Abstract

The inactivation of Bacillus anthracis spores on subway and used subway railcar materials was evaluated using fogged peracetic acid/hydrogen peroxide (PAA) and hydrogen peroxide (H2O2). A total of 21 separate decontamination tests were conducted using bacterial spores of both B. anthracis Ames (B.a.) and Bacillus atrophaeus (B.g.) inoculated onto several types of materials. Tests were conducted using commercial off-the-shelf fogging equipment filled with either PAA or H2O2 to fumigate a ~15 cubic meter chamber under uncontrolled ambient relative humidity and controlled temperature (10 or 20 °C) from 8 to 168 h. For the present study, no conditions were found that resulted in complete inactivation of either B.a. Ames or B.g. on all test materials. Approximately 41% and 38% of the decontamination efficacies for B.a. and B.g., respectively, exhibited ≥6 log10 reduction (LR); efficacy depended greatly on the material. When testing at 10 °C, the mean LR was consistently lower for both B.a. and B.g. as compared to 20 °C. Based on the statistical comparison of the LR results, B.g. exhibited equivalent or greater resistance than B.a. for approximately 92% of the time across all 21 tests. The efficacy data suggest that B.g. may be a suitable surrogate for B.a. Ames when assessing the decontamination efficacy of fogged PAA or H2O2. Moreover, the results of this testing indicate that in the event of B.a. spore release into a subway system, the fogging of PAA or H2O2 represents a decontamination option for consideration.

Keywords: Bacillus anthracis, Decontamination, Hydrogen peroxide, Peracetic acid, Fogging, Subway

1. Introduction

The deliberate release of Bacillus anthracis spores in the mail in 2001 led to the contamination of offices, buildings and residences across Washington DC, New York, New Jersey, and Florida. The resulting decontamination and remediation efforts were estimated to be approximately 320 million dollars (Canter et al., 2009, 2005). From the knowledge gained during cleanup and remediation of the 2001 bioterrorist attack, it has been suggested that the process include characterization, decontamination, and source reduction (Canter et al., 2009).

In the event of a wide area release of B. anthracis spores within a subway system, rapid remediation will be a challenge due to the vast and complex system of tunnels and platforms. Moreover, the abundance of porous structural materials (e.g., concrete) in a subway system may be problematic for surface treatment. Additionally, there are several factors that should be considered if cleanup and remediation of a subway system is needed following the intentional release of a biological agent. These include surface area and volume of the contaminated space, composition and porosity of contaminated surfaces, environmental conditions (temperature and relative humidity), type of decontaminant(s), and method of delivery (e.g., fumigant).

In the event of a biological contamination incident with B. anthracis spores or other agent, there are several considerations that must be made to implement the best strategy for large-scale remediation (Krauter et al., 2011; Rogers et al., 2008). For example, a volumetric decontamination approach (e.g., gases and vapors) is advantageous when decontaminating rooms or buildings that contain complex surfaces within a sealed area. However, this approach often requires large, expensive equipment requiring experienced and knowledgeable operators. For decontamination of smaller areas and surfaces, fogging of liquids and sporicides using commercial off-the-shelf (COTS) equipment is a strategy that could be implemented with less training and expertise than would be required for fumigation.

The inactivation of vegetative bacteria, viruses, and bacterial spores has been demonstrated using commercially-available fogging machines generating aerosolized droplets of hypochlorous acid (Clark et al., 2006; Park et al., 2007), quaternary ammonium compounds (Friedman et al., 1968), peroxymonosulfate (Dunowska et al., 2005), peracetic acid (Wood et al., 2013), and hydrogen peroxide/silver nitrate (Taneja et al., 2011). These fogging demonstrations have been mainly employed for disinfecting healthcare environments. Whereas the use of fogging as a sporicide against B.a. and surrogate spores has not been extensively investigated. One such study used a pilot-scale test chamber to evaluate the decontamination efficacy of fogging a peracetic acid (PAA) solution (Wood et al., 2013) against a B. antharcis surrogate spore. The present study builds on the previous work by evaluating additional experimental parameters that may impact efficacy. These include (but not limited to) the use of two types of foggers, fogging greater/varying amounts of sporicidal solution to seek improved efficacy, a wider range of materials, an additional sporicide (aqueous hydrogen peroxide), and a virulent microorganism.

In this investigation, the efficacy of fogging two sporicidal liquids, PAA and hydrogen peroxide (H2O2) solutions, to inactivate B. anthracis Ames and potential surrogate B. atrophaeus spores at different temperatures was evaluated on both used subway car materials and common building materials. Both microorganisms were included to compare their resistance to inactivation by the PAA and H2O2 fog. Similar resistance would allow the use of B. atrophaeus in lieu of B. anthracis in future decontamination studies using PAA and H2O2 fog. The results of this investigation provide decontamination stakeholders and decision-makers with data on the effectiveness of dispersing sporicidal liquids as a fog onto subway materials as a function of the spore contaminant, material type, temperature, equipment type, and sporicidal liquid. Moreover, implementation of fogging could provide an easier and inexpensive approach to decontaminate an area in the event of a wide-area B. anthracis release.

2. Materials and methods

2.1. Test organisms

Bacillus anthracis Ames spores (referred hereafter as B.a.) were prepared by fermentation as previously described (Rogers et al., 2005). Lyophilized B. atrophaeus (ATCC 9372; formerly B. subtilis var. niger and B. globigii) spores (referred hereafter as B.g.) were prepared in sterile phosphate-buffered saline containing 0.1% Triton X-100 surfactant (PBST). Both preparations were diluted to approximately 1 × 109 colony-forming units (CFU) mL−1 in sterile-filtered water, and stored at 2–8 °C.

2.2. Test materials and inoculation

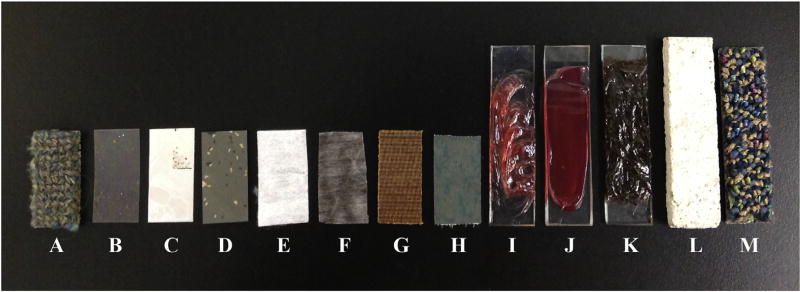

Test materials were prepared from a retired subway railcar and included used railcar carpet, Mylar® coating (used on glass windows), aluminum seat back, rubber flooring, seat upholstery, fiberglass interior siding, new railcar air filter, and a used railcar air filter. Other common building materials (unpainted concrete and new industrial carpet) were also used for decontamination testing. In addition, both new and used grease (from a railcar) were used as a coupon when applied to a glass slide. Materials (Fig. 1) were cut into equally sized coupons (pieces), and then were sterilized. All coupons were sterilized via autoclave (121 °C, 60 min), with the exception of the carpet coupons, which were sterilized by electron beam (E-beam) irradiation (~200 kGy; E-Beam Services, Inc., Lebanon, Ohio).

Fig. 1.

Coupon materials consisted of railcar carpet (A), Mylar® (B), aluminum seat back (C), rubber flooring (D), new railcar air filter (E), used railcar air filter (F), fiberglass interior siding (G), upholstery (H), new grease with spores mixed (I), new grease SOT (J), used grease SOT (K), unpainted concrete (L), new industrial carpet (M).

Coupons of railcar carpet, aluminum, upholstery, rubber flooring, Mylar® coating, fiberglass, new cabin air filter, and used cabin air filter coupons were 1.9 cm × 3.8 cm. Glass, new industrial carpet, and unpainted concrete coupons were 1.9 cm × 7.6 cm. New or used grease (1 mL) was applied to glass coupons. The grease test materials were prepared by first applying 1 mL of grease using a 3 mL syringe at one end of the glass material. The grease was then spread across the test material using a sterile colony spreader, creating a thin film, and then the target organism was applied in an identical manner as other test materials, designated as spores on top (SOT). For the “coupon” where the spores were mixed, or encapsulated, into the clean grease, after the spore inoculum was dried, a sterile glass rod was used to mix the dried spores into the grease using a circular motion across the glass. All coupons were inoculated inside a Class II biological safety cabinet (BSC) with ten droplets, 100 µl total volume, of the stock suspension, yielding an inoculum of approximately 1 × 108 CFU per coupon. All coupons were transferred to a Class III BSC and left undisturbed overnight to dry under ambient conditions, approximately 22 °C and 40% relative humidity (RH).

2.3. Decontaminants and application procedures

The sporicidal liquids used for decontamination testing included a ready-to-use solution of PAA (Minncare® Cold Sterilant; 22% H2O2/4.5% PAA; Minntech Corporation, Minneapolis, MN) and H2O2. Three concentrations of H2O2 in aqueous solution (8%, 22%, and 35%; Bioquell HPV-AQ; Bioquell, Horsham, PA) were tested (Table 1). The 8 and 22% solutions were prepared fresh on each day of testing while the 35% stock solution was used as received.

Table 1.

Test matrix.

| Test No. | Equipment | Decon | Temp (°C) | Decon Volume (mL) | Contact Time (hrs) | Materials |

|---|---|---|---|---|---|---|

| 1 | Sani-Tizer | PAA | 20 | 78 | 8 | R, M, F, Co, NGM, UF |

| 2 | Sani-Tizer | PAA | 20 | 78 | 18 | R, M, F, Ca, NGSOT, NF |

| 3 | Sani-Tizer | PAA | 20 | 160 | 18 | R, U, A, M, F, Ca |

| 4 | Sani-Tizer | PAA | 20 | 160 | 24–168 | Ca |

| 5 | Sani-Tizer | PAA | 20 | 160 | 18 | Ca, Co, NGSOT, NGM, UGSOT, UF |

| 6 | Sani-Tizer | PAA | 20 | 500 | 18 | F, Ca, Co, NGM, UGSOT, UF |

| 7 | Sani-Tizer | PAA | 20 | 1000 | 18 | F, Ca, Co, NGSOT, NGM, UGSOT |

| 8 | Sani-Tizer | PAA | 10 | 78 | 18 | R, M, F, Ca, NGSOT, NF |

| 9 | Sani-Tizer | PAA | 10 | 160 | 18 | Ca, Co, NGSOT, NGM, UGSOT, UF |

| 10 | Sani-Tizer | PAA | 10 | 160 | 18 | R, U, A, M, F, Ca |

| 11 | Sani-Tizer | PAA | 10 | 1000 | 18 | F, Ca, Co, NGM, UGSOT, IC |

| 12 | Sani-Tizer | 8% H2O2 | 20 | 2635 | 168 | R, U, A, M, F, Ca |

| 13 | Sani-Tizer | 22% H2O2 | 20 | 78 | 18 | R, M, F, Ca, NGSOT, NF |

| 14 | Sani-Tizer | 35% H2O2 | 20 | 1000 | 18 | F, Ca, Co, NGM, UGSOT, UF |

| 15 | Sani-Tizer | 35% H2O2 | 10 | 1000 | 18 | F, Ca, Co, NGM, UGSOT, UF |

| 16 | MinnCare | PAA | 20 | 160 | 18 | Ca, Co, NGSOT, NGM, UGSOT, UF |

| 17 | MinnCare | PAA | 20 | 160 | 18 | R, U, A, M, F, Ca |

| 18 | MinnCare | PAA | 20 | 500 | 18 | F, Ca, Co, NGM, UGSOT, UF |

| 19 | MinnCare | PAA | 10 | 160 | 18 | Ca, Co, NGSOT, NGM, UGSOT, UF |

| 20 | MinnCare | PAA | 10 | 500 | 18 | F, Ca, Co, NGM, UGSOT, UF |

| 21 | MinnCare | 35% H2O2 | 20 | 500 | 18 | F, Ca, Co, NGM, UGSOT, UF |

Material Key: R = Rubber Flooring, U=Seat Upholstery, A = Aluminum Seat Back, M = Mylar Glass Window Coating, F=Fiberglass Side Panel, Ca=Railcar Carpet, Co=Unpainted Concrete, NGSOT=New Grease (Spores on top of grease), NGM=New Grease (Spores mixed in to grease), UGSOT=Used Grease (Spores on top of grease), UGM=Used Grease (Spores mixed in to grease), NF=Railcar Air Filter (New), UF=Railcar Air Filter (Used), IC=New Industrial Carpet.

Two commercially-available fogging technologies were utilized for dissemination of the PAA and H2O2. The Sani-Tizer 3001-1 (Curtis Dyna-Fog Ltd., Jackson, GA) was equipped with a one-gallon tank, three spray nozzles, and a rotary knob for control of liquid flow rates. All testing conducted used the low flow setting as indicated on the rotary knob and resulted in flow rates ranging from 63 to 187 mL min−1. The Minncare mini Dry Fog System (Mar Cor Purification, Plymouth, MN), was equipped with one spray nozzle, 500 mL liquid reservoir, and an in-line regulator to maintain pressure at the nozzle. The device required a controlled pressure of 75 pounds per square inch (psi) change to metric as well as minimum flow rate of 56 L min−1. Pressure was measured using a Dwyer DPG-205-NIST (Dwyer, Michigan City, IN). Flow rate was measured using an Aalborg GFM47 flow meter (Aalborg Instruments and Controls, Orangeburg, NY). Data from these devices was recorded every minute during operation using a UX120-006M HOBO data logger.

Decontamination testing was conducted inside the Aerosol Research and Component Assessment (ARCA) test chamber (Rogers et al., 2009), with the supply and exhaust system closed to create a sealed, static chamber. On the day following inoculation, coupons intended for decontamination (including blanks) were transferred into the ARCA and placed in one of five designated positions (three horizontal, one vertical, and one inverted position). That is, one replicate spore-inoculated coupon of each material was placed at each of the five locations in the chamber. One position was located off the main chamber. This position was selected to challenge the ability of the decontaminant fog through a more complex area, as the duct was off set from the main ARCA test chamber.

The fogging technology selected for each test was placed in the center of the ARCA chamber with the nozzles positioned upwards. A measured amount of sporicidal liquid was placed into the liquid reservoir and each technology operated until all the liquid had been disseminated. After the specified contact time, the exhaust and supply were opened to allow for any residual fumigant to be removed at which point the test materials were collected for extraction and downstream sample processing.

2.4. Environmental conditions

For testing conducted at a target of 10 °C, the temperature in the ARCA was controlled using a Krack HTSS-0100MSD air cooled condensing unit and KR26A-089EB low profile evaporator (Krack, Bolingbrook, IL) refrigerant system. Temperature was uncontrolled for testing conducted at a target of 20 °C; RH was uncontrolled during all tests. Both temperature and RH were measured and recorded every minute using a HMT368 temperature and humidity probe (Vaisala, Inc., Woburn, MA).

2.5. Sample processing

Spores were extracted from each test, positive control, and blank coupon by placing in a 50 mL polypropylene conical tube containing 10 mL of sterile PBST. The vials were capped, placed on their side, and agitated on an orbital shaker set to 200 rpm for 15 min at room temperature. Following agitation, the liquid extract was removed and a series of 1:10 dilutions was prepared in sterile filtered water. An aliquot (0.1 mL) of the undiluted extract and/or each serial dilution was spread-plated onto tryptic soy agar in triplicate and incubated for 18–24 h at 37 ± 2 °C. Following incubation, colonies were manually counted and the abundance of CFU recovered from each sample was determined. Negative controls (blanks) were analyzed in parallel with the inoculated coupons (both test and positive controls) and all demonstrated no CFU. The theoretical limit of detection was approximately 33 CFU if 100% recovery was achieved.

2.6. Data analysis

Decontamination efficacy for each material was calculated in terms of mean log10 CFU reduced (Log Reduction; LR) by comparing the CFU recovered from the positive control coupons and test coupons. Five replicate positive control coupons (unexposed to the fog) and five replicate test coupons were used for each material in each test. Recoveries and reductions were determined from these five replicate coupons for each combination of material type and organism for each test, as previously described (Wood et al., 2016a). For statistical comparisons, the mean and 95% confidence interval (CI) on the percent recovery for the positive control coupons were calculated by agent and material. For each agent, Kruskal-Wallis tests were performed to compare whether percent recovery differs by material. Kruskal-Wallis tests also were performed to compare whether percent recovery differs by agent for each material. No adjustment for multiple tests was applied. For comparing decontamination efficacy of B.a. and B.g. on all materials for each test, a paired t-test was used in which the observations were paired based on location within the ARCA chamber to account for the correlation in decontamination performance for samples at the same location. All statistical analyses were performed using SAS (version 9.4, Cary NC) with P < 0.05 used as the level of significance.

3. Results

For all tests when fogging at a target temperature of 10 °C, the mean temperature for all tests ranged from 9.32 to 9.64 °C, while the average RH ranged from 57.08 to 84.57%. At 20 °C, the mean temperature for all tests ranged from 20.04 to 21.80 °C, while RH ranged from 48.32 to 94.83%. For all tests, the temperature and RH in the control chamber ranged from 18.10 to 20.44 °C and 21.31–61.36%. Environmental conditions data are summarized in Table 2.

Table 2.

Environmental conditions for all 21 tests. 1.

| Test No. | Sporicidal Liquid Volume (mL) |

Mean Temperature (°C) ± SD | Mean RH (%) ± SD | Contact Time (hours) | |||||

|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|||||||

| Target | Actual | Target | Fogging Actual | Control Actual | Target | Fogging Actual | Control Actual | ||

| 1 | 78 | 78 | 20 | 20.96 ± 0.12 | 19.43 ± 0.05 | None | 70.08 ± 7.10 | 54.20 ± 0.18 | 8 |

| 2 | 78 | 82 | 20 | 20.45 ± 0.23 | 19.14 ± 0.25 | None | 69.86 ± 4.94 | 59.11 ± 0.24 | 18 |

| 3 | 160 | 154 | 20 | 20.58 ± 0.14 | 18.10 ± 0.13 | None | 80.73 ± 5.25 | 60.49 ± 0.52 | 18 |

| 4 | 160 | 162 | 20 | 20.45 ± 0.24 | 18.48 ± 0.38 | None | 72.37 ± 4.05 | 61.36 ± 0.21 | 24–168 |

| 5 | 160 | 166 | 20 | 21.46 ± 0.18 | 18.75 ± 0.35 | None | 78.46 ± 5.17 | 59.57 ± 0.19 | 18 |

| 6 | 500 | 506 | 20 | 20.18 ± 0.21 | 19.70 ± 0.15 | None | 90.75 ± 3.79 | 55.05 ± 0.31 | 18 |

| 7 | 1000 | 1001 | 20 | 21.80 ± 0.22 | 19.86 ± 0.35 | None | 92.93 ± 2.32 | 56.16 ± 1.32 | 18 |

| 8 | 78 | 104 | 10 | 9.88 ± 0.54 | 19.87 ± 0.12 | None | 80.69 ± 6.83 | 44.21 ± 0.16 | 18 |

| 9 | 160 | 166 | 10 | 9.87 ± 0.57 | 19.78 ± 0.15 | None | 79.42 ± 7.18 | 44.63 ± 0.31 | 18 |

| 10 | 160 | 187 | 10 | 9.70 ± 0.71 | 19.67 ± 0.41 | None | 82.19 ± 7.63 | 43.31 ± 1.17 | 18 |

| 11 | 1000 | 1001 | 10 | 9.32 ± 0.63 | 19.95 ± 0.26 | None | 78.87 ± 10.13 | 44.77 ± 1.96 | 18 |

| 12 | 2365 | 2627 | 20 | 21.18 ± 0.28 | 18.05 ± 0.37 | None | 94.83 ± 1.10 | 60.89 ± 0.22 | 168 |

| 13 | 78 | 78 | 20 | 20.67 ± 0.34 | 18.60 ± 0.15 | None | 68.49 ± 4.20 | 57.57 ± 0.15 | 18 |

| 14 | 1000 | 998 | 20 | 20.60 ± 0.32 | 19.51 ± 0.25 | None | 94.83 ± 3.69 | 53.85 ± 0.27 | 18 |

| 15 | 1000 | 1000 | 10 | 9.64 ± 0.57 | 18.65 ± 0.26 | None | 82.23 ± 10.37 | 59.62 ± 0.04 | 18 |

| 16 | 160 | 161 | 20 | 20.96 ± 0.27 | 20.44 ± 0.22 | None | 66.30 ± 11.61 | 58.20 ± 0.24 | 18 |

| 17 | 160 | 160 | 20 | 20.32 ± 0.10 | 19.83 ± 0.03 | None | 67.24 ± 13.31 | 53.16 ± 0.16 | 18 |

| 18 | 500 | 497 | 20 | 21.73 ± 0.17 | 19.53 ± 0.36 | None | 76.09 ± 9.52 | 21.31 ± 1.51 | 18 |

| 19 | 160 | 161 | 10 | 9.64 ± 0.68 | 20.17 ± 0.49 | None | 57.08 ± 5.66 | 56.52 ± 0.92 | 18 |

| 20 | 500 | 497 | 10 | 9.64 ± 0.59 | 19.96 ± 0.74 | None | 84.57 ± 8.98 | 48.62 ± 2.18 | 18 |

| 21 | 500 | 500 | 20 | 20.04 ± 0.26 | 20.05 ± 0.13 | None | 48.32 ± 10.83 | 47.58 ± 0.36 | 18 |

The decontamination efficacy of fogged peracetic acid/hydrogen peroxide (PAA) and three concentrations of H2O2 (8%, 22%, and 35%) against B.a. Ames and B.g. was evaluated at target delivery volumes of 78, 160, 500, 1000, and 2365 mL, target temperatures of 10 or 20 °C, and contact times ranging from 8 to 168 h, for a total of 21 tests. The average percent recovery with upper and lower 95% CI of B.a. and B.g. spores from all of the positive control coupons used in the study is provided in Tables 3 and 4. For both B.a. and B.g., unpainted concrete yielded the lowest average percent recovery, while the highest average percent recovery was from new industrial carpet. The Kruskal-Wallis test of differences showed that material type exhibited a significant effect on the percent recovery of each organism for both B.a. (p < 0.001) and B.g. (p < 0.001) across all materials. Moreover, the Kruskal-Wallis test also showed that the percent recovery for B.a. was significantly higher (P < 0.001 to 0.008) when compared to the percent recovery for B.g. on each material. This result is consistent with Wood et al. (2011), in which B. subtilis (genetically similar to B.g.) was recovered from control coupons significantly less than B. a. (Ames).

Table 3.

Mean Percent Recovery for Positive Control Coupons for B.a. and Material with 95 Percent Confidence Intervals. Confidence limits less than 0 or greater than 100 truncated to 0 or 100 to reflect valid range of percent recovery values.

| Organism | Material | Na | Mean Percent Recovery (95% Confidence Interval) |

|---|---|---|---|

| B.a. | New Railcar Air Filter | 15 | 82.30 (70.94,93.67) |

| Aluminum | 20 | 82.93 (73.42,92.45) | |

| New Industrial Carpet | 5 | 97.82 (89.17,100.0) | |

| New Grease SOT | 40 | 86.52 (78.30,94.75) | |

| New Grease with Spores Mixed | 65 | 41.50 (11.35,71.65) | |

| Fiberglass Interior Siding | 80 | 37.55 (33.63,41.47) | |

| Mylar | 40 | 72.88 (67.11,78.66) | |

| Rubber Flooring | 40 | 73.58 (70.28,76.88) | |

| Unpainted Concrete | 65 | 14.30 (4.23,24.36) | |

| Upholstery | 20 | 92.77 (85.39,100.0) | |

| Railcar Carpet | 100 | 40.47 (35.15,45.79) | |

| Used Grease SOT | 60 | 83.89 (77.17,90.61) | |

| Used Railcar Air Filter | 55 | 70.73 (67.14,74.32) |

N is the total number of positive controls used in study for by material.

Table 4.

Mean Percent Recovery for Positive Control Coupons for B.g. and Material with 95 Percent Confidence Intervals. Confidence limits less than 0 or greater than 100 truncated to 0 or 100 to reflect valid range of percent recovery values.

| Organism | Material | Na | Mean Percent Recovery (95% Confidence Interval) |

|---|---|---|---|

| B.g. | New Railcar Air Filter | 15 | 3.14 (2.40, 3.88) |

| Aluminum | 20 | 24.45 (17.95,30.94) | |

| New Industrial Carpet | 5 | 39.14 (24.15,54.14) | |

| New Grease SOT | 40 | 6.07 (4.26, 7.88) | |

| New Grease with Spores Mixed | 65 | 1.18 (0.69, 1.67) | |

| Fiberglass Interior Siding | 80 | 4.71 (3.91, 5.51) | |

| Mylar | 40 | 16.54 (9.90,23.18) | |

| Rubber Flooring | 40 | 17.84 (13.32,22.36) | |

| Unpainted Concrete | 65 | 0.53 (0.41, 0.65) | |

| Upholstery | 20 | 19.53 (7.34,31.71) | |

| Railcar Carpet | 100 | 17.47 (13.54,21.40) | |

| Used Grease SOT | 60 | 8.81 (7.04,10.59) | |

| Used Railcar Air Filter | 55 | 7.46 (6.03, 8.89) |

N is the total number of positive controls used in study by material.

The calculated LR by material for each test are shown in Supplementary Tables S1 through S4. For most tests, B.g. was more resistant to both PAA and H2O2 as compared to B.a. For all tests, excluding test 4, paired t-tests were performed to compare the differences in decontamination efficacy of B.a. and B.g. per material. Overall, there were 16 instances in which significant differences (P < 0.05) were observed between B.a. and B.g. For test 4, railcar carpet was the only material subjected to decontamination for contact times up to 7 days. When comparing the decontamination efficacy of B.a. and B.g. for this test, there were no significant differences observed at any contact time.

The decontamination efficacy of PAA and H2O2 against B.a. and B.g. was evaluated at target temperatures of 10 or 20 °C. The tests conducted at 20 °C are representative of the ambient environmental conditions that would be expected at an above ground subway platform, while tests conducted at 10 °C would be more representative of the underground temperatures in the platforms and tunnels. These temperatures were tested at controlled liquid injection volumes, and contact time. Five identical test conditions were tested where only the temperature varied (Tests: 2/8, 3/10, 5/ 9,14/15, and 18/20). For the tests conducted at 10 °C, lower mean LR values for both B.a. and B.g. were observed in 90% and 63% of materials tested, respectively, when compared to tests conducted at 20 °C. Nonetheless, many of these differences were not statistically significant.

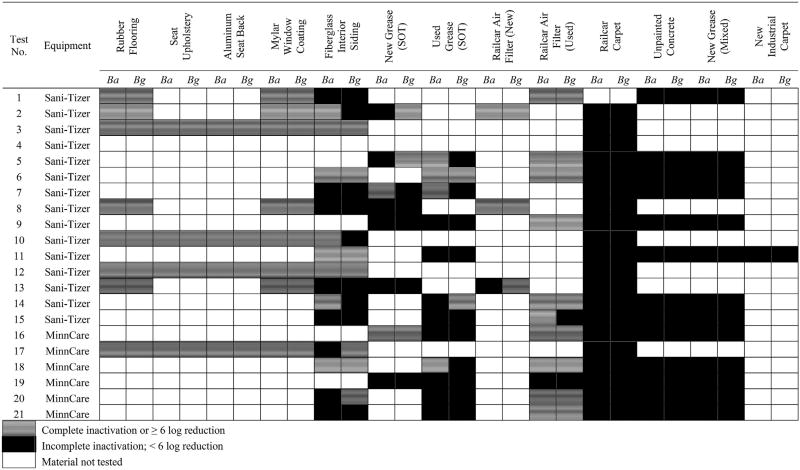

For this testing, a 6 LR was used as a benchmark since a decontaminant achieving 6 LR or greater is considered an effective sporicidal decontaminant (US EPA, 2007). All test results were transformed to binary measurement of either successful decontamination (pass) or fail. A trial was recorded as a success if either 1) the LR is greater than or equal to 6, or 2) the LR is equal to the average control recovery (e.g., no spores recovered from test coupons, i.e., complete inactivation). Materials such as such rubber flooring, upholstery, aluminum, and Mylar exhibited ≥6 LR for all conditions tested, whereas unpainted concrete and new grease with spores mixed were decontaminated at generally lower LR values, e.g., there were no test conditions promoting 6 LR for these materials. Fig. 2 provides a visual representation of all tests showing ≥6 LR or <6 LR or both B.a. and B.g. on all materials.

Fig. 2.

Visual representation of decontamination efficacy for all 21 tests.

At the end of each decontamination test, the procedural blanks were visually compared to the laboratory blanks, and test coupons were visually compared to positive controls to assess any impact PAA or H2O2 may have had on each material type. Based on the visual appearance of the decontaminated coupons, there were no apparent changes in the color, reflectivity, or roughness of the thirteen material surfaces after being exposed to the sporicidal fog.

4. Discussion

The implementation of a volumetric decontamination approach is one suggested strategy following a biological incident within a large complex facility (Krauter et al., 2011). To expedite the remediation process, use of COTS fogging equipment can provide a less expensive approach for dispersing sporicidal compounds. Studies have evaluated the fogging of PAA or H2O2 solutions using COTS equipment as less expensive alternatives to more sophisticated technologies. These studies demonstrated varying degrees of inactivation up to ≥6 LR for spores, vegetative bacteria, and viruses on porous and non-porous surfaces (Gregersen and Roth, 2012; Mana et al., 2016; Oh et al., 2005; Portner and Hoffman, 1968; Taneja et al., 2011; Wood et al., 2016a, 2013).

This study focused on the decontamination of eleven types of subway railcar materials and a common subway tunnel structural material (concrete). Decontamination tests were performed using two COTS foggers aerosolizing either PAA or hydrogen peroxide solutions containing no peracetic acid to assess the inactivation of B.a. and B.g. spores deposited on various subway car and building materials. Other fogger operational and environmental variables were evaluated for their effect on decontamination efficacy, such as air temperature, location within the test chamber, sporicidal liquid chemical, sporicidal liquid volume used, and fogging equipment.

Decontamination testing using complex material surfaces, such as those in the current study, is complicated by variables such as sampling method, spore recovery from control and test coupons, consistent application and penetration of the decontaminant into the material, and effective neutralization of the decontaminant. The results of the current study indicate that recovery of viable spores from positive control coupons varied and appeared to be dependent upon material type and complexity. With respect to the inoculated surface, five of these test materials (Mylar, aluminum, rubber flooring, fiberglass interiors siding, upholstery) can be considered non-porous, while five test materials (railcar carpet, new railcar air filter, used railcar air filter, new industrial carpet, unpainted concrete) can be considered porous. The new and used grease with spores inoculated on top as well as the new grease with spores mixed represented unique test materials.

A criterion of the current study was to recover at least one percent of the inoculum (i.e., 1 × 106 CFU) from the positive controls for both B.a. and B.g. on all material types, which assured at least a 6 LR in decontamination efficacy could be calculated. Recoveries of B.a. and B.g. from all materials in all tests were above the 1% requirement; however, the mean recovery of B.g. from unpainted concrete was 0.53%. When used as a test material surface in decontamination studies, unpainted concrete has been observed to yield low recoveries and is typically a difficult material to decontaminate (Calfee et al., 2011; Calfee and Wendling, 2013; Rastogi et al., 2009; Wood et al., 2016a, 2015, 2013). In the current study, the mean LR for B.a. and B.g. on unpainted concrete ranged from <1.0 to 2.70 despite the observed mean CFU recoveries of less than 1%. These data are consistent with Wood et al. (2016a) in which B.g. was inactivated by approximately 1.90 LR on unpainted concrete when fogged with H2O2.

For the present study, no conditions were found that resulted in complete inactivation of either B.a. Ames or B.g. on all test materials. Across all 21 tests, 41% and 38% of the average LR for B.a. and B.g., respectively, exhibited ≥6 LR. Four of the materials tested (rubber flooring, upholstery, aluminum, and Mylar) resulted in ≥6 LR at each condition tested for B.a. Ames. Six other materials (fiberglass, railcar carpet, new grease SOT, used grease SOT, New Filter, and railcar air filter) resulted in LR above and below 6. Two materials (unpainted concrete and new grease with spores mixed) resulted in all LR below 6. Although not all test materials were subjected to each test of the study matrix (Table 1), the test materials can be grouped based on observed LR into categories such as highly effective, moderately effective, and marginally effective decontamination. Such differences in decontamination efficacy as a function of material porosity/complexity are similar to previous investigations (Calfee et al., 2011; Calfee and Wendling, 2013; Rastogi et al., 2009; Rogers et al., 2007, 2005; Wood et al., 2016a, 2015, 2013, 2011).

In the field, it is important to understand that environmental conditions and method of decontaminant application can influence efficacy. Therefore, choosing test parameters that provide a realistic representation of how the decontaminant would be used in the field is necessary. In this study, two temperatures representing an underground subway tunnel (10 °C) and an outdoor subway platform (20 °C) were controlled. In the present study, the mean LR was generally lower when conducting the decontamination tests for both B.a. and B.g. at 10 °C as compared to 20 °C. This temperature effect on LR when compared to LR observed at 20 °C is similar to that previously observed for the inactivation of spores (Guan et al., 2013; Sagripanti and Bonifacino, 1996).

For bacterial spore decontamination studies, a surrogate should exhibit resistance to the decontamination treatment equivalent to or greater than B.a. (Wood et al., 2011). Decontamination efficacy tests were conducted with spores of virulent B.a. Ames and non-virulent B.g., to assess the potential use of B.g. as a surrogate for B.a. for future studies with the fogging of sporicidal liquids. Based on the statistical comparison of the LR results, B.g. exhibited equivalent or greater resistance than B.a. for approximately 90% of the time across all 21 tests. Therefore, the efficacy data generated from this evaluation suggest that B.g. may be a suitable surrogate for B.a. Ames when assessing the decontamination efficacy of PAA or H2O2 using fogging equipment. These observations are consistent with previous studies showing surrogates for virulent B.a. spores are equivalent or more resistant to fogged or fumigated decontaminants (Rogers et al., 2007, 2005; Wood et al., 2016a, 2016b, 2013).

In this study, B.g. was recovered from positive control coupons significantly less than for B.a., decontamination efficacy is determined based on the recovery of spores from positive control coupons, and not the inoculated quantity, precisely to mitigate differences in recoveries as a function of microorganism as well as material. The recovery rates from the positive control coupons was less than 100%, indicating that the CFU counting method used for determining spore viability in the present study may not provide an absolute determination of microorganism viability, which could be assessed using alternative culturing methods (e.g., broth cultures) of the material coupons without the need for extraction of spores. As the objective of this study was not to demonstrate sterility, but rather utilize a 6 LR as a quantitative approach for assessing efficacy (US EPA, 2007), CFU counting was chosen as the method for viability.

In terms of the effect of chamber location on efficacy, there was minimal difference in average LR by location within the test chamber. However, as would be expected, coupons stationed at location 3 (coupons placed horizontally on a cart facing upward, in the center of the chamber), were more likely to result in a complete kill compared to the other four locations in the chamber.

5. Conclusions

In the event of a wide-area release of B.a. in a subway system, remediation efforts could be extensive. The fogging of PAA or H2O2 with commercial off-the-shelf technologies could provide one approach to decontaminate subway railcars or other areas of a subway system. Although we caveat that decontamination was mostly ineffective for a few materials (e.g., concrete, carpet, grease) and conditions (e.g., lower temperature). Based on the conditions evaluated in this study, this work provides information on the efficacy of PAA and H2O2 delivered as a fog for decontamination of common subway railcar and building materials that have been contaminated with B.a. spores. Such results may be useful in the development of guidance to aid in deployment of sporicidal liquid fog after a wide-area release of B.a. spores in a subway environment. Moreover, this study provides data to assist in selection of an avirulent surrogate for B.a. Ames, for use in future field studies and additional lab-based investigations utilizing PAA and H2O2.

Supplementary Material

Acknowledgments

This work was funded by the U.S. EPA through its Office of Research and Development, National Homeland Security Research Center under Contract Number EP-C-11-038, Task Order 0017, with Battelle. The authors thank Dr. Gregory Stark for the statistical analysis.

Footnotes

Conflict of interest

The authors declare no conflict of interest.

Disclaimer

The US Environmental Protection Agency (EPA), through its Office of Research and Development, funded and directed the research described herein under contract EP-C-11-038 with Battelle Memorial Institute. It has been subjected to the Agency's review and has been approved for publication. Mention of trade names, products or services does not convey official EPA approval, endorsement or recommendation.

Appendix A. Supplementary data

Supplementary data related to this article can be found at https://doi.org/10.1016/j.jenvman.2017.11.027.

References

- Calfee MW, Choi Y, Rogers J, Kelly T, Willenberg Z, Riggs K. Lab-scale assessment to support remediation of outdoor surfaces contaminated with Bacillus anthracis spores. J. Bioterror. Biodef. 2011;2:1–8. [Google Scholar]

- Calfee MW, Wendling M. Inactivation of vegetative bacterial threat agents on environmental surfaces. Sci. Total Environ. 2013;443:387–396. doi: 10.1016/j.scitotenv.2012.11.002. [DOI] [PubMed] [Google Scholar]

- Canter DA, Gunning D, Rodgers P, O'Connor L, Traunero C, Kempter CJ. Remediation of Bacillus anthracis contamination in the U.S. Department of Justice mailfacility. Biosecur. Bioterror. 2005;3:119–127. doi: 10.1089/bsp.2005.3.119. [DOI] [PubMed] [Google Scholar]

- Canter DA, Sgroi TJ, O'Connor L, Kempter CJ. Source reduction in an anthrax-contaminated mail facility. J. Bioterror. Biodef. 2009;7:405–412. doi: 10.1089/bsp.2009.0028. [DOI] [PubMed] [Google Scholar]

- Clark J, Barrett SP, Rogers M, Stapleton R. Efficacy of super-oxidized water fogging in environmental decontamination. J. Hosp. Infect. 2006;64:386–390. doi: 10.1016/j.jhin.2006.07.019. [DOI] [PubMed] [Google Scholar]

- Dunowska M, Morley PS, Hyatt DR. The effect of Virkon® S fogging on survival of Salmonella enterica and Staphylococcus aureus on surfaces in a veterinary teaching hospital. Vet. Microbiol. 2005;105:281–289. doi: 10.1016/j.vetmic.2004.11.011. [DOI] [PubMed] [Google Scholar]

- Friedman H, Volin E, Laumann D. Terminal disinfection in hospitals with quaternary ammonium compounds by use of a spray-fog technique. Appl. Microbiol. 1968;16:223–227. doi: 10.1128/am.16.2.223-227.1968. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gregersen J-P, Roth B. Inactivation of stable viruses in cell culture facilities by peracetic acid fogging. Biologicals. 2012;40:282–287. doi: 10.1016/j.biologicals.2012.02.004. [DOI] [PubMed] [Google Scholar]

- Guan J, Chan M, Brooks BW, Rohonczy L. Influence of temperature and organic load on chemical disinfection of Geobacillus stearothermophilus spores, a surrogate for Bacillus anthracis. Can. J. Vet. Res. 2013;77:100–104. [PMC free article] [PubMed] [Google Scholar]

- Krauter P, Edwards D, Yang L, Tucker M. A systematic methodology for selecting decontamination strategies following a biocontamination event. Biosecur. Bioterror. 2011;9:262–270. doi: 10.1089/bsp.2010.0071. [DOI] [PubMed] [Google Scholar]

- Mana TSC, Sitzlar B, Cadnum JL, Jencson AL, Koganti S, Donskey CJ. Evaluation of an automated room decontamination device using aerosolized peracetic acid. Am. J. Infect. Contr. 2016;45:327–329. doi: 10.1016/j.ajic.2016.10.006. [DOI] [PubMed] [Google Scholar]

- Oh S-W, Gray PM, Dougherty RH, Kang D-H. Aerosolization as a novel sanitizer delivery system to reduce food-borne pathogens. Lett. Appl. Microbiol. 2005;41:56–60. doi: 10.1111/j.1472-765X.2005.01711.x. [DOI] [PubMed] [Google Scholar]

- Park GW, Boston DM, Kase JA, Sampson MN, Sobsey MD. Evaluation of liquid- and fog-based application of Sterilox hypochlorous acid solution for surface inactivation of human norovirus. Appl. Environ. Microbiol. 2007;73:4463–4468. doi: 10.1128/AEM.02839-06. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Portner DM, Hoffman RK. Sporicidal effect of peracetic acid vapor. Appl. Microbiol. 1968;16:1782–1785. doi: 10.1128/am.16.11.1782-1785.1968. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rastogi VK, Wallace L, Smith LS, Ryan SP, Martin B. Quantitative method to determine sporicidal decontamination of building surfaces by gaseous fumigants, and issues related to laboratory-scale studies. Appl. Environ. Microbiol. 2009;75:3688–3694. doi: 10.1128/AEM.02592-08. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rogers JV, Choi YW, Richter WR, Rudnicki DC, Joseph DW, Sabourin CLK, Taylor ML, Chang JCS. Formaldehyde gas inactivation of Bacillus anthracis, Bacillus subtilis and Geobacillus stearothermophilus spores on indoor surface materials. J. Appl. Microbiol. 2007;103:1104–1112. doi: 10.1111/j.1365-2672.2007.03332.x. [DOI] [PubMed] [Google Scholar]

- Rogers JV, Choi YW, Richter WR, Stone HJ, Taylor ML. Bacillus anthracis spore inactivation by fumigant decontamination. Appl. Bioinf. 2008;13:89–98. [Google Scholar]

- Rogers JV, Richter WR, Shaw MQ, Shesky AM. Large-scale inactivation of Bacillus anthracis Ammes, Vollum, and Sterne spores using vaporous hydrogen peroxide. Appl. Bioinf. 2009;14:127–134. [Google Scholar]

- Rogers JV, Sabourin CL, Choi YW, Richter WR, Rudnicki DC, Riggs KB, Taylor ML, Chang J. Decontamination assessment of Bacillus anthracis, Bacillus subtilis, and Geobacillus stearothermophilus spores on indoor surfaces using a hydrogen peroxide gas generator. J. Appl. Microbiol. 2005;99:739–748. doi: 10.1111/j.1365-2672.2005.02686.x. [DOI] [PubMed] [Google Scholar]

- Sagripanti J-L, Bonifacino A. Comparative sporicidal effects of liquid chemical agents. Appl. Environ. Microbiol. 1996;62:545–551. doi: 10.1128/aem.62.2.545-551.1996. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Taneja N, Biswal M, Kumar A, Edwin A, Sunita T, Emmanuel R, Gupta AK, Sharm M. Hydrogen peroxide vapour for decontaminating air-conditioning ducts and rooms of an emergency complex in northern India: time to move on. J. Hosp. Infect. 2011;78:200–203. doi: 10.1016/j.jhin.2011.02.013. [DOI] [PubMed] [Google Scholar]

- U.S. EPA. Transmittal of Meeting Minutes of the FIFRA Scientfic Advisory Panel Meeting Held July 17–18, 2007 on Guidance on Test Methods for Demonstrating the Efficacy of Antimicrobial Products for Inactivating Bacillus Anthracis Spores on Environmental Surfaces. [Accessed 23 January 2017];2007 http://archive.epa.gov/scipoly/sap/meetings/web/pdf/july2007_sap_finalreport.pdf.

- Wood JP, Calfee MW, Clayton M, Griffin-Gatchalian N, Touati A, Egler K. Evaluation of peracetic acid fog for the inactivation of Bacillus anthracis spore surrogates in a large decontamination chamber. J. Hazard. Mater. 2013;250:61–67. doi: 10.1016/j.jhazmat.2013.01.068. [DOI] [PubMed] [Google Scholar]

- Wood JP, Calfee MW, Clayton M, Griffin-Gatchalian N, Touati A, Ryan S, Mickelsen L, Smith L, Rastogi V. A simple decontamination approach using hydrogen peroxide vapor for Bacillus anthracis spore inactivation. J. Appl. Microbiol. 2016a;121:1603–1615. doi: 10.1111/jam.13284. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wood JP, Choi YW, Rogers JV, Kelly TJ, Riggs KB, Willenberg ZW. Efficacy of liquid spray decontaminants for inactivation of Bacillus anthracis spores on building and outdoor materials. J. Appl. Microbiol. 2011;110:1262–1273. doi: 10.1111/j.1365-2672.2011.04980.x. [DOI] [PubMed] [Google Scholar]

- Wood JP, Meyer KM, Kelly TJ, Choi YW, Rogers JV, Riggs KB, Willenberg ZW. Environmental persistence of Bacillus anthracis and Bacillus subtilis spores. PLos One. 2015;10:e0138083. doi: 10.1371/journal.pone.0138083. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wood JP, Wendling M, Richter W, Lastivka A, Mickelsen L. Evaluation of the efficacy of methyl bromide in the decontamination of building and interior materials contaminated with Bacillus anthracis spores. Appl. Environ. Microbiol. 2016b;82:2003–2011. doi: 10.1128/AEM.03445-15. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.