Abstract

The aim of this study was to evaluate the microtextural properties of optimized wheat bread formulation consisting sourdough (A) prepared with two different fermentation methods [spontaneous fermentation (F1) versus starter of lactic acid bacteria added fermentation (F2)], instant active dry yeast (B) and wheat bran (C) during shelf life. The optimized levels for F1 were 11.45 g 100 g−1 for sourdough, 1.10 g 100 g−1 for dry yeast and 1.58 g 100 g−1 for wheat bran and for F2 6.99 g 100 g−1 for sourdough, 1.02 g 100 g−1 for dry yeast and 38.84 g 100 g−1 for wheat bran. The addition of sourdough significantly decreased the diameters of starch granules of sourdough breads, and affected shape and surface apparance of starch granules. The retrogradation phenomena during storage was explained with the change of interaction between starch granules and protein matrix. The F1 fermentation method was found to be more effective in terms of bread textural properties examined.

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-017-2823-1) contains supplementary material, which is available to authorized users.

Keywords: Microtexture, Bread, Scaning electron microscopy, Image analysis, Sourdough

Introduction

Sourdough is a mixture of wheat flour and water, which is made metabolically active by hetero/homofermentative lactic acid bacteria (LAB) and yeasts, either by spontaneous fermentation or by fermentation initiated through the addition of a sourdough starter culture. Moreover, it is a traditional bread production method which is known to improve volume, shelf-life, nutritional and textural properties of wheat bread (Liukkonen et al. 2003). Due to the metabolites that are produced through the interaction between LAB and yeast, the usage of sourdough affects of textural properties of final bakery products. One of the important metabolites is organic acids that have various effects on the bread quality. Primarily, they results in the acidic flavor and depending on the findings of recent studies they also affect the enzyme activity, bioactivity, biochemical changes on starch and on other structural components (Rizzello et al. 2012; Gobbetti et al. 2014).

Examination of the microtexture of wheat bread has been helpful in determining the changes that occur in physical structure during the various stages of bread preparation. The changes not only occure in various processing stages but also continue during shelf life. The various methods such as texture profile analysis, differential scanning calorimetry, sensory profile analysis have been performed to assess the changes occurring during the shelf life. Scanning electron microscopy (SEM), which is used to determine the structural alterations within the food matrix like other materials, permits observation of three dimensional structures. By the tecnique, it was revealed that protein matrix formed a smooth, enveloping, veil-like network stretched over the starch granules (Indrani et al. 2003). Moreover, SEM was effectively used in several studies for examining brought about the functioning of different enzymes, organic acids, additives or fermentation on the major constituents of wheat flour or dough (Aponte et al. 2014).

However, the studies on the employment of SEM together with image analysis (IA) regarding the microtextural alterations during shelf life, of sourdough bread are scanty. Therefore, the present work aimed to examine the microtexture of sourdough breads prepared with two fermentation methods and compare with control wheat bread during shelf life. In addition SEM and IA results were also interpreted to assess the interaction between protein and starch granules.

Material and method

Materials

The wheat flour (14.3% moisture, 0.63% ash, 11.3% protein, 59.2% water absorption) and bran samples were obtained from a milling company (Cesur Milling Co., Trabzon). The salt and instant active dry yeast (Dr. Oetker) were bought from a local supermarket.

Experimental design and optimization

The bran content of sourdough, utilization ratio of yeast and sourdough of bread were considered as three independent factors and two main responses were bread desirability (BD) and bread value (BV) as explained in Hayta and Hendek Ertop (2017). Response surface methodology (RSM)-Central composite rotatable design (CCRD) desirability function was used for the effect of the three factors on the two responses (Design Expert 7.0.0, Stat-Ease Inc., Minneapolis, USA). The experimental levels of factors were for instant active dry yeast: 0, 0.41, 1.00, 1.59, 2.00 g 100 g−1, for sourdough: 5, 9.05, 15.00, 20.95, 25.00 and for wheat bran: 0, 8.11, 20.00, 31.89, 40.00 g 100 g−1. This experimental design was carried out for both fermentation method F1 and F2 (Hayta and Hendek Ertop 2017).

Bread desirability (BD) BD values were estimated by using sensory evaluation test (five-point hedonic scale with “5″ as “I like it very much” and “1″ as “I didn’t like it at all”), respectively (Keswet et al. 2003; Olapade and Adetuyi 2007).

Bread value (BV) BV is a parameter which enables evaluation of volume, texture and crumb properties of bread samples together. BV was calculated by the following equation according to Pelshenke et al. (1964):

| 1 |

The method was slightly modified and Image Pro Plus 6.0 (Media Cybernetics Inc., USA) software was used instead of Dalmann scale (Pelshenke et al. 1964) for determination of pore factor. Images of both faces of the two central slices (20 mm thickness) from each loaf were captured with a flatbed scanner (Model Scanjet 8200, HP, Cupertino, USA) having a resolution of 600 dots per inch (dpi) and converted from true color to grayscale. The images were calibrated, standardized and optimized by applying appropriate filters to measure pore size and their distribution with an Image-Pro Plus 6.0 (Media Cybernetics Inc., USA) software. The number and the area of pores were characterized by enumerating the pores present in five pre-selected dimensional classes based on their area (class1 = 0.05–0.49 mm2; class 2 = 0.50–0.99 mm2; class 3 = 1.00–4.99 mm2; class 4 = 5.00–49.99 mm2; class 5 = >50 mm2) as previously reported (Bianchia et al. 2008).The pore numbers of each class, which were calculated by software, were multiplied with their own coefficient (for class 1:1.0, class 2: 0.8, class 3:0.6, class 4:0.4, class 5:0.2) and pore factors were calculated. Since Class 1 contains pores having smallest area, the highest coefficient was given to Class 1, similar to Dallman Scale.

Preparation of sourdoughs

The dough yield value (DY), which is proportion between flour and water, was 200 for the sourdoughs (Chavan 2011):

Sourdough prepared by spontaneous fermentation (F1) The traditional “back-sloping method” was used. 200 g wheat flour and 200 g water were mixed and fermented spontaneously until the dough reached a pH value below 4.5.

Sourdough prepared by starter (F2) LAB (Lb.brevis, Lb.plantarum and, Lb.delbrueckii) were activated on MRS broth culture to obtain a cellular suspension of 107 cfu mL−1. Bacterial suspensions were washed two times. Each LAB culture which was 107 cells mL−1 was added at a ratio of 1% (Wu et al. 2012).

Preparation of bread samples

The bread production formula and the straight dough method of Keswet et al. (2003) were used as slightly modified. The water (59% based on flour), salt (1.5% based on dry matter), dry yeast, flour (300 g) and sourdough were added to kneading bowl and mixed (KitchenAid KSM150PSER, Belgium) for 15 min. Bread production followed the main steps as premixing, kneading, fermentation for 40 min, shaping, proofing for 50 min, and finally baking at 185 °C.

pH and total titratable acidity (TTA)

The bread and distilled water were mixed in a weight: volume ratio of 1:9. The mixture was crumbled by ultra turrax (IKA, T25, Germany) until a homogeneous mixture was obtained. The mixture was then kept for 10 min and pH was measured with a pH meter. The mixture was titrated with 0.1 mol mL−1 NaOH (Rizzello et al. 2016).

Evaluation of microtextural properties

Scanning electron microscopy (SEM)

Products that were kept under the same conditions after baking were examined by SEM on days 0, 3, 5, and 8. The samples dehydrated in acetone were again dried in acetone with a Polaran E3100 Critical Point Dryer at Critical point. After dried samples were adhered on sample holder with double sided tape, the dried samples coated with about 135 Angstrom Au/Pd (device coating speed 3 Å s−1) with SC 7620 mini Sputter Coater then they were examined by SEM (Aponte et al. 2014).

Image analysis (IA)

The evaluation of SEM views, Image Pro Plus 6.0 (Media Cybernetics Inc., USA) software was used. The diameter of starch granules were measured through the software with appropriate calibration.

Statistical analysis

After optimization, obtained results were validated experimentally. One sample t test and variance of analyses (ANOVA) (SPSS 17.0.1) were used for the comparison (p < 0.05) of results.

Results and discussion

Optimization

“Sequential model sum of squares” and “lack of fit” tests were evaluated for BV and BD. Standard deviation, R-squared (R2) and adjusted R2 were calculated for each function (Table 1). Quadratic function was approved in terms of BV and BD (p < 0.05). “Lack of fit” was determined as insignificant (p > 0.05) for both properties. When the effects of factors on BV and BD were evaluated (Table 1), both the influence of bran usage on BV was statistically significant (p < 0.05), and the influence of instant active dry yeast and sourdough usage on BD were statistically significant (p < 0.05) for fermentation type F1. The effects of bran and sourdough usage on BV and BD were statistically significant (p < 0.05), for fermentation type F2. The model was statistically significant (p < 0.05) for both response and fermentation types. Variance analysis results for quadratic function are given in Table 1.

Table 1.

Statistical parameters of optimization; p values for model selection and lack of fit tests; model and independent variable factors (a), variance analysis results of quadratic function (b)

| Fermentation type | p values* | |||

|---|---|---|---|---|

| F1 | F2 | |||

| BV | BD | BV | BD | |

| a | ||||

| Model selection and lack of fit test | ||||

| Quadratic | 0.0041 | 0.0066 | 0.0030 | 0.0040 |

| Lack of fit | 0.1990 | 0.1178 | 0.1092 | 0.1304 |

| Model and independent variable factors | ||||

| Model | 0.0062 | 0.0121 | 0.0082 | 0.0005 |

| A-Yeast | 0.6824 | 0.0152 | 0.4068 | 0.2089 |

| B-Sourdough | 0.2907 | 0.0169 | 0.0481 | <0.0001 |

| C-Bran | 0.0013 | 0.7131 | 0.0338 | 0.0364 |

| b | ||||

| Response | ||||

| R2 | 0.835 | 0.808 | 0.825 | 0.906 |

| Intercept | 154.65 | 3.24 | 143.45 | 2.74 |

| A-Yeast (%) | −1.61 | −0.48 | −3.39 | −0.14 |

| B-Sourdough (%) | −4.25 | −0.47 | −8.81 | −0.73 |

| C-Bran (%) | −16.87 | −0.06 | −9.63 | −0.25 |

| AB | −4.78 | −0.31 | −4.15 | 0.47 |

| AC | −8.75 | −0.19 | −3.66 | −0.03 |

| BC | −0.59 | 0.00 | −12.49 | −0.16 |

| A2 | −12.92 | −0.56 | −10.58 | −0.30 |

| B2 | 11.79 | 0.15 | 7.98 | 0.23 |

| C2 | 3.49 | 0.42 | 14.22 | 0.32 |

* The values p < 0.05 statistically significant

BV bread value, BD bread desirability, F1 spontan fermentation, F2 starter LAB added fermentation

Final equations (Eqs. 2, 3, 4 and 5) were coded with the following factors;

For fermentation type F1

| 2 |

| 3 |

For fermentation type F2

| 4 |

| 5 |

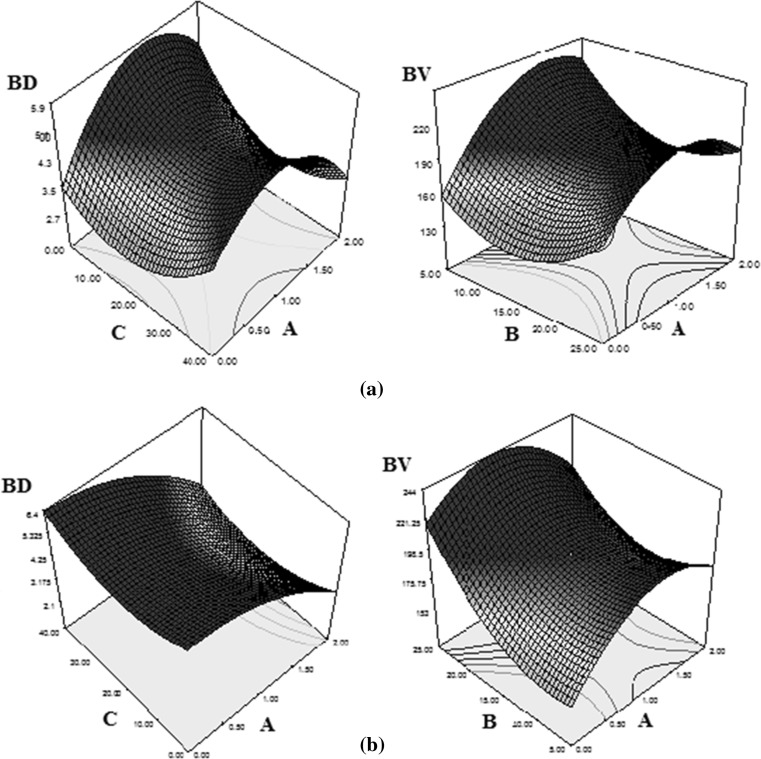

Figure 1 shows the response for the interaction of the level of C and A on BD; and the level of B and A on BV for fermentation types F1 and F2. BD and BV increased with the increase in the level of A. However, both responses exhibited a tendency to decrease after the central point with the increase in A. This was opposite for the levels of B and C. The purpose of optimization was to determine accurate values of parameters which may help in obtaining the desired response.

Fig. 1.

Response surface plots showing mutual effects of the amount of instant active dry yeast, A sourdough, B and bran, C on BD and BV according to fermentation type F1 a and F2 b

Numerical optimization was used in this study. BV and BD values were evaluated together according to desirability function. The desirability approach was based on the idea that the “quality” of a product or process that has multiple quality characteristics. The first solution from the 30 solutions, which have desirability value = 1 offered by the software, was selected and applied in this study (Table 2a).

Table 2.

First solution from the thirty solutions determined by desirability function (a), comparison of the results obtained from optimum point verification tests with the estimated values from model (b)

| Fermentation type | The level of usage (g) | BV | BD | Desirability | |||

|---|---|---|---|---|---|---|---|

| A | B | C | |||||

| a | |||||||

| F1 | 1.10 | 11.45 | 1.58 | 197.42 | 4.65 | 1.000 | Selected |

| F2 | 1.02 | 6.99 | 38.84 | 212.76 | 4.75 | 1.000 | Selected |

| Fermentation type | Response | Estimated value | Average experimental result* | Difference | p value* |

|---|---|---|---|---|---|

| b | |||||

| F1 | BV | 197.42 | 190.22 ± 7.29 | −7.19 | 0.229 |

| BD | 4.65 | 4.57 ± 0.06 | −0.08 | 0.130 | |

| F2 | BV | 212.76 | 202.26 ± 5.12 | −10.5 | 0.071 |

| BD | 4.75 | 4.67 ± 0.12 | −0.083 | 0.338 | |

* Average ± standart deviation; Values p < 0.05 statistically significant

BV bread value, BD bread desirability, F1 spontan fermentation, F2 starter LAB added fermentation, A dry yeast, B sourdough, C bran

Experimental validation of optimization results

The breads were produced, in triplicate, using optimized levels given in Table 2a. The BV and BD values of optimized breads were determined for F1 and F2, and the average values were calculated. It was also investigated whether there was a statistically significant (p < 0.05) difference between the average and estimated values from the model by applying the one sample t test. The results of the one sample t test for each response are given in Table 2b. No statistically significant difference (p > 0.05) was determined between the results obtained from the validation test. This indicates that the model obtained with optimization was experimentally successful.

Determination of differences between optimized breads (OBF1 and OBF2) and control bread (CB)

The breads produced according to the optimized model and fermentation types, OBF1 and OBF2, were compared with the CB in terms of microtexture after baking, and during shelf life.

pH and total titratable acidity (TTA)

The pH and TTA were found 6.15 and 2.65 ± 0.067 for CB; 5.29 and 4.60 ± 0.012 for OBF2; 5.04 and 5.34 ± 0.016 for OBF2. While the use of sourdough caused a decrease in bread pH, it caused an increase in TTA. Since the CB samples were produced using bakery yeast only, the pH was higher than that in sourdough breads, and the TTA was lower. The acidity of sourdough results from lactic acid bacteria which synthesized lactic acid by homofermentation of hexoses and synthesized lactic acid, acetic acid, ethanol and CO2 by heterofermentation of hexoses. A reduction in pH also causes an increase in protease activity of cereals. Additionally, lactic acid bacteria also have their own enzyme activity. Increased enzyme activity raises the free amino acid content by hydrolyzing proteins (Hansen and Schieberle 2005) therefore may lead to higher TTA value.

Microstructure

The cereal-based bakery products have a micro-textured structure carried from the grain to the final product (Autio and Salmenkallio-Marttila 2001). The structure is formed by a protein-based matrix and components which are taken place in this structure such as starch and water. The bread structure consists of water and wheat fractions such as starch, protein, bran. Since water must be removed from the sample at the basis of the SEM technique, the water molecules can not be displayed in SEM images, while only protein structure and starch granules views can be captured (Gorinstein et al. 2004).

SEM images were evaluated by Image ProPlus software, the diameters of starch granules were measured after appropriate calibration. The SEM images (1000×) of bread samples CB, OBF1 and OBF2 first day of baking are shown in Online Resource 1. For the purpose of understanding effect of the fermentation methods and optimized formulas, the microtextures were compared through the SEM images.

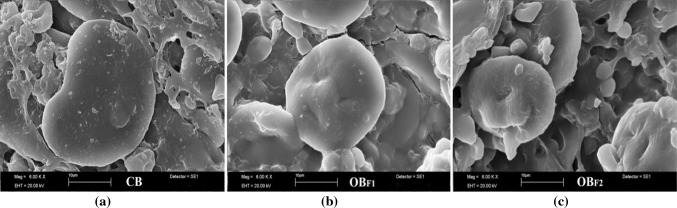

All bread samples contained small as well as large starch granules of spherical and lenticular shapes that were distributed throughout the protein matrix. This observation is resembled to the reports of Aponte et al. (2014) on sourdough and bread. The microstructure of CB (a) was characterized by a compact protein network including starch granules rather than other sourdough breads. Starch granules present in CB were smooth, oval shaped and homogeneous distributed in protein matrix. On the other hand, in OBF1 and OBF2- added sourdough breads, the protein matrix appeared less structured and organized during fermentation likely because proteins of dough are not capable of forming three dimensional structures due to enzyme activity and acidic profile based on lactic acid bacteria, especially in OBF2 rather than OBF1. The starch granules which were intricate with protein matrix, lost their round/oval structure according to the starch structure in CB, and the number of smooth starch granules were less. The protein structure of OBF2 (c) was further fragmented, the starch granules which lost their shape, were very dispersed within the matrix as smaller pieces. This structure image (600K×) are also clearly seen in Fig. 2.

Fig. 2.

Scanning Electron Microscopy (SEM) micrographs (600K×) of starch granules of CB, OB F1 and OB F2

It was remarkable that the sizes of the starch molecules in the images were visually different. Therefore, all three images were evaluated in the Image ProPlus software, the image calibration was adjusted to 20 mμ, and the diameters of the starch molecules were measured (Table 3). Wheat starch granules generally exhibit bimodal distribution in the structure and can be classified as A-type: 20–35 μm and B-type: 2–10 μm (Delcour and Hoseney 2010). In Fig. 1, the A type starch granules seem to form a separate phase from the gluten phase, whereas the B type starch granules are directly embedded within the protein network. On the first day images, A type starch granules were found to be have larger granules (29.904 ± 4.007) in CB, smaller (23.831 ± 2.399) in OBF1 and granules with the lowest diameter (18.356 ± 2.478) in OBF2 (Table 3). While the starch molecules of CB had the largest diameter, starch molecules of OBF2 had the smallest diameter. The difference between the diameters was found statistically significant (p < 0.05). Deckardt et al. (2014) evaluated the effects of organic acid application on the starch granule and reported that lactic acid application led to modification starch granules. Moreover, they found that changes in the starch granules and slightly deformation on the surface with increased acidity in the images obtained by SEM.

Table 3.

Diameter of starch granules of CB, OBF1 and OBF2 bread samples

| Sample | Diameter (mµ)/1000 |

|---|---|

| CB | 29.904 ± 4.007a |

| OBF1 | 23.831 ± 2.399b |

| OBF2 | 18.356 ± 2.478c |

OB F1 optimized bread produced with F1 fermentation; OB F2 optimized bread produced with F2 fermentation; CB control bread

a–c Means with different superscripts in the same column are significantly different (p < 0.05)

When starch granule images of bread samples (600K×) were examined, similar results were observed. The smooth surface appearance of CB starch granule is visible at Fig. 2a. However, the SEM data of the present study showed significant surface modifications of starch granules in OBF1 and OBF2. Siverely changes and deformation in surface appearance especially in OBF2 are also visible at Fig. 2c.

In this study, the highest acidity was determined in OBF2, OBF1 and CB, respectively, according to TTA results in bread samples. Similar to previous studies, it was determined that the physical structure of starch granules were affected by acidity increase, and that their upper surfaces were detoriated. The starch granules appeared entrapped within the compact protein matrix of images for sourdough bread samples, especially of OBF2. This interaction visually detected between starch granules and matrix may decrease of enzymatic hydrolysis of starch, and may increase the amount of resistant starch in final product (Hallström et al. 2011; Deckardt et al. 2014; Hayta and Hendek Ertop 2017).

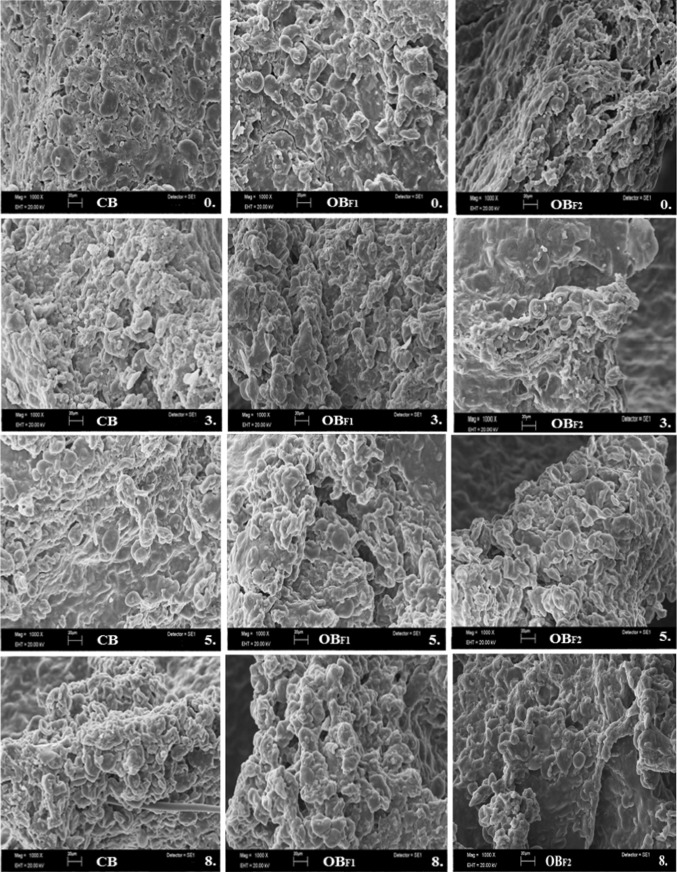

Micro-textural changes during shelf life

In this study, as the purpose was to evaluate the change of bread microstructure during shelf life, the structural changes of starch molecules were observed, and this was related to retrogradation. In addition, during the shelf life of bread samples, the alterations in starch and protein matrix structure were visually interpreted. The SEM images (1000×) of 0, 3, 5 and 8 days of bread samples were compared (Fig. 3).

Fig. 3.

Scanning Electron Microscopy (SEM) micrographs of CB, OB F1 and OB F2 sourdoughs after 0, 3, 5 and 8 day of baking

On the first day, SEM images of the CB show that the microstructure was more uniform and firm. The starch granules were smooth, oval and regular. SEM data indicated that spontaneous fermentation method in OBF1 slightly modified the starch granules, which can be seen with a rougher surface. However, the image of OBF2 characterized with compact protein network including starch granules suggested a highly likely interaction between them. These images may be examined in terms of both protein and starch. The interaction might result from primary and secondary impacts of organic acids produced by lactic acid bacteria. The acids may have activated proteases in grain. Moreover LAB also have protease enzyme activity (Loponen et al. 2004). Therefore, the protein matrix seems to be transformed into compact, discontinued and fragmented mass, which facilitates the interaction with starch granules. The protein aggregation and entrapped starch granules may have affected the characteristics of microtexture. Previous research has also revealed that organic acids such as lactic and acetic have the ability to slow down the enzymatic activity of native amylases of grain, leading to a decrease in the digestability of starch in human and in vitro studies (Deckardt et al. 2014). Another explanation of higher resistance starch contents with sourdough method may be due to interactions between gluten and organic acids that made the starch more resistant and provided a barrier for enzymatic attack.

The staling of bakery products is due to combination of physical and chemical changes that take place during storage after baking. It is characterized by the tightened and crumbly texture, due to the interaction between starch and proteins, the retrogradation of starch and migration of water from crumb to crust. The changes became more evident at the 3rd day as revealed by comparison of samples micrographs. With progress of storage, the microstructures of breads were characterized by a compact network. It was seen that in bread microstructures, from the 3rd day, the proper form was lost and turned into aggregate form. The starch granules could not be clearly seen in the protein matrix. In fact, most of the granules turned into amorphous structures, with disappearance of smooth shape, volume and outer surface tension. In breads and many other bakery products, the loss of moisture and staling indications generally occur red in the first 3 days. The previous studies revealed that the specific interaction between B type starch and gluten proteins matrix resulted in modification of gluten properties (Hermansson and Svegmark 1996). This specific association caused to appeared of protein matrix as if still structured and organized, in OBF2–SEM images of eighth day. However, more aggregated structure was observed in CB sample.

The microscopic observations indicated structural changes connected with retrogradation during storage. The starch–protein matrix forming the microstructure of stored bread was more discontinuous and seemed to be weaker than that in fresh bread. Because, crumb firmness (hardness and gumminess) is increases, but springiness (elasticity and cohesiveness) is decreased for all breads during storage (Błaszczak et al. 2004). This alteration in the microstructure of stored bread also indicated the starch–starch interaction resulted from retrogradation rather than from starch–gluten interaction. The microscopic observation showed that sourdoughs especially F2 had a substantial effect on starch/protein matrix behaviour during staling. The released amylose, underwent structural changes after 3–5 days of storage and formed minute aggregates associated with granule remnants. This phenomonia can be observed as crumbly texture in bread after 3–5 days storage.

Conclusion

In this study, the effects of different optimized sourdough formula on the microtextural properties of bread were evaluated. The effects were much more pronounced in F2 prepared with starter culture. The addition of F2 sourdough rather than F1 resulted in an increase in TTA as well as a decrease in pH, when compared with CB. The microscopic observation showed that sourdough had a substantial effect on starch behaviour during bread staling. Moreover, fermentation types- F1 and F2- showed different effect on it. The fermentation type F2 induced more significant structural changes in the starch–protein matrix showing a different anti-staling mechanism from that of the CB and OBF1. Microstructures of sourdoughs breads formed a compact network including starch granules, while CB-without sourdoughs showed more aggregated structure at the end of the storage. SEM data were consistent with the expected results of bread stailing and can be used in addition to other textural, sensorial or thermogravimetric methods for analysis and comparison of effects of different ingredient or evaluation of shelf life for industrial or scientific studies.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

The authors would like to thank Erciyes University Scientific Research Projects Coordination Unit (EUBAB) for their financial support to this research (Project No: FDK-2014-4526).

Footnotes

Electronic supplementary material

The online version of this article (doi:10.1007/s13197-017-2823-1) contains supplementary material, which is available to authorized users.

References

- Aponte M, Boscaino F, Sorrentino A, Coppola R, Masi P, Romano A. Effects of fermentation and rye flour on microstructure and volatile compounds of chestnut flour based sourdoughs. LWT-Food Sci Technol. 2014;58:387–395. doi: 10.1016/j.lwt.2014.03.022. [DOI] [Google Scholar]

- Autio K, Salmenkallio-Marttila M. Light microscopic investigations of cereal grains, doughs and breads. LWT-Food Sci Technol. 2001;34:18–22. doi: 10.1006/fstl.2000.0725. [DOI] [Google Scholar]

- Bianchia F, Careria M, Chiavarob E, Muscia M, Vittadinib E. Gas chromatographic–mass spectrometric characterisation of the Italian protected designation of origin “Altamura” bread volatile profile. Food Chem. 2008;110:787–793. doi: 10.1016/j.foodchem.2008.02.086. [DOI] [Google Scholar]

- Błaszczak W, Sadowska J, Rosell CM, Fornal F. Structural changes in the wheat dough and bread with the addition of alpha-amylases. Eur Food Res Technol. 2004;219:348–354. doi: 10.1007/s00217-004-0972-8. [DOI] [Google Scholar]

- Chavan RS, Chavan SR. Sourdough Technology—A traditional way for wholesome foods: a Review. Food Sci Food Saf. 2011;10:170–183. [Google Scholar]

- Deckardt K, Khiaosaard R, Grausgruber H, Zebeli Q. Evaluation of various chemical and thermal feed processing methods for their potential to enhance resistant starch content in barley grain. Starch/Stärke. 2014;66:558–565. doi: 10.1002/star.201300200. [DOI] [Google Scholar]

- Delcour JA, Hoseney RC. Principles of cereal science and technology. St. Paul: AACC Int; 2010. [Google Scholar]

- Gobbetti M, Rizzello CG, Di Cagno R, Angelis MD. How the sourdough may affect the functional features of leavened baked goods. Food Microbiol. 2014;37:30–40. doi: 10.1016/j.fm.2013.04.012. [DOI] [PubMed] [Google Scholar]

- Gorinstein S, Pawelzik E, Delgado-Licon E, Yamamoto K, Kobayashi S, Taniguchi H, Haruenkit R, Seo Park Y, Teck Jung S, Drzewiecki J, Trakhtenberg S. Use of scanning electron microscopy to indicate the similarities and differences in pseudocereal and cereal proteins. Int J Food Sci Technol. 2004;39:183–189. doi: 10.1046/j.0950-5423.2003.00773.x. [DOI] [Google Scholar]

- Hallström E, Sestili F, Lafiandra D, Björck I, Östman E. A novel wheat variety with elevated content of amylose increases resistant starch formation and may beneficially influence glycaemia in healthy subjects. Food Nutr Res. 2011;55:7074. doi: 10.3402/fnr.v55i0.7074. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hansen A, Schieberle P. Generation of aroma compounds during sourdough fermentation: applied and fundamental aspects. Trends Food Sci Technol. 2005;16:85–94. doi: 10.1016/j.tifs.2004.03.007. [DOI] [Google Scholar]

- Hayta M, Hendek Ertop M. Optimization of sourdough bread incorporation into wheat bread by response surface methodology: bioactive and nutritional properties. Int J Food Sci Technol. 2017 [Google Scholar]

- Hermansson AM, Svegmark K. Developments in the understanding of starch functionality. Trends Food Sci Technol. 1996;7:345–353. doi: 10.1016/S0924-2244(96)10036-4. [DOI] [Google Scholar]

- Indranı D, Prabhasankar P, Rajıv J, Venkateswara Rao G. Scanning electron microscopy, rheological characteristics, and bread-baking performance of wheat-flour dough as affected by enzymes. J Food Sci. 2003;68(9):2804–2809. doi: 10.1111/j.1365-2621.2003.tb05809.x. [DOI] [Google Scholar]

- Keswet LM, Ayo JA, Bello CB. The effect of four Nigerian wheat flours on the loaf volume and sensory quality of bread. Nutr Food Sci. 2003;33:34–37. doi: 10.1108/00346650310459554. [DOI] [Google Scholar]

- Liukkonen KH, Katina K, Wilhelmson A, Myllymaki O, Lampi AM, Kariluoto S, Piironen V, Heinonen SM, Nurmi T, Adlercreutz H, Peltoketo A, Pihlava JM, Hietaniemi V, Poutanen K. Process-induced changes on bioactive compounds in whole grain rye. Proc Nutr Soc. 2003;62:117–122. doi: 10.1079/PNS2002218. [DOI] [PubMed] [Google Scholar]

- Loponen J, Mikola M, Katina K, Sontag-Strohm T, Salovaara H. Degradation of HMW glutenins during wheat sourdough fermentations. Cereal Chem. 2004;81:87–90. doi: 10.1094/CCHEM.2004.81.1.87. [DOI] [Google Scholar]

- Olapade A, Adetuyi DO. Comparison of different methods of producing bambara (Voandzeia subterranean L. Thou) flours for preparation of ‘moin-moin’. Nıgerian Food J. 2007;25:150–157. [Google Scholar]

- Pelshenke PF, Boilling H, Hampel G, Kampw W, Menger A, Rotsch A, Schulz S, Spincher G, Tegge G (1964) Standart Methoden fur Getreide, Mehl und Brot. 4. Auflage. Im. Verlag Moritz Scheafer. 159 p., Detmold

- Rizzello CG, Coda R, Mazzacane F, Minervini D, Gobbetti M. Micronized by-products from debranned durum wheat and sourdough fermentation enhanced the nutritional, textural and sensory features of bread. Food Res Int. 2012;46:304–313. doi: 10.1016/j.foodres.2011.12.024. [DOI] [Google Scholar]

- Rizzello CG, Montemurro M, Lorusso A. Use of sourdough made with quinoa (Chenopodium quinoa) flour and autochthonous selected lactic acid bacteria for enhancing the nutritional, textural and sensory features of white bread. Food Microbiol. 2016;56:1–13. doi: 10.1016/j.fm.2015.11.018. [DOI] [PubMed] [Google Scholar]

- Wu C, Liu R, Huang W, Rayas-Duarte P, Wang F, Yao Y. Effect of sourdough fermentation on the quality of Chinese Northern-style steamed breads. J Cereal Sci. 2012;56:127–133. doi: 10.1016/j.jcs.2012.03.007. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.