Abstract

Morphology‐controlled nanomaterials such as silica play a crucial role in the development of technologies for addressing challenges in the fields of energy, environment, and health. After the discovery of Stöber silica, followed by that of mesoporous silica materials, such as MCM‐41 and SBA‐15, a significant surge in the design and synthesis of nanosilica with various sizes, shapes, morphologies, and textural properties has been observed in recent years. One notable invention is dendritic fibrous nanosilica, also known as KCC‐1. This material possesses a unique fibrous morphology, unlike the tubular porous structure of various conventional silica materials. It has a high surface area with improved accessibility to the internal surface, tunable pore size and pore volume, controllable particle size, and, importantly, improved stability. Since its discovery, a large number of studies have been reported concerning its use in applications such as catalysis, solar‐energy harvesting, energy storage, self‐cleaning antireflective coatings, surface plasmon resonance‐based ultrasensitive sensors, CO2 capture, and biomedical applications. These reports indicate that dendritic fibrous nanosilica has excellent potential as an alternative to popular silica materials such as MCM‐41, SBA‐15, Stöber silica, and mesoporous silica nanoparticles. This Review provides a critical survey of the dendritic fibrous nanosilica family of materials, and the discussion includes the synthesis and formation mechanism, applications in catalysis and photocatalysis, applications in energy harvesting and storage, applications in magnetic and composite materials, applications in CO2 mitigation, biomedical applications, and analytical applications.

Keywords: carbon dioxide capture, energy storage, heterogeneous catalysis, hybrid materials, nanostructures

1. Introduction

Porous materials have wide applications in materials science as exceptional building blocks for the development of various technologies.1, 2, 3, 4, 5 The use of silica as a porous material is well established owing to its useful properties such as low density, low toxicity with good biocompatibility, ease of surface modification, stability, and cost effectiveness.3, 4, 5 The need for silica nanospheres with different dimensions, surface areas, pore sizes, and morphologies is continuously growing. The investigation of silica nanospheres began after the development of Stöber's innovative method for the synthesis of monodispersed silica,6 which was followed by breakthrough work by Kresge on the template‐directed synthesis of mesoporous silica (such as MCM‐41)7 and then another breakthrough by Stucky on the triblock copolymer‐templated synthesis of mesoporous silica (SBA‐15).8, 9, 10 These templating protocols led to the synthesis of a wide range of mesoporous and nanosilica materials.11, 12, 13, 14, 15, 16 The efficiency of these materials for various applications is mainly due to their porous structure, which allows guest molecules to disperse on their large internal surfaces. However, owing to small tubular pores with only two openings, accessibility of the surface inside the pores is somewhat restricted, and this causes significant mass‐transport issues (Table 1). Additionally, the small pore mouth becomes blocked if loaded with guest molecules, which further reduces the accessibility of the internal surface. Stability is another critical challenge that these materials face as a result of their thin silica walls, which collapse upon heating at high temperatures (Table 1). However, both the accessibility and stability are improved to some extent in SBA‐15 materials. Given that both MCM‐41 and SBA‐15 have large particle sizes (microns in size), they do not disperse easily in solvents, which is critical for various applications. Thus, high surface area silica materials with improved internal surface accessibility, tunable pore sizes and pore volumes, controllable particle sizes, and, importantly, improved stability are needed for various applications in the fields of catalysis, gas capture, solar‐energy harvesting, energy storage, sensors, and biomedical applications. Control over the morphology of silica is also critical for tuning their functions and properties.

Table 1.

Comparison between DFNS, MCM‐41, SBA‐15, Stöber silica, and MSN.

| Sample | BET surface | Pore volume | Pore size | Mechanical | Hydrothermal | Thermal | Particle size | Morphology |

|---|---|---|---|---|---|---|---|---|

| area [m2 g−1] | [cm3 g−1] | [nm] | stability [MPa] | stability [°C] (time [h]) | stability [°C] | |||

| DFNS | 486–124419 | 0.54–2.1819 | 3–2519 | 21619 | 100 (24)17 | 95017 | 50–111019 | fibrous spheres |

| MCM‐41 | ≥10007 | 0.7–1.27 | 307a | 867b | <50 (20)7c | 7077d | bulk (μm) | hexagonal tubular |

| SBA‐15 | ≥10408a | 0.75–1.158a | 5–508b | 2608c | 100 (24)8d | 6008e | bulk (μm) | hexagonal tubular |

| Stöber silica | 10–3468b | 0.017–0.2178b | 1.2–5.98b | NA[a] | NA[a] | NA[a] | 20–30008a | solid spheres |

| MSN | 289–115711b | 0.85–0.9511b | 2.88–9.9211b | NA[a] | NA[a] | NA[a] | 78–44311b,11c | porous |

[a] NA: not available.

Dendritic fibrous nanosilica is a recent discovery of Polshettiwar and co‐workers17, 18 in morphology‐controlled nanomaterials, and it shows exceptional activities in almost all fields, including catalysis, gas capture, solar‐energy harvesting, energy storage, sensors, and biomedical applications. Owing to the fibrous morphology of this material, it was named fibrous nanosilica (KCC‐1) in our original report.17 However, the fibers are like thin sheets that are 3.5 to 5.2 nm thick (like the petals of a flower) rather than sharp needle‐shaped rods, and hence, several other names have been used in the literature, such as fibrous, wrinkled, nanoflower, dendritic, dandelion, and lamellar. To avoid confusion, in this Review, we try to use the name that was used in the respective original studies; however, to have continuity in reading, dendritic fibrous nanosilica is used as a common name for this family of materials.

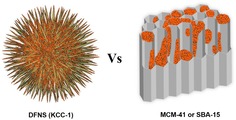

The uniqueness of DFNS is mainly due to its dendritic fibrous morphology, which is in principle accessible from all sides (as compared to the tubular pores of MCM‐41 and SBA‐15) (Figure 1). This improved accessibility allows increased loading of active sites (such as metals, metal oxides, organometallics, organic molecules, etc.) onto the silica surface without blocking the pores (channels) and, more importantly, allows increased accessibility of these generated active sites. The surface area of DFNS can vary from 450 to as high as 1244 m2 g−1 by tuning the particle size (40–1120 nm) and fiber density (number of fibers within one sphere).18 Notably, unlike the narrow pore‐size distribution found in conventional silica materials, DFNS possesses radially oriented pores (fibrous channels), the size of which increases from the center of the sphere to its outer surface. Control over the fiber density of DFNS allows pore sizes and volumes to be tuned. Its tunable pore sizes (3.7–25 nm) allow pores to be tailor‐made to fit specific guest molecules with various sizes, whereas its tunable pore volume (up to 2.18 cm3 g−1) also allows high loadings of these guests.18 Guests include organic molecules, organometallic complexes, inorganic salts, metals, metal oxides, peptides, proteins, enzymes, polymers, and carbon. The integrated porosity of DFNS in addition to its hierarchical pore arrangement containing mesopores of various sizes (including good amounts of micro‐ and macropores) help the guest molecules to adsorb efficiently and to diffuse inside the fibrous spheres with minimum constraints; this helps to increase the overall accessibility of the internal surface and active sites (a critical issue in conventional mesoporous materials). Macropores aid in the efficient initial adsorption/diffusion of guest molecules. DFNS also possesses better stability (chemical, mechanical, thermal, and hydrothermal) than conventional mesoporous materials, which is a serious concern because of their thin silica walls. DFNS is also nontoxic and biocompatible. Control over the particle size allows fine‐tuning of the dispersion and uptake of these nanospheres.

Figure 1.

Advantages of using DFNS over MCM‐41 or SBA‐15 as a support. Orange dots represent active sites. (The fibers of DFNS are not as sharp and pointed as is shown in this cartoon, and they more so resemble the wrinkled petals of a flower.) Adopted with permission from Ref. 77. Copyright 2016 American Chemical Society.

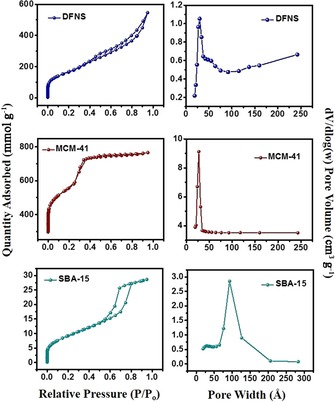

DFNS, owing to its unique properties, has become a family of dendritic fibrous nanosilica spheres with a wide range of applications. It seems to have excellent potential as an alternative to popular silica materials such as MCM‐41, SBA‐15, Stöber silica, and mesoporous silica nanoparticles (MSNs) (Table 1, Figure 2). Although the surface area of DFNS is lower than that of either MCM‐41 or SBA‐15, accessibility of the surface area of DFNS is dramatically better than that of conventional silica, which allows increased loading of active sites and better diffusion of the reactants than that observed for MCM‐41 and SBA‐15 (Figure 1). DFNS also has a very unique pore‐size distribution (distance between fibers or channel size), which gradually increases from 3 to approximately 25 nm, unlike the narrow pore‐size distribution observed in conventional porous materials (Figure 2).

Figure 2.

N2 sorption isotherms (left) and pore‐size distributions (right) of DFNS, MCM‐41, and SBA‐15.

Herein, we review the synthesis and mechanism of formation of DFNS, followed by its application in catalysis, photocatalysis, CO2 mitigation, biomedical technology, drug delivery, sensors, and supercapacitors. If possible, a comparison is made with conventional mesoporous materials, such as MCM‐41, SBA‐15, Stöber silica, and MSNs.

2. Synthesis and Mechanism of Formation of Dendritic Fibrous Nanosilica

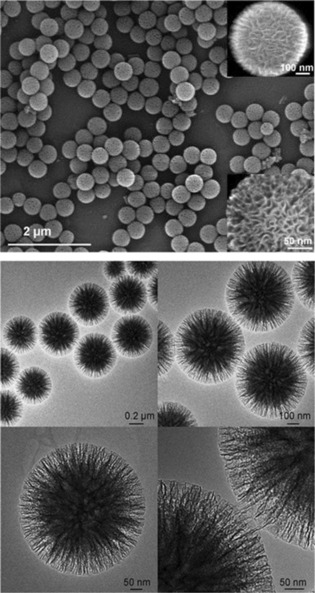

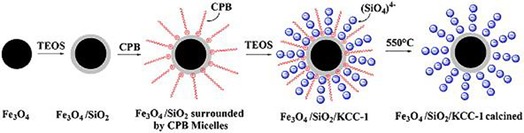

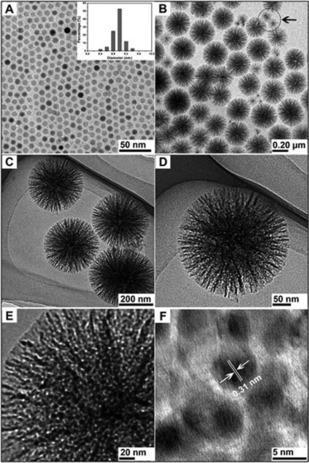

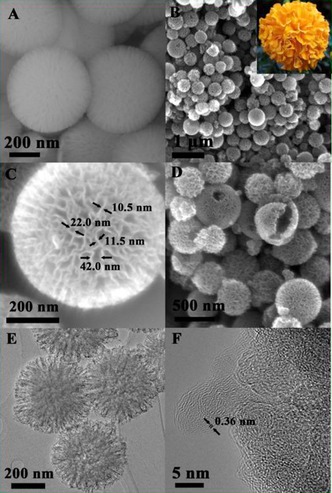

In our original work, the synthesis of DFNS was achieved by a microwave‐assisted templated solvothermal protocol.17, 19 We used cetylpyridinium bromide (CPB) or cetyltrimethylammonium bromide (CTAB) as the template (surfactant), 1‐pentanol was used as a co‐surfactant, tetraethyl orthosilicate (TEOS) acted as the Si source, urea served as the hydrolyzing agent (catalyst), and a mixture of cyclohexane and water was used as the reaction solvent. The synthesis involved the stepwise addition and systematic mixing of these chemicals, followed by microwave‐assisted heating in a closed vessel at 120 °C for various reaction times. After washing and calcination, silica nanospheres (250 to 450 nm in size) were obtained with dendritic fibrous morphologies (Figure 3).

Figure 3.

Top) Scanning electron microscopy (SEM) images and bottom) high‐resolution transmission electron microscopy images of fibrous silica nanospheres (DFNS).17

Close inspection of these images indicated that each sphere of DFNS was made up of dendritic fibers radially arranged and wrinkled with each other. Note that these fibers were not sharp hairy fibers but rather that they resembled the petals of a flower. Notably, the DFNS material was found to have a high surface area and pore volume. DFNS also inherently possesses excellent physicochemical properties, such as thermal stability up to 800 °C, mechanical stability up to 100 MPa, and hydrothermal stability. In our work,17 we also showed the possibility to control the sphere size, as well as the fiber density, simply by tuning the amount of urea and the reaction time.

After our discovery of DFNS,17 several reports appeared in the literature for the synthesis of DFNS with controllable sizes and textural properties by modifying the various reaction parameters (Table 2).

Table 2.

Summary of various synthesis conditions for DFNS.[a]

| Entry | Si precursor | Surfactant | Co‐surfactant | Base | Solvent | Reaction conditions | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | TEOS | CTAB or CPB | 1‐pentanol | urea | water/cyclohexane | 120 °C, 4 h | 17, 19 |

| 2 | TEOS | CPB | propan‐2‐ol or n‐butanol | urea | water/cyclohexane | 70 °C, 16‐20 h | 20, 21 |

| 3 | TEOS | CTAB | n‐butanol | urea | water/toluene | 120 °C, 4 h | 22 |

| 4 | TEOS | CTAT | none | organic amines | water | 80 °C, 2 h | 23 |

| 5 | TEOS | CTAT | [BMIM]OTf | triethanolamine | water | 80 °C, 3 h | 24 |

| 6 | TEOS | CPB | 1‐pentanol | urea | water/cyclohexane | 120 °C, 20 h | 25 |

| 7 | TEOS | CTAC | none | triethanolamine | water/1‐octadecene | 60 °C, 12 h | 26 |

| 8 | TEOS | CTAB | ethanol | aqueous NH3 | water/ethyl ether | 20 °C, 4 h | 27 |

| 9 | TMOS | CTAB | none | triethanolamine | water | 80 °C, 12 h | 28 |

| 10 | TEOS | CTAB | ethanol | lysine, AIBA | water/octane and styrene | 70 °C, 20 h | 29 |

[a] TEOS: tetraethoxysilane, TMOS: tetramethoxysilane, CTAB: cetyltrimethylammonium bromide, CPB: cetylpyridinium bromide, CTAT: cetyltrimethylammonium tosylate, [BMIM]OTf: 1‐butyl‐3‐methylimidazolium trifluoromethanesulfonate, CTAC: cetyltrimethylammonium chloride, AIBA: 2,2′‐azobis(2‐methylpropionamidine) dihydrochloride.

The mechanism of formation of DFNS seems to be very complex, and although we did not study the mechanism of formation of DFNS in our original study,17 we did propose a mechanism on the basis of experimental observations and literature reports. The mechanism was thought to include the formation of reverse micelles of surfactant (template) molecules, followed by the assembly of hydrolyzed TEOS molecules (negatively charges silicates) within the space available in the template molecules. Finally, condensation of these silicates leads to the formation of silica, which grow in the radial direction to form spheres. However, this proposed mechanism does not answer some key questions, such as the disparity between the micelle size and the DFNS particle size, variation in the sphere size, and the dendritic nature of the silica fibers. Hence, this initially proposed mechanism does not stand valid today.

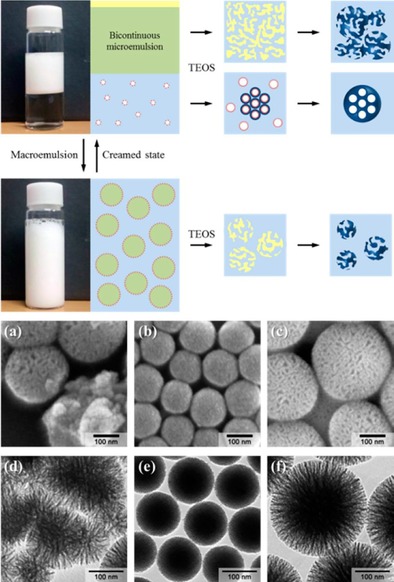

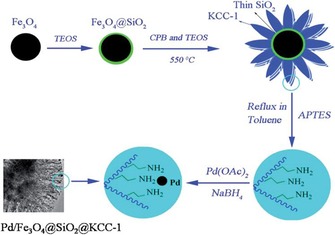

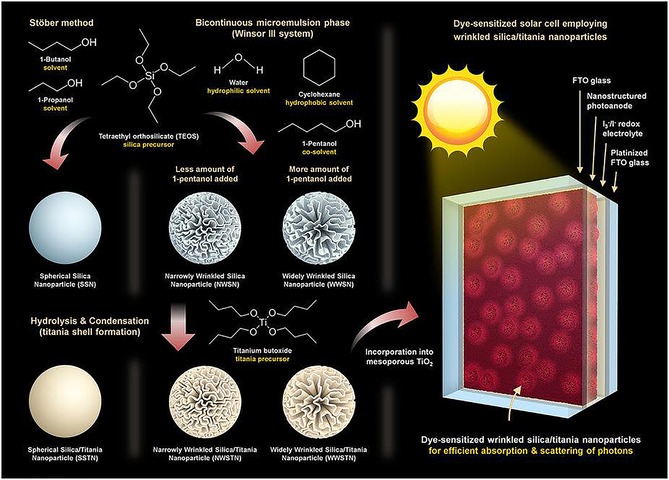

Nearly two years after of our initial DFNS report,17 Moon and Lee conducted an exceptionally detailed mechanistic study by using a bicontinuous microemulsion model (Winsor systems) to explain the mechanism of formation of DFNS, which they renamed wrinkled silica nanoparticles (WSNs).20 They proposed the formation of DFNS by using the Winsor III system, which was formed with a bicontinuous microemulsion phase consisting of the surfactant along with water and oil in the middle layer, and the excess amounts of water and oil were separated into the bottom and top layers.20 They investigated the wrinkled structure of the silica nanospheres generated under various reaction conditions by slightly modifying our original synthetic procedure:17 they replaced pentanol with propan‐2‐ol and replaced microwave heating with conventional heating at 70 °C for 16 h. They monitored the evolution of nanospheres at different time intervals. They observed an increase in the size of the particles with time but no change in the interwrinkle distances (the distance between two fibers). On the basis of these results, they proposed the bicontinuous template model (Winsor III) for the mechanism of formation. To study their hypothesis, they separated the middle bicontinuous microemulsion layer and the lower water layer (in a 1:1 volume ratio of cyclohexane/water), and silica was grown in each layer separately. They observed mesoporous silica nanoparticle formation in the water layer, whereas the formation of DFNS was observed in the microemulsion layer. This implied that bicontinuous microemulsion in a Winsor III system was the correct model.

Although wrinkled silica nanospheres were formed in the microemulsion layer, they were aggregated, unlike those in the stirred microemulsion system (Figure 4 e f). However, upon dilution of this separated microemulsion layer with water or cyclohexane, the layer dispersed quickly in water but remained as droplets in cyclohexane, which indicated that it was an oil‐in‐water‐type macroemulsion system, within which the bicontinuous microemulsion was distributed (Figure 4, top panel). They proposed that the hydrolysis–condensation of TEOS occurred in these bicontinuous microemulsion droplets within the macroemulsion system to yield monodisperse DFNS in contrast to the aggregated material in the separated creamed microemulsion layer. They also showed that by simply changing the ratio of cyclohexane to water, different microemulsion systems could be generated, and hence, silica nanospheres with different morphologies (dense mesoporous, expanded mesoporous, and wrinkled/fibrous structures) could be synthesized.20 They were also able to control the interwrinkle distance by changing the alcohol used in the synthesis of DFNS. The presence of small pores (2–4 nm) was due to micelle formation through the emulsion rupture–inversion process. This study provided remarkable insight into the mechanism of formation of DFNS.

Figure 4.

Top) Images and schematic of separated phases in the Winsor III system. Bottom) SEM/TEM images of silica nanoparticles from a, d) the upper microemulsion layer, b, e) the lower aqueous layer, and c, f) the macroemulsion system. Reprinted with permission from Ref. 20. Copyright 2012 American Chemical Society.

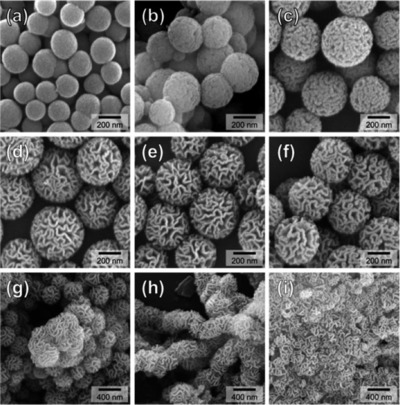

Moon and Lee then further tuned the DFNS synthesis on the basis of the phase behavior of the pseudoternary system by changing the water/surfactant/cyclohexane ratio.21 Here, water was a 0.4 m aqueous urea solution, and the surfactant was a CTAB/n‐butanol (1:1 w/w) mixture. Upon changing these ratios, they obtained DFNS with various amounts of wrinkling and varied pore sizes (Figure 5). They were also able to control the particle size of the nanospheres by further exploring our urea‐based synthetic approach.17

Figure 5.

SEM images of silica nanomaterials synthesized by changing the water/surfactant/cyclohexane ratio. Reprinted with permission from Ref. 21. Copyright 2014 American Chemical Society.

Recently, Febriyanti et al. also studied the mechanism of formation of DFNS22 by using gray value intensity patterns [generated from the transmission electron microscopy (TEM) images of DFNS], the critical micelle concentration (found by specific conductance measurements), and Raman spectroscopy. They observed different gray value patterns (U‐ and W‐shaped plots) for different silica morphologies. The DFNS gray value pattern was U shaped and was similar to that of core–shell silica nanomaterials. However, it had additional fine features in the center region, which were generally due to wrinkles, sheets, and lamellae, and thus, they found the DFNS morphology to consist of bicontinuous concentric lamellae. A Tyndall experiment was performed to infer that the DFNS colloidal mixture was a macroemulsion. In a conductivity measurement experiment, they observed an increase in the electrical conductivity upon increasing the CTAB concentration, and this was due to the formation of reverse micelles. Moon and Lee also observed the formation of reverse micelles,20, 21 although these micelles were attributed to small pore formation within each fiber of DFNS. Febriyanti et al. further studied the emulsion by using Raman spectroscopy to investigate the nature of the water molecules and their hydrogen bonding relative to that in pure water. They found that the emulsion had more confined water molecules, possibly confined in the center of the reverse micelles, which acted as a template for DFNS formation (Figure 6).22

Figure 6.

Schematic of the mechanism of formation of DFNS: a) diffusion of TEOS into a phase boundary, b) hydrolysis of TEOS, c) condensation of hydrolyzed TEOS, d) silicate oligomer formation, e) formation of bicontinuous structured silica, and f) silica with its final bicontinuous concentric morphology. Reprinted with permission from Ref. 22. Copyright 2016 American Chemical Society.

According to the authors, as a result of hydrophobic–hydrophobic interactions between TEOS and the tail of CTAB as well as the concentration gradient of TEOS inside and outside the reverse micelles (creating a high chemical potential), the TEOS molecules (present in the cyclohexane phase) reach the phase boundary of the reverse micelles.22 Hydrolysis of TEOS occurs at this phase boundary through interaction with water (and possibly decomposed urea catalysts), and hydrolyzed TEOS, in addition to the ethanol byproduct, penetrate inside the reverse micelle, as they are more soluble in the water phase. Further hydrolysis and condensation reactions occur to yield linear and branched siloxanes, and this causes the wrinkled nature of the silica fibers. Overall, this is an excellent study, although their proposed mechanism does not explain the formation of DFNS with various sizes or the dendritic nature of the fibers.

Using an organic amine (instead of urea) and cetyltrimethylamonium (CTA+) tosylate or bromide as templates, Zhang et al. synthesized 50 to 200 nm sized DFNS‐like materials.23 Smaller particles less than 50 nm in size were also prepared by simply using an additional nonionic surfactant, pluronic F127, which inhibited the growth of the silica particles.24 They also proposed a formation mechanism on the basis of self‐assembly and ion competition at the electrical shell of the micelles (Figure 7). Kinetically driven growth by the percolation of TEOS in the aggregated micelles, that is, the self‐assembly of micelles with hydrolyzed TEOS, could be the reason for the dendritic fibrous morphology.

Figure 7.

Proposed mechanism for the synthesis of dendritic silica nanospheres. TEAH3=triethanolamine. Reprinted with permission from Ref. 24. Copyright 2014 American Chemical Society.

Yang et al. investigated another protocol for the synthesis of DFNS by changing the reaction temperature, solvent ratio, and template concentration.25 They claimed that a high concentration of cyclohexane was crucial to form the fibrous morphology, which collapsed if a smaller amount of cyclohexane was used. However, the optimal solvent ratio of water/cyclohexane was 1:1 by volume, which was exactly the same as that in our initial report.17 Shen et al.26 also used our protocol for the synthesis of DFNS by using ethanolamine. They performed an extensive study and gained excellent understanding of the synthesis process, which helped them to tune the size and morphology of DFNS further by simply changing the base and solvent.26

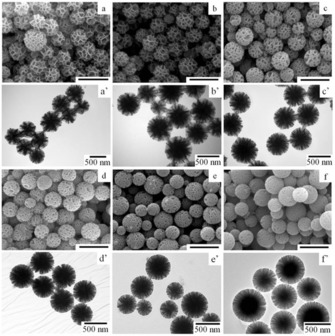

A less energy‐demanding protocol to synthesize DFNS at 20 °C was brilliantly developed by Du et al.27 They replaced urea with ammonium hydroxide, cyclohexane with ethyl ether, and pentanol with ethanol. Notably, they were able to produce amine‐functionalized DFNS in one step at room temperature with good control over the size and morphology of the material. They observed that the volume ratio of ethanol to ethyl ether affected the morphology of the materials. Interestingly, they were able to tune the particle size by controlling the stirring speed of the reaction mixture and the reaction temperature (Figure 8). Additionally, they explained that at a higher stirring rate, the size of the quasiemulsion (as it was not stable) droplets decreased with the formation of a large number of particles, and hence, a greater number of smaller particles was formed.

Figure 8.

a–f) SEM and a′–f′) TEM images of amine‐functionalized nanosilica synthesized in an ethanol/ethyl ether (10:20 mL) emulsion system at reaction temperatures of a, a′) 10, b, b′) 15, c, c′) 20, d, d′) 25, e, e′) 30, and f, f′) 35 °C. Scale bars in the SEM images are 1 μm. Reprinted with permission from Ref. 27. Copyright 2015 Royal Society of Chemistry.

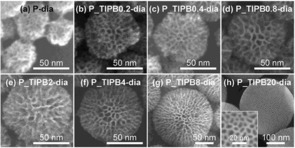

Yamada et al. then developed a swelling strategy to synthesize the DFNS family of silica nanospheres by modifying the standard DFNS protocol by replacing urea with triethanolamine.28 They used various trialkylbenzenes (TABs) as swelling agents or pore expanders, which allowed the hydrophobicity of the reaction medium to be tuned; this affected the hydrolysis rate of the silane precursors and thus the nucleation‐growth step. 1,3,5‐Triisopropylbenzene (TIPB) and 1,3,5‐trimethylbenzene (TMB) as TABs and tetrapropoxysilane (TPOS) and tetramethoxysilane (TMOS) as Si precursors were used to control the pore size and particle size of these silica nanospheres. The combination of TIPB and TPOS allowed tuning of the pore size from 4 to 8 nm and the particle size from 50 to 380 nm (Figure 9). The change in pore size was explained on the basis of the incorporation of TIPB inside the micelles (swelling), and the change in particle size was explained on the basis of a decrease in the rate of hydrolysis of the Si precursors, which accelerated the growth processes over nucleation.

Figure 9.

SEM images of silica nanospheres prepared by using TIPB and TPOS at various molar ratios (x), denoted P_TIPBx‐dia, for which x=a) 0, b) 0.2, c) 0.4, d) 0.8, e) 2, f) 4, g) 8, and h) 20. Reprinted with permission from Ref. 28. Copyright 2014 Royal Society of Chemistry.

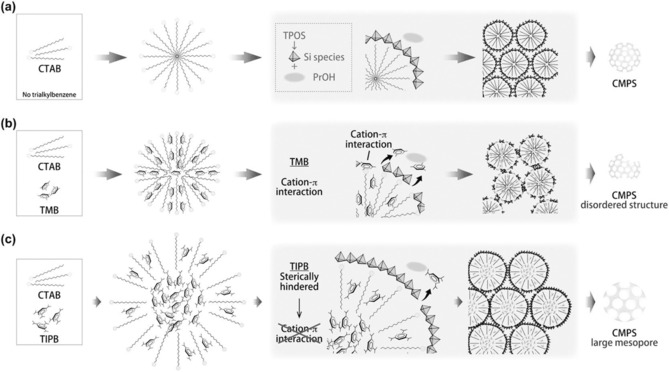

Unlike TIPB, TMB was not effective in controlling the pore size. The authors systematically explained why TMB did not alter the pore size even though TIPB did (Figure 10). As TMB is a planer molecule, it can disperse between the space of two adjacent surfactant molecules in the micelles (Figure 10 b) without causing the micelles to swell (hence, no enlargement of the pores). On the other hand, TIPB is a larger molecule, and this makes it difficult to disperse between surfactant molecules (e.g., TMB), and hence, it goes into the hydrophobic center of the micelles (Figure 10 c); this causes swelling of the micelles, and hence, the pore diameter is increased.

Figure 10.

Possible structures of the micelles and the formation of various silica nanospheres: a) without TAB, b) with TMB, and c) with TIPB. CMPS=colloidal mesoporous silica nanoparticles. Reprinted with permission from Ref. 28. Copyright 2014 Royal Society of Chemistry.

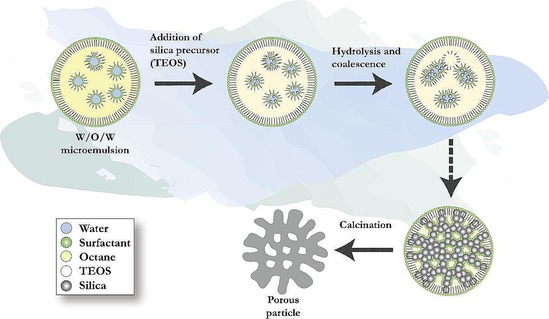

Gustafsson et al. used various template molecules to prepare nanosilica materials with very small sizes (≈40 nm).29, 30 They used lysine (instead of urea) in a mixed solvent system of water/octane/styrene. It was found that cationic surfactants, as well as cationic gemini surfactants with short or long spacers between their polar heads, yielded silica nanospheres with particle sizes of 46 to 91 nm.

They also proposed a formation mechanism for DFNS (Figure 11).29 They suggest that DFNS formation occurs inside the droplets of a water‐in‐oil microemulsion, and these droplets are stabilized by surfactants and are present within the superfluous oil phase. In these water‐in‐oil droplets, TEOS is present in the oil phase, and upon exposure to water (at the oil–water interface) it hydrolyzes and condenses to form a three‐dimensional silica network. This leads to the gradual transition of the water‐in‐oil microemulsion into a bicontinuous microemulsion, and this internal change in the droplet yields the wrinkled fibers of the silica nanospheres.

Figure 11.

Proposed mechanism for the formation of dendritic silica nanoparticles. Reprinted with permission from Ref. 29. Copyright 2016 Elsevier B.V.

After our discovery of DFNS, several reputed groups worldwide reported modified processes to synthesize DFNS, as discussed above. Over a similar time period, we also developed a simple protocol for the synthesis of monodisperse DFNS with controllable sizes, fiber densities, and textural properties.19 We were able to achieve fiber density control. The particle size, fiber density, surface area, and pore volume of DFNS were effectively controlled and tuned by changing various reaction parameters, such as the concentrations of urea, CTAB, and 1‐pentanol; the reaction time; the temperature; the solvent ratio; and even the outside stirring time. After this systematic study, we were able to tune the particle size, and now, one can synthesize DFNS with a particle size as small as 170 nm to as large as 1120 nm. Interestingly, we were also able to double the surface area of DFNS to 1244 m2 g−1 and to achieve a pore volume of 2.18 cm3 g−1, which are the highest values reported to date for DFNS.19

3. Catalysis using DFNS

3.1. DFNS‐supported metal nanoparticles

Metal nanoparticle (NP)‐based catalysts are key in most chemical transformations, and supporting them on solids makes them stable and reusable.5 Their activity generally depends on the surface area of the metal, which is dependent on its size and its accessibility. More often than not, the accessibility of these supported metal active sites is always a serious issue. These sites are less accessible owing to the porous nature of most supports, which causes a diffusion barrier for reactants and products, and this greatly hampers the accessibility of the active sites and thus the catalytic performance. Additionally, small‐sized active sites are also prone to agglomeration and sintering during reactions, which thus deactivates the catalyst. Therefore, a novel approach to design active and stable supported metal nanocatalysts was needed, and fibrous nanosilica helped in this regard.

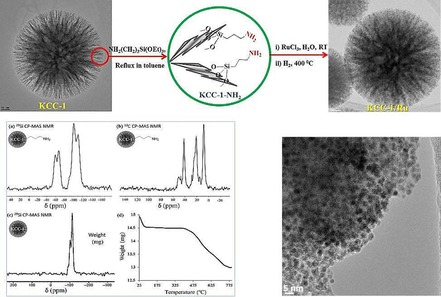

After the discovery of DFNS in 2010,17 the first application we considered was the exploration of its open and fibrous morphology for supporting metal nanoparticles and organometallic complexes to design nanocatalysts with more accessible active sites. In this regard, the very first application of DFNS that was explored was a ruthenium (Ru) catalyst (DFNS/Ru, Figure 12) for the hydrogenolysis of alkanes.31 The DFNS/Ru nanocatalyst was prepared by functionalizing the DFNS surface with 3‐aminopropyltriethoxysilane (APTS), which was then loaded with a ruthenium chloride salt (Figure 12). Reduction using hydrogen gas yielded DFNS/Ru with small (1–4 nm) Ru NPs uniformly dispersed over the fibers of DFNS. Solid‐state cross‐polarization magic‐angle spinning nuclear magnetic resonance (CP‐MAS NMR) spectroscopy and thermogravimetric analysis (TGA) indicated that a 10 wt % loading of covalently attached APTS helped in the formation of monodispersed Ru NPs on DFNS fibers (Figure 12).

Figure 12.

Design and synthesis of the DFNS/Ru nanocatalyst. Adapted with permission from Ref. 31. Copyright 2012 American Chemical Society.

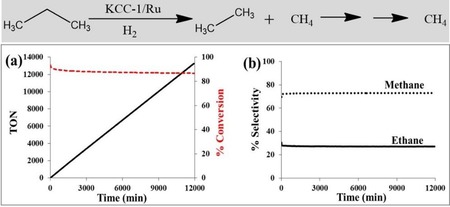

DFNS/Ru was then explored in the propane hydrogenolysis reaction (Figure 13). The reaction progressed efficiently with approximately 84 % conversion and 73 % selectivity toward methane and 27 % toward ethane. Notably, the cumulative turnover number (TON) was greater than 11 000, and even after 7 days, no change in the conversion or selectivity was observed; moreover, the recycled catalyst worked as efficiently as the fresh catalyst. Relative to the SBA‐15/Ru and MCM‐41/Ru catalysts, DFNS/Ru was superior in terms of TON (Table 3). The effectiveness of DFNS/Ru was due its fibrous morphology, as this increased the accessibility of the Ru sites, which are restricted in SBA‐15 and MCM‐41 due to the tubular pores having only two openings. The enhancement was also attributed to the smaller size and the presence of a fair amount of hexagonal nanoparticles of Ru, which had atoms (active sites) with low coordination numbers (more dangling bonds) and, hence, high surface energy. In the case of KCC‐/Ru, the fibers of DFNS (within which the Ru NPs were dispersed) restricted their agglomeration/sintering and, hence, particle growth, which helped to maintain catalyst activity.

Figure 13.

a) Conversion TON and b) selectivity for propane hydrogenolysis catalyzed by DFNS/Ru in a continuous‐flow reactor at 175 °C and 0.1 MPa pressure by using hydrogen.31

Table 3.

Comparison of DFNS/Ru with SBA‐15/Ru and MCM‐41/Ru for propane hydrogenolysis reaction.[a]

| Catalyst | T [°C] | Conversion [%] | C2H6 selectivity [%] | TON after 7 days |

|---|---|---|---|---|

| KCC‐1/Ru | 175 | 84 | 27 | 11010 |

| SBA‐15/Ru | 175 | 77 | 27 | 7210 |

| MCM‐41/Ru | 175 | 25 | 14 | 3927 |

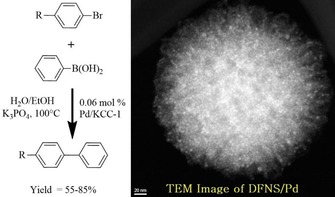

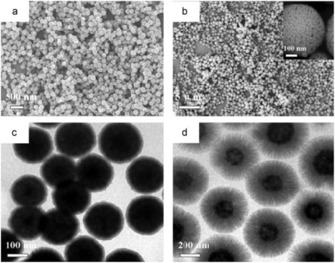

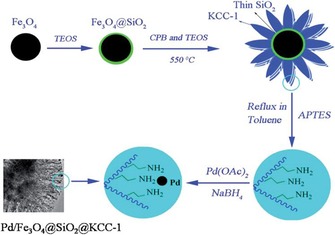

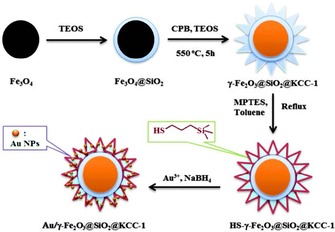

Like DFNS/Ru, we also prepared a supported palladium (Pd) catalyst (DFNS/Pd) by using a similar strategy.32 After APTS functionalization of DFNS, palladium chloride was loaded; this was followed by reduction of PdII to Pd0 by the hydrogen reduction method, which yielded DFNS/Pd that had fibers of DFNS that were fully loaded with well‐dispersed Pd NPs 1–5 nm in size. This catalyst showed excellent activity with 77 to 95 % conversion and stability (over at least seven cycles) in Suzuki carbon–carbon (C−C) coupling reactions by using both bromo‐ and chloroaromatics (Figure 14). However, the catalysts showed some deactivation after seven cycles, which indicated that some leaching of Pd occurred, and hence, a more leachproof catalyst was needed.

Figure 14.

DFNS‐NH2/Pd‐catalyzed Suzuki coupling reactions of bromoaromatics.32

The DFNS/Pd nanocatalyst was then further explored by D'Elia et al. for the transfer hydrogenation of alkenes.33 They obtained similar average sizes of the Pd NPs on all three supports; however, DFNS showed a better dispersion of metal NPs than the SBA‐15 and MCM‐41 supports. Pd/KCC‐1‐NH2 showed a conversion that was 1.6 times higher than that of Pd/MCM‐41‐NH2 and 2.6 times higher than that of Pd/SBA‐15‐NH2.

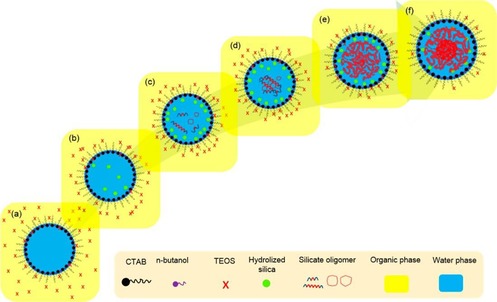

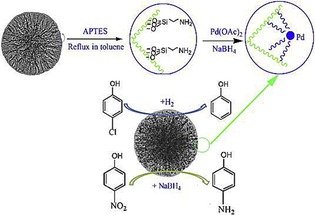

The DFNS/Pd catalyst was also used by Ma et al. in the reduction of 4‐nitrophenol and in the hydrodechlorination of 4‐chlorophenol.34 They also observed good catalytic activity under mild reaction conditions in addition to stability (recyclability) of the catalysts (Figure 15). DFNS/Pd was also explored for the aqueous‐phase hydrodechlorination and then the hydrogenation of chlorophenols to cyclohexanone.35 The catalysts worked well for this process and followed a pseudo‐first‐order rate equation with a rate constant per unit mass (k 1) of 13.2 min−1 g−1. Zhao's group36 explored DFNS/Pd for the Suzuki coupling reaction, although the activity was limited to iodo and bromoaromatics.

Figure 15.

Synthesis and application of the DFNS/Pd nanocatalyst. APTES=(3‐aminopropyl)triethoxysilane. Reprinted with permission from Ref. 34. Copyright 2015 Elsevier B.V.

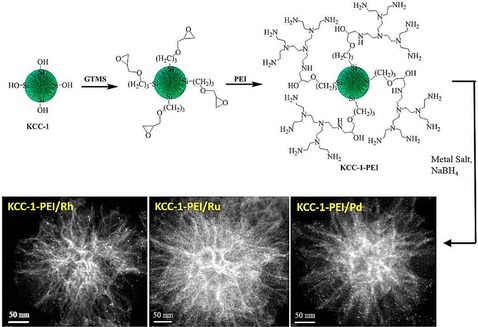

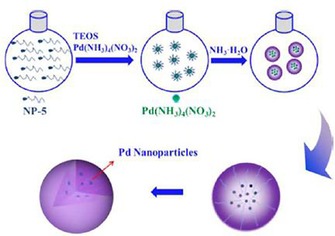

To improve the stability of DFNS/Pd, our group replaced APTS with polyethylenimine (PEI), which led to leachproof and monodisperse DFNS/X (X=Rh, Ru, Pd) catalysts.37 DFNS was first functionalized with (3‐glycidyloxypropyl)trimethoxysilane (GTMS), which upon reaction with PEI yielded PEI‐functionalized DFNS (Figure 16). These were then used as pseudoligands to produce and stabilize monodisperse metal nanoparticles, wherein the metal (i.e., Rh, Ru, and Pd) salts bound with the amines of PEI; reduction with NaBH4 produced metal(0) nanoparticles that were highly dispersed on the fibers of DFNS (Figure 16). These nanocatalysts showed good catalytic activity in the hydrogenation of phenylacetylene and styrene, and this was attributed to the smaller size of the metal NPs as well as their high accessibility owing to the fibrous nature of the support. The combination of PEI and DFNS also restricted metal leaching, which in turn increased the stability of the catalysts. However, some passivation of the active sites by PEI was observed.

Figure 16.

Design of DFNS‐supported metal (Rh, Ru, and Pd) nanoparticles by using PEI functionalization. Reprinted with permission from Ref. 37. Copyright 2015 American Chemical Society.

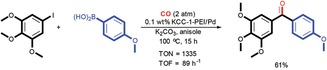

DFNS‐PEI/Pd was further explored by Bhanage and co‐workers in the carbonylation Suzuki–Miyaura cross‐coupling reaction.38 DFNS‐PEI/Pd catalysts with six different Pd loadings (i.e., 10, 2, 1, 0.5, 0.3, and 0.1 wt %) were prepared and evaluated for catalysis (Figure 17). The catalyst with 0.1 wt % Pd showed a 28‐fold higher TON and a 51‐fold higher turnover frequency (TOF) than the best supported Pd catalyst in the carbonylation cross‐coupling of 4‐iodoanisole and phenylboronic acid. The catalyst was recycled up to 10 times with marginal loss in activity after the 8th cycle.

Figure 17.

DFNS‐PEI/Pd‐catalyzed carbonylation Suzuki–Miyaura cross‐coupling reaction. Reprinted with permission from Ref. 38. Copyright 2016 Royal Society of Chemistry.

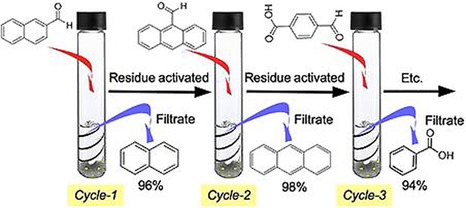

Interestingly, DFNS‐PEI/Pd could also catalyze the reverse carbonylation reaction, that is, the decarbonylation reaction by simply changing the reaction conditions. Kundu et al. used DFNS‐PEI/Pd in the decarbonylation of a variety of aromatic, heteroaromatic, and alkenyl aldehydes.39 Complete conversion of the aldehyde functionalities into their deformylated products was achieved with very pure isolated products without using any additives (e.g., oxidants, bases, or CO scavengers). This catalyst also showed excellent stability (recyclability), and even after eight cycles, the catalyst had the same activity (Figure 18). Thus, DFNS‐PEI/Pd could catalyze the carbonylation reaction as well as the decarbonylation reaction by simply changing the reaction conditions.

Figure 18.

Recyclability of DFNS‐PEI/Pd in the decarbonylation reaction. Reprinted with permission from Ref. 39. Copyright 2016 Wiley‐VCH.

Similar to the PEI approach,37 Sadeghzadeh developed a protocol for using multicarboxylic hyperbranched polyglycerol groups (HPGs) as robust anchors for various metal nanoparticles (e.g., Au, Pd, and Cu).40 The HPGs were directly grafted onto the DFNS fibers by the surface‐initiated ring‐opening polymerization of glycidol, and then the metal salts were loaded, which was followed by reduction with NaBH4. These catalysts were efficient in the reaction of CO2 with 2‐aminobenzonitriles to produce quinazoline‐2,4(1H,3H)‐diones in good yields.

Instead of confining or supporting these metal nanoparticles inside the DFNS spheres, Wang et al. attempted to coat Pd NPs by DFNS by using the microemulsion method to obtain core–shell‐type structures with Pd as the core and silica as the shell.41 They compared the activity of this catalyst in the oxidation of carbon monoxide (CO) with that of other catalysts prepared in the conventional way of silica coating (e.g., Stöber's method, impregnation, and reverse‐micelle method). Using the microemulsion method, they were able to obtain a Pd‐core DFNS‐shell catalyst with an average DFNS particle size of 350 nm and a Pd size of 14 nm. However, the catalytic activity of this catalyst was poor relative to that of the catalyst prepared by the reverse‐micelle method (Figure 19), the overall particle size of which was 30 nm with a Pd size of 1.1 nm. They found this catalyst to be sinterproof, even at high temperatures. However, this comparison may not be accurate, as there was a huge difference in the size of the Pd NPs as well as the overall size of the catalyst, which was 30 nm compared with 350 nm. Hence, a dependence on morphology cannot be concluded from this study.

Figure 19.

Schematic illustration of the synthesis of silica‐coated Pd by using the reverse‐micelle method. Reprinted with permission from Ref. 41. Copyright 2016 Royal Society of Chemistry.

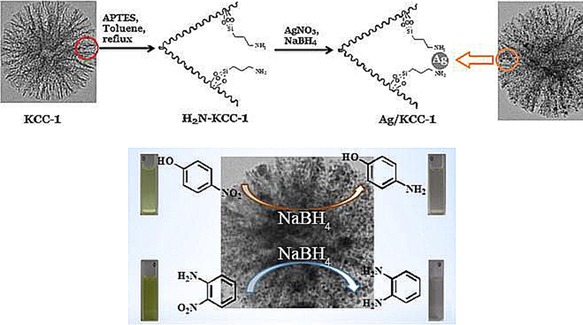

Using APTS‐functionalized DFNS, Dong et al. prepared a silver (Ag) catalyst (DFNS/Ag) and evaluated it in the reduction of 4‐nitrophenol and 2‐nitroaniline (Figure 20).42 They were able to perform this reaction at room temperature by using water as the solvent, which make this process green and energy efficient. The catalyst was stable for up to 10 cycles, which they attributed to the fibrous morphology and the APTS functionalization of DFNS. After 2 years, the group of Yan et al. prepared the catalyst (DFNS/Ag) and renamed it as dendritic‐mSiO2‐NH2‐Ag. They evaluated it for the same reaction, the reduction of 4‐nitrophenol and 2‐nitroaniline, and found similar catalytic performance.43

Figure 20.

Top) DFNS/Ag catalyst design and bottom) catalytic reduction of 4‐nitrophenol and 2‐nitroaniline by using the DFNS/Ag catalyst. Reprinted with permission from Ref. 42. Copyright 2014 Elsevier B.V.

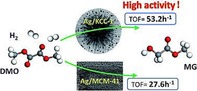

Ouyang et al. prepared DFNS/Ag catalysts by using the conventional impregnation method without APTS functionalization and evaluated them for the gas‐phase hydrogenation of dimethyl oxalate (DMO) to methyl glycolate (MG).44 They compared DFNS/Ag with MCM‐41/Ag and SBA‐15/Ag to study the role of morphology of the support. They observed that different silica supports resulted in different dispersions and accessibilities of the Ag sites. They screened these three catalysts for the hydrogenation of DMO with different liquid hourly space velocity values. The open fibrous structure of DFNS enhanced the diffusion of DMO and MG, which significantly improved the TOF value relative to that obtained for the MCM‐41‐ and SBA‐15‐based catalysts (Figure 21).

Figure 21.

Dimethyl oxalate (DMO) to methyl glycolate (MG) conversion by using Ag/KCC‐1 and Ag/MCM‐41. Reprinted with permission from Ref. 44. Copyright 2016 Royal Society of Chemistry.

D'Elia and co‐workers slightly modified the protocol for the synthesis of DFNS/Au by replacing the reducing agent (i.e., NaBH4) by CO and citrate.45 On the basis of the method of catalyst preparation and the reducing agent used, they obtained DFNS loaded with Au NPs of varying sizes and dispersions. These catalysts were then evaluated for the oxidation of CO, and the results showed that the activity of DFNS/Au was similar to that of other reported silica‐based Au catalyst.

3.2. DFNS‐supported pseudo‐single atoms of metals

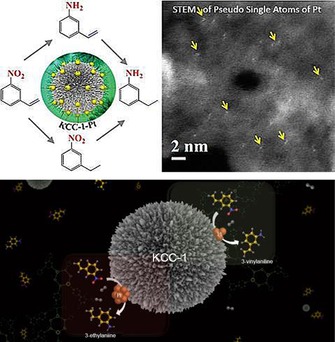

Nanocatalysis is no longer just a field of academic curiosity but is now an emerging field for industries to develop green and economical processes.5 Hutching's recent report on nanogold catalysts is a good example.46 However, next‐generation nanogold catalysts with very high turnover numbers and stability are needed to take this field to the next level. For this, new catalyst design approaches, such as Zhang's unique single‐atom catalysts,47 need to be developed. In this regard, we used DFNS to prepare active and stable pseudo‐single‐atom catalysts of Pt and Au.48, 49

At the time, most reported single‐atom catalysts were based on the utilization of active supports that exhibited strong metal–support interactions.47 We recently used DFNS to synthesize sub‐nanometer‐sized platinum nanoparticles and pseudo‐single atoms of Pt. This size tuning from the nanometer scale to the sub‐nanometer scale to pseudo‐single atoms was used to tune the chemoselectivity of the hydrogenation reaction of 3‐nitrostyrene (Figure 22).48 DFNS‐PEI/Pt (1 %) with ultrasmall and pseudo‐single atoms as active sites showed selectivity toward 3‐vinylaniline, whereas 10 and 5 % Pt loaded on DFNS‐PEI (with 2.2 and 1.8 nm active‐site average sizes, respectively) showed selectivity toward 3‐ethylaniline. DFNS‐PEI/Pt (1 %) displayed a TON of 1230 compared to a TON of 178 displayed by Pt/SiO2 for the hydrogenation of 3‐nitrostyrene with improved selectivity (70 % for 3‐vinylaniline compared to 40 % by Pt/SiO2).48 Notably, catalysts with sub‐nanometer Pt or pseudo‐single atoms of Pt had excellent selectivity of 60–70 %, which decreased drastically with an increase in the particle size.

Figure 22.

Engineering the reaction selectivity by controlling the Pt particle size supported on DFNS. Adapted with permission from Ref. 48. Copyright 2016 Royal Society of Chemistry.

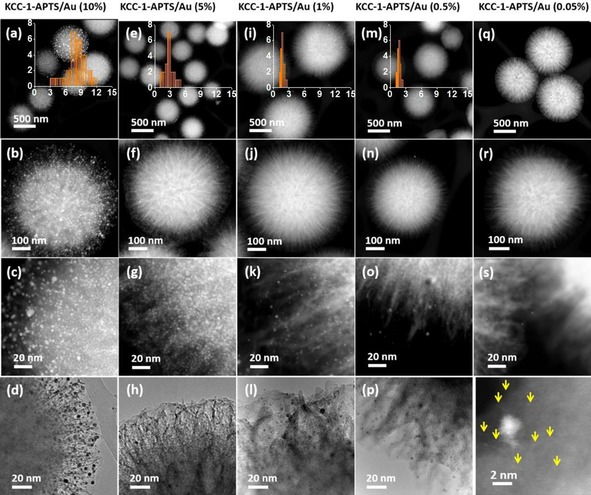

Nanogold catalysis has been a topic of considerable interest, and supported gold catalysts have dispelled the traditional belief about gold's unreactive behavior.46 Although these nanocatalytic transformations are very attractive, they are often limited by low turnover numbers in several cases. Atomically dispersed catalysts are the way forward in the field of Au nanocatalysis. Following our DFNS/Pt work, we also prepared ultrasmall/pseudo‐single‐atom gold catalysts supported on DFNS. Our approach involved grafting APTS onto the DFNS surface, which tethered with HAuCl4, and this was followed by NaBH4 reduction to afford DFNS‐supported Au nanoparticles.49

TEM analysis of the synthesized nanogold catalysts with different loadings (i.e., 10, 5, 1, 0.5, and 0.05 %), revealed the formation of ultrasmall Au NPs (Figure 23). The average particle size of the 10 % Au‐loaded sample was approximately 7.3 nm with a slightly broad particle‐size distribution. The average particle sizes of the 5, 1, and 0.5 % Au‐loaded on DFNS samples were approximately 2.7, 1.7, and 1.5 nm, respectively, with a very narrow particle distribution. Thus, DFNS appeared to be fully loaded and uniformly covered with monodisperse gold nanoparticles. Notably, at a 0.05 % loading, we also observed several pseudo‐single atoms.

Figure 23.

TEM images of DFNS‐APTES/Au with Au loadings of a–d) 10 %, e–h) 5 %, i– l) 1 %, m–p) 0.5 %, and q–t) 0.05 % . Reprinted with permission from Ref. 49. Copyright 2016 Royal Society of Chemistry.

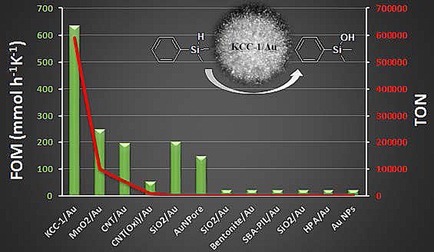

We used the silane to silanol reaction as a test reaction to evaluate various DFNS/Au catalysts. We demonstrated that DFNS decorated with ultrasmall Au NPs and their pseudo‐single atoms was one of the best catalysts for the oxidation of silane, as it provided a very high TON. For example, DFNS‐APTS/Au (0.05 %) showed a TON of 591 000 for the oxidation of dimethylphenylsilane, whereas the highest reported TON without using any catalyst activation was 98 333 by using the Au/MnO2 catalyst.49 However, for an integrated view of various other key factors, such as the rate of the reaction, that is, the turnover frequency, the energy required for the reaction, the scale of the reaction, and the number of catalyst recycles, the figure of merit (FOM) was used [Eq. (1)]:

| (1) |

in which N is the number of cycles, S is the scale of the reaction, and ΔT is the deviation in the reaction temperature from ambient temperature (298 K). DFNS‐APTS/Au (0.05 %) was found to have a FOM of 633 mmol h−1 K−1 compared to a FOM of 247 for the Au/MnO2 catalyst (Figure 24).49 The presence of ultrasmall nanoparticles and pseudo‐single atoms of Au and the fibrous morphology of DFNS contributed to the superior performance of DFNS/Au, as did the presence of Auδ+ species. DFNS‐APTS/Au was also able to catalyze two other reactions, the alcoholysis of silane and the hydrosilylation of aldehydes, which thus makes it a versatile nanocatalyst.49

Figure 24.

Comparison of the DFNS‐APTS/Au (0.05 %) catalyst with various other reported catalysts for the oxidation of dimethylphenylsilane. Single‐digit FOM values were scaled to 20 for visualization in the figure. Reprinted with permission from Ref. 49. Copyright 2017 Royal Society of Chemistry.

3.3. DFNS‐supported metals oxides and hydroxides

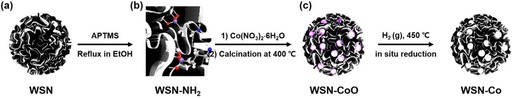

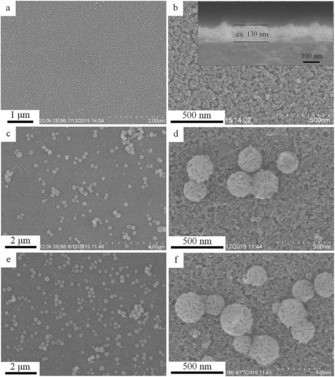

In addition to metals, metal oxides and metal hydroxides were also supported on DFNS to design novel nanocatalysts. Lee et al. prepared DFNS‐supported cobalt‐oxide catalysts for the Fischer–Tropsch (FT) reaction, which they renamed wrinkled silica nanoparticle (WSN)‐supported cobalt (Co) oxide (WSN‐CoO).50 Lee's group excellently used the fibrous nature of DFNS (or WSN) to stabilize cobalt oxide within these wrinkled fibers, which prevented sintering. To synthesize the catalyst, they used our APTS‐DFNS approach,32 for which APTS‐functionalized DFNS was treated with cobalt nitrate and then heated at 400 °C for 4 h to yield DFNS‐CoO (or WSN‐CoO), which was reduced to Co by the hydrogen reduction method (Figure 25). High‐resolution TEM studies showed that DFNS was fully loaded with cobalt‐oxide particles with an average size of 20 nm (Figure 26).

Figure 25.

a) Synthesis of WSN‐NH2 by APTS functionalization of WSNs, b) treatment with Co(NO3)2 ⋅6 H2O, and c) in situ reduction of WSN‐CoO. Reprinted with permission from Ref. 50. Copyright 2016 Korean Chemical Society and Wiley‐VCH.

Figure 26.

a) SEM and b) TEM images of WSNs. The inset scale bar is 100 nm. c) HRTEM image of WSN‐CoO. Bottom‐right panel) Energy‐dispersive X‐ray spectroscopy (EDS) elemental mapping of WSN‐CoO showing d) cobalt and e) silicon. Reprinted with permission from Ref. 50. Copyright 2016 Korean Chemical Society and Wiley‐VCH.

Notably, upon comparing DFNS/CoO (WSN‐CoO) with a conventional silica‐supported cobalt oxide (Co/SiO2) of similar loading, they observed that the initial activity of WSN‐CoO was lower than that of Co/SiO2, but in terms of stability, WSN‐CO remained nearly stable for 50 h, which confirmed the role of the DFNS fibers in stabilizing the Co active sites.50

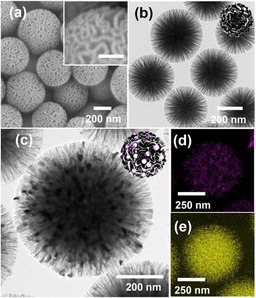

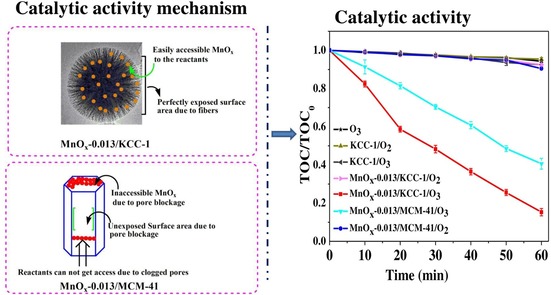

Quan's group incorporated manganese (Mn) oxide in DFNS51 by using a one‐pot DFNS protocol by incorporating a Mn precursor (manganese nitrate) in addition to the silica precursor (TEOS) with different Mn/Si ratios. The catalyst was named MnOx‐Y/DFNS, in which MnOx represents the multivalent states of manganese oxide and Y indicates the Mn/Si molar ratio (Figure 27). Noncatalytic ozonation and catalytic ozonation by MnOx‐0.013/DFNS and MnOx‐0.013/MCM‐41 led to 4, 85, and 60 % reduction in the total organic content (TOC), respectively. In terms of Mn leaching, 0.05 and 1.2 mg L−1 leaching were detected for MnOx‐0.013/DFNS and MnOx‐0.013/MCM‐41, that is, 2.0 and 42.0 % of the total Mn present in the corresponding catalyst, respectively. These results clearly indicate the advantages of the fibrous DFNS support over MCM‐41 with respect to the activity as well as the stability (leaching).

Figure 27.

The MnOx‐Y/DFNS catalyst in the ozonation of oxalic acid. Reprinted with permission from Ref. 51. Copyright 2016 Elsevier B.V.

Yan et al. also prepared DFNS/Mn3O4 by using a two‐step process.52 First, they prepared DFNS and then loaded it with manganese acetate (of different amounts), which was followed by treatment with hydrazine hydrate for 24 h to yield DFNS/Mn3O4. The removal of methyl orange (MO) from waste water was systematically studied, and they concluded that these adsorption processes were controlled by intraparticle diffusion as well as external mass transfer and both seemed efficient owing to the fibrous DFNS support.

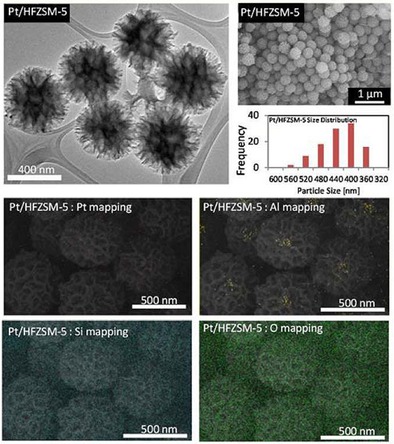

3.4. DFNS‐based zeolites

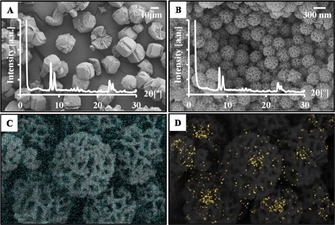

Excitingly, DFNS was converted into a zeolite‐based material. ZSM‐5 is an industrial zeolite used for its superior properties. However, the micropores of ZSM‐5 restrict access to the active sites and molecular diffusion, and hence, ZSM‐5 with a better pore structure was needed.53 Firmansyah et al. used the DFNS synthetic protocol to prepare fibrous ZSM‐5 by using zeolite crystal seeds and TEOS as precursors.53 After calcination, as‐prepared FZSM‐5 was exposed to twofold protonation (HFZSM‐5) and then Pt NP impregnation to yield Pt/HFZSM‐5. Pt/HFZSM‐5 was found to have the DFNS fibrous morphology with widely distributed Si and Al atoms and scarcely distributed Pt NPs (Figure 28). Pt/HFZSM‐5 showed 89.5 % total product yield in the hydrocracking of cumene and several other molecules compared to conventional Pt/HZSM‐5, which showed 65.8 % total product yield. Notably, Pt/HFZSM‐5 was stable and could maintain 88 % conversion, whereas the catalytic activity of Pt/HZSM‐5 was reduced to 15 % after 100 doses of cumene. The authors attributed this high activity to the fibrous morphology of FZSM‐5 as well as to the protonation ability and Pt NP sites.53

Figure 28.

TEM, field‐emission scanning electron microscopy (FESEM), particle‐size distribution, and EDS elemental mapping of Pt/HFZSM‐5. Reprinted with permission from Ref. 53. Copyright 2016 Royal Society of Chemistry.

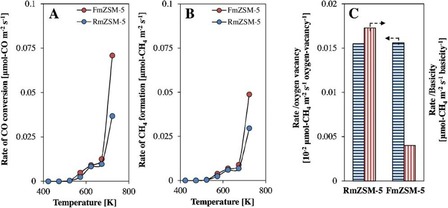

Then, they prepared fibrous ZSM‐5 (denoted FmZSM‐5) by using a modified DFNS protocol (Figure 29) for the CO methanation reaction and compared its performance to that of conventional recrystallized RmZSM‐5 (Figure 30).54 FmZSM‐5 was found to have superior CO conversion and CH4 formation rates of 0.0708 μmolCO m−2 s−1 and 0.0488 μmol m−2 s−1, respectively, which were twofold higher than the same values for conventional RmZSM‐5. Notably, FmZSM‐5 was stable for up to 50 h with no sign of deactivation.

Figure 29.

FESEM images and X‐ray diffraction patterns of a) RmZSM‐5 and b) FmZSM‐5 and EDS elemental mapping of c) Si and d) Al in FmZSM‐5. Reprinted with permission from Ref. 54. Copyright 2016 Elsevier B.V.

Figure 30.

Rates of a) CO conversion and b) CH4 formation at a gas hourly space velocity of 13 500 mL g−1 h−1 and H2/CO=8:1 and c) the rate versus oxygen vacancy and basicity. Reprinted with permission from Ref. 54. Copyright 2016 Elsevier B.V.

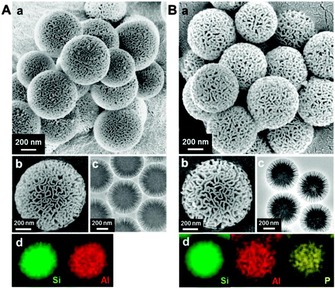

Yi et al. developed an exceptionally efficient postsynthetic method to incorporate aluminum (Al) sites in the fibers of DFNS without even minute changes in its wrinkled fibrous morphology.55 They developed a new “pH‐assisted delay addition” two‐step protocol, for which the Al precursor, aluminum sulfate octadecahydrate, was added to preformed DFNS (obtained by using the standard hydrothermal process),17 which was then subjected to a second hydrothermal treatment. Notably, before adding the Al precursor, they observed that the pH of the mother liquor (initial pH≈9–10) need to be reduced to pH 5 by adding 2 m HCl to retain the fibrous wrinkled morphology of the DFNS/Al spheres, denoted ASN‐X, in which X indicates the Si/Al ratio. Interestingly, by simply replacing the 2 m HCl solution with a 2 m H3PO4 solution, they were able to incorporate phosphorus (P) in addition to Al in DFNS, denoted ASPN‐X. Both of these materials were dendritic fibrous spheres of 450 to 600 nm size with radially oriented pores and uniformly distributed elements of Si, Al, and P (Figure 31). The surface areas of the samples with different Si/Al ratios were approximately 475 to 515 m2 g−1 with a multimodal pore‐size (slit‐shaped) distribution.55

Figure 31.

a, b) SEM images, c) TEM images, and d) EDS elemental mapping of the A) ASN‐40 and B) ASPN‐40 samples. Reprinted with permission from Ref. 55. Copyright 2014 Royal Society of Chemistry.

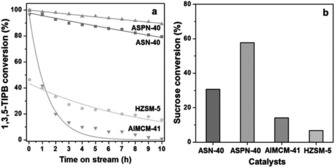

The catalytic performances of ASN‐40 and ASPN‐40 were evaluated and compared with those of HZSM‐5 and AlMCM‐41 by using the cracking of 1,3,5‐triisopropylbenzene and the hydrolysis of sucrose as test reactions (Figure 32). In the cracking reaction, HZSM‐1 showed poor activity, whereas AlMCM‐41, after initially showing moderate activity, was quickly deactivated. Notably, ASN‐40 (≈30 % conversion) and ASPN‐40 (60 % conversion) showed high activities (compared to ≈15 and ≈10 % conversions by AIMCM‐41 and ZHSM‐5, respectively) and long lifetimes (8–10 h compared to 4–5 h for the conventional catalysts),55 which possibly resulted from reduced coke formation owing to the fibrous morphology of the catalysts. These results clearly showed the potential of these DFNS‐based acid catalysts for industrial applications.

Figure 32.

a) Cracking of 1,3,5‐triisopropylbenzene (1,3,5‐TIPB) and b) hydrolysis of sucrose by using ASN‐40, ASPN‐40, AlMCM‐41, and HZSM‐5. Each line in panel a indicates a fitted curve by the first‐order deactivation model. Reprinted with permission from Ref. 55. Copyright 2014 Royal Society of Chemistry.

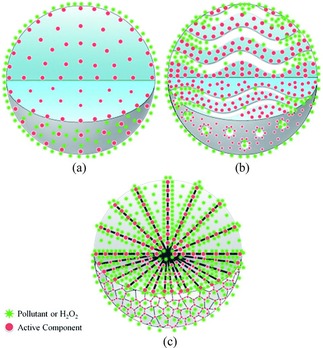

Fenton catalysts based on DFNS were designed and synthesized by Lyu et al.56 The Fenton process is a powerful method to degrade pollutants in wastewater, although the stability of the catalysts has been an issue. The authors used the DFNS synthetic protocol to prepare dandelion‐like copper (Cu)‐Al‐silica nanospheres (DCASNs) by using copper nitrate, aluminum nitrate, and TEOS as the precursors, and this catalyst was used for the degradation of various pollutants at neutral pH. The reaction rate upon using the DCASNs catalyst was 5.2–13.4 times higher than that reported for Fenton catalysts such as Cu‐γ‐Al2O3 and Cu‐MCM‐41 (Figure 33). Figure 34 shows that the Cu sites are in the bulk of Cu‐γ‐Al2O3, and this reduces the accessibility of the pollutants to this active sites, and although Cu‐MCM‐41 has a very high surface area, it struggles with diffusion of the pollutants, which reduces its catalytic activity. However, in the DFNS‐based DCASNs, the accessibly of the active sites and the diffusion of the pollutants are improved (Figure 34 c), which make this catalyst the best performing in its class.

Figure 33.

a) Degradation of 2,4‐dichlorophenoxyacetic acid (BPA) and b) total organic carbon (TOC) removal by using H2O2. Reprinted with permission from Ref. 56. Copyright 2016 Royal Society of Chemistry.

Figure 34.

Schematic illustration of pollutants or H2O2 in contact with a) a catalyst with the active component in the bulk (such as γ‐Al2O3), b) a multiporous catalyst (such as MCM‐41), and c) DCASNs. Reprinted with permission from Ref. 56. Copyright 2016 Royal Society of Chemistry.

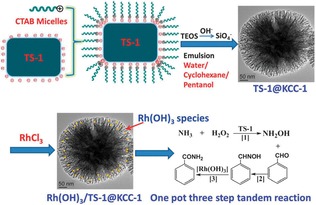

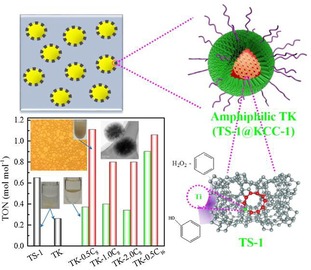

Wu's group prepared titanium silicalite‐1 (TS‐1) zeolites by coating TS‐1 with DFNS.57 Owing to the negatively charged TS‐1 surface, positively charged CTAB micelles were adsorbed on the surface and DFNS fibrous silica grew on the TS‐1 particle to produce a core–shell structure, named TS‐1@DFNS. The TS‐1 core was approximately 250–300 nm, with a fibrous shell of 80 nm. Rh(OH)3 was then supported on TS‐1@DFNS to produce a bifunctional nanocatalyst, Rh(OH)3/TS‐1@DFNS, for the one‐pot synthesis of amides by a tandem reaction involving the ammoximation and rearrangement of aldehydes, ammonia, and H2O2 (Figure 35). These two tandem steps occurred on Rh(OH)3/TS‐1@DFNS with good activity (93.5 % in terms of aldehyde conversion) and excellent stability (at least five cycle). Owing to confining and stabilizing effects, fibrous Rh(OH)3/TS‐1@DFNS showed negligible Rh leaching relative to conventional Rh(OH)3/TS‐1.58

Figure 35.

Schematic for the synthesis of Rh(OH)3/TS‐1@DFNS and its application in the one‐pot synthesis of amides. Reprinted with permission from Ref. 57. Copyright 2013 Royal Society of Chemistry.

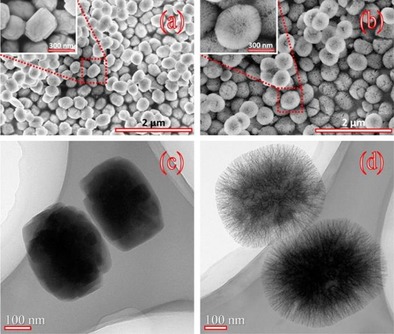

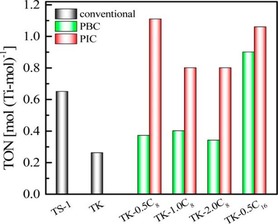

DFNS/TS‐1 was also used in the development of pickering interfacial catalysts by the Wu and Pera‐Titus group.59 A pickering emulsion is an emulsion that is stabilized by solid particles, such as nanosilica, and one can perform catalysis in these emulsions, which is known as pickering interfacial catalysis (PIC). An amphiphilic zeolite/silica composite, named TS‐1@DFNS (TK), was synthesized by grafting octylsilane and hexadecylsilane (Figure 36). The catalysts were then evaluated in the hydroxylation of benzene by using hydrogen peroxide (H2O2) in PIC and phase‐boundary catalysis (PBC). PIC relies on the solid nanoparticles to act as emulsifiers as well as catalysts, whereas PBC relies on the solid nanoparticles lying at the boundary of the aqueous–organic phase (without emulsifying). Thus, ideally, pickering interfacial catalysts will have large interfacial surface areas, and this will increase the interaction of the catalysts with the reactants and, thus, expedite the catalytic process. TK showed a better TON than TS‐1 (Figure 37) as a result of its fibrous morphology and hydrophobic functionality on the surface, which helped the catalyst to disperse well (Figure 38).

Figure 36.

SEM and TEM images of a, c) TS‐1 and b, d) TK. Reprinted with permission from Ref. 59. Copyright 2015 American Chemical Society.

Figure 37.

Benzene hydroxylation under PIC, PBC, and conventional conditions. Reprinted with permission from Ref. 59. Copyright 2015 American Chemical Society.

Figure 38.

Schematic of the hydroxylation of benzene under pickering interfacial catalysis (PIC) by using TK. Reprinted with permission from Ref. 59. Copyright 2015 American Chemical Society.

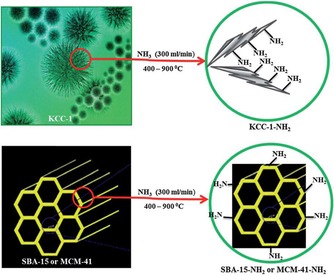

3.5. DFNS‐based solid bases and acids

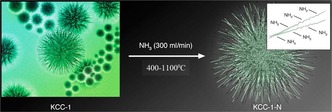

Solid bases, such as silica oxynitrides, are important catalysts for various processes in industry. The basicity of these nitrogen‐based hybrid materials is attributed to the various amine sites on their surface. High surface area silica materials, such as MCM‐41 and SBA‐15, were used to develop active solid bases by their nitridation with ammonia gas at high temperature.60, 61 Although both of these materials possess good basicity, their performance was limited because of restricted access of the amine sites inside the pores as well as their poor thermal stability during high‐temperature nitridation, which distorts their internal structures and further restricts accessibility of the active sites. We were able to overcome these issues by using DFNS as a support in oxynitride synthesis.62 DFNS‐oxynitrides (DFNS‐N) were prepared by an ammonia nitridation protocol at different temperatures (Figure 39), and then their base catalytic activities were compared with those of MCM‐41‐oxynitrides and SBA‐15‐oxynitrides by using the Knoevenagel condensation and transesterification reactions.

Figure 39.

Nitridation of DFNS by using ammonia at different temperatures. Reprinted with permission from Ref. 62. Copyright 2013 American Chemical Society.

Oxynitrides of DFNS performed better than their MCM‐41 and SBA‐15 counterparts in the Knoevenagel condensation reactions of various aldehyde molecules (Table 4) as well as the transesterification of esters with a wide range of alcohols. DFNS‐N‐500 (52 % conversion) showed higher activity than SBA‐15‐N, methylated Me‐NSBA‐51, and Me‐NMCM‐41, which showed conversions of 0, 15, and 9 %, respectively. This improvement was not only due to the open and flexible fibrous structure of DFNS but was also due to the presence of both basic (amines) and acidic (silanols) sites, which were tuned by optimizing the nitridation temperature.62

Table 4.

Comparison between nitridated DFNS, MCM‐41, and SBA‐15 for Knoevenagel condensation reactions of ethyl cyanoacetate with benzaldehyde.[a]

| Sample | N content [wt %] (mmol g−1) | Catalyst amount [mg] (mmol) | Conversion in 24 h [%] |

|---|---|---|---|

| DFNS‐N500 | 1.6 (1.14) | 90 (0.10) | 52 |

| NSBA61 | 24.2 (17.3) | 20 (0.34) | 0 |

| Me‐NSBA61 | 18.4 (13.1) | 20 (0.26) | 15 |

| Me‐NMCM61 | 1.1 (0.76) | 20 (0.015) | 9 |

[a] Adapted with permission from Ref. 62. Copyright 2013 American Chemical Society.

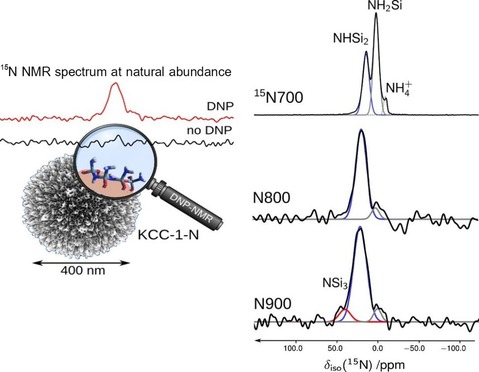

In DFNS‐oxynitrides,62 during optimization of the nitridation temperature, we observed that if the nitrogen content of these silicon oxynitrides was increased, their catalytic activity decreased even after an increase in the number of active N‐sites. We, in collaboration with Lafon's group, attempted to understand this counterintuitive behavior of DFNS oxynitrides by using solid‐state 15N NMR and 29Si NMR spectroscopy experiments with the sensitivity boosted by the dynamic nuclear polarization (DNP) technique.63 This work was the first application of DNP‐enhanced NMR spectroscopy to moisture‐sensitive fibrous silica oxynitrides. The nitridation of DFNS was performed in a flow reactor by exposing DFNS to ammonia gas (300 mL min−1) at various temperatures for 12 h (Table 5). The samples were denoted DFNS‐Nx, for which x is the nitridation temperature and 15N indicates 15N isotope enrichment.

Table 5.

Textural properties and nitrogen content of DFNS‐N at different temperatures.63

| Sample | Surface area [m2 g−1] | BJH pore | N content[a] | |

|---|---|---|---|---|

| BET | Langmuir | volume [cm3 g−1] | [wt %] | |

| DFNS | 669 | 964 | 1.27 | 0 |

| DFNS‐N600 | 603 | 871 | 1.22 | 2.02 |

| DFNS‐15N700 | 610 | 885 | 1.29 | 3.18 |

| DFNS‐N800 | 565 | 815 | 1.17 | 6.37 |

| DFNS‐N900 | 492 | 711 | 1.06 | 11.94 |

| DFNS‐15N1100 | 285 | 399 | 0.72 | 6.52 |

[a] Determined by C, H, and N analysis.

The DNP‐enhanced 15N NMR and 29Si NMR spectroscopy study showed that nitridated DFNS was covered by various silylamine sites and that the nature and relative amount of these sites depended on the nitridation temperature (Figure 40). Below 700 °C, more primary amines were observed, which at higher nitridation temperatures were converted into less basic secondary and tertiary silylamines; hence, the catalyst showed poor activity. The multifold DNP enhancement allowed for the detection of 15N NMR signals for the DFNS‐N surfaces in natural abundance. These DNP‐enhanced 15N NMR and 29Si NMR spectroscopy experiments provided key information about the nature of the active sites as a function of temperature.63

Figure 40.

DNP‐enhanced 15N NMR spectra of nitridated DFNS.63

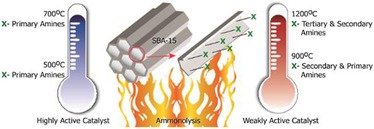

Learning from this DFNS‐oxynitride work, we, in collaboration with Madhu's group, were able to enhance the catalytic activity of SBA‐15‐based solid bases in the Knoevenagel condensation reaction by optimizing the temperature of nitridation (Figure 41) without the need for activation through N‐methylation.64

Figure 41.

Tuning the catalytic activity by the controlled ammonolysis of SBA‐15.64

DFNS was also used to design efficient solid acid catalysts. Siddiqui et al. prepared recyclable DFNS silica sulfuric acid catalysts by treatment with chlorosulfonic acid. This acid catalyst showed good activity by using a very small amount of the catalyst (98 % conversion in 2 min) for enaminone synthesis.65

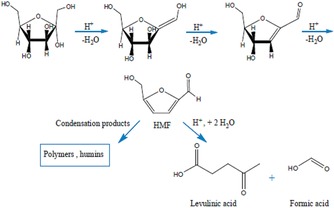

Chermahini et al. also synthesized propylsulfonic acid functionalized DFNS and evaluated this catalyst in the dehydration of fructose to produce 5‐hydroxymethylfurfural (Figure 42). The authors found that 5‐hydroxymethylfurfural could be produced in approximately 67 % yield with 68 % selectivity.66

Figure 42.

Dehydration of fructose to 5‐hydroxymethylfurfural (HMF) and possible byproducts by acid catalysis. Reprinted with permission from Ref. 66. Copyright 2016 Royal Society of Chemistry.

3.6. DFNS‐supported ionic liquids

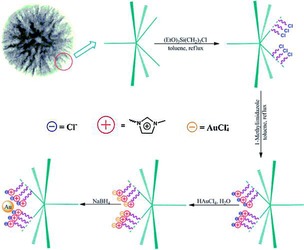

DFNS was also functionalized with ionic liquids (ILs). Yang et al. treated the DFNS surface with 1‐methylimidazole having preformed chloropropyl groups.67 These ionic liquids were then used as anchors to load Au NPs (Figure 43), which made them leachproof catalysts. Sadeghzadeh used a similar approach to functionalize DFNS by the reaction of chloropropyl with hexamethylenetetramine.68 DFNS/IL showed good activity in the synthesis of quinazoline‐2,4(1H,3H)‐diones by the reaction of CO2 with 2‐aminobenzonitriles under mild conditions. Sadeghzadeh then further explored this protocol to prepare PbS‐based ionic liquids supported on DFNS.69 This material showed excellent activity in the dehydrogenation of aqueous HCOOH/HCOONa to H2 and CO2 gas with a TOF of 604 h−1 compared to a TOF of 64 h−1 by using Pd/C.69

Figure 43.

Synthesis of a DFNS‐ionic liquid‐Au nanocatalyst . Reprinted with permission from Ref. 67. Copyright 2014 Royal Society of Chemistry.

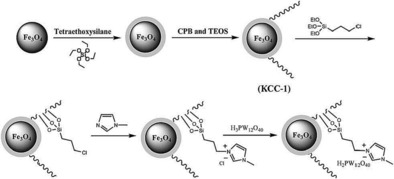

A heteropolyacid (HPW)‐containing ionic liquid supported on magnetic DFNS, named Fe3O4/DFNS/IL/HPW, was prepared by using a similar synthetic protocol (Figure 44);70 high loadings of HPW were possible as a result of IL functionalization. This catalyst was efficiently used to synthesize tetrahydrodipyrazolopyridines.71 The catalyst was recyclable up to 10 times without loss of activity, which was attributed to restricted aggregation of the active HPW owing to the ILs on the fibers of DFNS. This catalyst was also used in the synthesis of cyclic carbonate from carbon dioxide and epoxides under mild conditions.71

Figure 44.

Schematic for the synthesis of Fe3O4/DFNS/IL/HPW. Reprinted with permission from Ref. 70. Copyright 2016 Royal Society of Chemistry.

Similar to the work with ionic liquids, the TEMPO (2,2,6,6‐tetramethylpiperidin‐1‐oxyl) free radical was cleverly generated on the surface of DFNS to design an oxidation catalyst.72 First, DFNS was amine functionalized and then subjected to reductive amination with 4‐hydroxy‐2,2,6,6‐tetramethylpiperdin‐1‐oxyl (4‐oxo‐TEMPO) to yield DFNS/TEMPO. The material catalyzed the oxidation of a wide variety of aliphatic, aromatic, and heterocyclic alcohols in good yields with high selectivities. The catalyst was stable and recyclable up to five times. Because of its small size and fibrous nature, the catalyst particles formed a pseudo‐homogeneous system during catalysis, which improved the reaction efficiency.

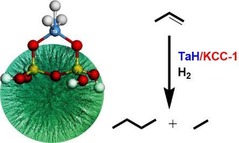

3.7. DFNS‐supported organometallic complexes

Organometallic complexes were also supported on DFNS. Tantalum hydride (TaH), the well‐known “Basset's metathesis catalyst”, was prepared by grafting the [Ta(=CHtBu)(CH2 tBu)3] complex onto the fibers of DFNS, followed by hydrogen treatment at 150 °C for 12 h (Figure 45).73 DFNS/TaH efficiently catalyzed the hydrometathesis reaction of olefins with good activity and was stable for several hours. The catalyst was regenerable and reusable with improved activity.

Figure 45.

DFNS‐supported tantalum hydride (TaH) for the hydrometathesis of olefins.73

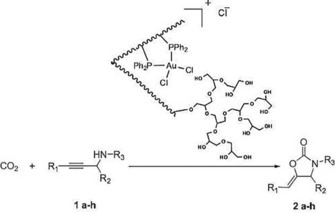

A gold(III) phosphorus complex was also immobilized on DFNS.74 The catalyst showed good activity in the cyclization of propargylic amines with CO2 to provide 2‐oxazolidinones (Figure 46).

Figure 46.

Synthesis of 2‐oxazolidinone by using the DFNS‐supported gold complex. Reprinted with permission from Ref. 74. Copyright 2016 Elsevier B.V.

3.8. DFNS‐supported enzyme

Even an enzyme was supported on DFNS to prepare a supported nano‐biocatalyst. Pang et al. prepared DFNS by modifying the standard DFNS synthetic protocol17 and by using polyvinylpyrrolidone (PVP) as the stabilizing agent for particle growth.75 They then immobilized Candida rugosa lipase (CRL) on the wrinkled silica spheres. The supported CRL was then evaluated as a biocatalyst for biodiesel production through the esterification of oleic acid with methanol. DFNS/CRL was found to be superior to free CRL with an 86 % conversion of oleic acid.

4. Photocatalysis using DFNS

The fibrous morphology of DFNS, which facilitates mass transfer and improves accessibility in thermal catalysis, can also facilitate the separation of light‐generated electron–hole pairs and improve their mobility in photocatalysis. This improved charge separation and transport helps to improve the photocatalytic activity of the materials. In this regard, the use of DFNS as a support for a nanoengineered photocatalyst was first explored by Wang et al. by using graphitic carbon nitride (g‐C3N4)76 and by our group by using titanium dioxide (TiO2).77

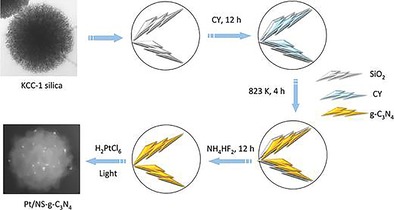

The moderate photocatalytic activity of g‐C3N4 could not be improved even by synthesizing nanosized versions owing to some of its inherent structural issues, especially its stability, which led to agglomeration, deformations, and reduced surface accessibility. Wang et al. nanoengineered g‐C3N4 in the form of spheres made up of interconnected sheets by using DFNS as a template.76 Additionally, these sharp sheets (fibers) could have a “lightning‐rod effect”,78 because the electric field is concentrated near the highly curved surface and the tips of the wrinkled fibers. The thermally induced self‐polymerization of cyanamide (adsorbed on the surface of DFNS fibers/sheets) (Figure 47) yielded g‐C3N4 nanospheres (NSs) with morphologies similar to that of DFNS and with good surface area, pore volume, and pore size of 160 m2 g−1, 0.4 cm3 g−1, and 3.8 nm, respectively.

Figure 47.

Synthesis of g‐C3N4 nanospheres by using DFNS as a template and cyanamide (CY) as a precursor.76

The g‐C3N4 nanospheres had a Brunauer–Emmett–Teller (BET) surface area of 160 m2 g−1, which was far greater than the surface area of its bulk counterpart (only 9 m2 g−1). Its optical properties were also different from those of its bulk counterpart, with a hypsochromic shift in the photoabsorption edge from λ=465 to 430 nm and a band gap shift from 2.67 to 2.86 eV owing to quantum confinement effects (similar to our observations in the DFNS/TiO2 work).77 This also indicated the improved light‐harvesting nature of the catalysts, particularly in the λ=430–590 nm region because of multiple reflections of incident light within the fibrous structure as well as defect sites associated with the sharp edges of the fibers of g‐C3N4.

Not only light harvesting, but a reduction in the recombination of excitons relative to that observed for bulk g‐C3N4 was also observed in a photoluminescence study. The improved charge separation was due to shortening of the charge migration/diffusion length and electron relocalization on the edges (tips) of the fibers. These attributes of the catalyst led to its excellent photocatalytic activity for hydrogen production by using a Pt cocatalyst. The hydrogen evolution rate by using g‐C3N4 nanospheres as a catalyst and a 3 wt % Pt cocatalyst was 574 μmol h−1, which was approximately 45 times higher than that of its bulk counterpart (12.5 μmol h−1). These results clearly indicate the advantages of the fibrous morphology of DFNS and its applications in the nanoengineering of photocatalysts.76

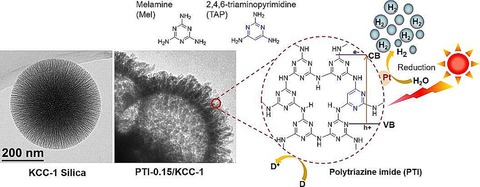

This DFNS/g‐C3N4 composite was further explored by Takanabe's group by replacing cyanamide with a mixture of melamine and 2,4,6‐triaminopyrimidine as precursors (Figure 48).79 They used a two‐step process: the solution phase deposition of the precursors (monomers) on the DFNS fibers followed by salt‐melt high‐temperature polycondensation. The highest hydrogen evolution rate obtained upon using these materials with 3 wt % Pt cocatalyst was 33 μmol h−1 compared to 574 μmol h−1 obtained by Wang et al.76 These results indicate that, for the synthesis of DFNS/g‐C3N4 with superior photocatalytic activity, cyanamide may be a better precursor than a mixture of melamine and 2,4,6‐triaminopyrimidine.

Figure 48.

Synthesis of g‐C3N4 nanospheres by using DFNS as a template and a mixture of melamine and 2,4,6‐triaminopyrimidine as precursors. Reprinted with permission from Ref. 79. Copyright 2015 American Chemical Society.

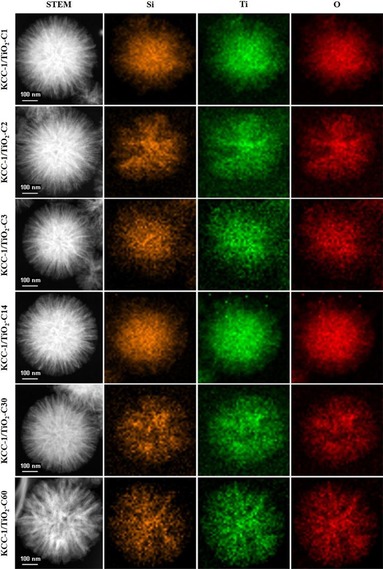

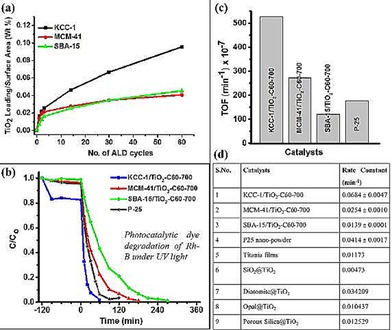

TiO2 is one of the most favored materials that can be used as a photocatalyst.77 However, the use of unsupported TiO2 nanopowder has several drawbacks, such as a small surface area, poor substrate adsorption ability, weak light‐harvesting properties, and difficulty isolating and reusing the catalysts. The issue of isolation and reusability was tackled by immobilizing TiO2 on a silica support. Although all of the supported catalysts allowed for the more efficient isolation and reuse of the catalyst relative to the use of a powdered nano‐TiO2 suspension, the catalytic activity remained poor because of the poor accessibility of the active sites (TiO2). This result implied that the support played a very important role in the design of the photocatalysts allowing for a greater loading of TiO2 with a high substrate adsorption capacity and, more importantly, accessible active sites was needed. In this regard, we designed and synthesized high surface area TiO2 coated on the fibers of fibrous nanosilica (DFNS/TiO2) (Figure 49).77 The synthesis of DFNS/TiO2 was achieved by the deposition of a titanium precursor on DFNS fibers by using atomic layer deposition (ALD) and then oxidizing the material to produce a TiO2 coating. To compare the DFNS/TiO2 materials with conventional materials, SBA‐15/TiO2 and MCM‐41/TiO2 were also prepared by using the same ALD and heat‐treatment procedure. Notably, we observed the formation of small and monodispersed TiO2 nanoparticles after heat treatment with variable sizes.

Figure 49.

Scanning transmission electron microscopy (STEM) and EDS mapping of the DFNS/TiO2 series materials with varied ALD cycles of TiO2. Reprinted with permission from Ref. 77. Copyright 2016 American Chemical Society.

We found that the DFNS/TiO2 catalysts had an array of advantages over conventional silica‐based TiO2 catalysts, such as MCM‐41 and SBA‐15 (Figure 50), in terms of the following: one, a uniform conformal coating, high TiO2 loading, less reduction in surface area, and better accessibility of active sites; two, the presence of TiO2 on the DFNS fibers, for which most of the excitons were on the surface and readily available for catalysis, and this allowed for excellent catalytic performance (Figure 50 c, d) (e.g., conversion, kinetics, and stability); three, enhanced light‐harvesting properties through scattering and reflecting a large amount of incident light owing to the fibrous structure of the material; four, high surface area, which facilitated the adsorption of a large amount of dye molecules during dye degradation. The combination of the unique textural and morphological properties of DFNS, TiO2 nanoparticle formation, and their size quantization were the reasons for the improved photocatalytic activity of the DFNS/TiO2 catalysts.77

Figure 50.

Advantages of using DFNS over MCM‐41 or SBA‐15 as a support for TiO2: a) TiO2 loading in weight % per unit surface area, b) photocatalytic dye degradation of rhodamine B (Rh‐B) under UV light, c) turnover frequency (TOF) values, and d) comparison with reported silica‐supported TiO2 catalysts. Adapted with permission from Ref. 77. Copyright 2016 American Chemical Society.

5. Energy Harvesting using DFNS for Solar Cells

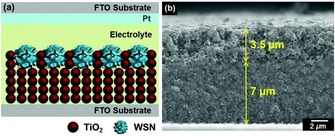

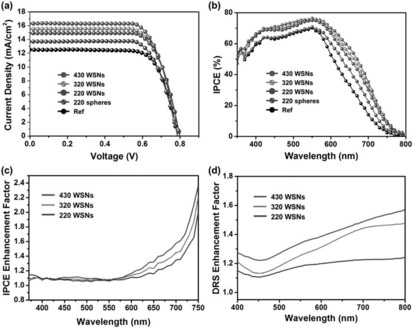

As presented in the work of Wang et al.76 and our group,77 the fibrous nature of DFNS‐based g‐C3N4 and TiO2 increased the light‐harvesting ability, provided better charge separation, and improved the adsorption of dye and water molecules, which in turn increased the photocatalytic performance. Jang et al. used these attributes of DFNS to improve the performance of dye‐sensitized solar cells (DSSCs) by using TiO2‐coated DFNS as a light scatterer in DSSCs—an impressive report and the first of its kind (Figure 51).80 They compared the light‐scattering capabilities of these DFNS/TiO2 materials (they named them WSNs) with solid silica spheres of the same size. The 220 nm WSNs exhibited a higher reflectance than similarly sized silica nanoparticles in the 400 to 900 nm wavelength range. This result indicated the role of the fibrous morphology in increasing light scattering owing to the multiple light‐scattering events at the abundant particle (fiber)–air interfaces. Such intraparticle scattering is minimal in conventional silica nanoparticles. Notably, the 220, 320, and 430 nm WSNs showed characteristic reflectance bands at λ=450, 700, and 850 nm, respectively. The authors suggested that these bands could be due to Mie scattering, for which the effective light scattering is approximately half the wavelength of the incident light.

Figure 51.

DSSC design containing DFNS/TiO2 as a scatterer (top layer): a) schematic illustration and b) cross‐sectional SEM image (the DFNS/TiO2 layer is 3.5 μm and the TiO2 nanoparticle layer is 7 μm). FTO=fluorine‐doped tin oxide. Reprinted with permission from Ref. 80. Copyright 2016 Royal Society of Chemistry.

The photovoltaic performance of these assembled DSSCs was evaluated, and they showed a remarkable improvement in the short‐circuit current (J sc), although the open‐circuit voltage (V oc) and the fill factor (FF) did not change (Figure 52). The 430 nm sized WSN showed the best performance with a power conversion efficiency (PCE) value of 9.53 % and a PCE enhancement of 30.19 relative to a reference cell.80

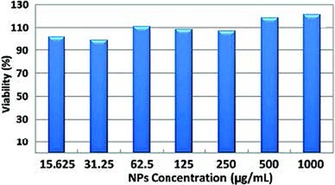

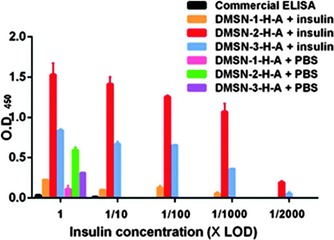

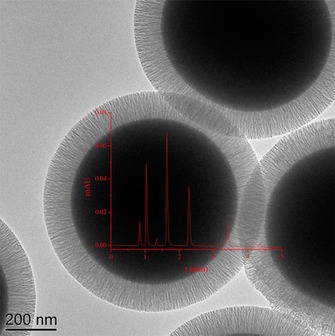

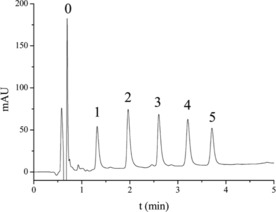

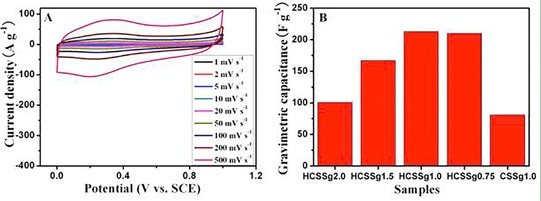

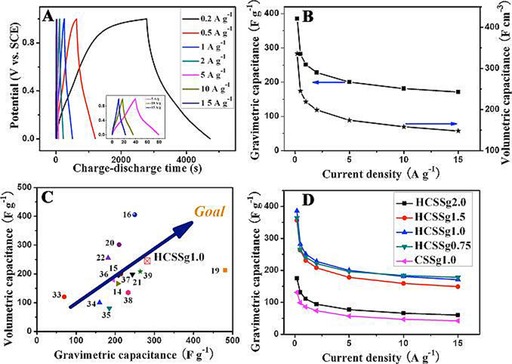

Figure 52.