Abstract

Minimal dimensional changes in free standing dental implants when incinerated in a kiln to a temperature of 1125°C have been reported previously. However, in the same study colour changes were observed between commercially pure titanium and titanium alloy type of implants, with speculation that this change may be a useful distinguishing tool in cases requiring forensic identification. The present study was instigated to determine what changes occur following cremation to bone-supported dental implants placed within mandibles of sheep. A selection of dental implants was photographed and radiographed. They were then surgically placed in sheep mandibles and the entire sheep heads cremated in a commercial cremator. There was detachment of the dental implants from the mandible, which could have implications for scene recovery. Following retrieval and re-irradiating of the implants, image subtraction evaluation of the radiographs was recorded using Adobe® Photoshop.® As with the previous study there was slight oxidation of the implant surfaces leading to minor alteration of the images. There was, however, no gold crust colour change in the commercially pure titanium. Photography within the retrieved implants revealed the batch number within the Straumann! implant was still visible, which could significantly add weight to the identification of deceased persons.

Keywords: Forensic odontology, dental implants, incineration, identification, sheep heads

INTRODUCTION

The identification of deceased victims is important for both moral and economic reasons. The family and friends of the victims are aided in closure with the certainty that identification brings. The legal and financial processes for the relatives and the relevant government authorities are also able to proceed. (1-3)

Current dental treatment practice has encompassed the use of implants as a viable method of replacing single or multiple missing teeth. This treatment option is occurring at a rapidly growing rate (4-6) increasing the likelihood that implants will be present in deceased victims and be detected in postmortem radiographic examination. As commercially pure titanium and titanium alloy dental implants have a melting point greater than 1650°C (7) the likelihood of implants surviving severe thermal insult is high.

If antemortem records are available, the matching of implants using postmortem radiographs or metric analysis is a straightforward process. If the deceased is unknown, the detection of dental implants could aid in the investigation of the victim by identifying the type, make and sizes of the implants. (8) Website search engines are available that can assist with the implant identification. (9) Regional manufacturers’ sales records for the particular type and size of implants recovered in a postmortem examination could narrow the possibilities from a list of missing persons. The results of our recent research suggest that free standing dental implants heated in a temperaturecontrolled kiln are still recognizable following incineration and that there appeared to be a colour difference between commercially pure titanium and titanium alloy on their oxidized surfaces. (10)

Since 2010, the Straumann™ company has been laser etching batch numbers within the chamber of their implants. The number of implants with the same batch number varies between 24 and 2400 implants (Per com. Schuler M, Head Clinical and Scientific Affairs, Straumann™ Company). Although this number is still quite high it reduces the frequency from many thousands in some cases. A recent pilot study tested the ability of the etched batch numbers to be identified following intense heat exposure in a furnace at 1125oC. (11) In this previous study the removal of the abutment following incineration in the furnace revealed an intact identifiable batch number.

An issue identified in the previous study was that the implants were free-standing within a furnace, with no osseointegration with bone, nor were they contained within biological tissue.

This study was instigated to determine:

Ą What changes occur following cremation to dental implants surgically placed within mandibles of adult sheep, in an environment closer to reality where the implants are located within bone and exposed to fire in the presence of tissues and fluids?

Ą Whether the numbers within an implant were still visible following this incineration.

MATERIALS AND METHODS

Implants were requested from various dental companies. A Straumann Regular 3.3 x 10mm, a Nobel Biocare Replace Select! 4.3 x 8mm, an Ankylos" plus 3.5 x 17mm, two Zimmer 3.7 x 13 mm, and a Neoss! 3.5 x 9mm implants were kindly donated for this study. Each implant was photographed with a digital camera (Nikon Coolpix 5900, Tokyo, Japan) externally then internally with the aid of a WILD Heerburg! microscope (Leica Microsystems, Wetzler, Germany). Each implant was irradiated for 0.18s at 65kVp, 8 mA using a Belmont Searcher model DX-068 (Takara Belmont, Osaka, Japan). The sensor was an MPSe Ethernet digital with Cygnus software (Cygnus Technologies, Scottsdale, USA). To allow standard methodology, purpose built apparatus made from a cold cure resin (VertexTM Trayplast, Zeist, The Netherlands) constructed for the previous study (10) was again utilized. To reproduce the rotation of the implant within the positioning aid, each implant was superficially marked on its leading head edge with a high speed diamond bur and this mark was aligned forward to the beam on a marked area on the positioning apparatus.

Two fresh adult sheep heads were sourced from a local abattoir. On the same day three mandibular incisor teeth were extracted from each head and spaced so that there was a tooth and supporting bone on each side of the extraction socket. The implant was then torque wrenched into each socket to bone level. An abutment or healing cap was then screwed on with tight finger pressure.

The heads were transported to a professional animal crematorium and placed in a gas fired Pathological Incinerator (Civil & Mechanical Services, Torrensville, Australia). Incineration continued for 2.5 hours, reaching a maximum temperature of 780 °C, before the heads were allowed to cool and the remains removed from the incinerator. The implants were retrieved from the carbonized material, re-photographed externally and internally, and re-irradiated.

As in the previous study (10) radiographic images of the implants taken before the firings were compared to the images taken after the firings utilizing the computer software Adobe® Photoshop® CS (Adobe Systems, San Jose, USA). An image subtraction function of the software was used to highlight differences between the images. (12) The retrieved incinerated implants were further examined using a Phillips XL20 Field Emission Scanning Electron Microscope (Amsterdam, Netherlands). The characteristic Xrays from the beam/specimen interaction, producing elemental spectra and maps of the surface, were analyzed with an EDAX® Unit (AMETEK, Inc, Mahwah, NJ USA).

RESULTS

During incineration teeth dislodged from their sockets in partially cremated sheep heads (Fig. 1) and following total incineration implants had fallen through the friable bone ash and had separated from the mandible (Fig. 2). All the implants appeared grey in colour (Fig. 3) and no distinctive gold-coloured crust was visible on the surfaces of the pure titanium implants.

Fig.1.

Partially incinerated sheep head showing dislodged tooth

Fig. 2.

Ashened sheephead mass following incineration and removal from incinerator

Fig.3.

The Nobel Biocare Replace Select! 4.3 x 8mm after incineration.

The results of the comparative analysis in Adobe® Photoshop® CS revealed minimal image differences of all implants (Fig. 4). No detectable sagging was noted and the recognition features of threads and grooves were still identifiable.

Fig.4.

Image subtraction results for Nobel Biocare Replace Select! 4.3 x 8mm, Similar results were observed for each brand of implant: minimal image difference after incineration.

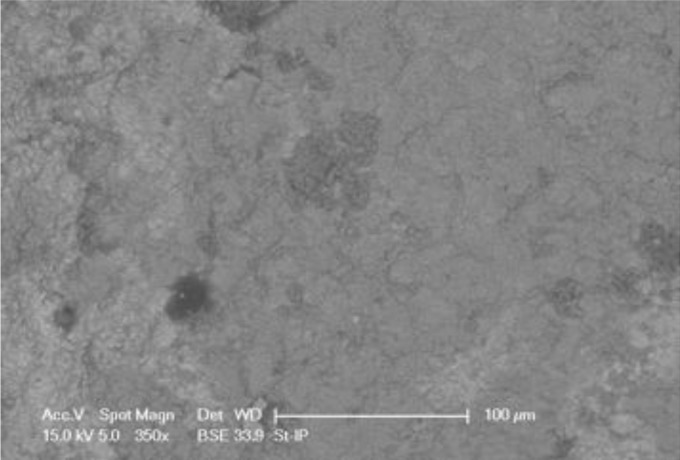

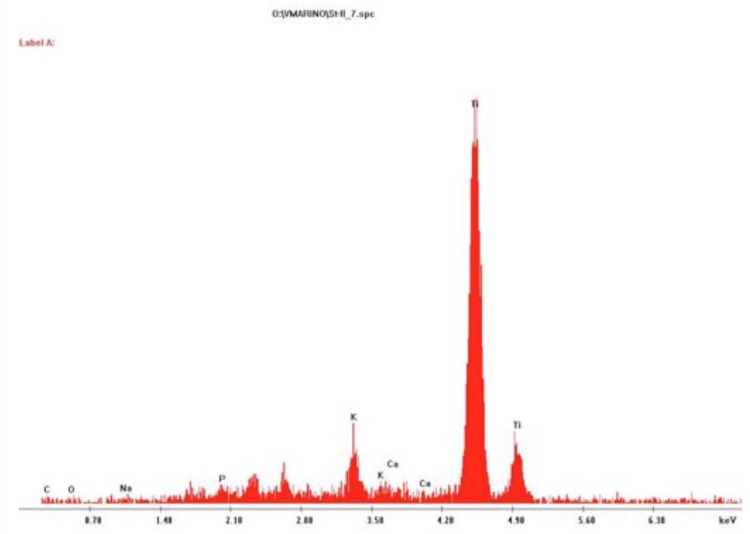

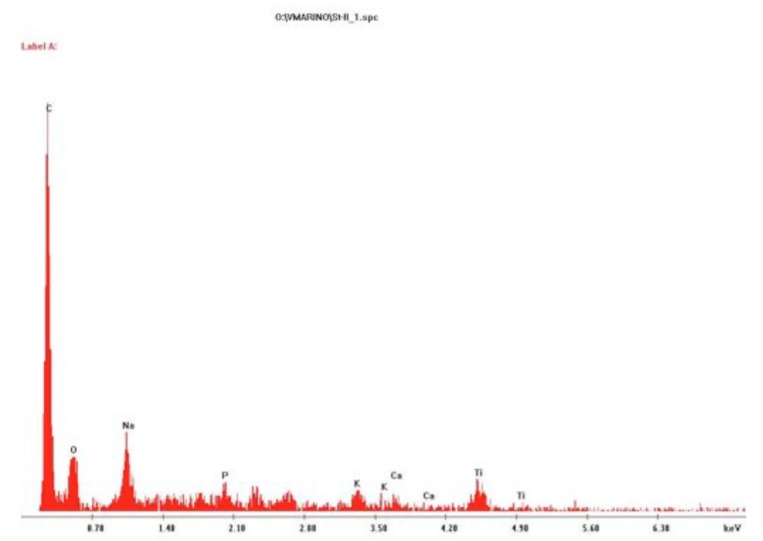

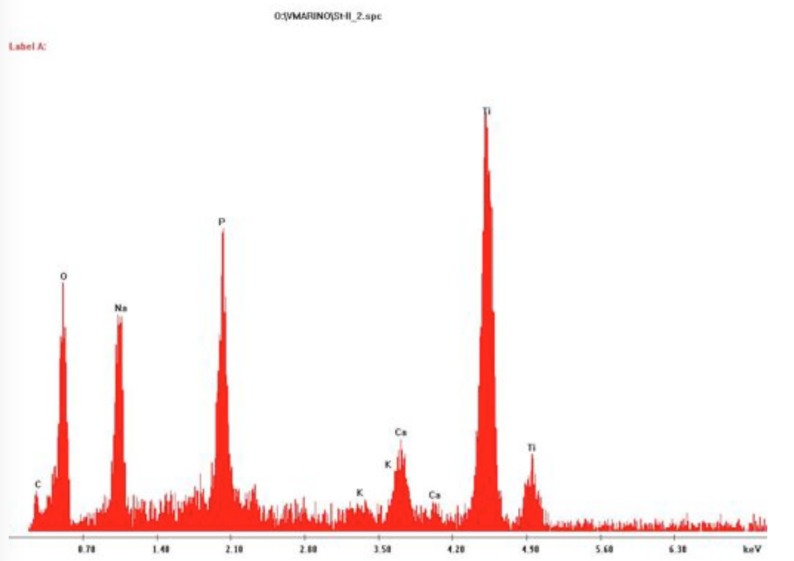

The SEM images of the implants indicated little crust formation on the surface as seen in Fig. 5. There were at least three distinct surface shade differences (black, grey and light grey) on the implants (Fig. 6). The elemental analysis revealed that the majority of the surface (light grey) consisted of titanium oxide (Fig. 7). Small black areas of carbon (Fig. 8) were identified and other areas contained bone elements (calcium and phosphorus) and serum salts (sodium, potassium, chlorine) (Fig. 9).

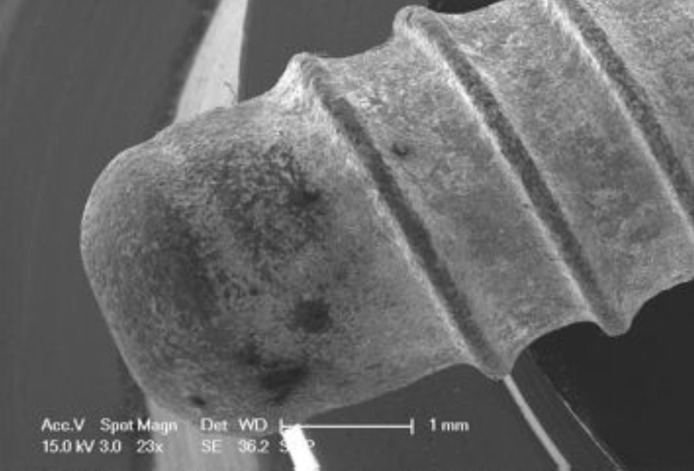

Fig.5.

Base of the Straumann! Regular 3.3 x 10mm showing little crust formation.

Fig. 6.

The three distinct surface shade differences (black, grey and light grey) on the implants

Fig. 7.

Elemental analysis of the grey area depicting a peak of titanium

Fig.8.

Elemental analysis of the black area depicting a peak of carbon.

Fig. 9.

Elemental analysis of the grey depicting bone elements and serum together with titanium

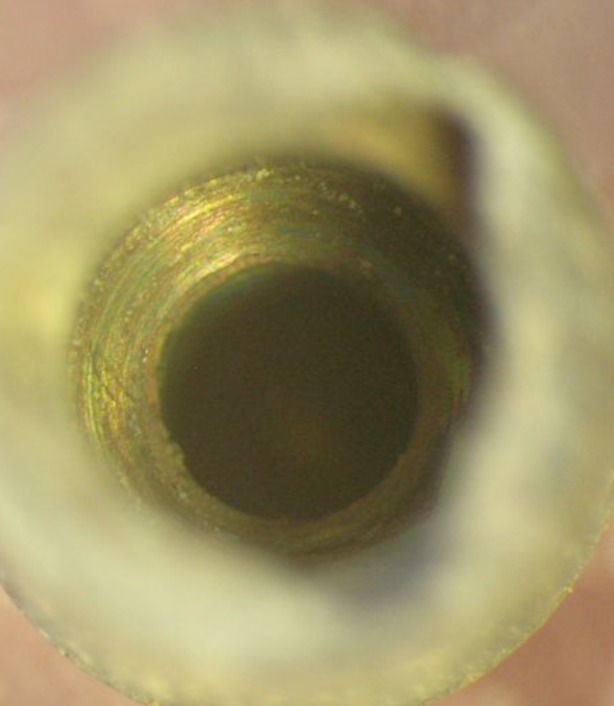

Microscopic examination of the chambers revealed the batch number clearly visible within the Straumann! implant before firing as shown in Fig. 10. Following the incineration the healing cap was removzed easily. It can be seen in Fig. 11, the number was still visible, although not as clearly as in Fig. 10. Following the removal from the furnace of implants from the other companies and unscrewing of the fixtures, their internal chambers also showed little oxidation (Fig. 12). No batch numbers were observed in the other studied implants.

Fig.10.

The batch number clearly visible within the Straumann! implant before firing.

Fig.11.

The batch number within the Straumann implant after firing.

Fig.12.

The internal chamber of the Nobel Biocare Replace Select! 4.3 x 8mm after incineration.

DISCUSSION

The observation that the some implants had fallen away reinforces the suggestion that odontologists should be involved in the scene phase of a fatality, especially where there has been severe incineration of the victims. (13, 14) The retrieval of small dental implants and other dental restorative material, which could be pivotal in identification, might be overlooked by personnel not accustomed to identifying dental structures. Retrieval and radiographic screening of debris from the area around the head in incineration cases will readily locate implants that have detached from the body.

The lack of gold colour or thick crust could be attributed to the lower temperature of the incinerator or the formation of carbon on the implant first creating a barrier or a combination of both factors. The exact temperature that the implant reached would be difficult to predict, as the sheep heads ignite. There could be localized hot spots but as the incinerator did indicate 780 °C it is assumed that this was the minimum temperature. A further study incinerating the implants within sheep to temperatures closer to 1100 °C, similar to the early study, (10) would be required to see if a crust forms and that a gold appearance also eventuates on commercially pure titanium implants.

The elemental analysis significantly found bone elements of calcium and phosphorus indicating some bone contact with the implants. Osseointegration of implants takes approximately three to four months in live animals or humans. (15) If osseointegration was allowed to occur before the animals were sacrificed it is presumed that the amount of bone elements would be greater. If an implant was found at the scene with no bone elements present (upon analysis) it may suggest that the implant had not been placed in bone – this may help confirm or refute the suspicion that it had been deliberately placed at the scene with intent to complicate identification.

As the batch number was still visible and all the chambers had little oxidation it can be assumed that if numbers were laser etched in all implants that they would also be visible. If all dental implant companies placed a serial number within them and the local authorities legislated that a register be kept, dental implants would become extremely important in identification. Similar registers are maintained in Australia and the United states for knee and hip replacements. (16, 17)

As well as having a high melting point, titanium is highly resistant to corrosion which could be useful in acidic or saline environments. Further studies would be required to prove this hypothesis.

CONCLUSION

Due to their physical properties, implants will resist thermal insult and will also retain the features such as shape and thread pattern necessary to identify the type of implant. The detachment of the implants from the mandible could have implications for scene recovery and debris collection from around and below the location of the head is recommended. The gold crust formation noted in the previous study was not visible under the present study conditions (possibly due to the lower temperature or to tissue contamination) but the ability to read the batch number within the Straumann™ implant following the incineration was replicated, adding weight to the previous study.

Ideally, for forensic identification purposes, each implant would be etched with an individual serial number. The survival of serial numbers would benefit forensic odontologists worldwide as data foridentification. It would strongly support the need for an odontologist to visit the scene of a disaster where severe incineration of victim or victims has occurred to search for possible implants.

ACKNOWLEDGEMENTS

The authors wish to thank the Straumann™, Nobel Biocare™, Ankylos", Zimmer!, and Neoss! companies for their generous donation of implants, and T&R Pastoral for their generous donation of sheep heads.

REFERENCES

- 1.Herschaft EE, Alder ME, Ord DK, Rawson RD, Smith ES, editors. Manual of Forensic Odontology 4th ed. Albany. Impress; 2006. p20-48. [Google Scholar]

- 2.Fairgrieve SI. Forensic Cremation: Recovery and Analysis. Boca Raton, Florida. CRC Press; 2008. p148-156. [Google Scholar]

- 3.Merlati G, Savio C, Danesino P, Fassina G, Menghini P. Further study of restored and unrestored teeth subjected to high temperature. J Forensic Odontostomatol. 2004;22:34–9. [PubMed] [Google Scholar]

- 4.Business Week No. 94: Straumann Holding [Internet]. [cited 2010 Feb 21]; Available from: http://www.businessweek.com/magazine/conte nt/05_43/b3956812.htm. 5. Iqbal MK, Kim S. A Review of Factors Influencing Treatment Planning Decisions of Single-tooth Implants versus Preserving Natural Teeth with Nonsurgical Endodontic Therapy. J Endod 2008;34:519-29. [DOI] [PubMed]

- 6.Laine P, Salo A, Kontio R, Ylijoki S, Lindqvist C, Suuronen R. Failed dental implants - clinical, radiological and bacteriological findings in 17 patients. J Craniomaxillofac Surg. 2005;33:212–7. 10.1016/j.jcms.2004.12.004 [DOI] [PubMed] [Google Scholar]

- 7.Ashby MF, Jones DRH. Engineering Materials. An Introduction to Their Properties and Applications. Oxford. Pergamon;1980. [Google Scholar]

- 8.Berketa JW, Hirsch RS, Higgins D, James H. Radiographic recognition of dental implants as an aid to identifying the deceased. J Forensic Sci. 2010;55:66–70. 10.1111/j.1556-4029.2009.01226.x [DOI] [PubMed] [Google Scholar]

- 9.whichimplant.com. [Internet]. [cited 2011 July 17]; Available from: http://www.whichimplant.com/

- 10.Berketa J, James H, Marino V. Dental implant changes following incineration. Forensic Sci Int. 2011;207:50–4. 10.1016/j.forsciint.2010.08.025 [DOI] [PubMed] [Google Scholar]

- 11.Berketa J, James H, Marino V. Survival of batch numbers within dental implants following incineration as an aid to identification. JFOS Online 2010;28:1-4. Available from: http://iofos.eu/Journals/newDecember%20201 0.htm. [cited 20 Oct 2010]. [PubMed]

- 12.Aligning Images in Photoshop [Internet]. [cited 2010 April 11]; Available from: http://www.astropix.com/HTML/J_DIGIT/PSALI GN.HTM.

- 13.Hill AJ, Lain R, Hewson I. Preservation of dental evidence following exposure to high temperatures. Forensic Sci Int. 2011;205:40–3. 10.1016/j.forsciint.2010.08.011 [DOI] [PubMed] [Google Scholar]

- 14.Cordner SM, Woodford N, Bassed R. Forensic aspects of the 2009 Victorian Bushfires Disaster. Forensic Sci Int. 2011;205:2–7. 10.1016/j.forsciint.2010.08.008 [DOI] [PubMed] [Google Scholar]

- 15.Albrektsson T, Brĺnemark PI, Hansson HA, Lindström J. Osseointegrated titanium implants. Requirements for ensuring a long-lasting, direct bone anchorage in man. Acta Orthop Scand. 1981;52:155–70. 10.3109/17453678108991776 [DOI] [PubMed] [Google Scholar]

- 16.National Joint Replacement Registry [Internet]. [cited 2011 July 17]; Available from: http://www.dmac.adelaide.edu.au/aoanjrr/

- 17.American Joint Replacement Registry [Internet]. [cited 2011 July 17]; Available from: http://www.orthodoc.aaos.org/ajrr/