Abstract

In this work the effects of pre-drying and frying time on colour, oil, texture and sensorial acceptability (overall liking) of potato chips were evaluated. Potato chips were pre-dried for 0, 10, 20 and 30 min at 60 °C and fried in soybean oil at 190 °C for 60, 70 and 80 s. The colour parameters (L*, a* and b*) increased or decreased depending on the pre-drying and frying time. Hardness increased as the pre-drying and frying time increased. On the other hand, the water initially removed by pre-drying decrease the gradient of mass transfer (water–oil). The oil content reduced to (about 21%) in pre-dried samples when compared to control sample. Finally, sensorial evaluation showed that samples without pre-drying and/or fried for very short or very long times had low acceptance levels. The pre-drying and frying times influenced the colour, texture, water and oil content, and resulted into fried potato chips with better acceptance scores.

Keywords: Drying, Frying, Physical properties, Sensorial acceptability, Potato chips

Introduction

Fried potato chips are a type of snack highly consumed by the food services sector and households. Frying process produce different modifications such as starch gelatinization, protein denaturation, surface browning, rapid water evaporation and oil absorption (Bouaziz et al. 2016a). The water contained in the raw material evaporates progressively during frying and is partially replaced by oil, constituting up to 40% of the final product, affecting its texture and sensorial properties (Kita et al. 2007). On the other hand, the high oil content in fried products is negatively related to consumer health, as it can lead to obesity, arterial hypertension and coronary diseases (Bouaziz et al. 2016a; Sayon-Orea et al. 2014). Therefore, investigations have been conducted using different techniques for reducing the oil absorption during frying process (Kim and Moreira 2013). Among the investigated techniques and/or processes are the blanching and pre-drying before frying (Niamnuy et al. 2014; Pedreschi and Moyano 2005a, b), frying at high temperatures and short times (Krokida et al. 2000; Millin et al. 2016), utilization of edible coatings prepared from food hydrocolloids (Bouaziz et al. 2016b; García et al. 2002; Garmakhany et al. 2008; Hua et al. 2015; Yu et al. 2016), microwave processing (Joshi et al. 2016) and electric field pulses as pre-treatment (Botero-Uribe et al. 2017; Ignat et al. 2015). The application of these technologies generally leads to many variations on the product sensory characteristics such as texture and colour, affecting the consumer acceptance (Heredia et al. 2014). Therefore, there must be a balance between the physical, nutritional and sensory properties of the products.

In the present work was sought to offer a value-added to the Amarilis-INIA potato variety, liberated by the National Institute of Agricultural Research (INIA) in 1993. This potato variety has suitable agronomic characteristics, widely consumed and cultivated in the Andean sierras of Peru, serving as economic sustenance for farmers, who are characterized by a high poverty index (Maldonado et al. 2008). This work was designed to evaluate the effect of pre-drying and frying process times on instrumental colour, texture, oil content, moisture and overall liking of potato chips.

Materials and methods

Raw material

Fresh potato (Amarilis variety) was obtained from a local market (San Ignacio, La Libertad, Peru). The potato was washed, peeled and using a precision cutter (Stainless, Germany) was sliced into chips of 5.20 cm in diameter and 0.13 ± 0.03 cm in thickness. To prevent browning, the potato slices were submerged for 1 min in sodium bisulfite 0.01% w/V solution.

Pre-drying process

Potato chips were pre-dried using an air recirculation oven (UF55PLUS Memeert, Germany). Taking into account that drying causes colour changes in the samples (Krokida et al. 2001a). To avoid the interference of colour in the subsequent frying process, were chosen pre-drying treatments less than 30 min, which did not show colour differences compared with the in-natura slices. In this way, the suitable selected treatments were 0 min (hereinafter named Control sample), 10 min (S1 sample), 20 min (S2 sample) and 30 min (S3 sample) of pre-drying at 60 °C.

Frying process

The potato slices were deep-fried at 190 °C in soybean vegetable oil (Cheff, Alicorp Peru) contained in an electric fryer of 2.5 L capacity (IMACO, China). The sample to oil mass rate was maintained lower than 0.0041 to avoid temperature variations, as recommended by Pedreschi and Moyano (2005a). The frying process was carried out at three times of 60 s (hereinafter named T1 sample), 70 s (T2 sample) and 80 s (T3 sample). Subsequently the surface oil excess was removed with absorbent towels.

Therefore, a factorial experimental design (A × B) was developed by taking account the pre-drying process times (A = 4 times, including the control samples) and the frying process times (B = 3 times), being a total of 12 treatments as observed in Table 1. For each treatment, the oil was renewed, and 6 replicates were performed.

Table 1.

Experimental design

| Drying time (min) | Frying time (s) | ||

|---|---|---|---|

| 60 | 70 | 80 | |

| 0 | CT1 | CT2 | CT3 |

| 10 | S1T1 | S1T2 | S1T3 |

| 20 | S2T1 | S2T2 | S2T3 |

| 30 | S3T1 | S3T2 | S3T3 |

C, control; T1, frying time of 60 s, T2, frying time of 70 s, T3, frying time of 80 s; S1, drying at 10 min, S2, drying at 20 min, S3, drying at 30 min

Instrumental colour

The instrumental Colour was measured using a colorimeter (JZ-300, Shenzhen Kingwell Instruments Co., China). The colour was recorded using the CIE (Commission Internationale d’Eclairage) colour scale, parameters of (Luminosity), (green to red) and (blue to yellow) were measured. Five measurements were taken for each treatment.

Instrumental texture

The instrumental texture was evaluated by a compressive test using a texturometer (TA-HDplus, UK). A stainless steel spherical probe (P/0.25 s) was inserted at constant rate of 1 mm/s over a distance of 3 mm until it cracked the potato chip. The maximum compression force considered as the highest point of the force (N) versus time (s) curve, was used for describing the sample texture (in terms of hardness). The analysis was performed in triplicate for each treatment.

Absorbed oil determination

The percentage of absorbed oil (Eq. 1) by the potato chips during frying was determined using the Soxhlet extraction method (AOAC 1990). After frying the samples were dried, triturated and placed inside a thick filter paper thimble, which were placed into the Soxhlet equipment for oil extraction. The determination was performed in triplicate for each treatment

| 1 |

where and represents the oil and the sample weight, respectively.

Moisture content

The moisture content of the fried potato chips was determined at 105 °C using a MX-50 Halogen Moisture Analyzer (A & D Company, Japan). Five measurements were performed for each treatment.

Sensory evaluation

A total of 80 untrained panellists (46% male and 54% female, age range 18–26 years) were recruited for the sensory analysis. All panellists participated in an orientation session where they were familiarized with the objectives and use of the scale. All participants were informed about the purpose of the study and signed an ethics consent form. Four coded samples per day were provided to each panellist for the evaluation and were evaluated in a monadic sequential order, the analysis was concluded in 3 days. The overall liking was determined using a 9-point unstructured hedonic scale.

Statistical analysis

Data were analysed using the Statistica 12 (StatSoft, USA) software. Analyses were performed through analysis of variance (ANOVA) at 95% confidence interval (p < 0.05), followed by Tukey’s test to identify significant differences among treatments.

Results and discussion

Instrumental colour

Table 2 shows the colour parameters L*, a* and b*. The luminosity (L* value) increased during the first pre-drying and frying stage, reaching the highest value at 10 min of pre-drying and at 70 s of frying, while the longer pre-drying and frying time this value decreased. This behaviour was observed in previous studies where the L* value depends on the amount of free water present on the sample surface that favours the reflection of light (Heredia et al. 2014; Krokida et al. 2001b), explaining the low L* value in pre-dried samples. In addition, after long frying process or with the increase of the frying temperature, the non-enzymatic browning reactions (Millard reaction) decreased the luminosity (Bunger et al. 2003; Pedreschi et al. 2007).

Table 2.

Colour parameters L*, a*, and b* of potato chips in function of pre-drying and frying time

| Colour parameters | Pre-drying time | Frying time | ||

|---|---|---|---|---|

| 60 s | 70 s | 80 s | ||

| L* | 0 min (control) | 56.3 ± 2.1bA | 57.4 ± 3.2cA | 53.2 ± 1.4bB |

| 10 min | 63.4 ± 4.3aB | 66.3 ± 2.7aA | 60.8 ± 1.8aC | |

| 20 min | 61.8 ± 2.0aB | 64.7 ± 3.2aA | 60.0 ± 1.0aC | |

| 30 min | 57.6 ± 3.4bB | 60.2 ± 0.9bA | 54.8 ± 4.9bC | |

| a* | 0 min (control) | −0.8 ± 0.0aA | −1.0 ± 0.0aB | −1.2 ± 0.0aC |

| 10 min | −1.0 ± 0.0bA | −1.4 ± 0.0bB | −1.8 ± 0.0bC | |

| 20 min | −1.3 ± 0.0cA | −1.6 ± 0.0cB | −1.8 ± 0.0bC | |

| 30 min | −1.7 ± 0.0dA | −1.8 ± 0.0cAB | −1.9 ± 0.0bB | |

| b* | 0 min (control) | 29.4 ± 1.5cA | 30.1 ± 2.6bA | 27.9 ± 2.1cB |

| 10 min | 30.0 ± 2.1cAB | 31.0 ± 1.1bA | 29.1 ± 1.9cB | |

| 20 min | 31.1 ± 2.0cAB | 31.8 ± 4.4bA | 30.6 ± 1.8bB | |

| 30 min | 32.5 ± 3.4aA | 32.7 ± 2.7aA | 31.7 ± 3.5aB | |

* Lower-case letters indicate significant differences between pre-drying times (p < 0.05)

* Capital letters indicate significant differences between frying times (p < 0.05)

The a* was used for determining the optimal frying point (Heredia et al. 2014). The a* value decreased as the pre-drying and frying time increased (Table 2). According to Pedreschi et al. (2005) and Hua et al. (2015), this may be due to the non-enzymatic browning reactions, being a* value for 30 min pre-dried and 80 s fried sample, the lowest value. On the other hand, b* increased as the pre-drying time increased, and for all pre-dried samples the b* value increased until 70 s of frying time, it means that the samples colour tends to yellow. These results were in accordance with Pedreschi et al. (2007), they reported that the b* increased with the frying time, however in this work b* value decreased after 80 s of frying. Different parameters such as moisture reduction, oil absorption, non-enzymatic browning reactions and the interaction of these was function of the pre-drying and frying time, influenced the observed variations in colour parameters (L*, a* and b*). The a* values between 0 and −5 and b* values greater than 10 were considered to be the optimal tonality for potato chips (Krokida et al. 2001b), coincided with the values reported in this investigation.

Texture

Texture is one of the most important sensory attributes for the acceptance of fried potato chips (Taniwaki et al. 2010). Samples with a very low solid content and high fat content were less crispy and stickier (Kita et al. 2007). Texture properties are influenced by different factors such as potato variety (Ngobese et al. 2017), composition, frying temperature and type of oil (Kita et al. 2005, 2007).

Table 3 shows the average of hardness measurements, expressed as the maximum force to break the potato chip. The pre-dried potato chips at 20 and 30 min exhibited the highest hardness (crispy texture), which were even greater when the frying time was increased. The pre-dried samples needed less frying time to increase the hardness value, it was important because by reducing frying time, the oil content and also the risk of acrylamide formation were reduced (Kita et al. 2007).

Table 3.

Hardness (N) of the potato chips in function of frying and pre-drying time

| Pre-drying time | Frying time | ||

|---|---|---|---|

| 60 s | 70 s | 80 s | |

| 0 min (control) | 30.72 ± 2.90a,A | 27.17 ± 1.63a,A | 25.85 ± 0.71a,A |

| 10 min | 31.17 ± 3.12a,A | 41.66 ± 4.14b,B | 28.48 ± 1.10a,A |

| 20 min | 42.71 ± 3.72b,A | 46.90 ± 2.42b,B | 48.67 ± 3.73b,B |

| 30 min | 41.52 ± 5.20b,A | 76.83 ± 6.24c,C | 55.57 ± 1.94c,B |

* Lower-case letters indicate significant differences between pre-drying times (p < 0.05)

* Capital letters indicate significant differences between frying times (p < 0.05)

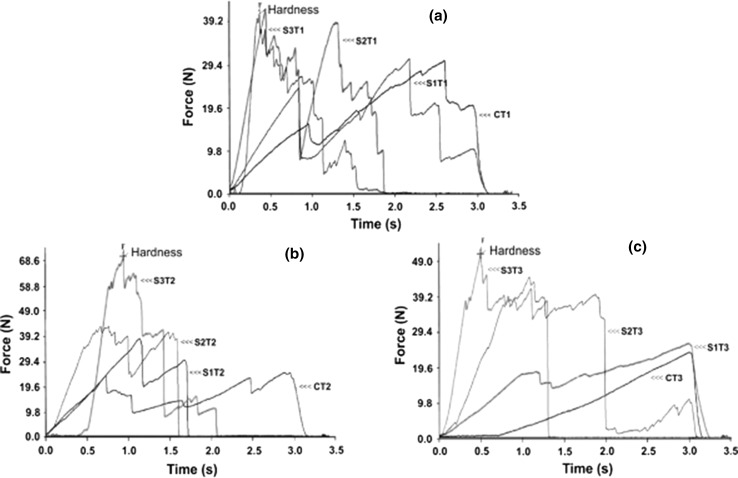

The Fig. 1 shows an example of the obtained force–displacement time curves for the different evaluated treatments. The curves show an irregular appearance with several fracture events, typically observed in crispy foods (Chen et al. 2005). The first important drop of force is associated with a major structural breakdown; in this region, the probe mainly deforms the potato chip (Salvador et al. 2009). The potato chips with greater hardness tend to be more breakable, which is evidenced in the drop of the curve at short times as consequence of chip break. As observed at frying time of 60 s (Fig. 1a), the samples S2T1 and S3T1 presented greater hardness than the S1T1 and control samples, which were more flexible. On the other hand, at frying time of 70 s (Fig. 1b), the control and S1T2 samples continued maintaining their flexibility, while the S2T2 and S3T2 presented short deformation distances when they were broken. Although, at frying time of 80 s (Fig. 1c), the S3T3 and S2T3 samples were deformed and fractured faster than the other treatments, suggesting that these samples presented the greatest hardness at frying times of 80 s. The S1T3 and control samples had similar deformation curves, with an initial resistance slowly accumulated, suggesting once more that the chips are flexible, similar results were reported by Hua et al. (2015). Additionally, as reported by Pedreschi and Moyano (2005a), it was found that pre-drying significantly increases potato crispiness.

Fig. 1.

Force-displacement curves obtained for one texture analysis replicate: a treatments at 60 s of frying, b treatments at 70 s of frying and c treatments at 80 s of frying

Absorbed oil and moisture content

Fat is an important component of potato chips that affect its taste and texture. However, the relationship among fat, moisture content and crispy texture of potato chips was still unclear (Pedreschi and Moyano 2005a).

Table 4 shows the oil and moisture content of pre-dried potato chips. No significant difference (p > 0.05) was evidenced among all pre-dried samples (including the control sample) fried for 60 and 70 s. When the frying time was 80 s, there was a significant fat reduction (p < 0.05) between the pre-dried and control samples. An increase in frying time increased the oil content of potato chips (p < 0.05). It has been demonstrated that the oil scarcely penetrates into the cooked nucleus of fried potato chip. According to Mellema (2003) the oil can only penetrate in space from which water has been evaporated and the temperature was sufficiently high. Pedreschi and Moyano (2005a) studied the effect of pre-drying on the potato chips fat content. They found that a pre-drying process reduced the oil absorption, which was consistent with the results obtained in this study. However, not only the potato chip process conditions also the raw potato characteristics significantly affect the fat content (Salvador et al. 2009). Significant differences in fat content among five potato varieties in relation to dry mass content was higher dry mass content was related to lower fat content in chips (Kita 2002). In this study, the control sample had the highest fat content, due to its high moisture content, allowing a greater exchange of water–oil in a longer frying time. Therefore, the pre-drying process allowed the fat content reduction, which would be useful for the food industry for producing fried foods with reduced fat content.

Table 4.

Oil and moisture content (%) of fried potato chips

| Pre-drying time | Frying time | ||

|---|---|---|---|

| 60 s | 70 s | 80 s | |

| Oil content (%) | |||

| 0 min (control) | 40.94 ± 1.21a,A | 48.33 ± 4.12a,B | 57.81 ± 5.80b,C |

| 10 min | 40.47 ± 4.72a,A | 45.81 ± 0.90a,B | 48.19 ± 4.92a,B |

| 20 min | 39.90 ± 3.10a,A | 43.83 ± 3.23a,AB | 47.67 ± 4.03a,B |

| 30 min | 39.54 ± 3.84a,A | 42.33 ± 2.73a,AB | 45.88 ± 1.82a,B |

| Moisture content (%) | |||

| 0 min (control) | 18.52 ± 1.21a,A | 16.00 ± 0.33a,AB | 13.64 ± 1.11a,B |

| 10 min | 14.81 ± 1.10b,A | 13.79 ± 2.04b,A | 12.50 ± 0.71a,A |

| 20 min | 11.54 ± 0.52b,A | 10.70 ± 0.85c,AB | 8.33 ± 0.61b,B |

| 30 min | 5.88 ± 0.42c,A | 4.76 ± 0.45d,A | 4.17 ± 0.63c,A |

* Lower-case letters indicate significant differences between pre-drying times (p < 0.05)

* Capital letters indicate significant differences between frying times (p < 0.05)

On the other hand, as observed (Table 4), the moisture content of potato chips after frying decreased with the increase in pre-drying and frying time, these results were in agreement with those reported earlier (Bouaziz et al. 2016a; Quasem et al. 2009). During the frying process, the heat was transferred from oil or fat to food, although water was evaporated from the food (Dagerskog 1977). Therefore, the lower amount of water was displaced during the frying process that implied lower absorption oil.

Sensory evaluation

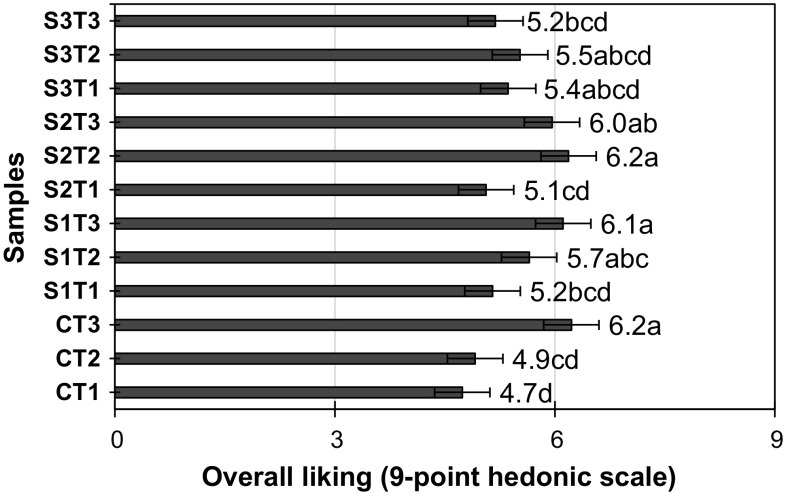

Figure 2 shows the overall liking, statistically (without significant differences) the samples that most liked the panellists were CT3, S1T2, S1T3, S2T2, S2T3, S3T1 and S3T2. Therefore, these samples could have great possibilities of being accepted by the consumers. Highlighting that CT3, S1T3 and S2T2 samples presented an average acceptance greater than 6 in a hedonic scale of 9 points. On the other hand, among the samples less accepted by the consumers was the control sample (CT1) fried for 60 s. It can be inferred that the samples which presented low acceptance scores, were those without pre-drying and/or short time of frying (CT1, CT2, S1T1 and S2T1), as well as the samples pre-dried and fried for long times (S3T3). Analysing the samples which have great possibilities of being accepted, these presented certain instrumental characteristics in the following ranges: Oil content from 39 ± 3.84 to 57.81 ± 5.80%, moisture content from 5.88 ± 0.42 to 13.79 ± 2.04%, hardness from 25.85 ± 0.71 to 76.83 ± 6.24 N, L* value from 53.2 ± 1.4 to 66.3 ± 2.7, a* value from −1.8 to −1.2 and b* value from 32.7 ± 2.7 to 29.9 ± 2.1. Finally, under process conditions of this work, it could be suggested that the treatment that gave the proper physicochemical and organoleptic properties (low fat and moisture content, hard and crispy texture, suitable colour and a high sensory acceptance score) was the process of pre-drying for 20 min and 70 s of frying.

Fig. 2.

Mean overall liking scores using 9-point hedonic scale. Different letters indicate significant differences according to Tukey’s HSD test (p < 0.05)

Conclusion

The pre-drying and frying times influenced directly (increasing or decreasing) the hardness and the colour parameters value L*, a* and b* of the potato chips. The pre-drying process reduced the oil absorption, allowing to obtain products with low fat content. The sensory evaluation (overall liking) demonstrates that samples without pre-drying need long frying time (80 s) for reach the same level of acceptance that the pre-dried samples, but the inconvenience of the control samples is the high fat content. Therefore, pre-drying process influenced positively on the characteristics of fried potato chips such as colour, texture, low fat content, and good acceptance scores.

Acknowledgements

The authors are grateful to Cienciactiva for the M.L. Rojas Ph.D. (CONCYTEC, Peru; Contract 087-2016-FONDECYT) scholarship, from the ‘‘Consejo Nacional de Ciencia, Tecnología e Inovación Tecnológica”.

References

- AOAC (1990) Official methods of analysis. 15th edn. Association of Official Analytical Chemist, INC., Virginia

- Botero-Uribe M, Fitzgerald M, Gilbert RG, Midgley J. Effect of pulsed electrical fields on the structural properties that affect French fry texture during processing. Trends Food Sci Technol. 2017;67:1–11. doi: 10.1016/j.tifs.2017.05.016. [DOI] [Google Scholar]

- Bouaziz F, Koubaa M, Neifar M, Zouari-Ellouzi S, Besbes S, Chaari F, Kamoun A, Chaabouni M, Chaabouni SE, Ghorbel RE. Feasibility of using almond gum as coating agent to improve the quality of fried potato chips: evaluation of sensorial properties. LWT Food Sci Technol. 2016;65:800–807. doi: 10.1016/j.lwt.2015.09.009. [DOI] [Google Scholar]

- Bunger A, Moyano P, Rioseco V. NaCl soaking treatment for improving the quality of French-fried potatoes. Food Res Int. 2003;36:161–166. doi: 10.1016/S0963-9969(02)00131-X. [DOI] [Google Scholar]

- Chen J, Karlsson C, Povey M. Acoustic envelope detector for crispness assessment of biscuits. J Texture Stud. 2005;36:139–156. doi: 10.1111/j.1745-4603.2005.00008.x. [DOI] [Google Scholar]

- Dagerskog M (1977) Time-temperature relationship in industrial cooking and frying. In: Hoyem T, Kvale O (eds) Physical, chemical and biological changes in foods caused by thermal processing. Applied Science Publishers, London, pp 77–100

- García MA, Ferrero C, Bértola N, Martino M, Zaritzky N. Edible coatings from cellulose derivatives to reduce oil uptake in fried products. Innov Food Sci Emerg. 2002;3:391–397. doi: 10.1016/S1466-8564(02)00050-4. [DOI] [Google Scholar]

- Garmakhany AD, Mirzaei HO, Nejad MK, Maghsudlo Y. Study of oil uptake and some quality attributes of potato chips affected by hydrocolloids. Eur J Lipid Sci Technol. 2008;110:1045–1049. doi: 10.1002/ejlt.200700255. [DOI] [Google Scholar]

- Heredia A, Castelló ML, Argüelles A, Andrés A. Evolution of mechanical and optical properties of French fries obtained by hot air-frying. LWT Food Sci Technol. 2014;57:755–760. doi: 10.1016/j.lwt.2014.02.038. [DOI] [Google Scholar]

- Hua X, Wang K, Yang R, Kang J, Yang H. Edible coatings from sunflower head pectin to reduce lipid uptake in fried potato chips. LWT Food Sci Technol. 2015;62:1220–1225. doi: 10.1016/j.lwt.2015.02.010. [DOI] [Google Scholar]

- Ignat A, Manzocco L, Brunton NP, Nicoli MC, Lyng JG. The effect of pulsed electric field pre-treatments prior to deep-fat frying on quality aspects of potato fries. Innov Food Sci Emerg. 2015;29:65–69. doi: 10.1016/j.ifset.2014.07.003. [DOI] [Google Scholar]

- Joshi A, Rudra SG, Sagar VR, Raigond P, Dutt S, Singh B, Singh BP. Development of low fat potato chips through microwave processing. JFST. 2016;53:3296–3303. doi: 10.1007/s13197-016-2304-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim T, Moreira RG. De-oiling and pretreatment for high-quality potato chips. J Food Process Eng. 2013;36:267–275. doi: 10.1111/j.1745-4530.2012.00686.x. [DOI] [Google Scholar]

- Kita A. The influence of potato chemical composition on crisp texture. Food chem. 2002;76:173–179. doi: 10.1016/S0308-8146(01)00260-6. [DOI] [Google Scholar]

- Kita A, Lisińska G, Powolny M. The influence of frying medium degradation on fat uptake and texture of French fries. J Sci Food Agric. 2005;85:1113–1118. doi: 10.1002/jsfa.2076. [DOI] [Google Scholar]

- Kita A, Lisińska G, Gołubowska G. The effects of oils and frying temperatures on the texture and fat content of potato crisps. Food Chem. 2007;102:1–5. doi: 10.1016/j.foodchem.2005.08.038. [DOI] [Google Scholar]

- Krokida MK, Oreopoulou V, Maroulis ZB. Effect of frying conditions on shrinkage and porosity of fried potatoes. J Food Eng. 2000;43:147–154. doi: 10.1016/S0260-8774(99)00143-0. [DOI] [Google Scholar]

- Krokida MK, Maroulis ZB, Saravacos GD. The effect of the method of drying on the colour of dehydrated products. Int J Food Sci Technol. 2001;36:53–59. doi: 10.1046/j.1365-2621.2001.00426.x. [DOI] [Google Scholar]

- Krokida MK, Oreopoulou V, Maroulis ZB, Marinos-Kouris D. Colour changes during deep fat frying. J Food Eng. 2001;48:219–225. doi: 10.1016/S0260-8774(00)00161-8. [DOI] [Google Scholar]

- Maldonado L, Suárez V, Thiele G. Estudio de la adopción de variedades de papa en zonas pobres del Perú. Lima: Centro Internacional de la Papa (CIP); 2008. [Google Scholar]

- Mazurek S, Szostak R, Kita A. Application of infrared reflection and Raman spectroscopy for quantitative determination of fat in potato chips. J Mol Struct. 2016;1126:213–218. doi: 10.1016/j.molstruc.2016.01.064. [DOI] [Google Scholar]

- Mellema M. Mechanism and reduction of fat uptake in deep-fat fried foods. Trends Food Sci Technol. 2003;14:364–373. doi: 10.1016/S0924-2244(03)00050-5. [DOI] [Google Scholar]

- Millin TM, Medina-Meza IG, Walters BC, Huber KC, Rasco BA, Ganjyal GM. Frying oil temperature: impact on physical and structural properties of French fries during the par and finish frying processes. Food Bioprocess Technol. 2016;9:2080–2091. doi: 10.1007/s11947-016-1790-2. [DOI] [Google Scholar]

- Ngobese NZ, Workneh TS, Siwela M. Effect of low-temperature long-time and high-temperature short-time blanching and frying treatments on the French fry quality of six Irish potato cultivars. JFST. 2017;54:507–517. doi: 10.1007/s13197-017-2495-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Niamnuy C, Devahastin S, Soponronnarit S. Some recent advances in microstructural modification and monitoring of foods during drying: a review. J Food Eng. 2014;123:148–156. doi: 10.1016/j.jfoodeng.2013.08.026. [DOI] [Google Scholar]

- Pedreschi F, Moyano P. Effect of pre-drying on texture and oil uptake of potato chips. LWT Food Sci Technol. 2005;38:599–604. doi: 10.1016/j.lwt.2004.08.008. [DOI] [Google Scholar]

- Pedreschi F, Moyano P. Oil uptake and texture development in fried potato slices. J Food Eng. 2005;70:557–563. doi: 10.1016/j.jfoodeng.2004.10.010. [DOI] [Google Scholar]

- Pedreschi F, Kaack K, Granby K. Reduction of acrylamide formation in potato slices during frying. LWT Food Sci Technol. 2004;37:679–685. doi: 10.1016/j.lwt.2004.03.001. [DOI] [Google Scholar]

- Pedreschi F, Moyano P, Kaack K, Granby K. Color changes and acrylamide formation in fried potato slices. Food Res Int. 2005;38:1–9. doi: 10.1016/j.foodres.2004.07.002. [DOI] [Google Scholar]

- Pedreschi F, León J, Mery D, Moyano P, Pedreschi R, Kaack K, Granby K. Color development and acrylamide content of pre-dried potato chips. J Food Eng. 2007;79:786–793. doi: 10.1016/j.jfoodeng.2006.03.001. [DOI] [Google Scholar]

- Quasem JM, Mazahreh AS, Abu-Alruz K, Afaneh IA, Al-Muhtaseb AH, Magee TRA. Effect of methyl cellulose coating and pre-treatment on oil uptake, moisture retention and physical properties of deep-fat fried starchy dough system. AJABS. 2009;4:156–166. [Google Scholar]

- Salvador A, Varela P, Sanz T, Fiszman SM. Understanding potato chips crispy texture by simultaneous fracture and acoustic measurements, and sensory analysis. LWT Food Sci Technol. 2009;42:763–767. doi: 10.1016/j.lwt.2008.09.016. [DOI] [Google Scholar]

- Sayon-Orea C, Martinez-Gonzalez MA, Gea A, Flores-Gomez E, Basterra-Gortari FJ, Bes-Rastrollo M. Consumption of fried foods and risk of metabolic syndrome: the SUN cohort study. Clin Nutr. 2014;33:545–549. doi: 10.1016/j.clnu.2013.07.014. [DOI] [PubMed] [Google Scholar]

- Taniwaki M, Sakurai N, Kato H. Texture measurement of potato chips using a novel analysis technique for acoustic vibration measurements. Food Res Int. 2010;43:814–818. doi: 10.1016/j.foodres.2009.11.021. [DOI] [Google Scholar]

- Yu L, Li J, Ding S, Hang F, Fan L. Effect of guar gum with glycerol coating on the properties and oil absorption of fried potato chips. Food Hydrocolloid. 2016;54:211–219. doi: 10.1016/j.foodhyd.2015.10.003. [DOI] [Google Scholar]