Abstract

The purpose of this research was to enhance the stab resistance of protective clothing material by developing a new high-density nonwoven structure. Ice picks often injure Japanese police officers due to the strict regulation of swords in the country. Consequently, this study was designed to improve stab resistance against ice picks. Most existing anti-stab protective clothing research has focused on various fabrics impregnated with resin, an approach that brings with it problems of high cost and complicated processing. Seldom has research addressed the potential for improving stab resistance by using nonwoven structures, which exhibit better stab resistance than fabric. In this research, we prepared a series of nonwoven structures with densities ranging from about 0.14 g/cm3 to 0.46 g/cm3 by varying the number of stacked layers of Kevlar/polyester nonwoven under a hot press. We then proposed two methods for producing such hot-press nonwovens: the multilayer hot-press method and the monolayer hot-press method. Stab resistance was evaluated according to NIJ Standard-0115.00. We also investigated the relationship among nonwoven density, stab resistance, and flexural rigidity, and here we discuss the respective properties of the two proposed methods. Our results show that stab resistance and flexural rigidity increase with nonwoven density, but flexural rigidity of nonwovens prepared using the monolayer hot-press method only shows a slight change as nonwoven density increases. Though the two methods exhibit little difference in maximum load, the flexural rigidity of nonwovens prepared using the monolayer hot-press method is much lower, which contributes to superior wear comfort. Finally, we investigated the mechanism behind the stabbing process. Stabbing with an ice pick is a complicated process that involves many factors. Our findings indicate that nonwovens stop penetration primarily in two ways: nonwoven deformation and fiber fractures.

Keywords: High-density, Nonwoven, Penetration energy, Stab resistance, Protective Clothing, Soft flexural rigidity

Introduction

Protective clothing, or special materials worn by police officers for protective purposes, is designed to absorb or deflect slashing, bludgeoning, and penetrating attacks using weapons. Large numbers of Japanese police officers risk their lives to help keep society safe and secure. However, due to strict regulation of swords in the country, police officers are most often injured by ice picks, rather than by guns or knives. Consequently, police must wear stab-resistant clothing during routine duty, creating high demand for such clothing in order to protect officers from assault. Unfortunately, most stab-resistant clothing incorporates a heavy, durable metal plate that imposes significant discomfort on the wearer. In recent years, some research has been carried out to improve wear comfort of stab-resistant clothing by relying on flexible stab-resistant materials utilizing soft Kevlar fabric. For example, Jessie B. Mayo Jr., researched the puncture resistance of thermoplastic film-laminated aramid fabric, which exhibits excellent properties, including flexibility1). M. J. Decker researched the stab resistance of treated Kevlar and nylon fabrics treated with shear thickening fluid and found them to exhibit significantly improved stab resistance and flexibility2). The authors3) added microscopic particles to a textile stab-proof material and verified the effectiveness of the resulting material in protecting against stabbing attacks. Based on the results of a verification experiment in which fabrics were impregnated with particles, the authors were able to verify the mechanism responsible for increased stab-proof performance: the particles increased friction drag, constraining movement of yarn strands and increasing stab-proof performance. Xuhong Miao investigated the stab resistance of warp knitted fabrics and found that knitted fabric with a moderate density and longer under-laps on the front guide bar performed better4). Yves Termonia built a new model to analyze factors that influence stab resistance and found that puncture processes could be divided into four stages and that maximum force occurs during friction against its conical section5).

In most recent research, stab impact testing focuses on knives or flat stabbing weapons. A. A. Levinsky compared the puncture resistance of two types of layered composite structure against knives and bullets6). Duong Tu Tien researched the anti-stabbing performance (vs. knives) of fabric layers woven with various hybrid yarns under different fabric conditions and developed an anti-stabbing index capable of predicting or determining anti-stabbing performance7). Magdi El Messiry investigated puncture behavior (vs. knives) of flexible silk fabric composites in soft body armor, finding that multi-layer silk fabric over a para-aramid triaxial weave fabric (TWF) is superior to para-aramid plain-weave fabric8). Stab-resistant materials usually incorporate woven fabrics, hybrid fabric, or uni-direction composites impregnated with thermoplastic materials. Chang-sheng Lia researched the stab resistance of UHMWPE fiber composites impregnated with thermoplastics. In addition, thermoplastic films, particularly polyethylene terephthalate and polypropylene films, can significantly improve the stab-resistance performance of composites9). When Silvio Leonardo Valença evaluated the mechanical behavior of epoxy composite reinforced with Kevlar plain fabric and glass/Kevlar hybrid fabric, he found that composites with a Kevlar/glass hybrid structure in the reinforcing fabric exhibited better performance10).

When stabbed with an ice pick, the fibers near the point of encroachment move away to create an increasingly large opening, allowing the pick to readily penetrate the material11). To date, we have pursued the approach of impregnating fabrics that have a large cover factor with elastomers to “lock” the yarn in place as a way of boosting stab resistance. We have proposed a nonwoven fabric structure that consists of dense, randomly positioned fibers as a low-cost, stab-proof material, and the advantages of that structure have been verified12). The higher the nonwoven density, the better the stab resistance. However, the biggest issue is the lack of research dedicated to achieving high density while retaining good flexibility.

In this research, we sought to develop a new low-cost, high-density structure made of fiber materials to improve wear comfort and stab resistance. We also optimized the new structure and clarified the stabbing mechanism. Stab-resistant body armor is classified according to the National Institute of Justice (NIJ) Standard 0115.0013). We evaluated stab resistance and flexibility using a machine developed by our laboratory and a bending machine, respectively.

Experimental Method

Materials

The nonwoven used in this study, which was provided by Japan Wool Textile Co., Ltd., consisted of staple Kevlar fiber (90 wt%) blended with low-melting polyester fiber (10 wt%) and manufactured into a nonwoven by the needle punching method. The mass per unit area of this nonwoven was about 140 g/m2. Table 1 outlines the characteristics of the nonwoven. In recent years, Kevlar fiber has been widely used for protective clothing due to its high strength and flexibility. The melting point of polyester fiber is 110°C.

Table 1. Specifications of the nonwoven.

| Fiber | Fiber diameter (dtex) | Mass per unit area (g/m2) |

|---|---|---|

| Kevlar+10% PET | Kevlar: 2.25 PET: 4.4 |

140 |

Fabrication of a high-density nonwoven structure

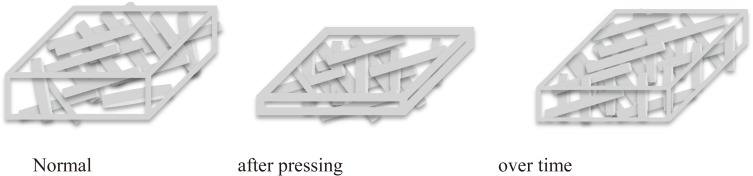

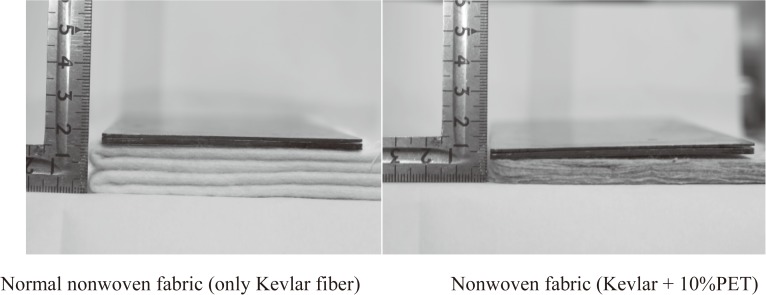

The density of traditional nonwovens is very low. In order to create high-density nonwovens, researchers in the past have hot-pressed pure Kevlar nonwovens to enhance their density. Figure 1 illustrates this traditional method for producing high-density nonwovens. Pressed Kevlar fibers are connected and spaces between fibers reduced to create a high-density nonwoven structure. However, pressed nonwovens revert to low density over time.

Fig. 1.

Traditional method for producing high-density nonwovens.

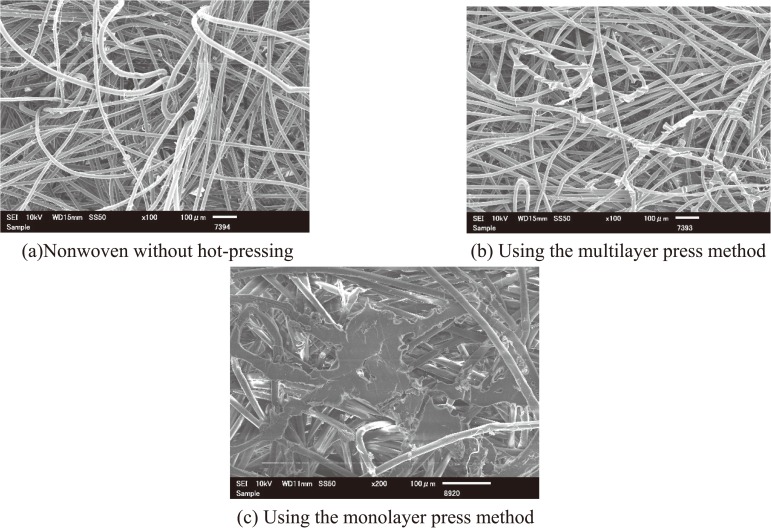

To address this shortcoming, we proposed a new method in which Kevlar fibers are mixed with low-melted PET and manufactured into a blended nonwoven using the needle-punching technique. Hot-pressing the low-density nonwoven to create a high-density nonwoven melts the PET and bonds the Kevlar fibers. Figure 2 illustrates this method, which allows the nonwoven to retain its high density.

Fig. 2.

Proposed method for producing high-density nonwovens.

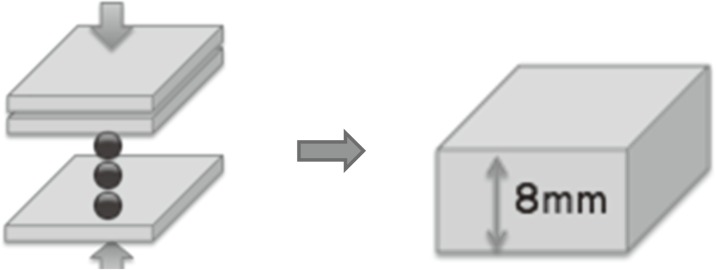

We hot-pressed nonwoven structures of varying density to investigate the relationship between density and stab resistance. To do so, we utilized two methods to fabricate a high-density structure. The first was the multilayer press method, in which several layers of nonwoven are laminated and then hot-pressed into an 8 mm thick mold. Figure 3 illustrates this method. The second was the monolayer press method, in which a single hot-pressed layer is laminated. The latter method embodies our proposal for improving the flexibility of high-density nonwovens. Figure 4 illustrates the monolayer press method.

Fig. 3.

Multilayer press method.

Fig. 4.

Monolayer press method.

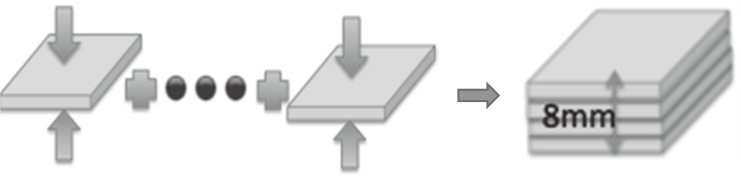

In order to confirm whether the polyester fibers melted as expected, we observed cross-section and surface specimens of the hot-pressed nonwovens using a JSM-6010LA In Touch Scope SEM (Japan). The difference in the extent of melting between the two methods was striking. Figure 5(a) illustrates a nonwoven without hot-pressing, while Fig. 5(b) depicts a nonwoven fabricated using the multilayer press method. Figure 5(c) shows a nonwoven fabricated using the monolayer press method. Bonded fibers were observed in the sample produced using the proposed method.

Fig. 5.

The SEM photograph cross-section of the nonwoven fabric after a hot press.

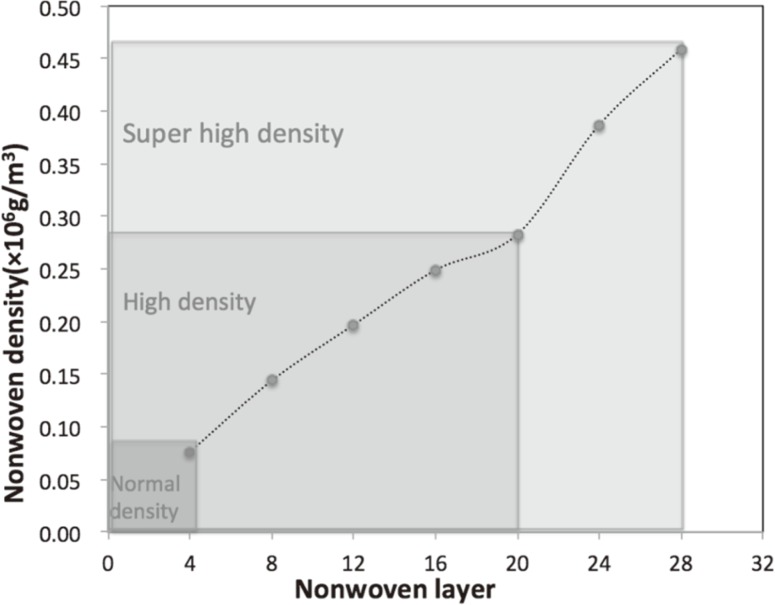

We then hot-pressed nonwoven structures of varying densities in order to investigate the relationship between density and stab resistance. Figure 6 shows nonwovens of varying densities. The nonwoven fabric machined by pre-study12) is called high-density nonwoven fabric. The density of the nonwoven fabric produced by the proposed method becomes fairly high, and is called super high-density nonwoven fabric. The densest nonwoven has a density that is almost 6 times higher than the density of normal nonwovens.

Fig. 6.

Nonwovens of varying densities.

Observation of density

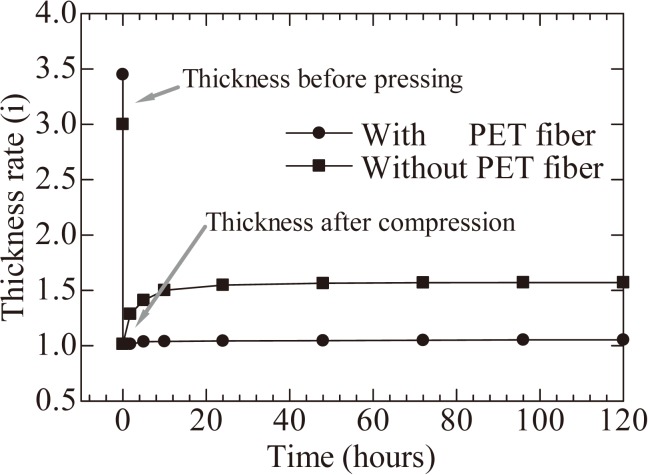

We tested the density of hot-pressed nonwovens over a period of five days to confirm the stability of the nonwoven structure’s high density. The nonwoven structures produced using the two methods had the same densities. In order to confirm stable density, we tested the thickness of the hot-pressed nonwovens since their width, length, and mass did not change. The thickness was tested in accordance with ISO standard 9073-2:199514). The testing method consisted of subjecting the nonwovens to additional pressure by placing a 300-gram iron plate on top of each sample and then testing the thickness. Figure 7 illustrates this testing process. Figure 8 provides thickness variability curves plus the difference between hot-pressed PET-nonwoven (Kevlar+10%PET fiber) and No-PET-nonwoven (only Kevlar fiber) after five days of testing. The thickness rate (i) refers to the ratio of present thickness to mold thickness. No-PET-nonwoven shows a change rate of about 54.8%, while PET-nonwoven shows a change rate of about 3.7%. It can be concluded that hot-pressed PET-nonwoven can maintain its high density perpetually.

Fig. 7.

Testing of nonwoven thickness.

Fig. 8.

Thickness variability curves for nonwovens with and without PET.

Results and Discussion

Flexibility of high-density nonwovens

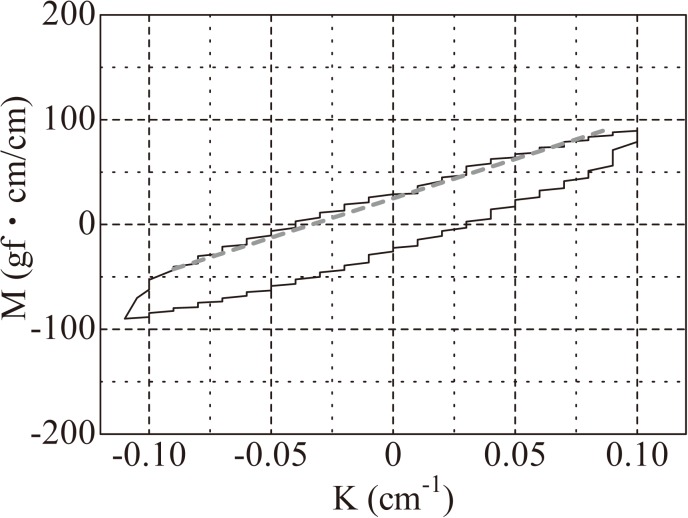

In order to identify flexible materials with high stab resistance, we tested specimens’ flexibility using a KES-FB2-S Multi-Purpose Bending Tester (Kato Tech Co., Ltd., Japan). We used 10 samples for each structure. Figure 9 illustrates the relationship between bending curvature and bending moment. We calculated the flexural rigidity (curvature: −0.08 to 0.08 cm−1) of the samples using a gradient of bending curvature and bending moment curve, and we investigated the relationship between flexibility and density. The difference between the two methods in terms of flexibility was striking.

Fig. 9.

Relationship between bending curvature and bending moment (example).

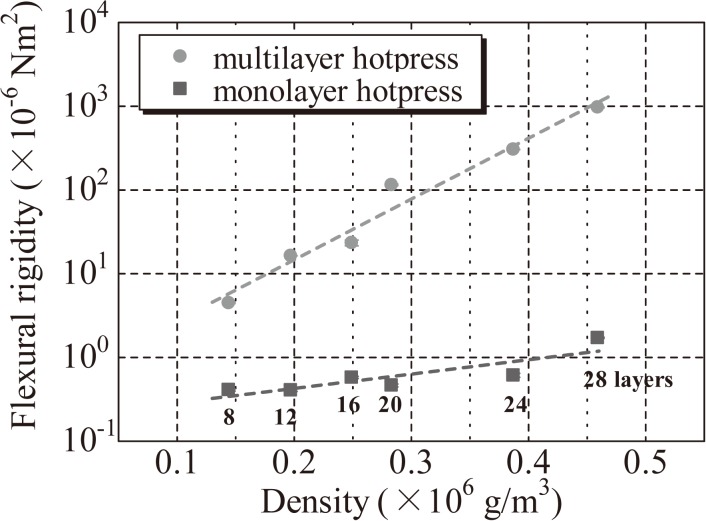

Figure 10 illustrates the flexibility of nonwovens produced using the two different methods. Higher flexural rigidity means worse flexibility. Flexibility can be seen to decline as the nonwovens’ density increases. However, nonwovens produced using the monolayer press method exhibit higher flexibility than nonwovens produced using the multilayer press method. The flexural rigidity obtained using the multilayer press method is about 1,000 times higher than that from the monolayer press method, particularly in the case of the 28-layer nonwoven. The nonwoven layers in the samples produced using the multilayer press method can be seen to have fully adhered to one another. However, nonwoven layers are only partially adhered in the samples produced using the new monolayer press method. Compared with the traditional method, flexural rigidity has been reduced by a factor of n2 (n: number of layers).

Fig. 10.

Flexibility of nonwovens produced using the multilayer press method and the monolayer press method.

Stab resistance

To test the anti-stab performance of the samples, we performed stab testing using a machine designed by the authors in accordance with the applicable NIJ standard3, 11, 12). The traditional testing method can only evaluate whether the implement penetrates with a certain energy, and it is not capable of applying a load after striking. Therefore, it does not provide an understanding of the maximum penetrating load and penetration energy if the sample cannot be penetrated. Our lab developed a new evaluation machine to address these shortcomings. In this test apparatus, the ice pick is attached to the tip of an air cylinder that propels it so that it strikes the specimen. A regulator adjusted the maximum collision speed of this apparatus to 5 m/s, but we also conducted tests at a collision speed of 2.83 m/s as specified by NIJ Standard-0115.00.

In the load-displacement curves obtained from the experiment, the impact load increased after the ice pick struck the specimen and peaked when the maximum diameter of the ice pick penetrated the specimen. We assumed that the maximum value at that moment was the maximum load. The integrated value of the load-displacement curve from collision to the maximum load represents the energy required for penetration (penetration energy), which we used as an index to evaluate the specimen’s stab protection.

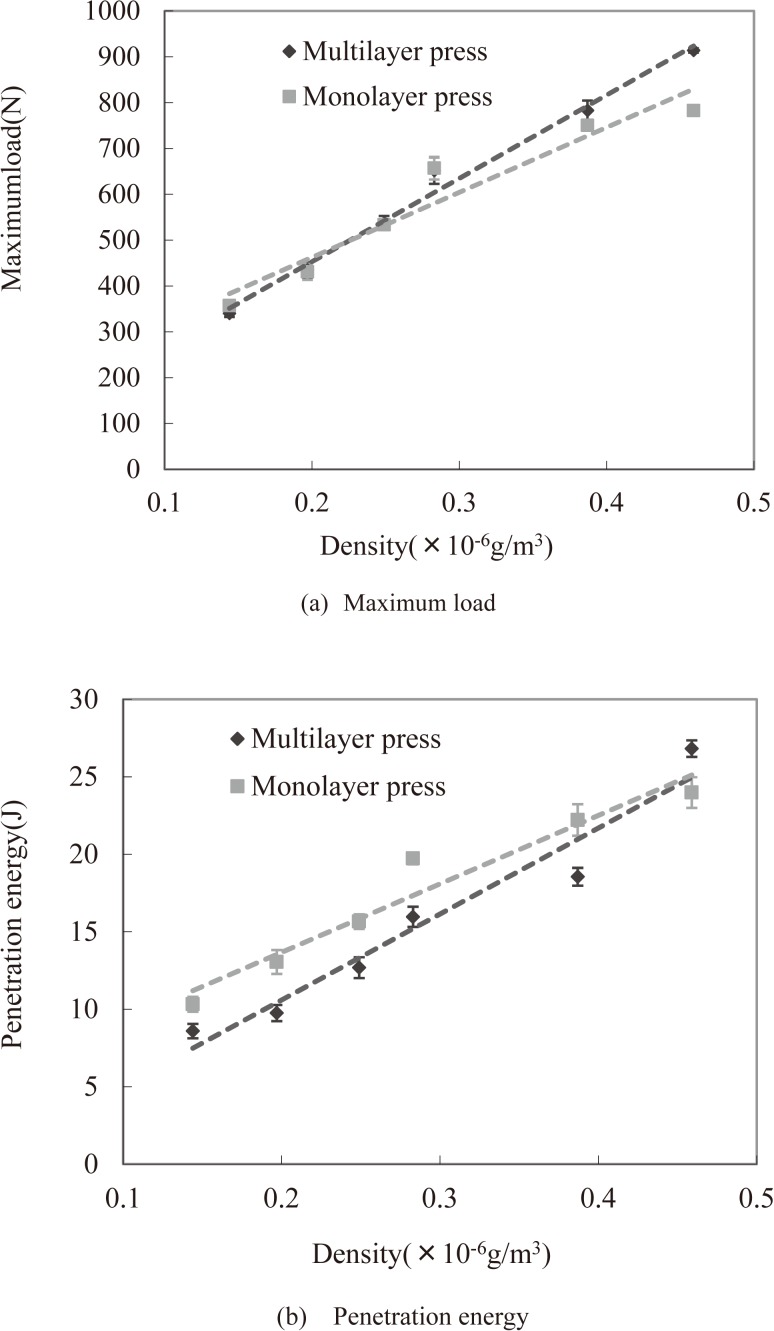

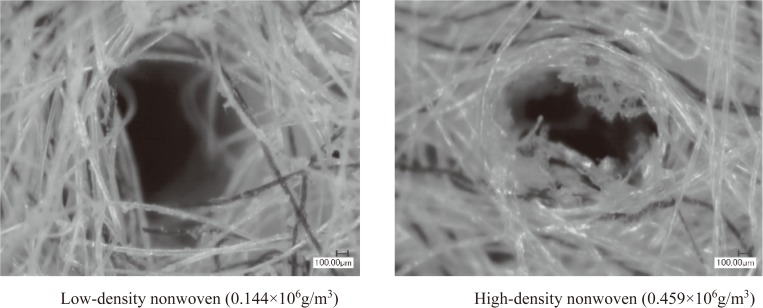

Figure 11 illustrates the results of testing the two methods’ stab resistance. The density of the nonwoven is shown on the horizontal axis, while the maximum load (a) and penetration energy (b) are shown on the vertical axis. Although there is a slight difference associated with higher density, it can be concluded that the stab resistance values of the high-density nonwovens prepared using the two methods are almost the same. The high-density nonwovens produced using the monolayer press method exhibit excellent stab resistance along with much better comfortableness at 3.1. Higher-density nonwovens exhibited better stab resistance. It was misleading display. I correct as follows. The maximum load of the new high-density nonwoven structure is superior by a factor of 3 compared to the normal nonwovens. Figure 12 shows the samples after penetration. Fibers in the low-density nonwoven were displaced during penetration, whereas fibers in the high-density nonwoven fractured, which increased stab resistance. In this way, we proved the effectiveness of the two methods.

Fig. 11.

Stab resistance curve for nonwovens produced using the monolayer press and multilayer press methods.

Fig. 12.

Kevlar nonwovens after stabbing test.

Conclusion

In this study, we focused on researching the stab resistance of nonwovens against ice picks and developed a new nonwoven structure that exhibits excellent stab resistance and flexibility. Recognizing that numerous factors influence nonwoven properties and final stab resistance, we carried out several different experiments and have provided their results.

After several trial experiments, we used Kevlar/polyester nonwovens to create a high-density nonwoven structure by hot-pressing the material. We found that increasing the nonwoven density greatly improved stab resistance.

In order to produce high-density nonwovens, we hot-pressed nonwovens using the multilayer press method but found that the approach led to reduced flexibility. To improve comfort, we proposed the monolayer press method. Our results showed that nonwovens produced using the monolayer press method were much more flexible than nonwovens produced using the multilayer press method. The stab resistance of the high-density nonwovens prepared using the two methods were almost the same.

Acknowledgments

This study was conducted using scientific research subsidies provided by the Ministry of Education, Culture, Sports, Science and Technology (JP26289005, JP16K14113, and JP15H01789).

References

- 1.Mayo J Jr, Wetzel ED, Hosur MV, Jeelani S (2009) Stab and puncture characterization of thermoplastic-impregnated aramid fabrics. Int J Impact Eng 36, 1095–105. [Google Scholar]

- 2.Decker M, Halbach CJ, Nam CH, Wagner NJ, Wetzel ED (2007) Stab resistance of shear thickening fluid (STF) treated fabrics. Compos Sci Technol 67, 565–78. [Google Scholar]

- 3.Bao L, Sato S, Wang Y, Wakatsuki K, Morikawa H (2017) Development of flexible stab-proof textiles impregnated with microscopic particles. Journal of Textile Engineering 63, 43–8. [Google Scholar]

- 4.Miao X, Jiang G, Kong X, Zhao S (2014) Experimental Investigation on the Stab Resistance of Warp Knitted Fabrics. Fibres Text East Eur 22, 65–70. [Google Scholar]

- 5.Termonia Y. (2006) Puncture resistance of fibrous structures. Int J Impact Eng 32, 1512–20. [Google Scholar]

- 6.Levinsky A, Sapozhnikov S, Grass T (2012) Development of knife and bullet resistant composite structures. Mech Compos Mater 48, 405–14. [Google Scholar]

- 7.Tien D, Kim J, Huh Y (2011) Evaluation of Anti-stabbing Performance of Fabric Layers Woven with Various Hybrid Yarns under Different Fabric Conditions. Fibers Polym 12, 808–15. [Google Scholar]

- 8.Messiry M. (2014) Investigation of Puncture Behaviour of Flexible Silk Fabric Composites for Soft Body Armour. Fibres Text East Eur 22, 71–6. [Google Scholar]

- 9.Lia C, Huang X, Li Y, Yang N, Shen Z, Fan X (2014) Stab resistance of UHMWPE fiber composites impregnated with thermoplastics. Polym Adv Technol 25, 1014–9. [Google Scholar]

- 10.Valenca S, Griza Z, Oliveira V, Sussuchi E, Cunha F (2015) Evaluation of the mechanical behavior of epoxy composite reinforced with Kevlar plain fabric and glass/Kevlar hybrid fabric. Compos, Part B Eng 70, 1–8. [Google Scholar]

- 11.Souma S, Bingo T, Morikawa H, Bao L (2011) Proceedings of the 2nd Asian Protective Clothing Conference, 13–15.

- 12.Bao L, Sato S, Morikawa H, Soma S (2016) Improving Stab-resistant Textile Materials with a Non-woven Fabric Structure. Journal of Textile Engineering 62, 37–42. [Google Scholar]

- 13.NIJ Standard-0115.00, Stab resistance of personal body armor (2000)

- 14.ISO 9073-2: 1995 Textiles-Test methods for nonwovens-Part 2: Determination of thickness