showed significantly lower redness than L-control sausage. At 28 d of storage period, the redness of low-salt sausage irradiated with E-beam was lower compared to L-control sausage, but higher that control sausage (p<0.05). At during storage period, the redness values of low-salt sausage irradiated with γ-ray and X-ray was similarly to L-control sausage. In relation to this observation, Ham et al. (2017) reported that irradiation up to 10 kGy decreased the redness of emulsion sausage, and they postulated that it might be related to the decomposition of nitrosyl hemochrome.

The initial yellowness of L-control sausage was slightly higher than that of low-salt sausages irradiated with E-beam or X-ray (p<0.05). As storage period increased, the yellowness of all sausage treatments increased (p<0.05). At final storage time (28 d), there was no significant difference in yellowness between sausage treatments. Thus, the results of this current study indicate that γ-ray, E-beam and X-ray irradiation at 5 kGy had little impacts on color characteristics of low-salt sausages during 28 d of refrigerated storage, however, the redness of irradiated/low-salt sausages higher values than control sausage.

Textural properties

Change in textural properties of irradiated/low-salt sausages during refrigerated storage is shown in Table 2. At 0 d, low-salt sausages exhibited significantly lower initial hardness, gumminess and chewiness than control sausage. The textural properties of emulsion sausage are associated with salt-soluble protein extraction, which greatly affects water and fat binding capacities, gel-formation, and viscosity (Lee et al., 1998; Ruusunen and Puolanne, 2005). In general, an increase in NaCl concentration could contribute to increase hardness of emulsion sausage (Tobin et al., 2013). Thus, the decreased hardness, gumminess and chewiness of low-salt sausages was likely due to a decrease in salt-soluble protein solubility with reduced level of NaCl. At 28 d of storage time, although the hardness of low-salt sausages irradiated with E-beam or X-ray was lower than that of L-control sausage (p<0.05), there was no significant differences in gumminess and chewiness between low-salt sausage treatments. In addition, all sausage treatments showed similar springiness and cohesiveness at each storage time (p>0.05). As similar observations, previous studies have reported that irradiation dose or irradiation source had no impacts on textural properties of processed meat products (Gámez et al., 2011; Ham et al., 2017; Park et al., 2010). Thus, our findings also show that the addition level of NaCl could be more critical factor affecting initial textural properties of emulsion sausage, such as hardness, gumminess and chewiness, rather than the application of irradiation and/or irradiation sources.

Table 2. Changes in textural properties of irradiated/low-salt sausage during refrigerated storage.

| Storage (d) | Control (1.5% NaCl) | Low-salt sausages1) (0.75% NaCl) | SEM2) | |||

|---|---|---|---|---|---|---|

| L-control | γ-ray | E-beam | X-ray | |||

| Hardness (g) | ||||||

| 0 | 369.77Ba3) | 291.19Aa | 302.56Aa | 287.82Aa | 294.56Aa | 6.176 |

| 7 | 449.59Bbc | 340.96Ab | 348.98Ab | 347.69Ac | 353.62Ab | 7.852 |

| 14 | 432.78Cb | 325.89ABb | 339.26Ba | 316.26Ab | 332.08ABb | 7.105 |

| 21 | 455.52Cbc | 385.09Bc | 362.68Ac | 361.08Ac | 355.31Ab | 6.233 |

| 28 | 478.26Cc | 389.13BCc | 367.77ABc | 358.28Ac | 348.86Ab | 7.760 |

| SEM | 6.961 | 6.662 | 5.205 | 5.421 | 4.729 | |

| Springiness | ||||||

| 0 | 0.94 | 0.93 | 0.93ab | 0.93ab | 0.93 | 0.003 |

| 7 | 0.95 | 0.94 | 0.93ab | 0.95b | 0.94 | 0.002 |

| 14 | 0.94 | 0.94 | 0.95b | 0.94b | 0.94 | 0.002 |

| 21 | 0.94 | 0.93 | 0.94ab | 0.94ab | 0.93 | 0.002 |

| 28 | 0.94 | 0.93 | 0.93a | 0.92a | 0.94 | 0.003 |

| SEM | 0.002 | 0.003 | 0.003 | 0.003 | 0.002 | |

| Cohesiveness | ||||||

| 0 | 0.44a | 0.44a | 0.45a | 0.45a | 0.44a | 0.002 |

| 7 | 0.46ab | 0.48b | 0.47b | 0.46bc | 0.46b | 0.005 |

| 14 | 0.45Aab | 0.48Bb | 0.47Bb | 0.45Aab | 0.44Aa | 0.003 |

| 21 | 0.45Aab | 0.46Aab | 0.47Bab | 0.48Bc | 0.47Bb | 0.003 |

| 28 | 0.47b | 0.46bc | 0.45ab | 0.46bc | 0.47b | 0.004 |

| SEM | 0.005 | 0.004 | 0.003 | 0.003 | 0.004 | |

| Gumminess (g) | ||||||

| 0 | 161.75Ba | 127.42Aa | 134.68Aa | 128.04Aa | 129.54Aa | 2.540 |

| 7 | 209.19Bbc | 162.00Ab | 163.52Ab | 160.81Ac | 163.71Ac | 3.983 |

| 14 | 194.48Cb | 156.14Bb | 159.30Bb | 142.34Ab | 145.74Ab | 3.195 |

| 21 | 205.10Bb | 175.67Ac | 169.00Bb | 171.80Ac | 167.39Ac | 2.564 |

| 28 | 225.76Bc | 180.69Ac | 167.34Ab | 165.63Ac | 164.99Ac | 4.191 |

| SEM | 4.331 | 3.215 | 2.758 | 3.051 | 2.652 | |

| Chewiness (g) | ||||||

| 0 | 152.21Ba | 118.28Aa | 125.84Aa | 119.07Aa | 120.54Aa | 2.458 |

| 7 | 197.79Bbc | 151.72Ab | 152.73Ab | 152.01Ac | 153.98Ac | 3.780 |

| 14 | 183.76Cb | 147.43Bb | 150.71Bb | 134.15Ab | 136.64Ab | 3.132 |

| 21 | 192.67Bbc | 163.70Ac | 158.50Ab | 160.91Ac | 156.32Ac | 2.428 |

| 28 | 211.49Bc | 167.76Ac | 154.99Ab | 153.14Ac | 154.82Ac | 4.034 |

| SEM | 4.084 | 2.984 | 2.606 | 2.913 | 2.515 | |

1)Low-salt sausages were non-irradiated (L-control) or irradiated with gamma-ray (γ-ray), electron-beam (E-beam), X-ray at 5 kGy, respectively.

2)SEM: the standard error of the means (n=3).

A-CMeans that different letters within the same row were significantly different (p<0.05).

a-cMeans that different letters within the same column were significantly different (p<0.05).

Sensory properties

Change in sensory properties of irradiated/low-salt sausages during refrigerated storage is shown in Table 3. During 28 d of refrigerated storage, all sausage treatments exhibited similar cured/cooked color intensity at each storage time (p>0.05). In terms of flavor parameters, the intensity of cooked meat flavor of low-salt sausages was lower than that of control during overall storage period (p<0.05). Previously, Gillette (1985) reported that NaCl added to meat products plays an important role in forming saltiness, mouthfeel, balance, and sweetness, while it could contribute to decrease off-flavor odors. Thus, it has been suggested that major limitation of low-salt meat products is the declines of perceived saltiness and the intensity of flavor (Desmond, 2006; Ruusunen and Puolanne, 2005). In this current study, low-salt sausage irradiated with γ-ray had a significantly lower cooked meat flavor score than L-control. In addition, irradiated/low-salt sausages showed a significantly higher radiolytic off-flavor scores than L-control, regardless of irradiation source. According to Ahn et al. (2000), radiolytic off-odor in irradiated pork could be due to the formation of volatile sulfur compounds, especially 2,3-dimethyl disulfide, derived from sulfur-containing amino acids. The tenderness and juiciness of emulsion sausages were greatly affected by the addition level of NaCl during overall storage period (p<0.05), rather than the application of irradiation and/or irradiation sources. These results could be due to the reduced addition of NaCl, as mentioned in the instrumental texture above. As expected, the reduced addition of NaCl decreased salty intensity of emulsion sausage (p<0.05). However, the salty intensity score of low-salt sausages was similar, regardless of irradiation source (p>0.05). The result of overall acceptability showed a significantly decreased score in irradiated/low-salt sausages compared to control sausage and even L-control sausage, resulting from the decreased intensity of cooked meat flavor, tenderness, juiciness and radiolytic off-flavor.

Table 3. Changes in sensory properties of irradiated/low-salt sausage during refrigerated storage.

| Storage (d) | Control (1.5% NaCl) | Low-salt sausages1) (0.75% NaCl) | SEM2) | |||

|---|---|---|---|---|---|---|

| L-control | γ-ray | E-beam | X-ray | |||

| Cured/cooked color | ||||||

| 0 | 7.89ab3) | 7.68b | 7.61ab | 7.64b | 7.46 | 0.079 |

| 7 | 7.93b | 7.57ab | 7.68b | 7.46ab | 7.57 | 0.077 |

| 14 | 7.79ab | 7.71b | 7.75b | 7.61b | 7.50 | 0.076 |

| 21 | 7.36a | 7.21ab | 7.39ab | 7.04a | 7.29 | 0.073 |

| 28 | 7.36a | 7.07a | 7.18a | 7.11a | 7.07 | 0.075 |

| SEM | 0.081 | 0.087 | 0.068 | 0.073 | 0.078 | |

| Cooked meat flavor | ||||||

| 0 | 7.36C | 6.64B | 6.04A | 6.43AB | 6.54AB | 0.089 |

| 7 | 7.11C | 6.86BC | 6.21A | 6.36AB | 6.29A | 0.085 |

| 14 | 7.46C | 6.64B | 5.86A | 6.14AB | 6.21AB | 0.090 |

| 21 | 7.11C | 6.50B | 5.86A | 6.14AB | 6.21AB | 0.079 |

| 28 | 7.32C | 6.64B | 5.93A | 6.21AB | 6.14A | 0.083 |

| SEM | 0.066 | 0.067 | 0.094 | 0.075 | 0.082 | |

| Radiolytic off-flavor | ||||||

| 0 | 2.00A | 2.50A | 3.64Ca | 3.54Ba | 3.21Ba | 0.116 |

| 7 | 2.21A | 2.32AB | 3.93Dab | 3.36BCa | 3.82CDab | 0.122 |

| 14 | 2.29A | 3.04A | 4.50Bb | 3.50BCa | 4.04Bb | 0.137 |

| 21 | 2.21A | 2.86AB | 4.21Bab | 3.79Bab | 4.18Bb | 0.130 |

| 28 | 2.04A | 2.79B | 4.14Cab | 4.29Cb | 4.07Cb | 0.119 |

| SEM | 0.095 | 0.1118 | 0.111 | 0.105 | 0.117 | |

| Tenderness | ||||||

| 0 | 7.68B | 6.89A | 6.68A | 6.50A | 6.79Ab | 0.106 |

| 7 | 7.46B | 6.46A | 6.46A | 6.36A | 6.54Aab | 0.088 |

| 14 | 7.25B | 6.68A | 6.46A | 6.50A | 6.61Aab | 0.086 |

| 21 | 7.25B | 6.61A | 6.18A | 6.21A | 6.25Aab | 0.081 |

| 28 | 7.18B | 6.39A | 6.18A | 6.07A | 6.18Aa | 0.084 |

| SEM | 0.081 | 0.086 | 0.083 | 0.090 | 0.084 | |

| Juiciness | ||||||

| 0 | 7.54B | 6.71A | 6.29A | 6.25A | 6.46A | 0.108 |

| 7 | 7.25B | 6.39A | 6.39A | 6.25A | 6.07A | 0.098 |

| 14 | 7.46B | 6.89A | 6.54A | 6.39A | 6.43A | 0.087 |

| 21 | 7.18B | 6.75B | 5.96A | 6.04A | 6.14A | 0.092 |

| 28 | 7.29B | 6.43A | 6.11A | 5.96A | 6.07A | 0.089 |

| SEM | 0.061 | 0.103 | 0.096 | 0.096 | 0.080 | |

| Saltiness | ||||||

| 0 | 5.79B | 4.61A | 4.46A | 4.43A | 4.64A | 0.099 |

| 7 | 5.93B | 4.71A | 4.61A | 4.46A | 4.50A | 0.100 |

| 14 | 5.71B | 4.50A | 4.25A | 4.39A | 4.50A | 0.097 |

| 21 | 5.50B | 4.64A | 4.54A | 4.32A | 4.64A | 0.094 |

| 28 | 6.00B | 4.57A | 4.46A | 4.18A | 4.36A | 0.109 |

| SEM | 0.091 | 0.095 | 0.092 | 0.090 | 0.079 | |

| Overall acceptability | ||||||

| 0 | 7.46B | 6.46A | 6.07A | 6.36Ab | 6.50Ab | 0.099 |

| 7 | 7.36B | 6.93B | 6.32A | 6.43Ab | 6.21Aab | 0.082 |

| 14 | 7.57C | 6.50B | 5.96A | 6.36ABb | 6.14ABab | 0.083 |

| 21 | 7.36C | 6.57B | 5.96A | 6.14Aab | 5.93Aa | 0.081 |

| 28 | 7.50C | 6.43B | 5.89A | 5.79Aa | 5.93Aa | 0.082 |

| SEM | 0.076 | 0.077 | 0.069 | 0.076 | 0.073 | |

1)Low-salt sausages were non-irradiated (L-control) or irradiated with gamma-ray (γ-ray), electron-beam (E-beam), X-ray at 5 kGy, respectively.

2)SEM: the standard error of the means (n=3).

A-DMeans that different letters within the same row were significantly different (p<0.05).

a,bMeans that different letters within the same column were significantly different (p<0.05).

2-Thiobarbituric acid-reactive substances (TBARS)

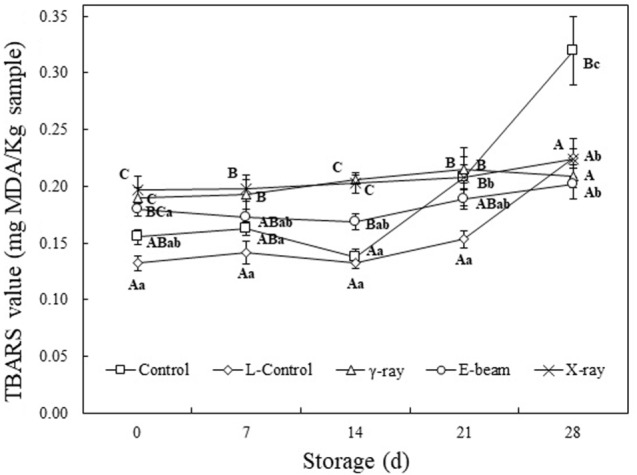

The effect of irradiation source on TBARS values of irradiated/low-salt sausages during 28 d of refrigerated storage is shown in Fig. 1. At initial storage time (0 d), L-control sausage (0.13 mg MDA/kg sample) had a slightly lower TBARS value than control sausage (0.16 mg MDA/kg sample), while it was not significant. However, irradiation obviously increased TBARS value of low-salt sausages, when compared to L-control sausage (p<0.05). As refrigerated storage period increased, TBARS value of all sausage treatment significantly increased. From 21 d of storage time, in addition, the TBARS value of control sausage noticeably increased. At the end of storage, the highest TBARS value was found at control (p<0.05), in which there was no significant difference in TBARS value between low-salt sausages. It could be interest to note that irradiated/low-salt sausages showed the delayed lipid oxidation compared to control sausage, since it has been known that irradiation accelerates lipid oxidation of meat products (Ahn et al., 2000). In general, lipid oxidation of processed meat products is highly dependent on the addition level of NaCl (Love and Pearson, 1971). Jin et al. (2012) reported that the TBARS value of pork muscle was greatly increased with increasing the adding amount of NaCl (0.5-4%). According to Lee et al. (1997), the addition of NaCl over 1% could accelerate lipid oxidation of pork meat during 4 wk of storage. In this current study, thus, the accelerated lipid oxidation of control sausage from 21 d could result from the relatively high amount of NaCl. As well as, E-beam irradiation could slowly accelerate lipid oxidation of low-salt sausages than γ-ray or X-ray irradiation. Ham et al. (2017) recently reported that gamma-ray or X-ray irradiation significantly increased the TBARS value of processed meat products, when compared to E-beam irradiation. Lee et al. (2008) reported that the gamma ray more affects the decomposition of the long chain of fatty acids and the double bonds of unsaturated fatty acids than E-beam, when irradiated at the same dose.

Fig. 1. Change in TBARS value of irradiated/low-salt sausages during refrigerated storage.

Treatments: Control ( □ ), sausage with 1.5% NaCl; L-control (◇), sausage with 0.75% NaCl; γ-ray (△), gamma-ray irradiated sausage with 0.75% NaCl; E-beam (○), E-beam irradiated sausage with 0.75% NaCl; X-ray (×), X-ray irradiated sausage with 0.75% NaCl. A-CMeans sharing different letters within each storage day are significantly different (p<0.05). a-cMeans sharing different letters within each treatment are significantly different (p<0.05).

Microbial properties

Change in microbial properties of irradiated/low-salt sausages during refrigerated storage is shown in Table 4. The initial total aerobic bacteria (TAB) populations in control and L-control treatments was less than 1 log CFU/g, whereas it was not detected in irradiated/low-salt sausages, regardless of irradiation source. At 28 d of storage time, the TAB population of control sausage and L-control sausage was 3.5 and 6.0 Log CFU/g, respectively. On the other hand, the growth of TAB in low-salt sausages irradiated with γ-ray was not observed until 28 d of storage. Similarly, Park et al. (2010) indicated that γ-ray irradiation was more effective in preventing the growth of TAB in beef sausage patty, rather than E-beam irradiation. The coliform and Enterobacteriaceae were detected in only L-control, at 14 (3.1 Log CFU/g) and 21 d (1.7 Log CFU/g). Pseudomonas spp. are well-known food spoilage gramnegative bacteria and are known to grow at low temperatures of less than 7°C as a halophilic bacteria (Jay et al., 2003; Ventosa et al., 1998). Our result showed no initial growth of Pseudomonas spp. in all treatments. At 21 d of storage, only L-control had the population of Pseudomonas spp. (2.0 Log CFU/g), but it was not detected in other treatments. Finally, at 28 d, control and L-control sausage had Pseudomonas spp. population of 0.6 and 5.1 Log CFU/g, respectively. Thus, the results of this current study indicate that irradiation technology could be the most effective way to inhibit microbial growth of low-salt sausage.

Table 4. Changes in microbial properties (Log CFU/g) of irradiated/low-salt sausage during refrigerated storage.

| Storage (d) | Control (1.5% NaCl) | Low-salt sausages1) (0.75% NaCl) | SEM2) | |||

|---|---|---|---|---|---|---|

| L-control | γ-ray | E-beam | X-ray | |||

| Aerobic count plates | ||||||

| 0 | 1<Aa | 1<Ba | NDA | NDAa | NDAa | 0.062 |

| 7 | 1<Bab | 1<Ba | NDA | NDAa | NDAa | 0.074 |

| 14 | 1.1Bab | 3.2Cb | NDA | NDAa | NDAa | 0.328 |

| 21 | 1.2Bb | 4.2Cc | NDA | NDAa | NDAa | 0.448 |

| 28 | 3.5Bc | 6.0Cd | NDA | 1<Ab | 1<Ab | 0.610 |

| SEM | 0.372 | 0.585 | - | 0.063 | 0.083 | |

| Coliform | ||||||

| 0 | ND3) | NDa | ND | ND | ND | 0.000 |

| 7 | ND | NDa | ND | ND | ND | 0.000 |

| 14 | ND | 1<a | ND | ND | ND | 0.015 |

| 21 | ND | 1<a | ND | ND | ND | 0.015 |

| 28 | NDA | 3.1Ba | NDA | NDA | NDA | 0.347 |

| SEM | 0.000 | 0.345 | - | - | - | |

| Enterobacteriaceae | ||||||

| 0 | ND | NDa | ND | ND | ND | 0.000 |

| 7 | ND | NDa | ND | ND | ND | 0.000 |

| 14 | ND | NDa | ND | ND | ND | 0.000 |

| 21 | ND | 1<a | ND | ND | ND | 0.015 |

| 28 | NDA | 1.7Bb | NDA | NDA | NDA | 0.156 |

| SEM | 0.000 | 0.155 | - | - | - | |

| Pseudomonas spp. | ||||||

| 0 | ND | NDa | ND | ND | ND | 0.000 |

| 7 | ND | NDa | ND | ND | ND | 0.000 |

| 14 | ND | NDa | ND | ND | ND | 0.000 |

| 21 | NDA | 2.0Bb | NDA | NDA | NDA | 0.272 |

| 28 | 1<A | 5.1Bc | NDA | NDA | NDA | 0.479 |

| SEM | 0.124 | 0.509 | - | - | - | |

1)Low-salt sausages were non-irradiated (L-control) or irradiated with gamma-ray (γ-ray), electron-beam (E-beam), X-ray at 5 kGy, respectively.

2)SEM: the standard error of the means (n=3).

3)ND: Not detected.

A-CMeans that different letters within the same row were significantly different (p<0.05).

a-dMeans that different letters within the same column were significantly different (p<0.05).

Conclusion

In this study, our findings confirmed that 50% reduction in NaCl (from 1.5% to 0.75%) could decrease some quality attributes of emulsion sausage, particularly textural, sensory and microbial properties. Through irradiation technology, the microbial safety of low-salt emulsion sausages could be effectively improved. However, irradiation could result in negative impacts on sensory acceptance of low-salt emulsion sausages, regardless of irradiation sources. Therefore, this study indicates that irradiation technique could be used to improve microbial safety of low-salt meat products, and suggests that further studies for inhibiting and/or masking radiolytic off-flavor would be performed to ensure its practical use for low-salt meat products.

References

- Ahn D. U., Jo C., Olson D. G. Analysis of volatile components and the sensory characteristics of irradiated raw pork. Meat Sci. 2000;54:209–215. doi: 10.1016/S0309-1740(99)00081-9. [DOI] [PubMed] [Google Scholar]

- AOAC International. Official methods of analysis of AOAC International. 18th ed. AOAC International; Gaithersburg, Md: 2005. Aerobic plate count in food, dry rehydratable film, Method 990.12.; E. coli count in foods, dry rehydratable film, Method 991.14 [Google Scholar]

- Bergara-Almeida S., Aparecida M., Silva A. P. Hedonic scale with reference: performance in obtaining predictive models. Food Qual. Prefer. 2002;13:57–64. doi: 10.1016/S0950-3293(01)00057-X. [DOI] [Google Scholar]

- Byun M. W., Lee K. H., Kim D. H., Kim J. H., Yook H. S., Ahn H. J. Effects of gamma radiation on sensory qualities, micobilogical and chemical properties of salted and fermented squid. J. Food. Prot. 2000;63:934–939. doi: 10.4315/0362-028X-63.7.934. [DOI] [PubMed] [Google Scholar]

- Codex Alimentarius Commission. Codex general standard for irradiated foods. Codex stan,106-1983. Rev. 1-2003. 2003.

- Desmond E. Reducing salt: A challenge for the meat industry. Meat Sci. 2006;74:188–196. doi: 10.1016/j.meatsci.2006.04.014. [DOI] [PubMed] [Google Scholar]

- Gámez M. C., García M. L., Selgas M. D., Calvo M. M. Irradiation of ready-to-eat sausages containing lycopene. Ital. J. Food Sci. 2011;23:260–269. [Google Scholar]

- García-García E., Totosaus A. Low-fat sodium reduced sausages: Effect of the interaction between locust bean gum, potato starch and κ-carrageenan by a mixture design approach. Meat Sci. 2008;78:406–413. doi: 10.1016/j.meatsci.2007.07.003. [DOI] [PubMed] [Google Scholar]

- Georgantelis D., Ambrosiadis I., Katikou P., Blekas G., Georgakis S. A. Effect of rosemary extract, chitosan and α-tocopherol on microbiological parameters and lipid oxidation of fresh pork sausages stored at 4°C. Meat Sci. 2007;76:172–181. doi: 10.1016/j.meatsci.2006.10.026. [DOI] [PubMed] [Google Scholar]

- Gillette M. Flavor effects of sodium chloride. Food Tech. 1985;39:47–52. [Google Scholar]

- Go S. M. Effect of irradiation conditions on production of 2-alkylcyclobutanones in meat. M.S. thesis. Chonnam National Univ.; Gwanju, Korea: 2016. [Google Scholar]

- Grégoire O., Cleland M. R., Mittendorfer J., Dababneh S., Ehlermann D. A. E., Fan X., Käppeler F., Logar J., Meissner J., Mullier B., Stichelbaut F., Thayer D. W. Radiological safety of food irradiation with high energy X-rays: Theoretical expectations and experimental evidence. Radiat. Phy. Chem. 2003;67:169–183. doi: 10.1016/S0969-806X(02)00410-3. [DOI] [Google Scholar]

- Grossi A., Søltoft-Jensen J., Knudsen J. C., Christensen M., Orlien V. Reduction of salt in pork sausage by the addition of carrot fibre or potato starch and high pressure treatment. Meat Sci. 2012;92:481–489. doi: 10.1016/j.meatsci.2012.05.015. [DOI] [PubMed] [Google Scholar]

- Ham Y. K. Effects of irradiation source and dose level on quality characteristics and oxidative stability of meat and processed meat. Ph. D. thesis. Konkuk Univ.; Seoul, Korea: 2017. [Google Scholar]

- Ham Y. K., Kim H. Y., Hwang K. E., Song D. H., Kim Y. J., Choi Y. S., Song B. S., Park J. H., Kim C. J. Effects of irradiation source and dose level on quality characteristics of processed meat products. Radiat. Phy. Chem. 2017;130:259–264. doi: 10.1016/j.radphyschem.2016.09.010. [DOI] [Google Scholar]

- Hwang K. E., Kim H. W., Song D. H., Kim Y. J., Ham Y. K., Lee J. W., Choi Y. S., Kim C. J. Effects of antioxidant combinations on shelf stability of irradiated chicken sausage during storage. Radiat. Phys. Chem. 2015;106:315–319. doi: 10.1016/j.radphyschem.2014.08.014. [DOI] [Google Scholar]

- ISO/ASTM 51607, Practice for Use of an Alanine/EPR Dosimetry System. ASTM International; West Conshohocken, PA, USA: 2004. [Google Scholar]

- Jay J. M., Vilai J. P., Hughes M. E. Profile and activity of the bacterial biota of ground beef held from freshness to spoilage at 5-7°C. Int. J. Food Microbiol. 2003;81:105–111. doi: 10.1016/S0168-1605(02)00189-7. [DOI] [PubMed] [Google Scholar]

- Jin G., He L, Zhang J., Yu X., Wang J., Huang F. Effects of temperature and NaCl percentage on lipid oxidation in pork muscle and exploration of the controlling method using response surface methodology (RSM) Food Chem. 2012;131:817–825. doi: 10.1016/j.foodchem.2011.09.050. [DOI] [Google Scholar]

- Kim I. S., Jo C., Lee K. H., Lee E. J., Ahn D. U., Kang S. N. Effects of low-level gamma irradiation on the characteristics of fermented pork sausage during storage. Radiat. Phys. Chem. 2012;81:466–472. doi: 10.1016/j.radphyschem.2011.12.037. [DOI] [Google Scholar]

- Lawless H. T., Heymann H. Descriptive analysis. Sensory Evaluation of Food. 2nd ed. Spinger; Berlin. Germany: 2010. pp. 227–252. [Google Scholar]

- Lee H. S., Choi J. I., Kim H. J., Yoo C. W., Kim J. B., Hwang Y. J., Chung Y. J., Kim J. K., Byun M. W., Lee J. W. Study on the change of total fat content and fatty acid composition of the ethanol extract from cooking drips of Thunnus thynnus by ionizing irradiation. J. Radiat. Ind. 2008;2:65–71. [Google Scholar]

- Lee K. H., Ahn H. J., Jo C., Yook H. S., Byun M. W. Production of low salted and fermented shrimp by irradiation. J. Food. Sci. 2002;67:1772–1777. doi: 10.1111/j.1365-2621.2002.tb08721.x. [DOI] [Google Scholar]

- Lee S. K., Chang H. S., Kim H. J. Heat-induced denaturation of salt soluble protein extracted from spent layer meat. Korean J. Food Sci. An. 1998;18:209–215. [Google Scholar]

- Lee S. K., Mei L., Decker E. A. Influence of sodium chloride on antioxidant enzyme activity and lipid oxidation in frozen ground pork. Meat Sci. 1997;46:349–355. doi: 10.1016/S0309-1740(97)00029-6. [DOI] [PubMed] [Google Scholar]

- Love J. D., Pearson A. M. Lipid oxidation in meat and meat products-A review. J. Am. Oil Chem. Soc. 1971;48:547–549. doi: 10.1007/BF02544559. [DOI] [Google Scholar]

- Miller R. B. Food irradiation using bremsstrahlung X-rays. Radiat. Phys. Chem. 2003;68:963–974. doi: 10.1016/j.radphyschem.2003.06.002. [DOI] [Google Scholar]

- Park B. J., Jang K. S., Kim D. H., Yook H. S., Byun M. W. Changes of microbiological and physicochemical characteristics of Doenjang prepared tith low salt content and gamma irradiation. Korean J. Food Sci. Technol. 2002;34:79–84. [Google Scholar]

- Park J. G., Yoon Y., Park J. N., Han I. J., Song B. S., Kim J. H., Kim W. G., Hwang H. J., Han S. B., Lee J. W. Effects of gamma irradiation and electron beam irradiation on quality, sensory, and bacterial populations in beef sausage patties. Meat Sci. 2010;85:368–372. doi: 10.1016/j.meatsci.2010.01.014. [DOI] [PubMed] [Google Scholar]

- Roberts P. B. Food irradiation is safe: Half a century of studies. Radiat. Phys. Chem. 2014;105:78–82. doi: 10.1016/j.radphyschem.2014.05.016. [DOI] [Google Scholar]

- Ruusunen M., Puolanne E. Reducing sodium intake from meat products. Meat Sci. 2005;70:531–541. doi: 10.1016/j.meatsci.2004.07.016. [DOI] [PubMed] [Google Scholar]

- Shin M. H., Lee J. W., Yoon Y. M., Kim J. H., Moon B. G., Kim J. H., Song B. S. Comparison of quality of bologna sausage manufactured by electron beam or X-ray irradiated ground pork. Korean J. Food Sci. An. 2014;34:464–471. doi: 10.5851/kosfa.2014.34.4.464. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Silbernagel K. M., Lindberg K. G. 3M™ petrifilm™ Enterobacteriaceae count plate method for enumeration of Enterobacteriaceae in selected foods: Collaborative study. J. AOAC Int. 2003;86:802–815. [PubMed] [Google Scholar]

- Song D. H., Hwang K. E., Lim Y. B., Yeo I. J., Jeong T. J., Kim C. J. Effect of reducing sodium chloride and sodium nitrite concentrations on physicochemical properties of sausages; 46st Proceedings of Korean Society for Food Science of Animal Resources Conference; 2014. p. 283. [Google Scholar]

- Tobin B. D., O’Sullivan M. G., Hamill R. M., Kerry J. P. The impact of salt and fat level variation on the physiochemical properties and sensory quality of pork breakfast sausages. Meat Sci. 2013;93:145–152. doi: 10.1016/j.meatsci.2012.08.008. [DOI] [PubMed] [Google Scholar]

- Ventosa A., Nieto J. J., Oren A. Biology of moderately halophilic aerobic bacteria. Microbiol Mol. Biol. Rev. 1998;62:504–544. doi: 10.1128/mmbr.62.2.504-544.1998. [DOI] [PMC free article] [PubMed] [Google Scholar]