Summary

Aim

Aim of the study was to evaluate effectiveness of different heat treatments in improving Ni-Ti endodontic rotary instruments’ resistance to fracture.

Methods

24 new NiTi instruments similar in length and shape: 12 M3 instruments, tip size 25 and .06 taper (United Dental, Shanghai, China), and 12 M3 Pro Gold instruments tip size 25 and .06 taper (United Dental, Shanghai, China), were tested in a 60° curved artificial root canal. Each group received a different heat treatment. Cycles to fracture were calculated for each instrument. Differences among groups were evaluated with an analysis of variance test (significance level was set at P<0.05.).

Results

Statistical analysis found significant differences (p<0.0213) between groups. The M3 Pro Gold instruments were significantly more resistant to fatigue (mean values = 1012, SD +/− 77) than M3 instruments (mean values = 748, SD +/− 62). No statistically significant differences were found between fragments’ lengths (p>0,05).

Conclusions

An increased flexibility and the reduction of internal defects produced by heat treatments during or after manufacturing processes, may be responsible for improving resistance to cyclic fatigue and flexural stresses.

Keywords: endodontics, endodontic instruments, nickel-titanium, cyclic fatigue

Introduction

In the last decades the introduction of nickel-titanium (NiTi) alloy in the manufacturing of endodontic instruments resulted in a significant improvement for root canal preparations which resulted easier in shaping procedures, faster, and more predictable (1–3). The superior mechanical properties of the NiTi alloy allowed the clinical use of NiTi rotary instruments with greater tapers (4, 5). This increase in dimensions and continuous rotation movements significantly improved effectiveness and rapidity of the cutting and simplified the achievement of a successful root canal treatment (6–8). Unfortunately, these features could also lead to an increased risk of intracanal separation of the instruments (9–11).

Several clinical and experimental studies demonstrated that multiple factors contribute to instrument’s separation: cyclic fatigue has been proven to be one of the leading causes (12–14). Fatigue failure usually begins with the formation of microcracks that arise from the surface’s irregularities of the instruments. During each loading cycle, microcracks develop and deepening until complete separation of the file (15–17). All NiTi rotary instruments show some irregularities and inner defects on the surface as a consequence of the manufacturing processes and the distribution of these defects influences their strength (18).

In recent years, manufacturers tried to find different solutions to develop instruments with enhanced resistance to flexural and torsional stresses, aiming at reducing the incidence of intracanal breakage. The three basic ways to achieve these improvements were mainly related to changes in design, heat treatments of the alloy and the use of reciprocating motions (19–23). Different and proprietary heat treatments have been developed and commercialized in the last decade, aiming at improving both flexibility and resistance to breakage, but they are not disclosed by manufacturers in detail (24). Changing the thermal history of the alloy, could produce an alloy with different characteristics for the endodontic use. By changing the thermal treatments, manufacturer can quickly and significantly modify clinical performance of NiTi instruments, with no need of modifications to the quality of the raw material or grinding machines. M3 Rotary and M3 Pro Gold are an example of similar instruments, produced by same manufacturer (United Dental, Shanghai, China), but with different performance due to different heat treatments. The aim of the present study was to evaluate the hypothesis that different heat treatments can significantly affect the in vitro resistance to cyclic fatigue of NiTi rotary instruments. The null hypothesis was that no difference would be found between similar instruments with different heat treatments.

Material and methods

A total of 24 new NiTi instruments 25 mm in length was used in the present study: 12 M3 instruments, tip size 25 and .06 taper (United Dental, Shanghai, China) and 12 M3 Pro Gold instruments tip size 25 and .06 taper (United Dental, Shanghai, China). All instruments were the same in size and design, but they received a different heat treatment. All of them had been previously inspected using an optical stereomicroscope at ×20 magnification for morphological analysis and checked for any signs of visible deformation. If defective instruments were found, they were discarded.

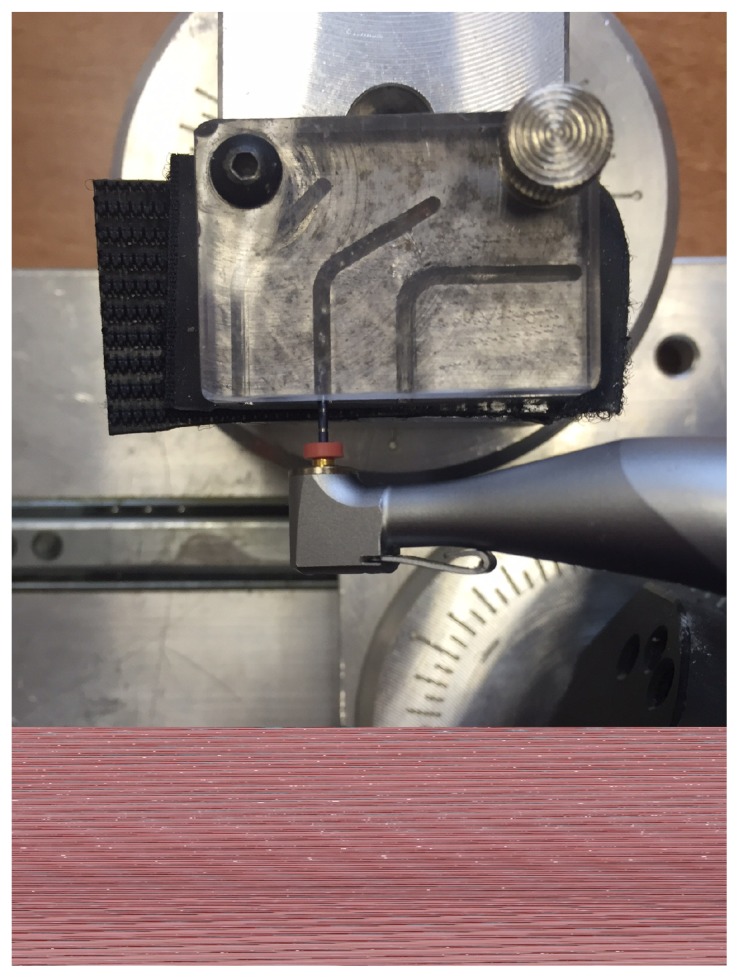

The cyclic fatigue testing device used in the present study has been used for previously performed studies on cyclic fatigue resistance (25, 26). The device consists of a mainframe to which is connected the electric handpiece and a stainless-steel block containing the artificial canal. The electric handpiece was mounted on a mobile device to allow precise and reproducible placement of each instrument inside the artificial canal to the same depth (18 mm) (Fig. 1). A simulated root canal with a 60° angle of curvature and 5 mm radius of curvature was used for all the tested instruments. All instruments were inserted at the same length (16 mm) and then rotated at 350 rpm with maximum torque until fracture occurred. For each instrument, the time to fracture was visually assessed and recorded with a 1/100 sec chronometer. Number of cycles to fracture was calculated for each instrument (NCF). Fragments were collected, measured and underwent to fractographic analysis performed by a scanning electron microscope (SEM) to determine fracture mode.

Figure 1.

The testing device for cyclic fatigue.

All data were recorded. For each group mean and standard deviations were calculated. Differences among groups were statistically evaluated with an analysis of variance test (significance level was set at P<0.05.). Data was statistically analyzed using the SPSS 17.0 software (SPSS Incorporated, Chicago, IL, USA).

Results

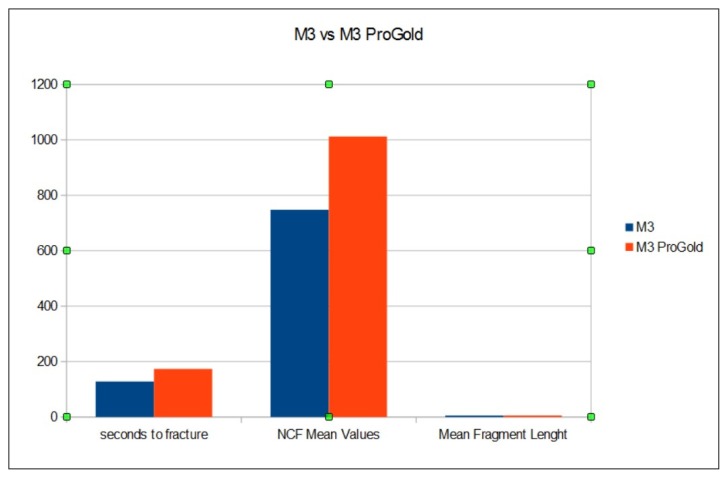

Results from the cyclic fatigue tests are shown in Tables 1 and 2. Mean values for time to fracture for M3 Pro Gold instruments were 173,5 seconds (SD +/− 14,7) and for M3 instruments were 128,3 seconds (SD +/− 11,6). Statistical analysis found significant differences (p < 0.0213) between the two groups. The M3 Pro Gold instruments were significantly more resistant to fatigue (NCF mean values = 1012, SD +/− 77) than M3 instruments (NCF mean values = 748, SD +/− 62). Mean value of the fragments’ length for M3 Pro Gold instruments was 5,5 mm (SD +/− 0,5) and for M3 instruments was 5,4 mm (SD +/− 0,4). No statistically significant differences were found between fragment lengths (p > 0,05), showing proper insertion of the instruments inside artificial canals and consequently the same mechanical stresses applied on the same portions of the instruments (Fig. 2).

Table 1.

Results of cyclic fatigue tests (number of cycles to failure).

| Group | NCF Mean Values | SD | Mean Fragment Lenght | SD |

|---|---|---|---|---|

| M3 | 748 | (+/− 62) | 5,4 | (+/− 0,4) |

| M3 ProGold | 1012 | (+/− 77) | 5,5 | (+/− 0,5) |

Table 2.

Time to fracture in seconds (s).

| Group | Seconds to fracture | SD |

|---|---|---|

| M3 | 128,3 | (+/− 11,6) |

| M3 ProGold | 173,5 | (+/− 14,7) |

Figure 2.

Differences between instruments’ time to fracture, number of cycles to fracture (NCF) and lenght of the fractured segment

Discussion

NiTi endodontic alloys can exhibit three phases (27): the high-temperature B2 austenitic phase, the low-temperature B19′ martensitic phase (monocyclic structure) and intermediate temperature R-phase (rhombohedral structure). Transformations of these phases are fundamental, because they determine the superelastic and shape memory characteristics of these instruments and their mechanical and functional properties and performance. These transformations can proceed by various ways, depending on the thermal history of the alloy during the manufacturing processes (18).

The heat treatment’s parameters which are chosen to set the properties of the NiTi instruments are critical (23). In general, temperatures as low as 400°C and times as short as 1–2 minutes can set the shape, but generally, endodontic instrument’s manufacturers prefer temperatures closer to 500°C for over 5 minutes. A rapid cooling of the instruments is preferred via water quench or rapid air cool. Longer heat treatment times and higher temperatures will increase the actuation temperature and often give a sharper thermal response (in the case of shape memory elements). However, there is usually a concurrent drop either in peak force (for shape memory alloys) or in plateau stresses (for superelastic alloys). There is also an accompanying decrease in the ability of the instruments to resist permanent deformation (28).

Clinically, such changes result in different mechanical properties and behaviour. Even if the raw material and the machining processes are the same, the different and proprietary heat treatment exhibits more evident superelastic characteristics. On the contrary, M3 Pro Gold instruments are more ductile and softer, exhibiting more evident shape memory characteristics. Differently than M3, M3 Pro Gold can be easily precurved for easier insertion in curved canal and to reduce restoring forces. In the present study, the last characteristic allowed M3 Pro Gold instruments to better withstand the bending stresses. The null hypothesis was rejected: M3 Pro Gold instruments were found to be significantly more resistant to fatigue when compared to M3. The originality of the present study was in the possibility of testing instruments produced by the same manufacturer with the same NiTi alloy, but with different heat treatments. In the majority of previous studies about heat treated NTRIs, different instruments were tested from different manufacturers. In many cases, when manufacturers produce a new version of endodontic instruments with a different heat treatment, they also change instruments’ design and this could make more difficult to evaluate the real effect of the heat treatment. The data are in accordance with previous studies which enlightened the importance of heat treatments in improving NiTi rotary instruments’ resistance to breakage (12, 15, 18).

However, it is always difficult to compare different cyclic fatigue studies, because many factors can influence the final results. The main factor is the shape and dimension of the artificial canal (16). Each variation of canal curvature and diameter may affect the way that mechanical loads are applied and consequently different mechanical stresses on the instruments are induced (11). Moreover, also room temperature can dramatically influence fatigue resistance of the NTRIs, as shown in recent studies (29, 30). Therefore a correct comparison can only be made if the NTRIs are tested with the same device and artificial canal in the same conditions.

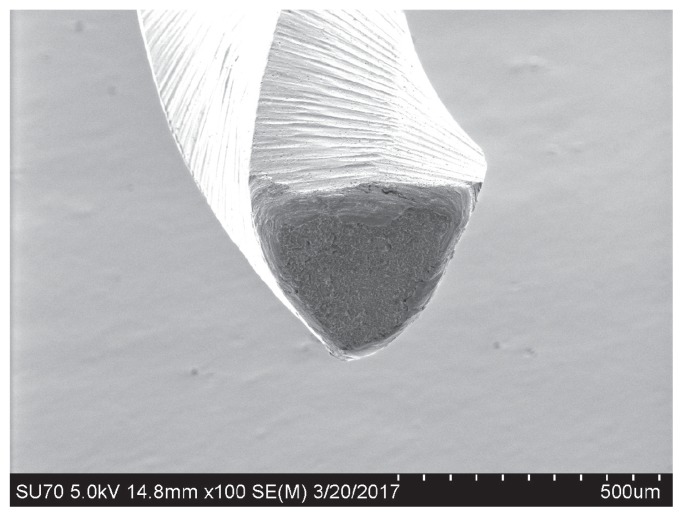

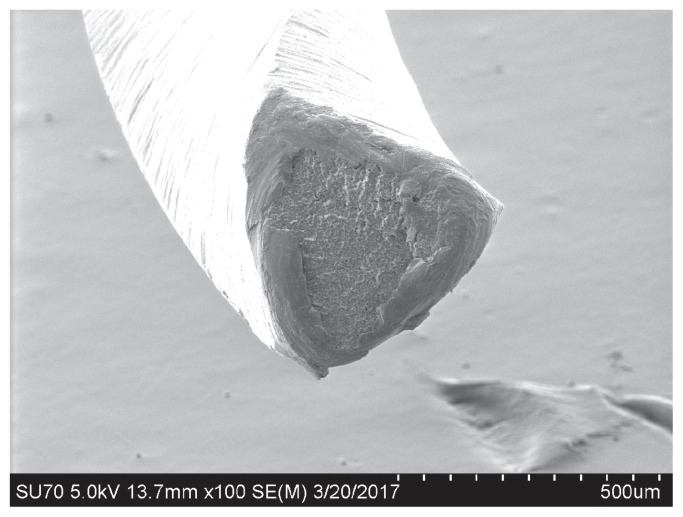

Fractographic analysis using SEM showed similar fracture patterns in both instruments. Metal fatigue commonly leads to ductile fracture with some plastic deformations and a typical dull dimpled surface (10). The dimpling involve the whole fracture surface, with some microvoids present as black dots (Figs. 3, 4). In ductile fracture, microvoids are produced inside the metal and their cohalescence weaken the structure and results in fracture.

Figure 3.

SEM microscope image of a fractured M3 Pro Gold instrument.

Figure 4.

SEM microscope image of a fractured M3 Pro Gold instrument.

NiTi instruments have constantly gained popularity during last decades because they offer more distinct clinical advantages with curved root canals than stainless-steel instruments, due to their higher flexibility, by virtue of their superelasticity. The superelasticity has made it possible to carry out conservative and better centered shapes, with less canal transportation and with more respect of the original anatomy (22). NiTi shape memory alloys undergo transformation from cubic austenitic to monocyclic martensite when the applied stress in the austenitic phase is enough to promote the stress-induced transformation (27). This stress-induced martensitic transformation reverses spontaneously upon release of the stress and the material returns to its original shape and size (23). Furthermore, the rhombohedral R-phase formation, thermoelastic phase, often precedes the martensitic transformation under certain conditions and is considered to be the main reason for increased flexibility of NiTi instruments over traditional stainless steel instruments. Such an increased flexibility and the reduction of internal defects produced by heat treatments during or after manufacturing processes, are responsible for greater resistance to flexural stresses and consequently to cyclic fatigue. Further studies, however, are needed to evaluate how much different heat treatments affect torsional resistance and hardness of the alloy in NiTi rotary instruments.

Conclusions

Changing the thermal treatments, allows manufacturers to quickly and significantly improve clinical performance of NTRIs, with no need of changing quality of the raw material or modifying the grinding machines. M3 Rotary and M3 Pro Gold are an example of NTRIs with same design and alloy, produced by the same manufacturer, which show different resistance to cyclic fatigue due to different heat treatments.

Footnotes

Declaration of conflicting interests

The Authors declare that there is no conflict of interest.

References

- 1.Kwak SW, Cheung GS, Ha JH, Kim SK, Lee H, Kim HC. Preference of undergraduate students after first experience on nickel-titanium endodontic instruments. Restor Dent Endod. 2016 Aug;41(3):176–181. doi: 10.5395/rde.2016.41.3.176. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Giansiracusa Rubini A, Plotino G, Al-Sudani D, Grande NM, Putorti E, Sonnino G, Cotti E, Testarelli L, Gambarini G. A new device to test cutting efficiency of mechanical endodontic instruments. Medical Science Monito. 2014 Mar 6;20:374–378. doi: 10.12659/MSM.890119. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Al-Sudani D, Grande NM, Plotino G, Pompa G, Di Carlo S, Testarelli L, Gambarini G. Cyclic fatigue of nickel-titanium rotary instruments in a double (S-shaped) simulated curvature. Journal of Endodontics. 2012;38(7):987–989. doi: 10.1016/j.joen.2012.03.025. [DOI] [PubMed] [Google Scholar]

- 4.Ebihara A, Yahata Y, Miyara K, Nakano K, Hayashi Y, Suda H. Heat treatment of nickel-titanium rotary endodontic instruments: effects on bending properties and shaping abilities. Int Endod J. 2011 Sep;44(9):843–849. doi: 10.1111/j.1365-2591.2011.01891.x. [DOI] [PubMed] [Google Scholar]

- 5.Testarelli L, Plotino G, Al-Sudani D, Vincenzi V, Giansiracusa Rubini A, Grande NM, Gambarini G. Bending properties of a new nickel-titanium alloy with a lower percent by weight of nickel. Journal of Endodontics. 2011;37(9):1293–1295. doi: 10.1016/j.joen.2011.05.023. [DOI] [PubMed] [Google Scholar]

- 6.Plotino G, Giansiracusa Rubini A, Grande NM, Testarelli L, Gambarini G. Cutting efficiency of reciproc and waveone reciprocating instruments. Journal of Endodontics. 2014;40(8):1228–1230. doi: 10.1016/j.joen.2014.01.041. [DOI] [PubMed] [Google Scholar]

- 7.Gambarini G, Pongione G, Rizzo F, Testarelli L, Cavalleri G, Gerosa R. Bending properties of nickel-titanium instruments: a comparative study. Minerva stomatologica. 2008;57(9):393–398. [PubMed] [Google Scholar]

- 8.Di Fiore PM, Genov KA, Komaroff E, Li Y, Lin L. Nickel-titanium rotary instrument fracture: a clinical practice assessment. Int Endod J. 2006 Sep;39(9):700–708. doi: 10.1111/j.1365-2591.2006.01137.x. [DOI] [PubMed] [Google Scholar]

- 9.Gambarini G, Giansiracusa Rubini A, Sannino G, Di Giorgio G, Piasecki L, Al-Sudani D, Plotino G, Testarelli L. Cutting efficiency of nickel-titanium rotary and reciprocating instruments after prolonged use. Odontology. 2016 Jan;104(1):77–81. doi: 10.1007/s10266-014-0183-0. [DOI] [PubMed] [Google Scholar]

- 10.Parashos P, Messer H. Rotary NiTi instrument fracture and its consequences. J Endod. 2006;32:1031–1043. doi: 10.1016/j.joen.2006.06.008. [DOI] [PubMed] [Google Scholar]

- 11.Plotino G, Grande NM, Cordaro M, Testarelli L, Gambarini G. Measurement of the trajectory of different NiTi rotary instruments in an artificial canal specifically designed for cyclic fatigue tests. Oral Surgery, Oral Medicine, Oral Pathology, Oral Radiology and Endodontology. 2009;108(3):e152–156. doi: 10.1016/j.tripleo.2009.05.046. [DOI] [PubMed] [Google Scholar]

- 12.Capar ID, Ertas H, Arslan H. Comparison of cyclic fatigue resistance of novel nickel-titanium rotary instruments. Aust Endod J. 2015 Apr;41(1):24–28. doi: 10.1111/aej.12067. [DOI] [PubMed] [Google Scholar]

- 13.Gambarini G, Plotino G, Sannino GP, Grande NM, Giansiracusa Rubini A, Piasecki L, da Silva Neto UX, Al-Sudani D, Testarelli L. Cyclic fatigue of instruments for endodontic glide path. Odontology. 2015;103(1):56–60. doi: 10.1007/s10266-013-0138-x. [DOI] [PubMed] [Google Scholar]

- 14.Plotino G, Costanzo A, Grande NM, Petrovic R, Testarelli L, Gambarini G. Experimental evaluation on the influence of autoclave sterilization on the cyclic fatigue of new nickel-titanium rotary instruments. Journal of Endodontics. 2012;38(2):222–225. doi: 10.1016/j.joen.2011.10.017. [DOI] [PubMed] [Google Scholar]

- 15.Zinelis S, Darabara M, Takase T, Ogane K, Papadimitriou GD. The effect oft hermal treatment on the resistance of nickel-titanium rotary files in cyclic fatigue. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2007 Jun;103(6):843–847. doi: 10.1016/j.tripleo.2006.12.026. [DOI] [PubMed] [Google Scholar]

- 16.Plotino G, Grande NM, Mazza C, Petrovic R, Testarelli L, Gambarini G. Influence of size and taper of artificial canals on the trajectory of NiTi rotary instruments in cyclic fatigue studies. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010 Jan;109(1):60–66. doi: 10.1016/j.tripleo.2009.08.009. [DOI] [PubMed] [Google Scholar]

- 17.Gambarini G, Gergi R, Grande NM, Osta N, Plotino G, Testarelli L. Cyclic fatigue resistance of newly manufactured rotary nickel titanium instruments used in different rotational directions. Australian Endodontic Journal. 2013;39(3):151–154. doi: 10.1111/j.1747-4477.2012.00353.x. [DOI] [PubMed] [Google Scholar]

- 18.Braga LC, Faria Silva AC, Buono VT, de Azevedo Bahia MG. Impact of heat treatments on the fatigue resistance of different rotary nickel-titanium instruments. J Endod. 2014 Sep;40(9):1494–1497. doi: 10.1016/j.joen.2014.03.007. [DOI] [PubMed] [Google Scholar]

- 19.Plotino G, Grande NM, Cotti E, Testarelli L, Gambarini G. Blue treatment enhances cyclic fatigue resistance of vortex nickel-titanium rotary files. Journal of endodontics. 2014;40(9):1451–1453. doi: 10.1016/j.joen.2014.02.020. [DOI] [PubMed] [Google Scholar]

- 20.Pereira ES, Peixoto IF, Viana AC, Oliveira II, Gonzalez BM, Buono VT, Bahia MG. Physical and mechanical properties of a thermomechanically treated NiTi wire used in the manufacture of rotary endodontic instruments. Int Endod J. 2012 May;45(5):469–474. doi: 10.1111/j.1365-2591.2011.01998.x. [DOI] [PubMed] [Google Scholar]

- 21.Gambarini G, Di Nardo D, Miccoli M, Guerra F, Di Giorgio R, Di Giorgio G, Glassman G, Piasecki L, Testarelli L. The Influence of a New Clinical Motion for Endodontic Instruments on the Incidence of Postoperative Pain () Clinica Terapeutica. 2017;168(1):23–27. doi: 10.7417/CT.2017.1977. [DOI] [PubMed] [Google Scholar]

- 22.Plotino G, Testarelli L, Al-Sudani D, Pongione G, Grande NM, Gambarini G. Fatigue resistance of rotary instruments manufactured using different nickel-titanium alloys: A comparative study. Odontology. 2014;102(1):31–35. doi: 10.1007/s10266-012-0088-8. [DOI] [PubMed] [Google Scholar]

- 23.Shen Y, Zhou HM, Zheng YF, Peng B, Haapasalo M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod. 2013 Feb;39(2):163–172. doi: 10.1016/j.joen.2012.11.005. [DOI] [PubMed] [Google Scholar]

- 24.De Almeida BC, Ormiga F, de Araújo MC, Lopes RT, Lima IC, dos Santos BC, Gusman H. Influence of Heat Treatment of Nickel-Titanium Rotary Endodontic Instruments on Apical Preparation: A Micro-Computed Tomographic Study. J Endod. 2015 Dec;41(12):2031–2035. doi: 10.1016/j.joen.2015.09.001. [DOI] [PubMed] [Google Scholar]

- 25.Gambarini G, Gergi R, Naaman A, Osta N, Al Sudani D. Cyclic fatigue analysis of twisted file rotary NiTi instruments used in reciprocating motion. Int Endod J. 2012 Sep;45(9):802–806. doi: 10.1111/j.1365-2591.2012.02036.x. [DOI] [PubMed] [Google Scholar]

- 26.Gambarini G, Tucci E, Bedini R, Pecci R, Galli M, Milana V, De Luca M, Testarelli L. The effect of brushing motion on the cyclic fatigue of rotary nickel titanium instruments. Annali dell’Istituto Superiore di Sanità. 2010;46(4):400–404. doi: 10.4415/ANN_10_04_07. [DOI] [PubMed] [Google Scholar]

- 27.Hou X, Yahata Y, Hayashi Y, Ebihara A, Hanawa T, Suda H. Phase transformation behaviour and bending property of twisted nickel-titanium endodontic instruments. Int Endod J. 2011 Mar;44(3):253–258. doi: 10.1111/j.1365-2591.2010.01818.x. [DOI] [PubMed] [Google Scholar]

- 28.Alapati SB, Brantley WA, Iijima M, Schricker SR, Nusstein JM, Li UM, Svec TA. Micro-XRD and temperature-modulated DSC investigation of nickel-titanium rotary endodontic instruments. Dent Mater. 2009 Oct;25(10):1221–1229. doi: 10.1016/j.dental.2009.04.010. [DOI] [PubMed] [Google Scholar]

- 29.Plotino G, Grande NM, Mercadé Bellido M, Testarelli L, Gambarini G. Influence of Temperature on Cyclic Fatigue Resistance of ProTaper Gold and ProTaper Universal Rotary Files. J Endod. 2017 Feb;43(2):200–202. doi: 10.1016/j.joen.2016.10.014. [DOI] [PubMed] [Google Scholar]

- 30.Grande NM, Plotino G, Silla E, Pedullà E, DeDeus G, Gambarini G, Somma F. Environmental Temperature Drastically Affects Flexural Fatigue Resistance of Nickeltitanium Rotary Files. J Endod. 2017 May 2; doi: 10.1016/j.joen.2017.01.040. (Epub ahead of print) [DOI] [PubMed] [Google Scholar]