Abstract

In this data article, laboratory experimental investigation results carried out at National Centre for Agricultural Mechanization (NCAM) on moisture content, machine speed, die diameter of the rig, and the outputs (hardness, durability, bulk density, and unit density of the pellets) at different levels of cassava pellets were observed. Analysis of variance using randomized complete block design with factorial was used to perform analysis for each of the outputs: hardness, durability, bulk density, and unit density of the pellets. A clear description on each of these outputs was considered separately using tables and figures. It was observed that for all the output with the exception of unit density, their main factor effects as well as two and three ways interactions is significant at 5% level. This means that the hardness, bulk density and durability of cassava pellets respectively depend on the moisture content of the cassava dough, the machine speed, the die diameter of the extrusion rig and the combinations of these factors in pairs as well as the three altogether. Higher machine speeds produced more quality pellets at lower die diameters while lower machine speed is recommended for higher die diameter. Also the unit density depends on die diameter and the three-way interaction only. Unit density of cassava pellets is neither affected by machine parameters nor moisture content of the cassava dough. Moisture content of cassava dough, speed of the machine and die diameter of the extrusion rig are significant factors to be considered in pelletizing cassava to produce pellets. Increase in moisture content of cassava dough increase the quality of cassava pellets.

Keywords: Moisture content, Machine speed, Die diameter, Hardness, Durability, Bulk density, Unit density, Cassava pellets, Cassava dough

Specification Table

| Subject area | Engineering and Bio-system |

| More specific subject area | Post Harvest, Food Process, Biomass and Bioenergy |

| Type of data | Tables and figures |

| How data was acquired | Unprocessed secondary data |

| Data format | Laboratory experimental investigation results on moisture content, machine speed, die diameter of the rig, and the outputs (hardness, durability, bulk density, and unit density of the pellets) |

| Experimental factors | Moisture content, machine speed, die diameter of the rig |

| Experimental features | Computational analysis: Analysis of variance (ANOVA), Randomized Complete Block Design with Factorial Experiment, Histogram. |

| Data source location | Agro-Industrial Development and Extension (AIDE) Department, National Centre for Agricultural Mechanization (NCAM), Idofian, Ilorin, Nigeria. |

| Data accessibility | All the data are in this data article as aSupplementary data file |

| Software | SPSS Statistical program and Microsoft Excel |

Value of the data

-

•

The data on cassava pellets is useful for the Agencies saddled with the statutory responsible of food Storage and preservation.

-

•

The data can be useful for policy makers in area of food security. This is due to the high level of cassava consumption among the populace in sub-Sahara Africa.

-

•

The data is a good indicator for entrepreneurs or market operators dealing in the exporting cassava inform of pellets.

-

•

The data can be useful in post- harvest and bio-system engineering studies.

-

•

The data will be useful in biomass and bioenergy researches especially in the area of biofuel.

-

•

The data are for educational purposes and food processing assessment studies.

-

•

The unit density in the data is a measure parameter.

-

•

The data can be used to determine the durability of conversion of cassava dough into pellets.

-

•

The data can be useful in processing poultry feeds into pellets form.

-

•

Several known statistical models, for example, Complete Randomized Design (CRD), factor analysis design, multiple regression, can be applied which provides alternatives to Randomised Complete Block Design with factorial experiment.

1. Data

The data for this paper were obtained from AIDE Department, National Centre for Agricultural Mechanization (NCAM), Idofian, Ilorin, Nigeria. The data are on experimental investigation performed on Cassava. Three factors were involved, each with four levels: moisture content (48.5%(wb), 50.5%(wb), 52.5%(wb), 54.5%(wb)); machine speed (1.5 mm|min, 2.5 mm|min, 3.5 mm|min, 4.5 mm|min); die diameter of the rig (6 mm, 8 mm, 10 mm, 12 mm), and each combination of this experiment (43) were replicated three times. Altogether there were 192 experimental units. The analysis was done using 43 factorial design with randomized complete block design.

The raw data with the three factors: moisture content, speed, die diameter, and their replication, and also each of the four outputs: hardness, bulk density, durability and unit density. Altogether, there are eight (8) columns and 192 rows, in the file, which can be assessed as Supplementary data.

Statistical summary of each of the outputs: hardness, bulk density, durability, unit density are presented in Table 1. It was observed that the average hardness in N, bulk density in kg|m3; durability in % and unit density of cassava pellets are 10.9505, 56.9264, 31.4840 and 0.0120 respectively.

Table 1.

Summary statistics of the hardness, bulk density, durability and unit density of cassava pellets.

| Statistic | Hardness | Bulk density | Durability | Unit density | |

|---|---|---|---|---|---|

| N | 192 | 192 | 192 | 192 | |

| Missing | 0 | 0 | 0 | 0 | |

| Mean | 10.9505 | 56.9264 | 31.4840 | 0.0112 | |

| Median | 10.0000 | 55.6800 | 31.3400 | 0.0082 | |

| Mode | 5.0000 | 45.6400 | 27.5900 | 0.0055a | |

| Std. Deviation | 6.7222 | 6.8852 | 12.0979 | 0.0146 | |

| Variance | 45.1870 | 47.4050 | 146.3600 | 0.0000 | |

| Skewness | 1.3430 | 0.2210 | 0.0180 | 5.7720 | |

| Std. Error of Skewness | 0.1750 | 0.1750 | 0.1750 | 0.1750 | |

| Kurtosis | 2.0360 | -0.6260 | 0.0480 | 39.3270 | |

| Std. Error of Kurtosis | 0.3490 | 0.3490 | 0.3490 | 0.3490 | |

| Minimum | 3.0000 | 45.6400 | 7.6900 | 0.0013 | |

| Maximum | 40.0000 | 73.0200 | 61.6400 | 0.1400 | |

| Percentiles | 25 | 5.0000 | 52.0300 | 25.0450 | 0.0059 |

| 50 | 10.0000 | 55.6800 | 31.3400 | 0.0082 | |

| 75 | 15.0000 | 62.9800 | 38.4600 | 0.0141 | |

Multiple modes exist. The smallest value is shown.

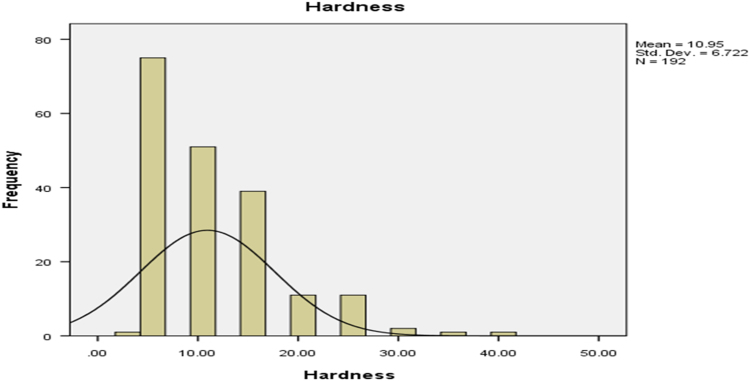

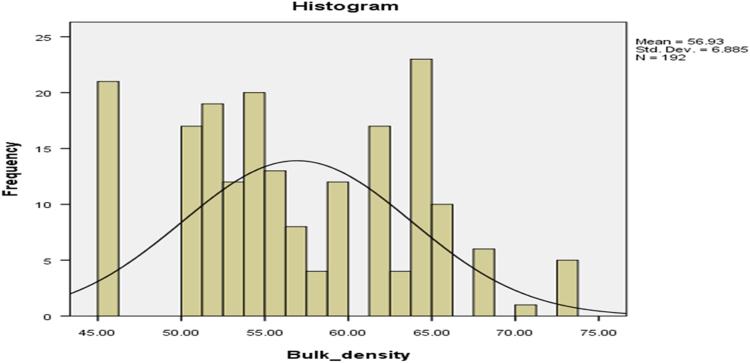

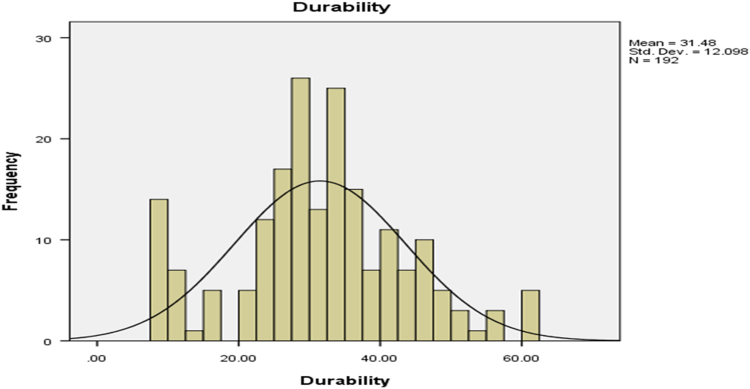

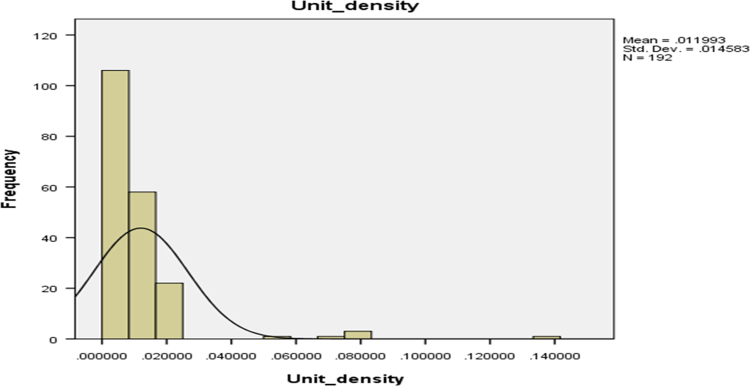

Histograms for the hardness, bulk density, durability and unit density of cassava pellets are presented in Fig. 1, Fig. 2, Fig. 3, Fig. 4 respectively.

Fig. 1.

The hardness of cassava pellets.

Fig. 2.

The bulk density of cassava pellets.

Fig. 3.

the durability of cassava pellets.

Fig. 4.

The unit density of cassava pellets.

The parameters on Fig. 1, Fig. 2, Fig. 3, Fig. 4 are contained in Table 1 and normal plots on the figures showed how the distributions were fitted by the normal distribution. Other distributions may be applied when the raw data is analyzed further.

2. Experimental design, materials and methods

Several studies have been conducted on the pellets [1], [2], [3], [4], [5], [6], [7], [8], [9]. Similar data articles on pellets that applied statistical tools can be helpful, readers are referred to [10], [11], [12], [13], [14], [15], [16], [17], [18].

The materials used for this experiment are classified into two groups namely: the cassava powder and the mechanical extrusion rig.

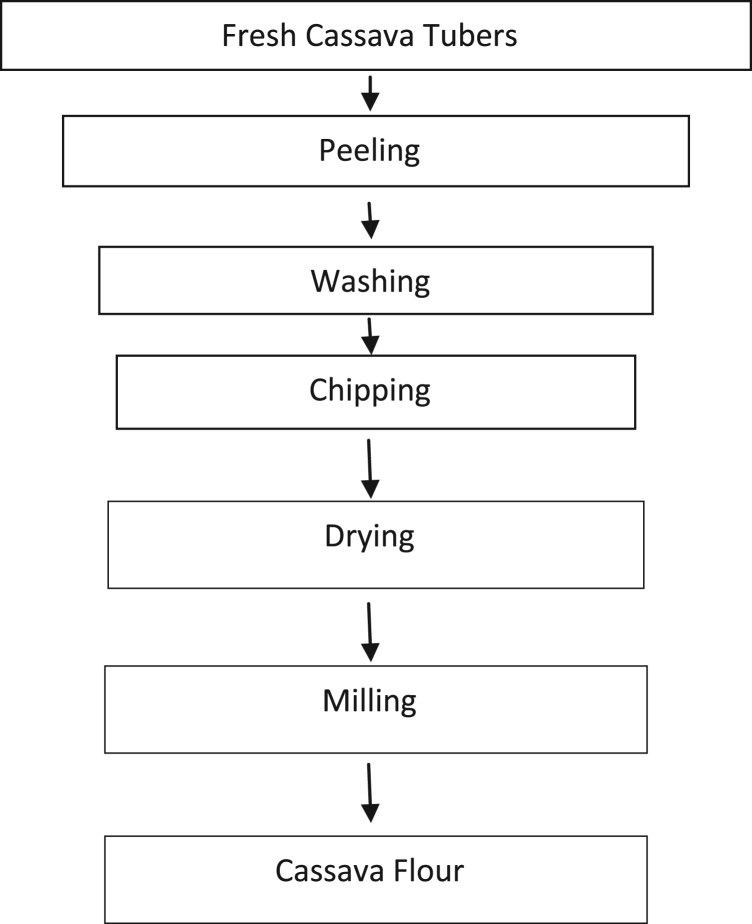

2.1. Cassava preparation

Cassava tubers were bought from Idofian market in Ifelodun Local Government area of Kwara State Nigeria. The tubers were processed into cassava powder as shown in Fig. 5. The moisture content of the cassava powder was 10%wb and it was conditioned to form cassava dough using Eq. (1). Weight of water () to be added is

| (1) |

where

Present moisture content

Required moisture content

Weight of sample in grams

Fig. 5.

Flow chart for the processing of cassava tubers into cassava powder.

2.2. Pelletization process

The mechanical extrusion process (pelletization) involves the application of a compressive force on the cassava dough enclosed in a cylinder with replaceable die called pelletization rig and is shown in Fig. 7. The pelletization rig containing the cassava dough was mounted on the “TESTOMETRICS” universal testing machine (model M500 50kN) as shown in Fig. 6 and extraction process took place on the “TESTOMETRICS” Universal testing machine.

Fig. 7.

Showing the dies.

Fig. 6.

Showing the Piston-Cylinder Assembly on the Universal Testing Machine.

2.2.1. Description of the TESTOMETRICS universal testing machine

As shown in Fig. 6, the mechanical extrusion rig consists of two parts. The TESTOMETRICS universal testing machine (UTM Model M500 50KN, England, United Kingdom) and a piston cylinder rig which has been in use for extrusion purposes on the UTM. The UTM consists of the control console, load frame. crosshead, load cell, a computer and printer.

The load frame of the U T M is an extrusion support column with the slot for accessory mounting (cross head) twin re-circulatory ball screws. The cross-head range is 0.001 to 500 mm/min. Maximum cross head travels is 1000 mm. Load cells (load indicating mechanism) are automatically identified and have 800% overload protection capacity.

The machine can be programmed with 100 different test methods/definitions for quick menu recall using Win test software. Results, statistics and graphs can be generated with or without the use of a computer with optional long term data storage and retrieval. Test model/type includes tension, compression, flexural, cyclic etc with appropriate grip and fixtures available for each test type.

2.2.2. The piston cylinder assembly

The piston cylinder assembly (shown in Fig. 6) is made up of three major components: the compression piston, the press cage cylinder, and the supporting platform.

The press cage cylinder is made of mild steel pipe with inside diameter of 160 mm, length of 105 mm, and thickness of 6 mm.

The compression piston is made up of mild steel of 104.23 mm diameter and 126.33 mm height. The supporting platform was made up of angle iron of 3 mm thick, inside dimension of 35 mm by 20 mm and 25 mm height. The dies were four in number; cut from 4 mm thick mild steel plate with holes of 6 mm diameter, 8 mm diameter, 10 mm diameter and 12 mm diameter, with circumference forming about 8 percent of the total area of the plate to cover the cylinder with wire quase, which was improvised for the collection of pellets formed for carefulness and ease of drying in the batch drier.

2.3. Data analysis

The 43 factorial experiment design with randomized complete block design was adopted for the analysis. 43 factorial design implies three (3) factors (moisture content, speed and die diameter) each at four (4) levels. The factor and levels are: moisture content (48.5%(wb), 50.5%(wb), 52.5%(wb), 54.5%(wb)), machine speed (1.5 mm/min, 2.5 mm/min, 3.5 mm/min, 4.5 mm/min), die diameter of the rig (6 mm, 8 mm, 10 mm, 12 mm). Each of these experiments was replicated three times. The total units of experiment were 4×4×4×3 which is 192 altogether. Analysis of variance (ANOVA) table was derived on each output (hardness, bulk density, durability and unit density).

Four moisture contents of 48.5%wb, 50.5%wb, 52.5%wb and 54.5%wb were therefore obtained altogether with 10%wb corresponding to the initial moisture.

Table 2, Table 6, Table 10 present the analysis of variance results for hardness, bulk density and durability of cassava pellets respectively. It was observed from the three tables that all their main factor effects as well as two and three ways interactions are significant at 5% level. This means that the hardness, bulk density and durability of cassava pellets respectively depend on the moisture content of the cassava mash, the machine speed, the die diameter of the rig and the combinations of these factors in pairs as well as three altogether.

Table 2.

Analysis of variance for hardness of cassava pellets.

| Tests of Between-Subjects Effects | |||||

|---|---|---|---|---|---|

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

| Corrected Model | 7561.947a | 63 | 120.031 | 14.375 | 0.00 |

| Intercept | 23023.470 | 1 | 23023.470 | 2757.216 | 0.00 |

| Moisture content | 3068.848 | 3 | 1022.949 | 122.505 | 0.00 |

| Speed | 293.327 | 3 | 97.776 | 11.709 | 0.00 |

| Die diameter | 255.827 | 3 | 85.276 | 10.212 | 0.00 |

| Moisture content * Speed | 316.960 | 9 | 35.218 | 4.218 | 0.00 |

| Moisture content * Die diameter | 950.293 | 9 | 105.588 | 12.645 | 0.00 |

| Speed * Die diameter | 477.897 | 9 | 53.100 | 6.359 | 0.00 |

| Moisture content * Speed * Die diameter | 2198.796 | 27 | 81.437 | 9.753 | 0.00 |

| Error | 1068.833 | 128 | 8.350 | ||

| Total | 31654.250 | 192 | |||

| Corrected Total | 8630.780 | 191 | |||

R Squared = .876 (Adjusted R Squared = .815), Dependent Variable: Hardness.

Table 6.

Analysis of variance for bulk density of cassava pellets.

|

Tests of Between-Subjects Effects | |||||

|---|---|---|---|---|---|

| Dependent Variable: Bulk_density | |||||

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

| Corrected Model | 6697.337a | 63 | 106.307 | 5.773 | 0.000 |

| Intercept | 622198.220 | 1 | 622198.220 | 33787.909 | 0.000 |

| Moisture content | 1458.475 | 3 | 486.158 | 26.400 | 0.000 |

| Speed | 422.526 | 3 | 140.842 | 7.648 | 0.000 |

| Die diameter | 1413.111 | 3 | 471.037 | 25.579 | 0.000 |

| Moisture content * Speed | 923.230 | 9 | 102.581 | 5.571 | 0.000 |

| Moisture content * Die diameter | 756.710 | 9 | 84.079 | 4.566 | 0.000 |

| Speed * Die diameter | 550.249 | 9 | 61.139 | 3.320 | 0.001 |

| Moisture content * Speed * Die diameter | 1173.036 | 27 | 43.446 | 2.359 | 0.001 |

| Error | 2357.097 | 128 | 18.415 | ||

| Total | 631252.654 | 192 | |||

| Corrected Total | 9054.434 | 191 | |||

R Squared = .740 (Adjusted R Squared = .612).

Table 10.

Analysis of variance for durability of cassava pellets.

|

Tests of Between-Subjects Effects | |||||

|---|---|---|---|---|---|

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

| Corrected Model | 26758.625a | 63 | 424.740 | 45.452 | 0.00 |

| Intercept | 190318.009 | 1 | 190318.009 | 20366.381 | 0.00 |

| Moisture content | 16320.740 | 3 | 5440.247 | 582.174 | 0.00 |

| Speed | 1296.492 | 3 | 432.164 | 46.247 | 0.00 |

| Die diameter | 3716.795 | 3 | 1238.932 | 132.581 | 0.00 |

| Moisture content * Speed | 1842.024 | 9 | 204.669 | 21.902 | 0.00 |

| Moisture content * Die diameter | 1335.656 | 9 | 148.406 | 15.881 | 0.00 |

| Speed * Die diameter | 407.097 | 9 | 45.233 | 4.840 | 0.00 |

| Moisture content * Speed * Die diameter | 1839.820 | 27 | 68.141 | 7.292 | 0.00 |

| Error | 1196.123 | 128 | 9.345 | ||

| Total | 218272.758 | 192 | |||

| Corrected Total | 27954.748 | 191 | |||

R Squared = .957 (Adjusted R Squared = .936), Dependent Variable: Durability.

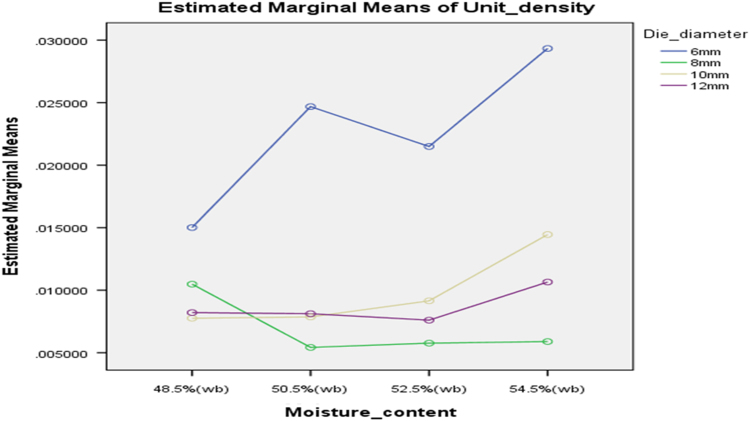

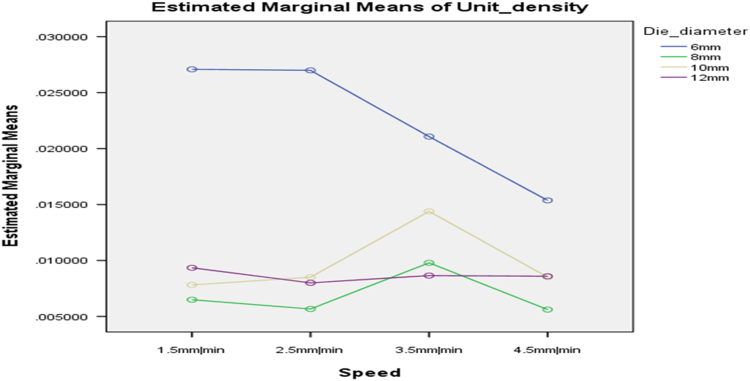

Table 14 presents the analysis of variance result for the unit density of cassava pellets. However, only the die diameter and the three-way interaction are significant at 5% level. This implies that the unit densities of cassava pellets only depends on the die diameter of the rig and the effect of the combination of moisture content, machine speed and die diameter of the rig.

Table 14.

Analysis of variance for unit density of cassava pellets.

|

Tests of Between-Subjects Effects | |||||

|---|---|---|---|---|---|

| Source | Type III Sum of Squares | Df | Mean Square | F | Sig. |

| Corrected Model | 0.020a | 63 | 0.000 | 1.960 | 0.001 |

| Intercept | 0.028 | 1 | 0.028 | 170.986 | 0.000 |

| Moisture content | 0.001 | 3 | 0.000 | 1.327 | 0.269 |

| Speed | 0.000 | 3 | 0.000 | 0.879 | 0.454 |

| Die diameter | 0.007 | 3 | 0.002 | 15.371 | 0.000 |

| Moisture content * Speed | 0.002 | 9 | 0.000 | 1.227 | 0.284 |

| Moisture content * Die diameter | 0.001 | 9 | 0.000 | 0.890 | 0.537 |

| Speed * Die diameter | 0.001 | 9 | 0.000 | 0.821 | 0.598 |

| Moisture content * Speed * Die diameter | 0.007 | 27 | 0.000 | 1.641 | 0.036 |

| Error | 0.021 | 128 | 0.000 | ||

| Total | 0.068 | 192 | |||

| Corrected Total | 0.041 | 191 | |||

R Squared = .491 (Adjusted R Squared = .240), Dependent Variable: Unit density.

Table 3, Table 4, Table 5, Table 7, Table 8, Table 9, Table 11, Table 12, Table 13 present post hoc test for significant differences in the levels of moisture content, machine speed and die diameter of the rig for hardness, bulk density and durability of cassava pellets respectively. Durable cassava pellets which can withstand stress during handling can be obtained at moisture content level above 48.5%wb and below 55.5%wb.

Table 3.

Post hoc test for significant differences in moisture content under hardness of cassava pellets in %(wb).

| Waller-Duncan | ||||

|---|---|---|---|---|

| Moisture content | N | Subset |

||

| 1 | 2 | 3 | ||

| 54.5%(wb) | 48 | 4.9479 | ||

| 52.5%(wb) | 48 | 9.7917 | ||

| 48.5%(wb) | 48 | 13.8542 | ||

| 50.5%(wb) | 48 | 15.2083 | ||

Table 4.

Post hoc test for significant differences in machine speed under hardness of cassava pellets in mm|min.

| Waller-Duncan | ||||

|---|---|---|---|---|

| Speed | N | Subset |

||

| 1 | 2 | 3 | ||

| 1.5 mm|min | 48 | 9.2708 | ||

| 2.5 mm|min | 48 | 10.8333 | ||

| 3.5 mm|min | 48 | 10.9375 | ||

| 4.5 mm|min | 48 | 12.7604 | ||

Table 5.

Post hoc test for significant differences in die diameter under hardness of cassava pellets in mm.

| Waller-Duncan | |||

|---|---|---|---|

| Die_diameter | N | Subset |

|

| 1 | 2 | ||

| 10 mm | 48 | 9.7917 | |

| 12 mm | 48 | 9.8438 | |

| 8 mm | 48 | 11.7708 | |

| 6 mm | 48 | 12.3958 | |

Table 7.

Post hoc test for significant differences in moisture content under bulk density of cassava pellets in %(wb).

| Waller-Duncan | |||

|---|---|---|---|

| Moisture content | N | Subset |

|

| 1 | 2 | ||

| 48.5%(wb) | 48 | 54.1785 | |

| 50.5%(wb) | 48 | 55.6527 | |

| 52.5%(wb) | 48 | 56.3754 | |

| 54.5%(wb) | 48 | 61.4990 | |

Table 8.

Post hoc test for significant differences in machine speed under bulk density of cassava pellets in mm|min.

| Waller-Duncan | |||

|---|---|---|---|

| Speed | N | Subset |

|

| 1 | 2 | ||

| 4.5 mm|min | 48 | 54.5113 | |

| 1.5 mm|min | 48 | 57.0598 | |

| 2.5 mm|min | 48 | 57.6498 | |

| 3.5 mm|min | 48 | 58.4848 | |

Table 9.

Post hoc test for significant differences in die diameter under bulk density of cassava pellets in mm.

| Waller-Duncan | |||

|---|---|---|---|

| Die_diameter | N | Subset |

|

| 1 | 2 | ||

| 12 mm | 48 | 54.0167 | |

| 10 mm | 48 | 54.4640 | |

| 6 mm | 48 | 59.1229 | |

| 8 mm | 48 | 60.1021 | |

Table 11.

Post hoc test for significant differences in moisture content under durability of cassava pellets in %(wb).

| Waller-Duncan | |||||

|---|---|---|---|---|---|

| Moisture_content | N | Subset |

|||

| 1 | 2 | 3 | 4 | ||

| 54.5%(wb) | 48 | 18.7585 | |||

| 52.5%(wb) | 48 | 28.7656 | |||

| 50.5%(wb) | 48 | 34.1346 | |||

| 48.5%(wb) | 48 | 44.2771 | |||

Table 12.

Post hoc test for significant differences in machine speed under durability of cassava pellets in mm|min.

| Waller-Duncan | ||||

|---|---|---|---|---|

| Speed | N | Subset |

||

| 1 | 2 | 3 | ||

| 3.5 mm|min | 48 | 27.6985 | ||

| 2.5 mm|min | 48 | 30.4727 | ||

| 4.5 mm|min | 48 | 33.6046 | ||

| 1.5 mm|min | 48 | 34.1600 | ||

Table 13.

Post hoc test for significant differences in die diameter under durability of cassava pellets in mm.

| Waller-Duncan | |||||

|---|---|---|---|---|---|

| Die_diameter | N | Subset |

|||

| 1 | 2 | 3 | 4 | ||

| 12 mm | 48 | 26.2444 | |||

| 10 mm | 48 | 28.1465 | |||

| 8 mm | 48 | 34.7581 | |||

| 6 mm | 48 | 36.7869 | |||

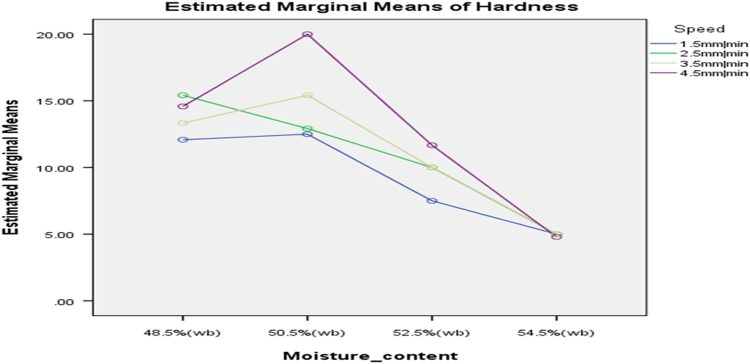

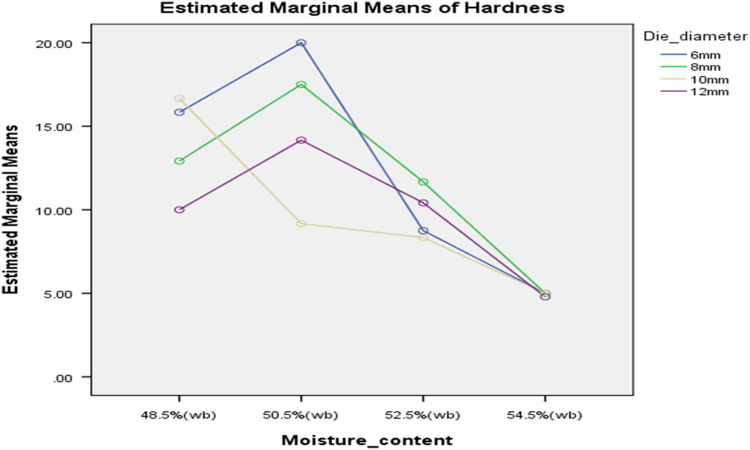

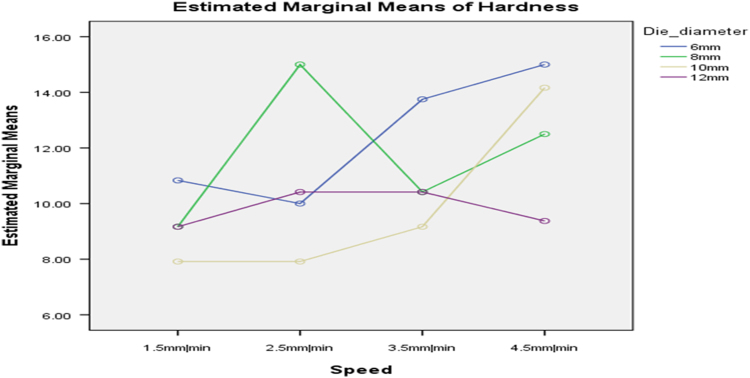

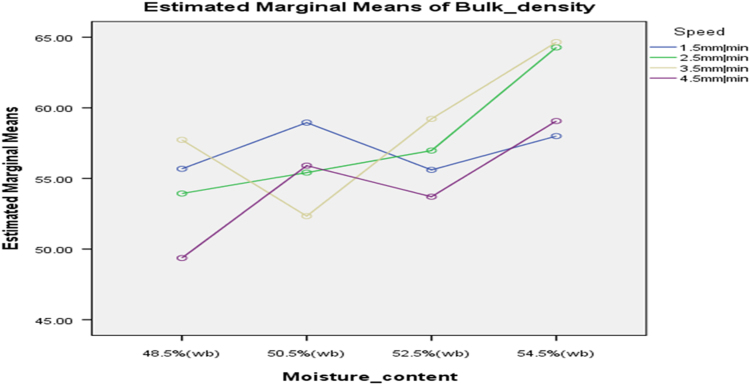

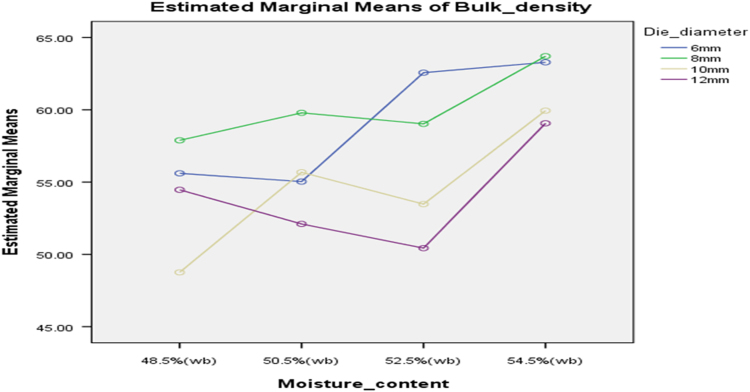

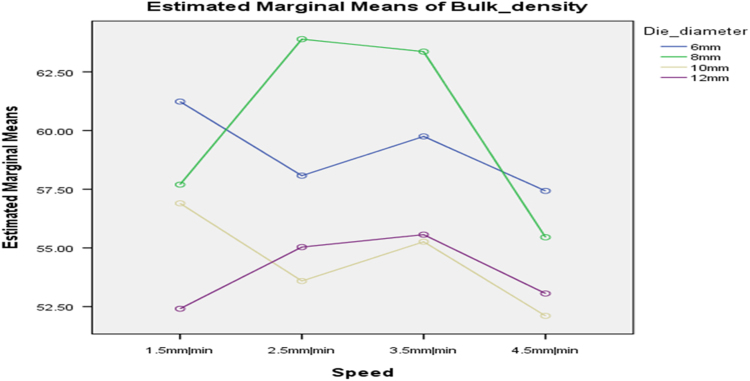

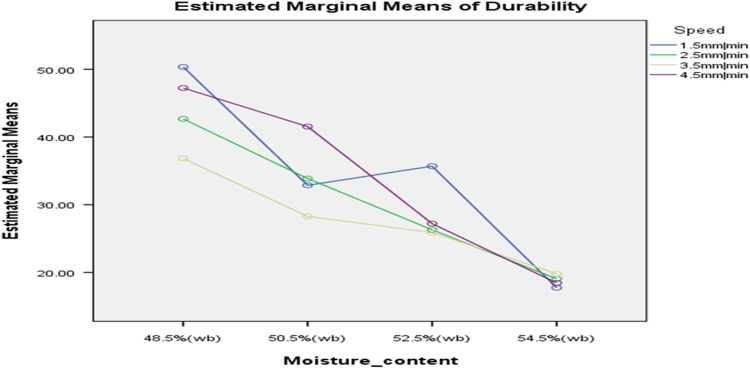

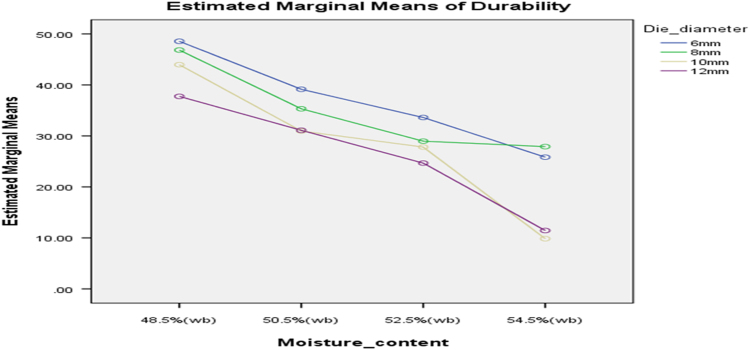

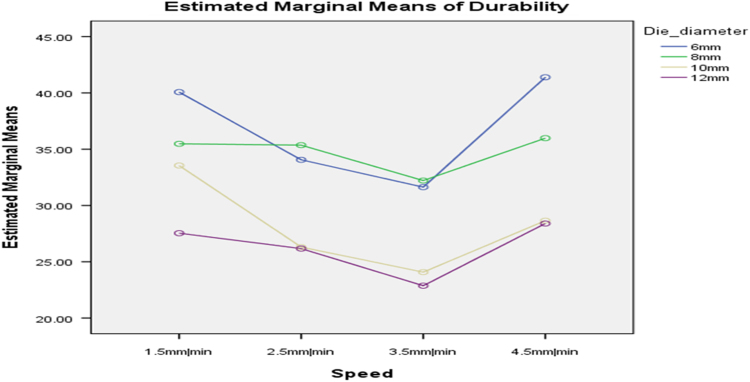

Table 15 presents the post hoc test for significant differences in the levels of die diameter of the rig for unit density of cassava pellets. Likewise, Fig. 8, Fig. 9, Fig. 10, Fig. 11, Fig. 12, Fig. 13, Fig. 14, Fig. 15, Fig. 16 present the graphs for interactions between: moisture content and machine speed; moisture content and die diameter; machine speed and die diameter respectively on hardness, bulk density and durability of cassava pellets.

Table 15.

Post hoc test for significant differences in die diameter under unit density of cassava pellets in mm.

| Waller-Duncan | |||

|---|---|---|---|

| Die diameter | N | Subset |

|

| 1 | 2 | ||

| 8 mm | 48 | 0.00689062 | |

| 12 mm | 48 | 0.00864625 | |

| 10 mm | 48 | 0.00980583 | |

| 6 mm | 48 | 0.02263021 | |

Fig. 8.

Graph of interactions between moisture content and machine speed on hardness of cassava pellets.

Fig. 9.

Graph of interactions between moisture content and die diameter on hardness of cassava pellets.

Fig. 10.

Graph of interactions between speed and die diameter on hardness of cassava pellets.

Fig. 11.

Graph of interactions between moisture content and machine speed on Bulk density of cassava pellets.

Fig. 12.

Graph of interactions between moisture content and die diameter on Bulk Density of cassava pellets.

Fig. 13.

Graph of interactions between speed and die diameter on Bulk Density of cassava pellets.

Fig. 14.

Graph of interactions between moisture content and machine speed on Durability of cassava pellets.

Fig. 15.

Graph of interactions between moisture content and die diameter on durability of cassava pellets.

Fig. 16.

Graph of interactions between speed and die diameter on durability of cassava pellets.

Lastly, Fig. 17, Fig. 18 present graphs for interactions between: moisture content and die diameter; machine speed and die diameter on unit density respectively.

Fig. 17.

Graph of interactions between moisture content and die diameter on Unit Density of cassava pellets.

Fig. 18.

Graph of interactions between speed and die diameter on unit density of cassava pellets.

Acknowledgements

This work is a benefit of sponsored from the Centre for Research, Innovation and Discovery, Covenant University, Ota, Nigeria. Also, we thank the management of National Centre for Agricultural Mechanization (NCAM), Ilorin, for making the data available for us.

Footnotes

Supplementary data associated with this article can be found in the online version at doi:10.1016/j.dib.2017.11.044.

Supplementary data associated with this article can be found in the online version at doi:10.1016/j.dib.2017.11.044.

Transparency document. Supplementary material

Supplementary material

.

Appendix A. Supplementary material

Supplementary material

.

References

- 1.ASAE . Standard S358.2 Moisture Measurement Forages ASAE; ST Joseph,MI: 2002. Standard S269.4- Cubes, Pellets, and Crumbles – Definitions and Methods for Determining Density, Durability, and Moisture Content ASAE DEC 96. [Google Scholar]

- 2.Bellinger P.L., McColly M. Energy requirements for forming hay pellets agric. Engine. 1961;42(5-6):180–181. [Google Scholar]

- 3.Bruhn H.D. Engineering problems in pelletized feeds. Agric. Eng. 1957;38(7):522–525. [Google Scholar]

- 4.Dobie J.B. Engineering appraisal of hay pelleting. Agric. Eng. 1959;40(2):76–92. [Google Scholar]

- 5.Hill B., Pulkinen D.A. A study of factors affecting pellet durability and pelleting efficiency in the production of dehydration Alfalfa pellets. Sask. Dehydrators Assoc. 1988:20–23. [Google Scholar]

- 6.Leaver R.H. Pelleting dies: characteristics and selection sprout. Wald. Feed Pointer. 1985;26:1–6. [Google Scholar]

- 7.MacBain R. American Feed Manufacturers Association; Arlington, VA: 1966. Pelleting Animal Feed. [Google Scholar]

- 8.Samson R.A., Duxbury P., Drisdell M., Lapointe C. PERD Program, Natural Resources Canada; Ottawa, Ontario: 2000. Assessment of Pelletized Biofuels. [Google Scholar]

- 9.Skoch E.R., Behnke K.,C., Deyoe C.W., Binder S.F. The Effect of steam conditioning rate on the pelleting process. Anim. Feed Sci. Technol. 1981;6:83–90. [Google Scholar]

- 10.Uarrota V.G., Moresco R., Schmidt E.C., Bouzon Z.L., Nunes E.C., Neubert E.O., Peruch L.A.M., Rocha M., Maraschin M. Data supporting the role of enzymes and polysaccharides during cassava postharvest physiological deterioration. Data Brief. 2016;6:503–506. doi: 10.1016/j.dib.2015.12.043. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Coufal-Majewsk S., Stanford K., McAlliste T., Wang Y., Blakley B., McKinno J., Chaves A.V. Effects of pelleting diets containing cereal ergot alkaloids on nutrient digestibility, growth performance and carcass traits of lambs. Anim. Feed. Sci. Technol. 2017;230:103–113. [Google Scholar]

- 12.Ogbo F.C., Okafor E.N. The resistant starch content of some cassava based Nigerian foods. Nig.Food J. 2015;33(1):29–34. [Google Scholar]

- 13.Anyanwu C.N., Ibeto C.N., Ezeoha S.L., Ogbuagu N.J. Sustainability of cassava (Manihot esculenta Crantz) as industrial feedstock, energy and food crop in Nigeria. Renew. Energy. 2015;81:745–752. [Google Scholar]

- 14.Adekunle A., Orsat V., Raghavan V. Lignocellulosic bioethanol: a review and design conceptualization study of production from cassava peels. Renew. Sust. Energy Rev. 2016;64:518–530. [Google Scholar]

- 15.Olufayo A.A., Ogunkunle O.J. Natural drying of cassava chips in the humid zone of Nigeria. Bioresour. Technol. 1996;58(1):89–91. [Google Scholar]

- 16.Eni A.O., Fasasi D.K. Molecular detection of two cassava Begomoviruses in some parts of Southern Nigeria. Afr. J. Agric. Res. 2013;8(16):1350–1353. [Google Scholar]

- 17.O.A. Odetunmibi, O.A. Adejumo, P.E. Oguntunde, H.I. Okagbue, A.O. Adejumo, E.A. Suleiman, Drying kinetic of industrial cassava flour: Experimental data in view, Data in Brief, 15, 2017, 501-510. [DOI] [PMC free article] [PubMed]

- 18.Ozoegwu C.G., Eze C., Onwosi C.O., Mgbemene C.A., Ozor P.A. Biomass and bioenergy potential of cassava waste in Nigeria: estimations based partly on rural-level garri processing case studies. Renew. Sustain. Energy Rev. 2017;72:625–638. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary material

Supplementary material