Abstract

Yam (Dioscorea spp) is an essential tuber crop for hundreds of millions of people in many African, Asian and South American countries. Considering in particular Southwest Nigeria, chips, flakes and flours are amongst the most common shelf-stable traditionally-processed yam products. This paper reports a systematic study on the proximate (moisture, protein, carbohydrate, fibre, fat, ash and gross energy) and mineral composition of these three food commodities sold in Nigerian markets. Results showed no significant differences in the moisture, crude protein and fibre content of all samples (10.0–12.3, 2.7–4.3 and 1.3–2.0 wt%, respectively). Gross energy was also comparable for all yam derived food items (between 3300 and 3507 kcal/kg), contradicting the common belief that yam flakes have lower nutritional value than chips and flours. Considering the mineral composition, Ca, Mg, P and K were the predominant macronutrients. Micronutrients such as Zn, Co, Mn and Cu were also detected. Significant differences existed between products, and their various sources (markets). Principal component analysis showed a direct correlation between ash content of the samples and the assessed macronutrients, irrespective of the market, or the seller of the commodities. This study confirmed that yam derived food stuffs have an adequate nutritional composition, irrespective of their form and/or origin.

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-017-2761-y) contains supplementary material, which is available to authorized users.

Keywords: Chemical composition, Minerals, Yam-derived food items, Nutritional value, PCA

Introduction

Yams are staple foods with cultural, economic and nutritional importance in many parts of Africa and Southeast Asia. They belong to the Dioscorea genus that produces edible starchy storage tubers. Yams are the third most important tropical root crop in Africa after cassava and sweet potatoes, with Nigeria reported as the leading producer (Ferraro et al. 2016). Yams contribute to more than 200 daily dietary calories per capita for more than 150 million people in West Africa. Furthermore, they serve as an important source of income (Abiodun and Akinoso 2014).

The most common cooking methods for white yam in Western and Central Africa are boiling, frying and roasting. Yams are also processed into dried yam chips and flakes by peeling, slicing, blanching, steeping and sun-drying. This is done to overcome the high perishability of fresh tubers due to their high moisture content and enzymatic activity (Jonathan et al. 2011). Yam chips and flakes may be crushed, milled and processed into flour, locally known as “elubo”. The flour can then be reconstituted with hot water to form a thick paste known as “amala” and consumed with soup. “Elubo” and “amala” can be prepared in a similar manner using other root crops, such as cassava or unripe plantain (Fetuga et al. 2014).

The production of yam chips and flakes is mainly performed at a small-scale level by local household producers. This may bring variability in the quality of the final products, both across processors and different locations.

The sale of yam chips and flour is quite common in most markets in Southwest Nigeria, while yam flakes can only be found in markets close to the processing area of the commodities (Oyo State). Yam flakes are known to be purchased by the lower class (economically) in society, because of their low price compared with yam chips. This is due to the belief that yam flakes are of lower nutritional quality. Also, some “amala” consumers prefer to buy the chips and mill them themselves rather than buying the ready-made flour. This is done to prevent buying flour that could have been mixed with different roots or tubers. This is a common occurrence, since items sold in markets often do not have labelling regarding the composition and the nutritional values. Most mothers from Southwest Nigeria feed their infants with “amala” from either yam, cassava, cocoyam or plantain flour as part of their weaning diet.

Minerals are inorganic nutrients that are essential to life, and are usually required in relatively small quantities-generally less than 100 mg/day; however, they can be toxic at concentrations beyond those necessary for their biological functions. Although they are not an energy yielding component of food, they are critical to countless body processes, playing important roles in biochemical functions and enzymatic activity (Saraf and Samant 2013). Essential minerals are classified into macro minerals (g or mg/day) where Ca, K, Na and Mg are the most physiologically important and micro minerals (few mg or µg/day) where Fe, Cu and Zn are the most physiologically important (Silvera and Rohan 2007). Micronutrient deficiency is a serious public health concern worldwide, especially in poorer developing countries, with infants and pregnant women being at high risk. Some factors such as inadequate food intake, food processing practices, the presence of other dietary factors and other chemicals in foods are responsible for bioaccessibility and bioavailability of minerals.

Some literature data about the nutritional composition of different cultivars of yam in comparison with other tuber crops are available (Alinnor and Akalezi 2010; Senanayake et al. 2012). The impact of cooking on the proximate composition of water yam has also been discussed in terms of moisture, protein, carbohydrate, fibre, fat, ash and gross energy (Ezeocha and Ojimelukwe 2012). Some studies have also investigated the effect of processing conditions on the nutritional composition and functional properties of laboratory processed yam chips (Djeri et al. 2015) and flour (Abioye 2012; Adejumo et al. 2013; Obadina et al. 2014; Ajala and Idowu 2016). Only one study, on the other hand, is available on the assessment of the effect of storage duration on the nutritional composition of yam chips from Itamerin market (Oyo state, Nigeria) (Jonathan et al. 2011). Hence, scarce data is available on the nutritional composition of traditionally processed yam chips, flakes and flours produced and sold in Southwest Nigeria as in other markets and no mineral profiles have been reported. This study therefore aims to investigate the proximate and mineral composition of different samples of yam chips, flakes and flours from some key markets in Southwest Nigeria, which may impact and promote world consumption of yam.

Materials and methods

Sampling and preparation of samples

Figure 1 of the supplementary material shows a schematic diagram of the sample collection procedure. Dried yam chips were purchased from three markets—Saki and Bodija in Oyo State, and Mile12 in Lagos, south western Nigeria. Yam flakes were obtained from two markets, Bodija in Oyo State and Mile12 in Lagos. Yam flour samples, on the other hand, were purchased from three sites, Mile12 market in Lagos, Lafenwa market in Abeokuta (Ogun State) and a store or supermarket in Lagos (packaged flours). In each market, samples were purchased from two different sellers. Regarding the packaged flours, two different commercial brands were chosen.

Sixteen samples were obtained from each collection. A further 16 samples were collected after 4 and 8 months, giving a total of 48 samples. The collections were done in May 2013, September 2013 and January 2014.

In all cases, approximately 2 kg of samples were purchased.

The materials were placed in sterile air tight bags and transported to the laboratory. The yam chips and flakes were crushed and milled into flour using a laboratory attrition mill, sieved through 250 µm mesh and stored in plastic containers until use.

Each sample was analysed to determine the proximate concentration and the minerals, as detailed below. The values reported in the tables represent an average of the three measurements, collected in 4 month intervals, for each of the 16 samples.

Proximate analysis

Standard methods of the Association of Official Analytical Chemists (AOAC 2000) were used to determine the crude protein content, total ash, crude fat, crude fibre and moisture content of each sample. The carbohydrate was determined by difference while the nitrogen-free extract (NFE) of the samples was determined by subtracting the percentage of crude fibre from total carbohydrate (Ndidi et al. 2014). The gross energy (GE) was analysed using a bomb calorimeter.

Crude protein (% total nitrogen × 6.25) was determined by the Kjeldahl method. Ash was determined by the incineration of 2 g samples placed in a muffle furnace and maintained at 550 °C for 5 h. Crude fibre was obtained by digesting 2 g of sample with H2SO4 and NaOH, and incinerating the residue in a muffle furnace maintained at 550 °C for 5 h. Moisture content was determined by heating 2 g of each sample to a constant weight in a crucible placed in an oven maintained at 105 °C.

Mineral analysis

Prior to the mineral analysis, the samples were dried to a constant weight, and underwent a microwave assisted digestion. For this, a weighed amount of each sample (about 200 mg) was mixed with 5 ml of 65% HNO3 in a Teflon reaction vessel and heated in a Speedwave™ MWS–3 + (Berghof, Germany) microwave system. Digestion procedure was conducted in five steps: (1) 130 °C/10 min, (2) 160 °C/15 min, (3) 170 °C/12 min, (4) 100 °C/7 min and (5) 100 °C/3 min. The resulting clear solutions after the digestion procedure were transferred into 50 ml tubes and then brought to 20 ml with deionised water.

The elemental composition was determined using an inductively coupled plasma (ICP) optical emission spectrometer model Optima™ 7000 DV ICP-OES (Dual View, PerkinElmer Life and Analytical Sciences, Shelton, CT, USA) with radial plasma configuration. Standard plasma conditions were used namely 1300 W for radio-frequency power, 1.5 ml/min pump rate, and 15.0, 0.2 and 0.8 l/min for plasma, auxiliary and nebulizer gas flow, respectively.

Statistical analysis

SPSS Statistics Software Version 20 (IBM, New York, USA) was used for the statistical analysis. Data generated from the three batches of samples collected, and significant differences between their mean values, were analysed using analysis of variance (ANOVA), while the mean values were compared by Duncan’s multiple range tests at a level of 5% significance, and reported as mean ± standard deviation of triplicate measurements. Principal component analysis (PCA) was used to establish eventual patterns, and explore the relationships between the various parameters and the samples.

Results and discussion

Composition

The results of the proximate compositions of the yam flakes, chips and flour samples from the various markets are presented in Table 1. Moisture content ranged from 10.0 to 12.3%, with no significant (p > 0.05) difference between samples, irrespective of sample form, market and seller. The moisture content reported in this study were lower than the values reported by Jonathan et al. (2011) on the nutritional composition of 1 (13.3%) and 6 (14.4%) month stored yam chips (gbodo). Another study on yam chips collected from processors in Benin, at the beginning and after 3 months of storage, reported moisture content with a larger interval, from 9.2 to 15.3% (Gnonlonfin et al. 2007). All the samples assessed in the present study (with the exception of the packaged flours) were displayed for outdoor sale, possibly in the sun; this could have caused a reduction in the moisture content of the commodities. Hence, the relative low moisture content of the commodities below 13% can assure longer shelf-life without spoilage and pathogenic microbial proliferation, if stored under low relative humidity.

Table 1.

Proximate composition of market samples of yam chips, flakes and flour (wt%) and gross energy (kcal/kg)

| Moisture | Crude protein | CHO | Crude fibre | NFE | Crude fat | Ash | Gross energy | |

|---|---|---|---|---|---|---|---|---|

| Yam chips | ||||||||

| Saki 1 | 10.7 ± 2.1a | 4.0 ± 1.0a | 81.6 ± 0.67bcde | 1.3 ± 0.6a | 80.3 ± 0.43de | 1.1 ± 0.02b | 1.3 ± 0.6a | 3522.7 ± 195.6a |

| Saki 2 | 10.3 ± 2.1a | 3.0 ± 2.7a | 82.2 ± 0.25e | 1.7 ± 0.7a | 80.6 ± 0.05e | 1.1 ± 0.01b | 1.7 ± 0.6a | 3400.3 ± 144.5a |

| Mile12 1 | 12.3 ± 1.2a | 4.0 ± 0.0a | 79.7 ± 0.42a | 1.7 ± 0.6a | 78.0 ± 0.63b | 1.0 ± 0.02ab | 1.3 ± 0.6a | 3463.0 ± 167.5a |

| Mile12 2 | 12.0 ± 0.0a | 4.0 ± 0.0a | 79.6 ± 1.39a | 1.7 ± 0.6a | 78.0 ± 0.74a | 1.0 ± 0.01ab | 1.7 ± 0.6a | 3465.0 ± 102.4a |

| Bodija 1 | 12.00 ± 1.0a | 3.67 ± 0.6a | 79.90 ± 0.00abc | 2.0 ± 0.0a | 77.90 ± 0.00a | 0.8 ± 0.12ab | 1.7 ± 0.6a | 3378.7 ± 58.8a |

| Bodija 2 | 11.3 ± 0.6a | 4.0 ± 1.0a | 80.6 ± 0.43abcde | 1.3 ± 0.6a | 79.2 ± 0.28bcd | 1.1 ± 0.01b | 1.7 ± 0.6a | 3418.3 ± 17.5a |

| Yam flakes | ||||||||

| Mile12 1 | 11.0 ± 1.7a | 3.7 ± 0.6a | 80.8 ± 1.29abcde | 2.0 ± 0.0a | 78.8 ± 0.68bc | 0.9 ± 0.03ab | 1.7 ± 0.6a | 3493.3 ± 227.9a |

| Mile12 2 | 11.0 ± 1.0a | 4.0 ± 0.0a | 81.7 ± 0.18cde | 1.3 ± 0.6a | 80.3 ± 0.11de | 0.7 ± 0.50a | 1.3 ± 0.6a | 3348.0 ± 137.8a |

| Bodija 1 | 12.0 ± 1.7a | 4.3 ± 0.6a | 81.1 ± 0.38abcde | 1.7 ± 0.6a | 79.4 ± 0.42bcd | 0.9 ± 0.01ab | 2.0 ± 0.0ab | 3300.0 ± 117.9a |

| Bodija 2 | 11.3 ± 4.04a | 4.0 ± 0.0a | 80.0 ± 0.02abcd | 2.0 ± 0.0a | 78.0 ± 0.00b | 0.9 ± 0.01ab | 1.7 ± 0.6a | 3396.3 ± 274.5a |

| Yam flour | ||||||||

| Mile12 1 | 10.67 ± 1.5a | 3.0 ± 0.0a | 81.1 ± 0.18abcde | 2.0 ± 0.0a | 79.1 ± 0.09bcd | 0.9 ± 0.01ab | 2.3 ± 0.0ab | 3507.3 ± 83.09a |

| Mile12 2 | 10.0 ± 1.0a | 3.0 ± 0.0a | 81.1 ± 0.21abcde | 2.0 ± 0.0a | 79.1 ± 0.19bcd | 0.9 ± 0.01ab | 3.0 ± 0.0b | 3418.3 ± 95.5a |

| Lafenwa 1 | 12.0 ± 2.7a | 3.0 ± 0.0a | 80.4 ± 0.87abcd | 2.0 ± 0.0a | 78.4 ± 0.65bc | 0.9 ± 0.01ab | 1.7 ± 0.6a | 3333.3 ± 106.4a |

| Lafenwa 2 | 11.3 ± 2.5a | 2.7 ± 1.2a | 81.8 ± 0.04de | 1.3 ± 0.6a | 80.4 ± 0.03e | 0.9 ± 0.02ab | 2.0 ± 1.0ab | 3362.3 ± 75.8a |

| Supermarket 1 | 11.0 ± 1.73a | 4.3 ± 0.6a | 79.8 ± 0.30b | 2.0 ± 0.0a | 77.8 ± 0.02a | 0.9 ± 0.02ab | 2.0 ± 1.0ab | 3459.0 ± 122.02a |

| Supermarket 2 | 10.7 ± 1.2a | 4.3 ± 0.6a | 80.2 ± 0.20abcd | 1.7 ± 0.6a | 78.5 ± 0.02bc | 0.8 ± 0.01ab | 2.3 ± 0.6ab | 3344.3 ± 55.5a |

Values are mean ± standard deviations of three measurements of samples collected in 3 batches (n = 3). Different superscript letters within columns are significantly different (p ≤ 0.05). NFE nitrogen free extract; CHO carbohydrate

The crude protein content of the samples ranged 2.7 and 4.3%, with yam flour sample from Lafenwa 2 market showed the lowest value. No significant difference (p > 0.05) was observed across the samples.

The only available literature (Jonathan et al. 2011) on the proximate composition of market samples of traditionally processed yam chips reported a higher protein content for 1 (7.3%) and 6 (7.7%) month old yam chips. However, varying ranges of values were reported for laboratory processed yam chips and flour samples. Values smaller than those obtained in this study were reported by Abioye (2012) (2.6–2.9%), Adejumo et al. (2013) (2.4–2.6%) and Djeri et al. (2015) (3.5–5.7%). However, all these authors used Dioscorea cayennensis subsp. rotundata for the laboratory production of yam flour (“elubo”), whereas in the current study other subspecies of Dioscorea might have been used, which could explain the differences. On the other hand, higher values were reported by Ajala and Idowu (2016) (5.2–5.3%) while Obadina et al. (2014) reported lower range of values (0.9–1.5%).

The difference in the values obtained could also be attributed to the different sampling location or the processing conditions used.

Senanayake et al. (2012) reported 10.2 and 6.2% for D. alata Rajala and D. alata Hingurala, respectively, while Alinnor and Akalezi (2010), on the other hand, reported a very low value (0.087%) for flour from D. rotundata. However, similar ranges of values to those obtained in this study was reported for flour from white yam by Polycarp et al. (2012) (4.0–6.5%), and Ayodele et al. (2013), and for sweet potato flour by Fetuga et al. (2014) (2.2–4.6%). The low values of protein obtained in this study shows that the yam derived products are limited in the provision of recommended dietary allowance (RDA) of protein in the diet. According to Kafatos and Hatzis (2008), the RDA for adults, adolescents and children are 0.8, 1.0 and 1.5 g protein/kg body weight/day, respectively.

All tested samples showed low crude fat content. Fat concentration, in fact, was lower than 1%, with only a few chip samples containing slightly higher values. These data are in agreement with other studies that reported a comparable low amount of fat in different yam species (Polycarp et al. 2012; Ferraro et al. 2016). The fat content had values that did not show significant difference in the yam flours, and which were lower than that reported by Abioye (2012) (0.4–0.6%), but similar to that reported by Fetuga et al. (2014) (0.1–1.6%). Higher values were, however, reported by Obadina et al. (2014) (1.1–2.2%) and Ajala and Idowu (2016) (4.0–4.4%). Variation in variety and processing methods could also be responsible for these differences.

Significant (p ≤ 0.05) differences existed in the carbohydrate and nitrogen-free extract (NFE) contents of the samples, as the values obtained ranged from 79.7 to 82.2% and 77.8 to 80.6%, respectively. A lower range of values was reported by Ajala and Idowu (2016) (73.3–75.5%), while Abioye (2012) (86.9–87.3%), Adejumo et al. (2013) (83.8–84.4%), Fetuga et al. (2014) (76.9–87.7%) and Obadina et al. (2014) (83.1–86.1%) all reported higher values. The variation observed in these previous studies and the current one could be attributed to differences in variety or processing methods used.

Fibre has a useful role in providing roughage that aids digestion. Dietary fibre (DF), an essential component in human and animal nutrition, has the ability to bind and flush cholesterol, carcinogens and undesirable chemicals from the body, thereby preventing the development of chronic diseases including coronary heart disease, colonic cancer and other disorders of the gastrointestinal lining. Furthermore, fibre has a relevant role in the enhancement of gut motility that can help to control increasing levels of constipation in the population. This study reports crude fibre contents in the range of 1.33 and 2.0%, in agreement with the values reported by Jonathan et al. (2011) (1.3–2.0%), despite the difference in sampling location and time. Similar values were also reported for laboratory processed yam flour by Abioye (2012) (2.0–2.1%) and Obadina et al. (2014) (1.2–2.4%). This could be attributed to the similarities in the composition of the yam varieties used in the different studies.

Values reported for the yam chips, flakes and flour from different sources were not significantly different from one another. These data show that the fibre content of these food commodities is comparable to those of other crop-derived food stuffs, such as cassava (Charoenkul et al. 2011) and sweet potato flour (Fetuga et al. 2014).

The ash content of the various commodities was found to be between 1.3 and 3.0%, with significant (p < 0.05) differences in the yam flakes and flour from different markets, but no significant (p > 0.05) difference in the yam chip samples. Comparable ash content was previously reported for laboratory processed yam flours samples by Abioye (2012) (2.2–2.3%) and Adejumo et al. (2013) (2.1–2.4%) and sweet potato flour (1.8–2.1%) (Fetuga et al. 2014). Ash content is an indication of the mineral proportion of foodstuff, even though sample contamination can lead to higher ash content. Yam flour is a derivative product from either yam chips or flakes, after milling. The ~25% higher ash proportion in the flour samples than the yam chips and flakes could, therefore, be attributed to the presence of more minerals that could have been introduced into the flour during the milling process, as most of the millers use their milling machines for the milling of other food products such as grains, cereals, dried plantain, etc.

According to FAO, gross energy (GE) or ingested energy (IE) represents the heat production of foods and nutrients when completely oxidized to carbon dioxide and water, which is required for body metabolism and physical activity. The calculated GE values in this study show no significant (p > 0.05) difference in the three commodities from the different markets. This gives an indication that the flakes, which are also used as part of weaning food for infants, but are believed to be of lower nutritional quality, could also give as much energy as the chips. The values obtained in this study are within the range of values reported by Polycarp et al. (2012), Emmanuel et al. (2012) and Thomas et al. (2013) for different yam varieties, cassava varieties and rice varieties, respectively.

Mineral composition

The compositions of macro and micro minerals of yam chips, flakes and flour samples are presented in Tables 2 and 3, respectively.

Table 2.

Mineral composition (macro elements, mg/100 g) of yam chips, flakes and flour from selected markets in South West Nigeria

| Samples | P | Mg | Ca | Na | K | Ca/P ratio |

|---|---|---|---|---|---|---|

| Yam chips | ||||||

| Saki 1 | 96.8 ± 22.3ab | 36.0 ± 3.7ab | 25.9 ± 9.8ab | 10.7 ± 7.8a | 786.0 ± 198.8a | 1:3.7 |

| Saki 2 | 104.7 ± 34.2ab | 31.1 ± 4.0a | 16.1 ± 7.4a | 6.5 ± 6.1a | 788.5 ± 175.5a | 1:6.5 |

| Mile12 1 | 100.4 ± 9.2ab | 33.3 ± 3.4a | 18.8 ± 3.5ab | 6.9 ± 6.0a | 777.9 ± 67a | 1:5.3 |

| Mile12 2 | 81.1 ± 10.8ab | 33.1 ± 3.1a | 18.0 ± 6.4a | 7.7 ± 8.7a | 717.1 ± 94.6a | 1.4.5 |

| Bodija 1 | 87.9 ± 8.8ab | 33.4 ± 3.0a | 17.5 ± 8.0a | 8.2 ± 7.3a | 756.0 ± 89.5a | 1:2.6 |

| Bodija 2 | 83.1 ± 25.2ab | 33.9 ± 3.6a | 22.3 ± 7.5ab | 11.4 ± 9.9a | 720.2 ± 226.5a | 1:3.7 |

| Yam flakes | ||||||

| Mile12 1 | 73.1 ± 6.7a | 29.8 ± 0.5a | 34.3 ± 4.3abc | 4.4 ± 6.4a | 636.5 ± 54.9a | 1:2.1 |

| Mile12 2 | 77.7 ± 16.6a | 31.0 ± 4.7a | 40.0 ± 9.2bcd | 11.0 ± 7.7a | 641.8 ± 82.6a | 1:1.9 |

| Bodija 1 | 85.0 ± 11.5ab | 33.9 ± 2.0a | 33.2 ± 15.5abc | 13.5 ± 11.8a | 750.3 ± 132.8a | 1:2.5 |

| Bodija 2 | 84.7 ± 6.2ab | 30.9 ± 0.8a | 32.1 ± 9.4abc | 22.2 ± 17.8a | 656.1 ± 32.1a | 1:2.6 |

| Yam flour | ||||||

| Mile12 1 | 76.9 ± 17.5a | 56.8 ± 17.5c | 54.9 ± 14.3d | 8.4 ± 6.7a | 810.7 ± 256.6a | 1:1.4 |

| Mile12 2 | 85.1 ± 18.3ab | 58.7 ± 9.8c | 74.1 ± 26.2e | 15.6 ± 11.9a | 879.4 ± 175.4a | 1:1.2 |

| Lafenwa 1 | 74.2 ± 8.5a | 48.0 ± 6.0c | 39.8 ± 11.2bcd | 9.0 ± 7.3a | 683.5 ± 89.4a | 1:1.9 |

| Lafenwa 2 | 80.9 ± 25.6ab | 54.8 ± 14.9c | 51.7 ± 8.4 cd | 16.4 ± 14.3a | 605.6 ± 199.9a | 1:1.6 |

| Supermarket 1 | 105.0 ± 10.4ab | 37.6 ± 5.5ab | 18.1 ± 6.7a | 8.7 ± 9.7a | 843.9 ± 92.4a | 1:5.8 |

| Supermarket 2 | 112.8 ± 10.5b | 37.8 ± 5.3ab | 20.7 ± 8.2ab | 11.8 ± 10.3a | 857.1 ± 103.9a | 1:5.4 |

Values are mean ± standard deviations of three measurements of samples collected in 3 batches (n = 3). Different superscript letters within columns are significantly different (p ≤ 0.05)

Table 3.

Mineral composition (micro elements, mg/100 g) of yam chips, flakes and flour from selected markets in South West Nigeria

| Samples | Fe | Zn | Co | Mn | Cu |

|---|---|---|---|---|---|

| Yam chips | |||||

| Saki 1 | 7.61 ± 5.0a | 0.70 ± 0.2a | 0.002 ± 0.001a | 0.21 ± 0.03a | 0.32 ± 0.06bcde |

| Saki 2 | 11.49 ± 12.94a | 0.84 ± 0.2a | 0.002 ± 0.003a | 0.16 ± 0.04a | 0.37 ± 0.04de |

| Mile12 1 | 9.37 ± 8.5a | 0.85 ± 0.4a | 0.01 ± 0.00ab | 0.12 ± 0.1a | 0.36 ± 0.1cde |

| Mile12 2 | 8.26 ± 5.4a | 0.83 ± 0.5a | 0.007 ± 0.00ab | 0.12 ± 0.03a | 0.33 ± 0.1bcde |

| Bodija 1 | 7.88 ± 4.8a | 0.65 ± 0.1a | 0.005 ± 0.01ab | 0.13 ± 0a | 0.33 ± 0.1bcde |

| Bodija 2 | 5.83 ± 3.1a | 0.82 ± 0.2a | 0.005 ± 0.01ab | 0.11 ± 0.02a | 0.34 ± 0.08bcde |

| Yam flakes | |||||

| Mile12 1 | 8.70 ± 1.5a | 5.53 ± 2.4b | 0.005 ± 0.01ab | 0.35 ± 0.04ab | 0.27 ± 0.04abcd |

| Mile12 2 | 6.32 ± 3.5a | 2.37 ± 2.6a | 0.004 ± 0.01ab | 0.32 ± 0.15ab | 0.31 ± 0.03bcde |

| Bodija 1 | 11.41 ± 6.6a | 0.91 ± 0.2a | 0.007 ± 0.0ab | 0.45 ± 0.2abc | 0.32 ± 0.1bcde |

| Bodija 2 | 19.63 ± 14.5a | 1.80 ± 0.2a | 0.03 ± 0.04b | 0.92 ± 1.01c | 0.30 ± 0.05bcde |

| Yam flour | |||||

| Mile12 1 | 11.52 ± 5.8a | 1.55 ± 1.6a | 0.006 ± 0.01ab | 0.45 ± 0.03abc | 0.24 ± 0.1ab |

| Mile12 2 | 60.15 ± 55.8b | 1.22 ± 0.8a | 0.006 ± 0.01ab | 0.79 ± 0.3bc | 0.31 ± 0.1bcde |

| Lafenwa 1 | 13.90 ± 13.6a | 1.56 ± 1.4a | 0.006 ± 0.01ab | 0.38 ± 0.1ab | 0.25 ± 0.02abc |

| Lafenwa 2 | 11.11 ± 5.1a | 0.61 ± 0.14a | 0.011 ± 0.01ab | 0.49 ± 0.2abc | 0.19 ± 0.1a |

| Supermarket 1 | 4.09 ± 0.3a | 0.60 ± 0.133a | 0.008 ± 0.01ab | 0.10 ± 0.1a | 0.39 ± 0.01e |

| Supermarket 2 | 5.92 ± 1.3a | 0.64 ± 0.08a | 0.0003 ± 0.00a | 0.10 ± 0.03a | 0.38 ± 0.1de |

Values are mean ± standard deviations of three measurements of samples collected in 3 batches (n = 3). Different superscript letters within columns are significantly different (p ≤ 0.05)

Phosphorus (P) mean values ranged between 73.1 and 112.8 mg/100 g. All the yam chips purchased from different markets and sellers were very similar, irrespective of different processing locations. The lack of significant differences that existed between yam flake samples from the same market could be attributed to some of the sellers buying the commodities from one another within the same market and reselling. The low P concentration of the samples indicates that their consumption alone will not supply the recommended RDA of 800 mg/day for both adults and children, except when consumed with other P rich foods such as organ meats in soup. Significant differences, however, existed among the yam flakes and flour between markets and sellers. A baseline survey also revealed that the yam flour sellers sometimes obtain the yam chips or flakes from different sellers at different locations and pool them together before milling into flour. This could be the factor responsible for the variation. The only available literature on mineral compositions of traditionally processed yam chips sold in markets in Southwest Nigeria was reported by Jonathan et al. (2011). In their study, lower values (5.3–5.6 µg/100 g) were reported and this could be attributed to varietal difference in the yam cultivar used, as Polycarp et al. (2012) previously reported variation in the P contents of different yam varieties, although significantly higher values were reported.

The magnesium (Mg) content of the samples varied from 29.83 to 58.66 mg/100 g, with the yam flour samples from Mile12 and Lafenwa having the highest values, with significant (p ≤ 0.05) differences with respect to the rest of the samples. Moreover, in all yam flakes, Mg concentration was statistically equal to that of all yam chips, with the exception of Saki1, and no significant (p > 0.05) difference was found among the yam flours from the supermarkets. The high value for the yam flour samples from Mile12 and Lafenwa could be due to the fact that some of the yam flour sellers mill unfermented cassava chips with yam chips into flour, and sell the commodity as “yam flour” in order to maximize profit. The finding of Odebunmi et al. (2007) revealed that unfermented cassava flour has higher Mg content than yam flour and some other root crops. However, Jonathan et al. (2011) reported much lower values (2.5–3.9 µg/100 g) than those reported in this study.

The recommended dietary allowance of Mg for an adult is 350 and 170 mg/day for children. Basically, the consumption of 100 g (a serving) of yam-derived products contributes only to about 7–10% RDA of Mg. However, an average of 200–250 g (a serving) of “amala” is consumed by an adult, while some children less than 5 years could consume as much as 100 g. This goes further to show that the amount consumed per serving, both by adults and children, is not enough to meet the RDA. However, the consumption of “amala” with soups prepared with dark green leafy vegetables could make up for the inadequacy. However, nutritional dietary consumption studies would need to be undertaken to confirm this.

WHO recommends a daily intake of 800 mg Ca for both adults and children. This study shows that these products are below such recommendations. The Ca concentration (16.1–74.2 mg/100 g) in the samples also followed the same trend as Mg concentration, with the yam flour samples from Mile12 and Lafenwa having the highest values, although with significant differences existing between them and other samples. The report of Odebunmi et al. (2007) also showed higher Ca concentration in cassava flour (1.1 µg/100 mg) than yam (0.1 µg/100 mg) and some other root crops studied.

According to Lodi et al. (2016), Ca and P are the most important constituent elements of the bone mineral phase which form hydroxyapatite crystals [Ca10(PO4)6(OH)2]. These are the compounds which allow the maintenance of mineral homeostasis for important metabolic functions. Some studies (Kemi et al. 2010) reported evidence that low Ca:P dietary ratios may have an adverse effect on the skeleton. Also, prolonged periods on a low Ca:P diet have been considered an important risk factor that contributes to skeletal fractures (Anderson et al. 2006; Kemi et al. 2010). According to Adatorwovor et al. (2015), the RDA for calcium-to-phosphorus ratio (Ca:P) is ~2:1. In this study, however, the calculated Ca:P ratio was lower in all the three yam derived products; especially in the yam chips and the yam flour samples from the supermarket. This shows that a prolonged consumption of these products could lead to skeletal fracture; to compensate for this, the diet should be modified with foods with high calcium levels.

The sodium (Na) and potassium (K) contents of the yam chips, flakes and flour showed no significant differences irrespective of sample type and source. Sodium is essential for maintaining blood pressure and fluid balance, while K regulates acid-base balance, involved in the maintenance of osmotic pressure of the body fluids, activates nerve and muscle function, and involved in Na+/K+-ATPase (Murray et al. 2000). The Na and K concentration in the samples ranged from 4.4 to 22.2 mg/100 g and 605.6 to 879.4 mg/100 g, respectively. Contrary to these findings, Jonathan et al. (2011) reported lower values for Na (1.5–1.9 µg/100 g) and K (6.5–8.3 µg/100 g) in some yam chips, while Polycarp et al. (2012) reported higher values for Na (above 62.5 mg/100 g) and values within the same range as reported in this study for K (475–1475 mg/100 g). The Na:K ratios presented in this study (1:40–1:140) can be highlighted as a very positive result towards hypertension control, since Na restriction and K supplementation are recommended dietary measures to prevent cardiovascular disease (Whelton et al. 2012).

Although Na concentration did not show any significant difference between the various commodities, a definite trend across the different sample collection times was observed. For all samples, Na content was much lower in the samples from the last collection date, with more than 50% of the samples having no Na. The reason for these unusually low values could be linked to the yam varieties used by the different processors. Jonathan et al. (2011) reported the increase in the mineral composition of stored yam chips (“gbodo”) as the storage period advanced. Hence, the low or no Na concentration in the last batch of samples` collection might not be linked to storage. Therefore, this suggests the possibility of preventing cardiovascular disease through the consumption of some selected yam varieties with low Na content. The World Health Organization recommendations of Na intake per day are 500 and 400 mg for adult and children, respectively. Hence, these yam derived products are not sufficient sources of Na for the human diet, but can be seen as a positive factor in low salt diets (Na) frequently related with cardiovascular diseases and others.

Considering the micronutrients, iron is an important mineral for red blood cell formation and function: its presence in yam-derived products is, therefore, important for the assessment of the nutritional value. According to Mason (2008), the recommended dietary allowance of Fe for men and postmenopausal women is 8 mg/day, while 11, 15 and 30 mg/day were recommended for adolescents, premenopausal women and pregnant women, respectively. Our results show that these yam derived products can adequately supply Fe in the diet. The yam chips, flakes and flours showed comparable iron concentration values ranging from 5.8 to 19.6 mg/100 g, with no significant difference (p > 0.05). The only exception is the flour sample from seller 2 in the Mile12 market; these samples show a mean value of 60.2 mg/100 g, which is statistically different from the other values. This high mean concentration was due to the unusually high iron concentration levels found in one of the three flour samples collected in Mile12 market. In fact, an iron concentration as high as 121.6 mg/100 g was detected in the flour sample from the last batch. The observed high concentration of Fe could be due to the addition of other Fe-rich starch-based products to the flours. Cassava derivatives, for instance, could have been added to these yam flours. A previous study reported higher iron content in cassava than in other root and tuber crops; values as high as 40 mg/100 g (Albert et al. 2005).

The mean values of the zinc (Zn) content showed no significant (p < 0.05) difference across samples, irrespective of sample type and location sourced from; the only exception was the yam flakes sample from Mile12 market, which had the highest concentration (5.53 mg/100 g). The high level of Zn in the flake from Mile12 market could be attributed to the yam variety used; as Polycarp et al. (2012) had previously reported Zn concentration as high as 6.80 mg/100 g in some yam cultivars. Zn levels composition observed in this study are higher than values reported by some authors on yam chips (0.008–0.023 µg/100 g) (Jonathan et al. 2011), and other root crops (0.00–0.14 mg/100 g) (Odebunmi et al. 2007).

Zn is a mineral that is essential for cell development and replication. RDA of Zn is 8 mg/day for females and 11 mg/day for males (Mason 2008). Although, foods of animal origin are known to be the major source of Zn. However, data from this study indicate that these samples could also be considered a good Zn source for a healthy diet, since the consumption of about 150–200 g “amala” per serving could provide the recommended RDA. These yam derived products, except the Mile12 yam flake samples, could be consumed without exceeding the maximum Zn limit intake level, since the upper level of Zn intake according to FAO/WHO is 60 mg/day (Sarikurkcu et al. 2015).

Cobalt (Co) is required as a constituent of vitamin B12, and is also a cofactor of enzymes involved in DNA biosynthesis and amino acid metabolism. According to FAO/WHO (Sarikurkcu et al. 2015), Co intake for an adult should not be higher than 0.012 mg/day. It can be seen, therefore, from this study that consumption of 100 g flour reconstituted into ‘amala’ will adequately supply the recommended daily intake, except for the flake sample from Bodjia 2 which could lead to a higher Co intake. Co concentrations (0.003–0.03 mg/100 g) were not significantly different between samples, with the exception of the flake samples from Bodjia 2, which showed a higher Co concentration (0.03 ± 0.04 mg/100 g). However, the only available literature (Jonathan et al. 2011) on mineral composition of traditionally processed yam chips did not evaluate Co concentration.

Manganese (Mn) was detected in all the samples at all batches with mean values ranging from 0.1 to 0.9 mg/100 g. No significant difference existed across yam chips and flour samples from the supermarkets (p < 0.05), which could be connected with some of the packaged flour sellers sourcing their chips from either the same set of chip sellers or from the same processors. However, the yam flakes and the flour samples from the local markets were significantly different from one another. Values obtained in this study were in line with what was reported by Odebunmi et al. (2007) for some fresh tuber crops including yam (0.1–0.9 mg/100 g), but different from the findings of Jonathan et al. (2011) for traditionally processed yam chips (0.27–0.33 µg/100 g). According to Mason (2008), RDAs for females and males are 1.2 and −2.3 mg/day, respectively. This study shows that these yam commodities could provide appreciable amounts of Mn when combined with other foodstuffs in the diet.

Copper (Cu) is necessary for bone growth and formation; it also helps in the incorporation of Fe in hemoglobin, in the absorption of iron from the gastrointestinal tract and in the transfer of iron from tissues to the plasma (Murray et al. 2000). These products do not meet the RDA in a 100 g serving, as 3 and 2 mg/day is required for adults and children, respectively. The yam chips and flakes had similar Cu levels, irrespective of the markets and sellers (Table 3). However, the Cu levels in yam flour from Mile12 and Lafenwa were significantly different between markets and sellers, but the samples from the supermarkets were significantly the same, despite the difference in brands. Contrary to this study, lower values were reported by Jonathan et al. (2011) for yam chips while values reported by Polycarp et al. (2012) are in agreement with these results.

Principal component analysis (PCA)

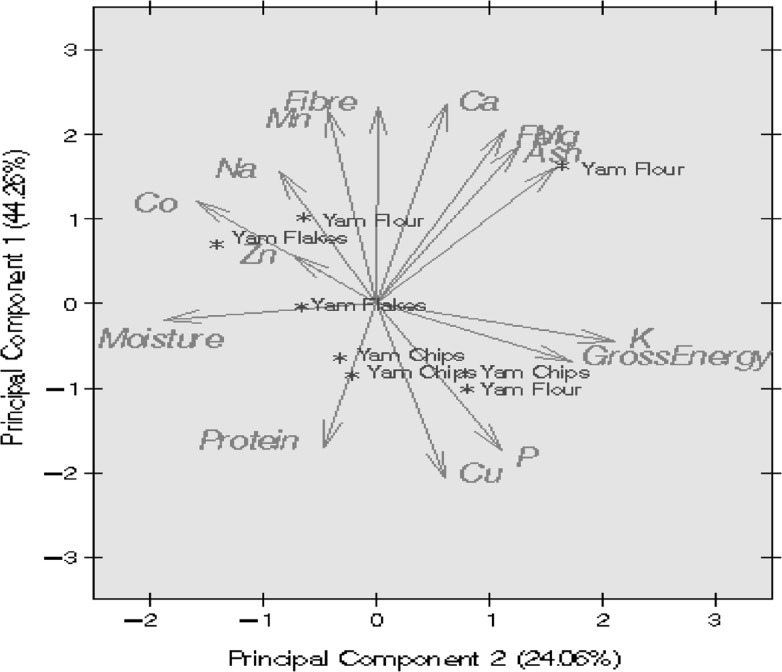

Figure 1 shows the relationship between each variable and the different yam derived products, i.e. yam chips, flakes and flour. The first two principal components (PCs) explained about 68.30% of the total variance. Ca had the greatest loading effect in the first PC, which explained 44.26% of the total variance, while Na had the least. On the second PC however, K was shown to have the greatest loading effects and Cu had the least (Table 4). The loading of the variables on the score plot shows that the yam flour samples were high in crude fibre, Ca and Mn. The yam flakes samples on the other hand were found to be rich in Na, Co and Zn while the yam chips were rich in crude protein, Cu and P.

Fig. 1.

Principal component analysis (PCA) of the relationship between the nutritional components of yam chips, flakes and flour and the origin

Table 4.

Factor loading of the principal components

| Factor | Principal components | |

|---|---|---|

| 1 | 2 | |

| Moisture | * | 0.644 |

| Protein | −0.694 | * |

| Fibre | 0.841 | * |

| Ash | 0.854 | * |

| Gross energy | * | −0.743 |

| Zn | * | * |

| P | −0.435 | −0.697 |

| Co | * | 0.783 |

| Mn | 0.751 | 0.545 |

| Fe | 0.938 | * |

| Mg | 0.892 | * |

| Ca | 0.958 | * |

| Cu | −0.640 | −0.574 |

| Na | 0.414 | 0.575 |

| K | * | −0.840 |

* Loading value <0.4

Conclusion

This study demonstrates that the processing involved in the production of chips, flakes and flour from yam has little or no negative impact on the nutritional composition; indeed some of the nutritional values obtained for these food commodities were similar to values reported for fresh yam. These findings contradict the common belief in Nigeria (and other countries) that yam flakes have lower nutritional value. Some differences, however, were found between the food stuffs sold in different markets, as items from some markets showed more favourable mineral compositions. Overall, this study showed that consumption of about 100–150 g per serving of “amala” will adequately supply the recommended dietary intake of micronutrients such as Zn, Co and Mg, whilst the RDA for only Fe may not be met. PCA showed that nutritional composition of the samples had a direct correlation with the form (i.e. chips, flakes or flour) of the commodities but not with the source.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

This work was financially supported by the Gratitude project (Ref. FP7-KBBE 2011.2.5-02/289843/2012) and by FCT – Fundação para a Ciência e a Tecnologia – through the project UID/Multi/50016/2013. Dr. Piccirillo thanks FCT for the Grant SFRH/BPD/86483/2012.

Footnotes

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-017-2761-y) contains supplementary material, which is available to authorized users.

References

- Abiodun OA, Akinoso R. Effect of the harvesting periods on the chemical and pasting properties of trifoliate yam flour. Food Chem. 2014;142:159–165. doi: 10.1016/j.foodchem.2013.07.015. [DOI] [PubMed] [Google Scholar]

- Abioye VF. Effect of some processing variables on the quality attributes of yam flour. J Agric Sci Technol B. 2012;2:621–626. [Google Scholar]

- Adatorwovor R, Roggenkamp K, Anderson JB. Intakes of calcium and phosphorus and calculated calcium-to-phosphorus ratios of older adults: NHANES 2005–2006 Data. Nutrients. 2015;7:9633–9639. doi: 10.3390/nu7115492. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Adejumo BA, Okundare RO, Afolayan OI, Balogun SA. Quality attributes of yam flour (Elubo) as affected by blanching water temperature and soaking time. Int J Eng Sci. 2013;2:216–221. [Google Scholar]

- Ajala AS, Idowu TO. Investigation on the quality of fermented white yam flour (Elubo) at different drying temperatures. Can J Agric Crops. 2016;1:1–10. [Google Scholar]

- Albert LC, Klanarong S, Tzou-chi H. Proximate composition, mineral contents, hydrogen cyanide and phytic acid of five cassava genotypes. Food Chem. 2005;92(4):615–620. doi: 10.1016/j.foodchem.2004.08.024. [DOI] [Google Scholar]

- Alinnor IJ, Akalezi EO. Proximate and mineral compositions of Dioscorea rotundata (White Yam) and Colocasia esculenta (white cocoyam) Pak J Nutr. 2010;9:998–1001. doi: 10.3923/pjn.2010.998.1001. [DOI] [Google Scholar]

- Anderson JJB, Klemmer PJ, SellWatts ML, Garner SC, Calvo MS. Phosphorus. In: Bowmn BA, Russell RM, editors. Present knowledge in nutrition. 9. Washington, DC: International Life Sciences Institute (ILSI) Press; 2006. [Google Scholar]

- AOAC (2000) Official methods of analysis. In: Association of official analytical chemists 17th edn. Sects 50.1.09 (985.33). Washington, DC

- Ayodele BC, Bolade MK, Usman MA. Quality characteristics and acceptability of “amala” (yam-based thick paste) as influenced by particle size categorization of yam (Dioscorea rotundata) flour. Food Sci Technol Internsh. 2013;19:35–43. doi: 10.1177/1082013212442181. [DOI] [PubMed] [Google Scholar]

- Charoenkul N, Uttapap D, Pathipanawat W, Takeda Y. Physicochemical characteristics of starches and flours from cassava varieties having different cooked root texture. LWT Food Sci Technol. 2011;44:1774–1781. doi: 10.1016/j.lwt.2011.03.009. [DOI] [Google Scholar]

- Djeri B, Tchobo PF, Adjrah Y, Karou DS, Ameyapoh Y, Soumanou MM, Souza C. Nutritional potential of yam chips (Dioscorea cayenensis and Dioscorea rotundata Poir) obtained using two methods of production in Togo. Afr J Food Sci. 2015;9:278–284. doi: 10.5897/AJFS2014.1207. [DOI] [Google Scholar]

- Emmanuel OA, Clement A, Agnes SB, Chiwona-Karltun L, Drinah BN. Chemical composition and cyanogenic potential of traditional and high yielding CMD resistant cassava (Manihot esculenta Crantz) varieties. Int Food Res J. 2012;19(1):175–181. [Google Scholar]

- Ezeocha VC, Ojimelukwe PC. The impact of cooking on the proximate composition and anti-nutritional factors of water yam (Dioscorea alata) J Stored Prod Postharvest Res. 2012;3(13):172–176. [Google Scholar]

- Ferraro V, Piccirillo C, Tomlins K, Pintado ME. Cassava (Manihot esculenta Crantz) and Yam (Discorea spp.) crops and their derived foodstuffs: safety, security and nutritional value. Crit Rev Food Sci Nutr. 2016;56:2714–2727. doi: 10.1080/10408398.2014.922045. [DOI] [PubMed] [Google Scholar]

- Fetuga G, Tomlins K, Henshaw F, Idowu M. Effect of variety and processing method on functional properties of tradition sweet potato flour (“elubo”) and sensory acceptability of cooked paste (“amala”) Food Sci Nutr. 2014;2:682–684. doi: 10.1002/fsn3.161. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gnonlonfin GJB, Hell K, Fandohan P, Siame SB. Mycoflora and natural occurrence of aflatoxins and fuminisin B1 in cassava and yam chipd from Benin, West Africa. Int J Food Microbiol. 2007;122:140–147. doi: 10.1016/j.ijfoodmicro.2007.11.047. [DOI] [PubMed] [Google Scholar]

- Jonathan G, Ajayi I, Omitade Y. Nutritional compositions, fungi and aflatoxins detection in stored ‘gbodo’ (fermented Dioscorea rotundata) and ‘elubo ogede’ (fermented Musa parasidiaca) from South western Nigeria. Afr J Food Sci. 2011;5:105–110. [Google Scholar]

- Kafatos A, Hatzis C. Clinical nutrition for medical students. Rethimno, Greece: University of Crete; 2008. [Google Scholar]

- Kemi VE, Karkkainen MUM, Rita HJ, Laaksonen MM, Outila TA, Lamberg-Allardt CJ. Low calcium: phosphorus ratio in habitual diets affects serum parathyroid hormone concentration and calcium metabolism in healthy women with adequate calcium intake. Br J Nutr. 2010;103:561–568. doi: 10.1017/S0007114509992121. [DOI] [PubMed] [Google Scholar]

- Lodi KB, Marchini AM, Santo AM, Rode S, Marchini L, Rocha RF. The influence of alcohol consumption in conjunction with sex hormone deficiency on Ca/P ratio in rats. Int J Endocrinol. 2016 doi: 10.1155/2016/3797139. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mason JB. Vitamins, trace minerals and other micronutrients. In: Goldman L, Ausiello DA, editors. Cecil medicine. 23. Philadelphia: Saunders Elsevier; 2008. pp. 1–10. [Google Scholar]

- Murray RK, Granner DK, Mayes PA, Rodwell VW. Harper’s biochemistry. 25. USA: Health Profession Division, McGraw-Hill; 2000. [Google Scholar]

- Ndidi US, Ndidi CU, Olagunju A, Muhammad A, Billy FG, Okpe O (2014) Proximate, antinutrients and mineral composition of raw and processed (Boiled and Roasted) Sphenostylis stenocarpa seeds from Southern Kaduna, Northwest Nigeria. Hindawi Publishing Corporation ISRN Nutrition, pp 1–9 [DOI] [PMC free article] [PubMed]

- Obadina AO, Babatunde BO, Olotu I. Changes in nutritional composition, functional, and sensory properties of yam flour as a result of presoaking. Food Sci Nutr. 2014;2:676–681. doi: 10.1002/fsn3.150. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Odebunmi EO, Oluwaniyi OO, Sanda AM, Kolade BO. Nutritional compositions of selected tubers and root crops used in Nigerian food preparations. Int J Chem. 2007;17(1):37–43. [Google Scholar]

- Polycarp D, Afoakwa EO, Budu AS, Otoo E. Characterization of chemical composition and anti-nutritional factors in seven species within the Ghanaian yam (Dioscorea) germplasm. Int Food Res J. 2012;19:985–992. [Google Scholar]

- Saraf A, Samant A. Evaluation of some minerals and trace elements in Achyranthes aspera Linn. Int J Pharma Sci. 2013;3:229–233. [Google Scholar]

- Sarikurkcu C, Tepe B, Kacak MS, Uren MC. Metal concentration and antioxidant activity of edible mushrooms from Turkey. Food Chem. 2015;175:549–555. doi: 10.1016/j.foodchem.2014.12.019. [DOI] [PubMed] [Google Scholar]

- Senanayake SA, Ranaweera KKDS, Bamunuarachchi A, Gunaratne A. Proximate analysis and phytochemical and mineral constituents in four cultivars of yams and tuber crops in Sri Lanka. Trop Agric Res Ext. 2012;15:32–36. doi: 10.4038/tare.v15i1.5240. [DOI] [Google Scholar]

- Silvera SAN, Rohan TE. Trace elements and cancer risk: a review of the epidemiologic evidence. Cancer Causes Control. 2007;18:7–27. doi: 10.1007/s10552-006-0057-z. [DOI] [PubMed] [Google Scholar]

- Thomas R, Wan-Nadiah WA, Bhat R. Physicochemical properties, proximate composition, and cooking qualities of locally grown and imported rice varieties marketed in Penang, Malaysia. Int Food Res J. 2013;20(3):1345–1351. [Google Scholar]

- Whelton PK, Appel LJ, Sacco RL, Anderson CA, Antman EM, Campbell N, Dunbar SB, Frohlich ED, Hall JE, Jessup M, Labarthe DR, MacGregor GA, Sacks FM, Stamler J, Vafiadis DK, Van Horn LV. Sodium, blood pressure, and cardiovascular disease: further evidence supporting the American Heart Association sodium reduction recommendations. Circulation. 2012;126:2880–2889. doi: 10.1161/CIR.0b013e318279acbf. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.